Assessment of Bacterial Nanocellulose Loaded with Acetylsalicylic Acid or Povidone-Iodine as Bioactive Dressings for Skin and Soft Tissue Infections

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Development of Bioactive Wound Dressings

2.3. Preparation of BNC Wound Dressings

2.4. Wound Dressing Characterization

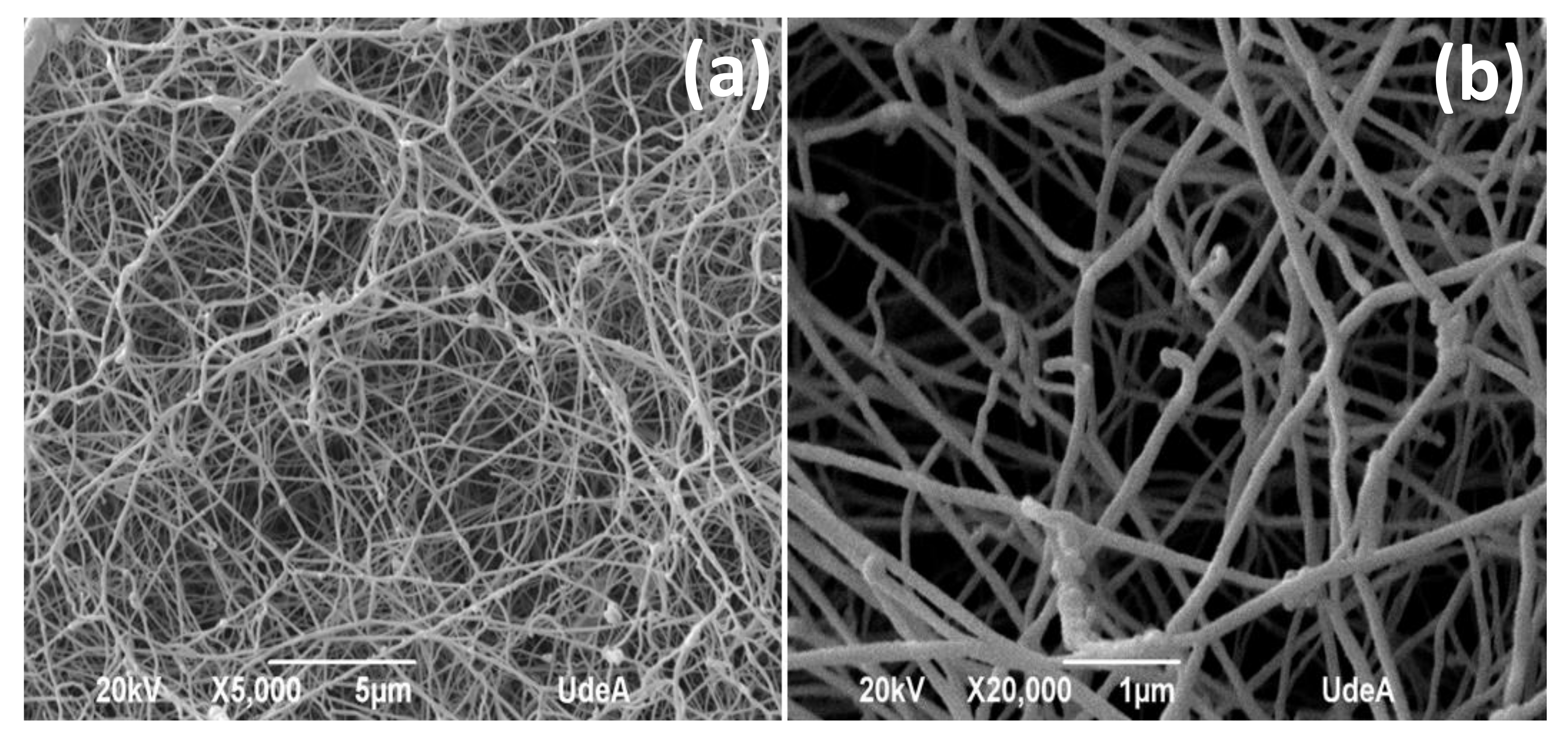

- Scanning electron microscopy (SEM)SEM was used to analyze the morphology of BNC dressings. The dressings were frozen at −196 °C using liquid nitrogen and freeze-dried for 24 h under 0.020 mBar of vacuum; then, the samples were coated with gold using ion sputtering. Finally, the samples were observed at 5000 and 20,000 magnifications using a Jeol JSM 5910 LV Scanning Electron Microscope operating at 20 kV.

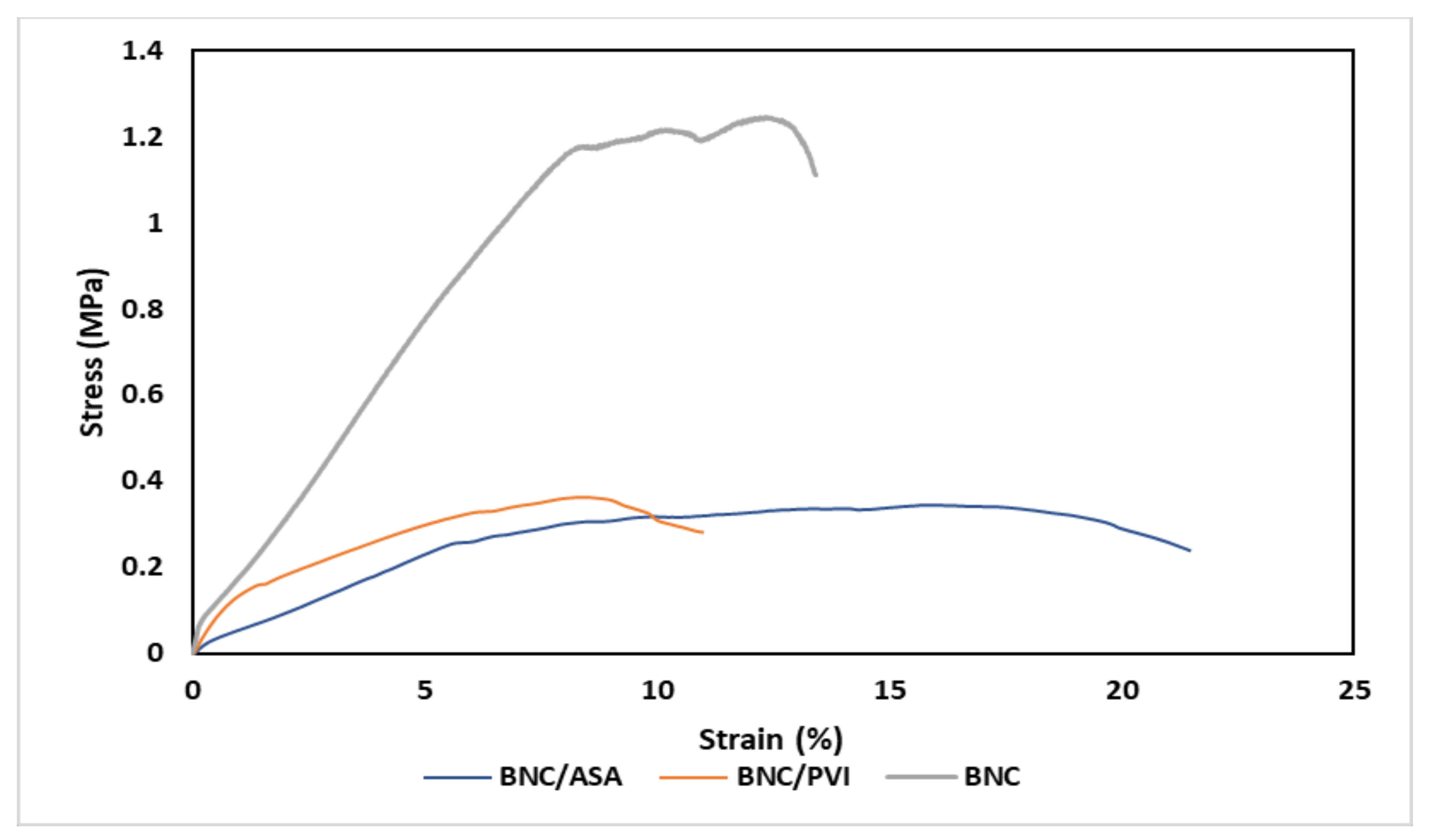

- Mechanical characterizationMechanical properties of BNC/PVI and BNC/ASA were analyzed using uniaxial tensile tests in an Instron Universal Testing Machine. The specimens were cut following ASTM D882 guidelines, producing samples with a thickness of 0.55 mm and length of 20 mm; samples were mounted in pneumatic clamps and stretched up to the point of failure. Twelve curves each were obtained for PVI and ASA; the representative curve was the average of all measurements. Young’s modulus, strain at break, and stress at break were obtained.

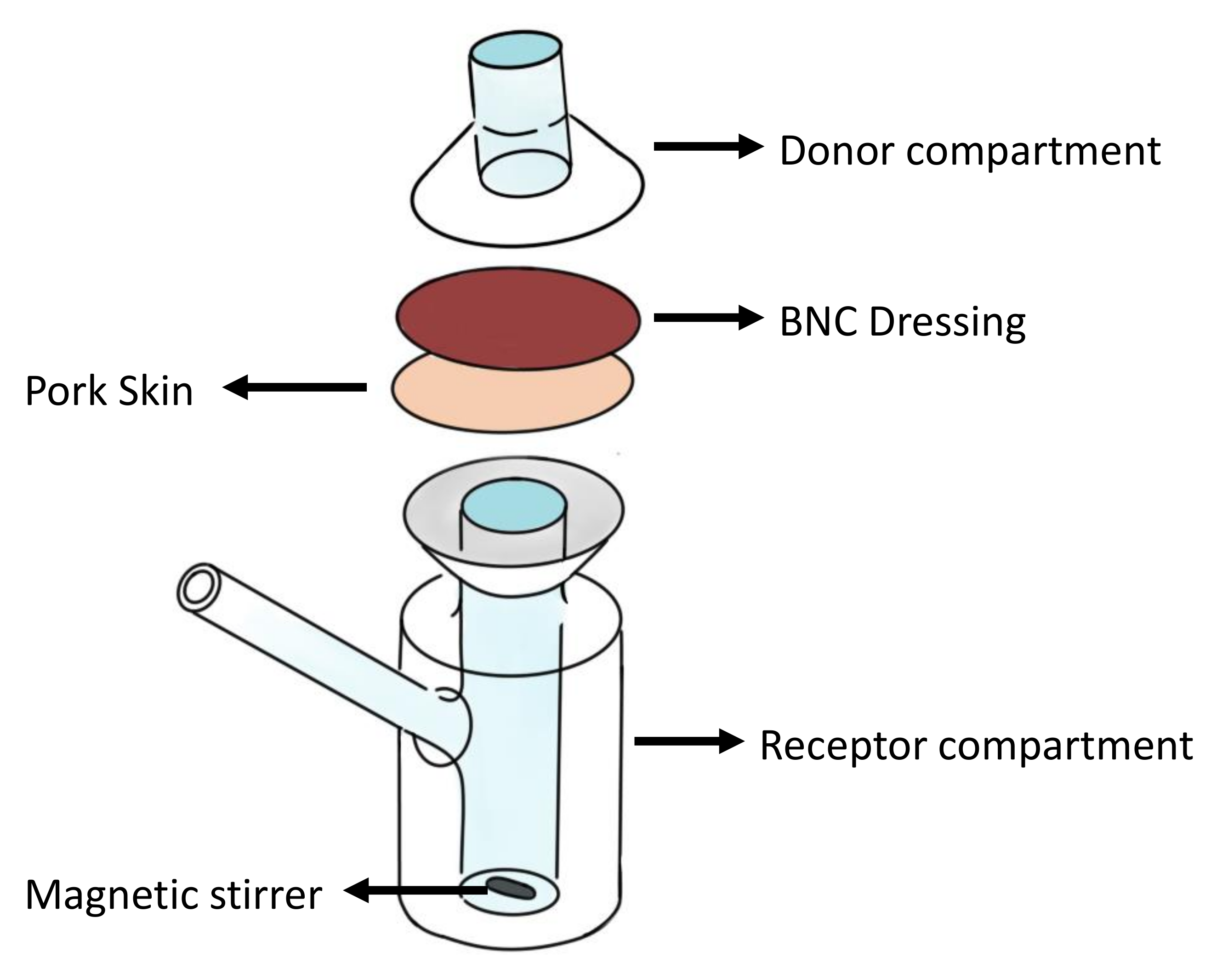

- Loading and release experimentsBNC dressings were deposited separately in 100 mL of both formulations (PVI and ASA) for 1 h without agitation, and aliquots of 100 µL were taken at 5, 10, 15, 20, 25, 30, 35, 40, 50, and 60 min. To measure the concentrations of PVI and ASA, a complexation process was performed. For PVI, the protocol established by Sulistyarti et al. (2015) was followed: 50 µL of the aliquot was diluted in 5 mL of KIO 3 mM; then, 100 µL was taken from the earlier solution and mixed with 100 µL of starch at 0.5 wt. %. The concentrations were determined using UV–Vis spectroscopy at a wavelength of 615 nm [31]. Following the protocol established by Chambers et al. (1993) for ASA, 100 µL of the aliquot was diluted in 8.9 mL of water and 1 mL of NaOH 2M; then, 100 µL from the earlier solution was diluted with FeCl 0.02 M. Then, the concentrations were measured with UV–Vis spectroscopy with a wavelength of 530 nm [32].The experimental data were modeled using kinetics for the PVI and ASA loaded (active compounds) into the adsorbent (BNC). The experimental loading capacity Qt of active compounds was calculated by the following equation [33,34]:where is the initial concentration of the compound in the solution (g/L); is the concentration in an instant t (g/L); V is the volume of the solution, which was constant throughout the assay (L); W is the weight of the BNC dressing (g). Then, is the mass absorbed by compounds by the mass of BNC (g of active compounds/g of BNC).Lagergren’s pseudo-first-order model was used as an loading model [34,35]. The model is described mathematically by the following equation:where K is the first-order kinetic constant. This constant represents the velocity of the process and can give an indication of the affinity between the components evaluated in the loading experiment, and is the concentration at equilibrium. Considering the adsorbent free of solute, initially, the resulting equation obtained in an integrated manner isFor release experiments, BNC/PVI and BNC/ASA dressings were initially oven-dried at 37 ºC for 1 h to remove excess liquid, and then two release kinetic assays were performed using static diffusion cells, following the method of Franz et al. [20]. Figure 1 shows a schematic image representing the assay performed. In the first test, the receptor compartment had an average volume of 12 mL and a donor compartment of 3 mL and was kept at 37 °C using a heating plate. Water and simulated acidic sweat media were used to reproduce the physiological working conditions of the dressings; acidic sweat was prepared following the AATCC 125-2004 [36]. The solution in each cell was continuously stirred using a magnetic stirrer at 100 rpm. Between the compartments, the sample was placed (23 mm diameter and 0.8 mm thickness). The test was carried out for 24 h, and at select time points of 2, 4, 6, 8, 12, and 24 h, aliquots of 100 µL solution were taken; each time, the volume was replaced with fresh simulated sweat or distilled water. Finally, the concentration of the samples was measured by absorbance, as described above. In the second trial, the penetration of active compounds in pork skin was evaluated, as explained by Schmook et al. (1993) [37]. A pig ear was obtained from a local butcher shop and the excess subcutaneous tissue was removed with a scalpel blade (fixation was not used). The remaining skin sheets were cut to a diameter of 2.3 cm, excluding sites that had scars, bruises, and earlier cuts. In this process, the skin was located with the epidermis towards the donor compartment [37]. Figure 1 illustrates the experimental setup.

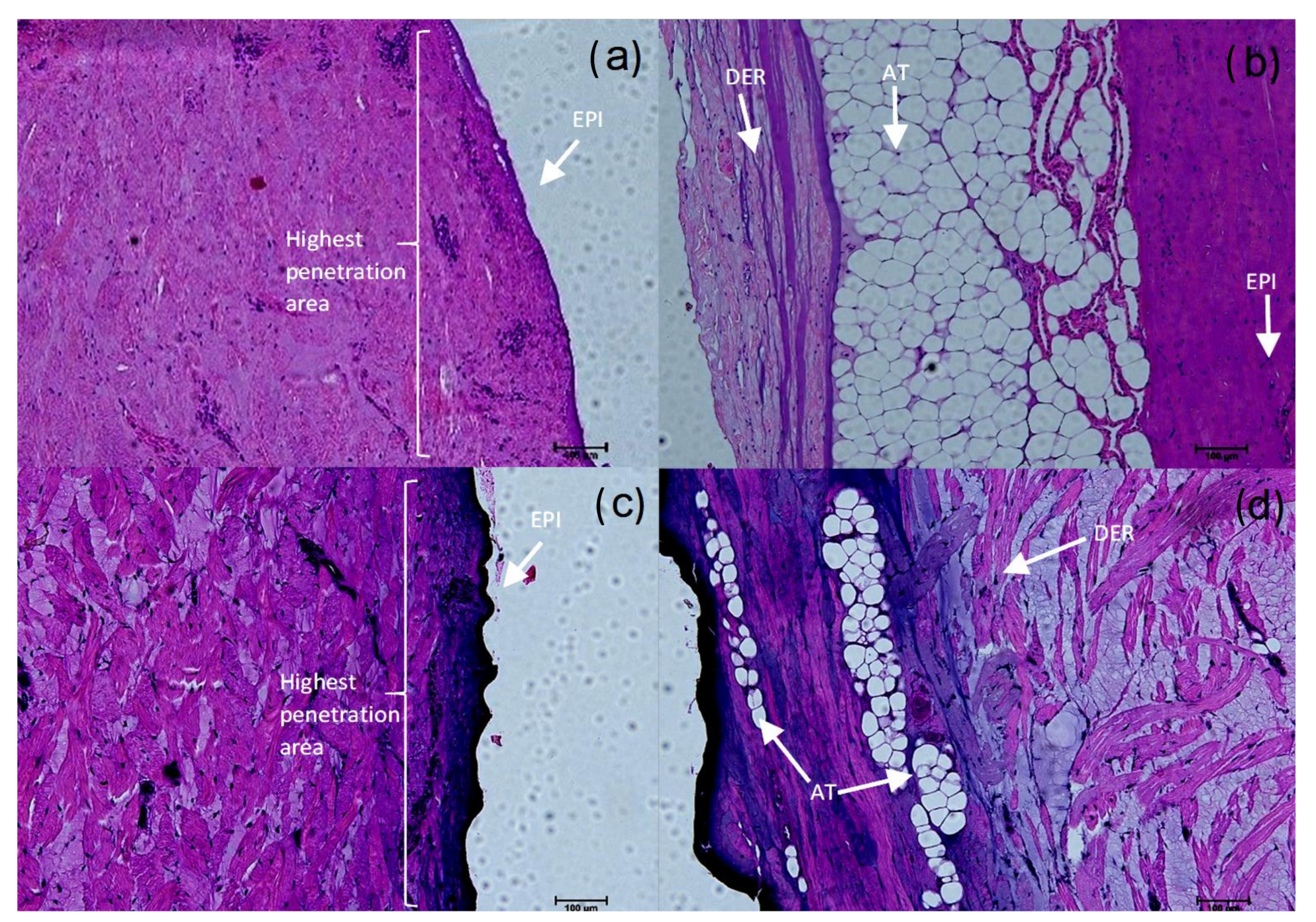

- HistologyTo evaluate the active components’ penetration throughout the skin, pork skin tissues were complexed as described above to reveal PVI and ASA in the tissue; then, they were stained according to the protocol of Osorio et al. (2019). First, the tissue was fixed using formalin 10% v/v, and then it was dehydrated in an alcohol solution and transferred to xylene; the tissues were subsequently incorporated into paraffin. Blocks of 5 µm thickness were obtained, which were stained with hematoxylin–eosin (HE) [27]. The cuts were observed in a standard Nikon microscope equipped with a DS-Fi3 integrated camera using 10X objective magnification.

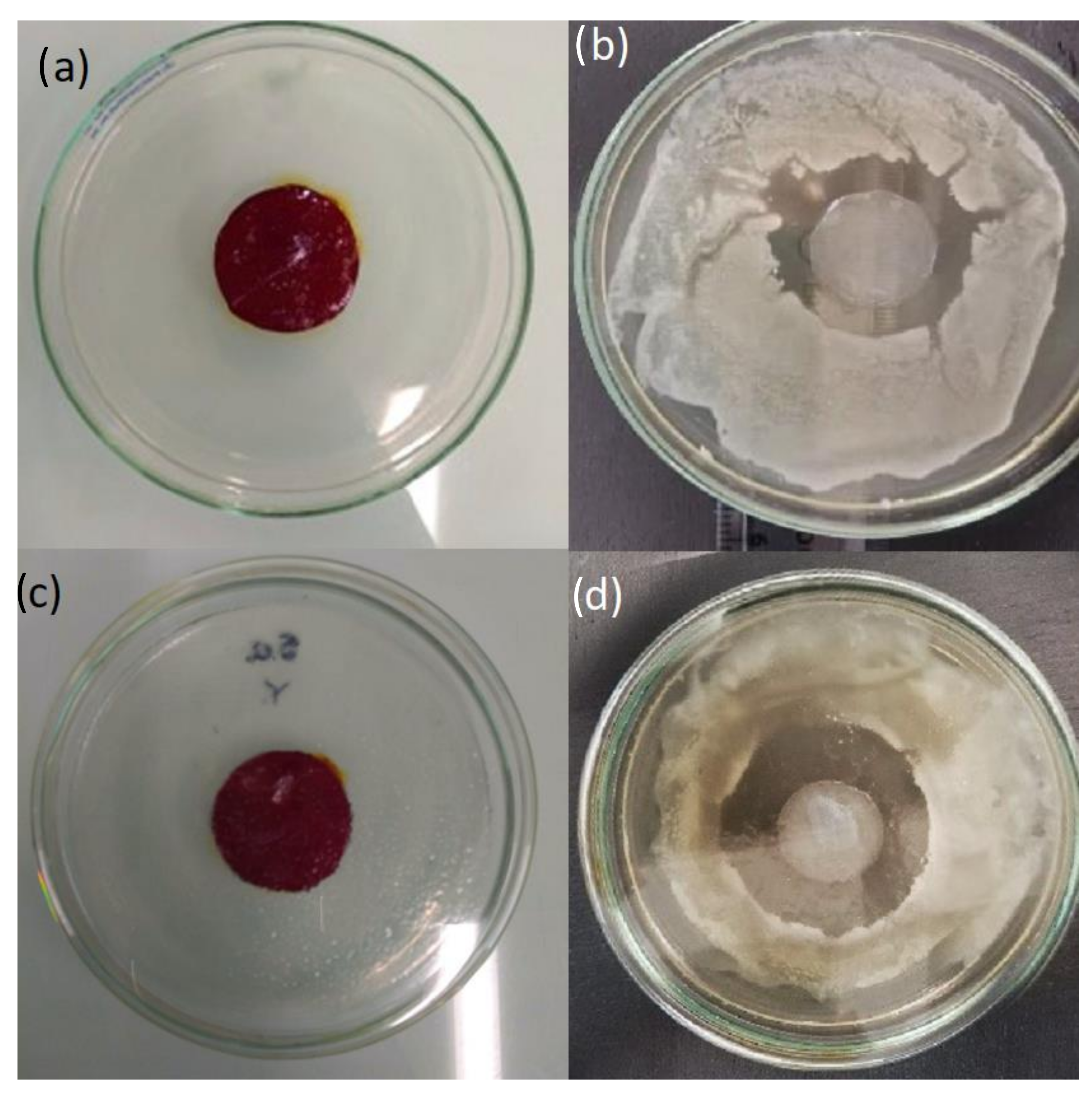

- Antimicrobial activityA modification of the disk-diffusion method was used to evaluate the antimicrobial activity of PVI against Gram-positive and Gram-negative bacteria. Four BNC/PVI dressings were placed on Petri dishes, where 20 mL of 0.5 McFarland microbial inoculum of Staphylococcus aureus and 20 mL of 0.5 McFarland microbial inoculum of Escherichia Coli were cultivated in 15 mL of nutritive agar and incubated for 24 h at 37 °C in a Moyco Electronics Incubator. Moreover, BNC dressings without any formulation were taken as blanks, with the aim of comparing the antibacterial effects of BNC/PVI dressings. The presence of inhibition halos at 24 h was measured and considered as an indication of antimicrobial activity against S. aureus and E. coli. Inhibition areas, subtraction of BNC/PVI diameter, average, and standard deviation calculations were performed using ImageJ software [38].

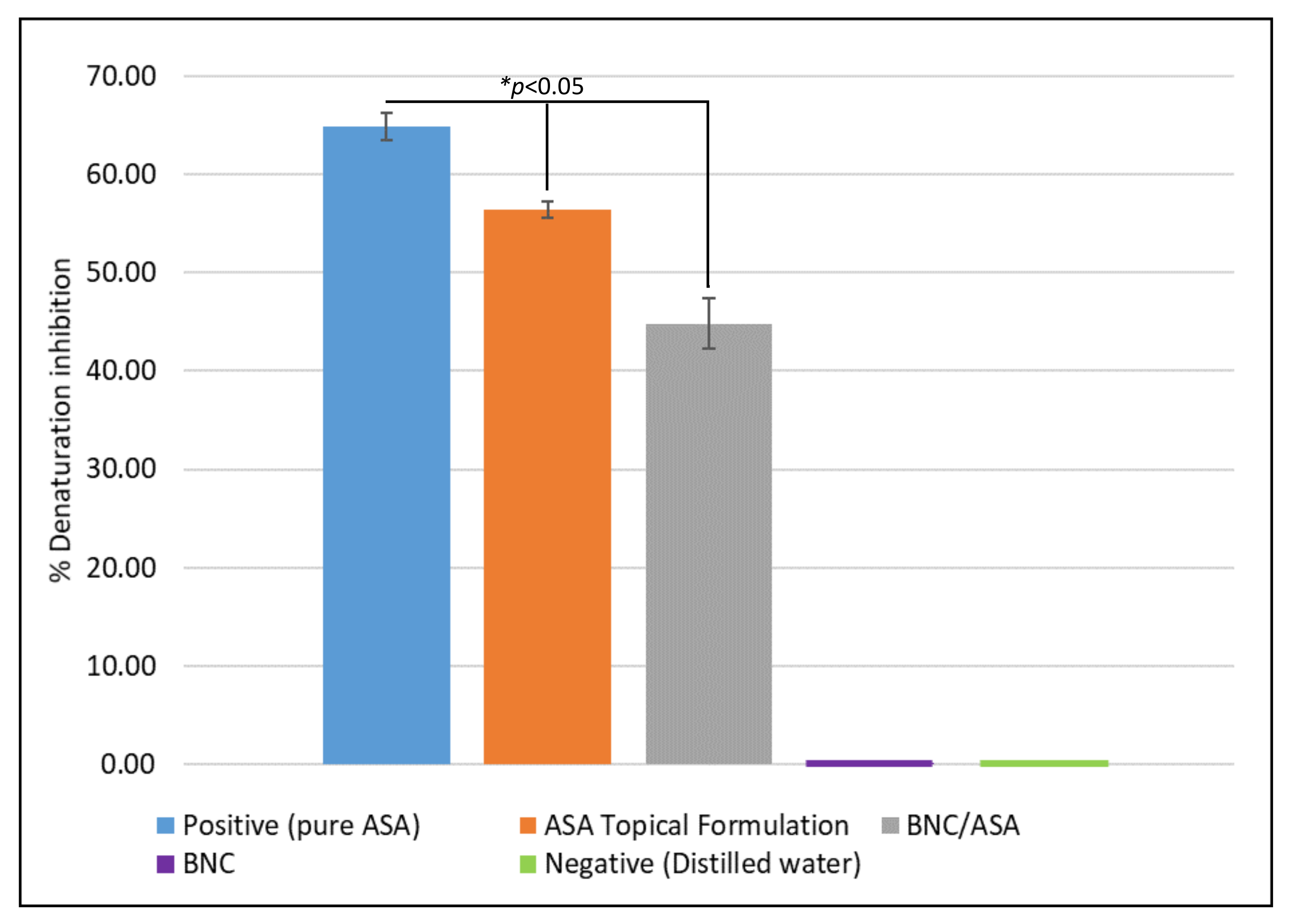

- Anti-inflammatory activityThe anti-inflammatory activity of BNC/ASA dressings was assessed due to the anti-inflammatory effect reported for ASA. The evaluation was performed through the method proposed by Gunathilake et al. (2018), Bashir et al. (2022), Begam et al. (2022), and Vanlalhruaii et al. (2019). A phosphate buffer solution (pH 6.4) was prepared, and 4.78 mL was mixed with 0.2 mL of the ASA formulation and 0.2 mL of bovine serum albumin (BSA) with a concentration of 50 µg/ml. The solution was placed in a water bath at 37 °C for 15 min, and then it was placed in an oven at 70 °C for 5 min. Then, the solution was cooled down to room temperature and the turbidity was measured using UV–Vis spectroscopy at 660 nm [39,40,41,42]. The denaturalization inhibition percentage is proportional to anti-inflammatory activity and was calculated according to Equation (4):where A is the absorbance of the control sample and A is the sample absorbance.Due to its natural anti-inflammatory activity, the positive control was taken as pure ASA, while the negative control was taken as a distilled water solution. Moreover, an additional sample, different from BNC/ASA, was utilized: BNC. This was used to assess the natural anti-inflammatory effect of BNC and the difference between the ASA topical formulation, the BNC/ASA dressings, BNC, and the positive control.

2.5. Statistical Analysis

3. Results

3.1. Development of Bioactive Wound Dressings

3.2. Wound Dressing Characterization

3.2.1. Scanning Electron Microscopy (SEM)

3.2.2. Mechanical Characterization

3.2.3. Loading and Release Kinetics

3.2.4. Histology

3.2.5. Antibacterial Activity

3.2.6. Anti-Inflammatory Activity

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kirsner, R.S.; Eaglstein, W.H. The wound healing process. Dermatol. Clin. 1993, 11, 629–640. [Google Scholar] [CrossRef]

- Hersh, A.L.; Chambers, H.F.; Maselli, J.H.; Gonzales, R. National trends in ambulatory visits and antibiotic prescribing for skin and soft-tissue infections. Arch. Intern. Med. 2008, 168, 1585–1591. [Google Scholar] [CrossRef] [PubMed]

- Simões, D.; Miguel, S.P.; Ribeiro, M.P.; Coutinho, P.; Mendonça, A.G.; Correia, I.J. Recent advances on antimicrobial wound dressing: A review. Eur. J. Pharm. Biopharm. 2018, 127, 130–141. [Google Scholar] [CrossRef] [PubMed]

- Contardi, M.; Heredia-Guerrero, J.A.; Perotto, G.; Valentini, P.; Pompa, P.P.; Spanò, R.; Goldoni, L.; Bertorelli, R.; Athanassiou, A.; Bayer, I.S. Transparent ciprofloxacin-povidone antibiotic films and nanofiber mats as potential skin and wound care dressings. Eur. J. Pharm. Sci. 2017, 104, 133–144. [Google Scholar] [CrossRef]

- Boateng, J.S.; Matthews, K.H.; Stevens, H.N.; Eccleston, G.M. Wound healing dressings and drug delivery systems: A review. J. Pharm. Sci. 2008, 97, 2892–2923. [Google Scholar] [CrossRef]

- Castro, C.; Zuluaga, R.; Putaux, J.L.; Caro, G.; Mondragon, I.; Gañán, P. Structural characterization of bacterial cellulose produced by Gluconacetobacter swingsii sp. from Colombian agroindustrial wastes. Carbohydr. Polym. 2011, 84, 96–102. [Google Scholar] [CrossRef]

- Moritz, S.; Wiegand, C.; Wesarg, F.; Hessler, N.; Müller, F.A.; Kralisch, D.; Hipler, U.C.; Fischer, D. Active wound dressings based on bacterial nanocellulose as drug delivery system for octenidine. Int. J. Pharm. 2014, 471, 45–55. [Google Scholar] [CrossRef]

- Bielecki, S.; Kalinowska, H.; Krystynowicz, A.; Kubiak, K.; Kołodziejczyk, M.; de Groeve, M. Wound dressings and cosmetic materials from bacterial nanocellulose. In Bacterial NanoCellulose: A Sophisticated Multifunctional Material; CRC Press: Boca Raton, FL, USA, 2016; pp. 157–174. [Google Scholar]

- Almeida, I.F.; Pereira, T.; Silva, N.H.; Gomes, F.P.; Silvestre, A.J.; Freire, C.S.; Sousa Lobo, J.M.; Costa, P.C. Bacterial cellulose membranes as drug delivery systems: An in vivo skin compatibility study. Eur. J. Pharm. Biopharm. 2014, 86, 332–336. [Google Scholar] [CrossRef]

- Warriner, R.; Burrell, R. Infection and the chronic wound: A focus on silver. Adv. Ski. Wound Care 2005, 18, 2–12. [Google Scholar] [CrossRef]

- Wright, J.B.; Lam, K.; Buret, A.G.; Olson, M.E.; Burrell, R.E. Early healing events in a porcine model of contaminated wounds: Effects of nanocrystalline silver on matrix metalloproteinases, cell apoptosis, and healing. Wound Repair Regen. 2002, 10, 141–151. [Google Scholar] [CrossRef]

- Berndt, S.; Wesarg, F.; Wiegand, C.; Kralisch, D.; Müller, F.A. Antimicrobial porous hybrids consisting of bacterial nanocellulose and silver nanoparticles. Cellulose 2013, 20, 771–783. [Google Scholar] [CrossRef]

- Hidalgo, E.; Bartolomé, R.; Barroso, C.; Moreno, A.; Domínguez, C. Silver nitrate: Antimicrobial activity related to cytotoxicity in cultured human fibroblasts. Ski. Pharmacol. Appl. Ski. Physiol. 1998, 11, 140–151. [Google Scholar] [CrossRef] [PubMed]

- Fjeld, H.; Lingaas, E. Polyheksanid-Sikkerhet og effekt som antiseptikum. Tidsskr. Nor. Legeforen. 2016, 8, 136. [Google Scholar] [CrossRef] [PubMed]

- Wiegand, C.; Moritz, S.; Hessler, N.; Kralisch, D.; Wesarg, F.; Müller, F.A.; Fischer, D.; Hipler, U.C. Antimicrobial functionalization of bacterial nanocellulose by loading with polihexanide and povidone-iodine. J. Mater. Sci. Mater. Med. 2015, 26, 245. [Google Scholar] [CrossRef]

- Jipa, I.M.; Stoica, A.; Stroescu, M.; Dobre, L.M.; Dobre, T.; Jinga, S.; Tardei, C. Potassium sorbate release from poly(vinyl alcohol)-bacterial cellulose films. Chem. Pap. 2012, 66, 138–143. [Google Scholar] [CrossRef]

- Trovatti, E.; Silva, N.H.; Duarte, I.F.; Rosado, C.F.; Almeida, I.F.; Costa, P.; Freire, C.S.; Silvestre, A.J.; Neto, C.P. Biocellulose membranes as supports for dermal release of lidocaine. Biomacromolecules 2011, 12, 4162–4168. [Google Scholar] [CrossRef]

- Shao, W.; Liu, H.; Wang, S.; Wu, J.; Huang, M.; Min, H.; Liu, X. Controlled release and antibacterial activity of tetracycline hydrochloride-loaded bacterial cellulose composite membranes. Carbohydr. Polym. 2016, 145, 114–120. [Google Scholar] [CrossRef]

- Khalid, A.; Khan, R.; Ul-Islam, M.; Khan, T.; Wahid, F. Bacterial cellulose-zinc oxide nanocomposites as a novel dressing system for burn wounds. Carbohydr. Polym. 2017, 164, 214–221. [Google Scholar] [CrossRef]

- Nesvadbova, M.; Crosera, M.; Maina, G.; Larese Filon, F. Povidone iodine skin absorption: An ex-vivo study. Toxicol. Lett. 2015, 235, 155–160. [Google Scholar] [CrossRef]

- Dydak, K.; Junka, A.; Dydak, A.; Brożyna, M.; Paleczny, J.; Fijalkowski, K.; Kubielas, G.; Aniołek, O.; Bartoszewicz, M. In vitro efficacy of bacterial cellulose dressings chemisorbed with antiseptics against biofilm formed by pathogens isolated from chronic wounds. Int. J. Mol. Sci. 2021, 22, 3996. [Google Scholar] [CrossRef]

- Preston, S.; Arnold, M.; Beller, E.; Brooks, P.; Buchanan, W. Comparative analgesic and anti-inflammatory properties of sodium salicylate and acetylsalicylic acid (aspirin) in rheumatoid arthritis. Br. J. Clin. Pharmacol. 1989, 27, 607–611. [Google Scholar] [CrossRef]

- Nugent, R.A.; Hall, C.M. Analgesics, Antipyretics, and Antiinflammatory Agents. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2000. [Google Scholar] [CrossRef]

- Darby, I.A.; Weller, C.D. Aspirin treatment for chronic wounds: Potential beneficial and inhibitory effects. Wound Repair Regen. 2017, 25, 7–12. [Google Scholar] [CrossRef]

- Scientific Committee on Emerging and Newly Identified Health Risks. Assessment of the Antibiotic Resistance Effects of Biocides Antibiotic Resistance Effects of Biocides 2 about the Scientific Committees; 2009. Available online: https://ec.europa.eu/health/ph_risk/committees/04_scenihr/docs/scenihr_q_012.pdf (accessed on 2 March 2022).

- Summa, M.; Russo, D.; Penna, I.; Margaroli, N.; Bayer, I.S.; Bandiera, T.; Athanassiou, A.; Bertorelli, R. A biocompatible sodium alginate/povidone iodine film enhances wound healing. Eur. J. Pharm. Biopharm. 2018, 122, 17–24. [Google Scholar] [CrossRef]

- Osorio, M.; Ortiz, I.; Gañán, P.; Naranjo, T.; Zuluaga, R.; van Kooten, T.G.; Castro, C. Novel surface modification of three-dimensional bacterial nanocellulose with cell-derived adhesion proteins for soft tissue engineering. Mater. Sci. Eng. C 2019, 100, 697–705. [Google Scholar] [CrossRef]

- Bigliardi, P.L.; Alsagoff, S.A.L.; El-Kafrawi, H.Y.; Pyon, J.K.; Wa, C.T.C.; Villa, M.A. Povidone iodine in wound healing: A review of current concepts and practices. Int. J. Surg. 2017, 44, 260–268. [Google Scholar] [CrossRef]

- Konishi, R.; Kawada, M.; Mizobuchi, N.; Seto, S.; Hatase, O.; Tokuda, M. Method for Treating a Skin Injury Comprising Topically Applying Acetylsalicylic Acid. U.S. Patent No. 5,916,918, 29 June 1999. [Google Scholar]

- Boghosian, M.P.; Koda, R.T. Medical Use of Esters of Acetylsalcylic Acid to Treat Acne. U.S. Patent No. 4,244,948, 13 January 1981. [Google Scholar]

- Sulistyarti, H.; Atikah, A.; Fardiyah, Q.; Febriyanti, S.; Asdauna, A. A Simple and Safe Spectrophotometric Method for Iodide Determination. Makara J. Sci. 2015, 19, 43–48. [Google Scholar] [CrossRef]

- Chambers, J.; Phillips, P.; Whitfield, K. Spectrophotometric Analysis of Aspirin; Technical Report; Purdue University Instrument Van Project: West Lafayette, IN, USA, 2010. [Google Scholar]

- Ngah, W.S.; Ab Ghani, S.; Kamari, A. Adsorption behaviour of Fe(II) and Fe(III) ions in aqueous solution on chitosan and cross-linked chitosan beads. Bioresour. Technol. 2005, 96, 443–450. [Google Scholar] [CrossRef]

- Figueroa, D.; Moreno, A.; Angelina, A. Equilibrio, termodinámica y modelos cinéticos en la adsorción de Rojo 40 sobre tuza de maíz. Rev. Ing. Univ. Medellín 2015, 14, 105–120. [Google Scholar] [CrossRef]

- Castro, S.; Cerda, R.; Betanco, N.; Canelo, F.; López, X.; García, A.; Benavente, M. Estudio del equilibrio y cinética de adsorción de Cd(II), Ni(II) y Cr(VI) usando Quitosano y Quitosano modificado con cobre. Nexo Rev. Cient. 2014, 26, 56–68. [Google Scholar] [CrossRef]

- American Association of Textile Chemists and Colorists. AATCC Test Method: Colorfastness to Perspiration and Light; Technical Report; AATCC: Research Triangle Park, NC, USA, 2007. [Google Scholar]

- Schmook, F.; Stutz, A.; Reinhardt, J. Penetration of sandimmune (Cyclosporin A) in rat skin in vitro. Ski. Pharmacol. 1993, 6, 116–124. [Google Scholar] [CrossRef]

- Rueden, C.T.; Schindelin, J.; Hiner, M.C.; DeZonia, B.E.; Walter, A.E.; Arena, E.T.; Eliceiri, K.W. ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinform. 2017, 18. [Google Scholar] [CrossRef] [PubMed]

- Gunathilake, K.; Ranaweera, K.; Rupasinghe, H. In Vitro Anti-Inflammatory Properties of Selected Green Leafy Vegetables. Biomedicines 2018, 6, 107. [Google Scholar] [CrossRef] [PubMed]

- Lawal, B.; Sani, S.; Onikanni, A.S.; Ibrahim, Y.O.; Agboola, A.R.; Lukman, H.Y.; Olawale, F.; Jigam, A.A.; Batiha, G.E.S.; Babalola, S.B.; et al. Preclinical anti-inflammatory and antioxidant effects of Azanza garckeana in STZ-induced glycemic-impaired rats, and pharmacoinformatics of it major phytoconstituents. Biomed. Pharmacother. 2022, 152, 113196. [Google Scholar] [CrossRef]

- Begam, R.; Shajahan, A.; Shefin, B.; Murugan, V. Synthesis of novel naphthalimide tethered 1,2,3-triazoles: In vitro biological evaluation and docking study of anti-inflammatory inhibitors. J. Mol. Struct. 2022, 1254, 132364. [Google Scholar] [CrossRef]

- Malsawmtluangi, C.; Lalhlenmawia, H. Evaluation of in vitro anti-inflammatory activity of the spadix of Colocasia affinis. Sci. Vis. 2019, 19. [Google Scholar] [CrossRef]

- Castro, C.; Zuluaga, R.; Álvarez, C.; Putaux, J.L.; Caro, G.; Rojas, O.J.; Mondragon, I.; Gañán, P. Bacterial cellulose produced by a new acid-resistant strain of Gluconacetobacter genus. Carbohydr. Polym. 2012, 89, 1033–1037. [Google Scholar] [CrossRef] [PubMed]

- Bernardelli de Mattos, I.; Nischwitz, S.P.; Tuca, A.C.; Groeber-Becker, F.; Funk, M.; Birngruber, T.; Mautner, S.I.; Kamolz, L.P.; Holzer, J.C. Delivery of antiseptic solutions by a bacterial cellulose wound dressing: Uptake, release and antibacterial efficacy of octenidine and povidone-iodine. Burns 2020, 46, 918–927. [Google Scholar] [CrossRef]

- Chiller, K.; Selkin, B.A.; Murakawa, G.J. Skin Microflora and Bacterial Infections of the Skin. J. Investig. Dermatol. Symp. Proc. 2001, 6, 170–174. [Google Scholar] [CrossRef]

- Hummudi, I.M. Evaluation effects of povidone iodine on some mechanical properties of soft liner materials. IOSR J. Dent. Med Sci. 2017, 16, 35–46. [Google Scholar] [CrossRef]

- Chomcharn, N.; Xanthos, M. Properties of aspirin modified enteric polymer prepared by hot-melt mixing. Int. J. Pharm. 2013, 450, 259–267. [Google Scholar] [CrossRef]

- Williams, A.C.; Barry, B.W. Penetration enhancers. Adv. Drug Deliv. Rev. 2012, 64, 128–137. [Google Scholar] [CrossRef]

- Ní Annaidh, A.; Cassidy, M.; Curtis, M.; Destrade, M.; Gilchrist, M.D. A combined experimental and numerical study of stab-penetration forces. Forensic Sci. Int. 2013, 233, 7–13. [Google Scholar] [CrossRef]

- Abd, E.; Yousef, S.A.; Pastore, M.N.; Telaprolu, K.; Mohammed, Y.H.; Namjoshi, S.; Grice, J.E.; Roberts, M.S. Skin models for the testing of transdermal drugs. Clin. Pharmacol. Adv. Appl. 2016, 8, 163. [Google Scholar] [CrossRef]

- Pereira, G.R.; Luís, A.; Ruela, M.; Gravinez Perissinato, A.; Esselin De Sousa Lino, M.; Mudrik, P.S.; Pereira, G.R. Evaluation of skin absorption of drugs from topical and transdermal formulations. Artic. Braz. J. Pharm. Sci. 2016, 52. [Google Scholar] [CrossRef]

- Kalia, Y.N.; Guy, R.H. Modeling transdermal drug release. Adv. Drug Deliv. Rev. 2001, 48, 159–172. [Google Scholar] [CrossRef]

- Moser, K.; Kriwet, K.; Naik, A.; Kalia, Y.N.; Guy, R.H. Passive skin penetration enhancement and its quantification in vitro. Eur. J. Pharm. Biopharm. 2001, 52, 103–112. [Google Scholar] [CrossRef]

- Farahmand, S.; Maibach, H.I. Transdermal drug pharmacokinetics in man: Interindividual variability and partial prediction. Int. J. Pharm. 2009, 367, 1–15. [Google Scholar] [CrossRef]

- Delgado-Charro, M.B.; Guy, R.H. Effective use of transdermal drug delivery in children. Adv. Drug Deliv. Rev. 2014, 73, 63–82. [Google Scholar] [CrossRef]

- Hassan, M.A.; Tamer, T.M.; Valachová, K.; Omer, A.M.; El-Shafeey, M.; Mohy Eldin, M.S.; Šoltés, L. Antioxidant and antibacterial polyelectrolyte wound dressing based on chitosan/hyaluronan/phosphatidylcholine dihydroquercetin. Int. J. Biol. Macromol. 2021, 166, 18–31. [Google Scholar] [CrossRef]

- Mora Igual, F.X. Diferenciando bacterias Gram + y Gram. Sel. Avíc. 2012, 54, 25–29. [Google Scholar]

- Kumar, J.K.; Babu, K.P.; Kumar Reddy, H.; Gunashakaran, V.; Ramesh, Y.; Narasimha, P.; Venkatewarulu, A.; Reddy, P.L. Application of Broad Spectrum Antiseptic Povidone Iodine as Powerful Action: A Review. J. Pharm. Sci. Technol. 2009, 1, 48–58. [Google Scholar]

- Diomedi Pacheco, A.; Chacón, E.; Delpiano, L.; Hervé, B.; Jemenao, M.I.; Medel, M.; Quintanilla, M.; Riedel, G.; Tinoco, J.; Cifuentes, M. Antiseptics and disinfectants: Aiming at rational use. recommendations of the advisory committee on healthcare associated infections. Sociedad Chilena de infectología. Rev. Chil. Infectol. 2017, 34, 156–174. [Google Scholar] [CrossRef]

- Guarín-Corredor, C.; Quiroga-Santamaría, P.; Landínez-Parra, N.S. Wound healing process of skin, endogenous fields related and chronic wounds. Rev. Fac. Med. 2013, 61, 441–448. [Google Scholar]

- Bareggi, S.R.; Pirola, R.; De Benedittis, G. Skin and plasma levels of acetylsalicylic acid: A comparison between topical aspirin/diethyl ether mixture and oral aspirin in acute herpes zoster and postherpetic neuralgia. Eur. J. Clin. Pharmacol. 1998, 54, 231–235. [Google Scholar] [CrossRef]

- Zagórska-Dziok, M.; Ziemlewska, A.; Bujak, T.; Nizioł-łukaszewska, Z.; Hordyjewicz-Baran, Z. Cosmetic and Dermatological Properties of Selected Ayurvedic Plant Extracts. Molecules 2021, 26, 614. [Google Scholar] [CrossRef]

- Sarveswaran, R.; Jayasuriya, W.J.A.B.; Suresh, T.S. In vitro assays to investigate the anti-inflammatory activity of herbal extracts: A review. World J. Pharm. Res. 2017, 6, 131. [Google Scholar] [CrossRef]

- Mizushima, Y.; Kobayashi, M. Interaction of anti-inflammatory drugs with serum proteins, especially with some biologically active proteins. J. Pharm. Pharmacol. 1968, 20, 169–173. [Google Scholar] [CrossRef]

- Yesmin, S.; Paul, A.; Naz, T.; Rahman, A.B.M.A.; Akhter, S.F.; Wahed, M.I.I.; Emran, T.B.; Siddiqui, S.A. Membrane stabilization as a mechanism of the anti-inflammatory activity of ethanolic root extract of Choi (Piper chaba). Clin. Phytosci. 2020, 6, 1–10. [Google Scholar] [CrossRef]

- Truong, D.H.; Nguyen, D.H.; Ta, N.T.A.; Bui, A.V.; Do, T.H.; Nguyen, H.C. Evaluation of the use of different solvents for phytochemical constituents, antioxidants, and in vitro anti-inflammatory activities of severinia buxifolia. J. Food Qual. 2019, 2019. [Google Scholar] [CrossRef]

| Dressing | Young’s Modulus (MPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|

| BNC | 28.73 ± 6.79 * | 1.94 ± 0.41 * | 13.63 ± 1.29 * |

| BNC/ASA | 5.94 ± 1.34 * | 0.34 ± 0.09 | 21.50 ± 1.76 * |

| BNC/PVI | 7.00 ± 1.32 * | 0.36 ± 0.09 | 11.00 ± 1.77 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Argel, S.; Castaño, M.; Jimenez, D.E.; Rodríguez, S.; Vallejo, M.J.; Castro, C.I.; Osorio, M.A. Assessment of Bacterial Nanocellulose Loaded with Acetylsalicylic Acid or Povidone-Iodine as Bioactive Dressings for Skin and Soft Tissue Infections. Pharmaceutics 2022, 14, 1661. https://doi.org/10.3390/pharmaceutics14081661

Argel S, Castaño M, Jimenez DE, Rodríguez S, Vallejo MJ, Castro CI, Osorio MA. Assessment of Bacterial Nanocellulose Loaded with Acetylsalicylic Acid or Povidone-Iodine as Bioactive Dressings for Skin and Soft Tissue Infections. Pharmaceutics. 2022; 14(8):1661. https://doi.org/10.3390/pharmaceutics14081661

Chicago/Turabian StyleArgel, Shaydier, Melissa Castaño, Daiver Estiven Jimenez, Sebastian Rodríguez, Maria Jose Vallejo, Cristina Isabel Castro, and Marlon Andres Osorio. 2022. "Assessment of Bacterial Nanocellulose Loaded with Acetylsalicylic Acid or Povidone-Iodine as Bioactive Dressings for Skin and Soft Tissue Infections" Pharmaceutics 14, no. 8: 1661. https://doi.org/10.3390/pharmaceutics14081661