Advanced Manufacturing Methods for High-Dose Inhalable Powders

Abstract

:1. Introduction

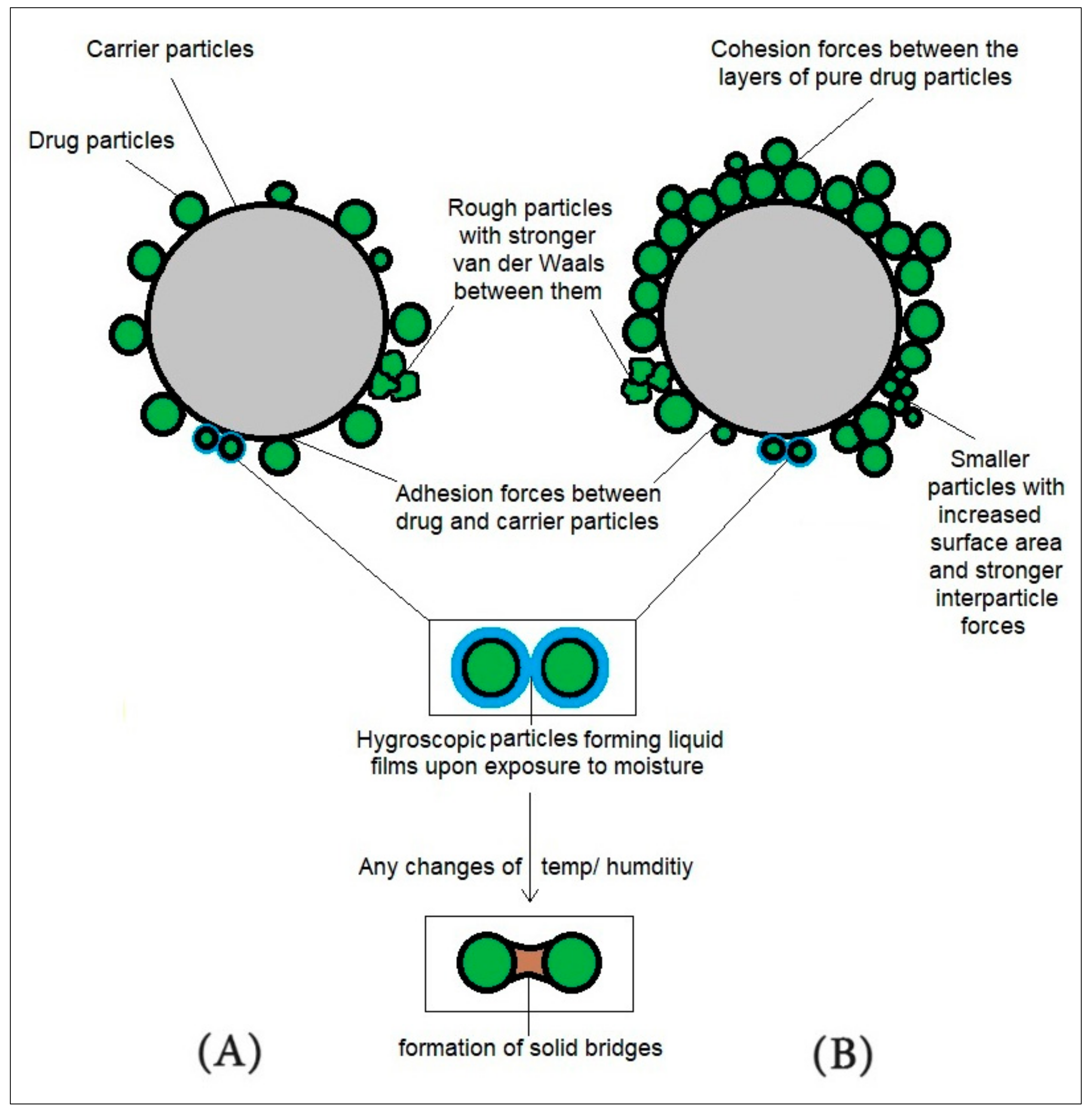

2. Challenges During Preparation and Formulation of Fine Powder

3. Particle Engineering Techniques for High-Dose Powders

3.1. Mechanofusion

3.2. Spray Drying

3.3. Supercritical Fluid Crystallization

3.4. Spray-Freeze Drying

3.5. Thin-Film Freezing

3.6. Isothermal Dry Particle Coating (iDPC)

4. Characterisation Techniques for Inhalation Formulations

4.1. Dissolution and Permeability Testing

4.2. Particle Size Distribution

4.3. Powder X-Ray Diffraction (PXRD)

4.4. Scanning Electron Microscopy (SEM)

4.5. Powder Flowability

4.6. Atomic Force Microscopy (AFM)

4.7. Solid-State Nuclear Magnetic Resonance (ssNMR) Spectroscopy

4.8. Fourier-Transform Infrared Spectroscopy (FT-IR) and Raman Spectroscopy (FT-Raman) Spectroscopy

4.9. Water Content Analysis

4.10. Zeta Potential Measurement

5. Conclusions and Perspectives

Funding

Conflicts of Interest

References

- Hoppentocht, M.; Hagedoorn, P.; Frijlink, H.; de Boer, A. Technological and practical challenges of dry powder inhalers and formulations. Adv. Drug Deliv. Rev. 2014, 75, 18–31. [Google Scholar] [CrossRef]

- Ye, Y.; Ma, Y.; Zhu, J. The future of dry powder inhaled therapy: Promising or discouraging for systemic disorders? Int. J. Pharm. 2022, 614, 121457. [Google Scholar] [CrossRef]

- Shetty, N.; Cipolla, D.; Park, H.; Zhou, Q.T. Physical stability of dry powder inhaler formulations. Expert Opin. Drug Deliv. 2020, 17, 77–96. [Google Scholar] [CrossRef]

- Mönckedieck, M.; Kamplade, J.; Fakner, P.; Urbanetz, N.A.; Walzel, P.; Steckel, H.; Scherließ, R. Dry powder inhaler performance of spray dried mannitol with tailored surface morphologies as carrier and salbutamol sulphate. Int. J. Pharm. 2017, 524, 351–363. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Connaughton, P.; Lachacz, K.; Carrigy, N.; Ordoubadi, M.; Lechuga-Ballesteros, D.; Vehring, R. Inhalable microparticle platform based on a novel shell-forming lipid excipient and its feasibility for respirable delivery of biologics. Eur. J. Pharm. Biopharm. 2022, 177, 308–322. [Google Scholar] [CrossRef] [PubMed]

- Adhikari, B.R.; Gordon, K.C.; Das, S.C. Solid state of inhalable high dose powders. Adv. Drug Deliv. Rev. 2022, 189, 114468. [Google Scholar] [CrossRef]

- Sibum, I.; Hagedoorn, P.; de Boer, A.H.; Frijlink, H.W.; Grasmeijer, F. Challenges for pulmonary delivery of high powder doses. Int. J. Pharm. 2018, 548, 325–336. [Google Scholar] [CrossRef] [PubMed]

- Tena, A.F.; Clarà, P.C. Deposition of Inhaled Particles in the Lungs. Arch. Bronconeumol. (Engl. Ed.) 2012, 48, 240–246. [Google Scholar] [CrossRef]

- Park, H.; Ha, E.-S.; Kim, M.-S. Surface modification strategies for high-dose dry powder inhalers. J. Pharm. Investig. 2021, 51, 635–668. [Google Scholar] [CrossRef]

- Rahimpour, Y.; Kouhsoltani, M.; Hamishehkar, H. Alternative carriers in dry powder inhaler formulations. Drug Discov. Today 2014, 19, 618–626. [Google Scholar] [CrossRef]

- Guo, Q.; Yang, Z.; Zhang, J. Influence of a combined external field on the agglomeration of inhalable particles from a coal combustion plant. Powder Technol. 2012, 227, 67–73. [Google Scholar] [CrossRef]

- Lohrmann, M.; Kappl, M.; Butt, H.-J.; Urbanetz, N.A.; Lippold, B.C. Adhesion forces in interactive mixtures for dry powder inhalers—Evaluation of a new measuring method. Eur. J. Pharm. Biopharm. 2007, 67, 579–586. [Google Scholar] [CrossRef]

- Spahn, J.E.; Zhang, F.; Smyth, H.D. Mixing of dry powders for inhalation: A review. Int. J. Pharm. 2022, 619, 121736. [Google Scholar] [CrossRef]

- Skoglund, S.; Hedberg, J.; Yunda, E.; Godymchuk, A.; Blomberg, E.; Wallinder, I.O. Difficulties and flaws in performing accurate determinations of zeta potentials of metal nanoparticles in complex solutions—Four case studies. PLoS ONE 2017, 12, e0181735. [Google Scholar] [CrossRef]

- Bouzakher Ghomrasni, N.; Chivas-Joly, C.; Devoille, L.; Hochepied, J.-F.; Feltin, N. Challenges in sample preparation for measuring nanoparticles size by scanning electron microscopy from suspensions, powder form and complex media. Powder Technol. 2020, 359, 226–237. [Google Scholar] [CrossRef]

- Chen, L.; Okuda, T.; Lu, X.-Y.; Chan, H.-K. Amorphous powders for inhalation drug delivery. Adv. Drug Deliv. Rev. 2016, 100, 102–115. [Google Scholar] [CrossRef] [PubMed]

- Raganati, F.; Chirone, R.; Ammendola, P. Gas–solid fluidization of cohesive powders. Chem. Eng. Res. Des. 2018, 133, 347–387. [Google Scholar] [CrossRef]

- Karner, S.; Maier, M.; Littringer, E.; Urbanetz, N.A. Surface roughness effects on the tribo-charging and mixing homogeneity of adhesive mixtures used in dry powder inhalers. Powder Technol. 2014, 264, 544–549. [Google Scholar] [CrossRef]

- ElKasabgy, N.A.; Adel, I.M.; Elmeligy, M.F. Respiratory Tract: Structure and Attractions for Drug Delivery Using Dry Powder Inhalers. AAPS PharmSciTech 2020, 21, 238. [Google Scholar] [CrossRef]

- Hickey, A.J. Fundamentals of Dry Powder Inhaler Technology. In Particles and Nanoparticles in Pharmaceutical Products: Design, Manufacturing, Behavior and Performance; Merkus, H.G., Meesters, G.M.H., Oostra, W., Eds.; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Hu, C.; Wang, F.; Cui, X.; Zhu, Y. Recent progress in textile-based triboelectric force sensors for wearable electronics. Adv. Compos. Hybrid Mater. 2023, 6, 70. [Google Scholar] [CrossRef]

- Wu, C.; Wang, A.C.; Ding, W.; Guo, H.; Wang, Z.L. Triboelectric Nanogenerator: A Foundation of the Energy for the New Era. Adv. Energy Mater. 2019, 9, 1802906. [Google Scholar] [CrossRef]

- Scherließ, R.; Bock, S.; Bungert, N.; Neustock, A.; Valentin, L. Particle engineering in dry powders for inhalation. Eur. J. Pharm. Sci. 2022, 172, 106158. [Google Scholar] [CrossRef] [PubMed]

- Fasiolo, L.T.; Manniello, M.D.; Tratta, E.; Buttini, F.; Rossi, A.; Sonvico, F.; Bortolotti, F.; Russo, P.; Colombo, G. Opportunity and challenges of nasal powders: Drug formulation and delivery. Eur. J. Pharm. Sci. 2018, 113, 2–17. [Google Scholar] [CrossRef]

- Begat, P.; Price, R.; Harris, H.; Morton, D.A.; Staniforth, J.N. The Influence of Force Control Agents on the Cohesive-Adhesive Balance in Dry Powder Inhaler Formulations. KONA Powder Part. J. 2005, 23, 109–121. [Google Scholar] [CrossRef]

- Zhou, Q.; Qu, L.; Gengenbach, T.; Larson, I.; Stewart, P.J.; Morton, D.A.V. Effect of Surface Coating with Magnesium Stearate via Mechanical Dry Powder Coating Approach on the Aerosol Performance of Micronized Drug Powders from Dry Powder Inhalers. AAPS PharmSciTech 2013, 14, 38–44. [Google Scholar] [CrossRef]

- Zhou, Q.T.; Qu, L.; Larson, I.; Stewart, P.J.; Morton, D.A. Improving aerosolization of drug powders by reducing powder intrinsic cohesion via a mechanical dry coating approach. Int. J. Pharm. 2010, 394, 50–59. [Google Scholar] [CrossRef]

- Lau, M.; Young, P.M.; Traini, D. Investigation into the Manufacture and Properties of Inhalable High-Dose Dry Powders Produced by Comilling API and Lactose with Magnesium Stearate. AAPS PharmSciTech 2017, 18, 2248–2259. [Google Scholar] [CrossRef]

- Herman, H.; Chen, Z.J.; Huang, C.C.; Cohen, R. Mechanofused powders for thermal spray. J. Therm. Spray Technol. 1992, 1, 129–135. [Google Scholar] [CrossRef]

- Nadimi, S.; Ghadiri, M. Stress and input energy analyses of shearing a particle bed under a centrifugal field. Powder Technol. 2021, 394, 575–583. [Google Scholar] [CrossRef]

- Nan, W.; Goh, W.P.; Rahman, M.T. Elasto-plastic and adhesive contact: An improved linear model and its application. Powder Technol. 2022, 407, 117634. [Google Scholar] [CrossRef]

- Omar, M.A.; Subuki, I.; Abdullah, N.; Ismail, M.F. The influence of palm stearin content on the rheological behaviour of 316L stainless steel MIM compact. J. Sci. Technol. 2010, 2. [Google Scholar]

- Zhou, Q.; Armstrong, B.; Larson, I.; Stewart, P.J.; Morton, D.A.V. Effect of host particle size on the modification of powder flow behaviours for lactose monohydrate following dry coating. Dairy Sci. Technol. 2010, 90, 237–251. [Google Scholar] [CrossRef]

- Begat, P.; Morton, D.A.; Shur, J.; Kippax, P.; Staniforth, J.N.; Price, R. The Role of Force Control Agents in High-Dose Dry Powder Inhaler Formulations. J. Pharm. Sci. 2009, 98, 2770–2783. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Wei, C.; Garayt, M.D.L.; MacInnis, J.; Obrovac, M.N. Spherically Smooth Cathode Particles by Mechanofusion Processing. J. Electrochem. Soc. 2019, 166, A2924. [Google Scholar] [CrossRef]

- Lakio, S.; Morton, D.A.V.; Ralph, A.P.; Lambert, P. Optimizing aerosolization of a high-dose L-arginine powder for pulmonary delivery. Asian J. Pharm. Sci. 2015, 10, 528–540. [Google Scholar] [CrossRef]

- Das, S.C.; Luu, J.; Morton, D.A.V.; Stewart, P. A novel approach to develop high dose drug alone inhaler. Drug Deliv Lungs 25 (DDL25) 2014, 140, 46–49. [Google Scholar]

- Chougule, B.M.; Padhi, K.B.; Jinturkar, A.K.; Misra, A. Development of Dry Powder Inhalers. Recent Pat. Drug Deliv. Formul. 2007, 1, 11–21. [Google Scholar] [CrossRef]

- Sosnik, A.; Seremeta, K.P. Advantages and challenges of the spray-drying technology for the production of pure drug particles and drug-loaded polymeric carriers. Adv. Colloid Interface Sci. 2015, 223, 40–54. [Google Scholar] [CrossRef]

- Momin, M.A.M.; Tucker, I.G.; Das, S.C. High dose dry powder inhalers to overcome the challenges of tuberculosis treatment. Int. J. Pharm. 2018, 550, 398–417. [Google Scholar] [CrossRef]

- Shahin, H.I.; Chablani, L. A comprehensive overview of dry powder inhalers for pulmonary drug delivery: Challenges, advances, optimization techniques, and applications. J. Drug Deliv. Sci. Technol. 2023, 84, 104553. [Google Scholar]

- George, S.; Thomas, A.; Kumar, M.V.P.; Kamdod, A.S.; Rajput, A.; Abdullah, S. Impact of processing parameters on the quality attributes of spray-dried powders: A review. Eur. Food Res. Technol. 2023, 249, 241–257. [Google Scholar] [CrossRef]

- Brunaugh, A.D.; Smyth, H.D. Formulation techniques for high dose dry powders. Int. J. Pharm. 2018, 547, 489–498. [Google Scholar] [CrossRef] [PubMed]

- Thi, T.H.H.; Danède, F.; Descamps, M.; Flament, M.-P. Comparison of physical and inhalation properties of spray-dried and micronized terbutaline sulphate. Eur. J. Pharm. Biopharm. 2008, 70, 380–388. [Google Scholar] [CrossRef] [PubMed]

- Tarara, T.E.; Miller, D.P.; Weers, A.E.; Muliadi, A.; Tso, J.; Eliahu, A.; Weers, J.G. Formulation of Dry Powders for Inhalation Comprising High Doses of a Poorly Soluble Hydrophobic Drug. Front. Drug Deliv. 2022, 2, 862336. [Google Scholar] [CrossRef]

- Stewart, I.E.; Durham, P.G.; Sittenauer, J.M.; Barreda, A.P.; Stowell, G.W.; Moody, C.; Mecham, J.B.; Simpson, C.; Daily, S.; Maloney, S.E.; et al. Optimization and Scale Up of Spray Dried CPZEN-45 Aerosol Powders for Inhaled Tuberculosis Treatment. Pharm. Res. 2022, 39, 3359–3370. [Google Scholar] [CrossRef]

- Shetty, N.; Park, H.; Zemlyanov, D.; Mangal, S.; Bhujbal, S.; Zhou, Q. Influence of excipients on physical and aerosolization stability of spray dried high-dose powder formulations for inhalation. Int. J. Pharm. 2018, 544, 222–234. [Google Scholar] [CrossRef]

- Tong, H.H.Y.; Chow, A.H.L. Control of Physical Forms of Drug Particles for Pulmonary Delivery by Spray Drying and Supercritical Fluid Processing. KONA Powder Part. J. 2006, 24, 27–40. [Google Scholar] [CrossRef]

- Chow, A.H.; Tong, H.H.; Chattopadhyay, P.; Shekunov, B.Y. Particle engineering for pulmonary drug de-livery. Pharm. Res. 2007, 24, 411–437. [Google Scholar] [CrossRef]

- Sapkale, G.; Patil, S.M.; Surwase, U.S.; Bhatbhage, P.K. Supercritical fluid extraction. Int. J. Chem. Sci. 2010, 8, 729–743. [Google Scholar]

- Herrero, M.; Mendiola, J.A.; Cifuentes, A.; Ibáñez, E. Supercritical fluid extraction: Recent advances and applications. J. Chromatogr. A 2010, 1217, 2495–2511. [Google Scholar] [CrossRef]

- Shekunov, B.Y.; Feeley, J.C.; Chow, A.H.; Tong, H.H.; York, P. Aerosolisation behaviour of micronised and supercritically-processed powders. J. Aerosol Sci. 2003, 34, 553–568. [Google Scholar] [CrossRef]

- Chaurasiya, B.; Zhao, Y.-Y. Dry Powder for Pulmonary Delivery: A Comprehensive Review. Pharmaceutics 2020, 13, 31. [Google Scholar] [CrossRef] [PubMed]

- Ishwarya, S.P.; Anandharamakrishnan, C.; Stapley, A.G. Spray-freeze-drying: A novel process for the drying of foods and bioproducts. Trends Food Sci. Technol. 2015, 41, 161–181. [Google Scholar] [CrossRef]

- Shoyele, S.A.; Cawthorne, S. Particle engineering techniques for inhaled biopharmaceuticals. Adv. Drug Deliv. Rev. 2006, 58, 1009–1029. [Google Scholar] [CrossRef] [PubMed]

- Saluja, V.; Amorij, J.-P.; Kapteyn, J.; de Boer, A.; Frijlink, H.; Hinrichs, W. A comparison between spray drying and spray freeze drying to produce an influenza subunit vaccine powder for inhalation. J. Control. Release 2010, 144, 127–133. [Google Scholar] [CrossRef]

- Sahakijpijarn, S.; Moon, C.; Koleng, J.J.; Christensen, D.J.; Williams, R.O. Development of Remdesivir as a Dry Powder for Inhalation by Thin Film Freezing. Pharmaceutics 2020, 12, 1002. [Google Scholar] [CrossRef]

- Pardeshi, S.R.; Kole, E.B.; Kapare, H.S.; Chandankar, S.M.; Shinde, P.J.; Boisa, G.S.; Salgaonkar, S.S.; Giram, P.S.; More, M.P.; Kolimi, P.; et al. Progress on Thin Film Freezing Technology for Dry Powder Inhalation Formulations. Pharmaceutics 2022, 14, 2632. [Google Scholar] [CrossRef]

- Jara, M.O.; Warnken, Z.N.; Sahakijpijarn, S.; Moon, C.; Maier, E.Y.; Christensen, D.J.; Koleng, J.J.; Peters, J.I.; Hackman Maier, S.D.; Williams, R.O., III. Niclosamide inhalation powder made by thin-film freezing: Multi-dose tolerability and exposure in rats and pharmacokinetics in hamsters. Int. J. Pharm. 2021, 603, 120701. [Google Scholar] [CrossRef]

- Jiang, J.; Peng, H.-H.; Yang, Z.; Ma, X.; Sahakijpijarn, S.; Moon, C.; Ouyang, D.; Williams, R.O., III. The applications of Machine learning (ML) in designing dry powder for inhalation by using thin-film-freezing technology. Int. J. Pharm. 2022, 626, 122179. [Google Scholar] [CrossRef]

- Moon, C.; Sahakijpijarn, S.; Koleng, J.J.; Williams, R.O. Processing design space is critical for voriconazole nanoaggregates for dry powder inhalation produced by thin film freezing. J. Drug Deliv. Sci. Technol. 2019, 54, 101295. [Google Scholar] [CrossRef]

- Praphawatvet, T.; Cui, Z.; Williams, R.O. Pharmaceutical dry powders of small molecules prepared by thin-film freezing and their applications—A focus on the physical and aerosol properties of the powders. Int. J. Pharm. 2022, 629, 122357. [Google Scholar] [CrossRef] [PubMed]

- Abiona, O.; Wyatt, D.; Koner, J.; Mohammed, A. The Optimisation of Carrier Selection in Dry Powder Inhaler Formulation and the Role of Surface Energetics. Biomedicines 2022, 10, 2707. [Google Scholar] [CrossRef]

- Koner, J.; Ershad, A.; Wyatt, D. Isothermal dry particle coating–Back to the future? ONdrugDelivery 2023, 145, 28–32. [Google Scholar]

- Dahmash, E.Z.; Al-Khattawi, A.; Iyire, A.; Al-Yami, H.; Dennison, T.J.; Mohammed, A.R. Quality by Design (QbD) based process optimisation to develop functionalised particles with modified release properties using novel dry particle coating technique. PLoS ONE 2018, 13, e0206651. [Google Scholar] [CrossRef]

- Nokhodchi, A.; Chavan, S.; Ghafourian, T. In Vitro Dissolution and Permeability Testing of Inhalation Products: Challenges and Advances. Pharmaceutics 2023, 15, 983. [Google Scholar] [CrossRef]

- Velaga, S.P.; Djuris, J.; Cvijic, S.; Rozou, S.; Russo, P.; Colombo, G.; Rossi, A. Dry powder inhalers: An overview of the in vitro dissolution methodologies and their correlation with the biopharmaceutical aspects of the drug products. Eur. J. Pharm. Sci. 2018, 113, 18–28. [Google Scholar] [CrossRef] [PubMed]

- May, S.; Jensen, B.; Wolkenhauer, M.; Schneider, M.; Lehr, C.M. Dissolution techniques for in vitro testing of dry powders for inhalation. Pharm. Res. 2012, 29, 2157–2166. [Google Scholar] [CrossRef] [PubMed]

- Floroiu, A.; Klein, M.; Krämer, J.; Lehr, C.-M. Towards standardized dissolution techniques for in vitro performance testing of dry powder inhalers. Dissolut. Technol. 2018, 25, 6–18. [Google Scholar] [CrossRef]

- Jadhav, S.Y.; Shinde, A.D.; Archive, B. A Review on Dry-powder Inhaler. Int. J. Pharm. Biol. Arch. 2019, 10, 232–241. [Google Scholar]

- Pourshahab, P.S.; Gilani, K.; Moazeni, E.; Eslahi, H.; Fazeli, M.R.; Jamalifar, H. Preparation and characterization of spray dried inhalable powders containing chitosan nanoparticles for pulmonary delivery of isoniazid. J. Microencapsul. 2011, 28, 605–613. [Google Scholar] [CrossRef]

- de Boer, A.; Gjaltema, D.; Hagedoorn, P.; Frijlink, H. Characterization of inhalation aerosols: A critical evaluation of cascade impactor analysis and laser diffraction technique. Int. J. Pharm. 2002, 249, 219–231. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, A.; Chauhan, P. Powder XRD technique and its applications in science and technology. J. Anal. Bioanal. Tech. 2014, 5, 1–5. [Google Scholar] [CrossRef]

- Pandey, A.; Dalal, S.; Dutta, S.; Dixit, A. Structural characterization of polycrystalline thin films by X-ray diffraction techniques. J. Mater. Sci. Mater. Electron. 2021, 32, 1341–1368. [Google Scholar] [CrossRef]

- Sharma, S.; Jaiswal, S.; Duffy, B.; Jaiswal, A.K. Nanostructured Materials for Food Applications: Spectroscopy, Microscopy and Physical Properties. Bioengineering 2019, 6, 26. [Google Scholar] [CrossRef] [PubMed]

- Kou, X.; Chan, L.W.; Steckel, H.; Heng, P.W. Physico-chemical aspects of lactose for inhalation. Adv. Drug Deliv. Rev. 2012, 64, 220–232. [Google Scholar] [CrossRef]

- Stegemann, S.; Kopp, S.; Borchard, G.; Shah, V.; Senel, S.; Dubey, R.; Urbanetz, N.; Cittero, M.; Schoubben, A.; Hippchen, C.; et al. Developing and advancing dry powder inhalation towards enhanced therapeutics. Eur. J. Pharm. Sci. 2013, 48, 181–194. [Google Scholar] [CrossRef]

- Kaialy, W.; Alhalaweh, A.; Velaga, S.P.; Nokhodchi, A. Effect of carrier particle shape on dry powder inhaler performance. Int. J. Pharm. 2011, 421, 12–23. [Google Scholar] [CrossRef] [PubMed]

- Kaialy, W.; Nokhodchi, A. Dry powder inhalers: Physicochemical and aerosolization properties of several size-fractions of a promising alterative carrier, freeze-dried mannitol. Eur. J. Pharm. Sci. 2015, 68, 56–67. [Google Scholar] [CrossRef]

- Wu, X.; Li, X.; Mansour, H.M. Surface analytical techniques in solid-state particle characterization for predicting performance in dry powder inhalers. KONA Powder Part. J. 2010, 28, 3–19. [Google Scholar] [CrossRef]

- Harder, C.; Lesniewska, E.; Laroche, C. Study of ageing of dry powder inhaler and metered dose inhaler by atomic force microscopy. Powder Technol. 2011, 208, 252–259. [Google Scholar] [CrossRef]

- Weiss, C.; McLoughlin, P.; Cathcart, H. Characterisation of dry powder inhaler formulations using atomic force microscopy. Int. J. Pharm. 2015, 494, 393–407. [Google Scholar] [CrossRef]

- Packhaeuser, C.B.; Lahnstein, K.; Sitterberg, J.; Schmehl, T.; Gessler, T.; Bakowsky, U.; Seeger, W.; Kissel, T. Stabilization of aerosolizable nano-carriers by freeze-drying. Pharm. Res. 2009, 26, 129–138. [Google Scholar] [CrossRef] [PubMed]

- Rogueda, P.G.; Price, R.; Smith, T.; Young, P.M.; Traini, D. Particle synergy and aerosol performance in non-aqueous liquid of two combinations metered dose inhalation formulations: An AFM and Raman investigation. J. Colloid Interface Sci. 2011, 361, 649–655. [Google Scholar] [CrossRef]

- Donovan, M.J.; Smyth, H.D. Influence of size and surface roughness of large lactose carrier particles in dry powder inhaler formulations. Int. J. Pharm. 2010, 402, 1–9. [Google Scholar] [CrossRef]

- Babenkoa, M.; Peron, J.M.R.; Kaialy, W.; Calabrese, G.; Alany, R.G.; Elshaer, A. 1H NMR quantification of spray dried and spray freeze-dried saccharide carriers in dry powder inhaler formulations. Int. J. Pharm. 2019, 564, 318–328. [Google Scholar] [CrossRef] [PubMed]

- Alhajj, N.; O’Reilly, N.J.; Cathcart, H. Development and characterization of a spray-dried inhalable ciprofloxacin-quercetin co-amorphous system. Int. J. Pharm. 2022, 618, 121657. [Google Scholar] [CrossRef] [PubMed]

- Duke, C.C.; Ong, H.X.; Chan, J.C.; Tyne, A.S.; Chan, H.-K.; Britton, W.J.; Young, P.M.; Traini, D. A Novel Inhalable Form of Rifapentine. J. Pharm. Sci. 2014, 103, 1411–1421. [Google Scholar]

- Varun, N.; Dutta, A.; Ghoroi, C. Influence of surface interaction between drug and excipient in binary mixture for dry powder inhaler applications. Adv. Powder Technol. 2022, 33, 103443. [Google Scholar] [CrossRef]

- Kaialy, W.; Hussain, T.; Alhalaweh, A.; Nokhodchi, A. Towards a More Desirable Dry Powder Inhaler Formulation: Large Spray-Dried Mannitol Microspheres Outperform Small Microspheres. Pharm. Res. 2014, 31, 60–76. [Google Scholar] [CrossRef]

- Kaialy, W.; Momin, M.N.; Ticehurst, M.D.; Murphy, J.; Nokhodchi, A. Engineered mannitol as an alternative carrier to enhance deep lung penetration of salbutamol sulphate from dry powder inhaler. Colloids Surf. B Biointerfaces 2010, 79, 345–356. [Google Scholar] [CrossRef]

- Mitra, H.; Pushpadass, H.A.; Franklin, M.E.E.; Ambrose, R.K.; Ghoroi, C.; Battula, S.N. Influence of moisture content on the flow properties of basundi mix. Powder Technol. 2017, 312, 133–143. [Google Scholar] [CrossRef]

- Wu, L.; Miao, X.; Shan, Z.; Huang, Y.; Li, L.; Pan, X.; Yao, Q.; Li, G.; Wu, C. Studies on the spray dried lactose as carrier for dry powder inhalation. Asian J. Pharm. Sci. 2014, 9, 336–341. [Google Scholar] [CrossRef]

- Vogel, R.; Pal, A.K.; Jambhrunkar, S.; Patel, P.; Thakur, S.S.; Reátegui, E.; Parekh, H.S.; Saá, P.; Stassinopoulos, A.; Broom, M.F. High-Resolution Single Particle Zeta Potential Characterisation of Biological Nanoparticles using Tunable Resistive Pulse Sensing. Sci. Rep. 2017, 7, 17479. [Google Scholar] [CrossRef] [PubMed]

- Aneta, S.; Alexander, G.S. Size and ζ-potential measurement of silica nanoparticles in serum using tunable resistive pulse sensing. Analyst 2016, 141, 641–647. [Google Scholar]

- Anoop, K.P.; Iraj, A.; Suresh, G. High-resolution characterization of engineered nanomaterial dispersions in complex media using tunable resistive pulse sensing technology. Anal. Chem. 2014, 86, 10065–10072. [Google Scholar]

| Manufacturing Technique | Principle of the Method | Key Outcomes | Applications | Scalability and Feasibility | Limitations |

|---|---|---|---|---|---|

| Mechanofusion | Host and guest particles rotating inside a cylindrical chamber at high speed, generating thermo-mechanical energy to coat a thin layer of guest particles on the surface of the host particles [25,33]. | Improved powder dispersibility, flowability, and separation of agglomerates without altering particle size significantly [26,28]. Achievement of complete, uniform ultra-thin coating [25]. | Widely used for preparing inhalable powders and optimizing formulations for high-dose medications such as L-arginine [35,36]. | Dry mechanofusion offers scalability and safety, making it suitable for large-scale production of powders without the need for solvents [26,27]. Can be used for moisture-sensitive materials [36]. A feasible method due to its ability to offer fine control over compressive and shear forces, along with minimal change to particle size [28,34]. | Alters particle shape and achieves uniformity when scaling up for complex formulations [36]. |

| Spray drying | Liquid preparation is atomized into droplets, rapidly dried with hot gas, and collected as dry fine powder [6,40]. | Produces low-density, highly dispersible powder, spherical particles with controlled properties [6,46]. | Used for pulmonary drug delivery and carrier material production; applied in high-dose inhalers like Aridol® and TOBI® Podhaler [43,45]. The use of closed spray drying cycle for handling oxygen-sensitive materials [45]. | Highly customizable with precise control over powder properties; cost-effective open cycle available (due to its use of air as the drying gas) [5,39,44]. | Challenges in maintaining physical stability; risk of recrystallization impacting particle stability [6,47]. |

| Supercritical fluid crystallization (SFC) | Uses supercritical fluids (SFs) to precipitate and extract pure drug particles via anti-solvent precipitation. It is achieved through precipitation, separation, and extraction of unwanted impurities from the final product [48,49]. | Produces fine, pure powders with enhanced dispersibility, low surface energy, and improved drug delivery efficiency [1,52]. | Suitable for pulmonary drug delivery and particle engineering of heat-sensitive materials [48,51]. | Highly efficient with low energy consumption; enables clean and solvent-reduced processing. CO2 (one of the most used gases) is non-toxic, cost-effective, and eco-friendly [49,50]. | Solubility of liquid extractant in SFs can impact particle purity and size distribution [51]. |

| Spray-freeze drying | Combines spray drying and freeze drying; involves atomization, freezing with cryogenic liquids, and sublimation under a vacuum [53,55]. | Produces highly porous, spherical microparticles with excellent dispersibility and good aerodynamic performance [1,55]. | Suitable for pulmonary drug delivery, particularly for heat-sensitive materials; used for vaccine formulations with long-term stability [54,56]. | Can produce microparticles without excipients; however, high bulk volume limits drug loading; it is time-consuming and expensive due to combined techniques [24,40]. | Risk of irreversible damage to biologicals due to particle stress at low temperature, leading to loss of activity; high production costs [55]. |

| Thin-film freezing | The formation of thin frozen film from a liquid preparation on a surface of cryogenically cooled rotating drum, followed by lyophilization and dry powder production [58]. | Nanoaggregates with high potency and surface area, a fragile matrix ideal for dry powder inhalers, and low-density particles deaggregate upon inspiration [57,61]. | Inhalable pharmaceutical powders, vaccines, and biopharmaceuticals. Also, commercializing small molecule products, and in food industry [58]. | Fast freezing prevents particle growth. Better solubility, stability, morphology compared to spray-freeze and spray drying. Production of more stable forms of vaccines, leading to better storage and handling conditions [58]. | Solvent mix ratio can affect the separation of the cryogenic fluid and the viscosity of liquid preparation. Could lead to particle agglomeration [62]. |

| Isothermal dry particle coating (iDPC) | Dry coating technique for blending powders. Drug particles adhere to the surface of the carrier particles without the use of solvents or heat [63,65]. | Produces high-content uniformity blends, and maintains chemical, biological, and physical stability [64]. | Used in inhalable drug formulations, including DPIs, to produce fluticasone propionate (FP) formulations with a high fine particle fraction (FPF) (27.2–56.8%) [64]. | Simple process parameters (rotation speed, nitrogen flow, batch size) that can be adjusted for optimal performance. Compatible with QbD framework for process control [65]. | A relatively new approach that has not yet been industrialized. Further research is needed to optimize scalability, reproducibility, and regulatory compliance for industrial implementation. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Assaf, H.A.; Papadimitriou, S.A.; Rahman, A.; Badhan, R.; Mohammed, A.R. Advanced Manufacturing Methods for High-Dose Inhalable Powders. Pharmaceutics 2025, 17, 359. https://doi.org/10.3390/pharmaceutics17030359

Al-Assaf HA, Papadimitriou SA, Rahman A, Badhan R, Mohammed AR. Advanced Manufacturing Methods for High-Dose Inhalable Powders. Pharmaceutics. 2025; 17(3):359. https://doi.org/10.3390/pharmaceutics17030359

Chicago/Turabian StyleAl-Assaf, Haia A., Sofia A. Papadimitriou, Ayesha Rahman, Raj Badhan, and Afzal R. Mohammed. 2025. "Advanced Manufacturing Methods for High-Dose Inhalable Powders" Pharmaceutics 17, no. 3: 359. https://doi.org/10.3390/pharmaceutics17030359

APA StyleAl-Assaf, H. A., Papadimitriou, S. A., Rahman, A., Badhan, R., & Mohammed, A. R. (2025). Advanced Manufacturing Methods for High-Dose Inhalable Powders. Pharmaceutics, 17(3), 359. https://doi.org/10.3390/pharmaceutics17030359