Determinants to Adopt Industrial Internet of Things in Small and Medium-Sized Enterprises

Abstract

1. Introduction

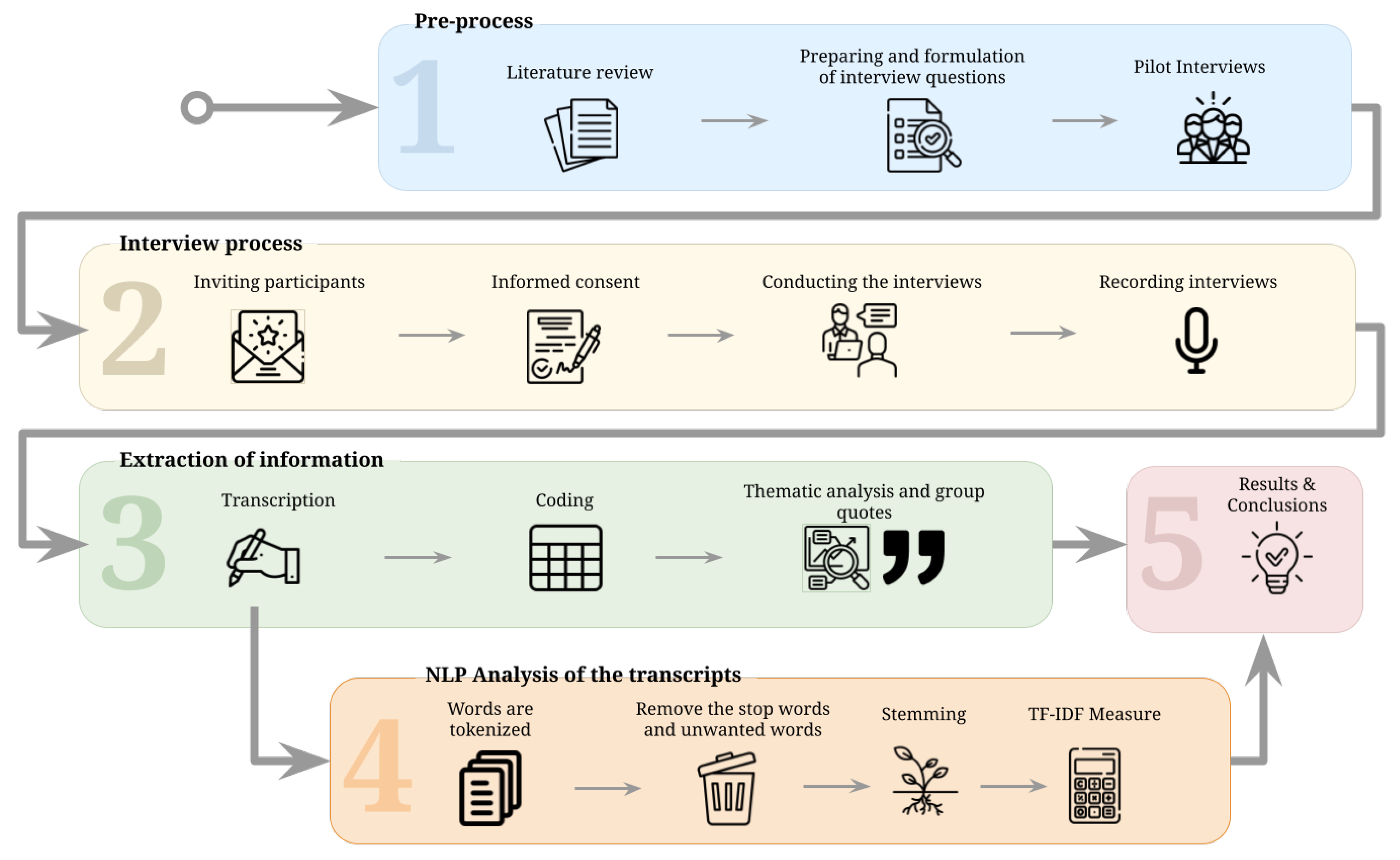

2. Materials and Methods

2.1. Participant Recruitment and Demographics

- Whether the participants were decision makers or owners of small or medium-size factories.

- Whether they understood the concept of IoT devices, communications, and platforms.

- Whether they have experience in the supply chain or manufacturing of at least one year.

- Whether they were implementing or considering the commission of an IoT solution in their workplaces.

2.2. Semi-Structured Interviews and Thematic Analysis

2.3. Ethics

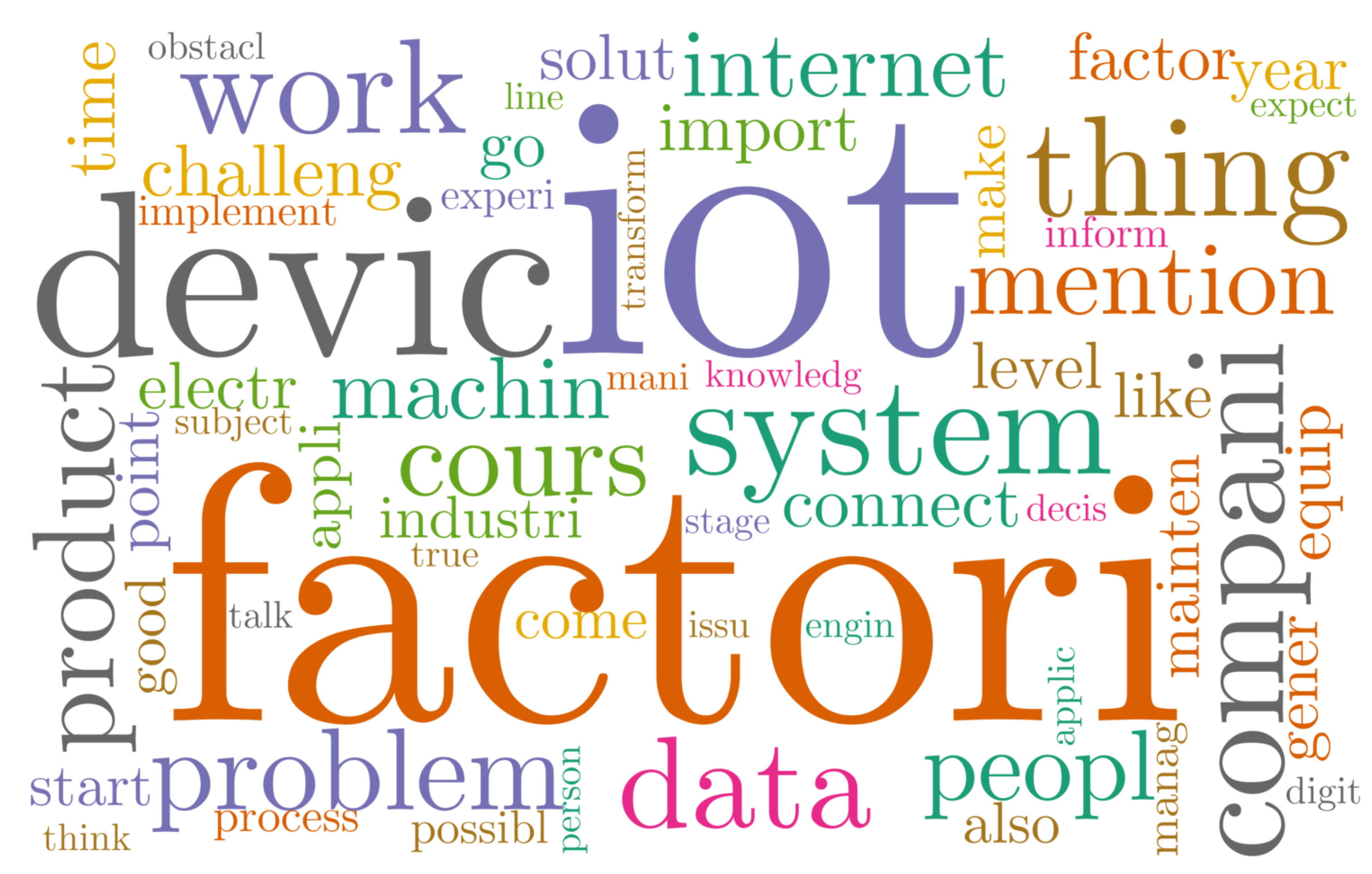

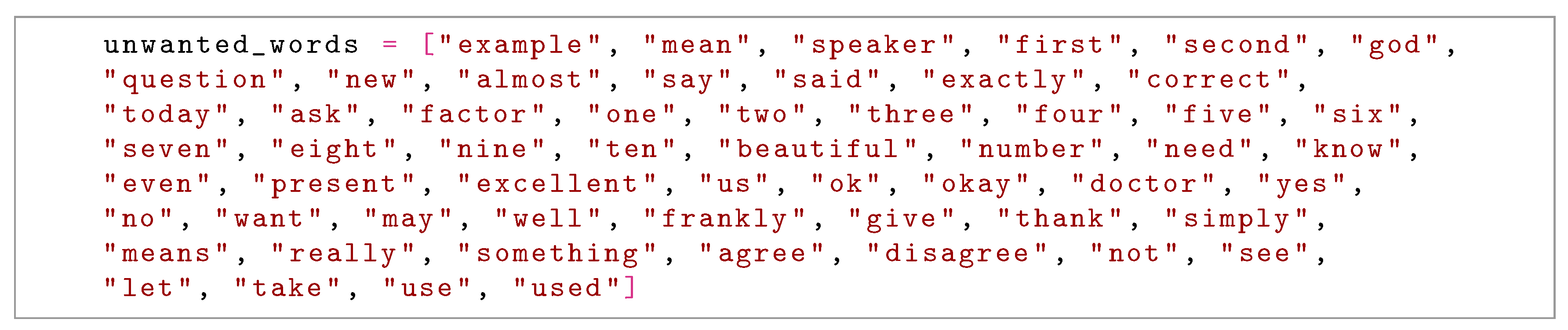

2.4. Natural Language Processing for Transcripts

3. Results

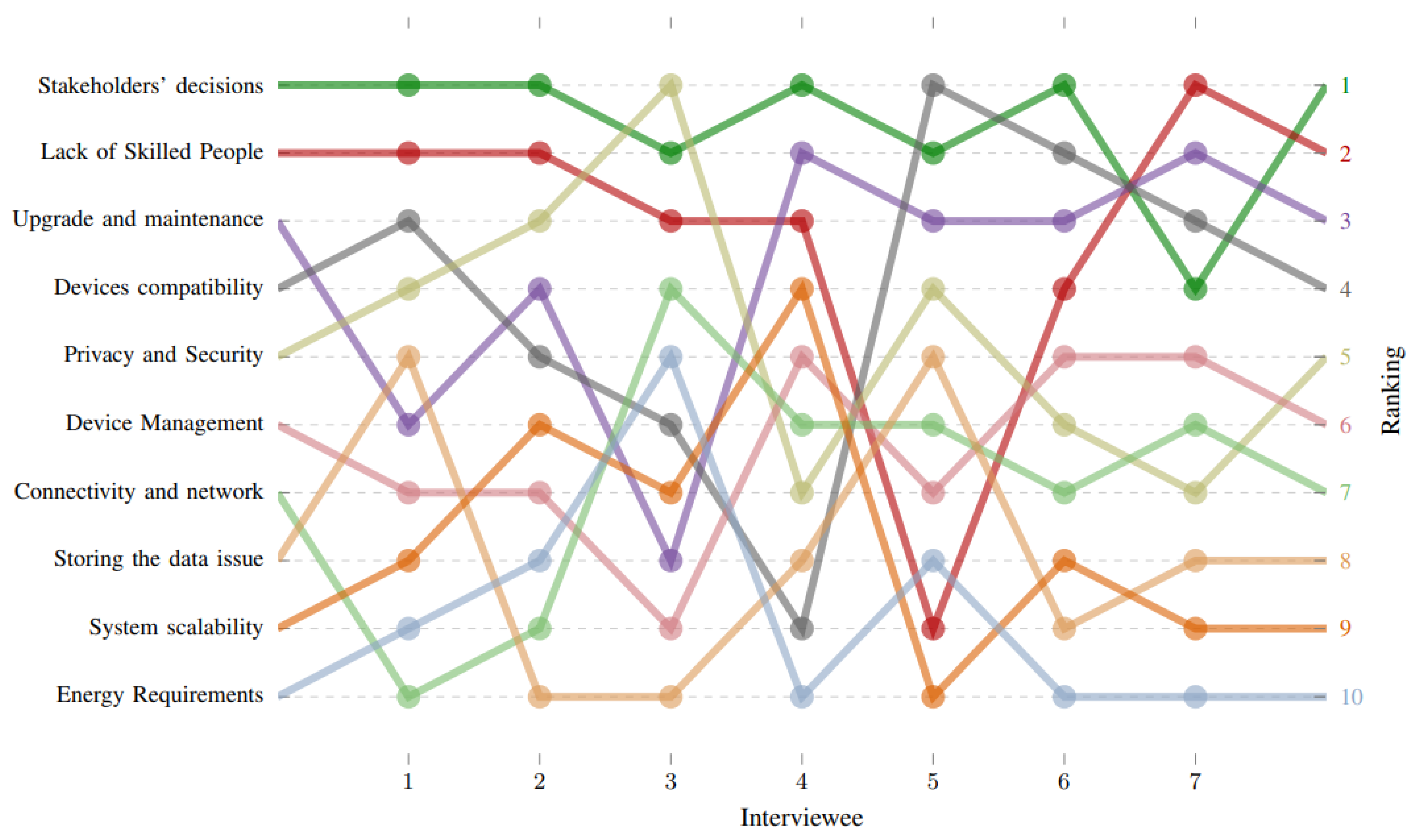

- To determine the most influential factors in adopting the IoT and the solutions to overcome the challenge.

- To assess the impact of challenging adoption factors on IoT solutions in the decision makers’ factories.

- To determine the effect of IoT adoption on factories’ productivity.

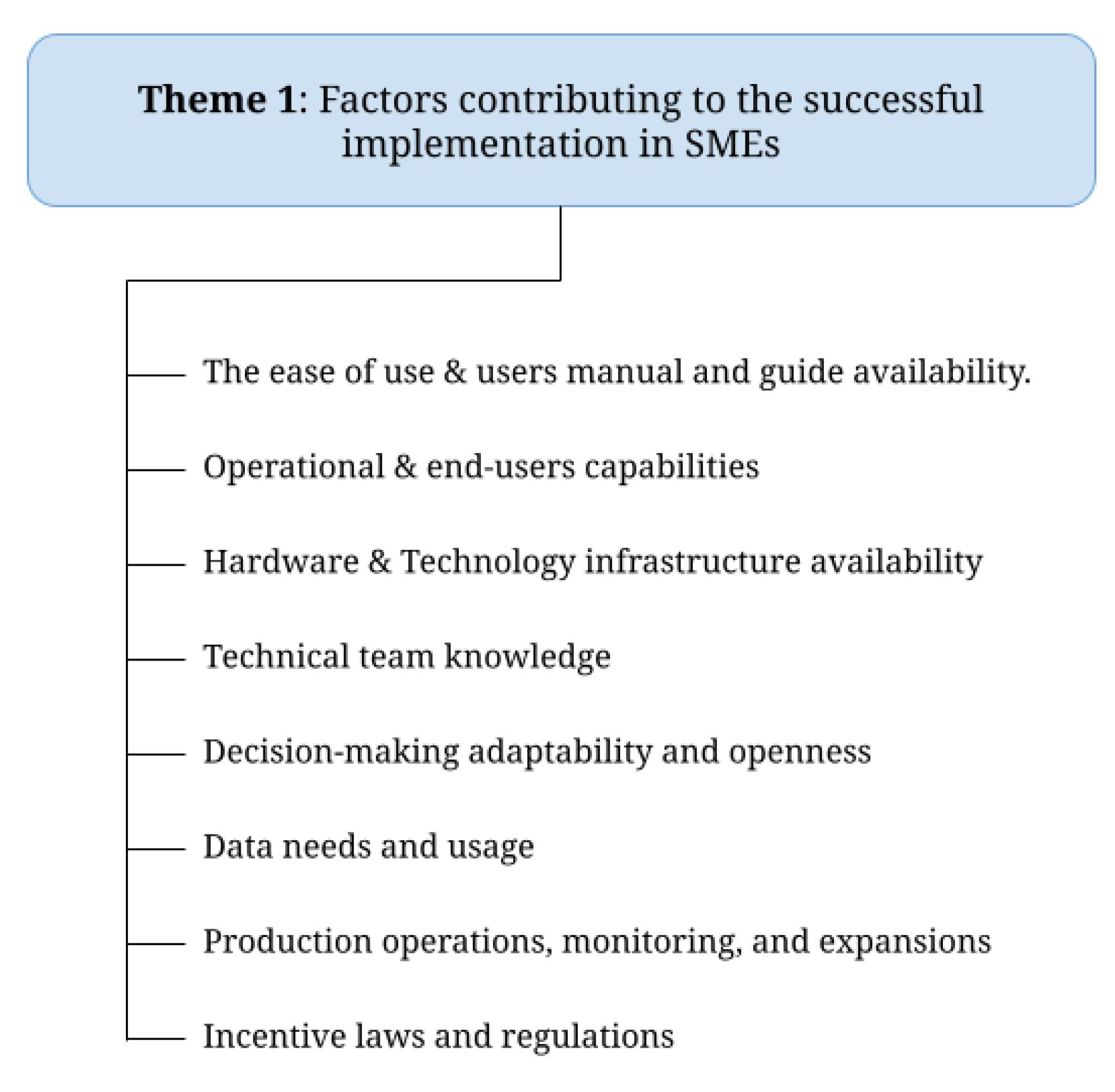

3.1. Theme 1: Factors Contributing to the Successful Implementation in SMEs

“Is there a user manual that explains the interaction between the user and the device? Relationships of technological capabilities related to factory equipment, such as technical specifications and integration. For example, capabilities related to cloud storage capabilities. Furthermore, the capabilities related to the organization’s hardware, infrastructure, knowledge, and technology”.(Participant 2)

“The technical team must have clear tasks to do. Usually, the technical team has several tasks. Some of these are minor and irrelevant tasks, and it is time-consuming to do all these tasks”.(Participant 5)

“Operational and management capability are divided into several areas, including how the IoT devices are used and the system is built. However, formulating the system, managing it, and integrating data require consideration. For example, how do you connect devices with some controller and analyze the data analytics?”(Participant 6)

“Currently, each production line has three or four sensors on each machine to collect data; in contrast, holding a paper and pen to write all this information will be time-consuming; thus, we are forced to apply IoT”.(Participant 3)

“One person controls the company, and all employees have nothing to do but listen, particularly if this person is from an uneducated background, is a non-academic person, or is interested in making profit only”.(Participant 3)

“We have ceramic design images and printable files. For ceramic tile printers, each image is approximately 6 GB. The amount of data required to be handled in an IoT system must to be considered. You will receive files that can be stored and used for years”.(Participant 3)

“The existing devices and the information they produce force us to use IoT systems”.(Participant 3)

“If it does not cause a loss in production and the factory assets, then it is one of the three most significant factors that can push me to implement the IoT system”.(Participant 7)

“We have approximately nine production lines operating 24 hours, seven days a week throughout the year. Four production lines will start work within the next three months”.(Participant 3)

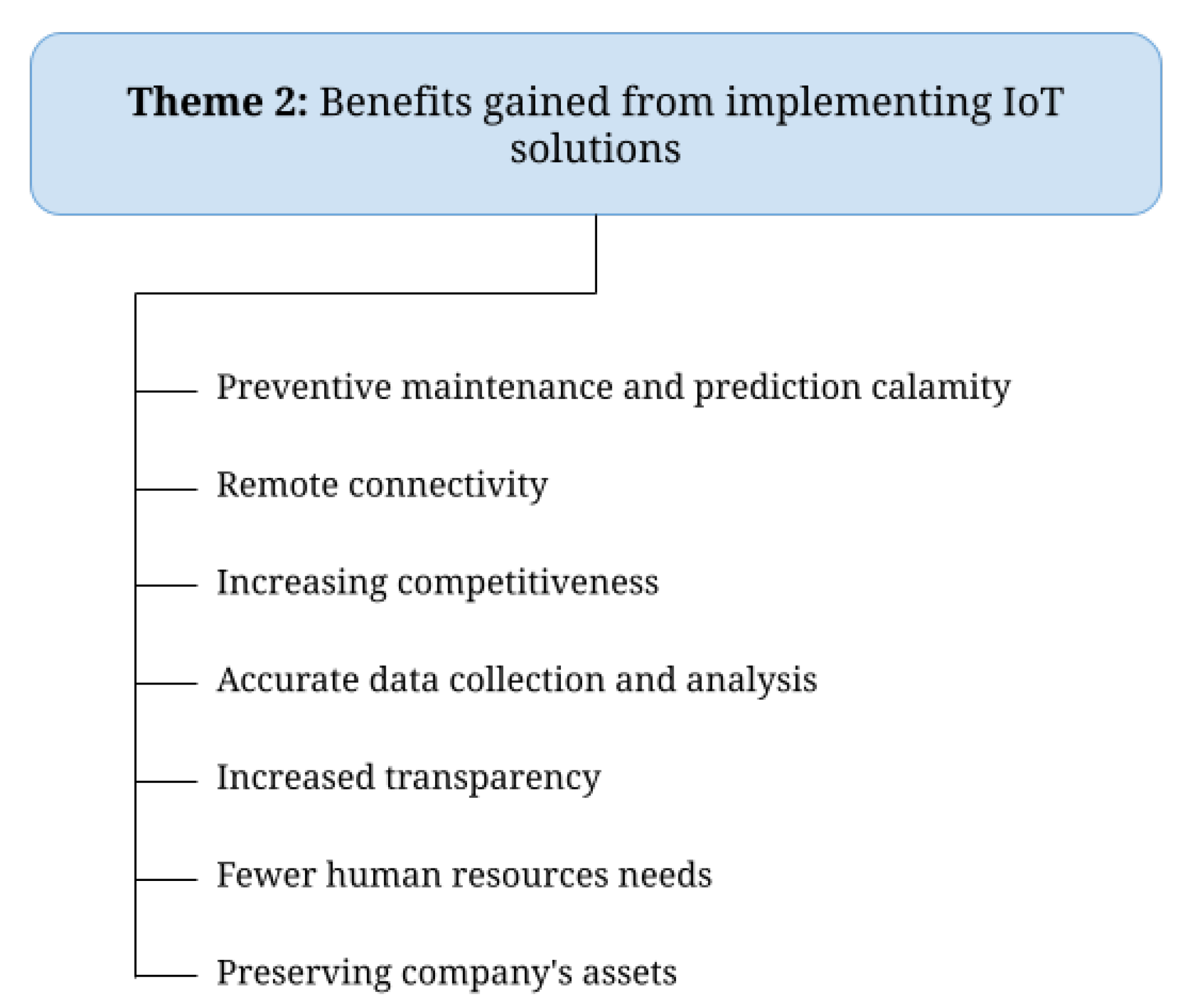

3.2. Theme 2: Benefits from Implementing IoT Solutions

“Connectivity is at the core of any manufacturing transformation program in general”.(Participant 6)

“Cloud connectivity, cloud computing, and cloud storage can accelerate the ease of implementation of the IIoT”.(Participant 2)

“Increase the competitiveness of factories in the future”.(Participant 1)

“You will discover that zones A or B always have waste in these production areas. Without you going through investigations by asking people and having several meetings… you can make the right decision without all those traditional processes”.(Participant 3)

“The presence of IoT helps keep everyone aware of any progress and problems. Because employees can communicate directly with the factory decision-makers about what is happening and how we can solve the problem, it speeds up communication between the factory floor and management”.(Participant 7)

“Fewer workers are required on the factory floor; thus, fewer workers must be trained. However, more skilled people must be hired”.(Participant 1)

“My goal is to preserve the company’s assets through IoT applications. For example, some machines in the production line keep working for fifteen to twenty years; therefore, a solution is required to maintain these essential assets”.(Participant 1)

“Preventive maintenance and predictive maintenance means to protect the machines from failure, which can be achieved using the IoT. ”(Participant 1)

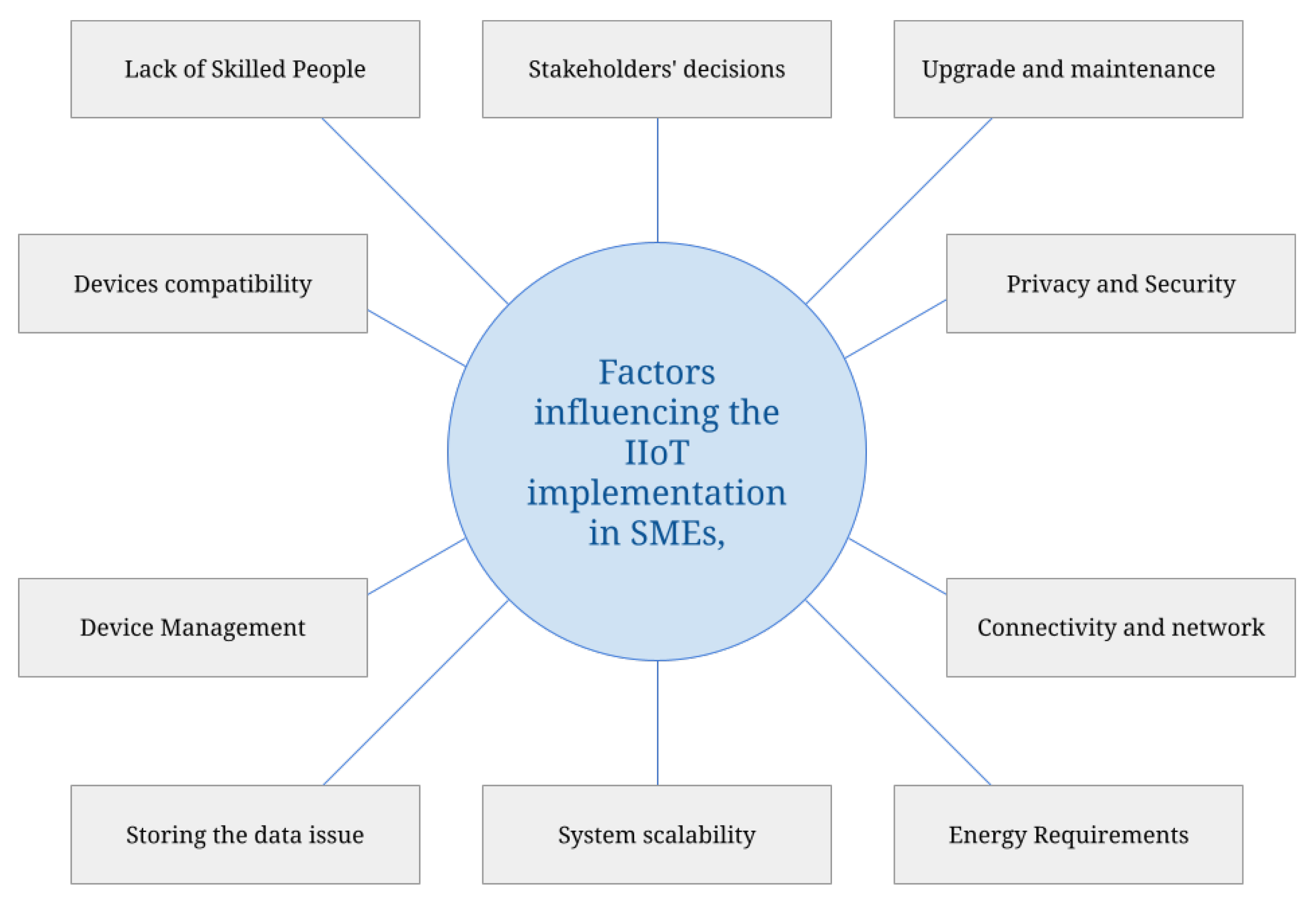

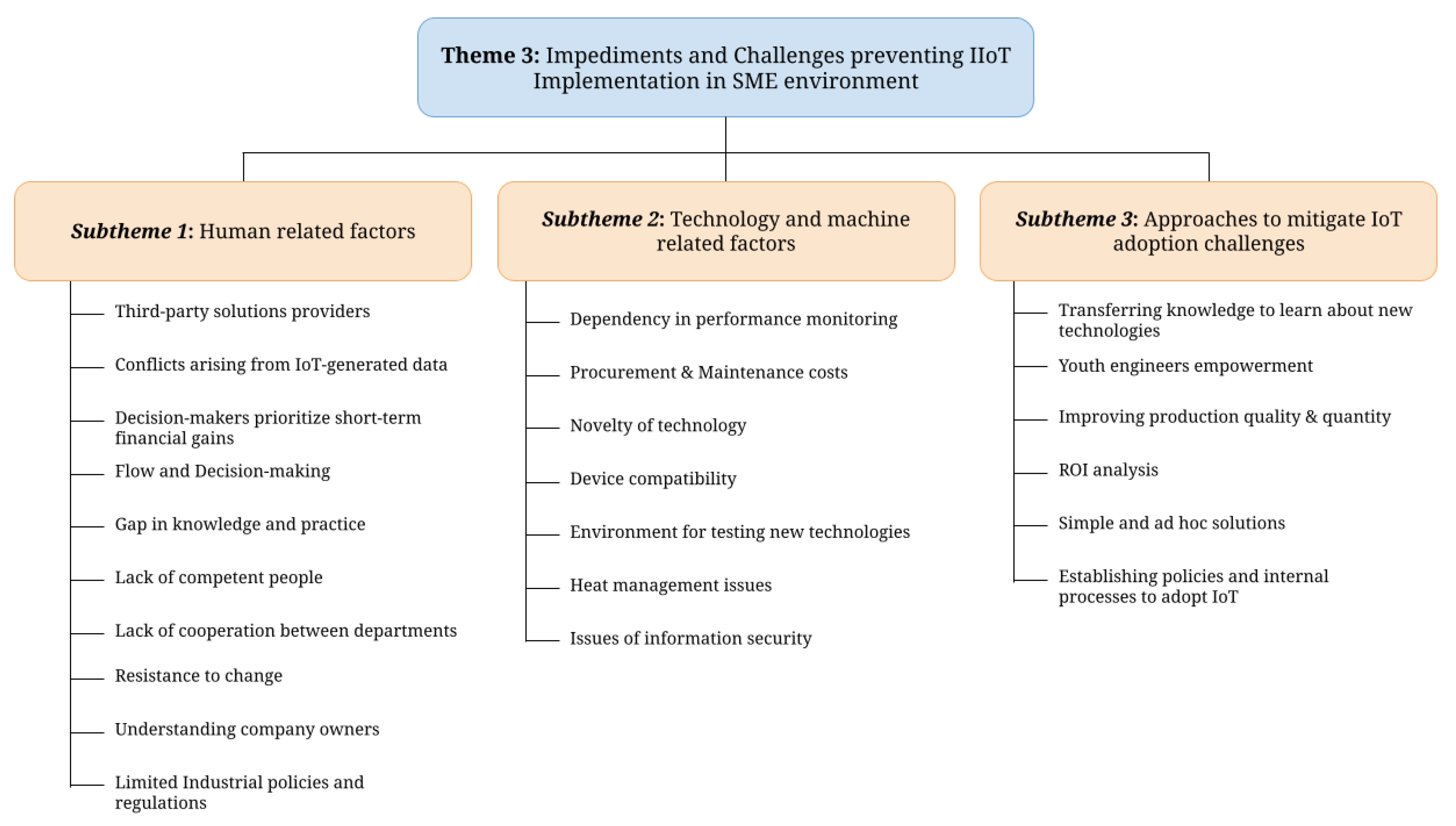

3.3. Theme 3: Impediments and Challenges Preventing IIoT Implementation in SME Environment

3.3.1. Human-Related Obstacles and Factors Prevent Implementing IoT in SMEs (Subtheme 1)

“To date, only one company exists in Saudi Arabia offering integrated solutions from A to Z. However, we face challenges with pricing and restricted conditions for their solutions”.(Participant 1)

“One of the most critical elements is the cost… Factories can be well equipped at the level of electrical and data communication systems; the infrastructure of industrial cities is good in many ways, but as far as digital transformation is still lacking, there is a need for more to be done”.(Participant 1)

“The owner who wants quick money directly tells you: What will I benefit from this technology?”(Participant 3)

“The meaning of the flow messages from the head of the pyramid, from the CEO to the end user, worker, or ordinary employee on the front desk. If we decide today, how long it will take to reach all the parties in the flow, and who must receive the message? In the company’s case, today, it decided to apply the IoT for a few months to all levels, which may change the decision of the CEO or the decision-maker whose implementation has not reached the bottom of the administrative hierarchy”.(Participant 4)

“There is a shortage of skills or a lack of competent people for these operations. Those who can operate this technology are rare in the industry, and few people know the industry”.(Participant 2)

“Lack of cooperation between departments because hostilities occur when a particular department has inefficiency or significant problems and you have uncovered them through the use of the IoT. Attempting to implement this creates a fierce hostility between all sections, particularly for the departments with shortcomings”.(Participant 3)

“There is a resistance issue in IT departments. In many companies and factories, we have ERP software. Unfortunately, some of the software is very old, and it is crucial to update it, but they refuse to open the software source completely. This is one of the obstacles they have now presented”.(Participant 1)

“Regulations and laws are relevant within the organization or the country of manufacturing the IoT devices, operating devices, or operating power means required to operate the IoT. These three needs involve knowledge capabilities, technical capabilities, or, say, administrative capabilities, systems, and laws”.(Participant 2)

“It is rare to find anyone with theoretical knowledge and, at the same time, practical knowledge of this technology”.(Participant 2)

3.3.2. Technology and Machine-Related Obstacles and Factors Prevent the Implementation of IoT in SMEs (Subtheme 2)

“All are human-based; one person watches and monitors the data on the computer. This reliance on human intervention limited the efficiency and scalability of IoT systems”.(Participant 2)

“The devices I have or those in the market are unfortunately incompatible with purchasing devices from other vendors to fit in the ecosystem. Unfortunately, this is the state of the market currently in the Kingdom, but compatible devices are limited”.(Participant 2)

“Without considering the risks, you cannot create IoT solutions because it requires a full test before it gets down to work”.(Participant 5)

“Most factories, from what I know, are happy if they have good maintenance services. However, they are not ready to upgrade these machines and will not bring new equipment. Consequently, digital transformation and the application of the IoT are being held up or delayed”.(Participant 1)

“The first and biggest problem is heat. The high temperature works in our factory like a heater. Devices can fail or die under extreme temperatures”.(Participant 3)

“Information security is crucial in the IoT. We must ensure our systems and data are secure from potential breaches”.(Participant 4)

3.3.3. Approaches to Mitigate IoT Challenges (Subtheme 3)

“The use of the IoT in the industrial sector depends on several capabilities. These capabilities are divided into knowledge capabilities related to the organization and individuals”.(Participant 2)

“Factories usually outsource IoT deployment to international companies from abroad because they already have the experience and skilled people to build the system. Subsequently, the factory workers will follow and use the system as it is. I do not see significant challenges in adopting technology for workers because the labor force that requires manual skills will be significantly reduced, and most factory workers will depend on technical skills, computer things, and other things. It will be easy for them to match the IoT system”.(Participant 7)

“We must give young people a chance to work and let them experiment in some companies. Technical programs for designing hardware and software systems must be provided. At least three to five years of training and fully developing skilled workforce assets”.(Participant 1)

“We must give young people a chance to work and let them experiment in some companies. Technical programs for designing hardware and software systems need to be provided. At least three to five years of training and fully developing skilled workforce assets”.(Participant 1)

“If the cost we pay by implementing the IoT system is what we will reap from sales, then it is feasible to adopt it”.(Participant 7)

“Effective and cost-effective steps can be taken in these areas. Using IoT kits installed on the compressor can help mitigate any failure that could occur and provide an early warning”.(Participant 1)

“It improves production by speeding up the output rate from the production line”.(Participant 7)

“It depends on the ROI and the current investment in software integration”.(Participant 6)

“Retrofitting IoT solutions for the company is a temptation. Its development is tempting because it seems to reduce costs, avoid throwing away equipment, and bring other new equipment that will be expensive”.(Participant 4)

“This can be achieved only by building internal divisions and contracts. Outsourcing expert professional companies can be costly and may strain the companies’ budgets”.(Participant 1)

4. Discussion

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- McKinsey Global Surveys, 2021: A Year in Review; McKinsey: New York, NY, USA, 2021; Available online: https://www.mckinsey.com/featured-insights/2021-year-in-review (accessed on 17 June 2023).

- Krämer, J.; Duke-Woolley, R.; Johnson, D.; Williams, R. White Paper: Why IoT Projects Fail and How to Beat the Odds; Technical report; Software AG: Darmstadt, Germany, 2022; Available online: https://www.idglat.com/afiliacion/whitepapers/2020-5-ar-why-iot-projects-fail-en.pdf (accessed on 1 May 2022).

- Gupta, S.; Modgil, S.; Bhushan, B.; Sivarajah, U.; Banerjee, S. Design and Implementation of an IIoT Driven Information System: A Case Study. Inf. Syst. Front. 2023, 25, 1–15. [Google Scholar] [CrossRef]

- Abdulaziz, Q.A.; Mad Kaidi, H.; Masrom, M.; Hamzah, H.S.; Sarip, S.; Dziyauddin, R.A.; Muhammad-Sukki, F. Developing an IoT Framework for Industry 4.0 in Malaysian SMEs: An Analysis of Current Status, Practices, and Challenges. Appl. Sci. 2023, 13, 3658. [Google Scholar] [CrossRef]

- Turcu, C.O.; Turcu, C.E. Industrial Internet of Things as a challenge for higher education. Int. J. Adv. Comput. Sci. Appl 2018, 9, 55–60. [Google Scholar] [CrossRef]

- Mohammadian, H.D. IoT-Education technologies as solutions towards SMEs’ educational challenges and I4.0 readiness. In Proceedings of the 2020 IEEE Global Engineering Education Conference (EDUCON), Porto, Portugal, 27–30 April 2020; pp. 1674–1683. [Google Scholar] [CrossRef]

- Pal, S.; Jadidi, Z. Analysis of security issues and countermeasures for the industrial internet of things. Appl. Sci. 2021, 11, 9393. [Google Scholar] [CrossRef]

- Liao, X.; Faisal, M.; QingChang, Q.; Ali, A. Evaluating the role of big data in IIOT-industrial internet of things for executing ranks using the analytic network process approach. Sci. Program. 2020, 2020, 1–7. [Google Scholar] [CrossRef]

- Lu, Y.; Witherell, P.; Jones, A. Standard connections for IIoT empowered smart manufacturing. Manuf. Lett. 2020, 26, 17–20. [Google Scholar] [CrossRef]

- Mumtaz, S.; Alsohaily, A.; Pang, Z.; Rayes, A.; Tsang, K.F.; Rodriguez, J. Massive Internet of Things for industrial applications: Addressing wireless IIoT connectivity challenges and ecosystem fragmentation. IEEE Ind. Electron. Mag. 2017, 11, 28–33. [Google Scholar] [CrossRef]

- Sinche, S.; Raposo, D.; Armando, N.; Rodrigues, A.; Boavida, F.; Pereira, V.; Silva, J.S. A survey of IoT management protocols and frameworks. IEEE Commun. Surv. Tutor. 2019, 22, 1168–1190. [Google Scholar] [CrossRef]

- Mukherjee, S.; Baral, M.M.; Chittipaka, V.; Nagariya, R.; Patel, B.S. Achieving organizational performance by integrating industrial Internet of things in the SMEs: A developing country perspective. TQM J. 2024, 36, 265–287. [Google Scholar] [CrossRef]

- Onu, P.; Mbohwa, C. Industry 4.0 opportunities in manufacturing SMEs: Sustainability outlook. Mater. Today Proc. 2021, 44, 1925–1930. [Google Scholar] [CrossRef]

- Khan, I.A.; Keshk, M.; Pi, D.; Khan, N.; Hussain, Y.; Soliman, H. Enhancing IIoT networks protection: A robust security model for attack detection in Internet Industrial Control Systems. Ad Hoc Netw. 2022, 134, 102930. [Google Scholar] [CrossRef]

- Arnold, C.; Voigt, K.I. Determinants of industrial internet of things adoption in German manufacturing companies. Int. J. Innov. Technol. Manag. 2019, 16, 1950038. [Google Scholar] [CrossRef]

- Savoury, R.D. Influential Determinants of Internet of Things Adoption in the US Manufacturing Sector. Ph.D. Thesis, Walden University, Minneapolis, MN, USA, 2019. [Google Scholar]

- Hsu, C.W.; Yeh, C.C. Understanding the factors affecting the adoption of the Internet of Things. Technol. Anal. Strateg. Manag. 2017, 29, 1089–1102. [Google Scholar] [CrossRef]

- Tu, M. An exploratory study of Internet of Things (IoT) adoption intention in logistics and supply chain management: A mixed research approach. Int. J. Logist. Manag. 2018, 29, 131–151. [Google Scholar] [CrossRef]

- Ding, Y.; Jin, M.; Li, S.; Feng, D. Smart logistics based on the internet of things technology: An overview. Int. J. Logist. Res. Appl. 2021, 24, 323–345. [Google Scholar] [CrossRef]

- Tran-Dang, H.; Krommenacker, N.; Charpentier, P.; Kim, D.S. The Internet of Things for logistics: Perspectives, application review, and challenges. IETE Tech. Rev. 2022, 39, 93–121. [Google Scholar] [CrossRef]

- Rey, A.; Panetti, E.; Maglio, R.; Ferretti, M. Determinants in adopting the Internet of Things in the transport and logistics industry. J. Bus. Res. 2021, 131, 584–590. [Google Scholar] [CrossRef]

- Mashat, R.M.; Abourokbah, S.H.; Salam, M.A. Impact of Internet of Things Adoption on Organizational Performance: A Mediating Analysis of Supply Chain Integration, Performance, and Competitive Advantage. Sustainability 2024, 16, 2250. [Google Scholar] [CrossRef]

- Fugard, A.J.; Potts, H.W. Supporting thinking on sample sizes for thematic analyses: A quantitative tool. Int. J. Soc. Res. Methodol. 2015, 18, 669–684. [Google Scholar] [CrossRef]

- Loper, E.; Bird, S. Nltk: The natural language toolkit. arXiv 2002, arXiv:cs/0205028. [Google Scholar] [CrossRef]

- Kolla, S.S.V.K.; Lourenço, D.M.; Kumar, A.A.; Plapper, P. Retrofitting of legacy machines in the context of industrial internet of things (IIoT). Procedia Comput. Sci. 2022, 200, 62–70. [Google Scholar] [CrossRef]

- Lee, G. What roles should the government play in fostering the advancement of the Internet of Things? Telecommun. Policy 2019, 43, 434–444. [Google Scholar] [CrossRef]

- Guo, L.; Chen, J.; Li, S.; Li, Y.; Lu, J. A blockchain and IoT-based lightweight framework for enabling information transparency in supply chain finance. Digit. Commun. Netw. 2022, 8, 576–587. [Google Scholar] [CrossRef]

- Rath, K.C.; Khang, A.; Roy, D. The Role of Internet of Things (IoT) Technology in Industry 4.0 Economy. In Advanced IoT Technologies and Applications in the Industry 4.0 Digital Economy; CRC Press: Boca Raton, FL, USA, 2024; pp. 1–28. [Google Scholar] [CrossRef]

| Participant | Age | Experience (Years) | Education (Degree) | Management Level |

|---|---|---|---|---|

| Participant 1 | 53 | 29 | Bachelor’s | Senior level |

| Participant 2 | 40 | 18 | Master’s | Mid-level |

| Participant 3 | 38 | 14 | Bachelor’s | Operations |

| Participant 4 | 47 | 23 | Ph.D. | Senior level |

| Participant 5 | 33 | 8 | Bachelor’s | Mid-level |

| Participant 6 | 28 | 6 | Master’s | Mid-level |

| Participant 7 | 32 | 8 | Master’s | Mid-level |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khanfor, A. Determinants to Adopt Industrial Internet of Things in Small and Medium-Sized Enterprises. Future Internet 2024, 16, 340. https://doi.org/10.3390/fi16090340

Khanfor A. Determinants to Adopt Industrial Internet of Things in Small and Medium-Sized Enterprises. Future Internet. 2024; 16(9):340. https://doi.org/10.3390/fi16090340

Chicago/Turabian StyleKhanfor, Abdullah. 2024. "Determinants to Adopt Industrial Internet of Things in Small and Medium-Sized Enterprises" Future Internet 16, no. 9: 340. https://doi.org/10.3390/fi16090340

APA StyleKhanfor, A. (2024). Determinants to Adopt Industrial Internet of Things in Small and Medium-Sized Enterprises. Future Internet, 16(9), 340. https://doi.org/10.3390/fi16090340