Battery Pack Prospects for Long-Haul Transport Trucks Considering Electrified Highways and Megawatt Charging

Abstract

:1. Introduction

2. Study Scope and Methodology

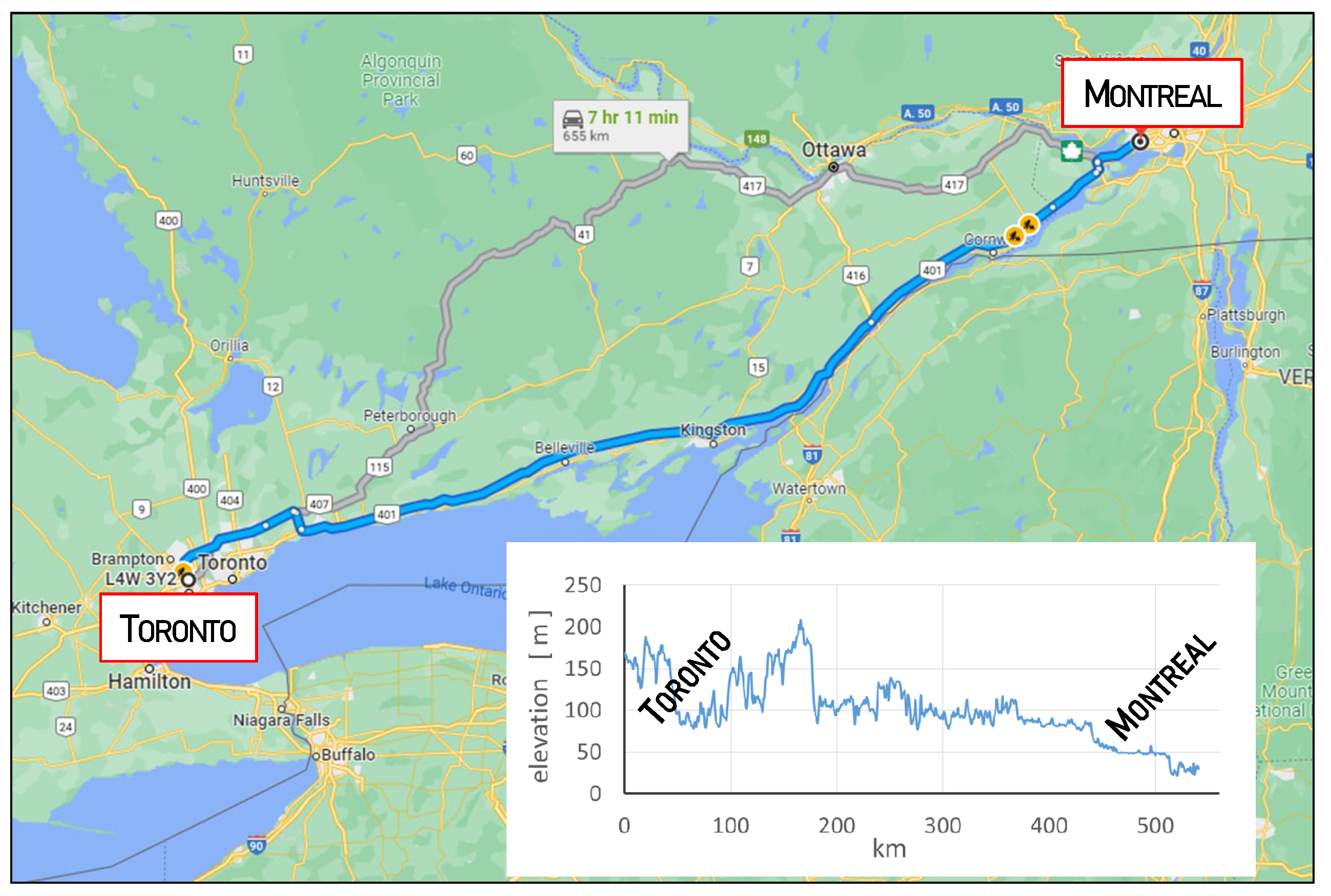

2.1. Route

2.2. Scenarios

- A 100% electrified highway (providing 200 kW at 85% uptake efficiency [10] to the truck)

- A 50% electrified highway with alternating sections of 20 km that are electrified (at 400 kW) or non-electrified

- A 50% electrified highway with alternating sections of 2 km that are electrified (at 400 kW) or non-electrified

2.3. Electric Truck Battery Sizing

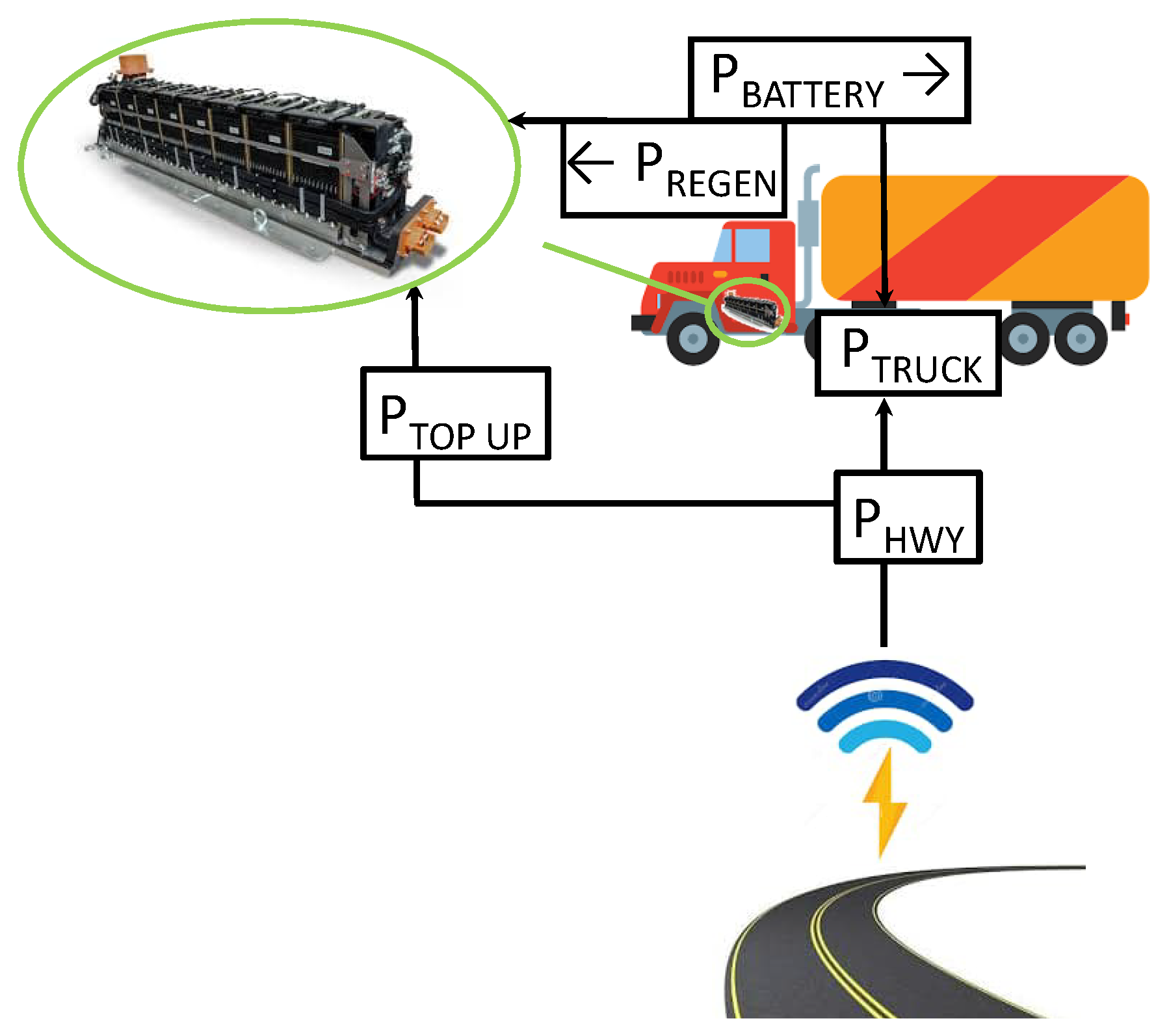

3. Modeling Overview

3.1. Primer on Battery Degradation

3.2. Mode Switching Effects

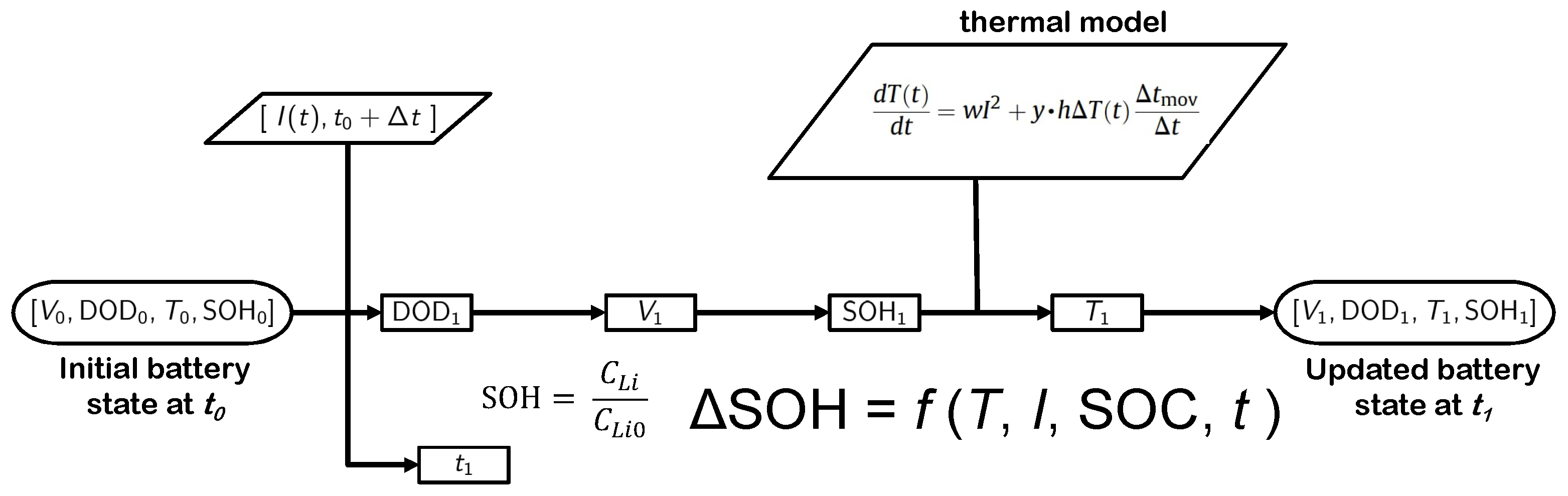

3.3. Battery Life Model

3.4. Economic Model

4. Results

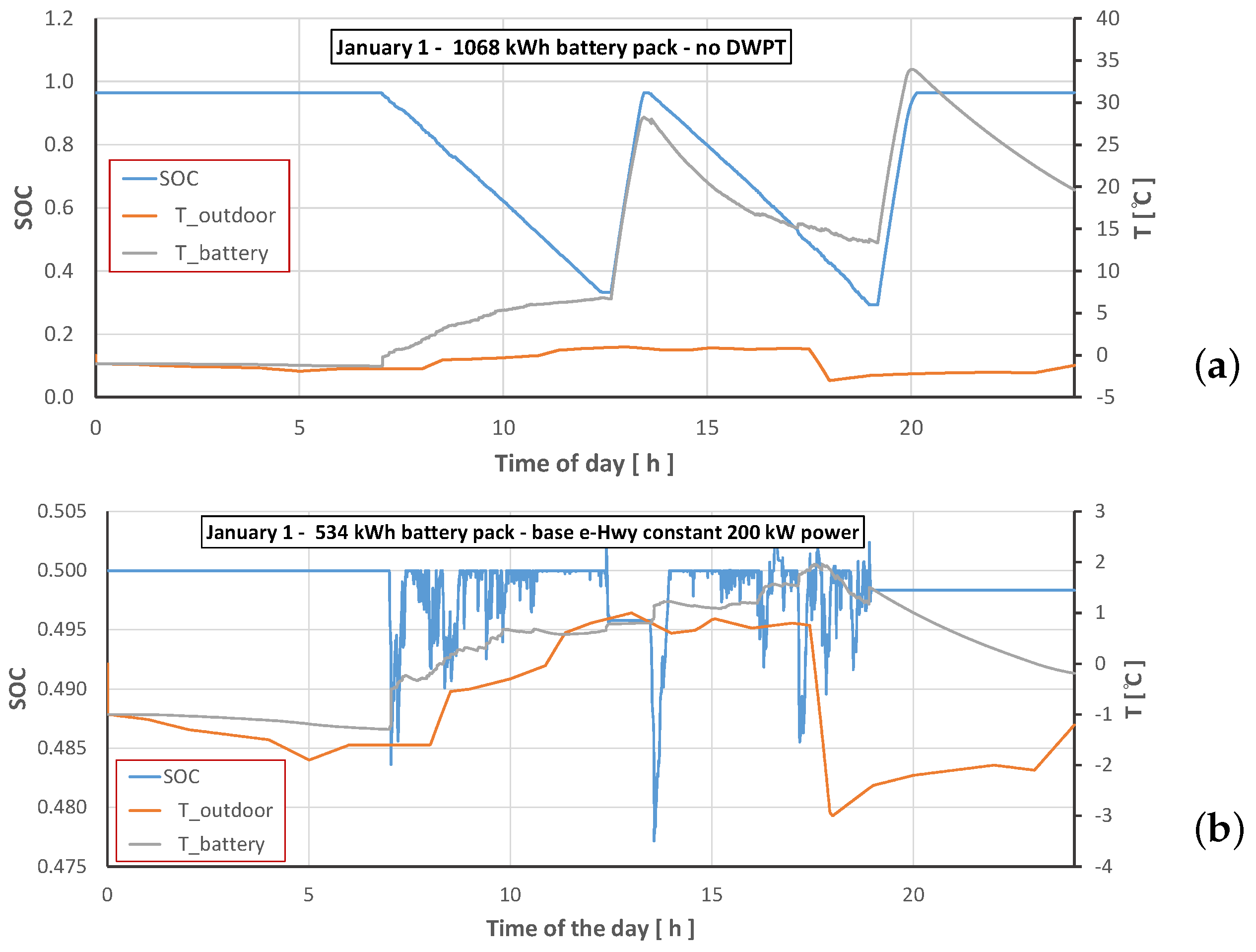

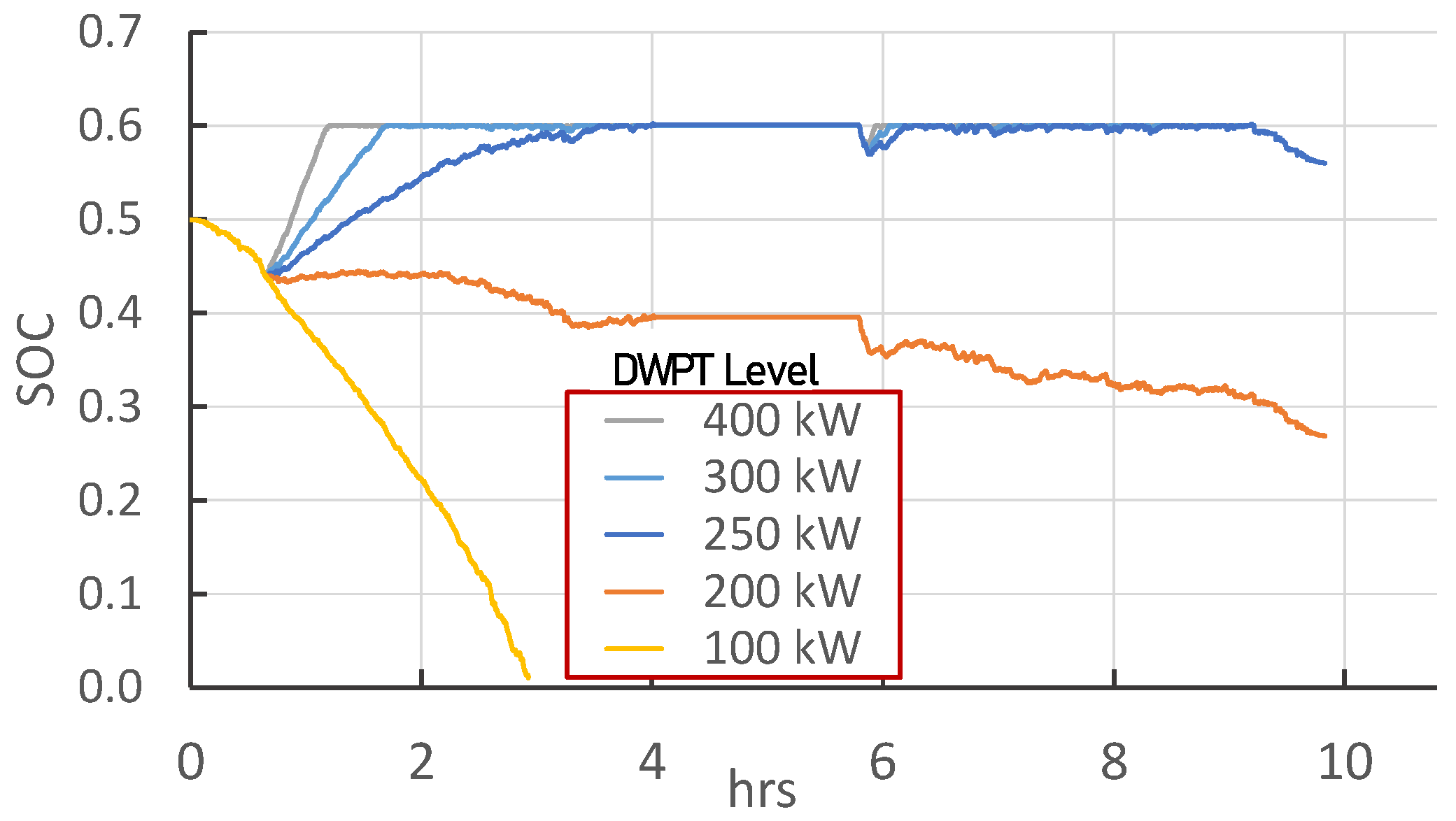

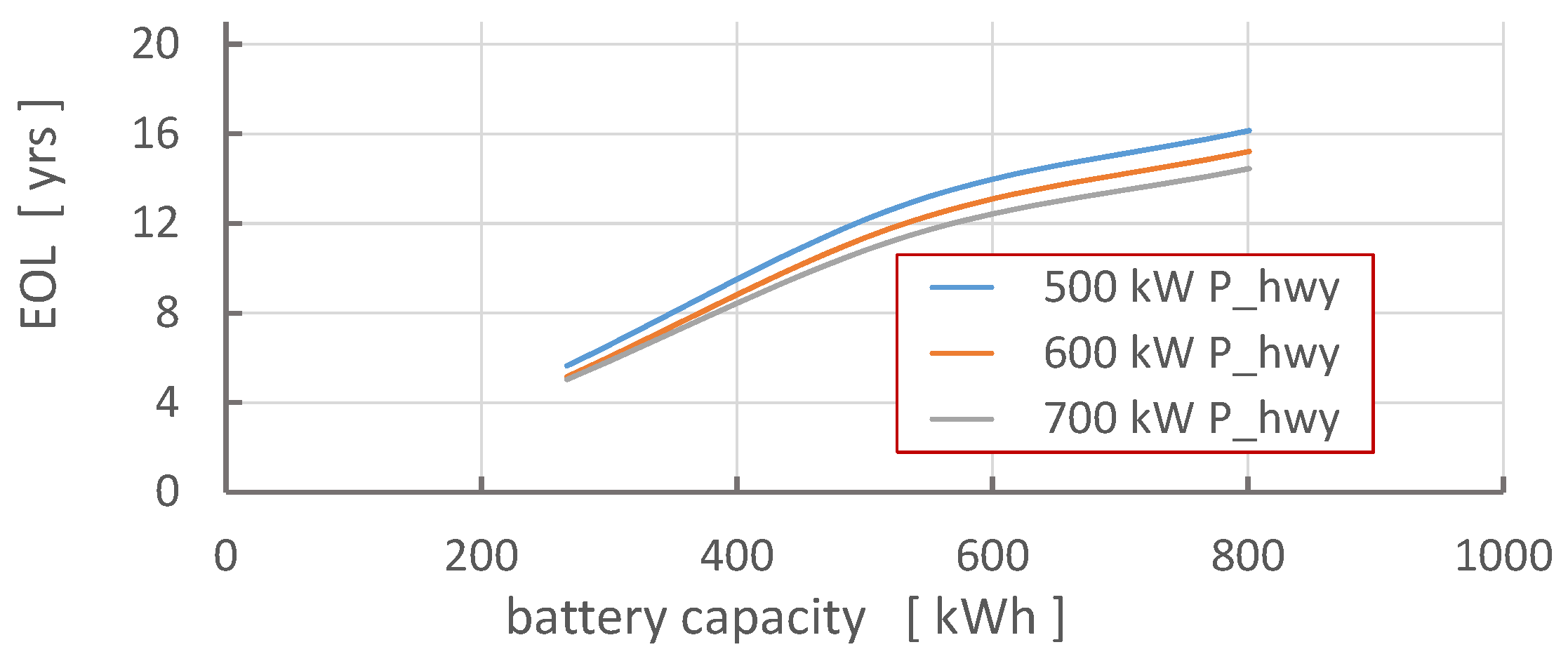

4.1. Daily Operation and Battery Life

4.2. Reference and Base e-Hwy Cases

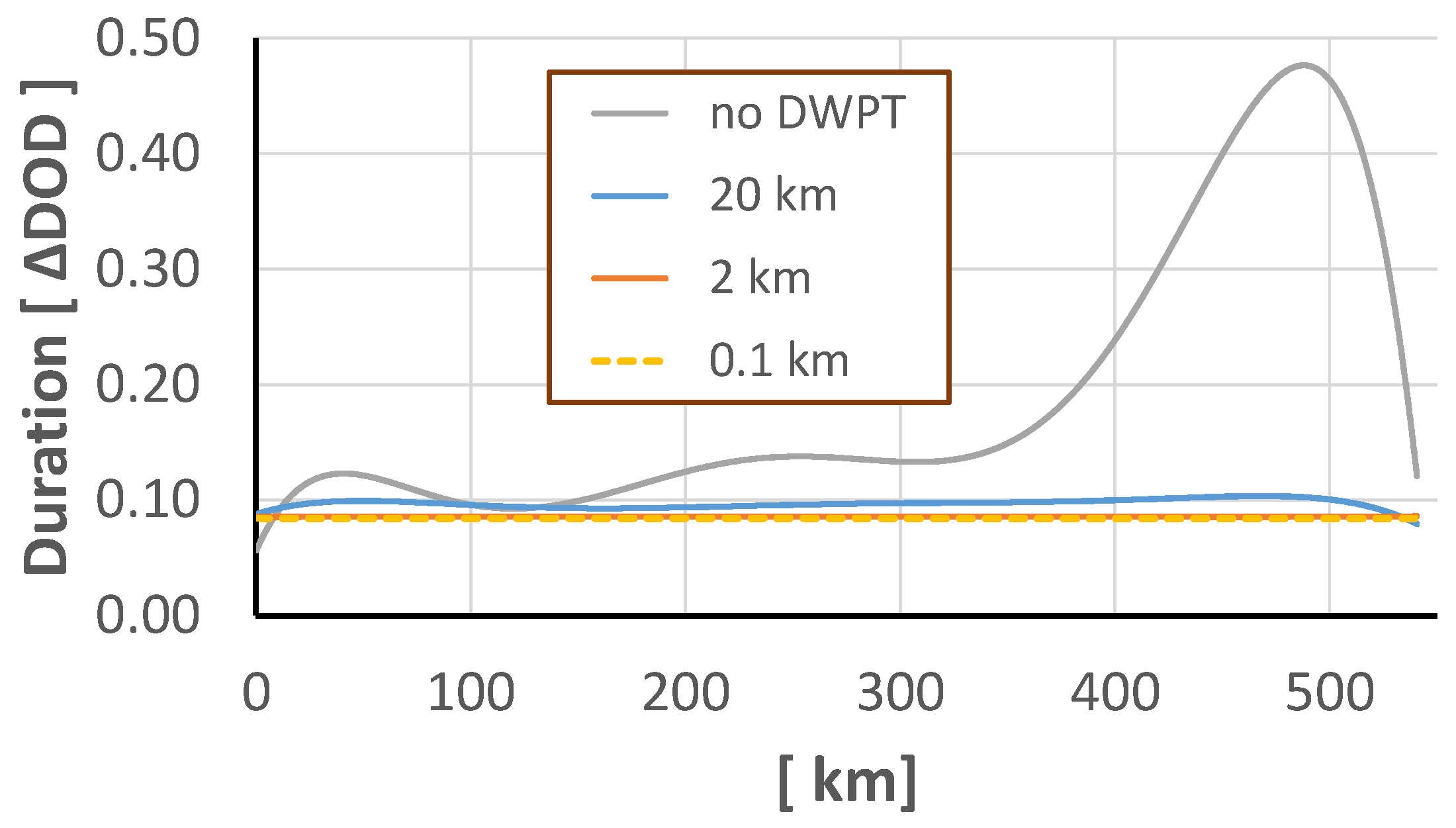

4.3. Intermittent e-Hwy Configurations

4.4. Effect of Highway Electrification Power Level

4.5. Highway Power Levels Allowing Intermittency

4.6. Discussion of the Operational Duration Effect

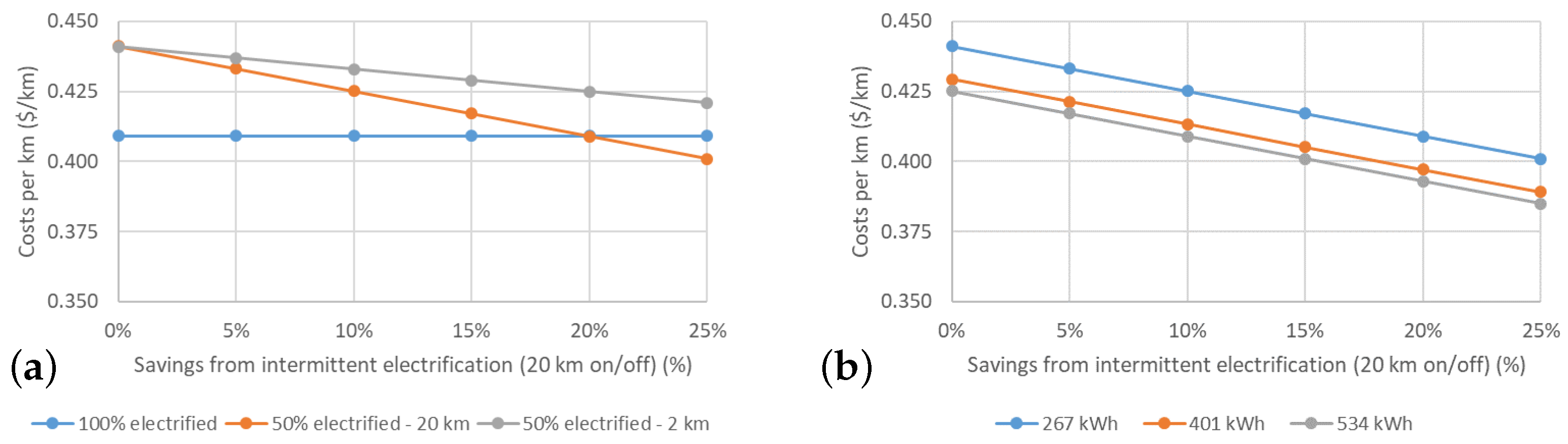

4.7. Economic Evaluation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BET | battery electric truck |

| BMS | battery management system |

| CPT | conductive power transfer |

| DOD | depth of discharge |

| DWPT | dynamic wireless power transfer |

| e-Hwy | electrified roadway furnishing DWPT |

| EOL | battery EOL life value, in years |

| EV | electric vehicle |

| OCV | open-circuit voltage |

| P2D | pseudo two-dimensional |

| SEI | solid-electrolyte interface |

| SOC | state of charge |

| SOH | state of health |

References

- Osieczko, K.; Zimon, D.; Płaczek, E.; Prokopiuk, I. Factors that influence the expansion of electric delivery vehicles and trucks in EU countries. J. Environ. Manag. 2021, 296, 113177. [Google Scholar] [CrossRef] [PubMed]

- Qiu, K.; Ribberink, H.; Entchev, E. Economic feasibility of electrified highways for heavy-duty electric trucks. Appl. Energy 2022, 326, 119935. [Google Scholar] [CrossRef]

- Triviño, A.; González-González, J.M.; Aguado, J.A. Wireless power transfer technologies applied to electric vehicles: A review. Energies 2021, 14, 1547. [Google Scholar] [CrossRef]

- Gustavsson, M.G.H. Research & Innovation for Electric Roads. In Proceedings of the EVS35 Symposium, Oslo, Norway, 11–15 June 2022. [Google Scholar]

- Dhayarkar, S.; Sontakke, S.; Shinde, V.; Ghuge, N. Electric Heavy Vehicle Transportation Highway (By Catenary System). ITM Web Conf. 2022, 44, 01004. [Google Scholar] [CrossRef]

- Gouvernement de France, Ministère de la Transition énérgetique, Système de Route électrique, Groupe de Travail no1. In Décarboner le Transport Routier de Marchandise par l’ERS, Enjeux et Stratégie; Trafigura: Singapore, 2021; 196p.

- Green Car Reports. Edelstein, S. Short-Loop Electric Bus Serves as a Proving Ground for Dynamic Wireless Charging. Available online: https://www.greencarreports.com/news/1131665_short-loop-electric-bus-serves-as-a-proving-ground-for-dynamic-wireless-charging (accessed on 12 January 2023).

- Google Earth. Available online: earth.google.com (accessed on 7 October 2021).

- Environment Canada, Historical Weather Data. Available online: climate.weather.gc.ca/historical_data/search_historic_data_e.html (accessed on 6 October 2021).

- Foote, A.; Onar, O.C.; Debnath, S.; Chinthavali, M.; Ozpineci, B.; Smith, D.E. Optimal sizing of a dynamic wireless power transfer system for highway applications. In Proceedings of the 2018 IEEE Transportation Electrification Conference and Expo, (ITEC), Long Beach, CA, USA, 13–15 June 2018; pp. 1–6. [Google Scholar]

- Tesla. Available online: www.tesla.com/enCA/semi (accessed on 2 October 2021).

- Darcovich, K.; Ribberink, H.; Michelet, C.; Lombard, K.; Ghorab, M. The Feasibility of Electric Vehicles as Taxis in a Canadian Context. In Proceedings of the 2019 Electric Vehicles International Conference (EV), Bucharest, Romania, 3–4 October 2019; pp. 1–6. [Google Scholar]

- Darcovich, K.; Recoskie, S.; MacNeil, D.D.; Darcovich, A. Operational intra-cycle temporal and current mode effects on battery capacity loss. eTransportation 2022, 13, 100185. [Google Scholar] [CrossRef]

- Darcovich, K.; Recoskie, S.; Fattal, F. Fast operational mode switching effects on battery degradation. J. Appl. Electrochem. 2020, 50, 111–124. [Google Scholar] [CrossRef]

- Darcovich, K.; MacNeil, D.D.; Recoskie, S.; Cadic, Q.; Ilinca, F. Comparison of cooling plate configurations for automotive battery pack thermal management. Appl. Therm. Eng. 2019, 155, 185–195. [Google Scholar] [CrossRef]

- Ribberink, H.; Lombardi, K.; Humphries, K.; Loiselle-Lapointe, A.; Stefopulos, N.; Varghese, S.; Pundsack, N. Impact of Ambient Temperature and Battery Activity on Internal Battery Temperatures of Electric Vehicles. In Proceedings of the 32nd International Electric Vehicle Symposium and Exhibition (EVS32), Lyon, France, 19–22 May 2019. [Google Scholar]

- Darcovich, K.; Recoskie, S.; Michelet, C.; Ribberink, H. The Impact of V2X Service under Local Climatic Conditions within Canada on EV Durability. eTransportation 2021, 9, 100124. [Google Scholar] [CrossRef]

- Gao, L.; Liu, S.; Dougal, R. Dynamic Lithium-Ion Battery Model for System Simulation. IEEE Trans. Components Packag. Technol. 2002, 25, 495–505. [Google Scholar]

- Qiu, K.; Ribberink, H.; Entchev, E. Technical and Economic Feasibility of Electrified Highways for Heavy-Duty Electric Trucks. In Proceedings of the Applied Energy Symposium: MIT A+B, Cambridge, MA, USA, 11–13 August 2021. Paper ID APEN-MIT-2021_122, 5p. [Google Scholar]

- Talebian, H.; Herrera, O.E.; Tran, M.; Mérida, W. Electrification of road freight transport: Policy implications in British Columbia. Energy Policy 2018, 115, 109–118. [Google Scholar] [CrossRef]

| Battery Size (kWh) [banks] | Megawatt Charging | = 200 kW 100% Electrified Highway | = 400 kW 50% Electrified (20 km on/off) | = 400 kW 50% Electrified (2 km on/off) | ||||

|---|---|---|---|---|---|---|---|---|

| equiv. cycles | EOL | equiv. cycles | EOL | equiv. cycles | EOL | equiv. cycles | EOL | |

| 267 [4] | 3872 | 15.89 | 6059 | 6.24 | 6888 | 6.98 | ||

| 401 [6] | 3089 | 18.86 | 7232 | 10.87 | 7667 | 11.22 | ||

| 534 [8] | 2481 | 20.12 | 7022 | 13.97 | 7194 | 14.08 | ||

| 1068 [16] | 4235 | 8.41 | ||||||

| Megwatt Charging | 100% Electrified Highway | 50% Electrified (20 km on/off) | 50% Electrified (2 km on/off) | ||||

|---|---|---|---|---|---|---|---|

| Battery size (kWh) | 1068 | 267 | 534 | 267 | 534 | 267 | 534 |

| banks | 16 | 4 | 8 | 4 | 8 | 4 | 8 |

| Battery use | $0.048 | $0.006 | $0.010 | $0.016 | $0.015 | $0.015 | $0.014 |

| Capital costs | $0.102 | $0.161 | $0.161 | $0.136 | $0.136 | $0.148 | $0.148 |

| Electricity | $0.243 | $0.242 | $0.241 | $0.264 | $0.250 | $0.266 | $0.250 |

| Total | $0.394 | $0.409 | $0.412 | $0.417 | $0.401 | $0.429 | $0.413 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darcovich, K.; Ribberink, H.; Qiu, K.; Soufflet, E. Battery Pack Prospects for Long-Haul Transport Trucks Considering Electrified Highways and Megawatt Charging. World Electr. Veh. J. 2023, 14, 60. https://doi.org/10.3390/wevj14030060

Darcovich K, Ribberink H, Qiu K, Soufflet E. Battery Pack Prospects for Long-Haul Transport Trucks Considering Electrified Highways and Megawatt Charging. World Electric Vehicle Journal. 2023; 14(3):60. https://doi.org/10.3390/wevj14030060

Chicago/Turabian StyleDarcovich, K., H. Ribberink, K. Qiu, and E. Soufflet. 2023. "Battery Pack Prospects for Long-Haul Transport Trucks Considering Electrified Highways and Megawatt Charging" World Electric Vehicle Journal 14, no. 3: 60. https://doi.org/10.3390/wevj14030060

APA StyleDarcovich, K., Ribberink, H., Qiu, K., & Soufflet, E. (2023). Battery Pack Prospects for Long-Haul Transport Trucks Considering Electrified Highways and Megawatt Charging. World Electric Vehicle Journal, 14(3), 60. https://doi.org/10.3390/wevj14030060