Multi-Wavelength Photoacoustic Temperature Feedback Based Photothermal Therapy Method and System

Abstract

1. Introduction

2. Materials and Methods

2.1. PA Temperature Measurement

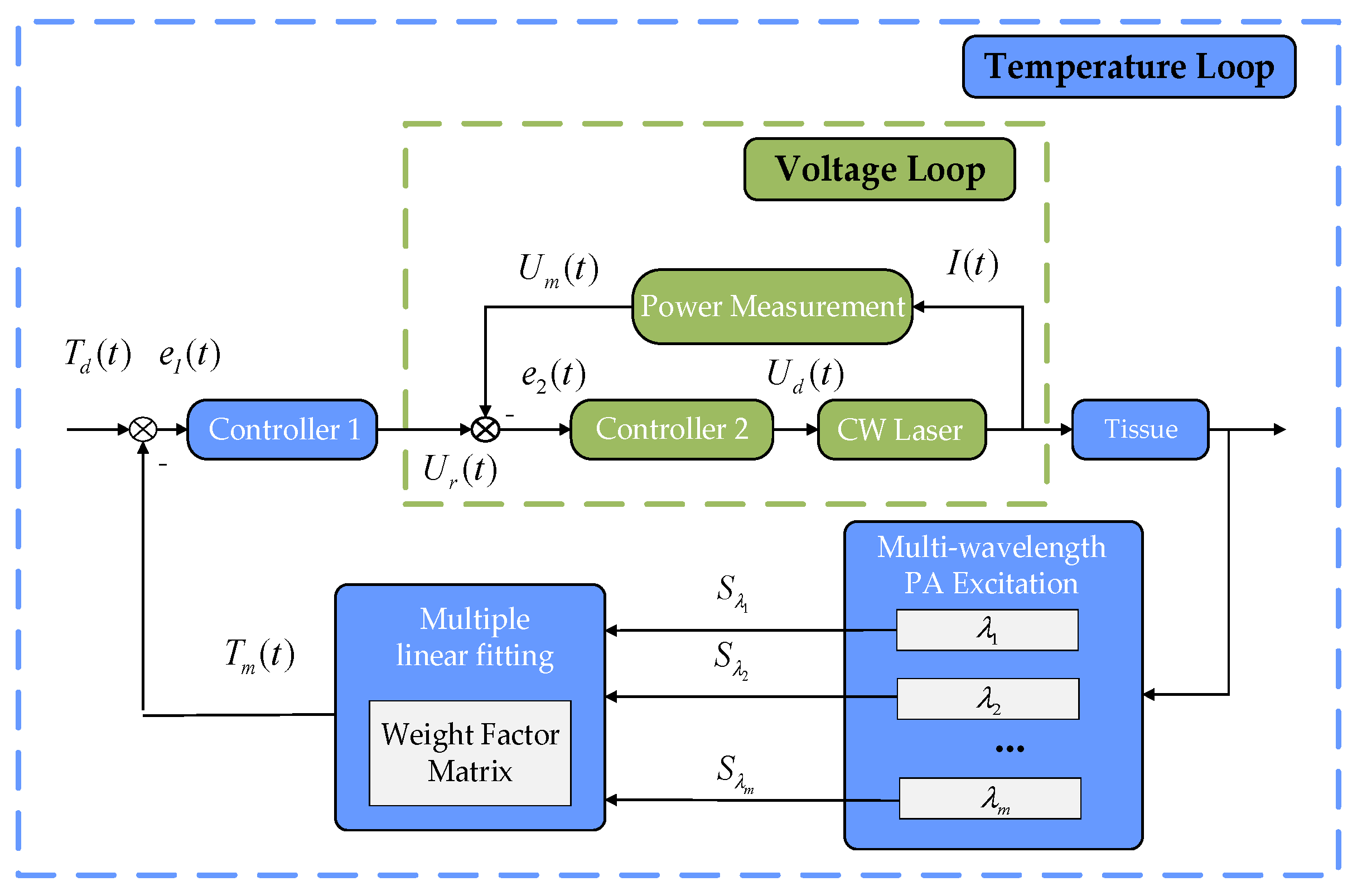

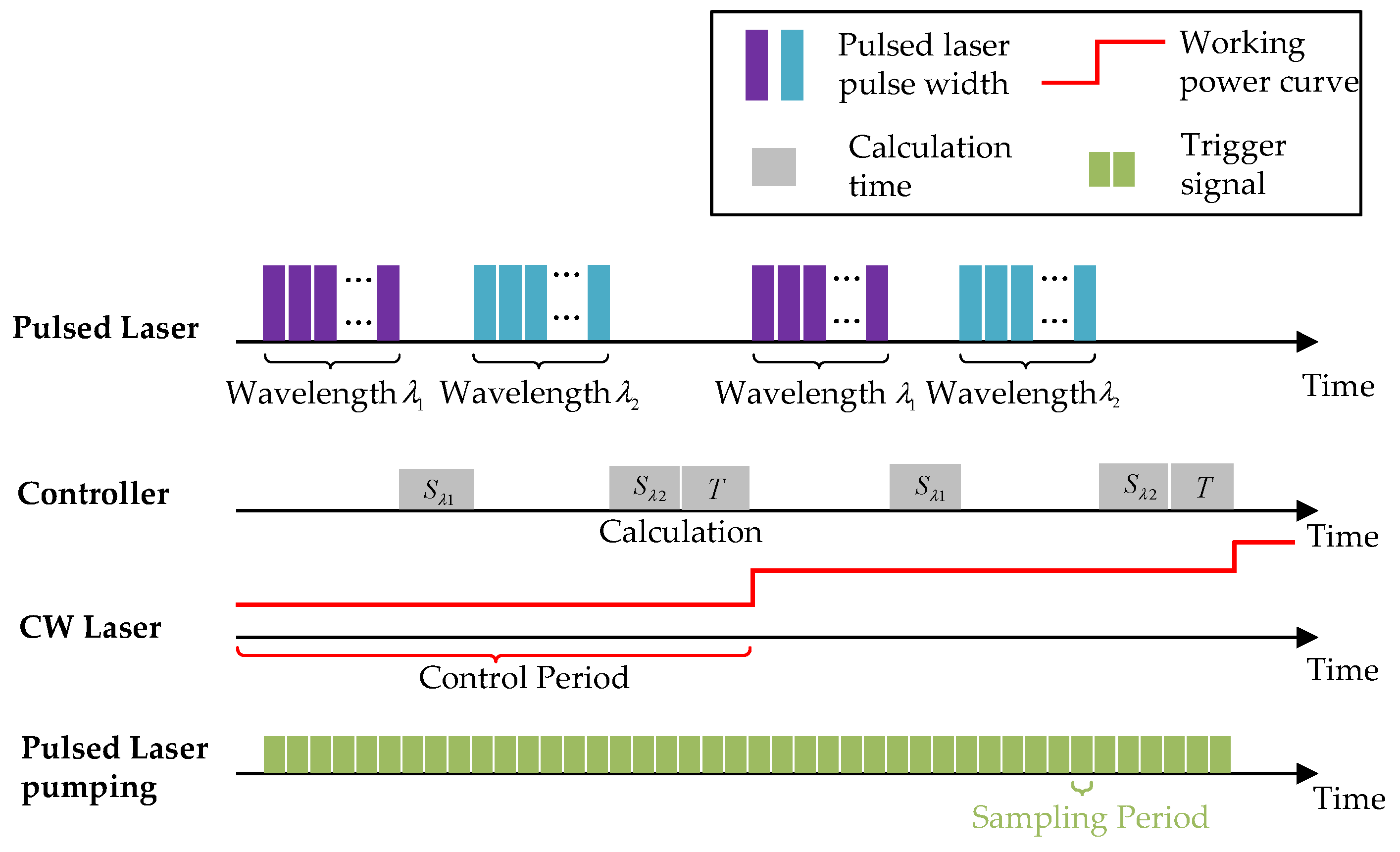

2.2. Multi-Wavelength PA-Excitation-Based Temperature Control

- where is the expected value of the target temperature during the PTT process, and are the error signals of the inner and outer loops, respectively, and are the control variables of the temperature and voltage loop, respectively, is the measured temperature based on the multi-wavelength PA temperature measurement, and is the working voltage of the CW laser measured by the measuring circuit. In a control cycle of the MPA-TCM, the above variables are calculated as shown in Equations (15)–(18). The inner and outer loops use a proportional–derivative and proportional–integral control strategy, respectively, where and are the proportional coefficients of the outer and inner loops, is the integral coefficient, and is the differential coefficient. The introduction of a proportional integral derivative (PID) control strategy can ensure the dynamic and static characteristics of the system. In addition, each wavelength of the laser is sequentially excited in a control cycle; finally, the feedback temperature value is calculated through the weight factor matrix.

3. Material and Methods

3.1. Construction of the MPA-PTT System

3.2. Sample Preparation

3.3. Multi-Wavelength PA Temperature Calibration and Measurement

3.4. Closed-Loop Photothermal Therapy

3.5. Anti-Interference Ability Test

4. Results

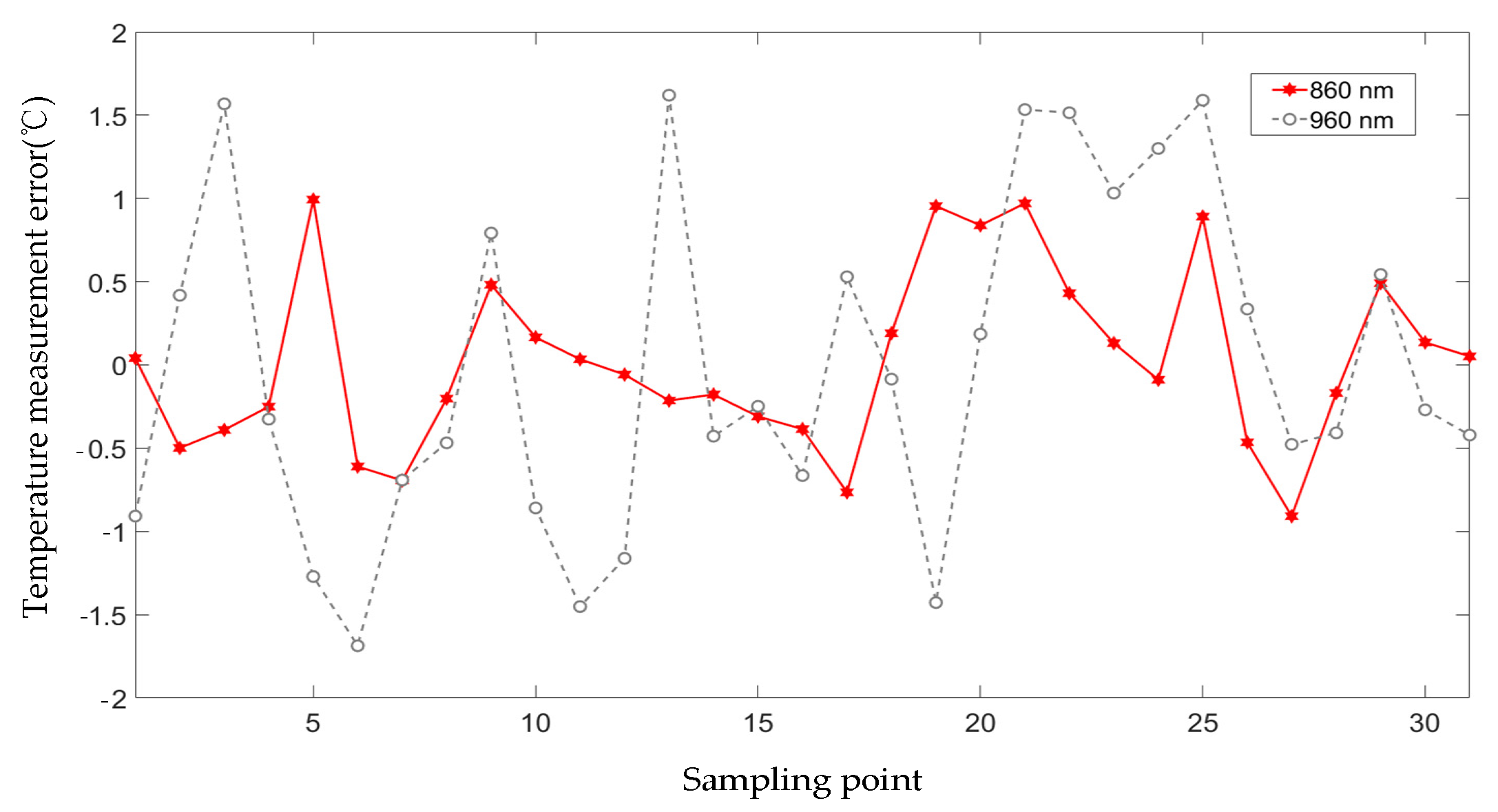

4.1. Multi-Wavelength PA Temperature Calibration and Measurement

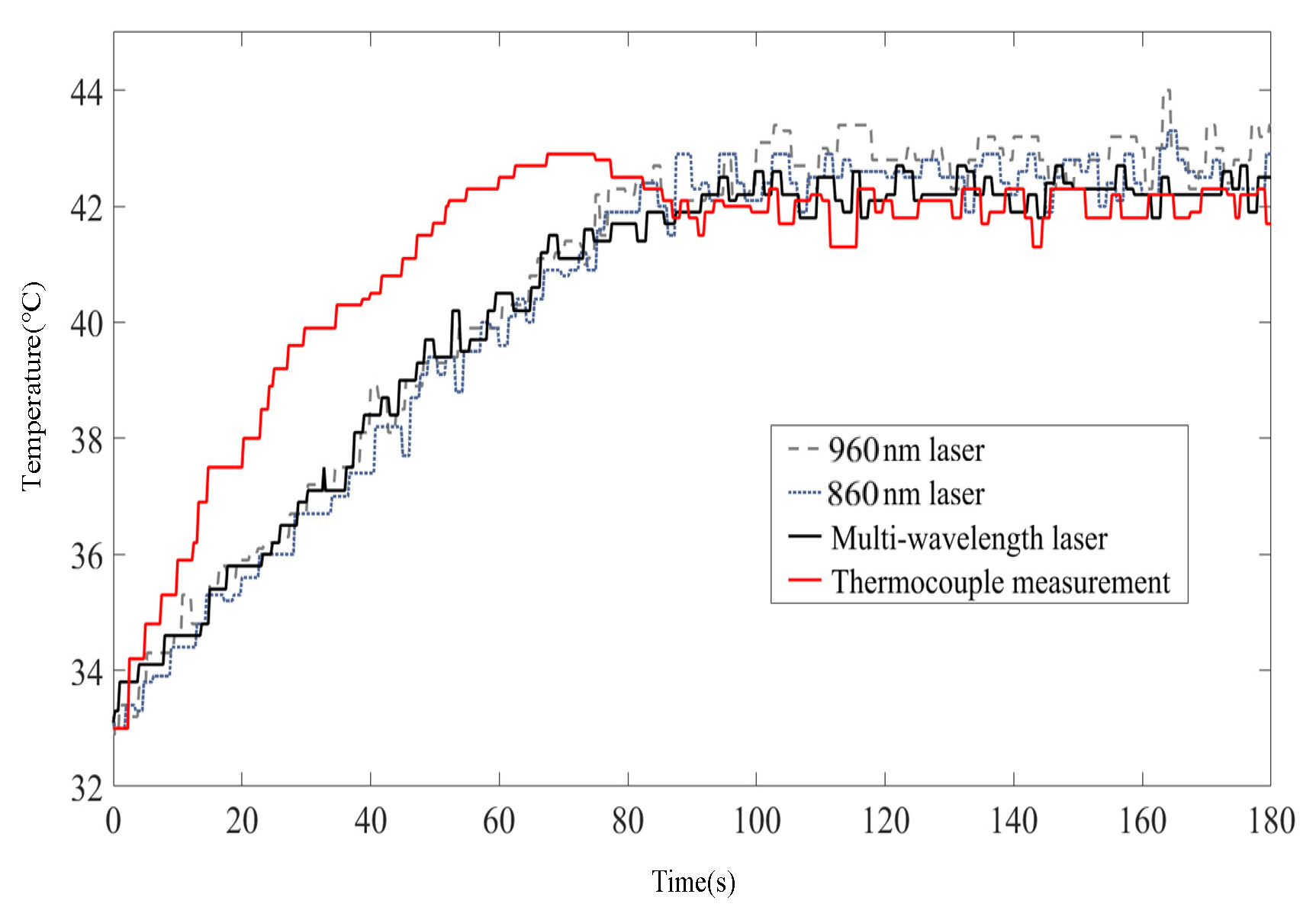

4.2. Closed-Loop Photothermal Therapy

4.3. Anti-Interference Ability Test

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, X.; El-Sayed, I.H.; Qian, W.; El-Sayed, M.A. Cancer cell imaging and photothermal therapy in the near-infrared region by using gold nanorods. J. Am. Chem. Soc. 2006, 128, 2115–2120. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.T.; Tabakman, S.M.; Liang, Y.; Wang, H.; Sanchez Casalongue, H.; Vinh, D.; Dai, H. Ultrasmall reduced graphene oxide with high near-infrared absorbance for photothermal therapy. J. Am. Chem. Soc. 2011, 133, 6825–6831. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Wan, J.; Zhang, S.; Tian, B.; Zhang, Y.; Liu, Z. The influence of surface chemistry and size of nanoscale graphene oxide on photothermal therapy of cancer using ultra-low laser power. Biomaterials 2012, 33, 2206–2214. [Google Scholar] [CrossRef] [PubMed]

- Yuan, H.; Fales, A.M.; Vo-Dinh, T. TAT peptide-functionalized gold nanostars: Enhanced intracellular delivery and efficient NIR photothermal therapy using ultralow irradiance. J. Am. Chem. Soc. 2012, 134, 11358–11361. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, H.; Wang, Z.; Feng, L. Photothermal Conjugated Polymers and Their Biological Applications in Imaging and Therapy. ACS. Appl. Mater. 2020, 2, 4222–4240. [Google Scholar] [CrossRef]

- Zhi, D.; Yang, T.; O’hagan, J.; Zhang, S.; Donnelly, R.F. Photothermal therapy. J. Control. Release 2020, 325, 52–71. [Google Scholar] [CrossRef]

- Sutrisno, L.; Chen, H.; Yoshitomi, T.; Kawazoe, N.; Yang, Y.; Chen, G. PLGA-collagen-BPNS Bifunctional composite mesh for photothermal therapy of melanoma and skin tissue engineering. J. Mater. Chem. B. 2022, 10, 204–213. [Google Scholar] [CrossRef]

- Li, X.; Xing, L.; Zheng, K.; Wei, P.; Du, L.; Shen, M.; Shi, X. Formation of Gold Nanostar-Coated Hollow Mesoporous Silica for Tumor Multimodality Imaging and Photothermal Therapy. ACS. Appl. Mater. Interfaces 2017, 9, 5817–5827. [Google Scholar] [CrossRef]

- Zheng, R.; Wang, S.; Tian, Y.; Jiang, X.; Fu, D.; Shen, S.; Yang, W. Polydopamine-Coated Magnetic Composite Particles with Enhanced Photothermal Effect. Appl. Mater. Interfaces 2015, 7, 15876–15884. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, J.; Yang, L.; Pan, W. Optical Properties of Gold Nanorods and its Application in Cancer Diagnosis and Photothermal Therapy. Appl. Las. 2009, 29, 260–264. [Google Scholar]

- Huang, L.; Li, Y.; Du, Y.; Zhang, Y.; Wang, X.; Ding, Y.; Yang, X.; Meng, F.; Tu, J.; Luo, L.; et al. Mild photothermal therapy potentiates anti-PD-L1 treatment for immunologically cold tumors via an all-in-one and all-in-control strategy. Nat. Commun. 2019, 10, 4871. [Google Scholar] [CrossRef] [PubMed]

- Papillion, P.; Wong, L.; Waldrop, J.; Sargent, L.; Brzezienski, M.; Kennedy, W.; Rehm, J. Infrared surface temperature monitoring in the postoperative management of free tissue transfers. Can. J. Plast. Surg. 2009, 17, 97–101. [Google Scholar] [CrossRef] [PubMed]

- Cui, S.; Xing, J. Research on Calibration Method of Infrared Temperature Measurement System near Room Temperature Field. Front. Phys. 2022, 9, 786443. [Google Scholar] [CrossRef]

- Su, R.J.; Wang, Y.B.; Yu, L.H.; Tang, H.; Du, Z.Z.; Zhang, Q.W. A Ferromagnetic Resonance Temperature Measurement Method Based on Sweep Frequency Technique. J. Nanoelectron. Optoelectron. 2021, 16, 1537–1543. [Google Scholar] [CrossRef]

- Karaszewski, B.; Wardlaw, J.M.; Marshall, I.; Cvoro, V.; Wartolowska, K.; Haga, K.; Armitage, P.A.; Bastin, M.E.; Dennis, M.S. Measurement of brain temperature with magnetic resonance spectroscopy in acute ischemic stroke. Ann. Neurol. 2010, 60, 438–446. [Google Scholar] [CrossRef]

- Morris, P.; Hurrell, A.; Shaw, A.; Zhang, E.; Beard, P. A Fabry-Perot fiber-optic ultrasonic hydrophone for the simultaneous measurement of temperature and acoustic pressure. J. Acoust. Soc. Am. 2009, 125, 3611–3622. [Google Scholar] [CrossRef]

- Miura, E.; Kato, K.; Takeuchi, A. Basic Study of 3-D Non-Invasive Measurement of Temperature Distribution Using Ultrasound Images during FUS Heating. Ther. Med. 2018, 34, 1–13. [Google Scholar] [CrossRef]

- Ren, X.Y. Temperature Correlation of Backscattered Ultrasound Time-shifts and Noninvasive Temperature Measurement in Tissue. Chin. J. Biomed. Eng. 2006, 25, 328–332. [Google Scholar]

- Costa, M.M.; Shah, A.; Rivens, I.; Box, C.; O’Shea, T.; Papaevangelou, E.; Bamber, J.; Ter Haar, G. Quantitative Photoacoustic Imaging. Photoacoustics 2019, 13, 53–65. [Google Scholar]

- Mallidi, S.; Kim, S.; Karpiouk, A.; Joshi, P.P.; Sokolov, K.; Emelianov, S. Visualization of molecular composition and functionality of cancer cells using nanoparticle-augmented ultrasound-guided photoacoustics. Photoacoustics 2015, 3, 26–34. [Google Scholar] [CrossRef]

- Mitsuhashi, K.; Wang, K.; Anastasio, M.A. Investigation of the far-field approximation for modeling a transducer’s spatial impulse response in photoacoustic computed tomography. Photoacoustics 2014, 2, 21–32. [Google Scholar] [CrossRef] [PubMed]

- Gulik, G.; Wijers, J.G.; Keurentjes, J. Measurement of 2D-temperature distributions in a pervaporation membrane module using ultrasonic computer tomography and comparison with computational fluid dynamics calculations. J. Mater. Chem. 2002, 204, 111–124. [Google Scholar]

- Meng, L.; Deschaume, O.; Larbanoix, L.; Fron, E.; Bartic, C.; Laurent, S.; Van der Auweraer, M.; Glorieux, C. Photoacoustic temperature imaging based on multi-wavelength excitation. Photoacoustics 2019, 13, 33–45. [Google Scholar] [CrossRef] [PubMed]

- Xiaohua, F.; Fei, G.; Yuanjin, Z. Photoacoustic-Based-Close-Loop Temperature Control for Nanoparticle Hyperthermia. IEEE. Trans. Biomed. Eng. 2015, 62, 1728. [Google Scholar] [CrossRef] [PubMed]

- Yu, L.; Xiao-Hua, J.; Yao-Yao, C.; Qi, Z. Photoacoustic temperature measurement based on dual-wavelength method. Acta. Phys. Sin. 2017, 66, 117802. [Google Scholar]

- Kim, J.; Choi, W.; Park, E.Y.; Kang, Y.; Lee, K.J.; Kim, H.H.; Kim, W.J.; Kim, C. Real-time Photoacoustic Thermometry Combined with Clinical Ultrasound Imaging and High Intensity Focused Ultrasound. IEEE. Trans. Biomed. Eng. 2019, 66, 3330–3338. [Google Scholar] [CrossRef]

- Ang, K.H.; Chong, G.; Yun, L. PID Control System Analysis, Design, and Technology. IEEE. Trans. Control. Syst. Technol. 2005, 13, 559–576. [Google Scholar]

- Ziegler, J.G.; Nichols, N.B. Optimum Settings for Automatic Controllers. Trans. Am. Soc. Mech. Eng. 1993, 64, 759–768. [Google Scholar] [CrossRef]

| Wavelength | Equation | RMSE | |

|---|---|---|---|

| 860-nm () | 0.89 | 0.78 | |

| 960-nm () | 0.86 | 0.92 |

| Equation | RMSE | |

|---|---|---|

| 0.96 | 0.56 |

| Temperature Loop Proportional Coefficient | Temperature Loop Differential Coefficient | Voltage Loop Proportional Coefficient | Voltage Loop Integral Coefficient |

|---|---|---|---|

| 3 | 1.2 | 0.89 | 0.78 |

| Equation Excitation Wavelength | RMSE |

|---|---|

| 860-nm | 0.96 |

| 960-nm | 1.14 |

| Multi-wavelength (860- and 960-nm) | 0.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Liu, Y.; Lei, Z.; Qin, Z.; Shen, Y.; Sun, M. Multi-Wavelength Photoacoustic Temperature Feedback Based Photothermal Therapy Method and System. Pharmaceutics 2023, 15, 555. https://doi.org/10.3390/pharmaceutics15020555

Ma Y, Liu Y, Lei Z, Qin Z, Shen Y, Sun M. Multi-Wavelength Photoacoustic Temperature Feedback Based Photothermal Therapy Method and System. Pharmaceutics. 2023; 15(2):555. https://doi.org/10.3390/pharmaceutics15020555

Chicago/Turabian StyleMa, Yiming, Yang Liu, Zhigang Lei, Zezheng Qin, Yi Shen, and Mingjian Sun. 2023. "Multi-Wavelength Photoacoustic Temperature Feedback Based Photothermal Therapy Method and System" Pharmaceutics 15, no. 2: 555. https://doi.org/10.3390/pharmaceutics15020555

APA StyleMa, Y., Liu, Y., Lei, Z., Qin, Z., Shen, Y., & Sun, M. (2023). Multi-Wavelength Photoacoustic Temperature Feedback Based Photothermal Therapy Method and System. Pharmaceutics, 15(2), 555. https://doi.org/10.3390/pharmaceutics15020555