Enhanced Rubber Yield Prediction in High-Density Plantation Areas Using a GIS and Machine Learning-Based Forest Classification and Regression Model

Abstract

1. Introduction

2. Materials and Methods

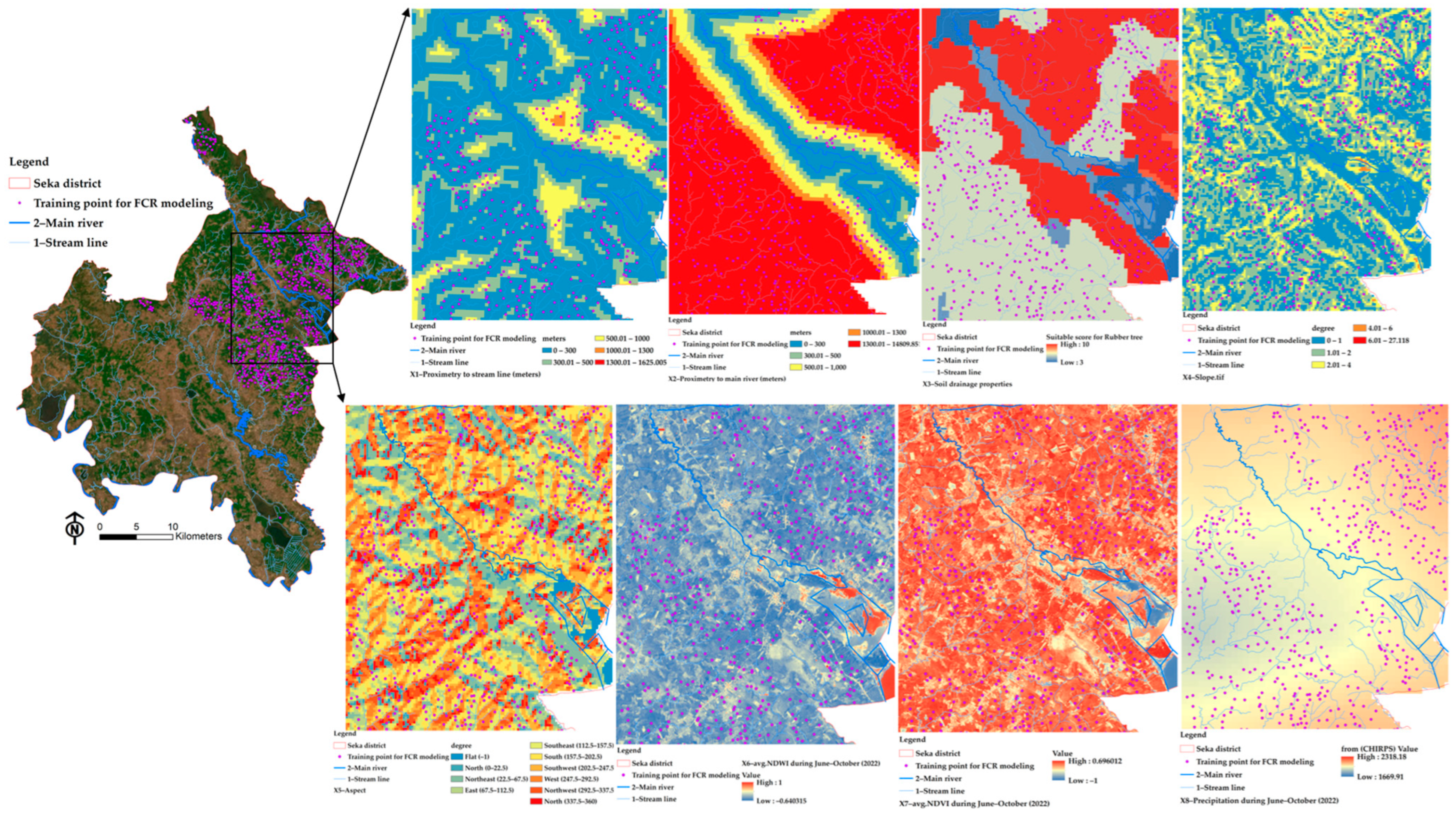

2.1. Spatial Factors

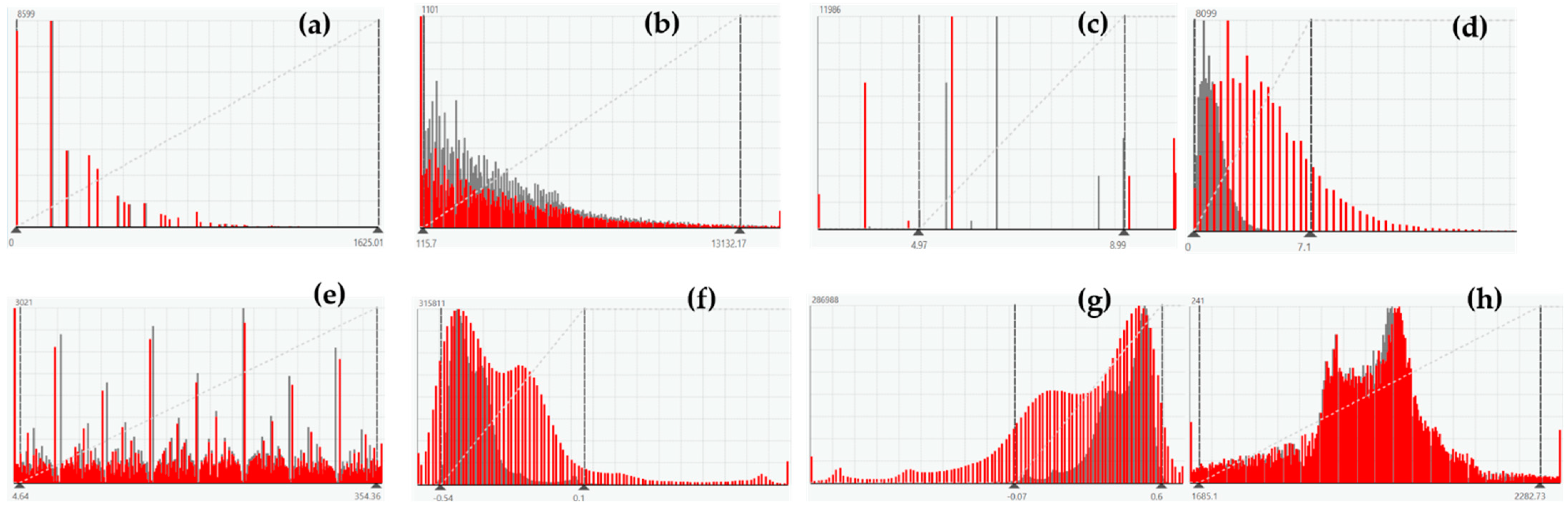

2.1.1. Proximity to Streamlines (X1)

2.1.2. Proximity to Main River (X2)

2.1.3. Soil Drainage (X3)

2.1.4. Slope (X4)

2.1.5. Aspect (X5)

2.1.6. NDWI (X6)

2.1.7. NDVI (X7)

2.1.8. Precipitation (X8)

2.2. Clustering Analysis for Training Point Selection

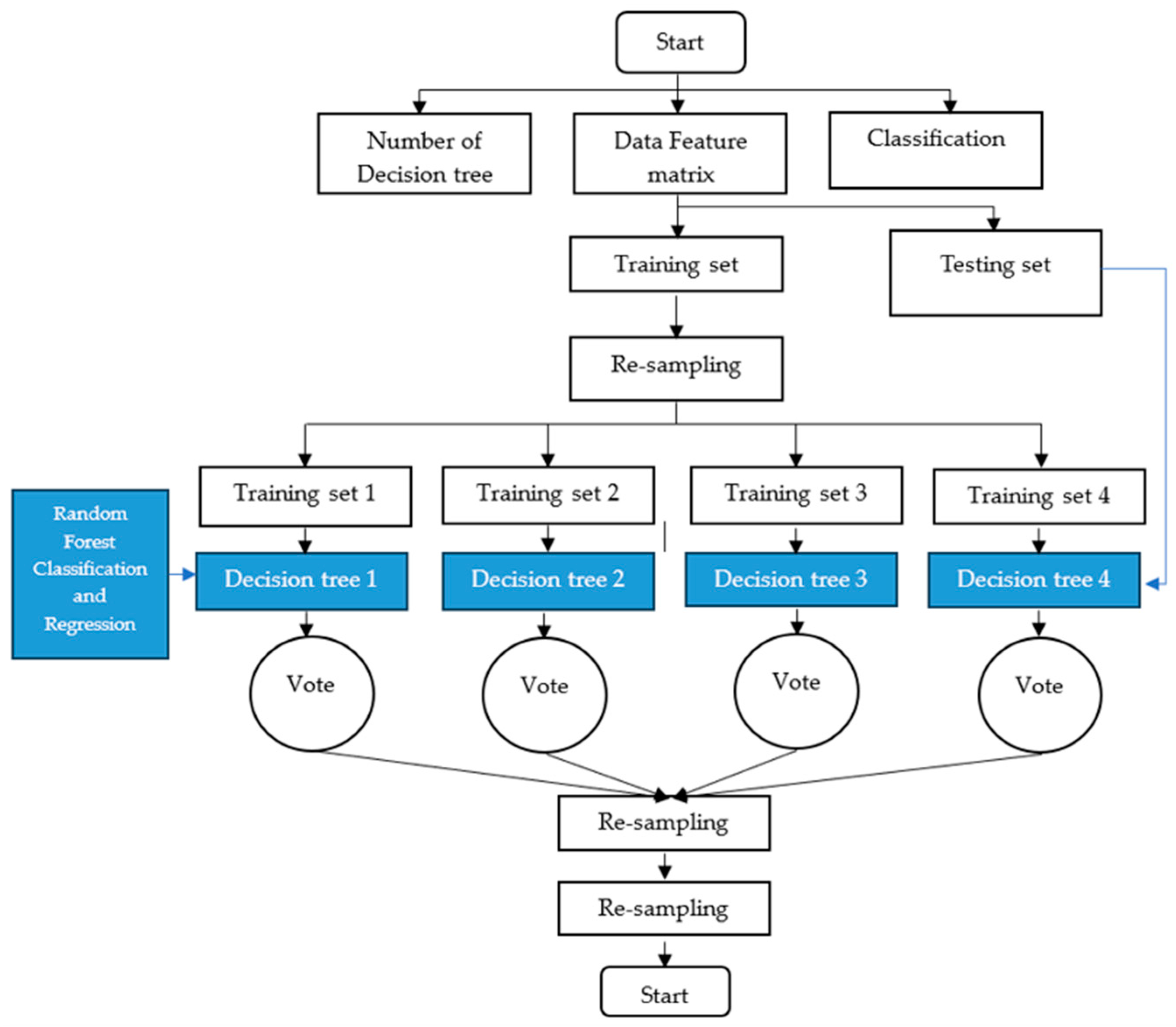

2.3. Predicting Rubber Yield

- Pre-processing

- Dimensions of the dataset in a random forest

- Feature selection

3. Results

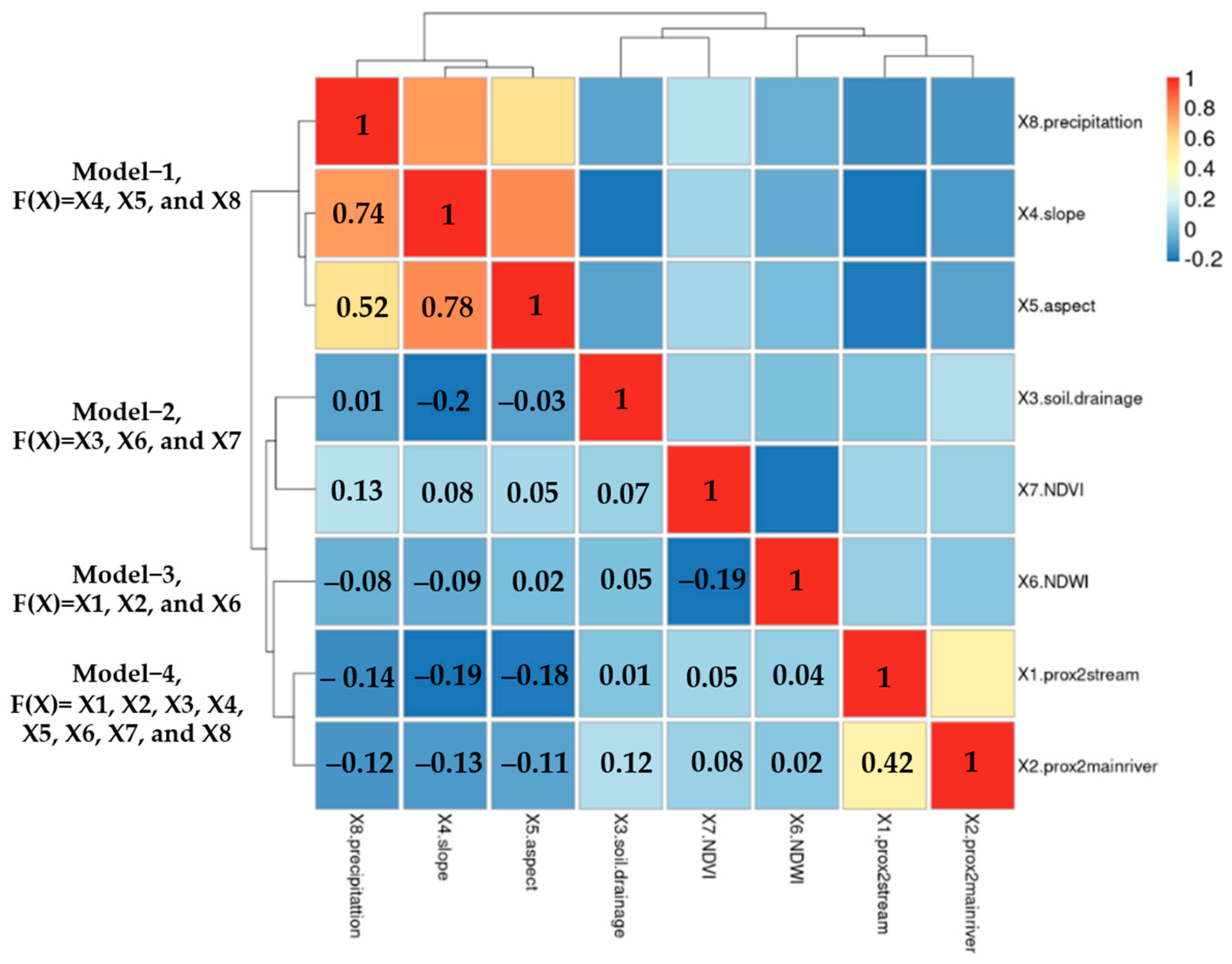

3.1. Correlation Analysis and Dendrogram

3.2. Predicting Rubber Yield Using a Machine Learning-Based FCR Model

4. Discussion

4.1. Focusing on the Areas Where the Projected Rubber Yield Results Were Implemented

4.2. Model Validation

4.3. Comparison of the Results Obtained with Previous Work

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bhumiphan, N.; Nontapon, J.; Kaewplang, S.; Srihanu, N.; Koedsin, W.; Huete, A. Estimation of Rubber Yield Using Sentinel-2 Satellite Data. Sustainability 2023, 15, 7223. [Google Scholar] [CrossRef]

- Yasen, K.; Koedsin, W. Estimating Aboveground Biomass of Rubber Tree Using Remote Sensing in Phuket Province, Thailand. J. Med. Bioeng. 2015, 4, 451–456. [Google Scholar] [CrossRef]

- Rao, P.S.; Saraswathyamma, C.K.; Sethuraj, M.R. Studies on the Relationship between Yield and Meteorological Parameters of Para Rubber Tree (Hevea Brasiliensis). Agric. For. Meteorol. 1998, 90, 235–245. [Google Scholar] [CrossRef]

- Krukanont, P.; Prasertsan, S. Geographical Distribution of Biomass and Potential Sites of Rubber Wood Fired Power Plants in Southern Thailand. Biomass Bioenergy 2004, 26, 47–59. [Google Scholar] [CrossRef]

- Chantuma, P.; Lacote, R.; Leconte, A.; Gohet, E. An Innovative Tapping System, the Double Cut Alternative, to Improve the Yield of Hevea Brasiliensis in Thai Rubber Plantations. Field Crops Res. 2011, 121, 416–422. [Google Scholar] [CrossRef]

- Nath, A.J.; Brahma, B.; Kumar Das, A. No TitleRubber Plantations and Carbon Management, 1st ed.; Apple Academic Press: Palm Bay, FL, USA, 2019; p. 166. [Google Scholar] [CrossRef]

- Liu, X.; Feng, Z.; Jiang, L.; Li, P.; Liao, C.; Yang, Y.; You, Z. Rubber Plantation and Its Relationship with Topographical Factors in the Border Region of China, Laos and Myanmar. J. Geogr. Sci. 2013, 23, 1019–1040. [Google Scholar] [CrossRef]

- Dauwalter, D.C.; Fesenmyer, K.A.; Bjork, R.; Leasure, D.R.; Wenger, S.J. Satellite and Airborne Remote Sensing Applications for Freshwater Fisheries. Fisheries 2017, 42, 526–537. [Google Scholar] [CrossRef]

- Gao, S.; Liu, X.; Bo, Y.; Shi, Z.; Zhou, H. Rubber Identification Based on Blended High Spatio-Temporal Resolution Optical Remote Sensing Data: A Case Study in Xishuangbanna. Remote Sens. 2019, 11, 496. [Google Scholar] [CrossRef]

- Nguyen, M.D.; Baez–Villanueva, O.M.; Bui, D.D.; Nguyen, P.T.; Ribbe, L. Harmonization of Landsat and Sentinel 2 for Crop Monitoring in Drought Prone Areas: Case Studies of Ninh Thuan (Vietnam) and Bekaa (Lebanon). Remote Sens. 2020, 12, 281. [Google Scholar] [CrossRef]

- Songsaengrit, S.; Kangrang, A. Dynamic Rule Curves and Streamflow under Climate Change for Multipurpose Reservoir Operation Using Honey–Bee Mating Optimization. Sustainability 2022, 14, 8599. [Google Scholar] [CrossRef]

- Zhang, M.; Lin, H.; Wang, G.; Sun, H.; Fu, J. Mapping Paddy Rice Using a Convolutional Neural Network (CNN) with Landsat 8 Datasets in the Dongting Lake Area, China. Remote Sens. 2018, 10, 1840. [Google Scholar] [CrossRef]

- Rao, D.V.K.N.; Jose, A.I.; Rao, A.V.R.K. Spectral Signature and Temporal Variation in Spectral Reflectance: Keys to Identify Rubber Vegetation. In Proceedings of the International Symposium on Remote Sensing, Crete, Greece, 17 March 2003; Volume 4879, pp. 114–124. [Google Scholar]

- Li, Z.; Fox, J.M. Mapping Rubber Tree Growth in Mainland Southeast Asia Using Time–Series MODIS 250 m NDVI and Statistical Data. Appl. Geogr. 2012, 32, 420–432. [Google Scholar] [CrossRef]

- Zhiming, F.; Luguang, J.; Xiaona, L.I.U.; Jinghua, Z. Rubber Plantations in Xishuangbanna: Remote Sensing Identification and Digital Mapping. Resour. Sci. 2012, 34, 1769–1780. [Google Scholar]

- Fan, H.; Fu, X.; Zhang, Z.; Wu, Q. Phenology-Based Vegetation Index Differencing for Mapping of Rubber Plantations Using Landsat OLI Data. Remote Sens. 2015, 7, 6041–6058. [Google Scholar] [CrossRef]

- Somching, N.; Wongsai, S.; Wongsai, N.; Koedsin, W. Using Machine Learning Algorithm and Landsat Time Series to Identify Establishment Year of Para Rubber Plantations: A Case Study in Thalang District, Phuket Island, Thailand. Int. J. Remote Sens. 2020, 41, 9075–9100. [Google Scholar] [CrossRef]

- Reynolds, C.A.; Yitayew, M.; Slack, D.C.; Hutchinson, C.F.; Huete, A.; Petersen, M.S. Estimating Crop Yields and Production by Integrating the FAO Crop Specific Water Balance Model with Real-Time Satellite Data and Ground-Based Ancillary Data. Int. J. Remote Sens. 2000, 21, 3487–3508. [Google Scholar] [CrossRef]

- Azizan, F.A.; Kiloes, A.M.; Astuti, I.S.; Aziz, A.A. Application of Optical Remote Sensing in Rubber Plantations: A Systematic Review. Remote Sens. 2021, 13, 429. [Google Scholar] [CrossRef]

- Whitcraft, A.K.; Becker-Reshef, I.; Justice, C.O.; Gifford, L.; Kavvada, A.; Jarvis, I. No Pixel Left behind: Toward Integrating Earth Observations for Agriculture into the United Nations Sustainable Development Goals Framework. Remote Sens. Environ. 2019, 235, 111470. [Google Scholar] [CrossRef]

- Bastiaanssen, W.G.M.; Ali, S. A New Crop Yield Forecasting Model Based on Satellite Measurements Applied across the Indus Basin, Pakistan. Agric. Ecosyst. Environ. 2003, 94, 321–340. [Google Scholar] [CrossRef]

- Rodriguez, J.C.; Duchemin, B.; Hadria, R.; Watts, C.; Garatuza, J.; Chehbouni, A.; Khabba, S.; Boulet, G.; Palacios, E.; Lahrouni, A. Wheat Yield Estimation Using Remote Sensing and the STICS Model in the Semiarid Yaqui Valley, Mexico. Agronomie 2004, 24, 295–304. [Google Scholar] [CrossRef]

- Chandra Paul, G.; Saha, S.; Hembram, T.K. Application of Phenology–Based Algorithm and Linear Regression Model for Estimating Rice Cultivated Areas and Yield Using Remote Sensing Data in Bansloi River Basin, Eastern India. Remote Sens. Appl. Soc. Environ. 2020, 19, 100367. [Google Scholar] [CrossRef]

- Zhang, P.-P.; Zhou, X.-X.; Wang, Z.-X.; Mao, W.; Li, W.-X.; Yun, F.; Guo, W.-S.; Tan, C.-W. Using HJ-CCD Image and PLS Algorithm to Estimate the Yield of Field-Grown Winter Wheat. Sci. Rep. 2020, 10, 5173. [Google Scholar] [CrossRef]

- Al–Gaadi, K.A.; Hassaballa, A.A.; Tola, E.; Kayad, A.G.; Madugundu, R.; Alblewi, B.; Assiri, F. Prediction of Potato Crop Yield Using Precision Agriculture Techniques. PLoS ONE 2016, 11, e0162219. [Google Scholar] [CrossRef]

- Awad, M.M. Toward Precision in Crop Yield Estimation Using Remote Sensing and Optimization Techniques. Agriculture 2019, 9, 54. [Google Scholar] [CrossRef]

- Gómez, D.; Salvador, P.; Sanz, J.; Casanova, J.L. Potato yield prediction using machine learning techniques and sentinel 2 data. Remote Sens. 2019, 11, 1745. [Google Scholar] [CrossRef]

- Goel, P.K.; Prasher, S.O.; Patel, R.M.; Landry, J.A.; Bonnell, R.B.; Viau, A.A. Classification of Hyperspectral Data by Decision Trees and Artificial Neural Networks to Identify Weed Stress and Nitrogen Status of Corn. Comput. Electron. Agric. 2003, 39, 67–93. [Google Scholar] [CrossRef]

- Ferencz, C.; Bognár, P.; Lichtenberger, J.; Hamar, D.; Tarcsai†, G.; Timár, G.; Molnár, G.; Pásztor, S.Z.; Steinbach, P.; Székely, B.; et al. Crop Yield Estimation by Satellite Remote Sensing. Int. J. Remote Sens. 2004, 25, 4113–4149. [Google Scholar] [CrossRef]

- Uno, Y.; Prasher, S.O.; Lacroix, R.; Goel, P.K.; Karimi, Y.; Viau, A.; Patel, R.M. Artificial Neural Networks to Predict Corn Yield from Compact Airborne Spectrographic Imager Data. Comput. Electron. Agric. 2005, 47, 149–161. [Google Scholar] [CrossRef]

- Peng, Y.; Gitelson, A.A. Application of Chlorophyll–Related Vegetation Indices for Remote Estimation of Maize Productivity. Agric. For. Meteorol. 2011, 151, 1267–1276. [Google Scholar] [CrossRef]

- Maresma, Á.; Lloveras, J.; Martínez-Casasnovas, J.A. Use of Multispectral Airborne Images to Improve In–Season Nitrogen Management, Predict Grain Yield and Estimate Economic Return of Maize in Irrigated High Yielding Environments. Remote Sens. 2018, 10, 543. [Google Scholar] [CrossRef]

- Van Kraalingen, D.W.G.; Breure, C.J.; Spitters, C.J.T. Simulation of Oil Palm Growth and Yield. Agric. For. Meteorol. 1989, 46, 227–244. [Google Scholar] [CrossRef]

- Chong, K.L.; Kanniah, K.D.; Pohl, C.; Tan, K.P. A Review of Remote Sensing Applications for Oil Palm Studies. Geo-Spat. Inf. Sci. 2017, 20, 184–200. [Google Scholar] [CrossRef]

- Hashemvand Khiabani, P.; Takeuchi, W. Assessment of Oil Palm Yield and Biophysical Suitability in Indonesia and Malaysia. Int. J. Remote Sens. 2020, 41, 8520–8546. [Google Scholar] [CrossRef]

- Rashid, M.; Bari, B.S.; Yusup, Y.; Kamaruddin, M.A.; Khan, N. A Comprehensive Review of Crop Yield Prediction Using Machine Learning Approaches With Special Emphasis on Palm Oil Yield Prediction. IEEE Access 2021, 9, 63406–63439. [Google Scholar] [CrossRef]

- Chang, K.-W.; Shen, Y.; Lo, J.-C. Predicting Rice Yield Using Canopy Reflectance Measured at Booting Stage. Agron. J. 2005, 97, 872–878. [Google Scholar] [CrossRef]

- Cui, B.; Huang, W.; Ye, H.; Chen, Q. The Suitability of PlanetScope Imagery for Mapping Rubber Plantations. Remote Sens. 2022, 14, 1061. [Google Scholar] [CrossRef]

- Dong, J.; Xiao, X.; Chen, B.; Torbick, N.; Jin, C.; Zhang, G.; Biradar, C. Mapping Deciduous Rubber Plantations through Integration of PALSAR and Multi–Temporal Landsat Imagery. Remote Sens. Environ. 2013, 134, 392–402. [Google Scholar] [CrossRef]

- Li, P.; Zhang, J.; Feng, Z. Mapping Rubber Tree Plantations Using a Landsat–Based Phenological Algorithm in Xishuangbanna, Southwest China. Remote Sens. Lett. 2015, 6, 49–58. [Google Scholar] [CrossRef]

- Xiao, C.; Li, P.; Feng, Z.; Liu, X. An Updated Delineation of Stand Ages of Deciduous Rubber Plantations during 1987–2018 Using Landsat-Derived Bi-Temporal Thresholds Method in an Anti-Chronological Strategy. Int. J. Appl. Earth Obs. Geoinf. 2019, 76, 40–50. [Google Scholar] [CrossRef]

- Li, J.; Roy, D.P. A Global Analysis of Sentinel-2A, Sentinel-2B and Landsat-8 Data Revisit Intervals and Implications for Terrestrial Monitoring. Remote Sens. 2017, 9, 902. [Google Scholar] [CrossRef]

- Singh, D.; Slik, J.W.F.; Jeon, Y.S.; Tomlinson, K.W.; Yang, X.; Wang, J.; Kerfahi, D.; Porazinska, D.L.; Adams, J.M. Tropical Forest Conversion to Rubber Plantation Affects Soil Micro– & Mesofaunal Community & Diversity. Sci. Rep. 2019, 9, 5893. [Google Scholar] [CrossRef]

- Ullah, T.; Muhammad, Z.; Shah, I.A.; Bourhia, M.; Nafidi, H.A.; Salamatullah, A.M.; Younous, Y.A. Multivariate Analysis of the Summer Herbaceous Vegetation and Environmental Factors of the Sub-Tropical Region. Sci. Rep. 2024, 14, 15657. [Google Scholar] [CrossRef] [PubMed]

- Hazir, M.H.M.; Muda, T.M.T. The Viability of Remote Sensing for Extracting Rubber Smallholding Information: A Case Study in Malaysia. Egypt. J. Remote Sens. Space Sci. 2020, 23, 35–47. [Google Scholar] [CrossRef]

- Littidej, P.; Buasri, N. Built–up Growth Impacts on Digital Elevation Model and Flood Risk Susceptibility Prediction in Muaeng District, Nakhon Ratchasima (Thailand). Water 2019, 11, 1496. [Google Scholar] [CrossRef]

- Littidej, P.; Uttha, T.; Pumhirunroj, B. Spatial Predictive Modeling of the Burning of Sugarcane Plots in Northeast Thailand with Selection of Factor Sets Using a GWR Model and Machine Learning Based on an ANN-CA. Symmetry 2022, 14, 1989. [Google Scholar] [CrossRef]

- Pumhirunroj, B.; Littidej, P.; Boonmars, T.; Bootyothee, K.; Artchayasawat, A.; Khamphilung, P.; Slack, D. Machine-Learning-Based Forest Classification and Regression (FCR) for Spatial Prediction of Liver Fluke Opisthorchis Viverrini (OV) Infection in Small Sub-Watersheds. ISPRS Int. J. Geo-Inf. 2023, 12, 503. [Google Scholar] [CrossRef]

- Prasertsri, N.; Littidej, P. Spatial Environmental Modeling for Wildfire Progression Accelerating Extent Analysis Using Geo-Informatics. Pol. J. Environ. Stud. 2020, 29, 3249–3261. [Google Scholar] [CrossRef]

- Hussain, M.A.; Chen, Z.; Zheng, Y.; Shoaib, M.; Shah, S.U.; Ali, N.; Afzal, Z. Landslide Susceptibility Mapping Using Machine Learning Algorithm Validated by Persistent Scatterer In–SAR Technique. Sensors 2022, 22, 3119. [Google Scholar] [CrossRef]

- Achour, Y.; Pourghasemi, H.R. How Do Machine Learning Techniques Help in Increasing Accuracy of Landslide Susceptibility Maps? Geosci. Front. 2020, 11, 871–883. [Google Scholar] [CrossRef]

- Kumar, R.; Anbalagan, R. Landslide Susceptibility Mapping Using Analytical Hierarchy Process (AHP) in Tehri Reservoir Rim Region, Uttarakhand. J. Geol. Soc. India 2016, 87, 271–286. [Google Scholar] [CrossRef]

- Tengtrairat, N.; Woo, W.L.; Parathai, P.; Aryupong, C.; Jitsangiam, P.; Rinchumphu, D. Automated Landslide-Risk Prediction Using Web GIS and Machine Learning Models. Sensors 2021, 21, 4620. [Google Scholar] [CrossRef]

- Park, S.; Choi, C.; Kim, B.; Kim, J. Landslide Susceptibility Mapping Using Frequency Ratio, Analytic Hierarchy Process, Logistic Regression, and Artificial Neural Network Methods at the Inje Area, Korea. Environ. Earth Sci. 2013, 68, 1443–1464. [Google Scholar] [CrossRef]

- Tien Bui, D.; Pradhan, B.; Lofman, O.; Revhaug, I. Landslide Susceptibility Assessment in Vietnam Using Support Vector Machines, Decision Tree, and Naïve Bayes Models. Math. Probl. Eng. 2012, 2012, 974638. [Google Scholar] [CrossRef]

- Mandal, S.; Mandal, K. Modeling and Mapping Landslide Susceptibility Zones Using GIS Based Multivariate Binary Logistic Regression (LR) Model in the Rorachu River Basin of Eastern Sikkim Himalaya, India. Model. Earth Syst. Environ. 2018, 4, 69–88. [Google Scholar] [CrossRef]

- Pourghasemi, H.R.; Rahmati, O. Prediction of the Landslide Susceptibility: Which Algorithm, Which Precision? Catena 2018, 162, 177–192. [Google Scholar] [CrossRef]

- Youssef, A.M.; Pourghasemi, H.R.; Pourtaghi, Z.S.; Al-Katheeri, M.M. Landslide Susceptibility Mapping Using Random Forest, Boosted Regression Tree, Classification and Regression Tree, and General Linear Models and Comparison of Their Performance at Wadi Tayyah Basin, Asir Region, Saudi Arabia. Landslides 2016, 13, 839–856. [Google Scholar] [CrossRef]

- Rossi, M.; Guzzetti, F.; Reichenbach, P.; Mondini, A.C.; Peruccacci, S. Optimal Landslide Susceptibility Zonation Based on Multiple Forecasts. Geomorphology 2010, 114, 129–142. [Google Scholar] [CrossRef]

- Park, S.; Kim, J. Landslide Susceptibility Mapping Based on Random Forest and Boosted Regression Tree Models, and a Comparison of Their Performance. Appl. Sci. 2019, 9, 942. [Google Scholar] [CrossRef]

- Sevgen, E.; Kocaman, S.; Nefeslioglu, H.A.; Gokceoglu, C. A Novel Performance Assessment Approach Using Photogrammetric Techniques for Landslide Susceptibility Mapping with Logistic Regression, ANN and Random Forest. Sensors 2019, 19, 3940. [Google Scholar] [CrossRef]

- Pérez-Díaz, P.; Martín-Dorta, N.; Gutiérrez-García, F.J. Construction Labour Measurement in Reinforced Concrete Floating Caissons in Maritime Ports. Civ. Eng. J. 2022, 8, 195–208. [Google Scholar] [CrossRef]

- Hussain, M.A.; Chen, Z.; Wang, R.; Shoaib, M. PS-InSAR-Based Validated Landslide Susceptibility Mapping along Karakorum Highway, Pakistan. Remote Sens. 2021, 13, 4129. [Google Scholar] [CrossRef]

- Taalab, K.; Cheng, T.; Zhang, Y. Mapping Landslide Susceptibility and Types Using Random Forest. Big Earth Data 2018, 2, 159–178. [Google Scholar] [CrossRef]

- Conoscenti, C.; Ciaccio, M.; Caraballo-Arias, N.A.; Gómez-Gutiérrez, Á.; Rotigliano, E.; Agnesi, V. Assessment of Susceptibility to Earth–Flow Landslide Using Logistic Regression and Multivariate Adaptive Regression Splines: A Case of the Belice River Basin (Western Sicily, Italy). Geomorphology 2015, 242, 49–64. [Google Scholar] [CrossRef]

- Felicísimo, Á.M.; Cuartero, A.; Remondo, J.; Quirós, E. Mapping Landslide Susceptibility with Logistic Regression, Multiple Adaptive Regression Splines, Classification and Regression Trees, and Maximum Entropy Methods: A Comparative Study. Landslides 2013, 10, 175–189. [Google Scholar] [CrossRef]

- Vorpahl, P.; Elsenbeer, H.; Märker, M.; Schröder, B. How Can Statistical Models Help to Determine Driving Factors of Landslides? Ecol. Model. 2012, 239, 27–39. [Google Scholar] [CrossRef]

- Ghasemian, B.; Shahabi, H.; Shirzadi, A.; Al-Ansari, N.; Jaafari, A.; Kress, V.R.; Geertsema, M.; Renoud, S.; Ahmad, A. A Robust Deep-Learning Model for Landslide Susceptibility Mapping: A Case Study of Kurdistan Province, Iran. Sensors 2022, 22, 1573. [Google Scholar] [CrossRef]

- Ma, J.; Wang, Y.; Niu, X.; Jiang, S.; Liu, Z. A Comparative Study of Mutual Information-Based Input Variable Selection Strategies for the Displacement Prediction of Seepage-Driven Landslides Using Optimized Support Vector Regression. Stoch. Environ. Res. Risk Assess. 2022, 36, 3109–3129. [Google Scholar] [CrossRef]

- Kalantar, B.; Pradhan, B.; Naghibi, S.A.; Motevalli, A.; Mansor, S. Assessment of the Effects of Training Data Selection on the Landslide Susceptibility Mapping: A Comparison between Support Vector Machine (SVM), Logistic Regression (LR) and Artificial Neural Networks (ANN). Geomat. Nat. Hazards Risk 2018, 9, 49–69. [Google Scholar] [CrossRef]

- Pham, B.T.; Tien Bui, D.; Pourghasemi, H.R.; Indra, P.; Dholakia, M.B. Landslide Susceptibility Assesssment in the Uttarakhand Area (India) Using GIS: A Comparison Study of Prediction Capability of Naïve Bayes, Multilayer Perceptron Neural Networks, and Functional Trees Methods. Theor. Appl. Climatol. 2017, 128, 255–273. [Google Scholar] [CrossRef]

- Pham, B.T.; Pradhan, B.; Tien Bui, D.; Prakash, I.; Dholakia, M.B. A Comparative Study of Different Machine Learning Methods for Landslide Susceptibility Assessment: A Case Study of Uttarakhand Area (India). Environ. Model. Softw. 2016, 84, 240–250. [Google Scholar] [CrossRef]

- Mehrabi, M.; Pradhan, B.; Moayedi, H.; Alamri, A. Optimizing an Adaptive Neuro-Fuzzy Inference System for Spatial Prediction of Landslide Susceptibility Using Four State-of-the-Art Metaheuristic Techniques. Sensors 2020, 20, 1723. [Google Scholar] [CrossRef] [PubMed]

- Dehnavi, A.; Aghdam, I.N.; Pradhan, B.; Morshed Varzandeh, M.H. A New Hybrid Model Using Step-Wise Weight Assessment Ratio Analysis (SWARA) Technique and Adaptive Neuro-Fuzzy Inference System (ANFIS) for Regional Landslide Hazard Assessment in Iran. Catena 2015, 135, 122–148. [Google Scholar] [CrossRef]

- Aghdam, I.N.; Varzandeh, M.H.M.; Pradhan, B. Landslide Susceptibility Mapping Using an Ensemble Statistical Index (Wi) and Adaptive Neuro–Fuzzy Inference System (ANFIS) Model at Alborz Mountains (Iran). Environ. Earth Sci. 2016, 75, 553. [Google Scholar] [CrossRef]

- Kumar, R.; Anbalagan, R. Landslide Susceptibility Zonation in Part of Tehri Reservoir Region Using Frequency Ratio, Fuzzy Logic and GIS. J. Earth Syst. Sci. 2015, 124, 431–448. [Google Scholar] [CrossRef]

- Charandabi, S.E.; Kamyar, K. Prediction of Cryptocurrency Price Index Using Artificial Neural Networks: A Survey of the Literature. Eur. J. Bus. Manag. Res. 2021, 6, 17–20. [Google Scholar] [CrossRef]

- Roshani, M.; Sattari, M.A.; Muhammad Ali, P.J.; Roshani, G.H.; Nazemi, B.; Corniani, E.; Nazemi, E. Application of GMDH Neural Network Technique to Improve Measuring Precision of a Simplified Photon Attenuation Based Two-Phase Flowmeter. Flow Meas. Instrum. 2020, 75, 101804. [Google Scholar] [CrossRef]

- Moayedi, H.; Osouli, A.; Tien Bui, D.; Foong, L.K. Spatial Landslide Susceptibility Assessment Based on Novel Neural-Metaheuristic Geographic Information System Based Ensembles. Sensors 2019, 19, 4698. [Google Scholar] [CrossRef]

- Bui, D.T.; Moayedi, H.; Kalantar, B.; Osouli, A.; Pradhan, B.; Nguyen, H.; Rashid, A.S. A Novel Swarm Intelligence—Harris Hawks Optimization for Spatial Assessment of Landslide Susceptibility. Sensors 2019, 19, 3590. [Google Scholar] [CrossRef]

- Arnone, E.; Francipane, A.; Scarbaci, A.; Puglisi, C.; Noto, L. V Effect of Raster Resolution and Polygon–Conversion Algorithm on Landslide Susceptibility Mapping. Environ. Model. Softw. 2016, 84, 467–481. [Google Scholar] [CrossRef]

- Aditian, A.; Kubota, T.; Shinohara, Y. Comparison of GIS-Based Landslide Susceptibility Models Using Frequency Ratio, Logistic Regression, and Artificial Neural Network in a Tertiary Region of Ambon, Indonesia. Geomorphology 2018, 318, 101–111. [Google Scholar] [CrossRef]

- Kornejady, A.; Ownegh, M.; Bahremand, A. Landslide Susceptibility Assessment Using Maximum Entropy Model with Two Different Data Sampling Methods. Catena 2017, 152, 144–162. [Google Scholar] [CrossRef]

- Park, N.-W. Using Maximum Entropy Modeling for Landslide Susceptibility Mapping with Multiple Geoenvironmental Data Sets. Environ. Earth Sci. 2015, 73, 937–949. [Google Scholar] [CrossRef]

- Dang, V.-H.; Hoang, N.-D.; Nguyen, L.-M.-D.; Bui, D.T.; Samui, P. A Novel GIS-Based Random Forest Machine Algorithm for the Spatial Prediction of Shallow Landslide Susceptibility. Forests 2020, 11, 118. [Google Scholar] [CrossRef]

- Wu, X.; Ren, F.; Niu, R. Landslide Susceptibility Assessment Using Object Mapping Units, Decision Tree, and Support Vector Machine Models in the Three Gorges of China. Environ. Earth Sci. 2014, 71, 4725–4738. [Google Scholar] [CrossRef]

- Merghadi, A.; Yunus, A.P.; Dou, J.; Whiteley, J.; ThaiPham, B.; Bui, D.T.; Avtar, R.; Abderrahmane, B. Machine Learning Methods for Landslide Susceptibility Studies: A Comparative Overview of Algorithm Performance. Earth-Sci. Rev. 2020, 207, 103225. [Google Scholar] [CrossRef]

- Sahin, E.K. Comparative Analysis of Gradient Boosting Algorithms for Landslide Susceptibility Mapping. Geocarto Int. 2022, 37, 2441–2465. [Google Scholar] [CrossRef]

- Pumhirunroj, B.; Littidej, P.; Boonmars, T.; Artchayasawat, A.; Prasertsri, N.; Khamphilung, P.; Sangpradid, S.; Buasri, N.; Uttha, T.; Slack, D. Spatial Predictive Modeling of Liver Fluke Opisthorchis Viverrine (OV) Infection under the Mathematical Models in Hexagonal Symmetrical Shapes Using Machine Learning–Based Forest Classification Regression. Symmetry 2024, 16, 1067. [Google Scholar] [CrossRef]

- Guo, P.-T.; Zhu, A.-X.; Cha, Z.-Z.; Li, M.-F.; Luo, W. A Local Model Based on Environmental Variables Clustering for Estimating Foliar Phosphorus of Rubber Trees with Vis–NIR Spectroscopic Data. Heliyon 2022, 8, e09795. [Google Scholar] [CrossRef]

- Bunmi Mudashiru, R.; Sabtu, N.; Abdullah, R.; Saleh, A.; Abustan, I. Optimality of Flood Influencing Factors for Flood Hazard Mapping: An Evaluation of Two Multi-Criteria Decision-Making Methods. J. Hydrol. 2022, 612, 128055. [Google Scholar] [CrossRef]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Cutler, A.; Cutler, D.R.; Stevens, J.R. Random Forests BT–Ensemble Machine Learning: Methods and Applications; Zhang, C., Ma, Y., Eds.; Springer: New York, NY, USA, 2012; pp. 157–175. ISBN 978-1-4419-9326-7. [Google Scholar]

- Belgiu, M.; Drăguţ, L. Random Forest in Remote Sensing: A Review of Applications and Future Directions. ISPRS J. Photogramm. Remote Sens. 2016, 114, 24–31. [Google Scholar] [CrossRef]

- Li, H.; Beldring, S.; Xu, C.-Y.; Huss, M.; Melvold, K.; Jain, S.K. Integrating a Glacier Retreat Model into a Hydrological Model–Case Studies of Three Glacierised Catchments in Norway and Himalayan Region. J. Hydrol. 2015, 527, 656–667. [Google Scholar] [CrossRef]

- Prinzie, A.; Van den Poel, D. Random Multiclass Classification: Generalizing Random Forests to Random MNL and Random NB BT–Database and Expert Systems Applications; Wagner, R., Revell, N., Pernul, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 349–358. [Google Scholar]

- Choubin, B.; Borji, M.; Mosavi, A.; Sajedi–Hosseini, F.; Singh, V.P.; Shamshirband, S. Snow Avalanche Hazard Prediction Using Machine Learning Methods. J. Hydrol. 2019, 577, 123929. [Google Scholar] [CrossRef]

- Wang, H.; Zheng, H. True Positive Rate BT–Encyclopedia of Systems Biology; Dubitzky, W., Wolkenhauer, O., Cho, K.-H., Yokota, H., Eds.; Springer: New York, NY, USA, 2013; pp. 2302–2303. ISBN 978-1-4419-9863-7. [Google Scholar]

- Fawcett, T. An Introduction to ROC Analysis. Pattern Recognit. Lett. 2006, 27, 861–874. [Google Scholar] [CrossRef]

- Fan, J.; Upadhye, S.; Worster, A. Understanding Receiver Operating Characteristic (ROC) Curves. Can. J. Emerg. Med. 2006, 8, 19–20. [Google Scholar] [CrossRef]

| Number of Trees | 100 |

|---|---|

| Leaf Size | 5 |

| Tree Depth Range | 17–33 |

| Mean Tree Depth | 22 |

| % of Training Data Available per Tree | 100 |

| Number of Randomly Sampled Variables | 2 |

| % of Training Data Excluded for Validation | 10 |

| Number of Trees | 50 | 100 |

|---|---|---|

| MSE | 758.876 | 702.985 |

| % of Variation Explained | −25.169 | −15.951 |

| Variable | Importance | % |

|---|---|---|

| X2 | 79,633.31 | 15 |

| X5 | 78,805.16 | 15 |

| X4 | 78,556.29 | 15 |

| X8 | 77,602.85 | 15 |

| X6 | 75,886.30 | 14 |

| X7 | 73,357.62 | 14 |

| X1 | 48,716.34 | 9 |

| X3 | 18,135.91 | 3 |

| Alternative Models | Factors of FCR and OLS Model | RMSE (kg./ha.) | R2 (FCR) | R2 (OLS) | Difference in R2 (FCR > OLS) |

|---|---|---|---|---|---|

| Model 1 | X4, X5, X8 | 19.15 | 0.787 | 0.642 | +18.42% |

| Model 2 | X3, X6, X7 | 28.97 | 0.542 | 0.503 | +7.19% |

| Model 3 | X1, X2, X6 | 30.26 | 0.730 | 0.586 | +19.72% |

| Model 4 | X1, X2, X3, X4, X5, X6, X7, X8 | 15.87 | 0.821 | 0.678 | +17.41% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Littidej, P.; Kromkratoke, W.; Pumhirunroj, B.; Buasri, N.; Prasertsri, N.; Sangpradid, S.; Slack, D. Enhanced Rubber Yield Prediction in High-Density Plantation Areas Using a GIS and Machine Learning-Based Forest Classification and Regression Model. Forests 2024, 15, 1535. https://doi.org/10.3390/f15091535

Littidej P, Kromkratoke W, Pumhirunroj B, Buasri N, Prasertsri N, Sangpradid S, Slack D. Enhanced Rubber Yield Prediction in High-Density Plantation Areas Using a GIS and Machine Learning-Based Forest Classification and Regression Model. Forests. 2024; 15(9):1535. https://doi.org/10.3390/f15091535

Chicago/Turabian StyleLittidej, Patiwat, Winyoo Kromkratoke, Benjamabhorn Pumhirunroj, Nutchanat Buasri, Narueset Prasertsri, Satith Sangpradid, and Donald Slack. 2024. "Enhanced Rubber Yield Prediction in High-Density Plantation Areas Using a GIS and Machine Learning-Based Forest Classification and Regression Model" Forests 15, no. 9: 1535. https://doi.org/10.3390/f15091535

APA StyleLittidej, P., Kromkratoke, W., Pumhirunroj, B., Buasri, N., Prasertsri, N., Sangpradid, S., & Slack, D. (2024). Enhanced Rubber Yield Prediction in High-Density Plantation Areas Using a GIS and Machine Learning-Based Forest Classification and Regression Model. Forests, 15(9), 1535. https://doi.org/10.3390/f15091535