Biodegradable Alginate Films with ZnO Nanoparticles and Citronella Essential Oil—A Novel Antimicrobial Structure

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of ZnO Nanoparticles

2.3. Synthesis of Alginate/ZnO/CEO Films

2.4. Characterization of Alginate Composite Films

2.4.1. Microstructural Analysis

2.4.2. Fourier Transform Infrared Spectroscopy

2.4.3. Photoluminescence Spectroscopy

2.4.4. UV-Vis Spectroscopy

2.4.5. Thermal Analysis

2.4.6. Water Vapor Permeability (WVP)

2.4.7. Swelling Capacity

2.5. Antibacterial Assay

2.5.1. Antibacterial Qualitative Assessment—Growth Inhibition

2.5.2. Evaluation of the Planktonic Development of Microorganisms

2.5.3. Monospecific Biofilm Development

2.6. Preliminary Tests of AZ1-AZ4 Films as Packaging Material for Cheese

2.7. Statistical Analysis

3. Results and Discussion

3.1. Alginate Films Characterization

3.2. UV–Vis and PL Spectrometry

3.2.1. UV–Vis Spectrometry

3.2.2. PL Spectrometry

3.3. FTIR Spectroscopy and Microscopy

3.3.1. FTIR Spectroscopy

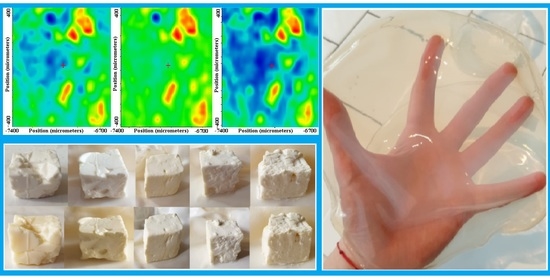

3.3.2. FTIR Microscopy

3.4. Thermal Analysis

3.5. Scanning Electron Microscopy (SEM)

3.6. Water Vapor Permeability (WVP)

3.7. Swelling Study

3.8. Antibacterial Activity

3.9. Preliminary Evaluation of AZ1–AZ4 Films as Coatings for Soft Cheese

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Artiga-Artigas, M.; Acevedo-Fani, A.; Martin-Belloso, O. Improving the shelf life of low-fat cut cheese using nanoemulsionbased edible coatings containing oregano essential oil and mandarin fiber. Food Control. 2017, 76, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Motelica, L.; Ficai, D.; Oprea, O.C.; Ficai, A.; Andronescu, E. Smart Food Packaging Designed by Nanotechnological and Drug Delivery Approaches. Coatings 2020, 10, 806. [Google Scholar] [CrossRef]

- Lemnaru (Popa), G.-M.; Trusca, R.D.; Ilie, C.-I.; Tiplea, R.D.; Ficai, D.; Oprea, O.; Stoica-Guzun, A.; Ficai, A.; Ditu, L.-M. Antibacterial Activity of Bacterial Cellulose Loaded with Bacitracin and Amoxicillin: In Vitro Studies. Molecules 2020, 25, 4069. [Google Scholar] [CrossRef]

- Makaremi, M.; Yousefi, H.; Cavallaro, G.; Lazzara, G.; Goh, C.B.S.; Lee, S.M.; Solouk, A.; Pasbakhsh, P. Safely Dissolvable and Healable Active Packaging Films Based on Alginate and Pectin. Polymers 2019, 11, 1594. [Google Scholar] [CrossRef] [Green Version]

- Motelica, L.; Ficai, D.; Ficai, A.; Trusca, R.D.; Ilie, C.I.; Oprea, O.C.; Andronescu, E. Innovative Antimicrobial Chitosan/ZnO/Ag NPs/Citronella Essential Oil Nanocomposite—Potential Coating for Grapes. Foods 2020, 9, 1801. [Google Scholar] [CrossRef]

- Motelica, L.; Ficai, D.; Ficai, A.; Oprea, O.C.; Kaya, D.A.; Andronescu, E. Biodegradable Antimicrobial Food Packaging: Trends and Perspectives. Foods 2020, 9, 1438. [Google Scholar] [CrossRef]

- Radulescu, M.; Ficai, D.; Oprea, O.; Ficai, A.; Andronescu, E.; Holban, A.M. Antimicrobial Chitosan based Formulations with Impact on Different Biomedical Applications. Curr. Pharm. Biotechnol. 2015, 16, 128–136. [Google Scholar] [CrossRef] [PubMed]

- Gherasim, O.; Popescu, R.C.; Grumezescu, V.; Mogosanu, G.D.; Mogoanta, L.; Iordache, F.; Holban, A.M.; Vasile, B.S.; Birca, A.C.; Oprea, O.C.; et al. MAPLE Coatings Embedded with Essential Oil-Conjugated Magnetite for Anti-Biofilm Applications. Materials 2021, 14, 1612. [Google Scholar] [CrossRef] [PubMed]

- Borkowski, D.; Krucinska, I.; Draczynski, Z. Preparation of Nanocomposite Alginate Fibers Modified with Titanium Dioxide and Zinc Oxide. Polymers 2020, 12, 1040. [Google Scholar] [CrossRef]

- Fahmy, A.; Khafagy, R.M.; Elhaes, H.; Ibrahim, M.A. Molecular properties of polyvinyl alcohol/sodium alginate composite. Biointerface Res. Appl. Chem. 2020, 10, 4734–4739. [Google Scholar]

- Vizzini, P.; Beltrame, E.; Zanet, V.; Vidic, J.; Manzano, M. Development and Evaluation of qPCR Detection Method and Zn-MgO/Alginate Active Packaging for Controlling Listeria monocytogenes Contamination in Cold-Smoked Salmon. Foods 2020, 9, 1353. [Google Scholar] [CrossRef] [PubMed]

- Paduraru, A.; Ghitulica, C.; Trusca, R.; Surdu, V.A.; Neacsu, I.A.; Holban, A.M.; Birca, A.C.; Iordache, F.; Vasile, B.S. Antimicrobial Wound Dressings as Potential Materials for Skin Tissue Regeneration. Materials 2019, 12, 1859. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Senturk Parreidt, T.; Muller, K.; Schmid, M. Alginate-Based Edible Films and Coatings for Food Packaging Applications. Foods 2018, 7, 170. [Google Scholar] [CrossRef] [Green Version]

- Anugrah, D.S.B.; Alexander, H.; Pramitasari, R.; Hudiyanti, D.; Sagita, C.P. A Review of Polysaccharide-Zinc Oxide Nanocomposites as Safe Coating for Fruits Preservation. Coatings 2020, 10, 988. [Google Scholar] [CrossRef]

- Avramescu, S.M.; Butean, C.; Popa, C.V.; Ortan, A.; Moraru, I.; Temocico, G. Edible and Functionalized Films/Coatings-Performances and Perspectives. Coatings 2020, 10, 687. [Google Scholar] [CrossRef]

- Bakil, S.N.A.; Kamal, H.; Abdullah, H.Z.; Idris, M.I. Sodium Alginate-Zinc Oxide Nanocomposite Film for Antibacterial Wound Healing Applications. Biointerface Res. Appl. Chem. 2020, 10, 6289–6296. [Google Scholar]

- Naskar, A.; Jana, B.; Kim, H.G.; Kwac, L.K. Effect of Ag2O on cell viability of ZnO nanoparticle synthesized by low temperature solution synthesis process. Biointerface Res. Appl. Chem. 2019, 9, 4011–4014. [Google Scholar]

- Motelica, L.; Popescu, A.; Razvan, A.G.; Oprea, O.; Trusca, R.D.; Vasile, B.S.; Dumitru, F.; Holban, A.M. Facile Use of ZnO Nanopowders to Protect Old Manual Paper Documents. Materials 2020, 13, 5452. [Google Scholar] [CrossRef]

- Motelica, L.; Marinof, L.; Holban, A.; Vasile, B.S.; Ficai, A. Optical, Photocatalytic and Antibacterial Properties of Zinc Oxide Nanoparticles Obtained by a Solvothermal Method. UPB. Sci. Bull. Ser. B 2020, 82, 59–70. [Google Scholar]

- Vaja, F.; Comanescu, C.; Oprea, O.; Ficai, D.; Guran, C. Effects of ZnO Nanoparticles on the Wet Scrub Resistance and Photocatalytic Properties of Acrylic Coatings. Revista Chimie 2012, 63, 722–726. [Google Scholar]

- Vaja, F.; Ficai, D.; Ficai, A.; Oprea, O.; Guran, C. Multifunctional advanced coatings based on ZnO/M obtained by nanocasting method. J. Optoelectron. Adv. Mater. 2013, 15, 107–113. [Google Scholar]

- Oprea, O.; Andronescu, E.; Ficai, D.; Ficai, A.; Oktar, F.N.; Yetmez, M. ZnO Applications and Challenges. Curr. Org. Chem. 2014, 18, 192–203. [Google Scholar] [CrossRef]

- Patino-Herrera, R.; Catarino-Centeno, R.; Robles-Martinez, M.; Zarate, M.G.M.; Flores-Arriaga, J.C.; Perez, E. Antimycotic activity of zinc oxide decorated with silver nanoparticles against Trichophyton mentagrophytes. Powder Technol. 2018, 327, 381–391. [Google Scholar] [CrossRef]

- Wasim, M.; Khan, M.R.; Mushtaq, M.; Naeem, A.; Han, M.C.; Wei, Q.F. Surface Modification of Bacterial Cellulose by Copper and Zinc Oxide Sputter Coating for UV-Resistance/Antistatic/Antibacterial Characteristics. Coatings 2020, 10, 364. [Google Scholar] [CrossRef] [Green Version]

- Sabry, N.M.; Tolba, S.T.M.; Abdel-Gawad, F.K.; Bassem, S.M.; Nassar, H.; El-Taweel, G.E.; Ibrahim, M.A. On the molecular modeling analyses of the interaction between nano zinc oxide and bacteria. Biointerface Res. Appl. Chem. 2018, 8, 3294–3297. [Google Scholar]

- Husain, Q. An overview on the green synthesis of nanoparticles and other nano-materials using enzymes and their potential applications. Biointerface Res. Appl. Chem. 2019, 9, 4255–4271. [Google Scholar]

- Vasile, O.R.; Serdaru, I.; Andronescu, E.; Trusca, R.; Surdu, V.A.; Oprea, O.; Ilie, A.; Vasile, B.S. Influence of the size and the morphology of ZnO nanoparticles on cell viability. Comptes Rendus Chim. 2015, 18, 1335–1343. [Google Scholar] [CrossRef]

- Tymoszuk, A.; Wojnarowicz, J. Zinc Oxide and Zinc Oxide Nanoparticles Impact on In Vitro Germination and Seedling Growth inAllium cepaL. Materials 2020, 13, 2784. [Google Scholar] [CrossRef] [PubMed]

- Taha, A.; Ben Aissa, M.; Da’na, E. Green Synthesis of an Activated Carbon-Supported Ag and ZnO Nanocomposite for Photocatalytic Degradation and Its Antibacterial Activities. Molecules 2020, 25, 1586. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, S.; Mudai, A.; Roy, B.; Basumatary, I.B.; Mukherjee, A.; Dutta, J. Biodegradable Hybrid Nanocomposite of Chitosan/Gelatin and Green Synthesized Zinc Oxide Nanoparticles for Food Packaging. Foods 2020, 9, 1143. [Google Scholar] [CrossRef] [PubMed]

- Espitia, P.J.P.; Otoni, C.G.; Soares, N.F.F. Zinc Oxide Nanoparticles for Food Packaging Applications. Antimicrob. Food Packag. 2016, 425–431. [Google Scholar] [CrossRef]

- Kumar, S.; Boro, J.C.; Ray, D.; Mukherjee, A.; Dutta, J. Bionanocomposite films of agar incorporated with ZnO nanoparticles as an active packaging material for shelf life extension of green grape. Heliyon 2019, 5, e01867. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Naamani, L.; Dutta, J.; Dobretsov, S. Nanocomposite Zinc Oxide-Chitosan Coatings on Polyethylene Films for Extending Storage Life of Okra (Abelmoschus esculentus). Nanomaterials 2018, 8, 479. [Google Scholar] [CrossRef] [Green Version]

- Istrati, D.; Lacatusu, I.; Bordei, N.; Badea, G.; Oprea, O.; Stefan, L.M.; Stan, R.; Badea, N.; Meghea, A. Phyto-mediated nanostructured carriers based on dual vegetable actives involved in the prevention of cellular damage. Mater. Sci. Eng. C-Mater. Biol. Appl. 2016, 64, 249–259. [Google Scholar] [CrossRef]

- Lacatusu, I.; Badea, N.; Niculae, G.; Bordei, N.; Stan, R.; Meghea, A. Lipid nanocarriers based on natural compounds: An evolving role in plant extract delivery. Eur. J. Lipid Sci. Technol. 2014, 116, 1708–1717. [Google Scholar] [CrossRef]

- Caputo, L.; Cornara, L.; Bazzicalupo, M.; de Francesco, C.; de Feo, V.; Trombetta, D.; Smeriglio, A. Chemical Composition and Biological Activities of Essential Oils from Peels of Three Citrus Species. Molecules 2020, 25, 1890. [Google Scholar] [CrossRef] [Green Version]

- Radulescu, M.; Andronescu, E.; Cirja, A.; Holban, A.M.; Mogoanta, L.; Balseanu, T.A.; Catalin, B.; Neagu, T.P.; Lascar, I.; Florea, D.A.; et al. Antimicrobial coatings based on zinc oxide and orange oil for improved bioactive wound dressings and other applications. Rom. J. Morphol. Embryol. 2016, 57, 107–114. [Google Scholar]

- Zhang, H.J.; Wang, J.Q. Constituents of the Essential Oils of Garlic and Citronella and Their Vapor-phase Inhibition Mechanism against S. aureus. Food Sci. Technol. Res. 2019, 25, 65–74. [Google Scholar] [CrossRef]

- Tadtong, S.; Watthanachaiyingcharoen, R.; Kamkaen, N. Antimicrobial Constituents and Synergism Effect of the Essential Oils from Cymbopogon citratus and Alpinia galanga. Nat. Prod. Commun. 2014, 9, 277–280. [Google Scholar] [CrossRef] [Green Version]

- Francikowski, J.; Baran, B.; Cup, M.; Janiec, J.; Krzyzowski, M. Commercially Available Essential Oil Formulas as Repellents Against the Stored-Product Pest Alphitobius diaperinus. Insects 2019, 10, 96. [Google Scholar] [CrossRef] [Green Version]

- Go, E.J.; Song, K.B. Effect of java citronella essential oil addition on the physicochemical properties of Gelidium corneum-chitosan composite films. Food Sci. Biotechnol. 2020, 29, 909–915. [Google Scholar] [CrossRef]

- Budiati, T.; Suryaningsih, W.; Umaroh, S.; Poerwanto, B.; Bakri, A.; Kurniawati, E. Antimicrobial activity of essential oil from Indonesian medicinal plants against food-borne pathogens. In Proceedings of the 1st International Conference on Food and Agriculture, Bali, Indonesia, 20–21 October 2018; p. 207. [Google Scholar]

- De Silva, B.C.J.; Hossain, S.; Wimalasena, S.H.M.P.; Pathirana, H.N.K.S.; Dahanayake, P.S.; Heo, G.J. Comparative in vitro efficacy of eight essential oils as antibacterial agents against pathogenic bacteria isolated from pet-turtles. Vet. Med. 2018, 63, 335–343. [Google Scholar] [CrossRef]

- Munteanu, S.B.; Vasile, C. Vegetable Additives in Food Packaging Polymeric Materials. Polymers 2020, 12, 28. [Google Scholar] [CrossRef] [Green Version]

- Valdes, A.; Garcia-Serna, E.; Martinez-Abad, A.; Vilaplana, F.; Jimenez, A.; Garrigos, M.C. Gelatin-Based Antimicrobial Films Incorporating Pomegranate (Punica granatum L.) Seed Juice by-Product. Molecules 2020, 25, 166. [Google Scholar]

- Becerril, R.; Nerin, C.; Silva, F. Encapsulation Systems for Antimicrobial Food Packaging Components: An Update. Molecules 2020, 25, 1134. [Google Scholar] [CrossRef] [Green Version]

- Mallakpour, S.; Sirous, F.; Hussain, C.M. A journey to the world of fascinating ZnO nanocomposites made of chitosan, starch, cellulose, and other biopolymers: Progress in recent achievements in eco-friendly food packaging, biomedical, and water remediation technologies. Int. J. Biol. Macromol. 2021, 170, 701–716. [Google Scholar] [CrossRef]

- Yadav, S.; Mehrotra, G.K.; Dutta, P.K. Chitosan based ZnO nanoparticles loaded gallic-acid films for active food packaging. Food Chem. 2021, 334. [Google Scholar] [CrossRef] [PubMed]

- Buyana, B.; Aderibigbe, B.A.; Ndinteh, D.T.; Fonkui, Y.T.; Kumar, P. Alginate-pluronic topical gels loaded with thymol, norfloxacin and ZnO nanoparticles as potential wound dressings. J. Drug Deliv. Sci. Technol. 2020, 60, 101960. [Google Scholar] [CrossRef]

- Al-Shabib, N.A.; Husain, F.M.; Ahmed, F.; Khan, R.A.; Ahmad, I.; Alsharaeh, E.; Khan, M.S.; Hussain, A.; Rehman, M.T.; Yusuf, M.; et al. Biogenic synthesis of Zinc oxide nanostructures from Nigella sativa seed: Prospective role as food packaging material inhibiting broad-spectrum quorum sensing and biofilm. Sci. Rep. 2016, 6, 36761. [Google Scholar] [CrossRef] [Green Version]

- Shi, L.E.; Li, Z.H.; Zheng, W.; Zhao, Y.F.; Jin, Y.F.; Tang, Z.X. Synthesis, antibacterial activity, antibacterial mechanism and food applications of ZnO nanoparticles: A review. Food Addit. Contam. Part A 2014, 31, 173–186. [Google Scholar] [CrossRef]

- McClements, D.J.; Xiao, H. Is nano safe in foods? Establishing the factors impacting the gastrointestinal fate and toxicity of organic and inorganic food-grade nanoparticles. Sci. Food 2017, 1, 6. [Google Scholar]

- Sruthi, S.; Ashtami, J.; Mohanan, P.V. Biomedical application and hidden toxicity of Zinc oxide nanoparticles. Mater. Today Chem. 2018, 10, 175–186. [Google Scholar] [CrossRef]

- Vandebriel, R.J.; de Jong, W.H. A review of mammalian toxicity of ZnO nanoparticles. Nanotechnol. Sci. Appl. 2012, 5, 61–71. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El Shemy, M.A.; Azab, N.I.; Salim, R.F. Zinc Oxide Nanoparticles: The Hidden Danger. Int. J. Biochem. Biophys. Mol. Biol. 2017, 2, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, Y.H.; Holmes, A.; Haridass, I.N.; Sanchez, W.Y.; Studier, H.; Grice, J.E.; Benson, H.A.E.; Roberts, M.S. Support for the Safe Use of Zinc Oxide Nanoparticle Sunscreens: Lack of Skin Penetration or Cellular Toxicity after Repeated Application in Volunteers. J. Investig. Dermatol. 2019, 139, 308–315. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feltis, B.N.; OKeefe, S.J.; Harford, A.J.; Piva, T.J.; Turney, T.W.; Wright, P.F.A. Independent cytotoxic and inflammatory responses to zinc oxide nanoparticles in human monocytes and macrophages. Nanotoxicology 2012, 6, 757–765. [Google Scholar] [CrossRef] [PubMed]

- Alaraby, M.; Annangi, B.; Hernandez, A.; Creus, A.; Marcos, R. A comprehensive study of the harmful effects of ZnO nanoparticles using Drosophila melanogaster as an in vivo model. J. Hazard. Mater. 2015, 296, 166–174. [Google Scholar] [CrossRef] [PubMed]

- Wright, P.F.A. Realistic Exposure Study Assists Risk Assessments of ZnO Nanoparticle Sunscreens and Allays Safety Concerns. J. Investig. Dermatol. 2019, 139, 277–278. [Google Scholar] [CrossRef] [Green Version]

- Wright, P.; Jackson, N. Safety of engineered nanomaterials and occupational health and safety issues for commercial scale production. In Handbook of Clinical Nanomedicine: Law, Business, Regulation, Safety, and Risk; Bawa, R., Audette, G., Reese, B., Eds.; Pan Stanford Publishing: Singapore, 2016; pp. 569–619. [Google Scholar]

- Souza, V.G.L.; Rodrigues, C.; Valente, S.; Pimenta, C.; Pires, J.R.A.; Alves, M.M.; Santos, C.F.; Coelhoso, I.M.; Fernando, A.L. Eco-Friendly ZnO/Chitosan Bionanocomposites Films for Packaging of Fresh Poultry Meat. Coatings 2020, 10, 110. [Google Scholar] [CrossRef] [Green Version]

- Abou Baker, D.H.; Al-Moghazy, M.; ElSayed, A.A.A. The in vitro cytotoxicity, antioxidant and antibacterial potential of Satureja hortensis L. essential oil cultivated in Egypt. Bioorganic Chem. 2020, 95, 103559. [Google Scholar] [CrossRef]

- Sinha, S.; Jothiramajayam, M.; Ghosh, M.; Mukherjee, A. Evaluation of toxicity of essential oils palmarosa, citronella, lemongrass and vetiver in human lymphocytes. Food Chem. Toxicol. 2014, 68, 71–77. [Google Scholar] [CrossRef]

- El-Sayed, H.S.; El-Sayed, S.M.; Mabrouk, A.M.M.; Nawwar, G.A.; Youssef, A.M. Development of Eco-friendly Probiotic Edible Coatings Based on Chitosan, Alginate and Carboxymethyl Cellulose for Improving the Shelf Life of UF Soft Cheese. J. Polym. Environ. 2021, 29, 1941–1953. [Google Scholar] [CrossRef]

- Kontominas, M.G. Use of Alginates as Food Packaging Materials. Foods 2020, 9, 1440. [Google Scholar] [CrossRef] [PubMed]

- Gheorghita, R.; Amariei, S.; Norocel, L.; Gutt, G. New Edible Packaging Material with Function in Shelf Life Extension: Applications for the Meat and Cheese Industries. Foods 2020, 9, 562. [Google Scholar] [CrossRef]

- Olivo, P.M.; Scapim, M.R.D.; Miazaki, J.; Madrona, G.S.; Maia, L.F.; Rodrigues, B.M.; Pozza, M.S.D. Sodium alginate with turmeric coating for ripened cheeses. J. Food Sci. Technol. 2020, 57, 2364–2369. [Google Scholar] [CrossRef] [PubMed]

- Mahcene, Z.; Khelil, A.; Hasni, S.; Bozkurt, F.; Goudjil, M.B.; Tornuk, F. Home-made cheese preservation using sodium alginate based on edible film incorporating essential oils. J. Food Sci. Technol. 2021, 58, 2406–2419. [Google Scholar] [CrossRef] [PubMed]

- El-sayed, S.M.; El-Sayed, H.S.; Salama, H.H.; Abd-Rabou, N.S. Processed Cheese Sauce Functionalized with Microencapsulated Fig Leaves Extract. Egypt. J. Chem. 2021, 64, 1665–1678. [Google Scholar]

- Kumar, S.; Mukherjee, A.; Dutta, J. Chitosan based nanocomposite films and coatings: Emerging antimicrobial food packaging alternatives. Trends Food Sci. Technol. 2020, 97, 196–209. [Google Scholar] [CrossRef]

- Divsalar, E.; Tajik, H.; Moradi, M.; Forough, M.; Lotfi, M.; Kuswandi, B. Characterization of cellulosic paper coated with chitosan-zinc oxide nanocomposite containing nisin and its application in packaging of UF cheese. Int. J. Biol. Macromol. 2018, 109, 1311–1318. [Google Scholar] [CrossRef]

- Arroyo, B.J.; Bezerra, A.C.; Oliveira, L.L.; Arroyo, S.J.; de Melo, E.A.; Santos, A.M.P. Antimicrobial active edible coating of alginate and chitosan add ZnO nanoparticles applied in guavas (Psidium guajava L.). Food Chem. 2020, 309. [Google Scholar] [CrossRef] [PubMed]

- Oprea, O.; Andronescu, E.; Vasile, B.S.; Voicu, G.; Covaliu, C. Synthesis and Characterization of Zno Nanopowder by Non-Basic Route. Dig. J. Nanomater. Biostructures 2011, 6, 1393–1401. [Google Scholar]

- Tymczewska, A.; Furtado, B.U.; Nowaczyk, J.; Hrynkiewicz, K.; Szydłowska-Czerniak, A. Development and Characterization of Active Gelatin Films Loaded with Rapeseed Meal Extracts. Materials 2021, 14, 2869. [Google Scholar] [CrossRef]

- Li, W.; Zheng, K.; Chen, H.; Feng, S.; Wang, W.; Qin, C. Influence of Nano Titanium Dioxide and Clove Oil on Chitosan–Starch Film Characteristics. Polymers 2019, 11, 1418. [Google Scholar] [CrossRef] [Green Version]

- Socaciu, M.I.; Fogarasi, M.; Semeniuc, C.A.; Socaci, S.A.; Rotar, M.A.; Muresan, V.; Pop, O.L.; Vodnar, D.C. Formulation and Characterization of Antimicrobial Edible Films Based on Whey Protein Isolate and Tarragon Essential Oil. Polymers 2020, 12, 1748. [Google Scholar] [CrossRef]

- Mohammed, H.B.; Rayyif, S.M.I.; Curutiu, C.; Birca, A.C.; Oprea, O.C.; Grumezescu, A.M.; Ditu, L.M.; Gheorghe, I.; Chifiriuc, M.C.; Mihaescu, G.; et al. Eugenol-Functionalized Magnetite Nanoparticles Modulate Virulence and Persistence in Pseudomonas aeruginosa Clinical Strains. Molecules 2021, 26, 2189. [Google Scholar] [CrossRef]

- Wang, H.; Wan, Y.F.; Wang, W.; Li, W.J.; Zhu, J. Effect of calcium ions on the III steps of self-assembly of SA investigated with atomic force microscopy. Int. J. Food Prop. 2018, 21, 1995–2006. [Google Scholar] [CrossRef] [Green Version]

- Kucuk, G.S.; Celik, O.F.; Mazi, B.G.; Ture, H. Evaluation of alginate and zein films as a carrier of natamycin to increase the shelf life of kashar cheese. Packag. Technol. Sci. 2020, 33, 39–48. [Google Scholar] [CrossRef]

- Fernandez-Marin, R.; Mujtaba, M.; Cansaran-Duman, D.; Ben Salha, G.; Sanchez, M.A.A.; Labidi, J.; Fernandes, S.C.M. Effect of Deterpenated Origanum majorana L. Essential Oil on the Physicochemical and Biological Properties of Chitosan/beta-Chitin Nanofibers Nanocomposite Films. Polymers 2021, 13, 1507. [Google Scholar] [PubMed]

- Ngo, T.M.P.; Dang, T.M.Q.; Tran, T.X.; Rachtanapun, P. Effects of Zinc Oxide Nanoparticles on the Properties of Pectin/Alginate Edible Films. Int. J. Polym. Sci. 2018, 2018, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Liu, C.; Zheng, X.J.; Chen, M.; Tang, K.Y. Soluble soybean polysaccharide/nano zinc oxide antimicrobial nanocomposite films reinforced with microfibrillated cellulose. Int. J. Biol. Macromol. 2020, 159, 793–803. [Google Scholar] [CrossRef]

- Dou, Y.; Huang, X.; Zhang, B.N.; He, M.; Yin, G.Q.; Cui, Y.D. Preparation and characterization of a dialdehyde starch crosslinked feather keratin film for food packaging application. Rsc Adv. 2015, 5, 27168–27174. [Google Scholar] [CrossRef]

- Trandafilovic, L.V.; Bozanic, D.K.; Dimitrijevic-Brankovic, S.; Luyt, A.S.; Djokovic, V. Fabrication and antibacterial properties of ZnO-alginate nanocomposites. Carbohydr. Polym. 2012, 88, 263–269. [Google Scholar] [CrossRef]

- Oprea, O.; Vasile, O.R.; Voicu, G.; Andronescu, E. The Influence of the Thermal Treatment on Luminescence Properties of Zno. Dig. J. Nanomater. Biostructures 2013, 8, 747–756. [Google Scholar]

- Lei, J.; Kim, J.H.; Jeon, Y.S. Preparation and properties of alginate/polyaspartate composite hydrogels. Macromol. Res. 2008, 16, 45–50. [Google Scholar] [CrossRef]

- Xing, Y.G.; Li, X.L.; Guo, X.L.; Li, W.X.; Chen, J.W.; Liu, Q.; Xu, Q.L.; Wang, Q.; Yang, H.; Shui, Y.R.; et al. Effects of Different TiO(2)Nanoparticles Concentrations on the Physical and Antibacterial Activities of Chitosan-Based Coating Film. Nanomaterials 2020, 10, 1365. [Google Scholar] [CrossRef] [PubMed]

- Hasan, I.; Shekhar, C.; Bin Sharfan, I.I.; Khan, R.A.; Alsalme, A. Ecofriendly Green Synthesis of the ZnO-Doped CuO@Alg Bionanocomposite for Efficient Oxidative Degradation of p-Nitrophenol. Acs Omega 2020, 5, 32011–32022. [Google Scholar] [CrossRef]

- Fajardo, A.R.; Silva, M.B.; Lopes, L.C.; Piai, J.F.; Rubira, A.F.; Muniz, E.C. Hydrogel based on an alginate-Ca2+/chondroitin sulfate matrix as a potential colon-specific drug delivery system. Rsc Adv. 2012, 2, 11095–11103. [Google Scholar] [CrossRef]

- Qiu, B.; Xu, X.F.; Deng, R.H.; Xia, G.Q.; Shang, X.F.; Zhou, P.H. Construction of chitosan/ZnO nanocomposite film by in situ precipitation. Int. J. Biol. Macromol. 2019, 122, 82–87. [Google Scholar] [CrossRef]

- Zayed, M.; Othman, H.; Ghazal, H.; Hassabo, A.G. Psidium Guajava Leave Extract as Reducing Agent for Synthesis of Zinc Oxide Nanoparticles and its Application to Impart Multifunctional Properties for Cellulosic Fabrics. Biointerface Res. Appl. Chem. 2021, 11, 13535–13556. [Google Scholar]

- Naidu, D.S.; John, M.J. Effect of Clay Nanofillers on the Mechanical and Water Vapor Permeability Properties of Xylan-Alginate Films. Polymers 2020, 12, 2279. [Google Scholar] [CrossRef]

- Timung, R.; Barik, C.R.; Purohit, S.; Goud, V.V. Composition and anti-bacterial activity analysis of citronella oil obtained by hydrodistillation: Process optimization study. Ind. Crop. Prod. 2016, 94, 178–188. [Google Scholar] [CrossRef]

- Lan, W.T.; Li, S.Y.; Shama, S.; Zhao, Y.Q.; Sameen, D.E.; He, L.; Liu, Y.W. Investigation of Ultrasonic Treatment on Physicochemical, Structural and Morphological Properties of Sodium Alginate/AgNPs/Apple Polyphenol Films and Its Preservation Effect on Strawberry. Polymers 2020, 12, 2096. [Google Scholar] [CrossRef] [PubMed]

- Jost, V.; Kobsik, K.; Schmid, M.; Noller, K. Influence of plasticiser on the barrier, mechanical and grease resistance properties of alginate cast films. Carbohydr. Polym. 2014, 110, 309–319. [Google Scholar] [CrossRef]

- Naik, M.I.; Fomda, B.A.; Jaykumar, E.; Bhat, J.A. Antibacterial activity of lemongrass (Cymbopogon citratus) oil against some selected pathogenic bacterias. Asian Pac. J. Trop. Med. 2010, 3, 535–538. [Google Scholar] [CrossRef] [Green Version]

- Viktorova, J.; Stupak, M.; Rehorova, K.; Dobiasova, S.; Hoang, L.; Hajslova, J.; Thanh, T.V.; Tri, L.V.; Tuan, N.V.; Ruml, T. Lemon Grass Essential Oil does not Modulate Cancer Cells Multidrug Resistance by Citral-Its Dominant and Strongly Antimicrobial Compound. Foods 2020, 9, 585. [Google Scholar] [CrossRef]

- Breijyeh, Z.; Jubeh, B.; Karaman, R. Resistance of Gram-Negative Bacteria to Current Antibacterial Agents and Approaches to Resolve It. Molecules 2020, 25, 1340. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nottagh, S.; Hesari, J.; Peighambardoust, S.H.; Rezaei-Mokarram, R.; Jafarizadeh-Malmiri, H. Effectiveness of edible coating based on chitosan and Natamycin on biological, physico-chemical and organoleptic attributes of Iranian ultra-filtrated cheese. Biologia 2020, 75, 605–611. [Google Scholar] [CrossRef]

| Sample Code | Alginate (g in 100 mL Water) | ZnO NPs (g in 15 mL Water) | Glycerol (mL Solution) | CEO (mL) |

|---|---|---|---|---|

| A | 3.00 | 0.00 | 2 | 0 |

| AZ1 | 3.00 | 0.05 | 2 | 1 |

| AZ2 | 3.00 | 0.10 | 2 | 1 |

| AZ3 | 3.00 | 0.25 | 2 | 1 |

| AZ4 | 3.00 | 0.50 | 2 | 1 |

| Sample | Transmittance (%) | Thickness (mm) | Opacity | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 200 nm | 300 nm | 400 nm | 500 nm | 600 nm | 700 nm | 800 nm | |||

| A | 4.42 | 10.87 | 45.76 | 72.74 | 85.27 | 91.07 | 94.09 | 0.25 ± 0.02 | 0.28 ± 0.02 a |

| AZ1 | 2.50 | 4.06 | 44.60 | 59.16 | 79.79 | 88.27 | 87.67 | 0.24 ± 0.06 | 0.39 ± 0.09 a,b |

| AZ2 | 2.44 | 4.01 | 34.98 | 50.76 | 73.84 | 85.11 | 85.95 | 0.30 ± 0.07 | 0.45 ± 0.09 b |

| AZ3 | 2.60 | 4.27 | 26.52 | 50.34 | 75.75 | 86.45 | 88.42 | 0.24 ± 0.03 | 0.50 ± 0.06 b |

| AZ4 | 2.35 | 4.16 | 18.08 | 33.72 | 56.58 | 68.21 | 70.86 | 0.29 ± 0.03 | 0.85 ± 0.07 c |

| Sample/Assignment | A | AZ1 | AZ2 | AZ3 | AZ4 |

|---|---|---|---|---|---|

| υZn-O | 426 | 427 | 428 | 429 | |

| 473 | 474 | 467 | 470 | ||

| υasC-O-C | 1027 | 1027 | 1028 | 1028 | 1027 |

| υsCOO− | 1408 | 1408 | 1409 | 1409 | 1408 |

| υasCOO− | 1600 | 1602 | 1602 | 1602 | 1601 |

| C=O group of CEO [41] | 1740 | 1737 | 1738 | 1737 | |

| υC-H (sat) | 2932 | 2924 | 2920 | 2922 | 2922 |

| υO-H | 3263 | 3273 | 3273 | 3273 | 3275 |

| Sample | T10 | T20 | T30 | T40 | T50 | Residual Mass |

|---|---|---|---|---|---|---|

| A | 180 | 207 | 216 | 229 | 245 | 12.77% |

| AZ1 | 171 | 200 | 211 | 222 | 235 | 11.37% |

| AZ2 | 165 | 198 | 209 | 220 | 233 | 12.28% |

| AZ3 | 165 | 194 | 206 | 219 | 235 | 15.01% |

| AZ4 | 176 | 198 | 211 | 225 | 242 | 18.15% |

| Film Code | WVP (10-10 g/Pa∙m∙s) |

|---|---|

| A (alginate control) | 5.718 ± 0.011 a |

| AZ1 | 4.542 ± 0.018 b |

| AZ2 | 4.126 ± 0.023 c |

| AZ3 | 3.687 ± 0.056 d |

| AZ4 | 3.043 ± 0.086 e |

| Sample | Water PBS | |||||

|---|---|---|---|---|---|---|

| 0.5 h | 1 h | 2 h | 3 h | 24 h | 48 h | |

| A | 552.29% | 578.36% | 596.51% | 616.29% | 600.99% | 590.38% |

| 539.12% | 652.05% | 701.89% | 719.90% | 742.41% | 739.26% | |

| AZ1 | 516.83% | 536.86% | 537.98% | 550.79% | 538.94% | 534.39% |

| 604.69% | 704.03% | 745.48% | 756.20% | 789.36% | 672.18% | |

| AZ2 | 484.78% | 477.38% | 528.66% | 542.09% | 522.53% | 528.36% |

| 456.87% | 634.35% | 708.18% | 723.69% | 762.62% | 750.84% | |

| AZ3 | 427.03% | 450.41% | 417.68% | 434.96% | 421.95% | 427.24% |

| 360.64% | 530.95% | 640.04% | 655.10% | 703.20% | 688.63% | |

| AZ4 | 297.27% | 342.73% | 379.77% | 398.08% | 394.69% | 354.96% |

| 282.05% | 374.36% | 595.63% | 659.27% | 741.75% | 684.43% | |

| Sample | Weight Loss (%) | ||||

|---|---|---|---|---|---|

| 1 Day | 4 Days | 7 Days | 10 Days | 14 Days | |

| A | 2.01 ± 0.15 a | 8.16 ± 0.12 a | 14.56 ± 0.16 a | 21.21 ± 0.18 a | 30.10 ± 0.23 a |

| AZ1 | 1.81 ± 0.09 a | 7.32 ± 0.11 b | 13.02 ± 0.12 b | 18.91 ± 0.15 b | 26.74 ± 0.19 b |

| AZ2 | 1.27 ± 0.05 b | 5.16 ± 0.04 c | 9.31 ± 0.07 c | 13.70 ± 0.11 c | 19.46 ± 0.12 c |

| AZ3 | 0.86 ± 0.06 c | 3.56 ± 0.06 d | 6.51 ± 0.10 d | 9.50 ± 0.11 d | 13.72 ± 0.15 d |

| AZ4 | 0.33 ± 0.03 d | 1.41 ± 0.04 e | 2.66 ± 0.08 e | 4.11 ± 0.07 e | 6.02 ± 0.11 e |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Motelica, L.; Ficai, D.; Oprea, O.; Ficai, A.; Trusca, R.-D.; Andronescu, E.; Holban, A.M. Biodegradable Alginate Films with ZnO Nanoparticles and Citronella Essential Oil—A Novel Antimicrobial Structure. Pharmaceutics 2021, 13, 1020. https://doi.org/10.3390/pharmaceutics13071020

Motelica L, Ficai D, Oprea O, Ficai A, Trusca R-D, Andronescu E, Holban AM. Biodegradable Alginate Films with ZnO Nanoparticles and Citronella Essential Oil—A Novel Antimicrobial Structure. Pharmaceutics. 2021; 13(7):1020. https://doi.org/10.3390/pharmaceutics13071020

Chicago/Turabian StyleMotelica, Ludmila, Denisa Ficai, Ovidiu Oprea, Anton Ficai, Roxana-Doina Trusca, Ecaterina Andronescu, and Alina Maria Holban. 2021. "Biodegradable Alginate Films with ZnO Nanoparticles and Citronella Essential Oil—A Novel Antimicrobial Structure" Pharmaceutics 13, no. 7: 1020. https://doi.org/10.3390/pharmaceutics13071020

APA StyleMotelica, L., Ficai, D., Oprea, O., Ficai, A., Trusca, R.-D., Andronescu, E., & Holban, A. M. (2021). Biodegradable Alginate Films with ZnO Nanoparticles and Citronella Essential Oil—A Novel Antimicrobial Structure. Pharmaceutics, 13(7), 1020. https://doi.org/10.3390/pharmaceutics13071020