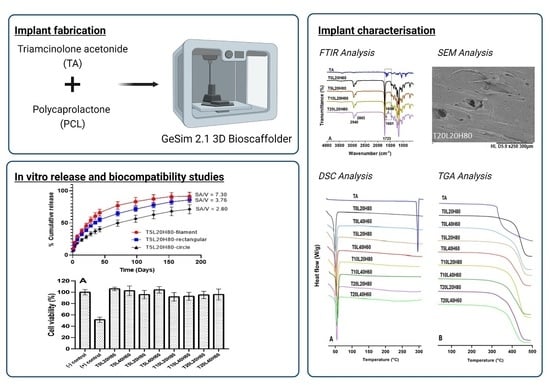

Fabrication and Characterisation of 3D-Printed Triamcinolone Acetonide-Loaded Polycaprolactone-Based Ocular Implants

Abstract

Share and Cite

Annuryanti, F.; Domínguez-Robles, J.; Anjani, Q.K.; Adrianto, M.F.; Larrañeta, E.; Thakur, R.R.S. Fabrication and Characterisation of 3D-Printed Triamcinolone Acetonide-Loaded Polycaprolactone-Based Ocular Implants. Pharmaceutics 2023, 15, 243. https://doi.org/10.3390/pharmaceutics15010243

Annuryanti F, Domínguez-Robles J, Anjani QK, Adrianto MF, Larrañeta E, Thakur RRS. Fabrication and Characterisation of 3D-Printed Triamcinolone Acetonide-Loaded Polycaprolactone-Based Ocular Implants. Pharmaceutics. 2023; 15(1):243. https://doi.org/10.3390/pharmaceutics15010243

Chicago/Turabian StyleAnnuryanti, Febri, Juan Domínguez-Robles, Qonita Kurnia Anjani, Muhammad Faris Adrianto, Eneko Larrañeta, and Raghu Raj Singh Thakur. 2023. "Fabrication and Characterisation of 3D-Printed Triamcinolone Acetonide-Loaded Polycaprolactone-Based Ocular Implants" Pharmaceutics 15, no. 1: 243. https://doi.org/10.3390/pharmaceutics15010243

APA StyleAnnuryanti, F., Domínguez-Robles, J., Anjani, Q. K., Adrianto, M. F., Larrañeta, E., & Thakur, R. R. S. (2023). Fabrication and Characterisation of 3D-Printed Triamcinolone Acetonide-Loaded Polycaprolactone-Based Ocular Implants. Pharmaceutics, 15(1), 243. https://doi.org/10.3390/pharmaceutics15010243