Range Extension via Electrothermal Recuperation

Abstract

:1. Introduction

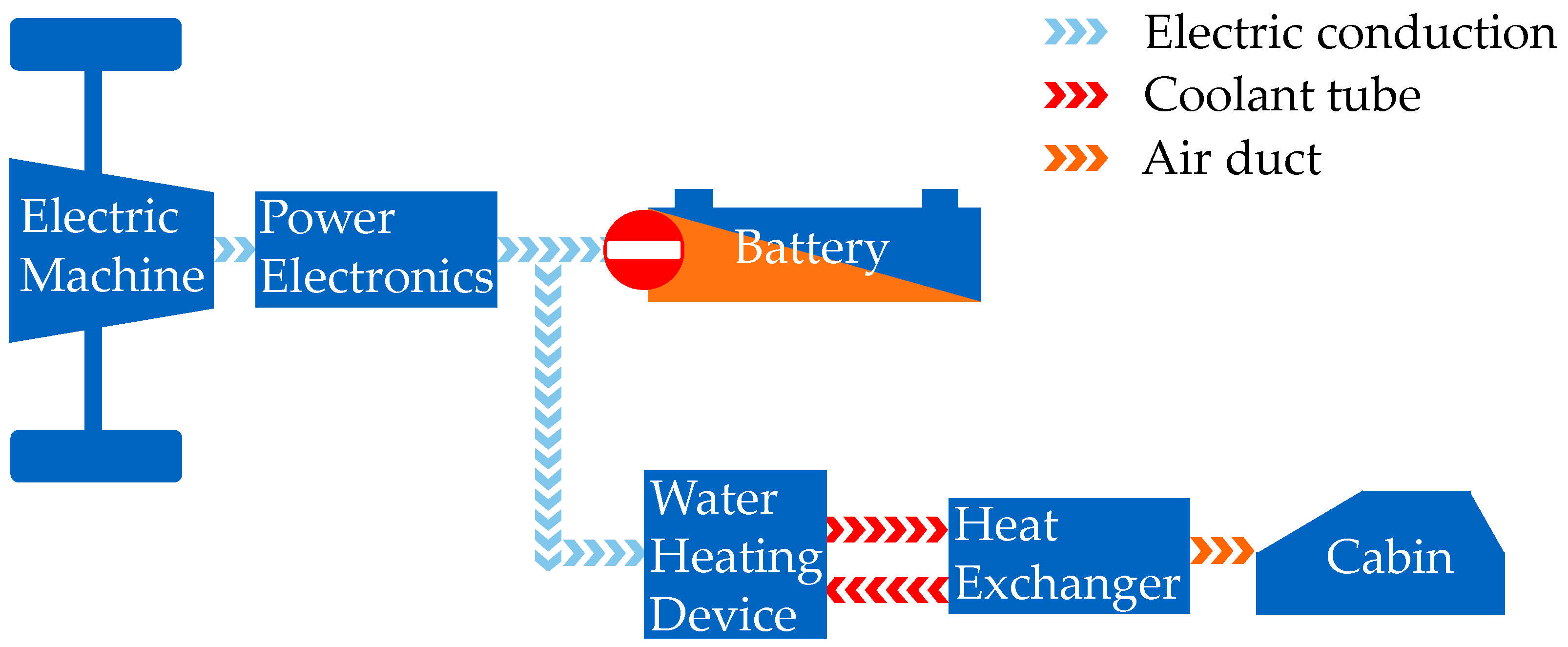

2. State of the Art

2.1. Electric Vehicle Interior Heating

2.2. Recuperation

2.2.1. Limitation of Recuperation due to the Battery

2.2.2. Electrothermal Recuperation (ETR)

2.3. Review of the State of the Art

3. Modeling

3.1. Longitudinal Dynamics

3.2. Battery Model

Limit of the Charging Power

3.3. Vehicle Heating Circuit

3.4. ETR Algorithm

4. Results and Discussion

4.1. Range Extension

4.2. Effects on Cabin Temperature

5. Conclusions

6. Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Noel, L.; de Rubens, G.Z.; Sovacool, B.K.; Kester, J. Fear and loathing of electric vehicles: The reactionary rhetoric of range anxiety. Energy Res. Soc. Sci. 2019, 48, 96–107. [Google Scholar] [CrossRef]

- Pasaoglu, G.; Scarcella, G.; Alemanno, A.; Zubaryeva, C.; Thiel, C. Attitude of European Car Drivers Towards Electric Vehicles: A Survey; European Commission: Luxembourg, 2012. [Google Scholar]

- Horrein, L.; Bouscayrol, A.; Lhomme, W.; Depature, C. Impact of Heating System on the Range of an Electric Vehicle. IEEE Trans. Veh. Technol. 2017, 66, 4668–4677. [Google Scholar] [CrossRef]

- Reyes, J.R.M.D.; Parsons, R.V.; Hoemsen, R. Winter Happens: The Effect of Ambient Temperature on the Travel Range of Electric Vehicles. IEEE Trans. Veh. Technol. 2016, 65, 4016–4022. [Google Scholar] [CrossRef]

- Samdani, E.; Lo, J.; Fowler, M.; Fraser, R.; Gimenez, L. Impact of Temperature on the A123 Li-Ion Battery Performance and Hybrid Electric Vehicle Range; SAE Technical Paper Series; SAE: Warrendale, PA, USA, 2013. [Google Scholar]

- Webasto Thermo & Comfort SE. Brochure: High Voltage Heater HVH 50/70 and HVH 100: The Future at Its Best: Innovative Heating Solution for E-Mobility. Available online: https://www.webasto-comfort.com/int/product-overview/product/show/hvh/## (accessed on 26 February 2020).

- Aris, A.M.; Shabani, B. An Experimental Study of a Lithium Ion Cell Operation at Low Temperature Conditions. Energy Procedia 2017, 110, 128–135. [Google Scholar] [CrossRef]

- Ge, H.; Aoki, T.; Ikeda, N.; Suga, S.; Isobe, T.; Li, Z.; Tabuchi, Y.; Zhang, J. Investigating Lithium Plating in Lithium-Ion Batteries at Low Temperatures Using Electrochemical Model with NMR Assisted Parameterization. J. Electrochem. Soc. 2017, A1050–A1059. [Google Scholar] [CrossRef]

- Waldmann, T.; Wilka, M.; Kasper, M.; Fleischhammer, M.; Wohlfahrt-Mehrens, M. Temperature dependent ageing mechanisms in Lithium-ion batteries—A Post-Mortem study. J. Power Sources 2014, 262, 129–135. [Google Scholar] [CrossRef]

- Sawazki, E.; Brüll, M.; Deinhard, S.; Baumgärtner, C. Potenziale zur Reichweitensteigerung von Elektrofahrzeugen im Winter. Automobiltechnische Zeitung 2015, 36–41. [Google Scholar] [CrossRef]

- Iora, P.; Tribioli, L. Effect of Ambient Temperature on Electric Vehicles’ Energy Consumption and Range: Model Definition and Sensitivity Analysis Based on Nissan Leaf Data. World Electr. Veh J. 2019, 10, 2. [Google Scholar] [CrossRef] [Green Version]

- Großmann, H. Pkw-Klimatisierung: Physikalische Grundlagen und Technische Umsetzung, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Adermann, J.; Kreibich, J.; Lienkamp, M. Experimental Study of Energy Consumption Variation in Recurring Driving Trips. J. Electr. Eng. 2017, 253–261. [Google Scholar] [CrossRef] [Green Version]

- Broglia, L.; Autefage, G.; Ponchant, M. Impact of passenger thermal comfort and electric devices temperature on range: A system simulation approach. In Proceedings of the EVS26 International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Los Angeles, CA, USA, 6–9 May 2012; pp. 1–8. [Google Scholar]

- Göhlich, D.; Ly, T.-A.; Kunith, A.; Jefferies, D. Economic assessment of different air-conditioning and heating systems for electric city buses based on comprehensive energetic simulations. In Proceedings of the EVS28 International Electric Vehicle Symposium and Exhibition, Goyang, Korea, 3–6 May 2015; pp. 1–9. [Google Scholar]

- Helfrich, T.; Lienkamp, M. Perceptible changes in driving dynamics due to regenerative braking: Analysis and reduction through active chassis systems. In Proceedings of the Advanced Vehicle Control AVEC’16, Munich, Germany, 13–16 September 2016; pp. 573–578. [Google Scholar]

- Breuer, B.; Bill, K.H. Bremsenhandbuch, 5th ed.; Springer: Wiesbaden, Germany, 2017. [Google Scholar]

- Spichartz, P.; Bubmann, L.; Sourkounis, C. Comparison of recuperation strategies for electric vehicles regarding energy efficiency. In Proceedings of the IECON 2014—40th Annual Conference of the IEEE Industrial Electronics Society, Dallas, TX, USA, 29 October–1 November 2014; pp. 2984–2990. [Google Scholar]

- Braess, H.-H.; Seiffert, U. Vieweg Handbuch Kraftfahrzeugtechnik, 7th ed.; Springer: Wiesbaden, Germany, 2013. [Google Scholar]

- Ferraris, A.; Airale, A.G.; Messana, A.; Xu, S.; Carello, M. The Regenerative Braking for a L7E Range Extender Hybrid Vehicle. In Proceedings of the IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I & CPS Europe), Palermo, Italy, 12–15 June 2018; IEEE: Piscataway, NJ, USA, 2018. [Google Scholar]

- Gao, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Ma, Z.; Jiang, Y. Lithium-ion battery aging mechanisms and life model under different charging stresses. J. Power Sources 2017, 356, 103–114. [Google Scholar] [CrossRef]

- BMW Group. Der Neue BMW i3; Technische Daten; BMW Group: Munich, Germany, 2017; pp. 1–8. [Google Scholar]

- Gewald, T.; Candussio, A.; Wildfeuer, L.; Lehmkuhl, D.; Hahn, A.; Lienkamp, M. Accelerated Aging Characterization of Lithium-ion Cells: Using Sensitivity Analysis to Identify the Stress Factors Relevant to Cyclic Aging. Batteries 2020, 6, 6. [Google Scholar] [CrossRef] [Green Version]

- Keil, P.; Jossen, A. Aging of Lithium-Ion Batteries in Electric Vehicles: Impact of Regenerative Braking. In Proceedings of the EVS28 International Electric Vehicle Symposium and Exhibition, Goyang, Korea, 3–6 May 2015. [Google Scholar] [CrossRef] [Green Version]

- Petzl, M.; Kasper, M.; Danzer, M.A. Lithium plating in a commercial lithium-ion battery—A low-temperature aging study. J. Power Sources 2015, 275, 799–807. [Google Scholar] [CrossRef]

- Keil, P. Aging of Lithium-Ion Batteries in Electric Vehicles. Ph.D. Thesis, Lehrstuhl für Elektrische Energiespeichertechnik, München, Germany, April 2017. [Google Scholar]

- Von Lüders, C.; Keil, J.; Webersberger, M.; Jossen, A. Modeling of lithium plating and lithium stripping in lithium-ion batteries. J. Power Sources 2019, 414, 41–47. [Google Scholar] [CrossRef]

- Zinth, V.; von Lüders, C.; Hofmann, M.; Hattendorff, J.; Buchberger, I.; Erhard, S.; Rebelo-Kornmeier, J.; Jossen, A.; Gilles, R. Lithium plating in lithium-ion batteries at sub-ambient temperatures investigated by in situ neutron diffraction. J. Power Sources 2014, 271, 152–159. [Google Scholar] [CrossRef]

- Bednorz, R.; Gewald, T. Investigation of the Effects of Charging Processes on Lithium-Ion Cells with SiC Anodes at Low Temperatures. In Proceedings of the Conference on Future Automotive Technology, Fürstenfeldbruck, Germany, 13–16 May 2020. [Google Scholar]

- Lieb, J.; Sawazki, E.; Brull, M.; Baker, B. Potential of an electric brake resistor to increase the efficiency of electric vehicles. In Proceedings of the Electric Vehicle Symposium 27, Barcelona, Spain, 17–20 November 2013. [Google Scholar] [CrossRef] [Green Version]

- Lieb, J. Effizienzsteigerung durch Bremswiderstände in batterieelektrischen Fahrzeugen. Ph.D. Thesis, Lehrstuhl für Fahrzeugmechatronik, Dresden, Germany, 2015. [Google Scholar]

- Danquah, B.; Koch, A.; Weiß, T.; Lienkamp, M. Modular, Open Source Simulation Approach: Application to Design and Analyze Electric Vehicles. In Proceedings of the Fourteenth International Conference on Ecological Vehicles and Renewable Energies, Monte-Carlo, Monaco, 8–10 May 2019. [Google Scholar] [CrossRef]

- Kalt, S. Electric Machine Design Tool for Permanent Magnet Synchronous Machines. In Proceedings of the Fourteenth International Conference on Ecological Vehicles and Renewable Energies, Monte-Carlo, Monaco, 8–10 May 2019. [Google Scholar] [CrossRef]

- Reiter, C.; Wildfeuer, L.; Wassiliadis, N.; Krahl, T.; Dirnecker, J.; Lienkamp, M. A Holistic Approach for Simulation and Evaluation of Electrical and Thermal Loads in Lithium-Ion Battery Systems. In Proceedings of the Fourteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 8–10 May 2019. [Google Scholar] [CrossRef]

- Nitz, J.; Hucho, W.-H. The Heat Transfer Coefficient of a Passenger Car’s Body; SAE Technical Paper No. 790399; SAE: Warrendale, PA, USA, 1979; pp. 1–12. [Google Scholar]

- Wagner, D.; Steinsträter, M.; Förth, M.; Stohwasser, M.; Hoffmann, J.; Lienkamp, M. Battery independent regenerative braking using model predictive control with auxiliary power consumers. Forsch. Ingenieurwes 2019, 843–852. [Google Scholar] [CrossRef]

| Cycle | Battery Starting Temperature in °C | Energy Consumption in kWh (ETR off) | Energy Consumption in kWh (ETR on) | Range in km (ETR off) | Range in km (ETR on) | Range Extension in % |

|---|---|---|---|---|---|---|

| FTM | 10 | 3.47 | 3.42 | 103.73 | 105.33 | 1.54 |

| 0 | 4.13 | 3.92 | 87.08 | 91.80 | 5.41 | |

| −10 | 4.99 | 4.62 | 72.09 | 77.89 | 8.04 | |

| WLTC | 10 | 4.34 | 4.31 | 100.61 | 101.15 | 0.53 |

| 0 | 5.01 | 4.84 | 87.09 | 90.08 | 3.43 | |

| −10 | 5.95 | 5.69 | 73.31 | 76.64 | 4.54 |

| Cycle | Battery Starting Temperature in °C | Energy Consumption in kWh (ETR off) | Energy Consumption in kWh (ETR on) | Range in km (ETR off) | Range in km (ETR on) | Range Extension in % |

|---|---|---|---|---|---|---|

| FTM | 10 | 3.41 | 3.40 | 72.92 | 73.30 | 0.52 |

| 0 | 3.98 | 3.89 | 62.52 | 63.98 | 2.32 | |

| −10 | 4.89 | 4.60 | 50.78 | 53.94 | 6.23 | |

| WLTC | 10 | 4.32 | 4.32 | 69.85 | 69.85 | 0 |

| 0 | 4.91 | 4.86 | 61.46 | 62.01 | 0.89 | |

| −10 | 5.89 | 5.71 | 51.17 | 52.84 | 3.26 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Steinstraeter, M.; Lewke, M.; Buberger, J.; Hentrich, T.; Lienkamp, M. Range Extension via Electrothermal Recuperation. World Electr. Veh. J. 2020, 11, 41. https://doi.org/10.3390/wevj11020041

Steinstraeter M, Lewke M, Buberger J, Hentrich T, Lienkamp M. Range Extension via Electrothermal Recuperation. World Electric Vehicle Journal. 2020; 11(2):41. https://doi.org/10.3390/wevj11020041

Chicago/Turabian StyleSteinstraeter, Matthias, Marcel Lewke, Johannes Buberger, Tobias Hentrich, and Markus Lienkamp. 2020. "Range Extension via Electrothermal Recuperation" World Electric Vehicle Journal 11, no. 2: 41. https://doi.org/10.3390/wevj11020041