Optimization of Quality Attributes and Atomic Force Microscopy Imaging of Reconstituted Nanodroplets in Baicalin Loaded Self-Nanoemulsifying Formulations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Solubility Studies

2.3. Screening of Surfactants for Emulsifying Ability

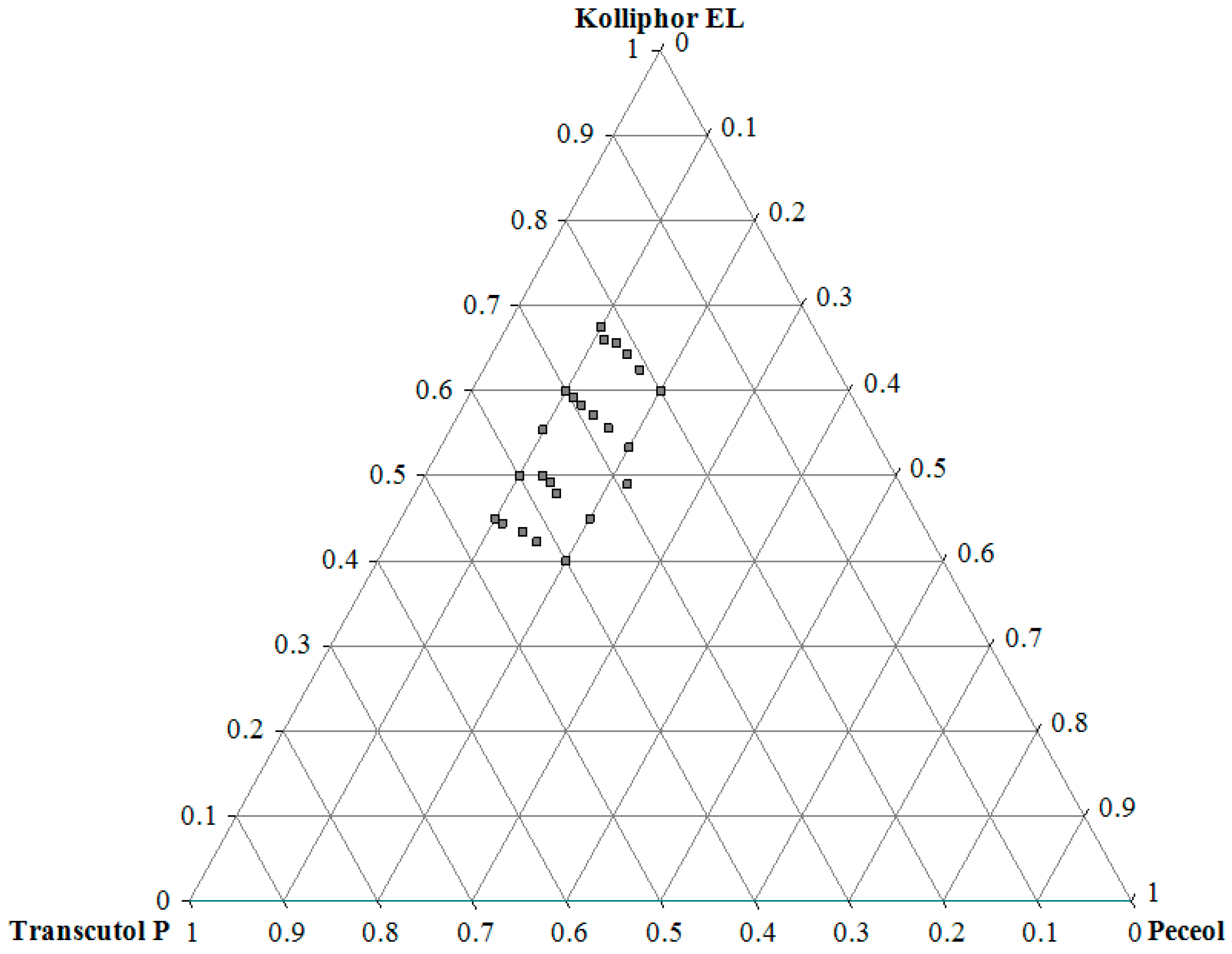

2.4. Construction of Ternary Phase Diagram

2.5. Preparation of Self-Nanoemulsifying Formulations without (SNEDDS) and with Baicalin (BSNEDDS)

2.6. Optimization of SNEDDS Pre-concentrates

2.7. Characterization of Optimized BSNEDDS

2.7.1. Droplet size, Transmittance, PDI, and Zeta-Potential Measurements

2.7.2. Determination of the Thermodynamic Solubility of Baicalin in Optimized SNEDDS

2.7.3. Cloudpoint Measurement

2.7.4. Effect of Dilution on Droplet Size and PDI

2.7.5. Long-Term Physical Stability of Nanoemulsions

2.7.6. Atomic Force Microscopy (AFM)

Sample Preparation for AFM Imaging

AFM Imaging and Analysis

2.8. In Vitro Dissolution Study and Nanoemulsifying Ability Test of BSNEDDS

3. Results

3.1. Solubility Studies

3.2. Screening of Surfactants for Emulsifying Ability

3.3. Construction of Ternary Phase Diagram

3.4. Optimization of SNEDDS Pre-concentrates

3.5. Characterization of Optimized BSNEDDS

3.5.1. Droplet Size, Transmittance, PDI, and Zeta-Potential Measurements. Comparison of Loaded and Unloaded SNEDDS

3.5.2. Determination of the Thermodynamic Solubility of Baicalin in Optimized SNEDDS

3.5.3. Cloudpoint Measurement

3.5.4. Effect of Dilution on Droplet Size and PDI

3.5.5. Long-Term Physical Stability of Nanoemulsions

3.5.6. Atomic Force Microscopy

3.6. In Vitro Dissolution Study and Nanoemulsifying Ability Test of BSNEDDS

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chen, H.; Gao, Y.; Wu, J.; Chen, Y.; Chen, B.; Hu, J.; Zhou, J. Exploring therapeutic potentials of baicalin and its aglycone baicalein for hematological malignancies. Cancer Lett. 2014, 354, 5–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- European Pharmacopoeia. Names of herbal drugs used in traditional Chinese medicine. In Ph. Eur. 9.3.; European Pharmacopoeia: Strasbourg, France, 2018; p. 01/2018:52200. [Google Scholar]

- Li-weber, M. New therapeutic aspects of flavones: The anticancer properties of Scutellaria and its main active constituents Wogonin, Baicalein and Baicalin. Cancer Treat. Rev. 2009, 35, 57–68. [Google Scholar] [CrossRef] [PubMed]

- Shin, S.H.; Bak, S.-S.; Kim, M.K.; Sung, Y.K.; Kim, J.C. Baicalin, a flavonoid, affects the activity of human dermal papilla cells and promotes anagen induction in mice. N.-S. Arch. Pharmacol. 2015, 388, 583–586. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Long, X.; Yuan, F.; Chen, L.; Pan, S.; Liu, Y.; Stowell, Y.; Li, X. Combined use of phospholipid complexes and self-emulsifying microemulsions for improving the oral absorption of a BCS class IV compound, baicalin. Acta Pharm. Sin. B 2014, 4, 217–226. [Google Scholar] [CrossRef] [PubMed]

- Liang, R.A.N.; Rui-Min, H.A.N.; Li-Min, F.U.; Xi-Cheng, A.I.; Zhang, J.P.; Skibsted, L.H. Baicalin in radical scavenging and its synergistic effect with β-carotene in antilipoxidation. J. Agric. Food Chem. 2009, 57, 7118–7124. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Wen, M.; Li, W.; He, M.; Yang, X.; Li, S. Preparation and characterization of baicalin-poly-vinylpyrrolidone coprecipitate. Int. J. Pharm. 2011, 408, 91–96. [Google Scholar] [CrossRef] [PubMed]

- Feng, Z.; Zhou, J.; Shang, X.; Kuang, G.; Han, J.; Lu, L.; Zhang, L. Comparative research on stability of baicalin and baicalein administrated in monomer and total flavonoid fraction form of Radix scutellariae in biological fluids in vitro. Pharm. Biol. 2017, 55, 1177–1184. [Google Scholar] [CrossRef] [PubMed]

- Xing, J.; Chen, X.; Zhong, D. Absorption and enterohepatic circulation of baicalin in rats. Life Sci. 2005, 78, 140–146. [Google Scholar] [CrossRef] [PubMed]

- Kalapos-Kovács, B.; Magda, B.; Jani, M.; Fekete, Z.; Szabó, P.T.; Antal, I.; Krajcsi, P.; Klebovich, I. Multiple ABC Transporters Efflux Baicalin. Phyther. Res. 2015, 29, 1987–1990. [Google Scholar] [CrossRef]

- Li, J.; Jiang, Q.; Deng, P.; Chen, Q.; Yu, M.; Shang, J.; Li, W. The formation of a host-guest inclusion complex system between β-cyclodextrin and baicalin and its dissolution characteristics. J. Pharm. Pharmacol. 2017, 69, 663–674. [Google Scholar] [CrossRef]

- Manconi, M.; Manca, M.L.; Caddeo, C.; Cencetti, C.; di Meo, C.; Zoratto, N.; Nacher, A.; Fadda, A.M.; Matricardi, P. Preparation of gellan-cholesterol nanohydrogels embedding baicalin and evaluation of their wound healing activity. Eur. J. Pharm. Biopharm. 2018, 127, 244–249. [Google Scholar] [CrossRef] [PubMed]

- Yeom, D.W.; Song, Y.S.; Kim, S.R.; Lee, S.G.; Kang, M.H.; Lee, S.; Choi, Y.W. Development and optimization of a self-microemulsifying drug delivery system for atorvastatin calcium by using D-optimal mixture design. Int. J. Nanomed. 2015, 10, 3865–3878. [Google Scholar] [CrossRef]

- Gershanik, T.; Benita, S. Self-dispersing lipid formulations for improving oral absorption of lipophilic drugs. Eur. J. Pharm. Biopharm. 2000, 50, 179–188. [Google Scholar] [CrossRef]

- Pouton, C.W.; Porter, C.J.H. Formulation of lipid-based delivery systems for oral administration: Materials, methods and strategies. Adv. Drug Deliv. Rev. 2008, 60, 625–637. [Google Scholar] [CrossRef]

- Chatterjee, B.; Almurisi, S.H.; Dukhan, A.A.M.; Mandal, U.K.; Sengupta, P. Controversies with self-emulsifying drug delivery system from pharmacokinetic point of view. Drug Deliv. 2016, 23, 3639–3652. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Anton, N.; Vandamme, T.F. Nano-emulsions and micro-emulsions: Clarifications of the critical differences. Pharm. Res. 2011, 28, 978–985. [Google Scholar] [CrossRef]

- McClements, D.J. Nanoemulsions versus microemulsions: Terminology, differences, and similarities. Soft Matter 2012, 8, 1719–1729. [Google Scholar] [CrossRef]

- Setya, S.; Talegaonkar, S.; Razdan, B.K. Nanoemulsions:Formulation Methods and Stability Aspects. World J. Pharm. Pharm. Sci. 2014, 3, 2214–2228. [Google Scholar]

- McClements, D.J.; Rao, J. Food-grade nanoemulsions: Formulation, fabrication, properties, performance, biological fate, and potential toxicity. Crit. Rev. Food Sci. Nutr. 2011, 51, 285–330. [Google Scholar] [CrossRef]

- Marques, S.; Sarmento, B. Measuring the emulsi fi cation dynamics and stability of self-emulsifying drug delivery systems. Eur. J. Pharm. Biopharm. 2018, 123, 1–8. [Google Scholar] [CrossRef]

- Sitterberg, J.; Özcetin, A.; Ehrhardt, C.; Bakowsky, U. Utilising atomic force microscopy for the characterisation of nanoscale drug delivery systems. Eur. J. Pharm. Biopharm. 2010, 74, 2–13. [Google Scholar] [CrossRef] [PubMed]

- Rehman, F.U.; Shah, K.U.; Shah, S.U.; Khan, I.U. From nanoemulsions to self-nanoemulsions, with recent advances in self-nanoemulsifying drug delivery systems (SNEDDS). Expert Opin. Drug Deliv. 2016, 5247, 1325–1340. [Google Scholar] [CrossRef] [PubMed]

- Patel, J.; Patel, A.; Raval, M.; Sheth, N. Formulation and development of a self-nanoemulsifying drug delivery system of irbesartan. J. Adv. Pharm. Technol. Res. 2011, 2, 9–16. [Google Scholar] [CrossRef]

- Date, A.A.; Nagarsenker, M.S. Design and evaluation of self-nanoemulsifying drug delivery systems (SNEDDS) for cefpodoxime proxetil. Int. J. Pharm. 2007, 329, 166–172. [Google Scholar] [CrossRef]

- Solanki, N. Self Emulsifying Drug Delivery System (Sedds): A Review. Int. J. Pharm. Res. Bio-Sci. 2012, 1, 313–323. [Google Scholar] [CrossRef]

- Gursoy, R.N.; Benita, S. Self-emulsifying drug delivery systems (SEDDS) for improved oral delivery of lipophilic drugs. Biomed. Pharmacother. 2004, 58, 173–182. [Google Scholar] [CrossRef] [PubMed]

- Gurram, A.K.; Deshpande, P.B.; Kar, S.S.; Nayak, U.Y.; Udupa, N.; Reddy, M.S. Role of Components in the Formation of Self-microemulsifying Drug Delivery Systems. Indian J. Pharm. Sci. 2015, 77, 249–257. [Google Scholar]

- Villar, A.M.S.; Naveros, B.C.; Campmany, A.C.C.; Trenchs, M.A.; Rocabert, C.B.; Bellowa, L.H. Design and optimization of self-nanoemulsifying drug delivery systems (SNEDDS) for enhanced dissolution of gemfibrozil. Int. J. Pharm. 2012, 431, 161–175. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pouton, C.W. Formulation of poorly water-soluble drugs for oral administration: Physicochemical and physiological issues and the lipid formulation classification system. Eur. J. Pharm. Sci. 2006, 29, 278–287. [Google Scholar] [CrossRef]

- Date, A.A.; Nagarsenker, M.S. Parenteral microemulsions: An overview. Int. J. Pharm. 2008, 355, 19–30. [Google Scholar] [CrossRef]

- Warisnoicharoen, W.; Lansley, A.B.; Lawrence, M.J. Nonionic oil-in-water microemulsions: The effect of oil type on phase behaviour. Int. J. Pharm. 2000, 198, 7–27. [Google Scholar] [CrossRef]

- Christiansen, A.; Backensfeld, T.; Denner, K.; Weitschies, W. Effects of non-ionic surfactants on cytochrome P450-mediated metabolism in vitro. Eur. J. Pharm. Biopharm. 2011, 78, 166–172. [Google Scholar] [CrossRef] [PubMed]

- Saritha, D.; Subhash, P.; Bose, C.; Nagaraju, R. Formulation and Evaluation of Self Emulsifying Drug Delivery System (Sedds) of Ibuprofen. Int. J. Pharm. Sci. Res. 2014, 5, 3511–3519. [Google Scholar] [CrossRef]

- Sood, S.; Jain, K.; Gowthamarajan, K. Optimization of curcumin nanoemulsion for intranasal delivery using design of experiment and its toxicity assessment. Colloids Surf. B Biointerfaces 2014, 113, 330–337. [Google Scholar] [CrossRef] [PubMed]

- Mbah, C.C.; Builders, P.F.; Attama, A.A. Nanovesicular carriers as alternative drug delivery systems: Ethosomes in focus. Expert Opin. Drug Deliv. 2014, 11, 45–59. [Google Scholar] [CrossRef]

- Tarr, B.D.; Yalkowsky, S.H. Enhanced intestinal absorption of cyclosporine in rats through the reduction of emulsion droplet size. Pharm. Res. 1989, 6, 40–43. [Google Scholar] [CrossRef] [PubMed]

- Ribeiro, R.C.d.; Barreto, S.M.A.G.; Ostrosky, E.A.; da Rocha-Filho, P.A.; Veríssimo, L.M.; Ferrari, M. Production and characterization of cosmetic nanoemulsions containing Opuntia ficus-indica (L.) Mill extract as moisturizing agent. Molecules 2015, 20, 2492–2509. [Google Scholar] [CrossRef] [PubMed]

- Na, G.C.; Yuan, B.O.; Stevens, H.J., Jr.; Weekley, B.S.; Rajagopalan, N. Cloud point of nonionic surfactants: Modulation with pharmaceutical excipients. Pharm Res. 1999, 16, 562–568. [Google Scholar] [CrossRef]

- Kassem, A.M.; Ibrahim, H.M.; Samy, A.M. Development and optimisation of atorvastatin calcium loaded self-nanoemulsifying drug delivery system (SNEDDS) for enhancing oral bioavailability: In vitro and in vivo evaluation. J. Microencapsul. 2017, 34, 319–333. [Google Scholar] [CrossRef] [PubMed]

| (A) | ||||

| Independent Variables | Symbol | Levels | ||

| −1 | 0 | +1 | ||

| Oil:Smix ratio | X1 | 1:8 | 1:6 | 1:4 |

| Emulgent:co-emulgent ratio | X2 | 1:1 | 2:1 | 3:1 |

| (B) | ||||

| Dependent Variables | Symbol | Goal | ||

| Z-avg (nm) | Y1 | Y1 < 200 nm | ||

| Transmittance (%) | Y2 | Y2 > 90% | ||

| Zeta-potential (mV) | Y3 | Y3 > ±20 mV | ||

| Polydispersity index (PDI) | Y4 | Y4 < 0.400 | ||

| Source | Z-avg (nm) | Transmittance (%) | Zeta-Potential (mV) | PDI |

|---|---|---|---|---|

| b0 | +97.24 | +96.74 | −27.61 | +0.46 |

| b1 | +67.77 * | −8.33 * | +1.05 * | +0.17 * |

| b2 | −21.00 * | +1.63 * | −4.87 * | +0.030 * |

| b12 | −14.30 * | +2.45 * | −0.43 | +0.045 * |

| b11 | −14.91 * | −5.58 | +6.54 * | −0.045 |

| b22 | +13.99 | +0.72 | −0.21 | +0.035 |

| R2 | 0.9885 | 0.9793 | 0.9728 | 0.9730 |

| Adj-R2 | 0.9803 | 0.9645 | 0.9533 | 0.9537 |

| Pred-R2 | 0.8887 | 0.8222 | 0.7732 | 0.9047 |

| Z-avg (nm) ± SD | ||

| pH | SNEDDS | BSNEDDS |

| 1.2 | 50.41 ± 0.321 | 84.93 ± 0.3235 |

| 6.8 | 52.84 ± 0.632 | 86.67 ± 0.2956 |

| PDI ± SD | ||

| pH | SNEDDS | BSNEDDS |

| 1.2 | 0.231 ± 0.01 | 0.321 ± 0.002 |

| 6.8 | 0.217 ± 0.01 | 0.347 ± 0.003 |

| Storage Intervals (days) | Z-avg (nm) | PDI |

|---|---|---|

| 0 | 81.24 ± 0.17 | 0.406 ± 0.007 |

| 1 | 80.14 ± 0.08 | 0.405 ± 0.006 |

| 5 | 79.23 ± 0.14 | 0.379 ± 0.002 |

| 7 | 82.37 ± 0.10 | 0.400 ± 0.002 |

| 21 | 79.53 ± 0.05 | 0.443 ± 0.003 |

| 28 | 80.86 ± 0.28 | 0.389 ± 0.003 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jakab, G.; Fülöp, V.; Bozó, T.; Balogh, E.; Kellermayer, M.; Antal, I. Optimization of Quality Attributes and Atomic Force Microscopy Imaging of Reconstituted Nanodroplets in Baicalin Loaded Self-Nanoemulsifying Formulations. Pharmaceutics 2018, 10, 275. https://doi.org/10.3390/pharmaceutics10040275

Jakab G, Fülöp V, Bozó T, Balogh E, Kellermayer M, Antal I. Optimization of Quality Attributes and Atomic Force Microscopy Imaging of Reconstituted Nanodroplets in Baicalin Loaded Self-Nanoemulsifying Formulations. Pharmaceutics. 2018; 10(4):275. https://doi.org/10.3390/pharmaceutics10040275

Chicago/Turabian StyleJakab, Géza, Viktor Fülöp, Tamás Bozó, Emese Balogh, Miklós Kellermayer, and István Antal. 2018. "Optimization of Quality Attributes and Atomic Force Microscopy Imaging of Reconstituted Nanodroplets in Baicalin Loaded Self-Nanoemulsifying Formulations" Pharmaceutics 10, no. 4: 275. https://doi.org/10.3390/pharmaceutics10040275

APA StyleJakab, G., Fülöp, V., Bozó, T., Balogh, E., Kellermayer, M., & Antal, I. (2018). Optimization of Quality Attributes and Atomic Force Microscopy Imaging of Reconstituted Nanodroplets in Baicalin Loaded Self-Nanoemulsifying Formulations. Pharmaceutics, 10(4), 275. https://doi.org/10.3390/pharmaceutics10040275