Nanofiber Scaffolds as Drug Delivery Systems Promoting Wound Healing

Abstract

:1. Introduction

2. Nanofiber Scaffold Technology

2.1. Methods for Preparation of Nanofibrous Scaffolds

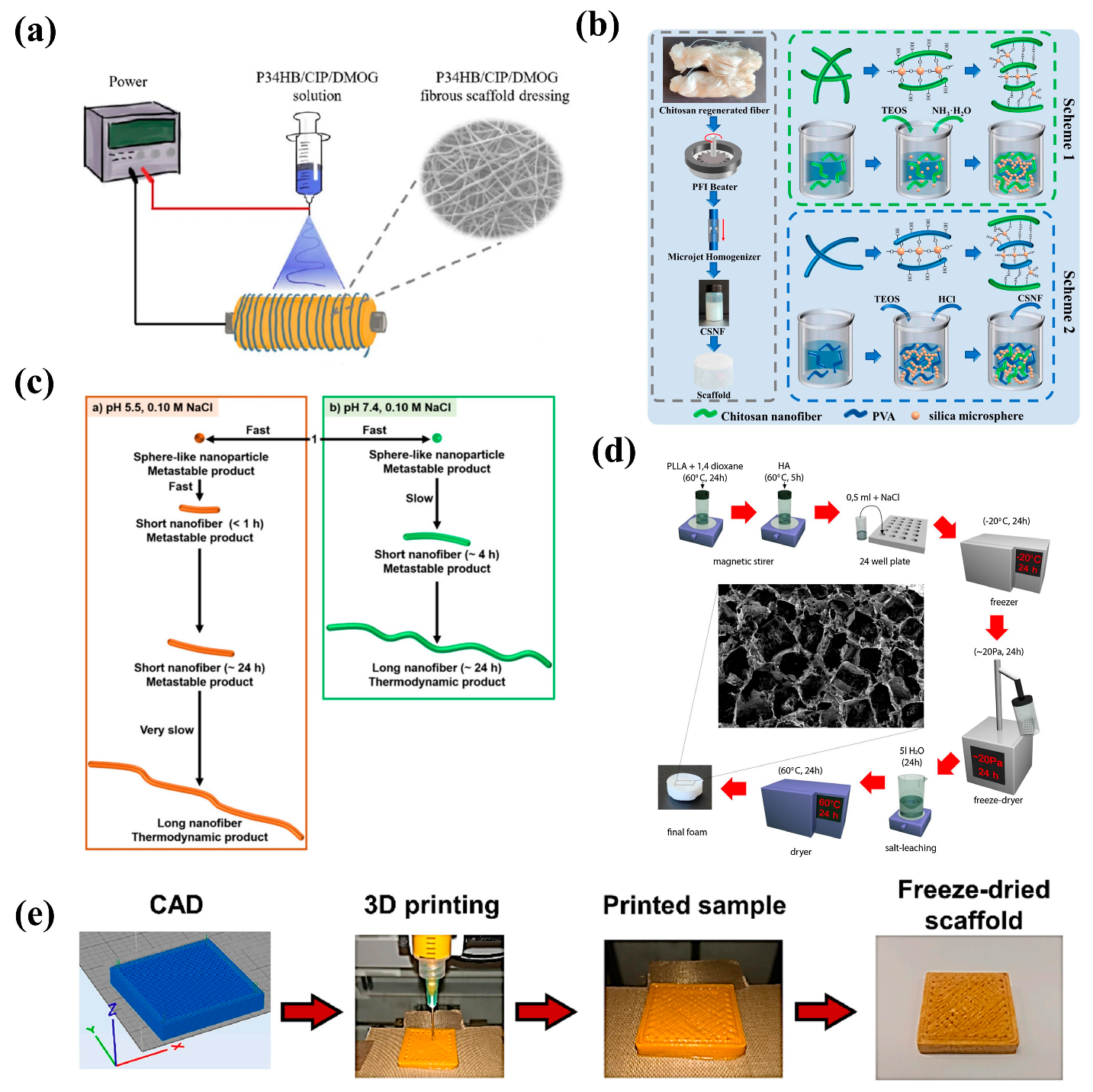

2.1.1. Electrospinning

2.1.2. Sol–Gel Method

2.1.3. Molecular Self-Assembly Technology

2.1.4. Thermally Induced Phase Separation (TIPS)

2.1.5. 3D Printing Technology

2.2. Polymers Used to Make Nanofibers

2.2.1. Natural Polymers

- (a)

- Chitosan

- (b)

- Starch

- (c)

- Alginate

- (d)

- Hyaluronic acid

- (e)

- Cellulose

- (f)

- Collagen

- (g)

- Silk fibroin (SF)

- (h)

- Fibroinogen

2.2.2. Synthetic Polymers

- (a)

- Polylactic acid (PLA)

- (b)

- Polyglycolic acid (PGA)

- (c)

- Polycaprolactone (PCL)

- (d)

- Poly(lactic-co-glycolic) acid (PLGA)

2.2.3. Multipolymer Blends

2.3. Drug Loading Method of Nanofiber Scaffold

2.3.1. Physical Adsorption Method

2.3.2. Chemical Conjugation Method

2.3.3. Coating Method

2.3.4. Coblending Electrospinning Method

3. Application of Nanofibrous Scaffolds in Wound Healing

3.1. Promotion of Hemostasis

3.2. Reduction in Chronic Inflammation

3.3. Enhancement of Cellular Proliferation, Migration, and Secretion

3.4. Neovascularization Support

3.5. Combating Bacterial Infections

3.6. Inhibition of Scar Formation

4. Multiresponse Intelligent Drug Delivery Systems Based on Nanofibrous Scaffolds

4.1. pH-Responsive Nanofiber Drug Delivery Systems

4.2. Temperature-Responsive Nanofiber Drug Delivery Systems

4.3. Photoresponsive Nanofiber Drug Delivery Systems

4.4. Electroresponsive Nanofiber Drug Delivery Systems

4.5. Magnetic-Responsive Nanofiber Drug Delivery Systems

5. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Son, Y.J.; Tse, J.W.; Zhou, Y.; Mao, W.; Yim, E.K.F.; Yoo, H.S. Biomaterials and controlled release strategy for epithelial wound healing. Biomater. Sci. 2019, 7, 4444–4471. [Google Scholar] [CrossRef]

- Chen, J.; Fan, Y.; Dong, G.; Zhou, H.; Du, R.; Tang, X.; Ying, Y.; Li, J. Designing biomimetic scaffolds for skin tissue engineering. Biomater. Sci. 2023, 11, 3051–3076. [Google Scholar] [CrossRef]

- Golder, H.J.; Papalois, V. Enhanced Recovery after Surgery: History, Key Advancements and Developments in Transplant Surgery. J. Clin. Med. 2021, 10, 1634. [Google Scholar] [CrossRef]

- Dreyfuss, I.; Ramnot, A.; Jean-Pierre, P.H.; Frech, F.; Hernandez, L.; Nouri, K. Review of the current antibiotic guidelines used in dermatologic surgery. Dermatol. Ther. 2022, 35, e15557. [Google Scholar] [CrossRef]

- Sheshala, R.; Anuar, N.K.; Abu Samah, N.H.; Wong, T.W. In Vitro Drug Dissolution/Permeation Testing of Nanocarriers for Skin Application: A Comprehensive Review. AAPS PharmSciTech 2019, 20, 164. [Google Scholar] [CrossRef]

- Peng, W.; Li, D.; Dai, K.; Wang, Y.; Song, P.; Li, H.; Tang, P.; Zhang, Z.; Li, Z.; Zhou, Y.; et al. Recent progress of collagen, chitosan, alginate and other hydrogels in skin repair and wound dressing applications. Int. J. Biol. Macromol. 2022, 208, 400–408. [Google Scholar] [CrossRef]

- Rahmani Del Bakhshayesh, A.; Annabi, N.; Khalilov, R.; Akbarzadeh, A.; Samiei, M.; Alizadeh, E.; Alizadeh-Ghodsi, M.; Davaran, S.; Montaseri, A. Recent advances on biomedical applications of scaffolds in wound healing and dermal tissue engineering. Artif. Cells Nanomed. Biotechnol. 2018, 46, 691–705. [Google Scholar] [CrossRef] [Green Version]

- Rani Raju, N.; Silina, E.; Stupin, V.; Manturova, N.; Chidambaram, S.B.; Achar, R.R. Multifunctional and Smart Wound Dressings—A Review on Recent Research Advancements in Skin Regenerative Medicine. Pharmaceutics 2022, 14, 1574. [Google Scholar] [CrossRef]

- Chappidi, S.; Buddolla, V.; Ankireddy, S.R.; Lakshmi, B.A.; Kim, Y.-J. Recent trends in diabetic wound healing with nanofibrous scaffolds. Eur. J. Pharmacol. 2023, 945, 175617. [Google Scholar] [CrossRef]

- Sharma, A.; Dheer, D.; Singh, I.; Puri, V.; Kumar, P. Phytoconstituent-Loaded Nanofibrous Meshes as Wound Dressings: A Concise Review. Pharmaceutics 2023, 15, 1058. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Jummaat, F.; Yahya, E.B.; Olaiya, N.G.; Adnan, A.S.; Abdat, M.; Nasir, N.A.M.; Halim, A.S.; Kumar, U.S.U.; Bairwan, R.; et al. A Review on Micro- to Nanocellulose Biopolymer Scaffold Forming for Tissue Engineering Applications. Polymers 2020, 12, 2043. [Google Scholar] [CrossRef]

- Chen, S.; Li, R.; Li, X.; Xie, J. Electrospinning: An enabling nanotechnology platform for drug delivery and regenerative medicine. Adv. Drug Deliv. Rev. 2018, 132, 188–213. [Google Scholar] [CrossRef]

- Yang, Y.; Du, Y.; Zhang, J.; Zhang, H.; Guo, B. Structural and Functional Design of Electrospun Nanofibers for Hemostasis and Wound Healing. Adv. Fiber Mater. 2022, 4, 1027–1057. [Google Scholar] [CrossRef]

- Rashad, A.; Suliman, S.; Mustafa, M.; Pedersen, T.Ø.; Campodoni, E.; Sandri, M.; Syverud, K.; Mustafa, K. Inflammatory responses and tissue reactions to wood-Based nanocellulose scaffolds. Mater. Sci. Eng. C 2019, 97, 208–221. [Google Scholar] [CrossRef]

- Yao, T.; Baker, M.B.; Moroni, L. Strategies to Improve Nanofibrous Scaffolds for Vascular Tissue Engineering. Nanomaterials 2020, 10, 887. [Google Scholar] [CrossRef]

- Sethuram, L.; Thomas, J. Therapeutic applications of electrospun nanofibers impregnated with various biological macromolecules for effective wound healing strategy—A review. Biomed. Pharmacother. 2023, 157, 113996. [Google Scholar] [CrossRef]

- El-Sherbeni, S.A.; Negm, W.A. The wound healing effect of botanicals and pure natural substances used in in vivo models. Inflammopharmacology 2023, 31, 755–772. [Google Scholar] [CrossRef]

- Serrano-Aroca, Á.; Cano-Vicent, A.; i Serra, R.S.; El-Tanani, M.; Aljabali, A.; Tambuwala, M.M.; Mishra, Y.K. Scaffolds in the microbial resistant era: Fabrication, materials, properties and tissue engineering applications. Mater. Today Bio 2022, 16, 100412. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Hashemi, S.A.; Kalashgrani, M.Y.; Omidifar, N.; Bahrani, S.; Vijayakameswara Rao, N.; Babapoor, A.; Gholami, A.; Chiang, W.H. Bioactive Graphene Quantum Dots Based Polymer Composite for Biomedical Applications. Polymers 2022, 14, 617. [Google Scholar] [CrossRef]

- Mousavi, S.-M.; Nejad, Z.M.; Hashemi, S.A.; Salari, M.; Gholami, A.; Ramakrishna, S.; Chiang, W.-H.; Lai, C.W. Bioactive Agent-Loaded Electrospun Nanofiber Membranes for Accelerating Healing Process: A Review. Membranes 2021, 11, 702. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Hashemi, S.A.; Bahrani, S.; Yousefi, K.; Behbudi, G.; Babapoor, A.; Omidifar, N.; Lai, C.W.; Gholami, A.; Chiang, W.-H. Recent Advancements in Polythiophene-Based Materials and their Biomedical, Geno Sensor and DNA Detection. Int. J. Mol. Sci. 2021, 22, 6850. [Google Scholar] [CrossRef]

- Farsheed, A.C.; Thomas, A.J.; Pogostin, B.H.; Hartgerink, J.D. 3D Printing of Self-Assembling Nanofibrous Multidomain Peptide Hydrogels. Adv. Mater. 2023, 35, 2210378. [Google Scholar] [CrossRef]

- Li, J.; Chen, J.-N.; Peng, Z.-X.; Chen, N.-B.; Liu, C.-B.; Zhang, P.; Zhang, X.; Chen, G.-Q. Multifunctional Electrospinning Polyhydroxyalkanoate Fibrous Scaffolds with Antibacterial and Angiogenesis Effects for Accelerating Wound Healing. ACS Appl. Mater. Interfaces 2023, 15, 364–377. [Google Scholar] [CrossRef]

- Ma, W.; Zhang, S.; Xie, C.; Wan, X.; Li, X.; Chen, K.; Zhao, G. Preparation of High Mechanical Strength Chitosan Nanofiber/NanoSiO(2)/PVA Composite Scaffolds for Bone Tissue Engineering Using Sol-Gel Method. Polymers 2022, 14, 2083. [Google Scholar] [CrossRef]

- Hisamatsu, Y.; Cheng, F.; Yamamoto, K.; Takase, H.; Umezawa, N.; Higuchi, T. Control of the stepwise self-assembly process of a pH-responsive amphiphilic 4-aminoquinoline-tetraphenylethene conjugate. Nanoscale 2023, 15, 3177–3187. [Google Scholar] [CrossRef]

- Szustakiewicz, K.; Gazińska, M.; Kryszak, B.; Grzymajło, M.; Pigłowski, J.; Wiglusz, R.J.; Okamoto, M. The influence of hydroxyapatite content on properties of poly(L-lactide)/hydroxyapatite porous scaffolds obtained using thermal induced phase separation technique. Eur. Polym. J. 2019, 113, 313–320. [Google Scholar] [CrossRef]

- Olmos-Juste, R.; Alonso-Lerma, B.; Pérez-Jiménez, R.; Gabilondo, N.; Eceiza, A. 3D printed alginate-cellulose nanofibers based patches for local curcumin administration. Carbohydr. Polym. 2021, 264, 118026. [Google Scholar] [CrossRef]

- Behroozi, A.H.; Al-Shaeli, M.; Vatanpour, V. Fabrication and modification of nanofiltration membranes by solution electrospinning technique: A review of influential factors and applications in water treatment. Desalination 2023, 558, 116638. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Low, S.C.; Xu, Z.; Tan, S.H. Electrospinning Technique Meets Solar Energy: Electrospun Nanofiber-Based Evaporation Systems for Solar Steam Generation. Adv. Fiber Mater. 2023, 1–31. [Google Scholar] [CrossRef]

- Si, Y.; Sun, J.; Liu, F.; Shen, H.; Qi, X.; Xu, Q.; Zhou, C.; Liu, Y.; Fu, Y. Rabbit-hair-like SiO2/PI composite nanofibers with super durability for thermal insulation. Compos. Part B Eng. 2023, 254, 110542. [Google Scholar] [CrossRef]

- Wang, L.; Ma, J.; Guo, T.; Zhang, F.; Dong, A.; Zhang, S.; Liu, Y.; Yuan, H.; Leng, J. Control of Surface Wrinkles on Shape Memory PLA/PPDO Micro-nanofibers and Their Applications in Drug Release and Anti-scarring. Adv. Fiber Mater. 2023, 5, 632–649. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, R.; Wang, C.; Song, X.; Wang, R.; Liu, J.; Zhang, M.; Huang, J.; You, T.; Zhang, Y.; et al. In Situ Embedding Hydrogen-Bonded Organic Frameworks Nanocrystals in Electrospinning Nanofibers for Ultrastable Broad-Spectrum Antibacterial Activity. Adv. Funct. Mater. 2023, 2214388. [Google Scholar] [CrossRef]

- Yan, G.; Yang, Z.; Zhang, X.; Li, H.; Wang, L.; Li, Z.; Chen, J.; Wu, Y. Antibacterial biodegradable nanofibrous membranes by hybrid needleless electrospinning for high-efficiency particulate matter removal. Chem. Eng. J. 2023, 461, 142137. [Google Scholar] [CrossRef]

- Zafirah Zulfikri, N.I.; Mustaffa, N.A.; Mohamed, R.; Supardan, S.N.; Kamil, S.A. Electrospun Light-emitting Tm3+-doped SiO2–HfO2 nanofiber for photonic applications. J. Lumin. 2023, 257, 119723. [Google Scholar] [CrossRef]

- Ayvazoğlu, B.Ş.; Ceylan, M.; Turan, A.A.I.; Yılmaz, E.B. Biodegradable Polycaprolactone Fibers with Silica Aerogel and Nanosilver Particles Produce a Coagulation Effect. Polymers 2023, 15, 2022. [Google Scholar] [CrossRef]

- Bokov, D.; Turki Jalil, A.; Chupradit, S.; Suksatan, W.; Javed Ansari, M.; Shewael, I.H.; Valiev, G.H.; Kianfar, E. Nanomaterial by Sol-Gel Method: Synthesis and Application. Adv. Mater. Sci. Eng. 2021, 2021, 5102014. [Google Scholar] [CrossRef]

- Sakka, S. Birth of the sol–gel method: Early history. J. Sol-Gel Sci. Technol. 2022, 102, 478–481. [Google Scholar] [CrossRef]

- Ju, Q.; Zenji, T.; Maçon, A.L.B.; Norris, E.; Poologasundarampillai, G.; Obata, A.; Jones, J.R.; Kasuga, T. Silver-doped calcium silicate sol-gel glasses with a cotton-wool-like structure for wound healing. Biomater. Adv. 2022, 134, 112561. [Google Scholar] [CrossRef]

- Ahmad, F.; Mushtaq, B.; Butt, F.A.; Zafar, M.S.; Ahmad, S.; Afzal, A.; Nawab, Y.; Rasheed, A.; Ulker, Z. Synthesis and Characterization of Nonwoven Cotton-Reinforced Cellulose Hydrogel for Wound Dressings. Polymers 2021, 13, 4098. [Google Scholar] [CrossRef]

- Norris, E.; Ramos-Rivera, C.; Poologasundarampillai, G.; Clark, J.P.; Ju, Q.; Obata, A.; Hanna, J.V.; Kasuga, T.; Mitchell, C.A.; Jell, G.; et al. Electrospinning 3D bioactive glasses for wound healing. Biomed. Mater. 2020, 15, 015014. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, D.; Jiang, X.; He, L.; Fu, L.; Zhao, Y.; Wang, Y.; Mo, H.; Shen, J. Multistructured vascular patches constructed via layer-by-layer self-assembly of heparin and chitosan for vascular tissue engineering applications. Chem. Eng. J. 2019, 370, 1057–1067. [Google Scholar] [CrossRef]

- Karballaei Mirzahosseini, H.; Sheikhi, M.; Najmeddin, F.; Shirangi, M.; Mojtahedzadeh, M. 3D self-assembled nanocarriers for drug delivery. Drug Metab. Rev. 2023, 55, 140–162. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, T.; Chen, L.; Chen, Y.; Yang, B.-R.; Luo, Y.; Liu, G.-S. Self-assembly, alignment, and patterning of metal nanowires. Nanoscale Horiz. 2022, 7, 1299–1339. [Google Scholar] [CrossRef]

- Zhao, L.; Zhao, Y.; Li, R.; Wu, D.; Xu, R.; Li, S.; Zhang, Y.; Ye, H.; Xin, Q. A porphyrin-based optical sensor membrane prepared by electrostatic self-assembled technique for online detection of cadmium(II). Chemosphere 2020, 238, 124552. [Google Scholar] [CrossRef]

- Lu, Y.; Lin, J.; Wang, L.; Zhang, L.; Cai, C. Self-Assembly of Copolymer Micelles: Higher-Level Assembly for Constructing Hierarchical Structure. Chem. Rev. 2020, 120, 4111–4140. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, Y.; Wang, X.; Guo, J.; Yan, B.; Guan, W. Development and solidification of multifunction stabilizers formulated self-assembled core-shell Deacetyl mycoepoxydience nanosuspensions. J. Mol. Liq. 2020, 312, 113480. [Google Scholar] [CrossRef]

- Borah, R.; AG, K.R.; Minja, A.C.; Verbruggen, S.W. A Review on Self-Assembly of Colloidal Nanoparticles into Clusters, Patterns, and Films: Emerging Synthesis Techniques and Applications. Small Methods 2023, 2201536. [Google Scholar] [CrossRef]

- Gao, Y.; Qi, Y.; Wang, S.; Zhou, X.; Lyu, L.; Jin, G. Superhydrophobic polyphenylene sulfide fiber paper with nanofiber network-like structure prepared via regulation of TIPS process for oil/water separation. J. Mater. Sci. 2022, 57, 20531–20542. [Google Scholar] [CrossRef]

- Umakoshi, K.; Gonzales, R.R.; Kato, N.; Zhang, P.; Ono, T.; Matsuyama, H. Effect of polymer-solvent compatibility on polyamide hollow fiber membranes prepared via thermally induced phase separation. Colloids Surf. A Physicochem. Eng. Asp. 2022, 642, 128704. [Google Scholar] [CrossRef]

- Sabzi, E.; Abbasi, F.; Ghaleh, H. Interconnected porous nanofibrous gelatin scaffolds prepared via a combined thermally induced phase separation/particulate leaching method. J. Biomater. Sci. Polym. Ed. 2021, 32, 488–503. [Google Scholar] [CrossRef]

- Ranjbarrad, S.; Chan, P.K. Morphology formation during the nonisothermal thermally-induced phase separation (TIPS) process. Can. J. Chem. Eng. 2023. [Google Scholar] [CrossRef]

- Yang, S.; Xiao, C.; Huang, Y.; Ji, D.; Chen, K. Effect of additive and coagulation bath temperature on structure and properties of HDPE membranes via thermally induced phase separation. J. Mater. Sci. 2022, 57, 4834–4849. [Google Scholar] [CrossRef]

- Alizadehgiashi, M.; Nemr, C.R.; Chekini, M.; Pinto Ramos, D.; Mittal, N.; Ahmed, S.U.; Khuu, N.; Kelley, S.O.; Kumacheva, E. Multifunctional 3D-Printed Wound Dressings. ACS Nano 2021, 15, 12375–12387. [Google Scholar] [CrossRef]

- Decante, G.; Costa, J.B.; Silva-Correia, J.; Collins, M.N.; Reis, R.L.; Oliveira, J.M. Engineering bioinks for 3D bioprinting. Biofabrication 2021, 13, 032001. [Google Scholar] [CrossRef]

- Du, X.; Dehghani, M.; Alsaadi, N.; Nejad, M.G.; Saber-Samandari, S.; Toghraie, D.; Su, C.-H.; Nguyen, H.C. A femoral shape porous scaffold bio-nanocomposite fabricated using 3D printing and freeze-drying technique for orthopedic application. Mater. Chem. Phys. 2022, 275, 125302. [Google Scholar] [CrossRef]

- Miguel, S.P.; Figueira, D.R.; Simões, D.; Ribeiro, M.P.; Coutinho, P.; Ferreira, P.; Correia, I.J. Electrospun polymeric nanofibres as wound dressings: A review. Colloids Surf. B Biointerfaces 2018, 169, 60–71. [Google Scholar] [CrossRef]

- Abraham, S.; Kuppan, P.; Raj, S.; Salama, B.; Korbutt, G.S.; Montemagno, C.D. Developing Hybrid Polymer Scaffolds Using Peptide Modified Biopolymers for Cell Implantation. ACS Biomater. Sci. Eng. 2017, 3, 2215–2222. [Google Scholar] [CrossRef] [Green Version]

- Talebi, N.; Lopes, D.; Lopes, J.; Macário-Soares, A.; Dan, A.K.; Ghanbari, R.; Kahkesh, K.H.; Peixoto, D.; Giram, P.S.; Raza, F.; et al. Natural polymeric nanofibers in transdermal drug delivery. Appl. Mater. Today 2023, 30, 101726. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Pan, S.; Rodrigues, J.; Elkodous, M.A.; Danquah, M.K. Medical applications of biopolymer nanofibers. Biomater. Sci. 2022, 10, 4107–4118. [Google Scholar] [CrossRef]

- Jie, X.; Shiu, B.-C.; Zhang, Y.; Wu, H.; Ye, Y.; Fang, R. Chitosan-Urushiol nanofiber membrane with enhanced acid resistance and broad-spectrum antibacterial activity. Carbohydr. Polym. 2023, 312, 120792. [Google Scholar] [CrossRef]

- Li, X.; Yue, X.; Huang, Q.; Xiong, S. Insight into the spatial distribution and interaction model of heat-induced micro- and nano-starch/myofibrillar protein blends. Int. J. Biol. Macromol. 2023, 240, 124366. [Google Scholar] [CrossRef]

- Wu, S.; Wang, L.; Zhao, Y.; Chen, B.; Qiu, D.; Sun, P.; Shao, P.; Feng, S. Fabrication of high strength cold-set sodium alginate/whey protein nanofiber double network hydrogels and their interaction with curcumin. Food Res. Int. 2023, 165, 112490. [Google Scholar] [CrossRef]

- Han, X.; Zhao, M.; Xu, R.; Zou, Y.; Wang, Y.; Liang, J.; Jiang, Q.; Sun, Y.; Fan, Y.; Zhang, X. Electrospun Hyaluronan Nanofiber Membrane Immobilizing Aromatic Doxorubicin as Therapeutic and Regenerative Biomaterial. Int. J. Mol. Sci. 2023, 24, 7023. [Google Scholar] [CrossRef]

- Qin, L.; Zhang, Y.; Fan, Y.; Li, L. Cellulose nanofibril reinforced functional chitosan biocomposite films. Polym. Test. 2023, 120, 107964. [Google Scholar] [CrossRef]

- Zhao, K.; Tian, X.; Huang, N.; Zhang, K.; Wang, Y.; Zhang, Y.; Wang, W. Tunable mechanical performances of collagen-based film: Effect of collagens in different hierarchies and cellulose nanofiber. Prog. Org. Coat. 2023, 176, 107404. [Google Scholar] [CrossRef]

- Nasser, S.; Ibrahim, M.; Atassi, Y. Hemostatic wound dressings based on drug loaded electrospun PLLA nanofibrous mats. Mater. Chem. Phys. 2021, 267, 124686. [Google Scholar] [CrossRef]

- Joshi, A.; Nuntapramote, T.; Brüggemann, D. Self-Assembled Fibrinogen Scaffolds Support Cocultivation of Human Dermal Fibroblasts and HaCaT Keratinocytes. ACS Omega 2023, 8, 8650–8663. [Google Scholar] [CrossRef]

- Du, P.; Chen, X.; Chen, Y.; Li, J.; Lu, Y.; Li, X.; Hu, K.; Chen, J.; Lv, G. In vivo and in vitro studies of a propolis-enriched silk fibroin-gelatin composite nanofiber wound dressing. Heliyon 2023, 9, e13506. [Google Scholar] [CrossRef]

- Fu, Z.; Li, W.; Wei, J.; Yao, K.; Wang, Y.; Yang, P.; Li, G.; Yang, Y.; Zhang, L. Construction and Biocompatibility Evaluation of Fibroin/Sericin-Based Scaffolds. ACS Biomater. Sci. Eng. 2022, 8, 1494–1505. [Google Scholar] [CrossRef]

- Sawadkar, P.; Mandakhbayar, N.; Patel, K.D.; Buitrago, J.O.; Kim, T.H.; Rajasekar, P.; Lali, F.; Kyriakidis, C.; Rahmani, B.; Mohanakrishnan, J.; et al. Three dimensional porous scaffolds derived from collagen, elastin and fibrin proteins orchestrate adipose tissue regeneration. J. Tissue Eng. 2021, 12, 20417314211019238. [Google Scholar] [CrossRef]

- Ghafari, F.; Karbasi, S.; Eslaminejad, M.B. Investigating of physical, mechanical, and biological properties of polyhydroxybutyrate-keratin/alumina electrospun scaffold utilized in bone tissue engineering. Mater. Chem. Phys. 2023, 297, 127340. [Google Scholar] [CrossRef]

- Samrot, A.V.; Sathiyasree, M.; Rahim, S.B.A.; Renitta, R.E.; Kasipandian, K.; Krithika Shree, S.; Rajalakshmi, D.; Shobana, N.; Dhiva, S.; Abirami, S.; et al. Scaffold Using Chitosan, Agarose, Cellulose, Dextran and Protein for Tissue Engineering—A Review. Polymers 2023, 15, 1525. [Google Scholar]

- Visser, D.; Rogg, K.; Fuhrmann, E.; Marzi, J.; Schenke-Layland, K.; Hartmann, H. Electrospinning of collagen: Enzymatic and spectroscopic analyses reveal solvent-independent disruption of the triple-helical structure. J. Mater. Chem. B 2023, 11, 2207–2218. [Google Scholar] [CrossRef]

- Kenny, M.; Stamboroski, S.; Taher, R.; Brüggemann, D.; Schoen, I. Nanofiber Topographies Enhance Platelet-Fibrinogen Scaffold Interactions. Adv. Healthc. Mater. 2022, 11, 2200249. [Google Scholar] [CrossRef]

- Kamaruzaman, N.; Fauzi, M.B.; Tabata, Y.; Yusop, S.M. Functionalised Hybrid Collagen-Elastin for Acellular Cutaneous Substitute Applications. Polymers 2023, 15, 1929. [Google Scholar] [CrossRef]

- Ye, W.; Qin, M.; Qiu, R.; Li, J. Keratin-based wound dressings: From waste to wealth. Int. J. Biol. Macromol. 2022, 211, 183–197. [Google Scholar] [CrossRef]

- Yang, F.; Wang, F.; Mazahreh, J.; Hu, X. Ultrasound-assisted air-jet spinning of silk fibroin-soy protein nanofiber composite biomaterials. Ultrason. Sonochemistry 2023, 94, 106341. [Google Scholar] [CrossRef]

- Dou, Z.; Li, B.; Wu, L.; Qiu, T.; Wang, X.; Zhang, X.; Shen, Y.; Lu, M.; Yang, Y. Probiotic-Functionalized Silk Fibroin/Sodium Alginate Scaffolds with Endoplasmic Reticulum Stress-Relieving Properties for Promoted Scarless Wound Healing. ACS Appl. Mater. Interfaces 2023, 15, 6297–6311. [Google Scholar] [CrossRef]

- Ghomi, E.R.; Lakshminarayanan, R.; Chellappan, V.; Verma, N.K.; Chinnappan, A.; Neisiany, R.E.; Amuthavalli, K.; Poh, Z.S.; Wong, B.H.S.; Dubey, N.; et al. Electrospun Aligned PCL/Gelatin Scaffolds Mimicking the Skin ECM for Effective Antimicrobial Wound Dressings. Adv. Fiber Mater. 2023, 5, 235–251. [Google Scholar] [CrossRef]

- Yao, F.; Zheng, Y.; Gao, Y.; Du, Y.; Chen, F. Electrospinning of peanut protein isolate/poly-L-lactic acid nanofibers containing tetracycline hydrochloride for wound healing. Ind. Crops Prod. 2023, 194, 116262. [Google Scholar] [CrossRef]

- Koohzad, F.; Asoodeh, A. Cross-Linked Electrospun pH-Sensitive Nanofibers Adsorbed with Temporin-Ra for Promoting Wound Healing. ACS Appl. Mater. Interfaces 2023, 15, 15172–15184. [Google Scholar] [CrossRef]

- Sun, C.; Yue, P.; Chen, R.; Wu, S.; Ye, Q.; Weng, Y.; Liu, H.; Fang, Y. Chitin-glucan composite sponge hemostat with rapid shape-memory from Pleurotus eryngii for puncture wound. Carbohydr. Polym. 2022, 291, 119553. [Google Scholar] [CrossRef]

- Latiyan, S.; Kumar, T.S.S.; Doble, M. Fabrication and evaluation of agarose-curdlan blend derived multifunctional nanofibrous mats for diabetic wounds. Int. J. Biol. Macromol. 2023, 235, 123904. [Google Scholar] [CrossRef]

- Palanisamy, C.P.; Cui, B.; Zhang, H.; Gunasekaran, V.P.; Ariyo, A.L.; Jayaraman, S.; Rajagopal, P.; Long, Q. A critical review on starch-based electrospun nanofibrous scaffolds for wound healing application. Int. J. Biol. Macromol. 2022, 222, 1852–1860. [Google Scholar] [CrossRef]

- Sadeghi, A.; Zare-Gachi, M.; Najjar-Asl, M.; Rajabi, S.; Fatemi, M.J.; Forghani, S.F.; Daemi, H.; Pezeshki-Modaress, M. Hybrid gelatin-sulfated alginate scaffolds as dermal substitutes can dramatically accelerate healing of full-thickness diabetic wounds. Carbohydr. Polym. 2023, 302, 120404. [Google Scholar] [CrossRef]

- Neamtu, B.; Barbu, A.; Negrea, M.O.; Berghea-Neamțu, C.Ș.; Popescu, D.; Zăhan, M.; Mireșan, V. Carrageenan-Based Compounds as Wound Healing Materials. Int. J. Mol. Sci. 2022, 23, 9117. [Google Scholar] [CrossRef]

- Nogueira, L.F.B.; Cruz, M.A.E.; de Melo, M.T.; Maniglia, B.C.; Caroleo, F.; Paolesse, R.; Lopes, H.B.; Beloti, M.M.; Ciancaglini, P.; Ramos, A.P.; et al. Collagen/κ-Carrageenan-Based Scaffolds as Biomimetic Constructs for In Vitro Bone Mineralization Studies. Biomacromolecules 2023, 24, 1258–1266. [Google Scholar] [CrossRef]

- Kotla, N.G.; Mohd Isa, I.L.; Larrañaga, A.; Maddiboyina, B.; Swamy, S.K.; Sivaraman, G.; Vemula, P.K. Hyaluronic Acid-Based Bioconjugate Systems, Scaffolds, and Their Therapeutic Potential. Adv. Healthc. Mater. 2023, 2203104. [Google Scholar] [CrossRef]

- Eskilson, O.; Zattarin, E.; Berglund, L.; Oksman, K.; Hanna, K.; Rakar, J.; Sivlér, P.; Skog, M.; Rinklake, I.; Shamasha, R.; et al. Nanocellulose composite wound dressings for real-time pH wound monitoring. Mater. Today Bio 2023, 19, 100574. [Google Scholar] [CrossRef]

- Naomi, R.; Bt Hj Idrus, R.; Fauzi, M.B. Plant- vs. Bacterial-Derived Cellulose for Wound Healing: A Review. Int. J. Environ. Res. Public Health 2020, 17, 6803. [Google Scholar] [CrossRef]

- Akturk, A. Enrichment of Cellulose Acetate Nanofibrous Scaffolds with Retinyl Palmitate and Clove Essential Oil for Wound Healing Applications. ACS Omega 2023, 8, 5553–5560. [Google Scholar] [CrossRef]

- Singh, S.; Nwabor, O.F.; Sukri, D.M.; Wunnoo, S.; Dumjun, K.; Lethongkam, S.; Kusolphat, P.; Hemtanon, N.; Klinprathum, K.; Sunghan, J.; et al. Poly (vinyl alcohol) copolymerized with xanthan gum/hypromellose/sodium carboxymethyl cellulose dermal dressings functionalized with biogenic nanostructured materials for antibacterial and wound healing application. Int. J. Biol. Macromol. 2022, 216, 235–250. [Google Scholar] [CrossRef]

- Kim, T.-H.; Kim, S.-C.; Park, W.S.; Choi, I.-W.; Kim, H.-W.; Kang, H.-W.; Kim, Y.-M.; Jung, W.-K. PCL/gelatin nanofibers incorporated with starfish polydeoxyribonucleotides for potential wound healing applications. Mater. Des. 2023, 229, 111912. [Google Scholar] [CrossRef]

- Rajora, A.D.; Bal, T. Evaluation of cashew gum-polyvinyl alcohol (CG-PVA) electrospun nanofiber mat for scarless wound healing in a murine model. Int. J. Biol. Macromol. 2023, 240, 124417. [Google Scholar] [CrossRef]

- Sadeghi, A.; Zandi, M.; Pezeshki-Modaress, M.; Rajabi, S. Tough, hybrid chondroitin sulfate nanofibers as a promising scaffold for skin tissue engineering. Int. J. Biol. Macromol. 2019, 132, 63–75. [Google Scholar] [CrossRef]

- Zhong, G.; Qiu, M.; Zhang, J.; Jiang, F.; Yue, X.; Huang, C.; Zhao, S.; Zeng, R.; Zhang, C.; Qu, Y. Fabrication and characterization of PVA@PLA electrospinning nanofibers embedded with Bletilla striata polysaccharide and Rosmarinic acid to promote wound healing. Int. J. Biol. Macromol. 2023, 234, 123693. [Google Scholar] [CrossRef]

- Amiryaghoubi, N.; Fathi, M.; Barar, J.; Omidian, H.; Omidi, Y. Hybrid polymer-grafted graphene scaffolds for microvascular tissue engineering and regeneration. Eur. Polym. J. 2023, 193, 112095. [Google Scholar] [CrossRef]

- Pandey, G.; Pandey, P.; Arya, D.K.; Kanaujiya, S.; Deepak Kapoor, D.; Gupta, R.K.; Ranjan, S.; Chidambaram, K.; Manickam, B.; Rajinikanth, P.S. Multilayered nanofibrous scaffold of Polyvinyl alcohol/gelatin/poly (lactic-co-glycolic acid) enriched with hemostatic/antibacterial agents for rapid acute hemostatic wound healing. Int. J. Pharm. 2023, 638, 122918. [Google Scholar] [CrossRef]

- Diedkova, K.; Pogrebnjak, A.D.; Kyrylenko, S.; Smyrnova, K.; Buranich, V.V.; Horodek, P.; Zukowski, P.; Koltunowicz, T.N.; Galaszkiewicz, P.; Makashina, K.; et al. Polycaprolactone–MXene Nanofibrous Scaffolds for Tissue Engineering. ACS Appl. Mater. Interfaces 2023, 15, 14033–14047. [Google Scholar] [CrossRef]

- Wang, G.; Ju, S.; Li, X.; Cai, Y.; Li, Y.; Li, W.; Zhou, S.; He, H.; Dong, Z.; Fu, W. Preclinical animal study of electrospun poly (l-lactide-co-caprolactone) and formulated porcine fibrinogen for full-thickness diabetic wound regeneration. Biomed. Pharmacother. 2023, 162, 114734. [Google Scholar] [CrossRef]

- Li, M.; Dong, Y.; Wang, M.; Lu, X.; Li, X.; Yu, J.; Ding, B. Hydrogel/nanofibrous membrane composites with enhanced water retention, stretchability and self-healing capability for wound healing. Compos. Part B Eng. 2023, 257, 110672. [Google Scholar] [CrossRef]

- Tian, Z.; Wu, G.; Libby, M.; Wu, K.; Jeong, K.J.; Kim, Y.J. Synthesis of biologically derived poly(pyrogallol) nanofibers for antibacterial applications. J. Mater. Chem. B 2023, 11, 3356–3363. [Google Scholar] [CrossRef]

- Farzaei, M.H.; Derayat, P.; Pourmanouchehri, Z.; Kahrarian, M.; Samimi, Z.; Hajialyani, M.; Bahrami, G.; Hosseinzadeh, L.; Rashidi, K.; Tajehmiri, A.; et al. Characterization and evaluation of antibacterial and wound healing activity of naringenin-loaded polyethylene glycol/polycaprolactone electrospun nanofibers. J. Drug Deliv. Sci. Technol. 2023, 81, 104182. [Google Scholar] [CrossRef]

- Mohammadalipour, M.; Asadolahi, M.; Mohammadalipour, Z.; Behzad, T.; Karbasi, S. Plasma surface modification of electrospun polyhydroxybutyrate (PHB) nanofibers to investigate their performance in bone tissue engineering. Int. J. Biol. Macromol. 2023, 230, 123167. [Google Scholar] [CrossRef]

- Injorhor, P.; Trongsatitkul, T.; Wittayakun, J.; Ruksakulpiwat, C.; Ruksakulpiwat, Y. Biodegradable Polylactic Acid-Polyhydroxyalkanoate-Based Nanocomposites with Bio-Hydroxyapatite: Preparation and Characterization. Polymers 2023, 15, 1261. [Google Scholar] [CrossRef]

- Khataei, S.; H.Al-Musawi, M.; Asadi, K.; Ramezani, S.; Abbasian, M.; Ghorbani, M. Effect of molecular weight and content of polyvinylpyrrolidone on cell proliferation, loading capacity and properties of electrospun green tea essential oil-incorporated polyamide-6/polyvinylpyrrolidone nanofibers. J. Drug Deliv. Sci. Technol. 2023, 82, 104310. [Google Scholar] [CrossRef]

- Tóth, K.; Fekete, N.; Klaudia Simon, V.; Tóth, B.; Ferenc Kovács, Á.; Pállinger, É.; Antal, I.; Kőhidai, L.; Jedlovszky-Hajdú, A.; Juriga, D.; et al. Different implantable electrospun meshes for simultaneous application of prednisone and doxorubicin. J. Mol. Liq. 2023, 381, 121854. [Google Scholar] [CrossRef]

- Aljohani, M.M.; Abu-Rayyan, A.; Elsayed, N.H.; Alatawi, F.A.; Al-Anazi, M.; Mustafa, S.K.; Albalawi, R.K.; Abdelmonem, R. One-pot microwave synthesis of chitosan-stabilized silver nanoparticles entrapped polyethylene oxide nanofibers, with their intrinsic antibacterial and antioxidant potency for wound healing. Int. J. Biol. Macromol. 2023, 235, 123704. [Google Scholar] [CrossRef]

- Serbanescu, O.S.; Voicu, S.I.; Thakur, V.K. Polysulfone functionalized membranes: Properties and challenges. Mater. Today Chem. 2020, 17, 100302. [Google Scholar] [CrossRef]

- Ji, D.; Li, T.; Hu, W.; Fuchs, H. Recent Progress in Aromatic Polyimide Dielectrics for Organic Electronic Devices and Circuits. Adv. Mater. 2019, 31, 1806070. [Google Scholar] [CrossRef]

- Yang, B.; Wang, L.; Zhao, J.; Pang, R.; Yuan, B.; Tan, J.; Song, S.; Nie, J.; Zhang, M. A Robust, Flexible, Hydrophobic, and Multifunctional Pressure Sensor Based on an MXene/Aramid Nanofiber (ANF) Aerogel Film. ACS Appl. Mater. Interfaces 2022, 14, 47075–47088. [Google Scholar] [CrossRef]

- Li, W.; Chao, S.; Li, Y.; Bai, F.; Teng, Y.; Li, X.; Li, L.; Wang, C. Dual-layered composite nanofiber membrane with Cu-BTC-modified electrospun nanofibers and biopolymeric nanofibers for the removal of uremic toxins and its application in hemodialysis. J. Membr. Sci. 2022, 642, 119964. [Google Scholar] [CrossRef]

- Zhao, M.; Chen, G.; Zhang, S.; Chen, B.; Wu, Z.; Zhang, C. A bioactive poly(ether-ether-ketone) nanocomposite scaffold regulates osteoblast/osteoclast activity for the regeneration of osteoporotic bone. J. Mater. Chem. B 2022, 10, 8719–8732. [Google Scholar] [CrossRef]

- Pan, Y.; Zheng, J.; Xu, Y.; Chen, X.; Yan, M.; Li, J.; Zhao, X.; Feng, Y.; Ma, Y.; Ding, M.; et al. Ultralight, highly flexible in situ thermally crosslinked polyimide aerogels with superior mechanical and thermal protection properties via nanofiber reinforcement. J. Colloid Interface Sci. 2022, 628, 829–839. [Google Scholar] [CrossRef]

- Hajili, E.; Sugawara, A.; Asoh, T.-A.; Uyama, H. Fabrication of 3D Hierarchically Porous Chitosan Monoliths by Thermally Induced Phase Separation of Chemically Modified Chitin. ACS Sustain. Chem. Eng. 2023, 11, 5473–5484. [Google Scholar] [CrossRef]

- Aguilar, A.; Zein, N.; Harmouch, E.; Hafdi, B.; Bornert, F.; Offner, D.; Clauss, F.; Fioretti, F.; Huck, O.; Benkirane-Jessel, N.; et al. Application of Chitosan in Bone and Dental Engineering. Molecules 2019, 24, 3009. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Tan, W.; Zhang, J.; Li, Q.; Guo, Z. Water-soluble amino functionalized chitosan: Preparation, characterization, antioxidant and antibacterial activities. Int. J. Biol. Macromol. 2022, 217, 969–978. [Google Scholar] [CrossRef]

- Rimoli, C.V.; de Oliveira Pedro, R.; Miranda, P.B. Interaction mechanism of chitosan oligomers in pure water with cell membrane models studied by SFG vibrational spectroscopy. Colloids Surf. B Biointerfaces 2022, 219, 112782. [Google Scholar] [CrossRef]

- Indrakumar, S.; Ghosh, S.; Dash, T.K.; Mishra, V.; Tandon, B.; Chatterjee, K. Silk composite interfacial layer eliminates rebleeding with chitosan-based hemostats. Carbohydr. Polym. 2023, 304, 120479. [Google Scholar] [CrossRef]

- Hasanbegloo, K.; Banihashem, S.; Faraji Dizaji, B.; Bybordi, S.; Farrokh-Eslamlou, N.; Abadi, P.G.-s.; Jazi, F.S.; Irani, M. Paclitaxel-loaded liposome-incorporated chitosan (core)/poly(ε-caprolactone)/chitosan (shell) nanofibers for the treatment of breast cancer. Int. J. Biol. Macromol. 2023, 230, 123380. [Google Scholar] [CrossRef]

- Tan, G.; Wang, L.; Pan, W.; Chen, K. Polysaccharide Electrospun Nanofibers for Wound Healing Applications. Int. J. Nanomed. 2022, 17, 3913–3931. [Google Scholar] [CrossRef]

- Grigoras, A.G. Drug delivery systems using pullulan, a biocompatible polysaccharide produced by fungal fermentation of starch. Environ. Chem. Lett. 2019, 17, 1209–1223. [Google Scholar] [CrossRef]

- Lee, J.; Choi, H.N.; Cha, H.J.; Yang, Y.J. Microporous Hemostatic Sponge Based on Silk Fibroin and Starch with Increased Structural Retentivity for Contact Activation of the Coagulation Cascade. Biomacromolecules 2023, 24, 1763–1773. [Google Scholar] [CrossRef]

- Watcharakitti, J.; Win, E.E.; Nimnuan, J.; Smith, S.M. Modified Starch-Based Adhesives: A Review. Polymers 2022, 14, 2023. [Google Scholar] [CrossRef]

- Hegde, V.; Uthappa, U.T.; Altalhi, T.; Jung, H.-Y.; Han, S.S.; Kurkuri, M.D. Alginate based polymeric systems for drug delivery, antibacterial/microbial, and wound dressing applications. Mater. Today Commun. 2022, 33, 104813. [Google Scholar] [CrossRef]

- Tan, J.; Luo, Y.; Guo, Y.; Zhou, Y.; Liao, X.; Li, D.; Lai, X.; Liu, Y. Development of alginate-based hydrogels: Crosslinking strategies and biomedical applications. Int. J. Biol. Macromol. 2023, 239, 124275. [Google Scholar] [CrossRef]

- Penton, K.E.; Kinler, Z.; Davis, A.; Spiva, J.A.; Hamilton, S.K. Electrospinning Drug-Loaded Alginate-Based Nanofibers towards Developing a Drug Release Rate Catalog. Polymers 2022, 14, 2773. [Google Scholar] [CrossRef]

- Niu, Y.; Galluzzi, M. Hyaluronic Acid/Collagen Nanofiber Tubular Scaffolds Support Endothelial Cell Proliferation, Phenotypic Shape and Endothelialization. Nanomaterials 2021, 11, 2334. [Google Scholar] [CrossRef]

- Alven, S.; Aderibigbe, B.A. Hyaluronic Acid-Based Scaffolds as Potential Bioactive Wound Dressings. Polymers 2021, 13, 2102. [Google Scholar] [CrossRef]

- Skuhrovcová, K.; Kotzianová, A.; Bardoňová, L.; Židek, O.; Toropitsyn, E.; Vágnerová, H.; Čápová, A.; Dostálová, K.; Hermannová, M.; Pokorný, M.; et al. Nanofibrous material from hyaluronan derivatives preserving fibrous structure in aqueous environment. Carbohydr. Polym. 2022, 276, 118785. [Google Scholar] [CrossRef]

- Chantre, C.O.; Gonzalez, G.M.; Ahn, S.; Cera, L.; Campbell, P.H.; Hoerstrup, S.P.; Parker, K.K. Porous Biomimetic Hyaluronic Acid and Extracellular Matrix Protein Nanofiber Scaffolds for Accelerated Cutaneous Tissue Repair. ACS Appl. Mater. Interfaces 2019, 11, 45498–45510. [Google Scholar] [CrossRef]

- Sun, M.; Cheng, J.; Zhang, J.; Wu, N.; Zhao, F.; Li, Z.; Yu, H.; Duan, X.; Fu, X.; Hu, X.; et al. Stepwise Cross-Linking of Fibroin and Hyaluronic for 3D Printing Flexible Scaffolds with Tunable Mechanical Properties. ACS Biomater. Sci. Eng. 2021, 7, 916–925. [Google Scholar] [CrossRef]

- Lamparelli, E.P.; Casagranda, V.; Pressato, D.; Maffulli, N.; Della Porta, G.; Bellini, D. Synthesis and Characterization of a Novel Composite Scaffold Based on Hyaluronic Acid and Equine Type I Collagen. Pharmaceutics 2022, 14, 1752. [Google Scholar] [CrossRef]

- Dong, R.; Li, Y.; Chen, M.; Xiao, P.; Wu, Y.; Zhou, K.; Zhao, Z.; Tang, B.Z. In Situ Electrospinning of Aggregation-Induced Emission Nanofibrous Dressing for Wound Healing. Small Methods 2022, 6, 2101247. [Google Scholar] [CrossRef]

- Guo, X.; Liu, Y.; Bera, H.; Zhang, H.; Chen, Y.; Cun, D.; Foderà, V.; Yang, M. α-Lactalbumin-Based Nanofiber Dressings Improve Burn Wound Healing and Reduce Scarring. ACS Appl. Mater. Interfaces 2020, 12, 45702–45713. [Google Scholar] [CrossRef]

- Khalid, A.; Bai, D.; Abraham, A.N.; Jadhav, A.; Linklater, D.; Matusica, A.; Nguyen, D.; Murdoch, B.J.; Zakhartchouk, N.; Dekiwadia, C.; et al. Electrospun Nanodiamond–Silk Fibroin Membranes: A Multifunctional Platform for Biosensing and Wound-Healing Applications. ACS Appl. Mater. Interfaces 2020, 12, 48408–48419. [Google Scholar] [CrossRef]

- Mistry, P.; Chhabra, R.; Muke, S.; Narvekar, A.; Sathaye, S.; Jain, R.; Dandekar, P. Fabrication and characterization of starch-TPU based nanofibers for wound healing applications. Mater. Sci. Eng. C 2021, 119, 111316. [Google Scholar] [CrossRef]

- Waghmare, V.S.; Wadke, P.R.; Dyawanapelly, S.; Deshpande, A.; Jain, R.; Dandekar, P. Starch based nanofibrous scaffolds for wound healing applications. Bioact. Mater. 2018, 3, 255–266. [Google Scholar] [CrossRef]

- Kharat, Z.; Amiri Goushki, M.; Sarvian, N.; Asad, S.; Dehghan, M.M.; Kabiri, M. Chitosan/PEO nanofibers containing Calendula officinalis extract: Preparation, characterization, in vitro and in vivo evaluation for wound healing applications. Int. J. Pharm. 2021, 609, 121132. [Google Scholar] [CrossRef]

- Hernández-Rangel, A.; Martin-Martinez, E.S. Collagen based electrospun materials for skin wounds treatment. J. Biomed. Mater. Res. Part A 2021, 109, 1751–1764. [Google Scholar] [CrossRef]

- Huang, W.-H.; Ding, S.-L.; Zhao, X.-Y.; Li, K.; Guo, H.-T.; Zhang, M.-Z.; Gu, Q. Collagen for neural tissue engineering: Materials, strategies, and challenges. Mater. Today Bio 2023, 20, 100639. [Google Scholar] [CrossRef]

- Chen, K.; Li, Y.; Li, Y.; Pan, W.; Tan, G. Silk Fibroin Combined with Electrospinning as a Promising Strategy for Tissue Regeneration. Macromol. Biosci. 2023, 23, 2200380. [Google Scholar] [CrossRef]

- Suter, N.; Joshi, A.; Wunsch, T.; Graupner, N.; Stapelfeldt, K.; Radmacher, M.; Müssig, J.; Brüggemann, D. Self-assembled fibrinogen nanofibers support fibroblast adhesion and prevent E. coli infiltration. Mater. Sci. Eng. C 2021, 126, 112156. [Google Scholar] [CrossRef]

- Minagawa, S.; Sekiguchi, S.; Nakaso, Y.; Igarashi, T.; Tomita, M. Production of a correctly assembled fibrinogen using transgenic silkworms. Transgenic Res. 2020, 29, 339–353. [Google Scholar] [CrossRef]

- Morin, A.; Alam, P. Comparing the properties of Bombyx mori silk cocoons against sericin-fibroin regummed biocomposite sheets. Mater. Sci. Eng. C 2016, 65, 215–220. [Google Scholar] [CrossRef]

- Guo, K.; Zhang, X.; Zhao, D.; Qin, L.; Jiang, W.; Hu, W.; Liu, X.; Xia, Q.; Dong, Z.; Zhao, P. Identification and characterization of sericin5 reveals non-cocoon silk sericin components with high β-sheet content and adhesive strength. Acta Biomater. 2022, 150, 96–110. [Google Scholar] [CrossRef]

- Sapru, S.; Das, S.; Mandal, M.; Ghosh, A.K.; Kundu, S.C. Prospects of nonmulberry silk protein sericin-based nanofibrous matrices for wound healing—In vitro and in vivo investigations. Acta Biomater. 2018, 78, 137–150. [Google Scholar] [CrossRef]

- Ramezani Dana, H.; Ebrahimi, F. Synthesis, properties, and applications of polylactic acid-based polymers. Polym. Eng. Sci. 2023, 63, 22–43. [Google Scholar] [CrossRef]

- Elsawy, M.A.; Kim, K.-H.; Park, J.-W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Arvindh Seshadri, S.; Devnani, G.L.; Sanjay, M.R.; Siengchin, S.; Prakash Maran, J.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites—A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, J.; Li, J.; Liang, X.; Zhou, W.; Peng, S. Strategies and techniques for improving heat resistance and mechanical performances of poly(lactic acid) (PLA) biodegradable materials. Int. J. Biol. Macromol. 2022, 218, 115–134. [Google Scholar] [CrossRef]

- Rickel, A.P.; Deng, X.; Engebretson, D.; Hong, Z. Electrospun nanofiber scaffold for vascular tissue engineering. Mater. Sci. Eng. C Mater. Biol. Appl. 2021, 129, 112373. [Google Scholar] [CrossRef]

- Li, J.-X.; Niu, D.-Y.; Xu, P.-W.; Sun, Z.-Y.; Yang, W.-J.; Ji, Y.; Ma, P.-M. Tailoring the Crystallization Behavior and Mechanical Property of Poly(glycolic acid) by Self-nucleation. Chin. J. Polym. Sci. 2022, 40, 365–372. [Google Scholar] [CrossRef]

- Samantaray, P.K.; Little, A.; Haddleton, D.M.; McNally, T.; Tan, B.; Sun, Z.; Huang, W.; Ji, Y.; Wan, C. Poly(glycolic acid) (PGA): A versatile building block expanding high performance and sustainable bioplastic applications. Green. Chem. 2020, 22, 4055–4081. [Google Scholar] [CrossRef]

- Wu, H.; Wang, C.; Ning, Z.; Jiang, N.; Gan, Z. Ultra-toughened poly(glycolic acid)-based blends with controllable hydrolysis behavior fabricated via reactive compatibilization. Eur. Polym. J. 2022, 181, 111661. [Google Scholar] [CrossRef]

- Kazempour, M.; Edjlali, L.; Akbarzadeh, A.; Davaran, S.; Farid, S.S. Synthesis and characterization of dual pH-and thermo-responsive graphene-based nanocarrier for effective anticancer drug delivery. J. Drug Deliv. Sci. Technol. 2019, 54, 101158. [Google Scholar] [CrossRef]

- Atta, S.; Cohen, J.; Kohn, J.; Gormley, A.J. Ring opening polymerization of ε-caprolactone through water. Polym. Chem. 2021, 12, 159–164. [Google Scholar] [CrossRef]

- Lv, C.; Xu, G.; Yang, R.; Zhou, L.; Wang, Q. Stereogradient polycaprolactones formed by asymmetric kinetic resolution polymerization of 6-methyl-ε-caprolactone. Polym. Chem. 2021, 12, 4856–4863. [Google Scholar] [CrossRef]

- Yoon, Y.; Park, H.; An, S.; Ahn, J.-H.; Kim, B.; Shin, J.; Kim, Y.-E.; Yeon, J.; Chung, J.-H.; Kim, D.; et al. Bacterial degradation kinetics of poly(Ɛ-caprolactone) (PCL) film by Aquabacterium sp. CY2-9 isolated from plastic-contaminated landfill. J. Environ. Manag. 2023, 335, 117493. [Google Scholar] [CrossRef]

- Geoghegan, N.; O’Loughlin, M.; Delaney, C.; Rochfort, K.D.; Kennedy, M.; Kolagatla, S.; Podhorska, L.; Rodriguez, B.J.; Florea, L.; Kelleher, S.M. Controlled degradation of polycaprolactone-based micropillar arrays. Biomater. Sci. 2023, 11, 3077–3091. [Google Scholar] [CrossRef]

- Oh, Y.-R.; Jang, Y.-A.; Song, J.K.; Eom, G.T. Efficient enzymatic depolymerization of polycaprolactone into 6-hydroxyhexanoic acid by optimizing reaction conditions and microbial conversion of 6-hydroxyhexanoic acid into adipic acid for eco-friendly upcycling of polycaprolactone. Biochem. Eng. J. 2022, 185, 108504. [Google Scholar] [CrossRef]

- Calderón-Villajos, R.; Fernández Sánchez-Romate, X.; Jiménez-Suárez, A.; Prolongo, S.G. An Analysis of the Effect of Activation Temperature and Crack Geometry on the Healing Efficiency of Polycaprolactone (PCL)/Epoxy Blends. Polymers 2023, 15, 336. [Google Scholar] [CrossRef]

- Lu, Y.; Cheng, D.; Niu, B.; Wang, X.; Wu, X.; Wang, A. Properties of Poly (Lactic-co-Glycolic Acid) and Progress of Poly (Lactic-co-Glycolic Acid)-Based Biodegradable Materials in Biomedical Research. Pharmaceuticals 2023, 16, 454. [Google Scholar] [CrossRef]

- Hu, W.-W.; Lin, Y.-T. Alginate/polycaprolactone composite fibers as multifunctional wound dressings. Carbohydr. Polym. 2022, 289, 119440. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, W.; Ren, M.; Li, Y.; Wang, Y.; Zhou, Y.; Wu, Y.; Zhang, Z.; Di, J. Moisture-Adaptive Contractile Biopolymer-Derived Fibers for Wound Healing Promotion. Small 2023, 2300589. [Google Scholar] [CrossRef]

- Mahmood, S.; Khan, N.R.; Razaque, G.; Shah, S.U.; Shahid, M.G.; Albarqi, H.A.; Alqahtani, A.A.; Alasiri, A.; Basit, H.M. Microwave-Treated Physically Cross-Linked Sodium Alginate and Sodium Carboxymethyl Cellulose Blend Polymer Film for Open Incision Wound Healing in Diabetic Animals—A Novel Perspective for Skin Tissue Regeneration Application. Pharmaceutics 2023, 15, 418. [Google Scholar]

- Ding, M.; Wang, X.; Man, J.; Li, J.; Qiu, Y.; Zhang, Y.; Ji, M.; Li, J. Antibacterial and hemostatic polyvinyl alcohol/microcrystalline cellulose reinforced sodium alginate breathable dressing containing Euphorbia humifusa extract based on microfluidic spinning technology. Int. J. Biol. Macromol. 2023, 239, 124167. [Google Scholar] [CrossRef]

- Rooholghodos, S.H.; Pourmadadi, M.; Yazdian, F.; Rashedi, H. Optimization of electrospun CQDs-Fe3O4-RE loaded PVA-cellulose nanofibrils via central composite design for wound dressing applications: Kinetics and in vitro release study. Int. J. Biol. Macromol. 2023, 237, 124067. [Google Scholar] [CrossRef]

- Cheah, Y.J.; Yunus, M.H.M.; Fauzi, M.B.; Tabata, Y.; Hiraoka, Y.; Phang, S.J.; Chia, M.R.; Buyong, M.R.; Yazid, M.D. Gelatin–chitosan–cellulose nanocrystals as an acellular scaffold for wound healing application: Fabrication, characterisation and cytocompatibility towards primary human skin cells. Cellulose 2023, 30, 5071–5092. [Google Scholar] [CrossRef]

- Dehghani, N.; Haghiralsadat, F.; Yazdian, F.; Sadeghian-Nodoushan, F.; Ghasemi, N.; Mazaheri, F.; Pourmadadi, M.; Naghib, S.M. Chitosan/silk fibroin/nitrogen-doped carbon quantum dot/α-tricalcium phosphate nanocomposite electrospinned as a scaffold for wound healing application: In vitro and in vivo studies. Int. J. Biol. Macromol. 2023, 238, 124078. [Google Scholar] [CrossRef]

- Habibi, S.; Mohammadi, T.; Hmtshirazi, R.; Atyabi, F.; Kiani, M.; Asadi, A.A. A bilayer mupirocin/bupivacaine-loaded wound dressing based on chitosan/poly (vinyl alcohol) nanofibrous mat: Preparation, characterization, and controlled drug release. Int. J. Biol. Macromol. 2023, 240, 124399. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, Y.; Lun, X.; Sheng, H.; Yan, A. Effects of wound dressing based on the combination of silver@curcumin nanoparticles and electrospun chitosan nanofibers on wound healing. Bioengineered 2022, 13, 4328–4339. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, Z.; Liu, J.; Dong, P.; Tian, F.; Li, F.; Meng, X. Electrospun kaolin-loaded chitosan/PEO nanofibers for rapid hemostasis and accelerated wound healing. Int. J. Biol. Macromol. 2022, 217, 998–1011. [Google Scholar] [CrossRef]

- de Castro, K.C.; Silva, E.K.; Campos, M.G.N.; Mei, L.H.I. Hyaluronic Acid/Polyvinyl Alcohol Electrospun Nanofiber Membranes Loaded with Plantago Major Extract for Smart Wound Dressings. ACS Appl. Nano Mater. 2022, 5, 12616–12625. [Google Scholar] [CrossRef]

- Eskandarinia, A.; Kefayat, A.; Gharakhloo, M.; Agheb, M.; Khodabakhshi, D.; Khorshidi, M.; Sheikhmoradi, V.; Rafienia, M.; Salehi, H. A propolis enriched polyurethane-hyaluronic acid nanofibrous wound dressing with remarkable antibacterial and wound healing activities. Int. J. Biol. Macromol. 2020, 149, 467–476. [Google Scholar] [CrossRef]

- AlSalem, H.S.; Bukhari, A.A.H. Biodegradable wound dressing-based collagen/hyaluronic acid loaded antibacterial agents for wound healing application. Int. J. Biol. Macromol. 2023, 242, 124700. [Google Scholar] [CrossRef]

- Pitpisutkul, V.; Prachayawarakorn, J. Hydroxypropyl methylcellulose/carboxymethyl starch/zinc oxide porous nanocomposite films for wound dressing application. Carbohydr. Polym. 2022, 298, 120082. [Google Scholar] [CrossRef]

- Adeli, H.; Khorasani, M.T.; Parvazinia, M. Wound dressing based on electrospun PVA/chitosan/starch nanofibrous mats: Fabrication, antibacterial and cytocompatibility evaluation and in vitro healing assay. Int. J. Biol. Macromol. 2019, 122, 238–254. [Google Scholar] [CrossRef]

- El-Hefnawy, M.E.; Alhayyani, S.; El-Sherbiny, M.M.; Sakran, M.I.; El-Newehy, M.H. Fabrication of Nanofibers Based on Hydroxypropyl Starch/Polyurethane Loaded with the Biosynthesized Silver Nanoparticles for the Treatment of Pathogenic Microbes in Wounds. Polymers 2022, 14, 318. [Google Scholar] [CrossRef]

- Liu, S.; Wu, G.; Wang, W.; Wang, H.; Gao, Y.; Yang, X. In Situ Electrospinning of “Dry-Wet” Conversion Nanofiber Dressings for Wound Healing. Mar. Drugs 2023, 21, 241. [Google Scholar]

- Chen, Z.; Xiao, L.; Hu, C.; Shen, Z.; Zhou, E.; Zhang, S.; Wang, Y. Aligned lovastatin-loaded electrospun nanofibers regulate collagen organization and reduce scar formation. Acta Biomater. 2023, 164, 240–252. [Google Scholar] [CrossRef]

- Ghorbani, M.; Nezhad-Mokhtari, P.; Ramazani, S. Aloe vera-loaded nanofibrous scaffold based on Zein/Polycaprolactone/Collagen for wound healing. Int. J. Biol. Macromol. 2020, 153, 921–930. [Google Scholar] [CrossRef]

- Lashkari, M.; Rahmani, M.; Yousefpoor, Y.; Ahmadi-Zeidabadi, M.; Faridi-Majidi, R.; Ameri, Z.; Salary, M.; Azizi, S.; Shahabi, A.; Rahi, A.; et al. Cell-based wound dressing: Bilayered PCL/gelatin nanofibers-alginate/collagen hydrogel scaffold loaded with mesenchymal stem cells. Int. J. Biol. Macromol. 2023, 239, 124099. [Google Scholar] [CrossRef]

- Yu, Q.; Shen, C.; Wang, X.; Wang, Z.; Liu, L.; Zhang, J. Graphene Oxide/Gelatin Nanofibrous Scaffolds Loaded with N-Acetyl Cysteine for Promoting Wound Healing. Int. J. Nanomed. 2023, 18, 563–578. [Google Scholar] [CrossRef]

- Li, P.; Ruan, L.; Jiang, G.; Sun, Y.; Wang, R.; Gao, X.; Yunusov, K.E.; Aharodnikau, U.E.; Solomevich, S.O. Design of 3D polycaprolactone/ε-polylysine-modified chitosan fibrous scaffolds with incorporation of bioactive factors for accelerating wound healing. Acta Biomater. 2022, 152, 197–209. [Google Scholar] [CrossRef]

- Casadidio, C.; Mayol, L.; Biondi, M.; Scuri, S.; Cortese, M.; Hennink, W.E.; Vermonden, T.; De Rosa, G.; Di Martino, P.; Censi, R. Anionic polysaccharides for stabilization and sustained release of antimicrobial peptides. Int. J. Pharm. 2023, 636, 122798. [Google Scholar] [CrossRef]

- Amokrane, G.; Humblot, V.; Jubeli, E.; Yagoubi, N.; Ramtani, S.; Migonney, V.; Falentin-Daudré, C. Electrospun Poly(ε-caprolactone) Fiber Scaffolds Functionalized by the Covalent Grafting of a Bioactive Polymer: Surface Characterization and Influence on in Vitro Biological Response. ACS Omega 2019, 4, 17194–17208. [Google Scholar] [CrossRef]

- Budi, H.S.; Davidyants, A.; Rudiansyah, M.; Ansari, M.J.; Suksatan, W.; Sultan, M.Q.; Jalil, A.T.; Kazemnejadi, M. Alendronate reinforced polycaprolactone-gelatin-graphene oxide: A promising nanofibrous scaffolds with controlled drug release. Mater. Today Commun. 2022, 32, 104108. [Google Scholar] [CrossRef]

- Chandika, P.; Oh, G.-W.; Heo, S.-Y.; Kim, S.-C.; Kim, T.-H.; Kim, M.-S.; Jung, W.-K. Electrospun porous bilayer nano-fibrous fish collagen/PCL bio-composite scaffolds with covalently cross-linked chitooligosaccharides for full-thickness wound-healing applications. Mater. Sci. Eng. C 2021, 121, 111871. [Google Scholar] [CrossRef]

- Beltrame, J.M.; Guindani, C.; Novy, M.G.; Felipe, K.B.; Sayer, C.; Pedrosa, R.C.; Hermes de Araújo, P.H. Covalently Bonded N-Acetylcysteine-polyester Loaded in PCL Scaffolds for Enhanced Interactions with Fibroblasts. ACS Appl. Bio Mater. 2021, 4, 1552–1562. [Google Scholar] [CrossRef]

- Kacvinská, K.; Pavliňáková, V.; Poláček, P.; Michlovská, L.; Blahnová, V.H.; Filová, E.; Knoz, M.; Lipový, B.; Holoubek, J.; Faldyna, M.; et al. Accelular nanofibrous bilayer scaffold intrapenetrated with polydopamine network and implemented into a full-thickness wound of a white-pig model affects inflammation and healing process. J. Nanobiotechnology 2023, 21, 80. [Google Scholar] [CrossRef]

- Kalwar, K.; Xi, J.; Ren, C.; Shen, M. Coating of Au@Ag on electrospun cellulose nanofibers for wound healing and antibacterial activity. Korean J. Chem. Eng. 2022, 39, 2165–2171. [Google Scholar] [CrossRef]

- Alizadeh, M.; Salehi, S.; Tavakoli, M.; Mirhaj, M.; Varshosaz, J.; Kazemi, N.; Salehi, S.; Mehrjoo, M.; Abadi, S.A.M. PDGF and VEGF-releasing bi-layer wound dressing made of sodium tripolyphosphate crosslinked gelatin-sponge layer and a carrageenan nanofiber layer. Int. J. Biol. Macromol. 2023, 233, 123491. [Google Scholar] [CrossRef]

- Sheng, Z.; Xu, Y.; Tong, Z.; Mao, Z.; Zheng, Y. Dual functional electrospun nanofiber membrane with ROS scavenging and revascularization ability for diabetic wound healing. Colloid Interface Sci. Commun. 2022, 48, 100620. [Google Scholar] [CrossRef]

- Táborská, J.; Blanquer, A.; Brynda, E.; Filová, E.; Stiborová, L.; Jenčová, V.; Havlíčková, K.; Riedelová, Z.; Riedel, T. PLCL/PCL Dressings with Platelet Lysate and Growth Factors Embedded in Fibrin for Chronic Wound Regeneration. Int. J. Nanomed. 2023, 18, 595–610. [Google Scholar] [CrossRef]

- Abdul Hameed, M.M.; Mohamed Khan, S.A.P.; Thamer, B.M.; Rajkumar, N.; El-Hamshary, H.; El-Newehy, M. Electrospun nanofibers for drug delivery applications: Methods and mechanism. Polym. Adv. Technol. 2023, 34, 6–23. [Google Scholar] [CrossRef]

- Jiffrin, R.; Razak, S.I.A.; Jamaludin, M.I.; Hamzah, A.S.A.; Mazian, M.A.; Jaya, M.A.T.; Nasrullah, M.Z.; Majrashi, M.; Theyab, A.; Aldarmahi, A.A.; et al. Electrospun Nanofiber Composites for Drug Delivery: A Review on Current Progresses. Polymers 2022, 14, 3725. [Google Scholar] [CrossRef]

- Abbasnezhad, N.; Kebdani, M.; Shirinbayan, M.; Champmartin, S.; Tcharkhtchi, A.; Kouidri, S.; Bakir, F. Development of a Model Based on Physical Mechanisms for the Explanation of Drug Release: Application to Diclofenac Release from Polyurethane Films. Polymers 2021, 13, 1230. [Google Scholar] [CrossRef]

- Wang, L.; Yang, J.; Ran, B.; Yang, X.; Zheng, W.; Long, Y.; Jiang, X. Small Molecular TGF-β1-Inhibitor-Loaded Electrospun Fibrous Scaffolds for Preventing Hypertrophic Scars. ACS Appl. Mater. Interfaces 2017, 9, 32545–32553. [Google Scholar] [CrossRef]

- Tavakoli, M.; Mirhaj, M.; Salehi, S.; Varshosaz, J.; Labbaf, S.; Golshirazi, A.; Kazemi, N.; Haghighi, V. Coaxial electrospun angiogenic nanofiber wound dressing containing advanced platelet rich-fibrin. Int. J. Biol. Macromol. 2022, 222, 1605–1618. [Google Scholar] [CrossRef]

- Zhang, D.; Li, L.; Shan, Y.; Xiong, J.; Hu, Z.; Zhang, Y.; Gao, J. In vivo study of silk fibroin/gelatin electrospun nanofiber dressing loaded with astragaloside IV on the effect of promoting wound healing and relieving scar. J. Drug Deliv. Sci. Technol. 2019, 52, 272–281. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, W.; Wang, W.; Xiao, Y.; Chen, Y.; Wang, X. Antibacterial Electrospun Nanofibrous Materials for Wound Healing. Adv. Fiber Mater. 2023, 5, 107–129. [Google Scholar] [CrossRef]

- Guo, B.; Dong, R.; Liang, Y.; Li, M. Haemostatic materials for wound healing applications. Nat. Rev. Chem. 2021, 5, 773–791. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, L.; Ling, J.; Yang, L.-Y.; Ouyang, X.-K. A quaternized chitosan and carboxylated cellulose nanofiber-based sponge with a microchannel structure for rapid hemostasis and wound healing. Int. J. Biol. Macromol. 2023, 233, 123631. [Google Scholar] [CrossRef]

- Nepal, A.; Tran, H.D.N.; Nguyen, N.-T.; Ta, H.T. Advances in haemostatic sponges: Characteristics and the underlying mechanisms for rapid haemostasis. Bioact. Mater. 2023, 27, 231–256. [Google Scholar] [CrossRef]

- Teixeira, M.A.; Antunes, J.C.; Seabra, C.L.; Fertuzinhos, A.; Tohidi, S.D.; Reis, S.; Amorim, M.T.P.; Ferreira, D.P.; Felgueiras, H.P. Antibacterial and hemostatic capacities of cellulose nanocrystalline-reinforced poly(vinyl alcohol) electrospun mats doped with Tiger 17 and pexiganan peptides for prospective wound healing applications. Biomater. Adv. 2022, 137, 212830. [Google Scholar] [CrossRef]

- Yu, X.; Gao, Z.; Mu, J.; Lian, H.; Meng, Z. Gelatin/calcium chloride electrospun nanofibers for rapid hemostasis. Biomater Sci. 2023, 11, 2158–2166. [Google Scholar] [CrossRef]

- Barbosa, R.; Villarreal, A.; Rodriguez, C.; De Leon, H.; Gilkerson, R.; Lozano, K. Aloe Vera extract-based composite nanofibers for wound dressing applications. Mater. Sci. Eng. C 2021, 124, 112061. [Google Scholar] [CrossRef]

- Davoudabadi, M.; Fahimirad, S.; Ganji, A.; Abtahi, H. Wound healing and antibacterial capability of electrospun polyurethane nanofibers incorporating Calendula officinalis and Propolis extracts. J. Biomater. Sci. Polym. Ed. 2023, 1–26. [Google Scholar] [CrossRef]

- Liu, L.; Wang, W.; Hong, W.; Jin, Y.; Wang, L.; Liu, S.; Wang, A.; Liu, X. Photothermal 2D Nanosheets Combined With Astragaloside IV for Antibacterial Properties and Promoting Angiogenesis to Treat Infected Wounds. Front. Bioeng. Biotechnol. 2022, 9, 826011. [Google Scholar] [CrossRef]

- Osanloo, M.; Noori, F.; Tavassoli, A.; Ataollahi, M.R.; Davoodi, A.; Seifalah-Zade, M.; Taghinezhad, A.; Fereydouni, N.; Goodarzi, A. Effect of PCL nanofiber mats coated with chitosan microcapsules containing cinnamon essential oil for wound healing. BMC Complement. Med. Ther. 2023, 23, 84. [Google Scholar] [CrossRef]

- Wang, Z.; You, W.; Wang, W.; Tian, W.; Chen, F.; Xiao, Y.; Chen, Y.; Wang, X. Dihydromyricetin-Incorporated Multilayer Nanofibers Accelerate Chronic Wound Healing by Remodeling the Harsh Wound Microenvironment. Adv. Fiber Mater. 2022, 4, 1556–1571. [Google Scholar] [CrossRef]

- Wu, K.; Wu, X.; Guo, J.; Jiao, Y.; Zhou, C. Facile Polyphenol–Europium Assembly Enabled Functional Poly(l-Lactic Acid) Nanofiber Mats with Enhanced Antioxidation and Angiogenesis for Accelerated Wound Healing. Adv. Healthc. Mater. 2021, 10, 2100793. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, J.; Liu, Y.; Li, Y.; Zhang, C.; Qi, W.; Yeung, K.W.K.; Wong, T.M.; Zhao, X.; Pan, H. Electrospun chitosan/PVA/bioglass Nanofibrous membrane with spatially designed structure for accelerating chronic wound healing. Mater. Sci. Eng. C 2019, 105, 110083. [Google Scholar] [CrossRef]

- Yu, H.; Li, Y.; Pan, Y.; Wang, H.; Wang, W.; Ren, X.; Yuan, H.; Lv, Z.; Zuo, Y.; Liu, Z.; et al. Multifunctional porous poly (L-lactic acid) nanofiber membranes with enhanced anti-inflammation, angiogenesis and antibacterial properties for diabetic wound healing. J. Nanobiotechnology 2023, 21, 110. [Google Scholar] [CrossRef]

- Sun, L.; Gao, W.; Fu, X.; Shi, M.; Xie, W.; Zhang, W.; Zhao, F.; Chen, X. Enhanced wound healing in diabetic rats by nanofibrous scaffolds mimicking the basketweave pattern of collagen fibrils in native skin. Biomater. Sci. 2018, 6, 340–349. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Q.; Hou, G.; Wang, C.; Yan, H. Sustained release of EGF/bFGF growth factors achieved by mussel-inspired core–shell nanofibers with hemostatic and anti-inflammatory effects for promoting wound healing. Eur. Polym. J. 2023, 190, 112003. [Google Scholar] [CrossRef]

- Atila, D.; Karataş, A.; Keskin, D.; Tezcaner, A. Pullulan hydrogel-immobilized bacterial cellulose membranes with dual-release of vitamin C and E for wound dressing applications. Int. J. Biol. Macromol. 2022, 218, 760–774. [Google Scholar] [CrossRef]

- Yalcınkaya, E.; Basaran, M.M.; Tunckasık, M.E.; Yazici, G.N.; Elmas, Ç.; Kocaturk, S. Efficiency of hypericum perforatum, povidone iodine, tincture benzoin and tretinoin on wound healing. Food Chem. Toxicol. 2022, 166, 113209. [Google Scholar] [CrossRef]

- Farzanfar, S.; Kouzekonan, G.S.; Mirjani, R.; Shekarchi, B. Vitamin B12-loaded polycaprolacton/gelatin nanofibrous scaffold as potential wound care material. Biomed. Eng. Lett. 2020, 10, 547–554. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, L.; Zhang, Q.; Li, H.; Xiang, Y.; Wang, X.; Hu, X. Effective electrical stimulation by a Poly(l-lactic acid)/Vitamin B2-Based piezoelectric generator promotes wound healing. Eur. Polym. J. 2023, 189, 111962. [Google Scholar] [CrossRef]

- Polcz, M.E.; Barbul, A. The Role of Vitamin A in Wound Healing. Nutr. Clin. Pract. 2019, 34, 695–700. [Google Scholar] [CrossRef]

- Jose, J.; Pai, A.R.; Gopakumar, D.A.; Dalvi, Y.; Ruby, V.; Bhat, S.G.; Pasquini, D.; Kalarikkal, N.; Thomas, S. Novel 3D porous aerogels engineered at nano scale from cellulose nano fibers and curcumin: An effective treatment for chronic wounds. Carbohydr. Polym. 2022, 287, 119338. [Google Scholar] [CrossRef]

- Li, J.; Xiao, L.; Gao, S.; Huang, H.; Lei, Q.; Chen, Y.; Chen, Z.; Xue, L.; Yan, F.; Cai, L. Radial Sponges Facilitate Wound Healing by Promoting Cell Migration and Angiogenesis. Adv. Healthc. Mater. 2023, 2202737. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, T.; Zhang, J.; Feng, Z.; Yin, M.; Mo, X. A bilayer vascular scaffold with spatially controlled release of growth factors to enhance in situ rapid endothelialization and smooth muscle regeneration. Mater. Des. 2021, 204, 109649. [Google Scholar] [CrossRef]

- Ardila, D.C.; Tamimi, E.; Doetschman, T.; Wagner, W.R.; Vande Geest, J.P. Modulating smooth muscle cell response by the release of TGFβ2 from tubular scaffolds for vascular tissue engineering. J. Control Release 2019, 299, 44–52. [Google Scholar] [CrossRef]

- Kim, K.; Mahajan, A.; Patel, K.; Syed, S.; Acevedo-Jake, A.M.; Kumar, V.A. Materials and Cytokines in the Healing of Diabetic Foot Ulcers. Adv. Ther. 2021, 4, 2100075. [Google Scholar] [CrossRef]

- Menicacci, B.; Margheri, F.; Laurenzana, A.; Chillà, A.; Del Rosso, M.; Giovannelli, L.; Fibbi, G.; Mocali, A. Chronic Resveratrol Treatment Reduces the Pro-angiogenic Effect of Human Fibroblast “Senescent-Associated Secretory Phenotype” on Endothelial Colony-Forming Cells: The Role of IL8. J. Gerontol. A Biol. Sci. Med. Sci. 2019, 74, 625–633. [Google Scholar] [CrossRef]

- Vijayan, V.; Sreekumar, S.; Singh, F.; Govindarajan, D.; Lakra, R.; Korrapati, P.S.; Kiran, M.S. Praseodymium-Cobaltite-Reinforced Collagen as Biomimetic Scaffolds for Angiogenesis and Stem Cell Differentiation for Cutaneous Wound Healing. ACS Appl. Bio Mater. 2019, 2, 3458–3472. [Google Scholar] [CrossRef]

- Long, G.; Liu, D.; He, X.; Shen, Y.; Zhao, Y.; Hou, X.; Chen, B.; OuYang, W.; Dai, J.; Li, X. A dual functional collagen scaffold coordinates angiogenesis and inflammation for diabetic wound healing. Biomater. Sci. 2020, 8, 6337–6349. [Google Scholar] [CrossRef]

- Zhan, A.; Chen, L.; Sun, W.; Tang, Y.; Chen, J.; Yu, D.; Zhang, W. Enhancement of diabetic wound healing using a core-shell nanofiber platform with sequential antibacterial, angiogenic, and collagen deposition activities. Mater. Des. 2022, 218, 110660. [Google Scholar] [CrossRef]

- Liu, M.; Wei, X.; Zheng, Z.; Li, Y.; Li, M.; Lin, J.; Yang, L. Recent Advances in Nano-Drug Delivery Systems for the Treatment of Diabetic Wound Healing. Int. J. Nanomed. 2023, 18, 1537–1560. [Google Scholar] [CrossRef]

- Wei, X.; Li, M.; Zheng, Z.; Ma, J.; Gao, Y.; Chen, L.; Peng, Y.; Yu, S.; Yang, L. Senescence in chronic wounds and potential targeted therapies. Burn. Trauma 2022, 10, tkab045. [Google Scholar] [CrossRef]

- Mohd Razali, N.A.; Lin, W.-C. Accelerating the excisional wound closure by using the patterned microstructural nanofibrous mats/gentamicin-loaded hydrogel composite scaffold. Mater. Today Bio 2022, 16, 100347. [Google Scholar] [CrossRef]

- Horue, M.; Cacicedo, M.L.; Fernandez, M.A.; Rodenak-Kladniew, B.; Torres Sánchez, R.M.; Castro, G.R. Antimicrobial activities of bacterial cellulose—Silver montmorillonite nanocomposites for wound healing. Mater. Sci. Eng. C 2020, 116, 111152. [Google Scholar] [CrossRef]

- Rafi, R.; Zulfiqar, S.; Asad, M.; Zeeshan, R.; Zehra, M.; Khalid, H.; Akhtar, N.; Yar, M. Smart wound dressings based on carbon doped copper nanoparticles for selective bacterial detection and eradication for efficient wound healing application. Mater. Today Commun. 2023, 35, 105914. [Google Scholar] [CrossRef]

- Zhu, C.; Cao, R.; Zhang, Y.; Chen, R. Metallic Ions Encapsulated in Electrospun Nanofiber for Antibacterial and Angiogenesis Function to Promote Wound Repair. Front. Cell Dev. Biol. 2021, 9, 660571. [Google Scholar] [CrossRef]

- Han, Z.; Deng, L.; Chen, S.; Wang, H.; Huang, Y. Zn2+-Loaded adhesive bacterial cellulose hydrogel with angiogenic and antibacterial abilities for accelerating wound healing. Burn. Trauma 2023, 11, tkac048. [Google Scholar] [CrossRef]

- He, W.; Wang, X.; Hang, T.; Chen, J.; Wang, Z.; Mosselhy, D.A.; Xu, J.; Wang, S.; Zheng, Y. Fabrication of Cu2+-loaded phase-transited lysozyme nanofilm on bacterial cellulose: Antibacterial, anti-inflammatory, and pro-angiogenesis for bacteria-infected wound healing. Carbohydr. Polym. 2023, 309, 120681. [Google Scholar] [CrossRef]

- Kumar, G.; Khan, F.G.; Abro, M.I.; Aftab, U.; Jatoi, A.W. Development of cellulose acetate/CuO/AgNP nanofibers based effective antimicrobial wound dressing. Compos. Commun. 2023, 39, 101550. [Google Scholar] [CrossRef]

- Alharthi, A.F.; Gouda, M.; Khalaf, M.M.; Elmushyakhi, A.; Abou Taleb, M.F.; Abd El-Lateef, H.M. Cellulose-Acetate-Based Films Modified with Ag2O and ZnS as Nanocomposites for Highly Controlling Biological Behavior for Wound Healing Applications. Materials 2023, 16, 777. [Google Scholar] [CrossRef]

- Wu, J.; Liu, F.; Chen, C.; Zhao, Z.; Du, Y.; Shi, X.; Wu, Y.; Deng, H. Long-term antibacterial activity by synergistic release of biosafe lysozyme and chitosan from LBL-structured nanofibers. Carbohydr. Polym. 2023, 312, 120791. [Google Scholar] [CrossRef]

- Kono, H.; Sogame, Y.; Purevdorj, U.-E.; Ogata, M.; Tajima, K. Bacterial Cellulose Nanofibers Modified with Quaternary Ammonium Salts for Antimicrobial Applications. ACS Appl. Nano Mater. 2023, 6, 4854–4863. [Google Scholar] [CrossRef]

- Pal-Ghosh, S.; Karpinski, B.A.; Datta Majumdar, H.; Ghosh, T.; Thomasian, J.; Brooks, S.R.; Sawaya, A.P.; Morasso, M.I.; Scholand, K.K.; de Paiva, C.S.; et al. Molecular mechanisms regulating wound repair: Evidence for paracrine signaling from corneal epithelial cells to fibroblasts and immune cells following transient epithelial cell treatment with Mitomycin C. Exp. Eye Res. 2023, 227, 109353. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, M.; Zhu, T.; Xiong, H.; Zhu, L.-M. A careob-like nanofibers with a sustained drug release profile for promoting skin wound repair and inhibiting hypertrophic scar. Compos. Part B Eng. 2022, 236, 109790. [Google Scholar] [CrossRef]

- Pandey, V.K.; Ajmal, G.; Upadhyay, S.N.; Mishra, P.K. Nano-fibrous scaffold with curcumin for anti-scar wound healing. Int. J. Pharm. 2020, 589, 119858. [Google Scholar] [CrossRef]

- Li, H.; Li, B.; Lv, D.; Li, W.; Lu, Y.; Luo, G. Biomaterials releasing drug responsively to promote wound healing via regulation of pathological microenvironment. Adv. Drug Deliv. Rev. 2023, 196, 114778. [Google Scholar] [CrossRef]

- Pan, Y.; Qi, K.; Fu, J.; Gao, W.; Li, Z.; Lin, Z. Editorial: Bioresponsive nanomaterials for drug delivery or controlled release. Front. Bioeng. Biotechnol. 2023, 11, 1165782. [Google Scholar] [CrossRef]

- Cui, L.; Wang, X.; Liu, Z.; Li, Z.; Bai, Z.; Lin, K.; Yang, J.; Cui, Y.; Tian, F. Metal-organic framework decorated with glycyrrhetinic acid conjugated chitosan as a pH-responsive nanocarrier for targeted drug delivery. Int. J. Biol. Macromol. 2023, 240, 124370. [Google Scholar] [CrossRef]

- Liang, Y.; Zhu, H.; Wang, L.; He, H.; Wang, S. Biocompatible smart cellulose nanofibres for sustained drug release via pH and temperature dual-responsive mechanism. Carbohydr. Polym. 2020, 249, 116876. [Google Scholar] [CrossRef]

- Kamsani, N.H.; Haris, M.S.; Pandey, M.; Taher, M.; Rullah, K. Biomedical application of responsive ‘smart’ electrospun nanofibers in drug delivery system: A minireview. Arab. J. Chem. 2021, 14, 103199. [Google Scholar] [CrossRef]

- Dong, D.; Chen, R.; Jia, J.; Zhao, C.; Chen, Z.; Lu, Q.; Sun, Y.; Huang, W.; Wang, C.; Li, Y.; et al. Tailoring and application of a multi-responsive cellulose nanofibre-based 3D nanonetwork wound dressing. Carbohydr. Polym. 2023, 305, 120542. [Google Scholar] [CrossRef]

- Han, Z.; Yuan, M.; Liu, L.; Zhang, K.; Zhao, B.; He, B.; Liang, Y.; Li, F. pH-Responsive wound dressings: Advances and prospects. Nanoscale Horiz. 2023, 8, 422–440. [Google Scholar] [CrossRef]

- Altinbasak, I.; Kocak, S.; Colby, A.H.; Alp, Y.; Sanyal, R.; Grinstaff, M.W.; Sanyal, A. pH-Responsive nanofiber buttresses as local drug delivery devices. Biomater. Sci. 2023, 11, 813–821. [Google Scholar] [CrossRef]

- Singh, B.; Shukla, N.; Kim, J.; Kim, K.; Park, M.-H. Stimuli-Responsive Nanofibers Containing Gold Nanorods for On-Demand Drug Delivery Platforms. Pharmaceutics 2021, 13, 1319. [Google Scholar] [CrossRef]

- Wang, X.; Yu, Y.; Yang, C.; Shang, L.; Zhao, Y.; Shen, X. Dynamically Responsive Scaffolds from Microfluidic 3D Printing for Skin Flap Regeneration. Adv. Sci. 2022, 9, e2201155. [Google Scholar] [CrossRef]

- Pang, Q.; Zheng, X.; Luo, Y.; Ma, L.; Gao, C. A photo-cleavable polyprodrug-loaded wound dressing with UV-responsive antibacterial property. J. Mater. Chem. B 2017, 5, 8975–8982. [Google Scholar] [CrossRef]

- Siebert, L.; Luna-Cerón, E.; García-Rivera, L.E.; Oh, J.; Jang, J.; Rosas-Gómez, D.A.; Pérez-Gómez, M.D.; Maschkowitz, G.; Fickenscher, H.; Oceguera-Cuevas, D.; et al. Smart Wound Scaffolds: Light-Controlled Growth Factors Release on Tetrapodal ZnO-Incorporated 3D-Printed Hydrogels for Developing Smart Wound Scaffold (Adv. Funct. Mater. 22/2021). Adv. Funct. Mater. 2021, 31, 2170154. [Google Scholar] [CrossRef]

- Liang, Y.; Ogawa, S.; Inaba, H.; Matsuura, K. Dramatic morphological changes in liposomes induced by peptide nanofibers reversibly polymerized and depolymerized by the photoisomerization of spiropyran. Front. Mol. Biosci. 2023, 10, 1137885. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Z.; Wei, X.; Chen, B.; Luo, Y. 3D printed hydrogel/PCL core/shell fiber scaffolds with NIR-triggered drug release for cancer therapy and wound healing. Acta Biomater. 2021, 131, 314–325. [Google Scholar] [CrossRef]

- Azlan, A.Y.H.N.; Katas, H.; Busra, M.F.M.; Salleh, N.A.M.; Smandri, A. Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy. Nanotechnol. Rev. 2021, 10, 653–670. [Google Scholar] [CrossRef]

- Jin, L.; Guo, X.; Gao, D.; Wu, C.; Hu, B.; Tan, G.; Du, N.; Cai, X.; Yang, Z.; Zhang, X. NIR-responsive MXene nanobelts for wound healing. NPG Asia Mater. 2021, 13, 24. [Google Scholar] [CrossRef]

- Croitoru, A.-M.; Karaçelebi, Y.; Saatcioglu, E.; Altan, E.; Ulag, S.; Aydoğan, H.K.; Sahin, A.; Motelica, L.; Oprea, O.; Tihauan, B.-M.; et al. Electrically Triggered Drug Delivery from Novel Electrospun Poly(Lactic Acid)/Graphene Oxide/Quercetin Fibrous Scaffolds for Wound Dressing Applications. Pharmaceutics 2021, 13, 957. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, H.; Liyanage, A.; Qiu, J.; Thushara, D.; Bao, B.; Zhao, S. Collective diffusion of charged nanoparticles in microchannel under electric field. Chem. Eng. Sci. 2022, 248, 117264. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, L.; Wang, J.; Cheng, Y.; Chen, Z.; Yang, R.; Zhao, G. Coaxial structured drug loaded dressing combined with induced stem cell differentiation for enhanced wound healing. Biomater. Adv. 2022, 134, 112542. [Google Scholar] [CrossRef]

- Chanthiwong, M.; Mongkolthanaruk, W.; Eichhorn, S.J.; Pinitsoontorn, S. Controlling the processing of co-precipitated magnetic bacterial cellulose/iron oxide nanocomposites. Mater. Des. 2020, 196, 109148. [Google Scholar] [CrossRef]

- Haniffa, M.A.C.M.; Munawar, K.; Chee, C.Y.; Pramanik, S.; Halilu, A.; Illias, H.A.; Rizwan, M.; Senthilnithy, R.; Mahanama, K.R.R.; Tripathy, A.; et al. Cellulose supported magnetic nanohybrids: Synthesis, physicomagnetic properties and biomedical applications-A review. Carbohydr. Polym. 2021, 267, 118136. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Habibovic, P. Magnetically responsive nanofibrous ceramic scaffolds for on-demand motion and drug delivery. Bioact. Mater. 2022, 15, 372–381. [Google Scholar] [CrossRef]

- Rahmati, M.; Blaker, J.J.; Lyngstadaas, S.P.; Mano, J.F.; Haugen, H.J. Designing multigradient biomaterials for skin regeneration. Mater. Today Adv. 2020, 5, 100051. [Google Scholar] [CrossRef]

- Ghosh, S.; Haldar, S.; Gupta, S.; Chauhan, S.; Mago, V.; Roy, P.; Lahiri, D. Single unit functionally graded bioresorbable electrospun scaffold for scar-free full-thickness skin wound healing. Biomater. Adv. 2022, 139, 212980. [Google Scholar] [CrossRef]

- Rizzo, F.; Kehr, N.S. Recent Advances in Injectable Hydrogels for Controlled and Local Drug Delivery. Adv. Health Mater. 2021, 10, e2001341. [Google Scholar] [CrossRef]

- Motealleh, A.; Kart, D.; Czieborowski, M.; Kehr, N.S. Functional Nanomaterials and 3D-Printable Nanocomposite Hydrogels for Enhanced Cell Proliferation and for the Reduction of Bacterial Biofilm Formation. ACS Appl. Mater. Interfaces 2021, 13, 43755–43768. [Google Scholar] [CrossRef]

- Xuan, H.; Wu, S.; Fei, S.; Li, B.; Yang, Y.; Yuan, H. Injectable nanofiber-polysaccharide self-healing hydrogels for wound healing. Mater. Sci. Eng. C Mater. Biol. Appl. 2021, 128, 112264. [Google Scholar] [CrossRef]

- Ding, Z.; Zhang, Y.; Guo, P.; Duan, T.; Cheng, W.; Guo, Y.; Zheng, X.; Lu, G.; Lu, Q.; Kaplan, D.L. Injectable Desferrioxamine-Laden Silk Nanofiber Hydrogels for Accelerating Diabetic Wound Healing. ACS Biomater. Sci. Eng. 2021, 7, 1147–1158. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, A.; Chauhan, N.S.; Yadav, G.; Goswami, M.; Packirisamy, G. Design and Fabrication of a Dual Protein-Based Trilayered Nanofibrous Scaffold for Efficient Wound Healing. ACS Appl. Bio Mater. 2022, 5, 2726–2740. [Google Scholar] [CrossRef]

- Tiwari, R.; Pathak, K. Local Drug Delivery Strategies towards Wound Healing. Pharmaceutics 2023, 15, 634. [Google Scholar] [CrossRef]

- Leng, Q.; Li, Y.; Pang, X.; Wang, B.; Wu, Z.; Lu, Y.; Xiong, K.; Zhao, L.; Zhou, P.; Fu, S. Curcumin nanoparticles incorporated in PVA/collagen composite films promote wound healing. Drug Deliv. 2020, 27, 1676–1685. [Google Scholar] [CrossRef]

- Alberti, T.B.; Coelho, D.S.; de Prá, M.; Maraschin, M.; Veleirinho, B. Electrospun PVA nanoscaffolds associated with propolis nanoparticles with wound healing activity. J. Mater. Sci. 2020, 55, 9712–9727. [Google Scholar] [CrossRef]

- Gao, F.; Li, W.; Deng, J.; Kan, J.; Guo, T.; Wang, B.; Hao, S. Recombinant Human Hair Keratin Nanoparticles Accelerate Dermal Wound Healing. ACS Appl. Mater. Interfaces 2019, 11, 18681–18690. [Google Scholar] [CrossRef]

- Koivuniemi, R.; Hakkarainen, T.; Kiiskinen, J.; Kosonen, M.; Vuola, J.; Valtonen, J.; Luukko, K.; Kavola, H.; Yliperttula, M. Clinical Study of Nanofibrillar Cellulose Hydrogel Dressing for Skin Graft Donor Site Treatment. Adv. Wound Care 2020, 9, 199–210. [Google Scholar] [CrossRef]

| Pros | Cons | References | |||

|---|---|---|---|---|---|

| Natural polymer | Proteinaceous polymers | Collagen | Good biocompatibility Good biodegradability Possesses natural bioactivity | Poor customizability, Significant batch-to-batch variations, Inferior mechanical properties | [73] |

| Fibrinogen | [74] | ||||

| Elastin | [75] | ||||

| Keratin | [76] | ||||

| Soy protein | [77] | ||||

| Silk protein | [78] | ||||

| Gelatin | [79] | ||||

| Peanut protein isolate | [80] | ||||

| Polysaccharide polymers | Chitosan | [81] | |||

| Dextran | [82] | ||||

| Agarose | [83] | ||||

| Starch | [84] | ||||

| Sulfated alginates | [85] | ||||

| Alginate | [78] | ||||

| Iota carrageenan | [86] | ||||

| Kappa carrageenan | [87] | ||||

| Hyaluronic acid | [88] | ||||

| Bacterial cellulose(BC) | [89] | ||||

| Plant cellulose(PC) | [90] | ||||

| Cellulose acetate (CA) | [91] | ||||

| Xanthan gum | [92] | ||||

| polydeoxyribonucleotides (PDRN) | [93] | ||||

| Cashew gum(CG) | [94] | ||||

| Chondroitin sulfate | [95] | ||||

| Synthetic polymers | Polylactic acid (PLA) | High customizability, High repeatability, Good mechanical properties | Poor biocompatibility, Difficult to degrade or rapid degradation, Lack of natural bioactivity | [96] | |

| Poly-L-lactic acid(PLLA) | [80] | ||||

| Polyglycolic acid (PGA) | [97] | ||||

| Poly(lactic-co-glycolic) acid (PLGA) | [98] | ||||

| ε-Polycaprolactone (PCL) | [99] | ||||

| Poly(L-lactic acid-co-ε-caprolactone) (PLCL) | [100] | ||||

| Polyurethane (PU) | [101] | ||||

| Poly(pyrogallol) | [102] | ||||

| Polyethylene glycol (PEG) | [103] | ||||

| Polyhydroxybutyrate (PHB) | [104] | ||||

| polyhydroxyalkanoate (PHA) | [105] | ||||

| Polyvinyl alcohol (PVA) | [94] | ||||

| Polyvinylpyrrolidone (PVP) | [106] | ||||

| Polysuccinimide (PSI) | [107] | ||||

| Poly(ethylene oxide) (PEO) | [108] | ||||

| Polysulfone | [109] | ||||

| Polythiophenen | [21] | ||||

| Aromatic polyimide | [110] | ||||

| Aramid | [111] | ||||

| Polyacrylonitrile(PAN) | [112] | ||||

| Poly(ether-ether-ketone) | [113] | ||||

| Polyimide | [114] | ||||

| Scaffold Material | Additional Polymer | Bioactive Ingredients | Highlights | References |

|---|---|---|---|---|

| Alginate | PCL | Ag NPs, plasmid DNA encoding platelet-derived growth factor-B (PDGF-B), polyethyleneimine (PEI) | Highly absorbent alginate provides a moist environment for the wound, PCL increases cell adhesion, and the scaffold adsorbs drugs through electrostatic interactions. | [164] |

| Silk Fibroin | Lactobacillus casei | Lactobacillus casei-loaded scaffolds introduce lactic acid with antimicrobial and wound-healing properties. In vitro, the cell-free supernatant of Lactobacillus casei inhibited the conversion of fibroblasts to myofibroblasts and attenuated endoplasmic reticulum stress. | [78] | |

| Gelatin | hydroxyl-rich silica nanoparticles | The incorporation of hydroxyl-rich silica nanoparticles into the sodium alginate/gelatin composite fiber greatly improved the hydrophilic, toughness, and axial shrinkage properties of the fiber. This fiber exhibits dynamic shrinkage behavior with humidity and can adapt to different wound shapes. | [165] | |