Abstract

Digital twinning technology originated in the field of aerospace. The real-time and bidirectional feature of data interaction guarantees its advantages of high accuracy, real-time performance and scalability. In this paper the digital twin technology was introduced to electric vehicle energy consumption research. First, an energy consumption model of an electric vehicle of BAIC BJEV was established, then the model was optimized and verified through the energy consumption data of the drum test. Based on the data of the vehicle real-time monitoring platform, a digital twin model was built, and it was trained and updated by daily new data. Eventually it can be used to predict and verify the data of vehicle. In this way the prediction of energy consumption of vehicles can be achieved.

1. Introduction

The Ethiopian Airlines crash on 10 March 2019, which resulted in the loss of so many lives, is deplorable. As a painful experience, the Boeing 737MAX 8 aircraft had two major accidents in less than half a year, which causes discussions on the daily maintenance of aircraft all around the word. As a result, the stocks about the digital twinning all rose by the daily limit, and digital twinning technology also attracted more and more attention [1]. For every serious accident, there are 29 mishaps, 300 attempted mishaps and 1000 potential mishaps, according to Hine’s method. If digital twinning can be used to predict the object in real time before the accident, the possibility of tragedy can be reduced by a great extent.

The Defense Acquisition University (DAU) defined digital twinning as: an integrated multi-physics, multi-scale, probabilistic simulation of an as-built system, enabled by Digital Thread, that uses the best available models, sensor information, and input data to mirror and predict activities/performance over the life of its corresponding physical twin [2]. Chen Gen describes digital twinning as follows in his book about digital twinning: digital twinning refers to the construction of a model in the digital world which is the same as the object in physical world through digital means, for the understanding, analysis and optimization of the physical object. From a professional point of view, digital twinning integrates techniques such as artificial intelligence (AI) and machine learning (ML) and combines data, algorithms and decision analysis to build simulations, or virtual mapping of physical objects, to detect problems before they happen, to monitor changes in the virtual model of physical objects, to diagnose complex processing of multidimensional data based on artificial intelligence and analysis of anomaly, and to predict the risk, to plan reasonably and effectively or to maintain the equipment.

With the growing popularity of digital technology, digital twin technology is gradually being put to use in more and more fields [3,4,5,6,7,8,9]. For example, Liu Zhansheng et al. applied digital twin technology to the construction industry: their paper proposes an intelligent method of building based on digital twin technology, and with an intelligent ascending scale model of spokes type tensioned cable truss test as an example he established and validated a digital twin model [7]. Shen Chen et al. applied digital twinning to energy Internet, and based on the existing energy Internet planning platform—CloudIEPS—verified the role of digital twinning technology through the modeling of energy Internet planning cases [6]. Zou Dong et al. analyzed and discussed the technical feasibility of digital twin technology in the power supply system of urban rail transit [8]. Wang Qingtao et al. proposed an application scheme of digital twin technology in the field of autonomous driving tests [9].

So far, a lot of papers about the energy consumption of electric vehicles with different themes have been published [10,11,12,13,14,15,16,17,18,19,20,21]. For example, Fernández determines the influence of urban traffic management policies on energy consumption [10]. Al-Wreikat Yazan evaluates how driving behavior and trip condition effects the energy consumption [12]. Huda, N researched the influence of regenerative braking on energy consumption [14]. Some of them are based on traditional models [14,15,16,17,19,20,21], for example, Anil K.Madhusudhanan and Miri Ilyès used Matlab to simulate the energy consumption, respectively [14,19]. Zhang Wenchao and Bogdan Varga used Cruise to obtain the energy consumption, respectively [16,17]. So far, there is no paper on the energy consumption of electric vehicles based on digital twin technology. So, in this paper this new and powerful technology is used to predict the energy consumption of an electric vehicle.

The difference between the digital twin and the traditional model is that digital twin not only describes a physical object, but also has a two-way data transmission with the physical object; on the one hand, the state of the physical object is transmitted to the digital twin for real-time correction of digital twin. On the other hand, digital simulation and results of optimization in the digital space can be fed back to the physical object to guide the decisions. Therefore, two-way data interaction with a physical object is a key feature of digital twinning and an important means to ensure the state of synchronization between digital twinning and physical object [6].

Besides the basic function of predicting energy consumption dynamically, the digital twin technology also has many other derivative functions that the traditional models do not have. With the use of cars, the normal aging of the battery can lead to a loss of capacity, motor and other parts also cause an increase of energy consumption inevitably because of aging. These changes can also be fed back into the digital twin model through two-way transmission of data, the modified model can predict the present and future automobile energy consumption in turn. In the other words, the prediction can not only be dynamic with the outside factors, but can also be updated with the state of itself. In addition to energy consumption prediction, it can also detect the health state of the vehicle in real time. When the deviation of the energy consumption between the real car and the digital twin model suddenly becomes larger and lasts for a long time, it indicates that the car is in trouble or hidden danger. The owner can repair the car in time before a major accident happens.

Due to the limitations of the equipment, it is difficult to update the model with all the factors. In the experiment in this paper, only important parameters are considered.

2. Electric Vehicle and Digital Twin

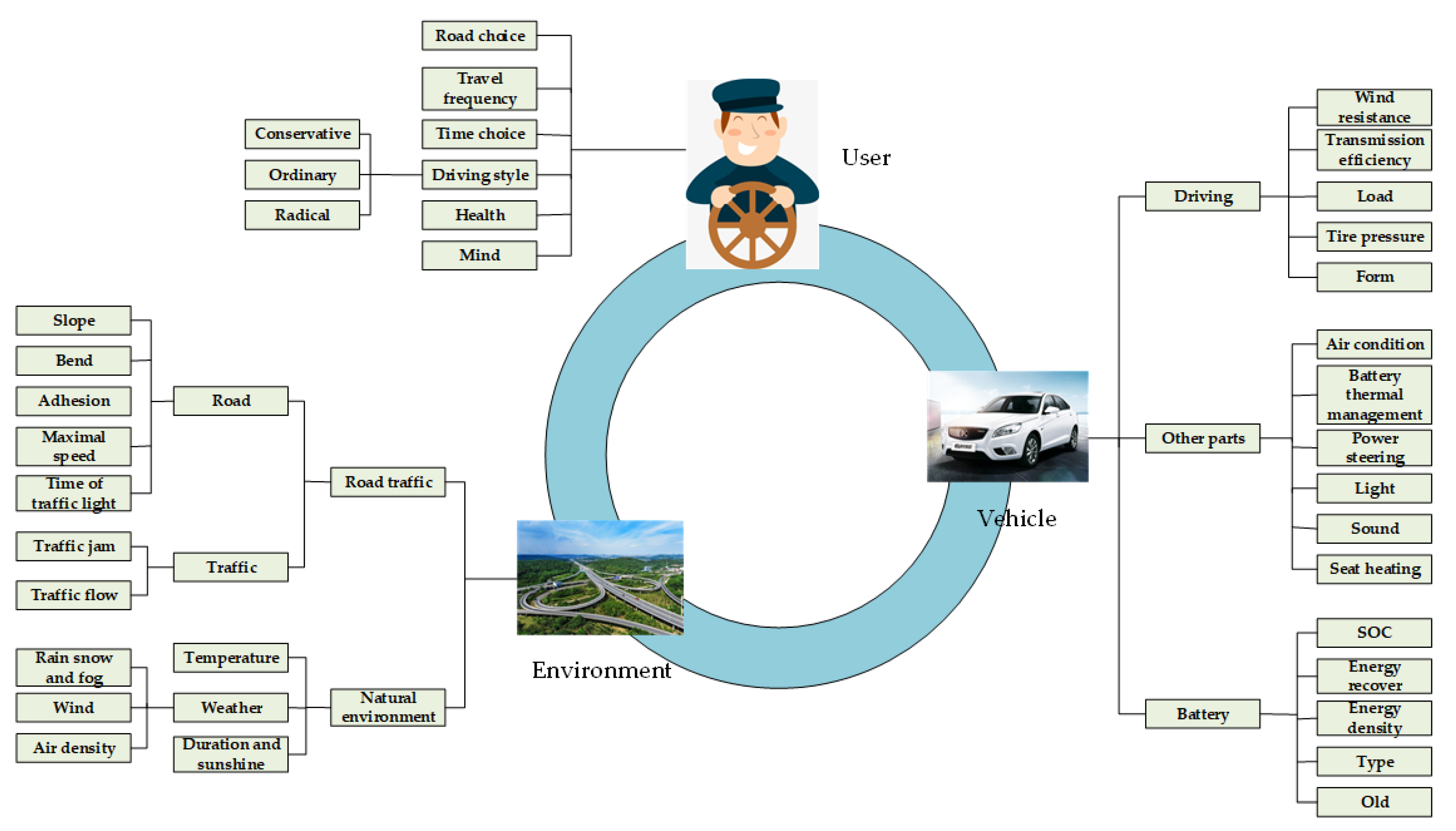

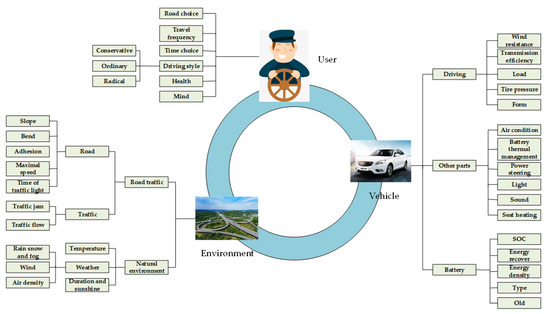

Electric cars have many advantages, such as high energy conversion efficiency, clean energy, low energy cost and low noise. The biggest weakness is that their range is shorter than traditional fuel vehicles, although currently on the market the latest electric car official NEDC range can reach 600 or even over 700 km, but real range is influenced by many factors, and especially in winter, the actual range will be greatly reduced. Gao Hongwei et al. divided the factors affecting vehicle energy consumption into three categories [22]: the configuration of the vehicle itself, the external environment in which the vehicle is driven, and the state of the driver, it is shown in Figure 1.

Figure 1.

Factors affecting energy consumption of electric vehicles [22].

Various factors are complexly interrelated, interchangeable with each other. For example, the traffic condition affects the driver’s psychological state [18], and the external temperature affects the opening and closing of air conditioning and the battery thermal management state. Among them, the influence of temperature on energy consumption is an important factor that cannot be ignored [23]. In this paper, the digital twin model for energy consumption prediction is based on a specific electric vehicle, which mainly takes temperature factor and covers a variety of other influencing factors.

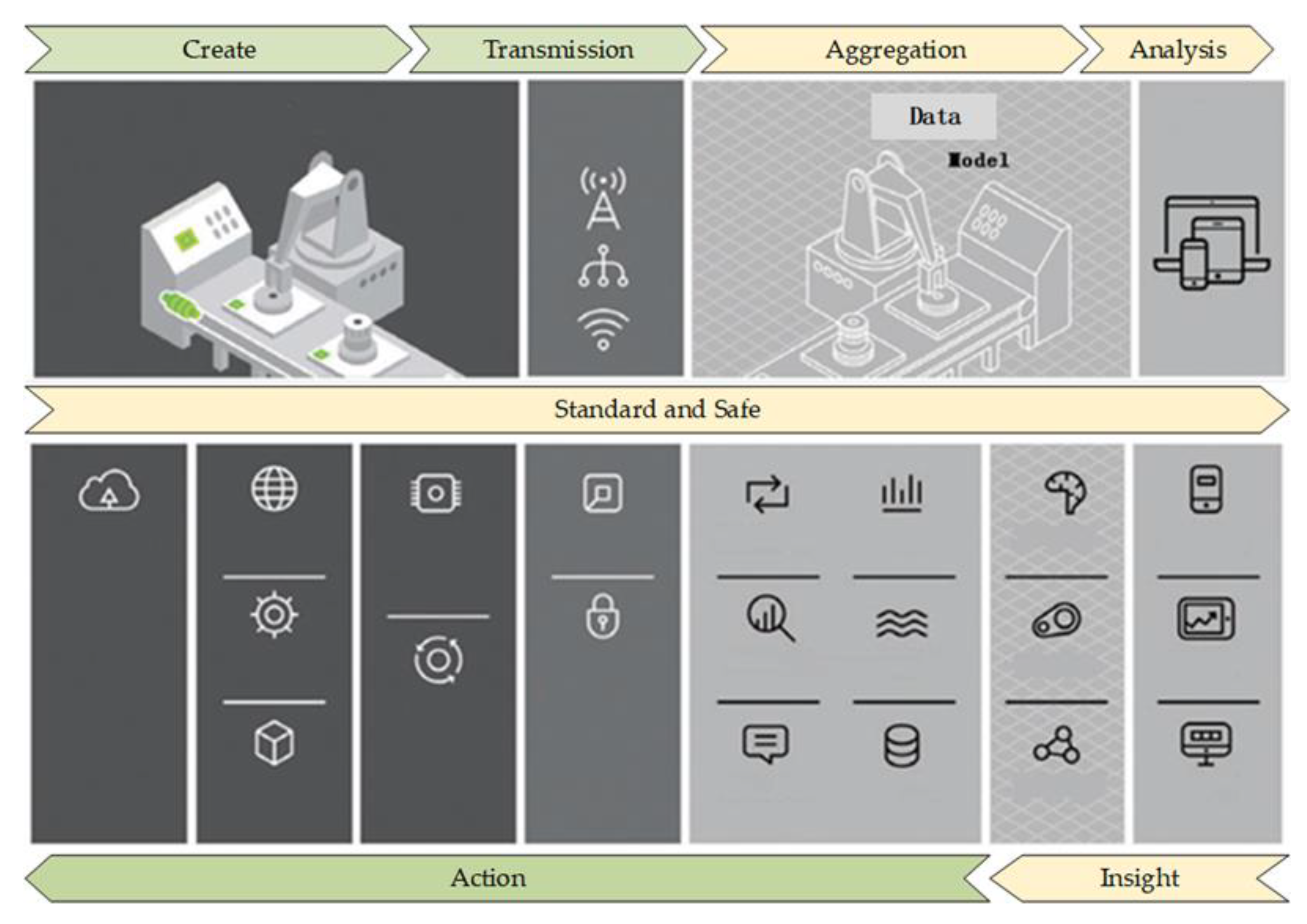

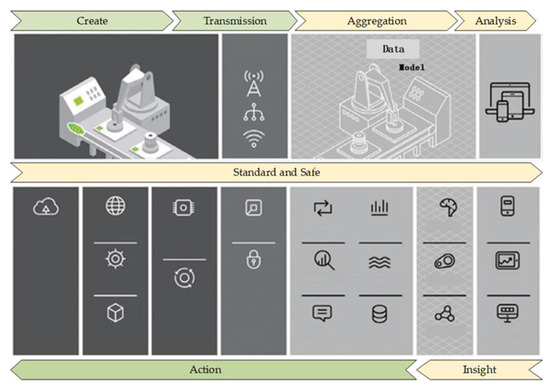

Deloitte’s “Industry 4.0 and Digital Twin” defines the conceptual architecture of digital twin as shown in the Figure 2 below. The architecture is divided into six steps: 1. Create, 2. Transmission, 3. Aggregation, 4. Analysis, 5. Insight and 6. Action. This basic principle can be generally applied to digital twin models in different fields [24].

Figure 2.

Digital Twin Conceptual Architecture [1].

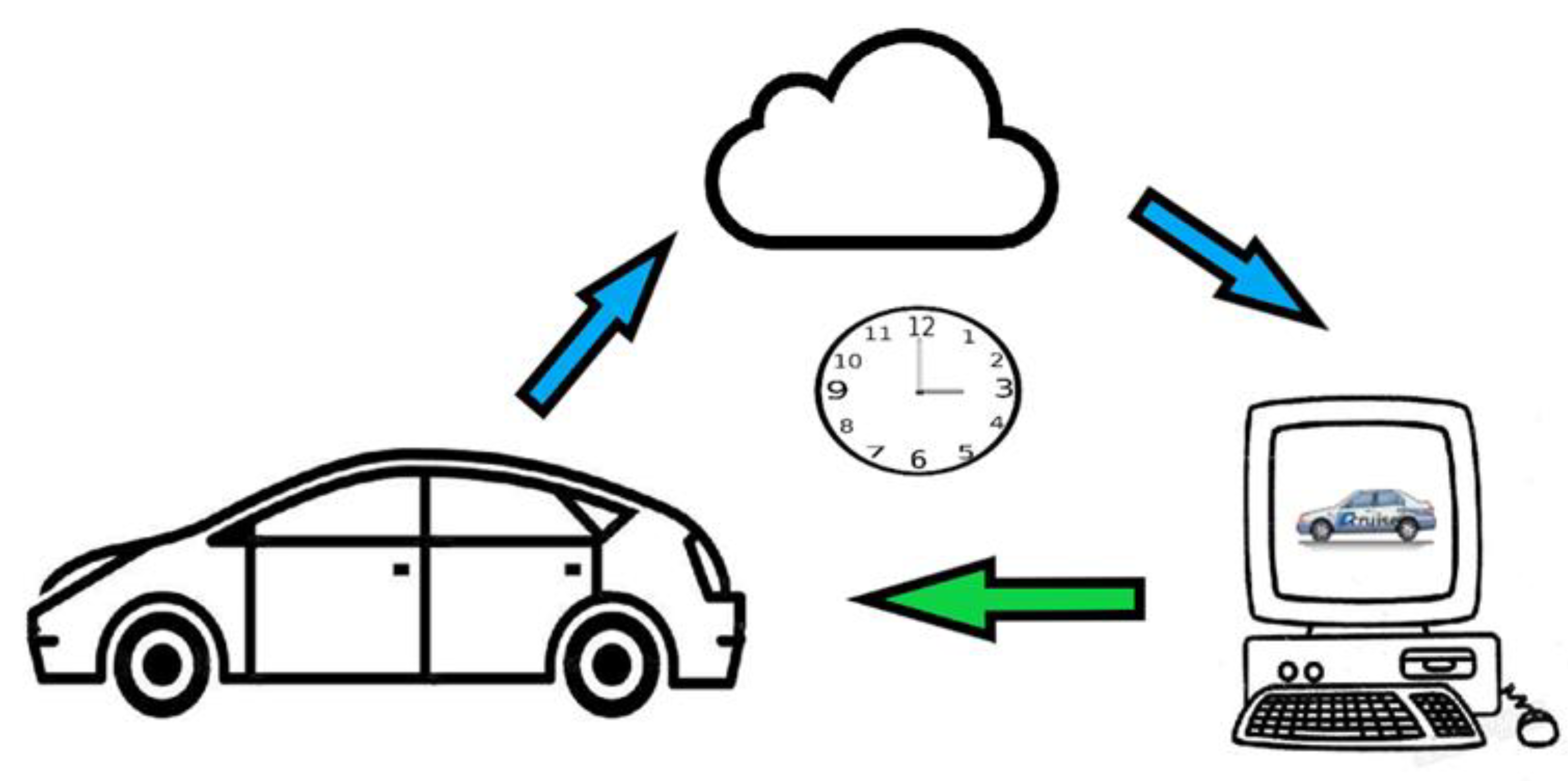

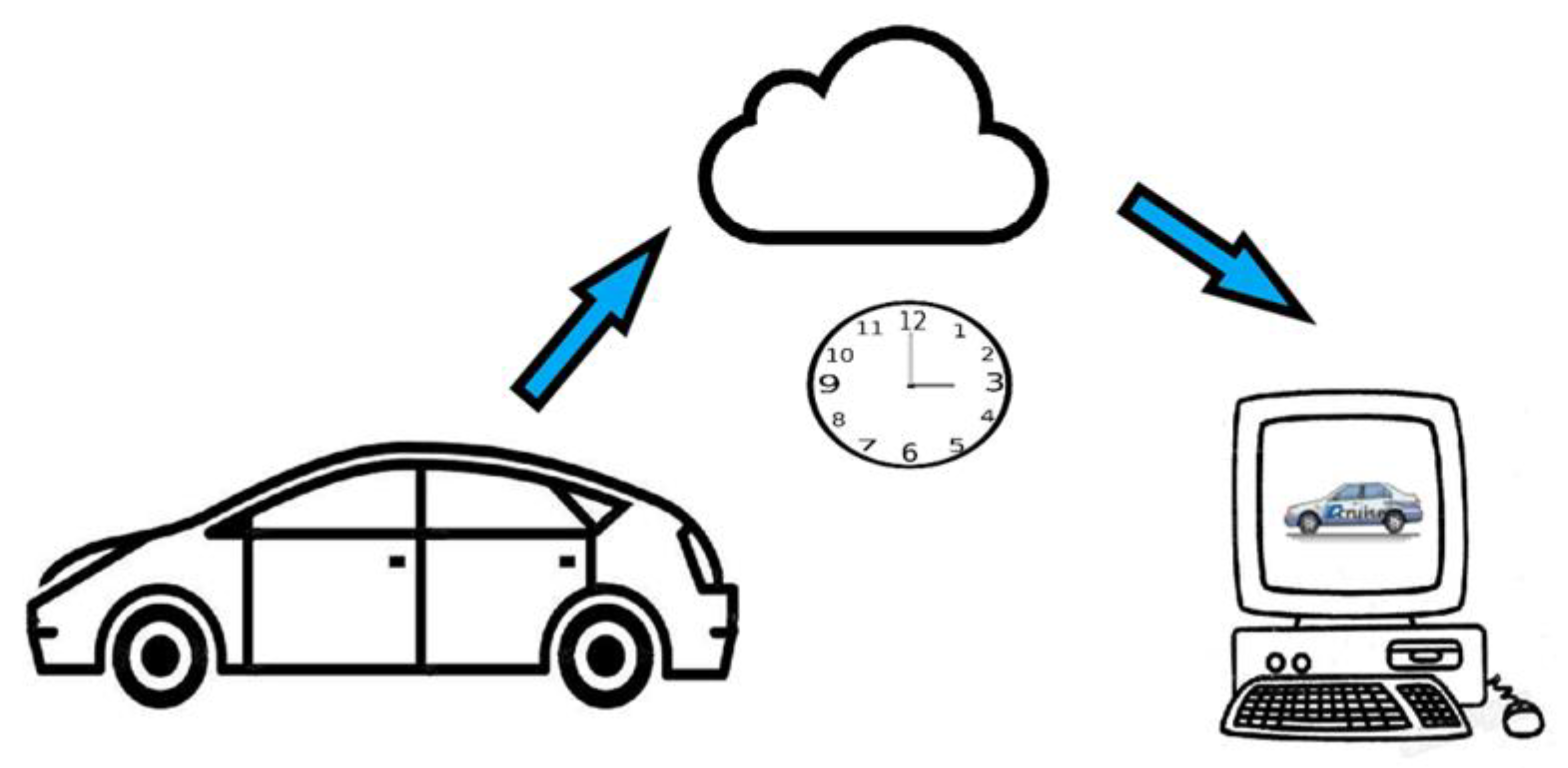

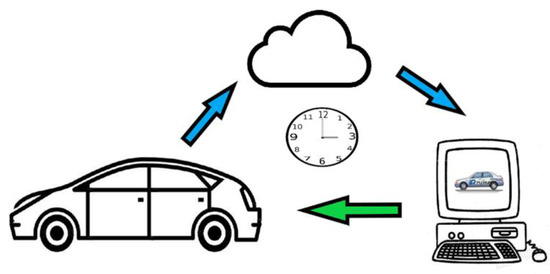

The digital twin model for electric vehicle energy consumption prediction will be built according to the above basic principles in Figure 2. In the “create” step, various data about the car is collected. Electric vehicles themselves have a large number of sensors; most common driving data can be read by external devices via the CAN bus, and the whole process is mature in the industry. In addition, the collected data also include external environmental data such as wind direction, temperature, traffic conditions, road conditions and so on. The second step—“transmission”—consists of two steps of transmission. The first step is the wire transmission inside the vehicle. The whole process includes data collection from sensors, preliminary data processing, and conversion into forms that can be read with CAN messages. The second step is vehicle–cloud wireless transmission. The preliminarily processed data is remotely transmitted to the cloud through the wireless network. Combined with the existing 5G technology, data can be monitored remotely in real time. The third step is “aggregation”, that is, the data of vehicle and external environment transmitted in the previous step is saved in the cloud database, and the real-time data collected by the sensor can be obtained through the data monitoring platform of the computer, and the historical data at any time can be also investigated. The fourth step, “analysis”, is the core step in the construction process of the whole digital twin conceptual architecture. In this step, the required data is processed and integrated with various data analysis tools and technologies. With the collection of new data, the database and model are continuously iterative upgraded. The construction of the core content of the digital twin model of an electric car is completed in this step. The fifth step, “insight”, as the name implies, is to present the processed data in a visual form, which needs to reflect the difference between the virtual model and the study object in the physical world in one or more dimensions. As stated in the abstract, the purpose of this paper is to use digital twinning to predict energy consumption. Therefore, it reflects the difference between the digital twin model of electric vehicle energy consumption and the actual energy consumption of the vehicle based on the main influence factors. The final step is “action”. Based on the difference of model and physical object, the physical object is purposefully changed. After the energy consumption model that can be updated in real time is built, and fully iteratively learns, until the model is fully credible, the energy consumption data is fed back to the real car. Therefore, the energy consumption of the car can be predicted accurately, and a variety of faults or hidden faults that cause increased energy consumption can be predicted in advance. The information transmission of digital twin model of electric vehicle energy consumption is shown in Figure 3.

Figure 3.

Information transmission diagram of digital twin model of electric vehicle energy consumption.

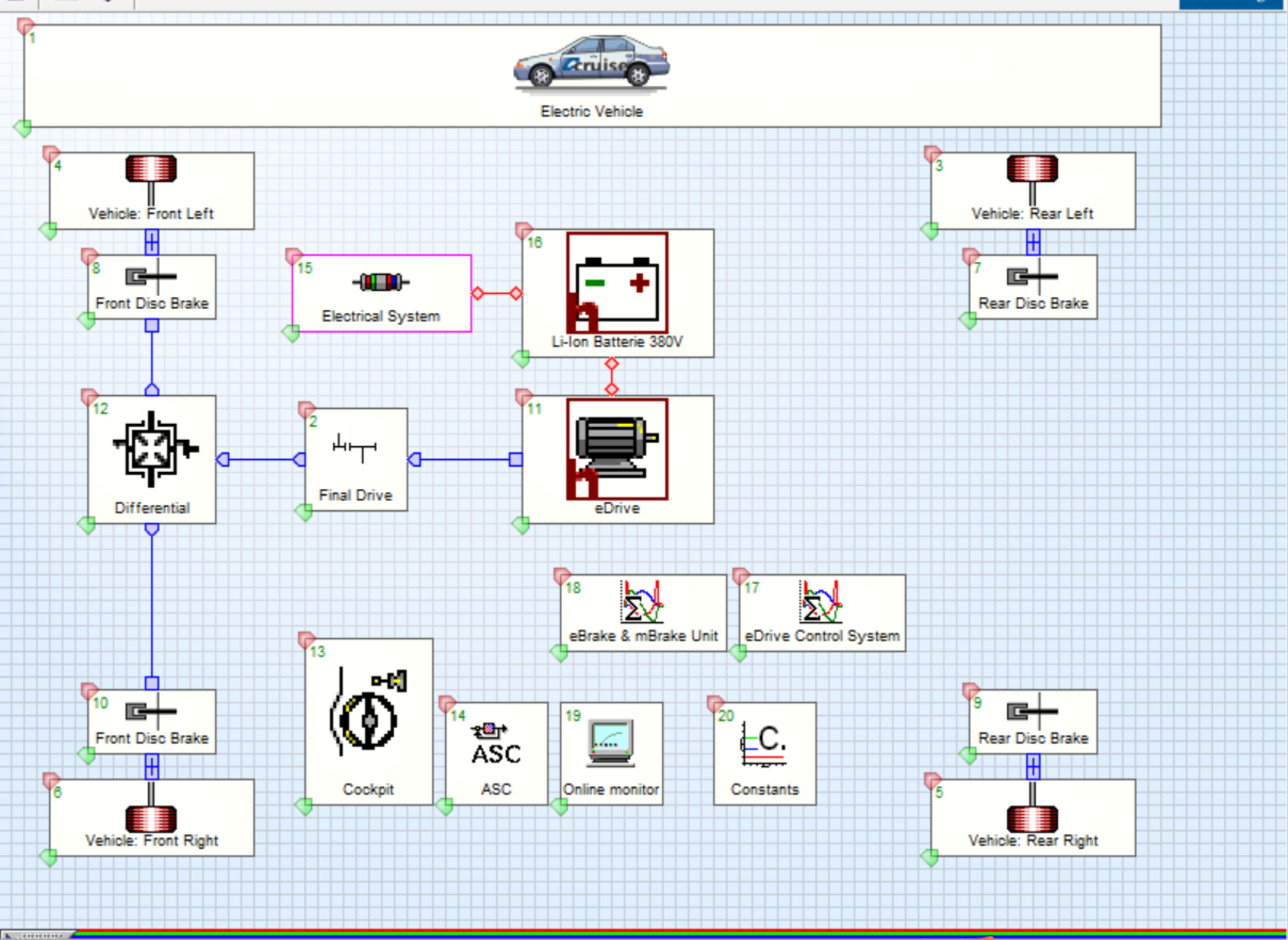

A pure electric vehicle EU300 of BJEV was used to build the model. Firstly, a basic vehicle model based on Cruise is established, which is the basis of the next digital twin model. The basic model is limited by software functions and cannot be optimized in real time based on data.

Before establishing the model, the vehicle body parameters of EU300 were collected in Table 1.

Table 1.

Body Parameter of the vehicle.

The parameters of electric systems and other parts that affect the energy consumption were collected in Table 2.

Table 2.

Performance Parameter of the vehicle.

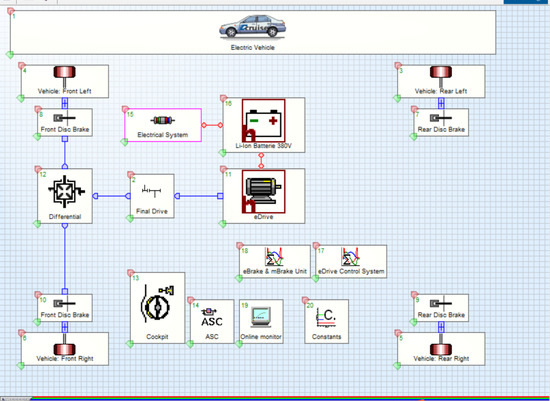

EU300 is a pure electric vehicle with automatic transmission and front drive. According to the structure and existing parameters of the car, the basic model of the vehicle is built as shown in the Figure 4 below:

Figure 4.

Cruise-based energy consumption model for the test vehicle.

After the initial model was established, it was verified and validated with laboratory data. Firstly, the EU300 model in Cruise was run under the virtual NEDC standard at 25 °C room temperature, and as the result, the energy consumption of the model was obtained. Then the actual vehicle was used to do the drum test in the laboratory at the same temperature and under the same working condition, as shown in Figure 5, and the measured data of the electric system and the actual energy consumption were read. The model was calibrated and optimized with the measured data in the experiment so as to ensure the credibility of the basic model.

Figure 5.

Drum test of a test car in the laboratory.

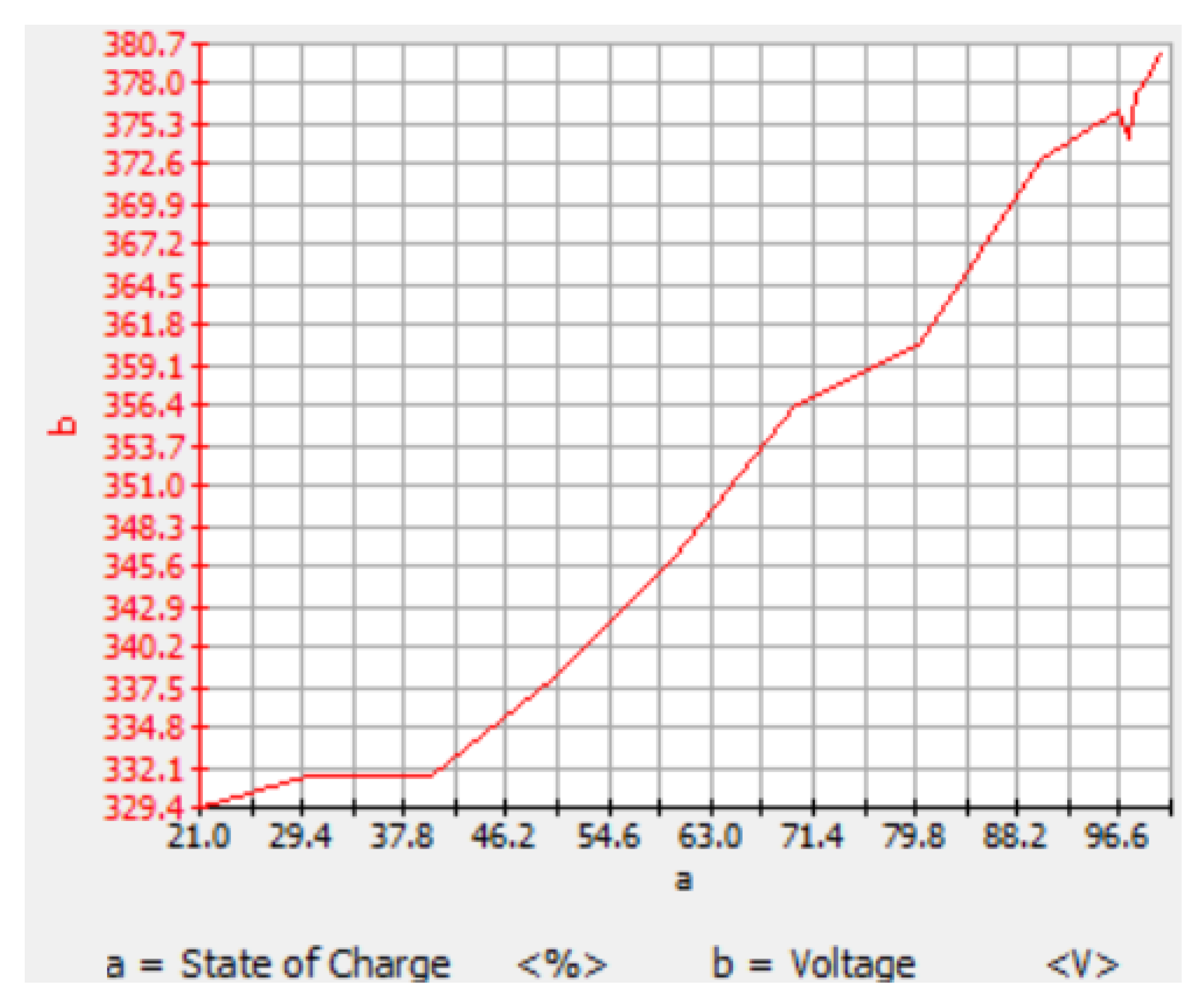

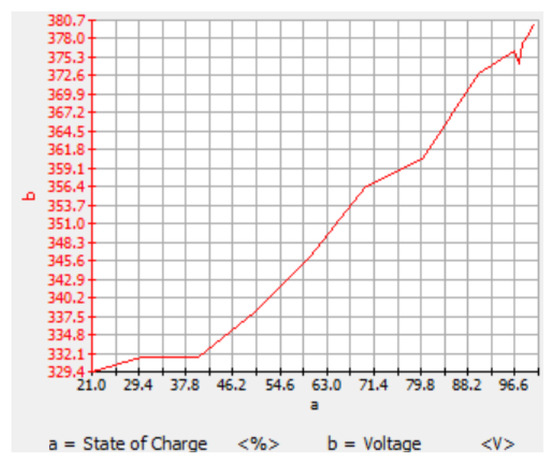

In the drum test, the relationship between the SOC and the battery voltage during discharge of this electric vehicle was measured. As shown in the Figure 6 below, a is the SOC and b is the output voltage of the battery. The actual nominal voltage of the power battery was 380.2 V.

Figure 6.

Relationship between battery SOC and battery output voltage.

According to laboratory data, the actual usable capacity of the battery is 39.3 kWh and the usable energy is 117.04 Ah. The battery fades little and can be used as an experimental vehicle.

After the relevant parameters were updated and optimized, the new basic model was run again to obtain the energy consumption of the new model. The energy consumption of the updated model was compared with the energy consumption measured in the laboratory, and the energy consumption data of the two and the deviation are shown in the Table 3 below.

Table 3.

Energy consumption comparison of the model and the car.

The deviation between model data and experimental data is 3.70% < 5%, so it can be considered that the energy consumption model built by us is accurate enough.

After the verification, this model was used as the base to build a digital twin model.

3. Building of a Digital Twin Energy Consumption Model of Electric Vehicle

The energy consumption of electric vehicles is largely affected by temperature. However, the energy consumption basic model of electric vehicles cannot reflect the dynamic state of energy consumption with the change of temperature as the vehicle is running in real time. Therefore, the next step is to dynamically update and optimize the energy consumption basic model of the electric vehicle in real time.

The test car was driven on the streets, and other power-consuming functions unrelated to car driving were turned off when they were not necessary, including air conditioning, seat heating and audio. The test vehicle monitoring cloud platform was used to obtain various data of the test vehicle, including time, vehicle speed, SOC, instantaneous output voltage of the battery, instantaneous output current of the battery, acceleration pedal opening, maximum temperature of the battery pack, minimum temperature of the battery pack, etc. The data transmission of the real-time optimization process of the model is shown in Figure 7.

Figure 7.

Data transmission diagram of the real-time optimization process of the model.

To make the data more targeted to reflect the relationship between the energy consumption and the temperature, invalid data in the monitoring platform was discarded with the following principles: in the process of driving if it was necessary to open other power-consuming functions such as air conditioning, the data was discarded when it was opened. When a power consumption function was opened, the ECU signal about it could be detected by the monitoring platform. When the car was braking and the energy was fed back to charge the battery, the measured data was also out of the scope of our research. At this time, the output current of the battery was negative as can be seen in the monitoring platform. It was found through the test that when the temperature changed rapidly, the deviation of the instantaneous energy consumption of the vehicle was very large. The process is complex and the error is large, so the data at that time was meaningless for the results, so it was discarded. The threshold of temperature change was set at 1 °C/100 s, that is, when the temperature change within 100 s was more than 1 °C the data was discarded. When the speed was maintained at 0 in a period of more than 3 min, it was regarded as a long stopping time, and the data at long stopping times was also discarded.

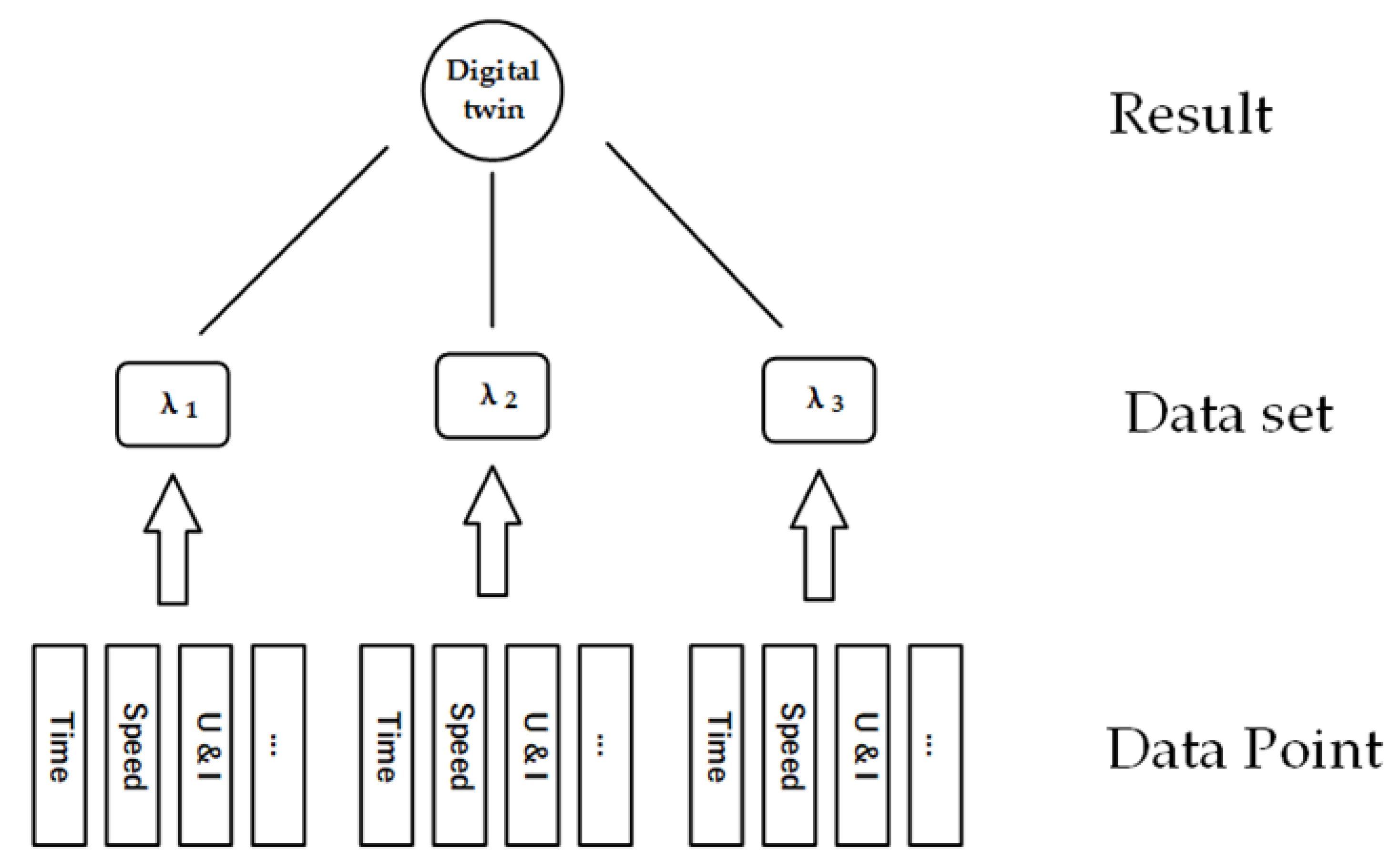

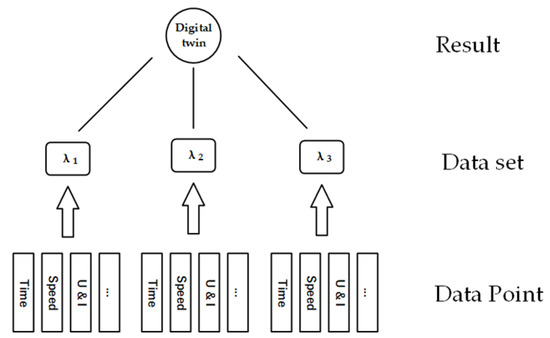

The effective data were selected according to the above principles, and the data at every moment in the effective data was called the data point. When the temperature did not change in a certain period of time, the data points in this period of time were processed iteratively to obtain the data set. To make the data set fully reliable, each data set was processed from more than 80 instantaneous points. As mentioned above, data points include time, vehicle speed, battery SOC, instantaneous output voltage of battery, instantaneous output current of battery, acceleration pedal opening, maximum temperature of battery pack, minimum temperature of battery pack, etc., while a data set only contains a specific temperature and its corresponding compensation coefficient λ. The compensation coefficient λ is the ratio of the actual energy consumption to the energy consumption of the basic model in the data points corresponding to this data set, namely:

W is the actual total energy consumption of the battery in a period of time, and w is the energy consumption in the basic model under the same working condition in this time. The compensation coefficient reflects the deviation of energy consumption between the basic model and the experimental vehicle, and it depends on temperature.

According to the battery instantaneous output voltage U and battery instantaneous output current I at each moment in the effective measurement data (i.e., data points), the following formula can be used to calculate the actual total output energy consumption W of the battery of the test vehicle in a specific period of time.

In the formula, t1 is the initial time and t2 is the end time.

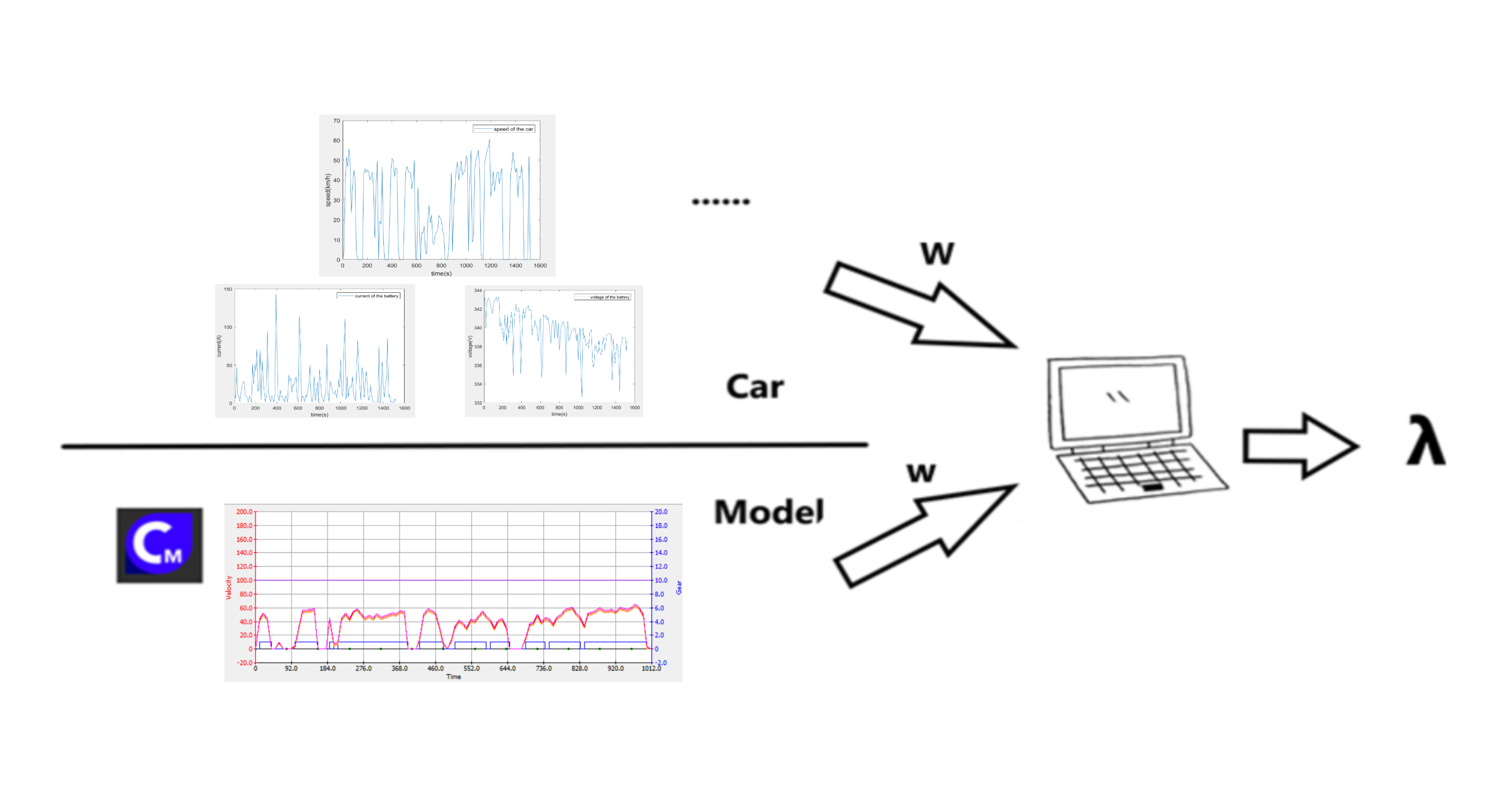

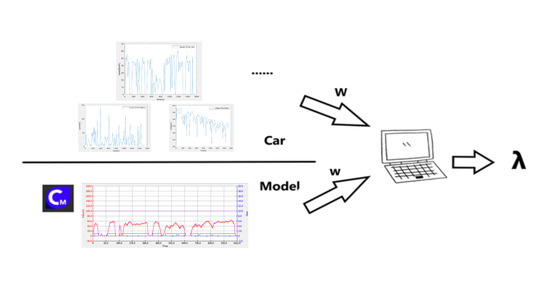

Figure 8 shows how the compensation coefficient λ is obtained generally. Firstly, the actual total energy consumption of the battery W is calculated with instantaneous output voltage U and instantaneous output current I of the battery according to Equation (2). Then, the energy consumption of the basic model w is obtained after the parameters of the car and the working conditions are input into the model. Finally, the compensation coefficient λ can be calculated with W and w according to Equation (1).

Figure 8.

The process to obtain the compensation coefficient λ.

As mentioned above, since the influence of other energy consumption functions on energy consumption is excluded, it can be considered that the actual total output energy consumption of electric vehicle battery in the experiment is the energy consumption consumed by driving.

After adjusting data for a certain period of time according to the format in Cruise, they were put into the corresponding folder in the computer, and then the Cruise base model ran so that the model energy consumption w for this period could be obtained.

To approach the real parameter, the new measured data was used repeatedly to update the model. The updated model was used as the original one with new measured data to be updated again and again. The data processing is shown in Figure 9.

Figure 9.

Iterative processing of the data.

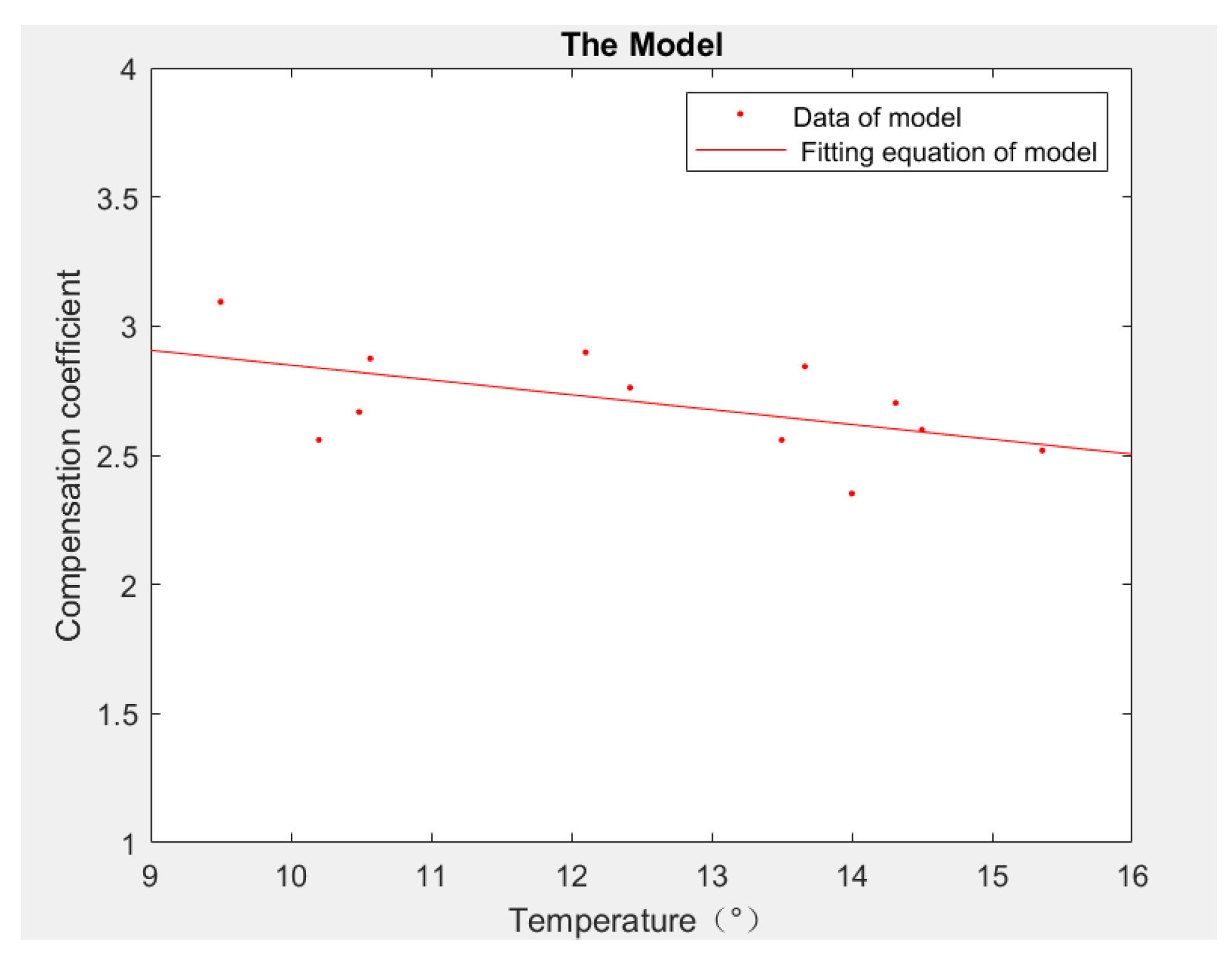

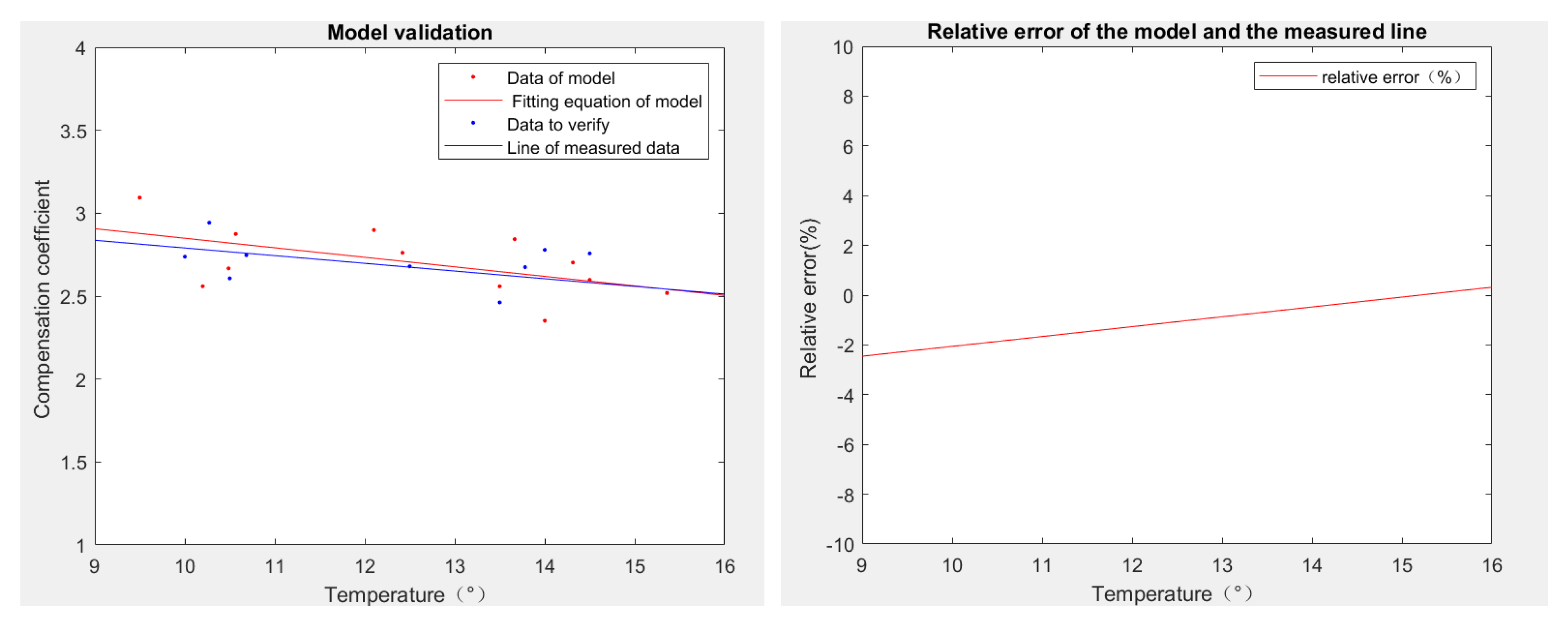

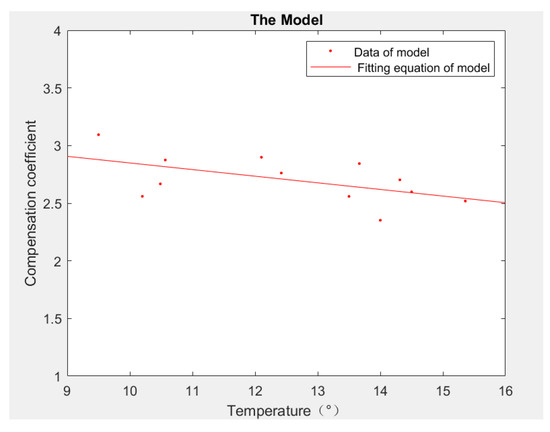

After getting enough data sets, the obvious abnormal points were removed, and the least square method was used to fit the relationship between the compensation coefficient and the temperature, the result is shown in Figure 10. The temperature was the independent variable, and the compensation coefficient was the dependent variable. There are many reasons for the occurrence of abnormal points, such as steep slopes and extreme traffic conditions, etc. However, such outliers are sporadic and do not last, so they can be identified in the process of data processing. After finding the relationship, the energy consumption result of the model is multiplied by the compensation coefficient at the corresponding temperature to obtain the modified theoretical actual energy consumption at the moment.

Figure 10.

Fitting process of compensation coefficient relationship.

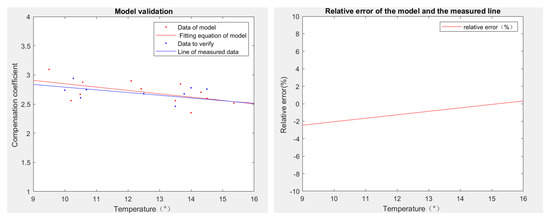

After the model was established, other data was used to verify the compensation coefficient, and the result was shown in Figure 11:

Figure 11.

Validation process of compensation coefficient relationship.

Although there are many practical factors, such as wind direction, mild uphill and downhill, road conditions, etc., that lead to actual data floating, judging from the results, the actual data is still distributed near the linear regression equation. As shown in Figure 11, the two lines are similar. The maximal relative error of the two lines from 9° to 16° is only 2.454%. The lower the temperature is, the bigger the error is.

Compensation coefficient can be constantly modified and optimized when real-time data uploads, then the digital twin model can be optimized continuously with the optimization of compensation coefficient. According to the optimized model, the future energy consumption of the electric vehicle at different temperatures can be predicted. Thus, the digital twin model is completed.

4. Conclusions and Prospects

A method with digital twin model is proposed to predict the energy consumption of electric vehicles. The digital twin model is built based on the traditional model in the dimension of temperature-energy consumption, which verifies the feasibility of the method.

As the real-time monitoring data used to modify the digital twin model continues to accumulate, the digital twin model will become more accurate and the predictions of actual energy consumption will become more reliable.

Constrained by the existing conditions, only the temperature effect of the digital twin model of the vehicle energy consumption is modified in real time through the data monitoring platform in this paper. For other non-major influencing factors, such as vehicle speed, braking energy feedback, rolling resistance, etc., we assumed that the model was the same as the actual situation without real-time optimization. Factors that cannot be simulated in the basic model, such as real-time wind and direction, up and down slopes, air conditioning, etc., are not reflected in the digital twin model.

In the future, when the digital twin model becomes more mature, more popular and even put onto the market, more parameters affecting energy consumption will be modified in real time. The data needed to optimize the digital twin model will also be greater, the sampling interval will be smaller and the whole process of collecting, processing, optimizing and forecasting will become more intelligent.

Author Contributions

Conceptualization, Z.Z. and Y.Z.; methodology, T.Z.; software, T.Z.; validation, X.Z. and Z.X.; formal analysis, Y.Z.; resources, Z.Z.; data curation, T.Z.; writing—original draft preparation, T.Z.; writing—review and editing, Z.Z.; supervision, Y.Z.; project administration, Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the National Natural Science Foundation of China under Grant 51775039, Grant 51861135301 and Grant 51805030.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest. Teng Zhou and Zhifeng Xu are employees of Beijing Automotive Industry Corporation–Beijing electric vehicle (BAIC BJEV). The paper reflects the views of the scientists, and not the company.

References

- Chen, G. Data Twinning; Publishing House of Electronics Industry: Beijing, China, 2020. [Google Scholar]

- Defense Acquisition University. Digital System Model [M/OL]//Glossary of Defense Acquisition Acronyms and Terms. Fort Belvoir: DAU Press (2015-09). Available online: https://www.dau.edu/tools/Documents/Glossary_16th%20_ed.pdf (accessed on 1 September 2015).

- Nguyen, H.X.; Trestian, R.; To, D.; Tatipamula, M. Digital Twin for 5G and Beyond. In IEEE Communications Magazine; IEEE: Piscataway, NJ, USA, February 2021; Volume 59, pp. 10–15. [Google Scholar] [CrossRef]

- Bamberg, A.; Urbas, L.; Bröcker, S.; Bortz, M.; Kockmann, N. The Digital Twin—Your Ingenious Companion for Process Engineering and Smart Production. Chem. Eng. Technol. 2021, 44, 954–961. [Google Scholar] [CrossRef]

- Möller, D.P.F.; Vakilzadian, H.; Hou, W. Intelligent Manufacturing with Digital Twin. In Proceedings of the 2021 IEEE International Conference on Electro Information Technology (EIT), Mt. Pleasant, MI, USA, 14–15 May 2021; pp. 413–418. [Google Scholar] [CrossRef]

- Shen, C.; Jia, M.; Chen, Y.; Huang, S.; Xiang, Y. Energy Internet Digital Twinning and Its Application. Glob. Energy Internet 2020, 3, 1–13. [Google Scholar]

- Liu, Z.; Liu, Z.; Sun, J.; Du, X. Intelligent Construction Method and Model Test Based on Digital Twin. J. Build. Struct. 2021, 42, 26–36. [Google Scholar]

- Zou, D.; Feng, J. Application Scenes Analysis of Digital Twin Technology in Power Supply System of Urban Rail Transports. Urban Rail Transit Res. 2021, 24, 158–162+165. [Google Scholar]

- Wang, Q.; Zhou, Z.; Li, C.; Gao, H. Overview of Digital Twin Technology in the Field of Autonomous Driving Test. Automob. Sci. Technol. 2021, 2, 11–15. [Google Scholar]

- Fernández, R.Á.; Caraballo, S.C.; López, F.C. A probabilistic approach for determining the influence of urban traffic management policies on energy consumption and greenhouse gas emissions from a battery electric vehicle. J. Clean. Prod. 2019, 236, 117604. [Google Scholar] [CrossRef]

- Doyle, A.; Muneer, T. Energy consumption and modelling of the climate control system in the electric vehicle. Energy Explor. Exploit. 2019, 37, 519–543. [Google Scholar] [CrossRef] [Green Version]

- Al-Wreikat, Y.; Serrano, C.; Sodré, J.R. Driving behaviour and trip condition effects on the energy consumption of an electric vehicle under real-world driving. Appl. Energy 2021, 297, 117096. [Google Scholar] [CrossRef]

- Madhusudhanan, A.K.; Na, X. Effect of a Traffic Speed Based Cruise Control on an Electric Vehicle’s Performance and an Energy Consumption Model of an Electric Vehicle. IEEE/CAA J. Autom. Sin. 2020, 7, 386–394. [Google Scholar] [CrossRef]

- Huda, N.; Kaleg, S.; Hapid, A.; Kurnia, M.R.; Budiman, A.C. The influence of the regenerative braking on the overall energy consumption of a converted electric vehicle. SN Appl. Sci. 2020, 2, 606. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.W.; Lin, F. Simulation and Experimental study on energy consumption Optimization of pure electric vehicles. Automot. Pract. Technol. 2019, 17, 33–35. [Google Scholar]

- Zhang, W.; Zhang, H. Analysis on Power Performance and Economy Shift of Cruise Pure Electric Manual Transmission Vehicle. Time Mot. 2021, 2, 112–118. [Google Scholar]

- Varga, B.O. Energy management of electric and hybrid vehicles dependent on powertrain configuration. Open Eng. 2012, 2, 253–263. [Google Scholar] [CrossRef]

- Zhao, J.; Hu, M.; Rong, Z.; Fu, C. Driving Style to the Energy Consuming of the Pure Electric Vehicle. Journal of Chongqing University. 29 August 2021, pp. 1–14. Available online: http://kns.cnki.net/kcms/detail/50.1044.n.20200908.1001.002.html (accessed on 1 September 2020).

- Miri, I.; Fotouhi, A.; Ewin, N. Electric vehicle energy consumption modelling and estimation—A case study. Int. J. Energy Res. 2021, 45, 501–520. [Google Scholar] [CrossRef]

- Li, G. An Energy Consumption Model of Electric Vehicle based on Neural Network. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; ISSN 17426588. [Google Scholar]

- Chen, J.; Liang, M.; Ma, X. Probabilistic analysis of electric vehicle energy consumption using MPC speed control and nonlinear battery model. In Proceedings of the IEEE Green Technologies Conference, Denver, CO, USA, 7–9 April 2021; pp. 181–186. [Google Scholar] [CrossRef]

- Gao, H.; Kang, Z.; Lv, G.; Wang, W.; He, Y. Research on Energy Consumption Prediction of Electric Vehicle. Automob. Abstr. 2021, 5, 8–13. [Google Scholar]

- Huo, Y.; Wang, Y.; Yang, F.; Liu, J.; Bai, Z. Research on Energy Management of Pure Electric Vehicle under High and Low Temperature Conditions. In Proceedings of the 2020 Annual Meeting Proceedings of China Society of Automotive Engineering, Shanghai, China, 27 October 2020. [Google Scholar]

- Manufacturing: Industry 4.0 and Digital Twin. Software and Integrated Circuits. 2018, pp. 42–49. Available online: http://www.clii.com.cn/lhrh/hyxx/201809/P020180917100214.pdf (accessed on 5 December 2017).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).