Strength Grading of Full-Scale Chinese Fast-Growing Poplar Wood for Structural Building Applications

Abstract

:1. Introduction

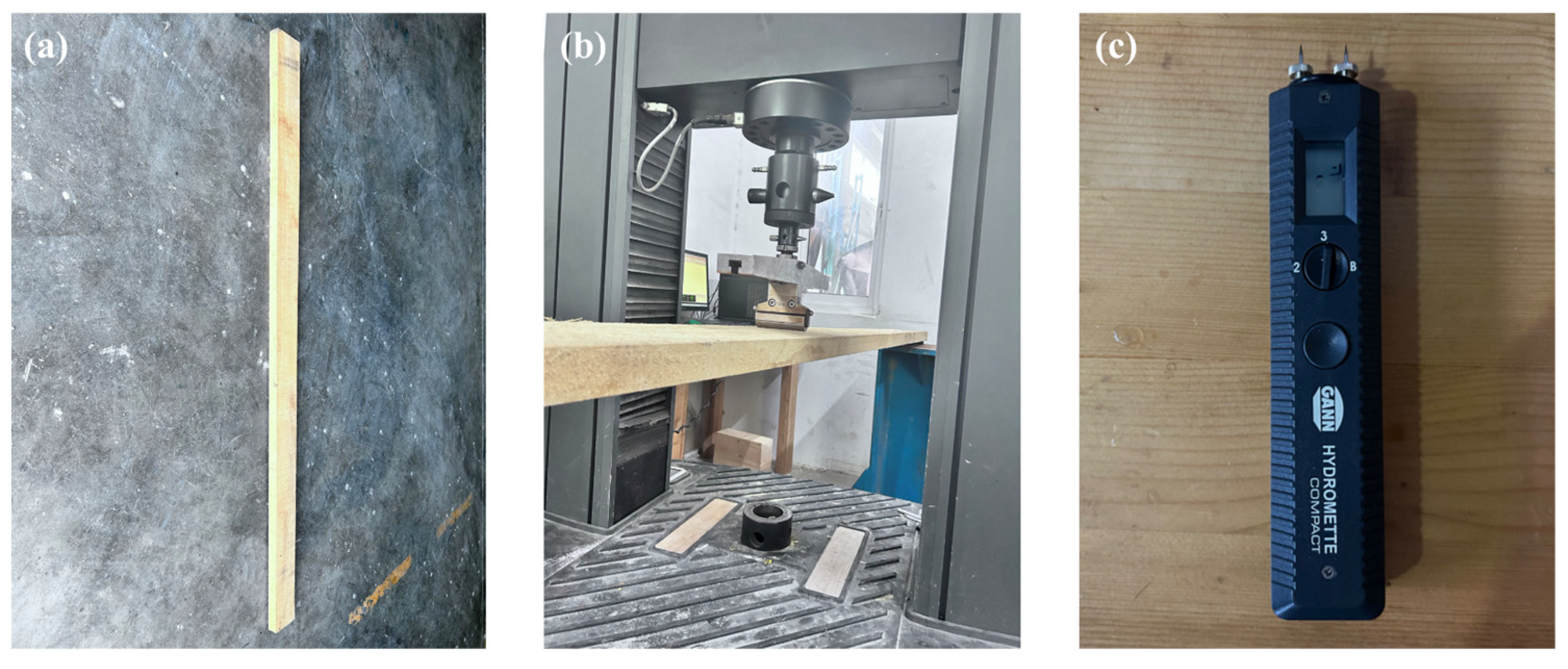

2. Materials and Methods

2.1. Materials

2.2. Methods

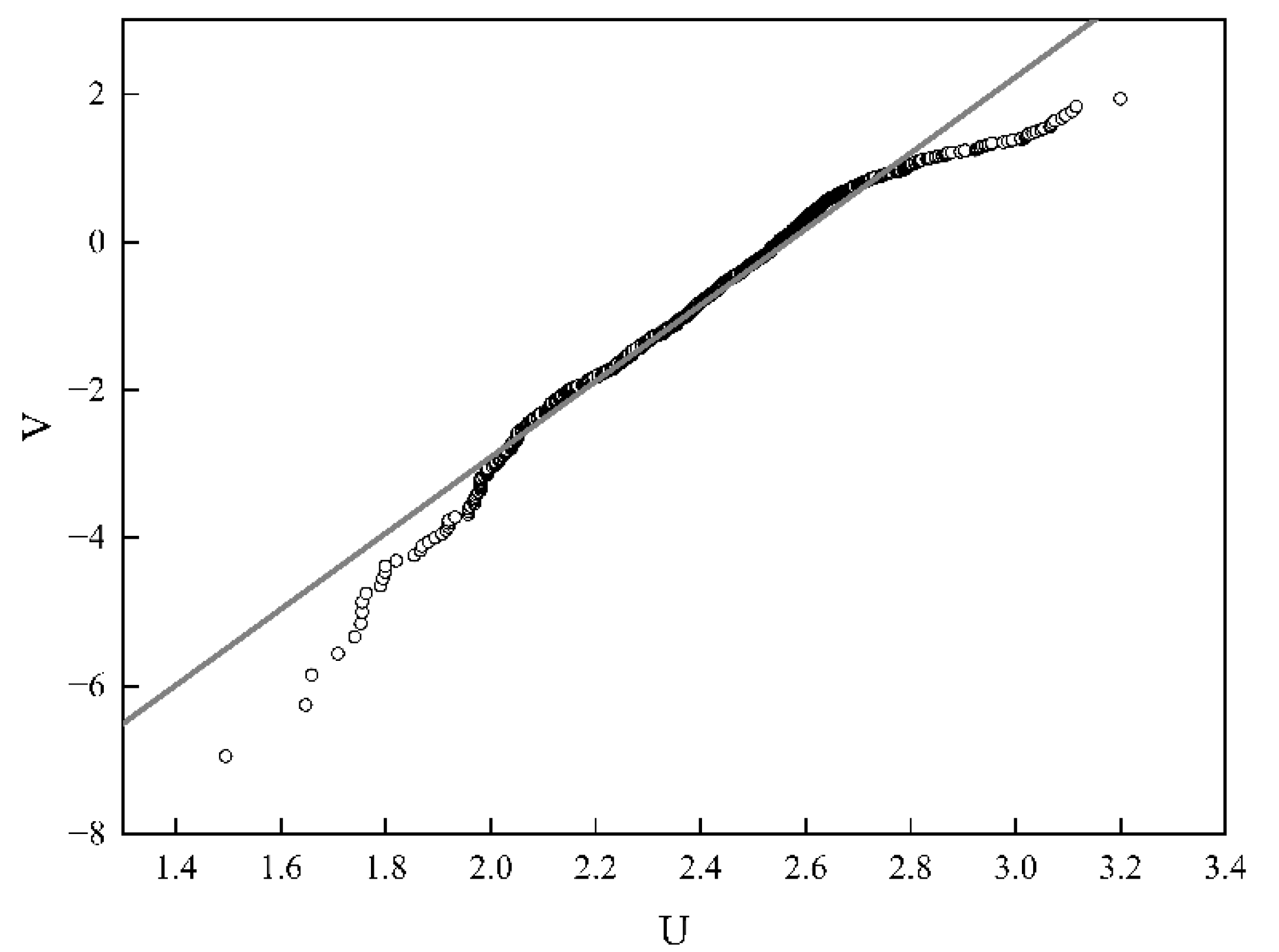

2.3. Weibull, Normal, and Log-Normal Distribution Fitting Tests

2.3.1. Weibull Distribution

2.3.2. Weibull Distribution Fitting Test

2.3.3. Normal and Log-Normal Distribution Fitting Tests

2.3.4. Parameter Estimation

2.4. Timber Classification

3. Results and Discussion

3.1. Normal Distribution and Log-Normal Distribution Tests

3.2. Weibull Distribution Test and Strength Grading of Poplar

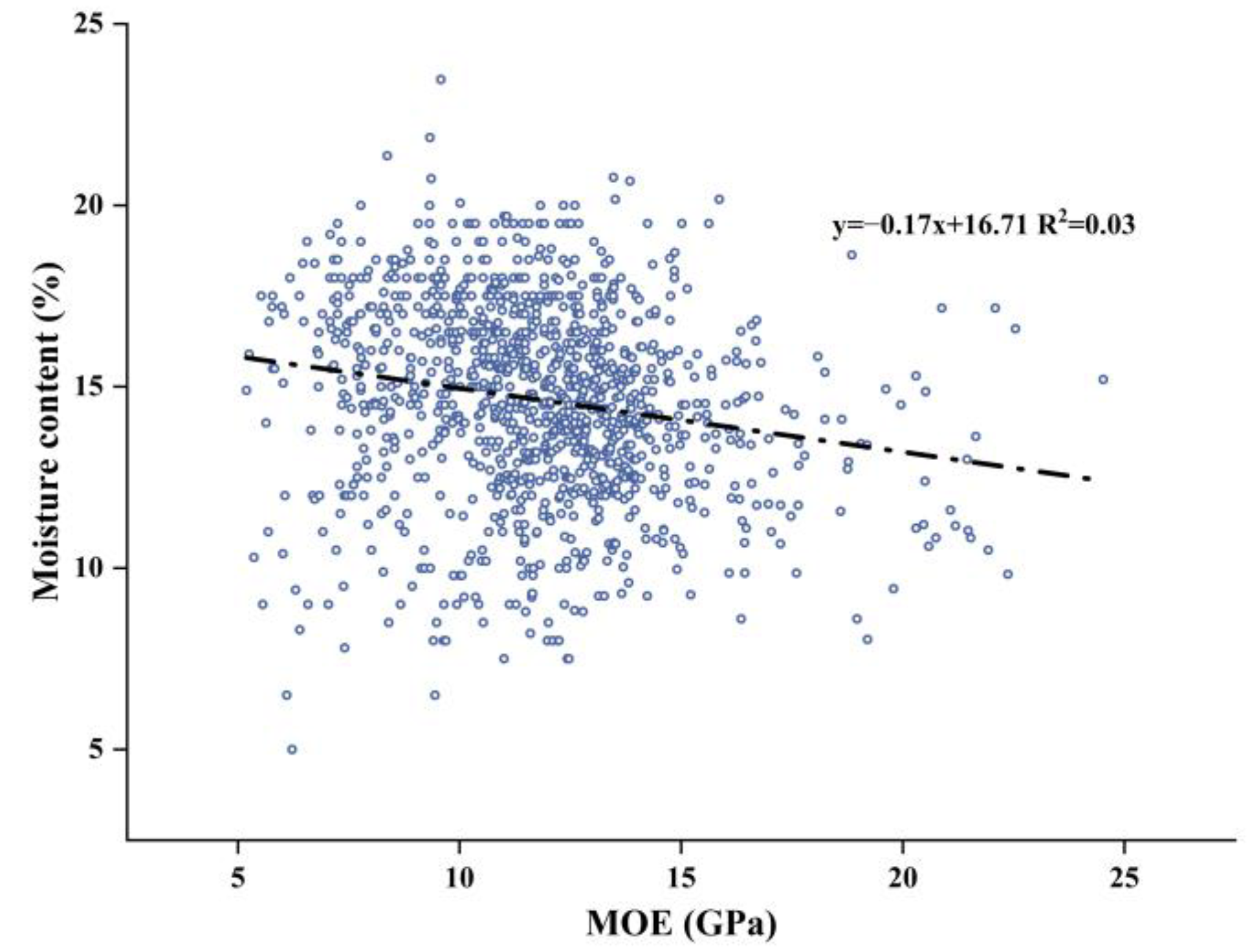

3.3. Effect of Density and Moisture Content on MOE

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Burawska-Kupniewska, I.; Krzosek, S.; Mankowski, P. Efficiency of visual and machine strength grading of sawn timber with respect to log type. Forests 2021, 12, 1467. [Google Scholar] [CrossRef]

- Cossalter, C.; Pye-Smith, C. Fast-Wood Forestry: Myths and Realities; CIFOR: Bogor, Indonesia, 2003. [Google Scholar]

- Lu, J.; Xu, K.; Liu, Y.; Wu, Y.; Li, X. Research progresses on reinforced modification of poplar wood from fast-growing plantation. J. Cent. South Univ. For. Technol. 2014, 34, 99–103. [Google Scholar]

- David, A.J.; Zasada, J.C.; Gilmore, D.W.; Landhausser, S.M. Current trends in the management of aspen and mixed aspen forests for sustainable production. For. Chron. 2001, 77, 525–532. [Google Scholar] [CrossRef]

- Niu, Z.; Li, J.; Zhang, Q.; Zhou, H.; Chen, Z. Achievements in the utilization of poplar wood in north America and guideposts for the future. World For. Res. 2007, 20, 58–62. [Google Scholar]

- Xu, B.H.; Wang, B.L.; Yu, K.B.; Bouchair, A. An optional connection material in timber structures: Densified poplar. J. Mater. Sci. 2021, 56, 14114–14125. [Google Scholar] [CrossRef]

- Shi, X.L.; Yue, K.; Jiao, X.K.; Zhang, Z.F.; Li, Z. Experimental investigation into lateral performance of cross-laminated timber (CLT) shear walls made from fast-growing poplar wood. Wood Mater. Sci. Eng. 2023, 18, 1212–1227. [Google Scholar] [CrossRef]

- Bytner, O.; Drożdżek, M.; Laskowska, A.; Zawadzki, J. Influence of thermal modification in nitrogen atmosphere on the selected mechanical properties of black poplar wood (Populus nigra L.). Materials 2022, 15, 7949. [Google Scholar] [CrossRef]

- Yue, K.; Qian, J.; Wu, P.; Jiao, X.K.; Lu, D.; Song, X.L. Experimental analysis of thermally-treated Chinese poplar wood with focus on structural application. Ind. Crop Prod. 2023, 197, 116612. [Google Scholar] [CrossRef]

- Yue, K.; Song, X.L.; Jiao, X.K.; Wang, L.; Jia, C.; Chen, Z.J.; Liu, W.Q. An experimental study on flexural behavior of glulam beams made out of thermally treated fast-growing poplar laminae. Wood Fiber Sci. 2020, 52, 152–164. [Google Scholar] [CrossRef]

- Peng, Y.; Fan, Q.; Ou, R.; Hao, X.; Guo, C.; Liu, Z.; Liu, T.; Sun, L.; Wang, Q. Modification of poplar wood cells using 1,3-dihydroxymethyl-4,5-dihydroxyethylideneurea/alkaline lignin for enhanced mechanical properties and decay resistance. Constr. Build. Mater. 2023, 368, 130354. [Google Scholar] [CrossRef]

- Cheng, X.W.; Lu, D.; Yue, K.; Lu, W.D.; Zhang, Z.F. Fire resistance improvement of fast-growing poplar wood based on combined modification by resin impregnation and compression. Polymers 2022, 14, 3574. [Google Scholar] [CrossRef] [PubMed]

- Candan, Z.; Korkut, S.; Unsal, O. Effect of thermal modification by hot pressing on performance properties of paulownia wood boards. Ind. Crop Prod. 2013, 45, 461–464. [Google Scholar] [CrossRef]

- Mederski, P.S.; Bembenek, M.; Karaszewski, Z.; Giefing, D.F.; Sulima-Olejniczak, E.; Rosinska, M.; Lacka, A. Density and mechanical properties of scots pine (Pinus sylvestris L.) wood from a seedling seed orchard. Drewno 2015, 58, 117–124. [Google Scholar] [CrossRef]

- Zeidler, A.; Boruvka, V.; Schonfelder, O. Comparison of wood quality of Douglas fir and spruce from afforested agricultural land and permanent forest land in the Czech Republic. Forests 2018, 9, 13. [Google Scholar] [CrossRef]

- GB/T 26899 2022; Glued Laminated Timber. Standardization Administration of China: Beijing, China, 2022.

- Jahedi, S.; Muszynski, L.; Riggio, M.; Blengino, B.B.; Bhandari, S. MOE distribution in visually graded ponderosa pine lumber harvested from restoration programs in southern Oregon and northern California. Wood Fiber Sci. 2022, 54, 90–98. [Google Scholar] [CrossRef]

- Green, D.W.; Kretschmann, D.E. Lumber property relationships for engineering design standards. Wood Fiber Sci. 1991, 23, 436–456. [Google Scholar]

- Zafeiropoulos, N.E.; Baillie, C.A. A study of the effect of surface treatments on the tensile strength of flax fibers: Part ii. Application of Weibull statistics. Compos. Part. A Appl. 2007, 38, 629–638. [Google Scholar] [CrossRef]

- Trustrum, K.; Jayatilaka, A.D. Applicability of Weibull analysis for brittle materials. J. Mater. Sci. 1983, 18, 2765–2770. [Google Scholar] [CrossRef]

- Shao, J.X.; Wang, F.; Li, L.; Zhang, J.Q. Scaling analysis of the tensile strength of bamboo fibers using Weibull statistics. Adv. Mater. Sci. Eng. 2013, 2013, 167823. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Y.; Liu, B. Probability distribution of MOE and mechanical properties of SPF dimension lumbers. J. Nanjing For. Univ. Nat. Sci. Ed. 2014, 38, 157–160. [Google Scholar]

- Klemenc, J.; Fajdiga, G. Statistical modelling of the fatigue bending strength of Norway spruce wood. Materials 2022, 15, 536. [Google Scholar] [CrossRef] [PubMed]

- Xie, W.; Wang, Z.; Zhang, Z.; Wang, Z. Dynamic test of laminated veneer lumber elastic modulus and its probability distribution. Bioresources 2021, 16, 3318–3327. [Google Scholar] [CrossRef]

- GB/T 1927.5 2021; Test Methods for Physical and Mechanical Properties of Small Clear Wood Specimens—Part 5: Determination of Density. Standardization Administration of China: Beijing, China, 2021.

- GB/T 1927.10 2021; Test Methods for Physical and Mechanical Properties of Small Clear Wood Specimens—Part 10: Determination of Modulus of Elasticity in Bending. Standardization Administration of China: Beijing, China, 2021.

- Weibull, W. A statistical distribution function of wide applicability. J. Appl. Mech. 1951, hal-03112318. Available online: https://hal.science/hal-03112318/document (accessed on 9 September 2024). [CrossRef]

- Lv, Y. Research on Maintenance Decision Making of Nuclear Power Plant Based on Multi-Objective Optimization. Master’s Thesis, Tsinghua University, Beijing, China, 2016. [Google Scholar]

- EN 338 2016; Structural Timber—Strength Classes. CEN: Brussels, Belgium, 2016.

- Yue, K.; Li, X.; Jiao, X.; Wu, P.; Song, X. Strength grading of Chinese poplar wood for structural use following thermal modification. Polym. Test. 2023, 123, 108032. [Google Scholar] [CrossRef]

- Yue, K.; Lu, D.; Song, X.S. The Influence of Thermal Modification on Poplar Strength Class by Fourier Infrared Spectrum Analysis. Spectrosc. Spect. Anal. 2023, 43, 848–853. [Google Scholar]

- EN 384 2016; Structural Timber—Determination of Characteristic Values of Mechanical Properties and Density. CEN: Brussels, Belgium, 2016.

- Tian, Z.P.; Xu, J.H.; Li, M.Y.; Wang, Z.H.; Serrano, E.R.; Gong, Y.C.; Ren, H.Q. Characteristic value of the modulus of elasticity (MOE) for natural and planted larch in northeast China. Forests 2021, 12, 883. [Google Scholar] [CrossRef]

- Ding, J.; Chen, G.; Huang, W.; Cheng, J.; Li, T.; Cheng, C.; Xu, J. Tensile strength statistics and fracture mechanism of ultrahigh molecular weight polyethylene fibers: On the Weibull distribution. ACS Omega 2024, 9, 12984–12991. [Google Scholar] [CrossRef]

- Xia, Y.; Yue, K.; Zhang, W.; Lu, X. Variations in wood density of fast-growing poplar and its relationship with mechanical strengths. J. Northeast For. Univ. 2010, 38, 5–6. [Google Scholar]

- Wang, S.Y.; Chen, J.H.; Tsai, M.J.; Lin, C.J.; Yang, T.H. Grading of softwood lumber using non-destructive techniques. J. Mater. Process. Tech. 2008, 208, 149–158. [Google Scholar] [CrossRef]

- Wang, S.Y.; Lin, S.H. Effect of plantation spacing with quality of visually graded limber and mechanical properties of Taiwan-growth Japanese cedar. Mokuzai Gakkaishi 1996, 42, 435–444. [Google Scholar]

- Burdzik, W.M.; Nkwera, P.D. Transverse vibration tests for prediction of stiffness and strength properties of full size eucalyptus grandis. For. Prod. J. 2002, 52, 63. [Google Scholar]

- Hou, J.; Taoum, A.; Nolan, G.; Kotlarewski, N. Study of the relationship between flatwise and edgewise modulus of elasticity of plantation fibre-managed E. nitens sawn boards. Constr. Build. Mater. 2022, 349, 128774. [Google Scholar] [CrossRef]

- Wang, X.; Ma, J.; Xu, W.; Fei, B.; Lian, C.; Sun, F. Effect of bending on radial distribution density, MFA and MOE of bent bamboo. Sci. Rep. 2022, 12, 8610. [Google Scholar] [CrossRef] [PubMed]

| Distribution | Skewness | Kurtosis | R2 | K–S |

|---|---|---|---|---|

| Z-Score | ||||

| Normal | 0.259 | 0.235 | / | / |

| Log-normal | 8.87 | 3.38 | / | / |

| Weibull | / | / | 0.969 | 0.051 |

| Given MOE Range | Probability |

|---|---|

| (μ − σ, μ + σ) | 0.959 |

| (μ − 2σ, μ + 2σ) | 0.999 |

| (μ − 3σ, μ + 3σ) | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, J.; Yue, K.; Li, X.; Pu, Y.; Chen, K.; Wu, P.; Zhang, Z. Strength Grading of Full-Scale Chinese Fast-Growing Poplar Wood for Structural Building Applications. Forests 2024, 15, 1602. https://doi.org/10.3390/f15091602

Qian J, Yue K, Li X, Pu Y, Chen K, Wu P, Zhang Z. Strength Grading of Full-Scale Chinese Fast-Growing Poplar Wood for Structural Building Applications. Forests. 2024; 15(9):1602. https://doi.org/10.3390/f15091602

Chicago/Turabian StyleQian, Jin, Kong Yue, Xiang Li, Yan Pu, Kaiyi Chen, Peng Wu, and Zhongfeng Zhang. 2024. "Strength Grading of Full-Scale Chinese Fast-Growing Poplar Wood for Structural Building Applications" Forests 15, no. 9: 1602. https://doi.org/10.3390/f15091602