Opposing Effects of Additives in Dry Milling and Tableting of Organic Particles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Methods

2.2.1. Processing

Blending

Micronization

Tableting

2.2.2. Analysis

Particle Size Distribution

Specific Surface Energy

True Density

Powder Flowability

Bulk and Tap Density

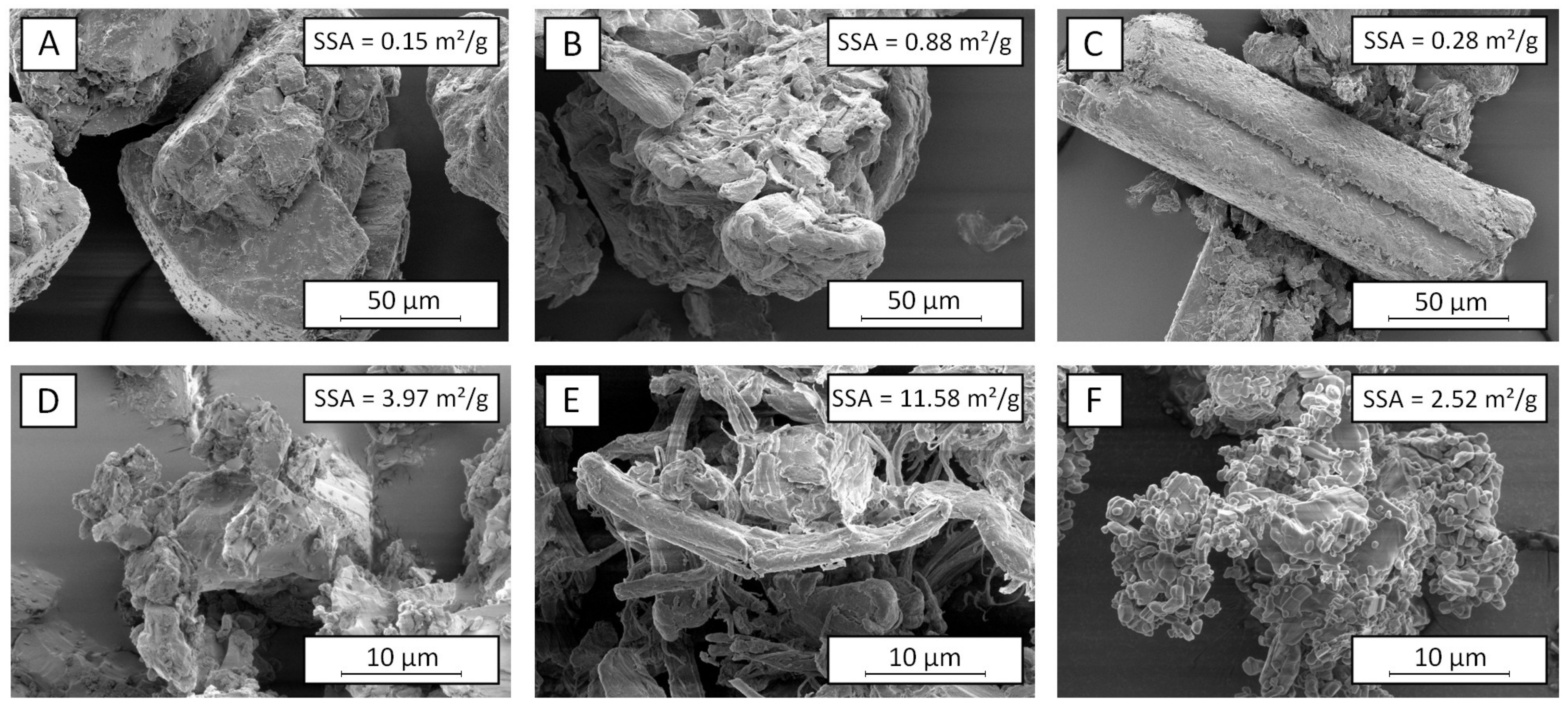

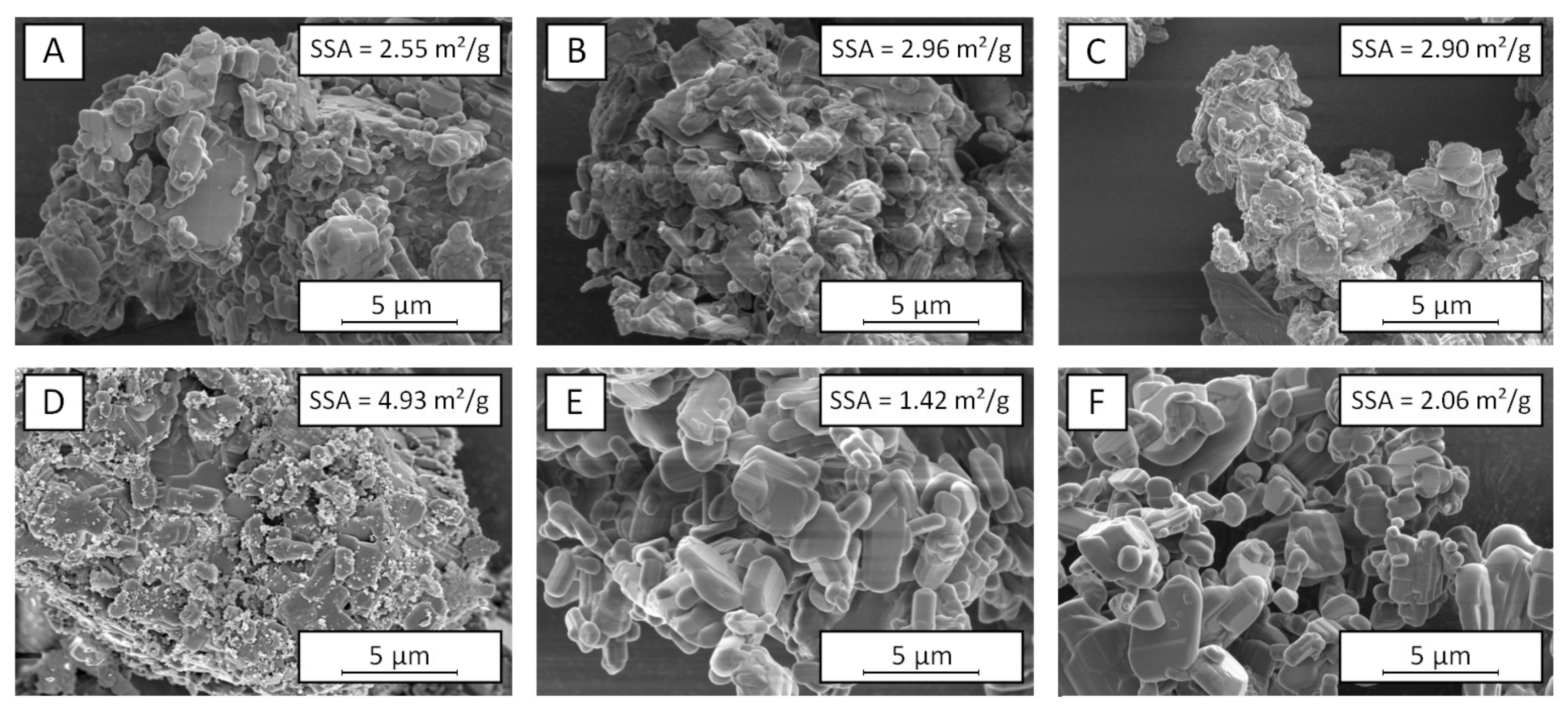

Particle Morphology

Mechanical Properties of Tablets

3. Results and Discussion

3.1. Fine Grinding

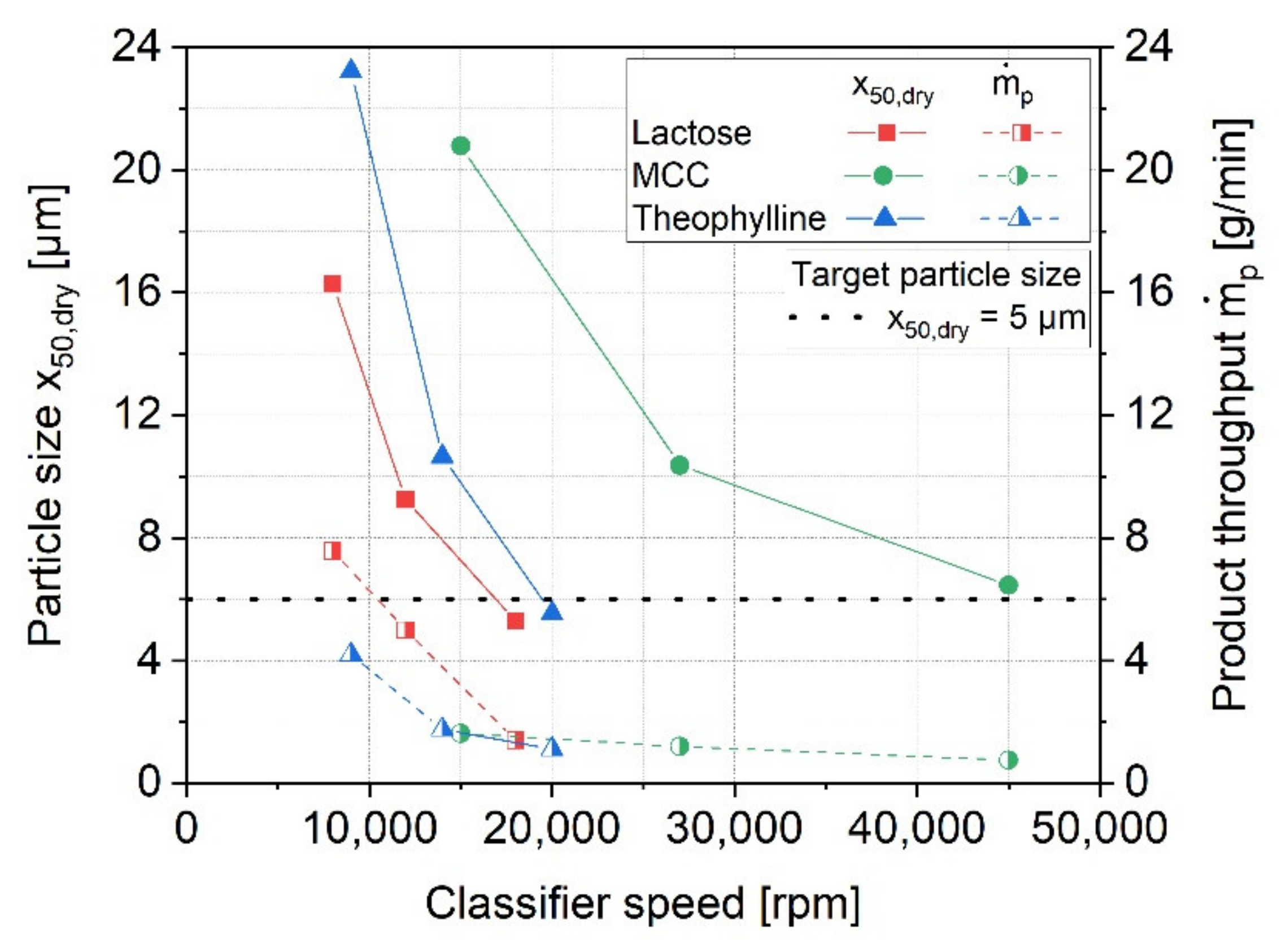

3.1.1. Micronization without Additives

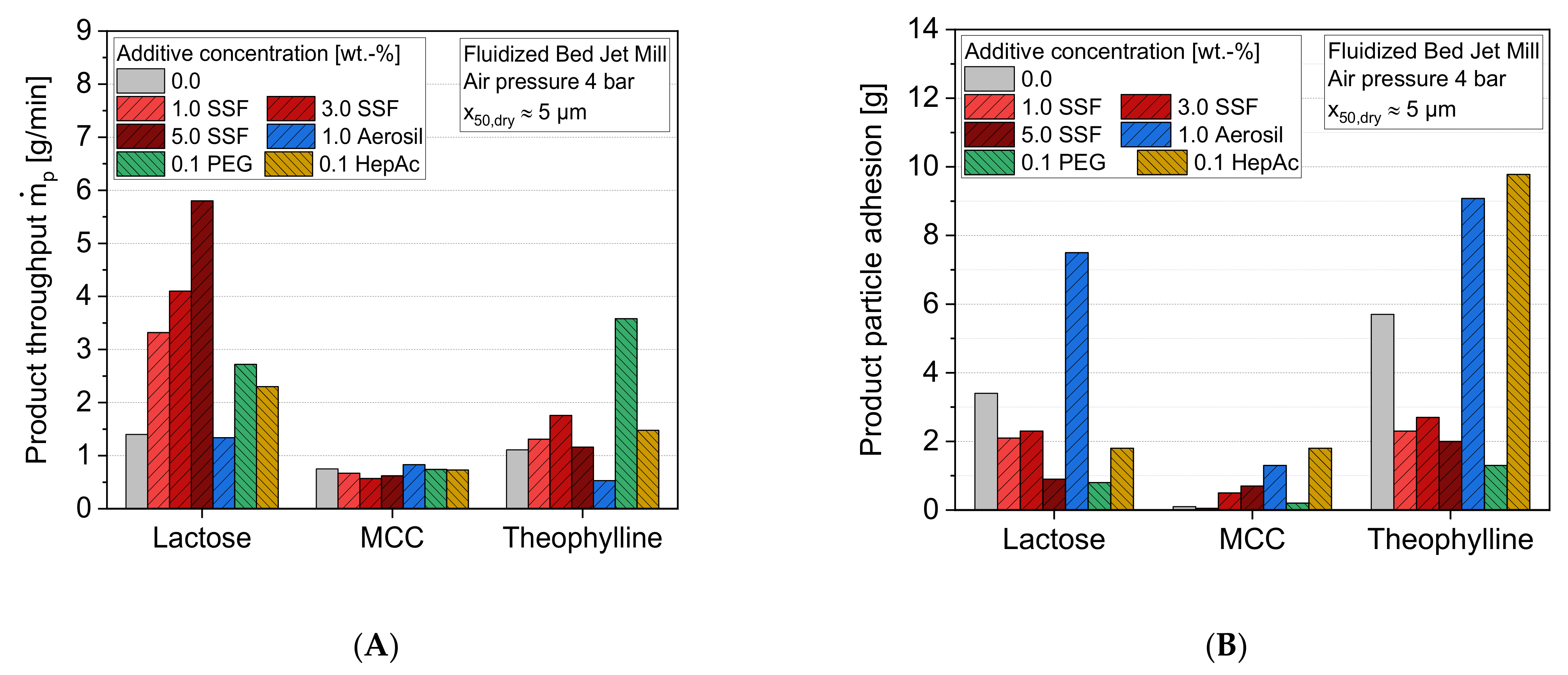

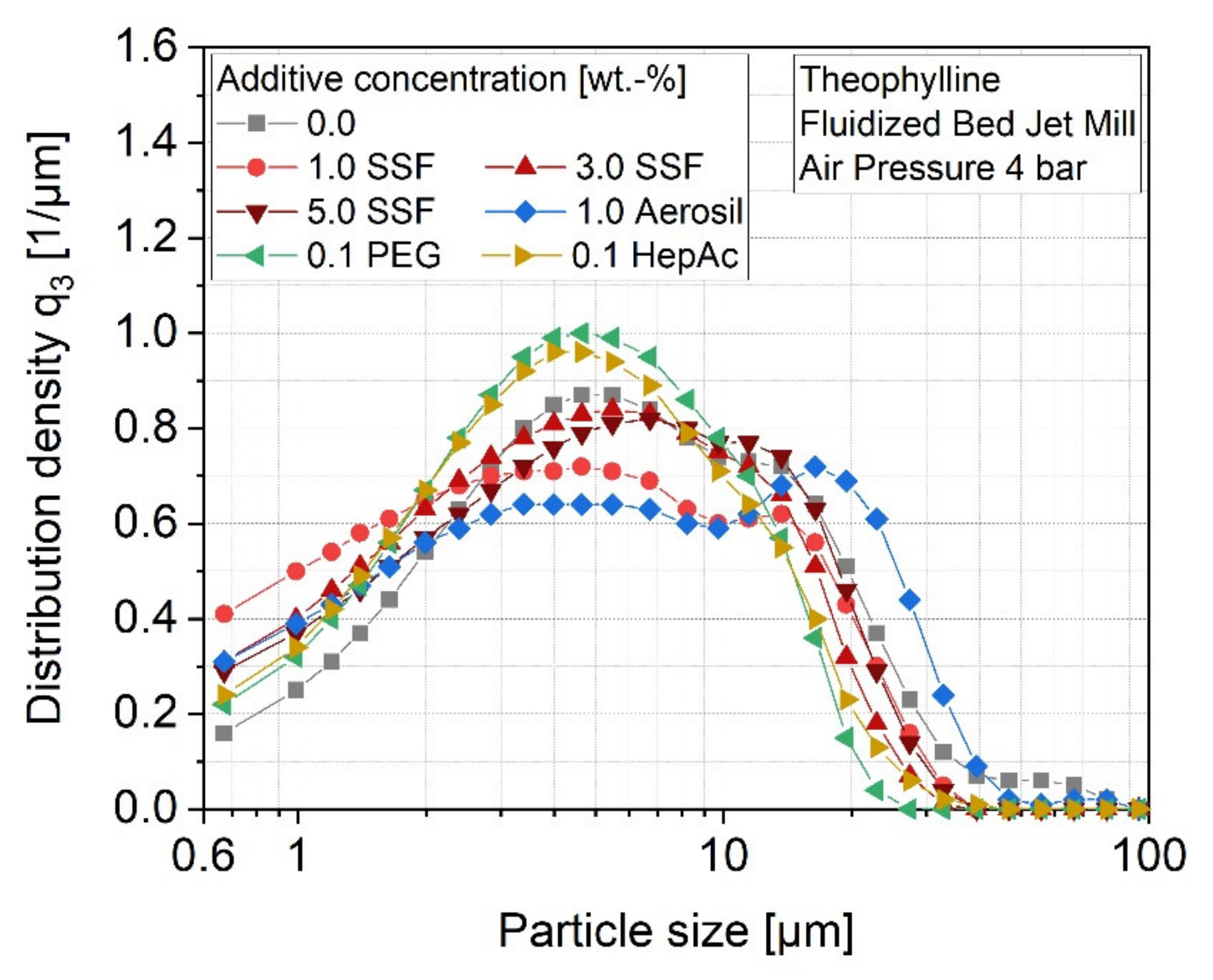

3.1.2. Micronization with Additives

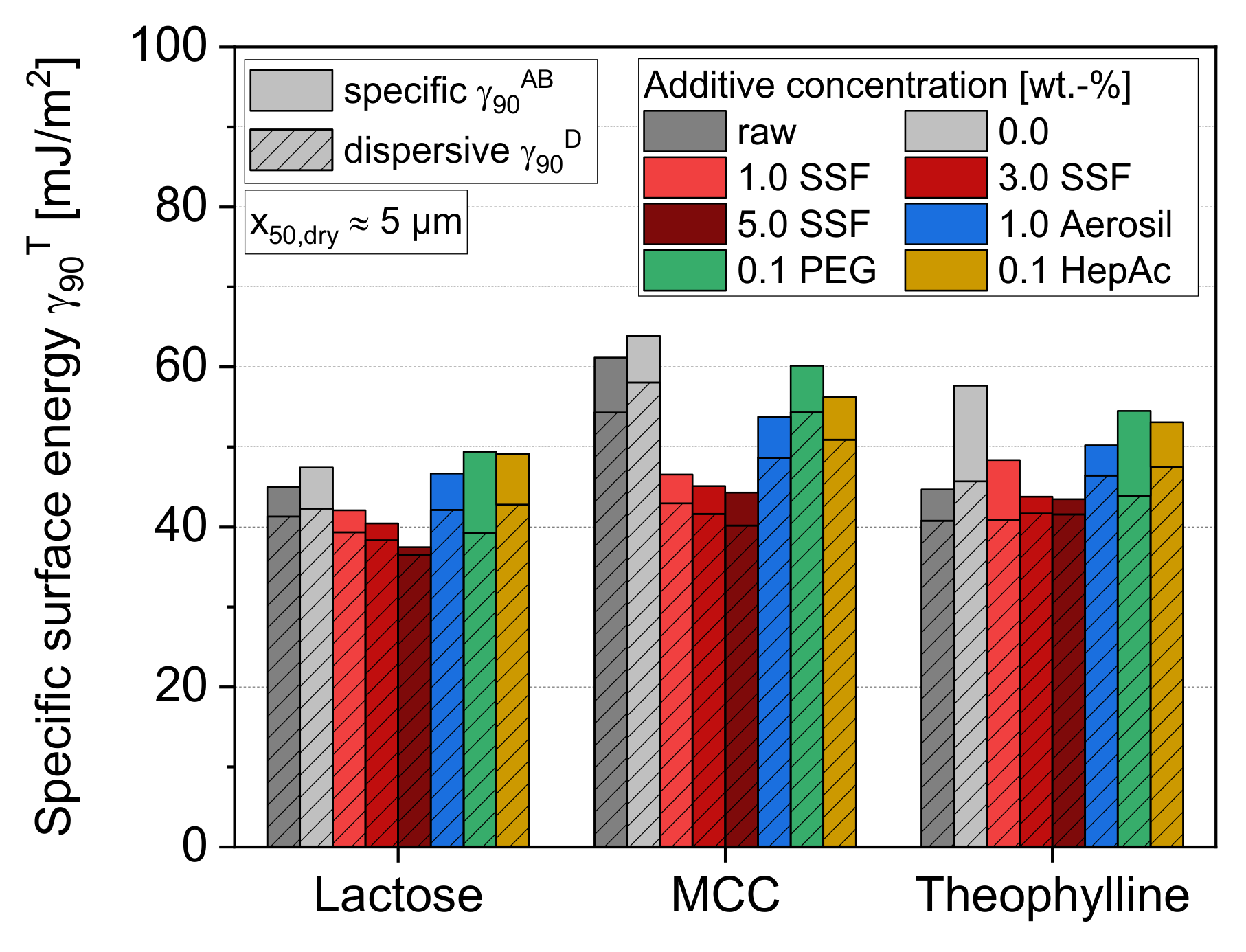

3.2. Effects on Particle and Bulk Properties Relevant for Further Processing

3.2.1. Specific Surface Energy

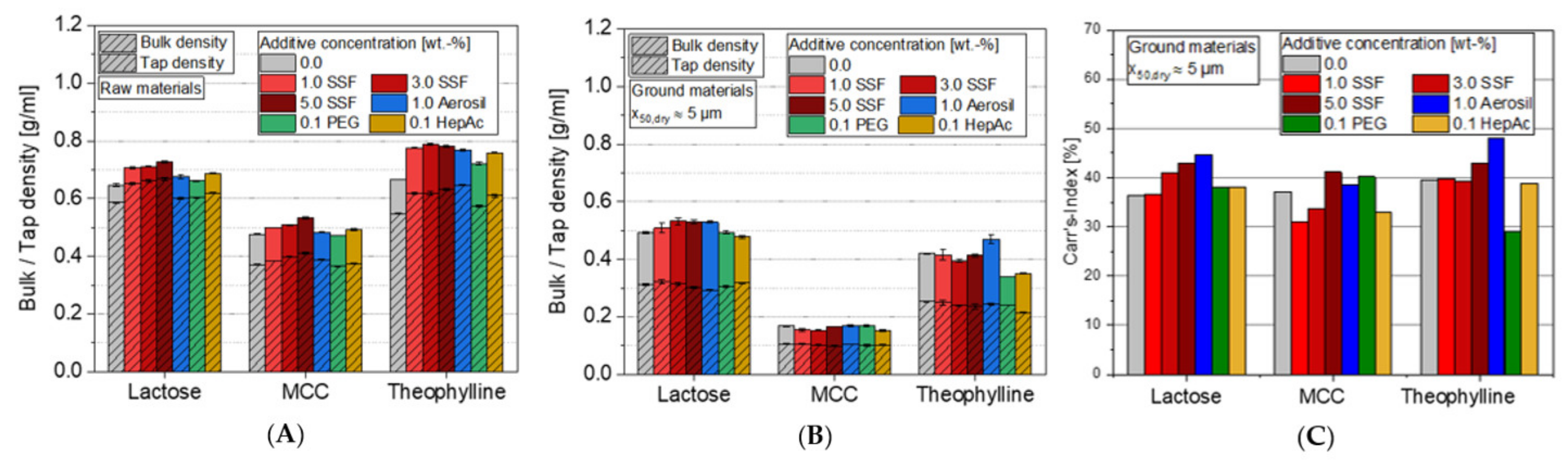

3.2.2. Powder Flowability

3.2.3. Powder Densities

3.3. Relation of Surface Energy and Powder Properties

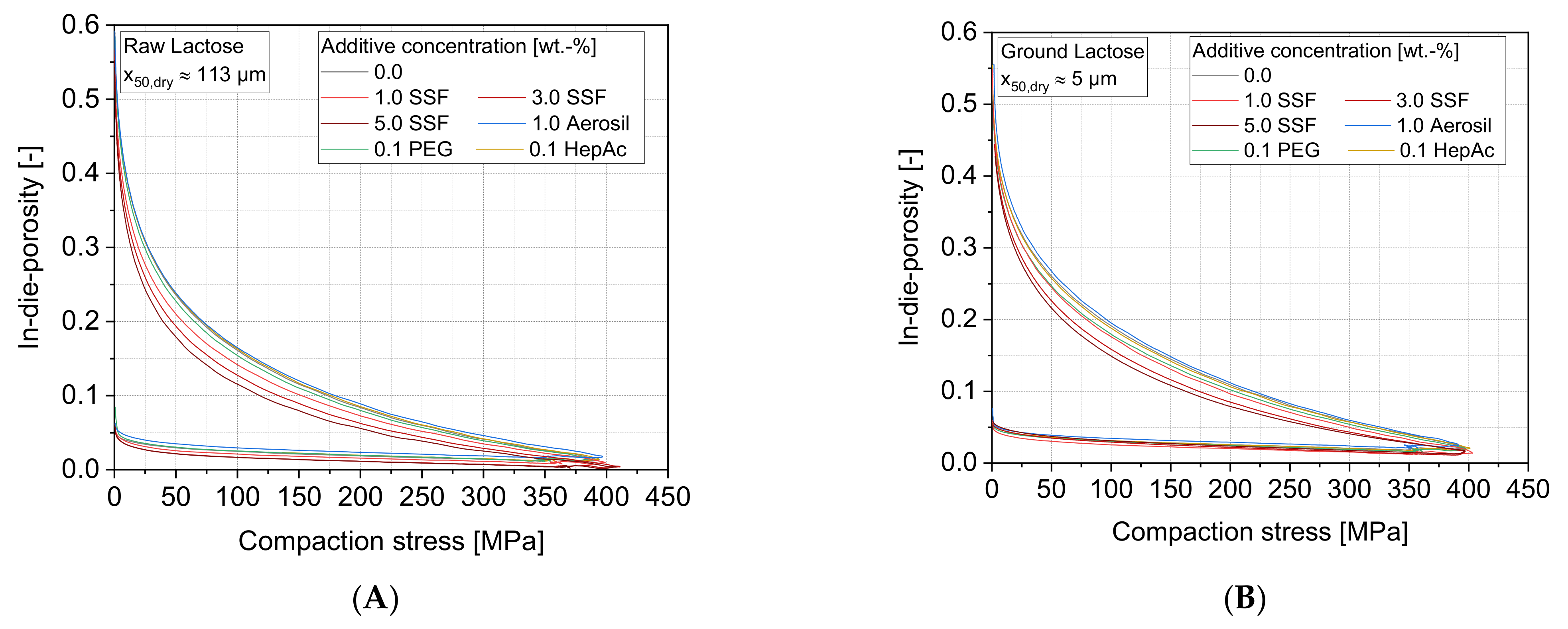

3.4. Tableting

3.4.1. Compression Behavior

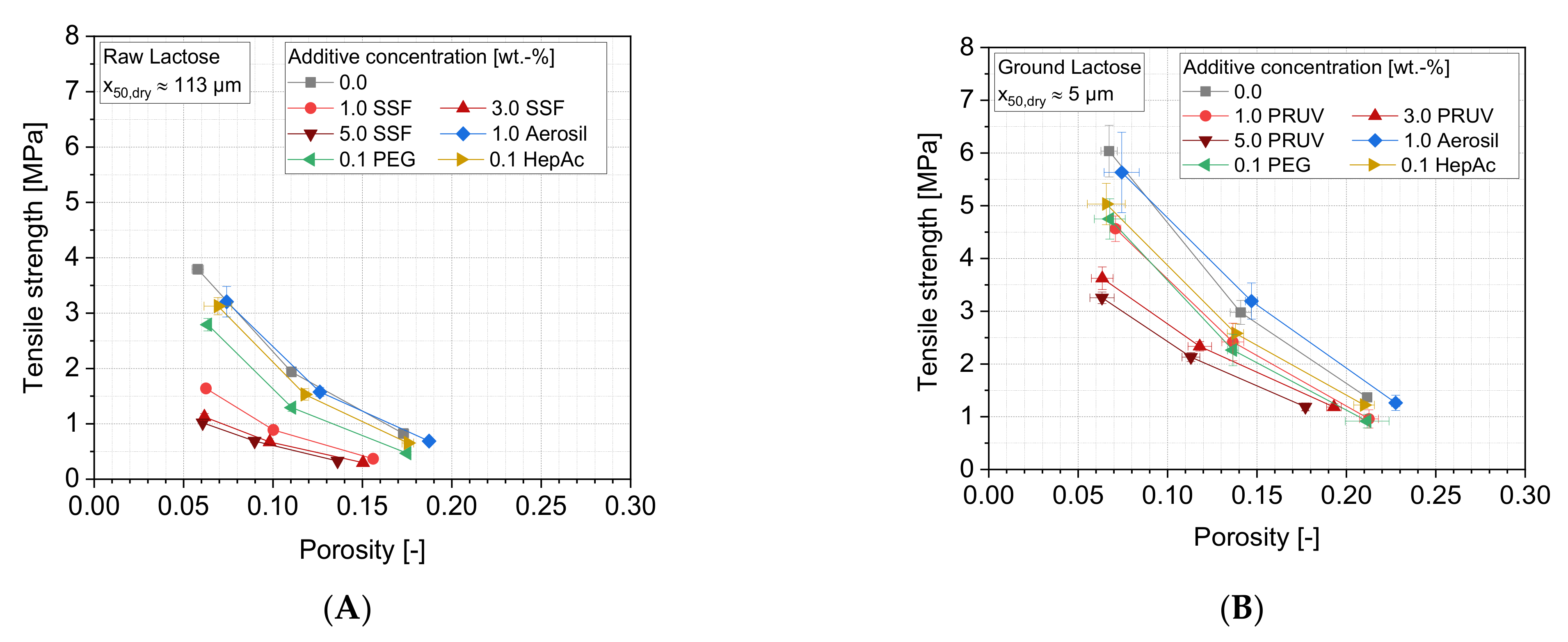

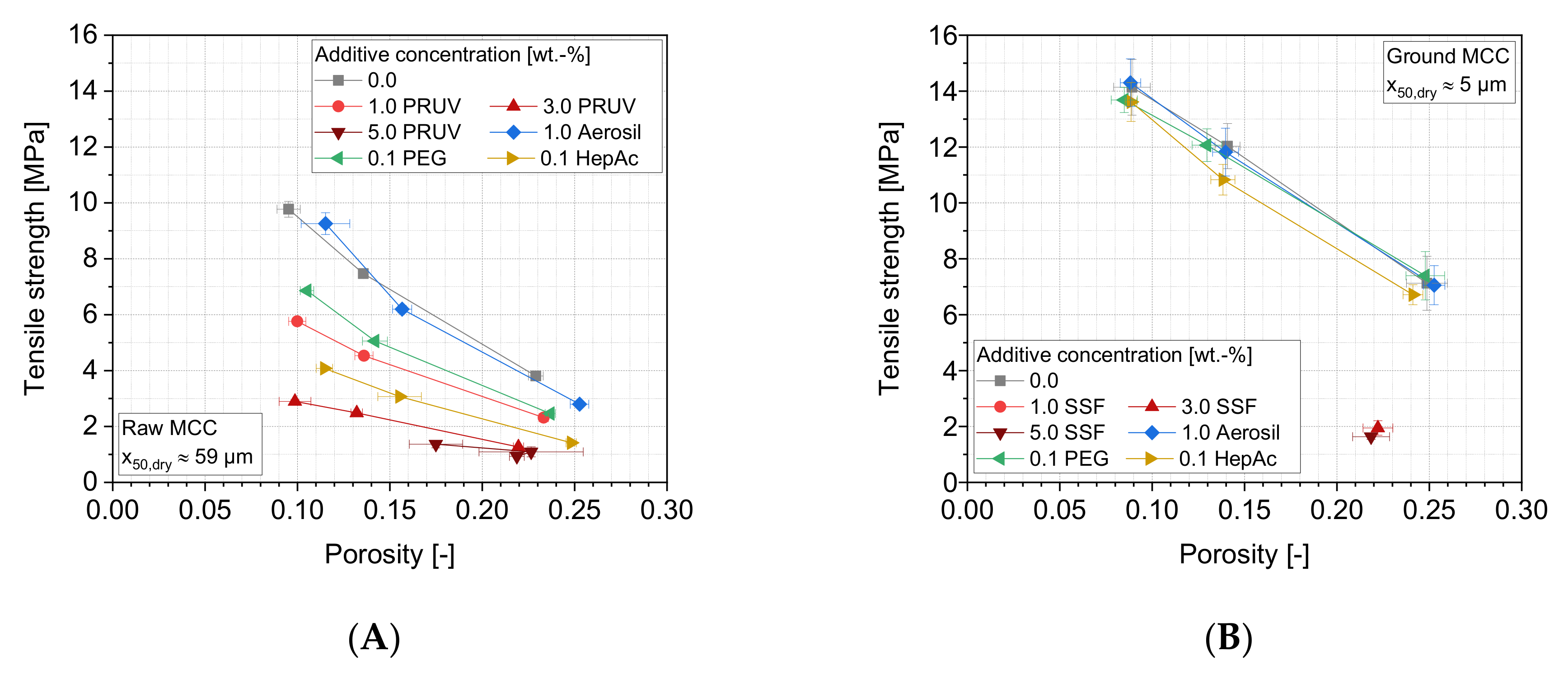

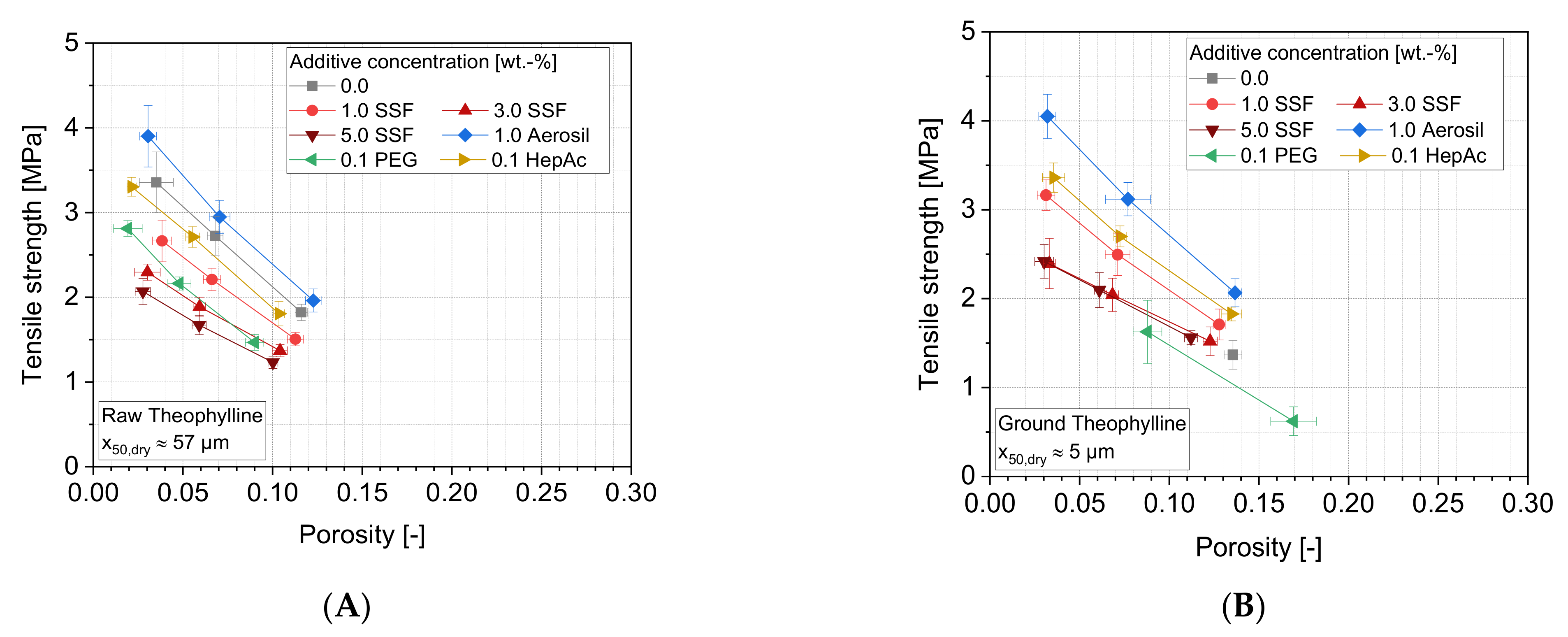

3.4.2. Tensile Strength

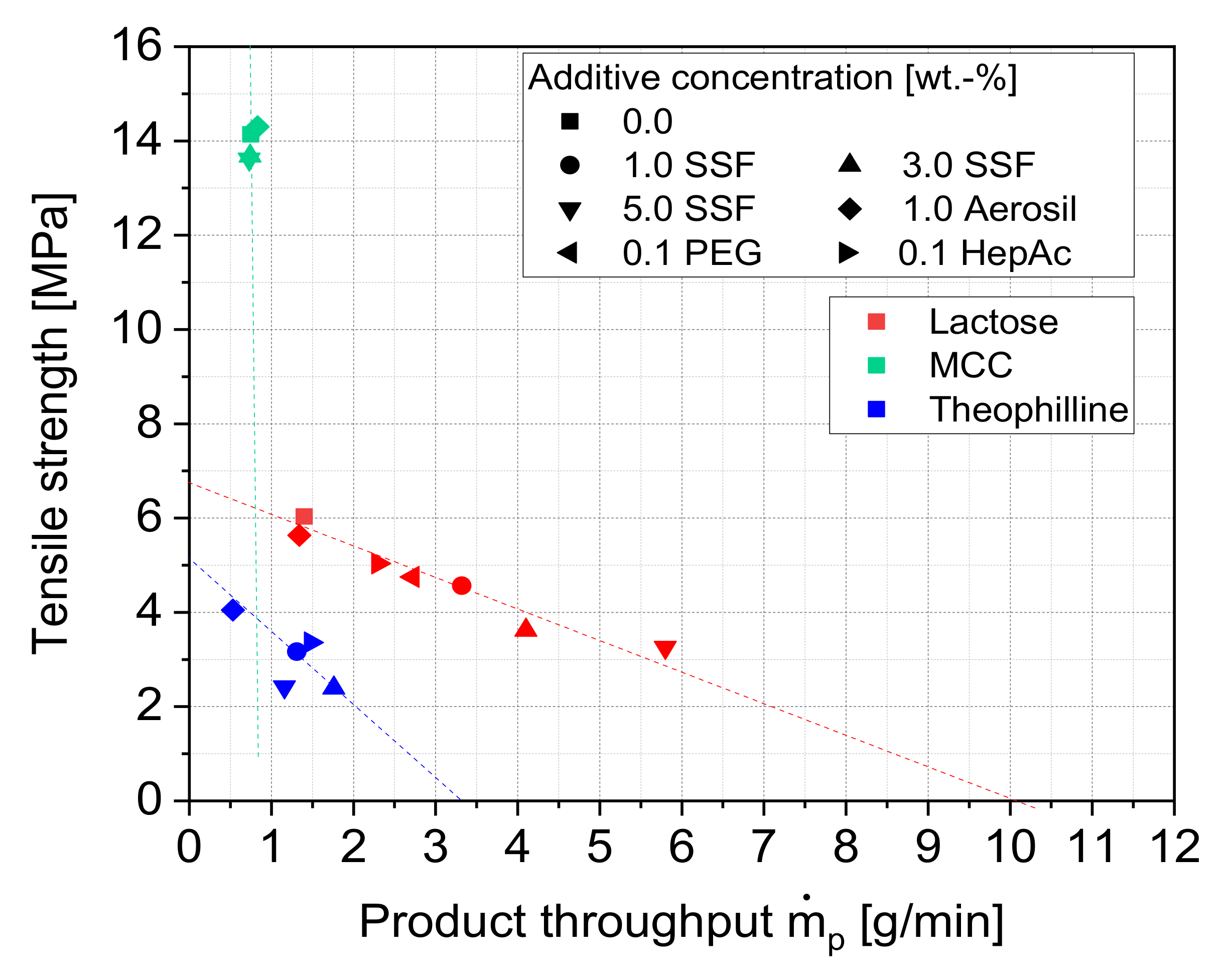

3.5. Correlation of the Grinding and the Compaction Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Khadka, P.; Ro, J.; Kim, H.; Kim, I.; Kim, J.T.; Kim, H.; Choa, J.M.; Yun, G.; Lee, J. Pharmaceutical particle technologies: An approach to improve drug solubility, dissolution and bioavailability. Asian J. Pharm. Sci. 2014, 9, 304–316. [Google Scholar] [CrossRef] [Green Version]

- Jinno, J.-I.; Kamada, N.; Miyake, M.; Yamada, K.; Mukai, T.; Odomi, M.; Toguchi, H.; Liversidge, G.G.; Higaki, K.; Kimura, T. Effect of particle size reduction on dissolution and oral absorption of a poorly water-soluble drug, cilostazol, in beagle dogs. J. Control. Release 2006, 111, 56–64. [Google Scholar] [CrossRef]

- Hao, Z.; Iqbal, A. Some aspects of organic pigments. Chem. Soc. Rev. 1997, 26, 203–213. [Google Scholar] [CrossRef]

- Schmid, M.; Wegener, K. Additive Manufacturing: Polymers Applicable for Laser Sintering (LS). Procedia Eng. 2016, 149, 457–464. [Google Scholar] [CrossRef] [Green Version]

- Nakach, M.; Authelin, J.-R.; Chamayou, A.; Dodds, J. Comparison of various milling technologies for grinding pharmaceutical powders. Int. J. Miner. Process. 2004, 74, S173–S181. [Google Scholar] [CrossRef]

- Nakach, M.; Authelin, J.-R.; Corsini, C.; Gianola, G. Jet milling industrialization of sticky active pharmaceutical ingredient using quality-by-design approach. Pharm. Dev. Technol. 2019, 24, 849–863. [Google Scholar] [CrossRef]

- Pfeffer, R.; Dave, R.; Wei, D.; Ramlakhan, M. Synthesis of engineered particulates with tailored properties using dry particle coating. Powder Technol. 2001, 117, 40–67. [Google Scholar] [CrossRef]

- Dahmash, E.; Mohammed, A.-U. Functionalised particles using dry powder coating in pharmaceutical drug delivery: Promises and challenges. Expert Opin. Drug Deliv. 2015, 12, 1867–1879. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tomas, J.; Kleinschmidt, S. Improvement of Flowability of Fine Cohesive Powders by Flow Additives. Chem. Eng. Technol. 2009, 32, 1470–1483. [Google Scholar] [CrossRef]

- Fulchini, F.; Zafar, U.; Hare, C.; Ghadiri, M.; Tantawy, H.; Ahmadian, H.; Poletto, M. Relationship between surface area coverage of flow-aids and flowability of cohesive particles. Powder Technol. 2017, 322, 417–427. [Google Scholar] [CrossRef]

- Miller, T.A.; York, P. Pharmaceutical tablet lubrication. Int. J. Pharm. 1988, 41, 1–19. [Google Scholar] [CrossRef]

- Li, J.; Wu, Y. Lubricants in Pharmaceutical Solid Dosage Forms. Lubricants 2014, 2, 21–43. [Google Scholar] [CrossRef]

- Bharate, S.S.; Bharate, S.B.; Bajaj, A.N. Interactions and incompatibilities of pharmaceutical excipients with active pharma-ceutical ingredients: A comprehesive review. J. Excipients Food Chem. 2010, 1, 3–26. [Google Scholar]

- Prziwara, P.; Breitung-Faes, S.; Kwade, A. Impact of grinding aids on dry grinding performance, bulk properties and surface energy. Adv. Powder Technol. 2018, 29, 416–425. [Google Scholar] [CrossRef]

- Weibel, M.; Mishra, R.K. Comprehensiv understanding of grinding aids. Zement-Kalk-Gips 2014, 6, 28–39. [Google Scholar]

- Schubert, H. Effects of fluid and additives on grinding processes. Aufbereitungstechnik 1988, 8, 115–120. [Google Scholar]

- Scheibe, W.; Hoffmann, B.; Dombrowe, H. Der Einsatz von Mahlhilfsmitteln als eine Möglichkeit zur Verbesserung von tro-ckenen Feinmahlprozessen. Freiber Forschungshefte A 1978, 602, 61–70. [Google Scholar]

- Dombrowe, H.; Hoffmann, B.; Scheibe, W. Über Wirkungsweise und Einsatzmöglichkeiten von Mahlhilfsmitteln. Zement-Kalk-Gips 1982, 11, 571–580. [Google Scholar]

- Sottili, L.; Padovani, D. Effect of grinding admixtures in the cement industry, Part 1. ZKG Int. 2000, 53, 568–575. [Google Scholar]

- Sottili, L.; Padovani, D. Effect of grinding admixtures in the cement industry, Part 2. ZKG Int. 2001, 54, 146–151. [Google Scholar]

- Toprak, N.A.; Altun, O.; Aydogan, N.; Benzer, H. The influences and selection of grinding chemicals in cement grinding circuits. Constr. Build. Mater. 2014, 68, 199–205. [Google Scholar] [CrossRef]

- Assaad, J.J. Industrial versus Laboratory Clinker Processing Using Grinding Aids (Scale Effect). Adv. Mater. Sci. Eng. 2015, 2015, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Prziwara, P.; Hamilton, L.; Breitung-Faes, S.; Kwade, A. Impact of grinding aids and process parameters on dry stirred media milling. Powder Technol. 2018, 335, 114–123. [Google Scholar] [CrossRef]

- Prziwara, P.; Breitung-Faes, S.; Kwade, A. Impact of the powder flow behavior on continuous fine grinding in dry operated stirred media mills. Miner. Eng. 2018, 128, 215–223. [Google Scholar] [CrossRef]

- Altun, O.; Benzer, H.; Toprak, A.; Enderle, U. Utilization of grinding aids in dry horizontal stirred milling. Powder Technol. 2015, 286, 610–615. [Google Scholar] [CrossRef]

- Pohl, M.; Obry, S.; Zysk, K.-H. Operating experience with a vertical roller mill for grinding granulated blast-furnace slag and composite cements. Cem. Int. 2012, 10, 57–69. [Google Scholar]

- Schwarzwälder, S.; Nied, R.; Sickel, H. Dry Fine Grinding with Jet Mills: Potentials of Energy Optimization. Chem. Eng. Technol. 2014, 37, 806–812. [Google Scholar] [CrossRef]

- Miranda, S.; Yilmaz, E. Dry Grinding of Technical Ceramics into the Submicron Range. Ceram. Forum Int. 2014, 91, 18–24. [Google Scholar]

- Godet-Morand, L.; Chamayou, A.; Dodds, J. Talc grinding in an opposed air jet mill: Start-up, product quality and production rate optimization. Powder Technol. 2002, 128, 306–313. [Google Scholar] [CrossRef] [Green Version]

- Fukumori, Y.; Tamura, I.; Jono, K.; Miyamoto, M.; Tokumitsu, H.; Ichikawa, H.; Block, L.H. Dry grinding of chitosan powder by a planetary ball mill. Adv. Powder Technol. 1998, 9, 281–292. [Google Scholar] [CrossRef]

- Mullarney, M.P.; Beach, L.E.; Davé, R.N.; Langdon, B.A.; Polizzi, M.; Blackwood, D.O. Applying dry powder coatings to phar-maceutical powders using a comil for improving powder flow and bulk density. Powder Technol. 2011, 212, 397–402. [Google Scholar] [CrossRef]

- Han, X.; Jallo, L.; To, D.; Ghoroi, C.; Davé, R. Passivation of High-Surface-Energy Sites of Milled Ibuprofen Crystals via Dry Coating for Reduced Cohesion and Improved Flowability. J. Pharm. Sci. 2013, 102, 2282–2296. [Google Scholar] [CrossRef]

- Vogt, M.; Kunath, K.; Dressman, J.B. Dissolution improvement of four poorly water soluble drugs by cogrinding with commonly used excipients. Eur. J. Pharm. Biopharm. 2008, 68, 330–337. [Google Scholar] [CrossRef]

- Han, X.; Ghoroi, C.; Dave, R. Dry coating of micronized API powders for improved dissolution of directly compacted tablets with high drug loading. Int. J. Pharm. 2013, 442, 74–85. [Google Scholar] [CrossRef]

- Wang, P.; Zhu, L.; Teng, S.; Zhang, Q.; Young, M.-W.; Gogos, C. A novel process for simultaneous milling and coating of particulates. Powder Technol. 2009, 193, 65–68. [Google Scholar] [CrossRef]

- Stank, K.; Steckel, H. Physico-chemical characterisation of surface modified particles for inhalation. Int. J. Pharm. 2013, 448, 9–18. [Google Scholar] [CrossRef]

- Kunnath, K.; Huang, Z.; Chen, L.; Zheng, K.; Davé, R. Improved properties of fine active pharmaceutical ingredient powder blends and tablets at high drug loading via dry particle coating. Int. J. Pharm. 2018, 543, 288–299. [Google Scholar] [CrossRef] [PubMed]

- Chattoraj, S.; Shi, L.; Sun, C.C. Profoundly improving flow properties of a cohesive cellulose powder by surface coating with nano-silica through comilling. J. Pharm. Sci. 2011, 100, 4943–4952. [Google Scholar] [CrossRef] [PubMed]

- Qu, L.; Zhou, Q.; Gengenbach, T.; Denman, J.A.; Stewart, P.J.; Hapgood, K.P.; Gamlen, M.; Morton, D.A.V. Investigation of the potential for direct compaction of a fine ibuprofen powder dry-coated with magnesium stearate. Drug Dev. Ind. Pharm. 2014, 41, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Qu, L.; Stewart, P.J.; Hapgood, K.P.; Lakio, S.; Morton, D.A.; Zhou, Q. Single-step Coprocessing of Cohesive Powder via Mechanical Dry Coating for Direct Tablet Compression. J. Pharm. Sci. 2016, 106, 159–167. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi-Jam, S.; Waters, K. Inverse gas chromatography applications: A review. Adv. Colloid Interface Sci. 2014, 212, 21–44. [Google Scholar] [CrossRef]

- Fowkes, F.M. Attractive forces at interfaces. Ind. Eng. Chem. 1964, 56, 40–52. [Google Scholar] [CrossRef]

- Jenike, A.W. Storage and Flow of Solids; Bulletin of the Utah Engineering Experiment Station; Utah State University: Logan, UT, USA, 1964. [Google Scholar]

- European Pharmacopoeia, 9th ed.; Deutscher Apotheker Verlag: Gerlingen, Germany, 2017.

- Fell, J.T.; Newton, J.M. Determination of Tablet Strength by the Diametral-Compression Test. J. Pharm. Sci. 1970, 59, 688–691. [Google Scholar] [CrossRef]

- Rumpf, H. Beanspruchungstheorie der Prallzerkleinerung. Chem. Ing. Tech. 1959, 31, 323–337. [Google Scholar] [CrossRef]

- Schilde, C.; Breitung-Faes, S.; Kwade, A. Dispersing and grinding of alumina nano particles by different stress mechanisms. Ceram. Forum Int. 2007, 84, 12–17. [Google Scholar]

- Zellmer, S.; Lindenau, M.; Michel, S.; Garnweitner, G.; Schilde, C. Influence of surface modification on structure formation and micromechanical properties of spray-dried silica aggregates. J. Colloid Interface Sci. 2016, 464, 183–190. [Google Scholar] [CrossRef] [PubMed]

- Spoetter, K.; Legenhausen, A.P. Weber, Influence of the Paddle Geometry on the Fluid Flow and Particle Movement of a Deflector Wheel Separator. Chem. Ing. Tech. 2018, 90, 493–506. [Google Scholar]

- Swaminathan, V.; Cobb, J.; Saracovan, I. Measurement of the surface energy of lubricated pharmaceutical powders by inverse gas chromatography. Int. J. Pharm. 2006, 312, 158–165. [Google Scholar] [CrossRef] [PubMed]

- Shah, U.V.; Wang, Z.; Olusanmi, D.; Narang, A.S.; Hussain, M.A.; Tobyn, M.J.; Heng, J.Y. Effect of milling temperatures on surface area, surface energy and cohesion of pharmaceutical powders. Int. J. Pharm. 2015, 495, 234–240. [Google Scholar] [CrossRef]

- Ho, R.; Naderi, M.; Heng, J.; Williams, D.; Thielmann, F.; Bouza, P.; Keith, A.R.; Thiele, G.; Burnett, D.J. Effect of Milling on Particle Shape and Surface Energy Heterogeneity of Needle-Shaped Crystals. Pharm. Res. 2012, 29, 2806–2816. [Google Scholar] [CrossRef]

- Prziwara, P.; Breitung-Faes, S.; Kwade, A. Comparative study of the grinding aid effects for dry fine grinding of different materials. Miner. Eng. 2019, 144, 106030. [Google Scholar] [CrossRef]

| Lactose | Microcrystalline Cellulose (MCC) | Theophylline | |

|---|---|---|---|

| Solid density (g/mL) | 1.535 | 1.562 | 1.445 |

| Bulk density (g/mL) | 0.587 | 0.371 | 0.406 |

| Median particle size x50,dry (µm) | 113.6 | 59.6 | 57.2 |

| Substance Class | Name | Manufacturer | Physical State | Boiling Point (°C) | BET-Surface (m2/g) |

|---|---|---|---|---|---|

| Carboxylic acid | Heptanoic acid 96% (HepAc) | Sigma Aldrich | liquid | 223 | - |

| Poly glycol | Polyethylene glycol 200 (PEG) | Sigma Aldrich | liquid | >150 | - |

| Flow additive | Silicon dioxide (Aerosil 200) | Evonik | solid | - | 175–225 |

| Lubricant | Sodium stearyl fumarate (SSF) | JRS Pharma | solid | - | 1.6 |

| Powder Flow Behavior | |

|---|---|

| < 2 | Very cohesive and not flowing |

| 2 < < 4 | Cohesive |

| 4 < < 10 | Easy flowing |

| 10 < | Free flowing |

| Material | Elastically Stored Energy (J) | Plastically Stored Energy (J) | Elastic/Plastic Ratio φ (−) | Mean Yield Pressure (MYP) (MPa) |

|---|---|---|---|---|

| Lactose | 0.5 | 11.8 | 0.04 | 150 |

| MCC | 1.1 | 15.6 | 0.07 | 105 |

| Theophylline | 1.4 | 7.6 | 0.19 | 70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miethke, L.; Prziwara, P.; Finke, J.H.; Breitung-Faes, S. Opposing Effects of Additives in Dry Milling and Tableting of Organic Particles. Pharmaceutics 2021, 13, 1434. https://doi.org/10.3390/pharmaceutics13091434

Miethke L, Prziwara P, Finke JH, Breitung-Faes S. Opposing Effects of Additives in Dry Milling and Tableting of Organic Particles. Pharmaceutics. 2021; 13(9):1434. https://doi.org/10.3390/pharmaceutics13091434

Chicago/Turabian StyleMiethke, Lina, Paul Prziwara, Jan Henrik Finke, and Sandra Breitung-Faes. 2021. "Opposing Effects of Additives in Dry Milling and Tableting of Organic Particles" Pharmaceutics 13, no. 9: 1434. https://doi.org/10.3390/pharmaceutics13091434

APA StyleMiethke, L., Prziwara, P., Finke, J. H., & Breitung-Faes, S. (2021). Opposing Effects of Additives in Dry Milling and Tableting of Organic Particles. Pharmaceutics, 13(9), 1434. https://doi.org/10.3390/pharmaceutics13091434