Application of Simulation Analysis for Thermal Management Technology on Main Parts of Pouch Cells

Abstract

:1. Introduction

2. Mathematical Models and Boundary Conditions

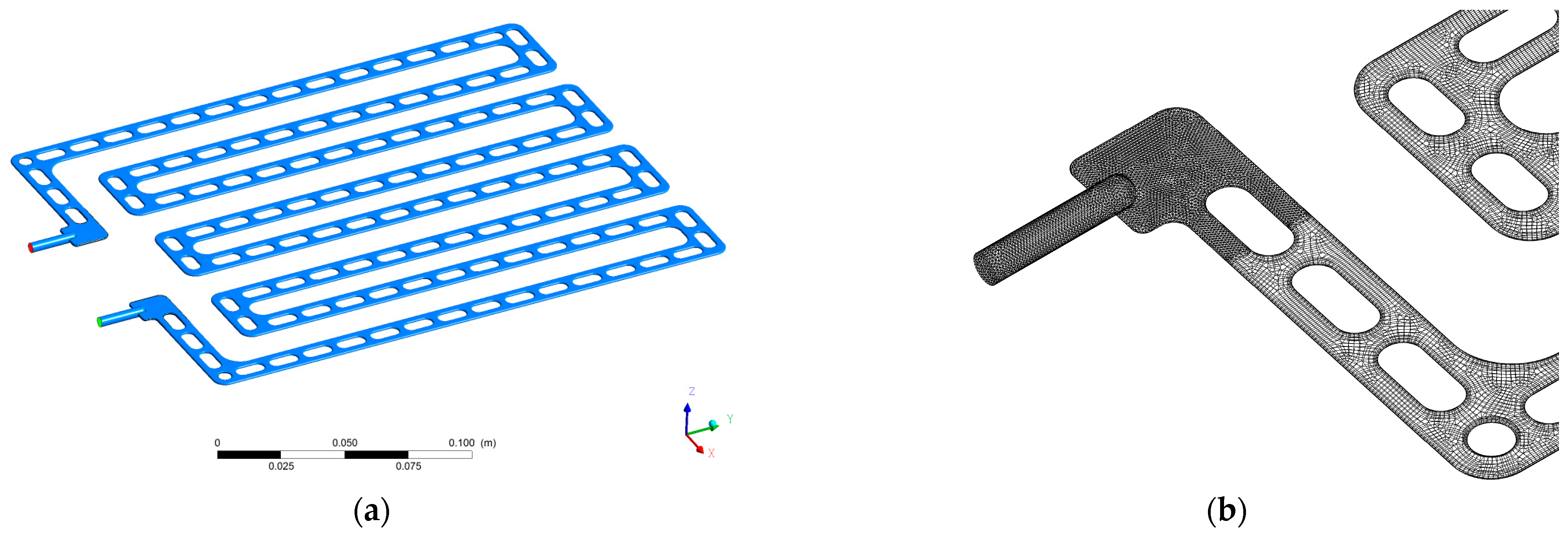

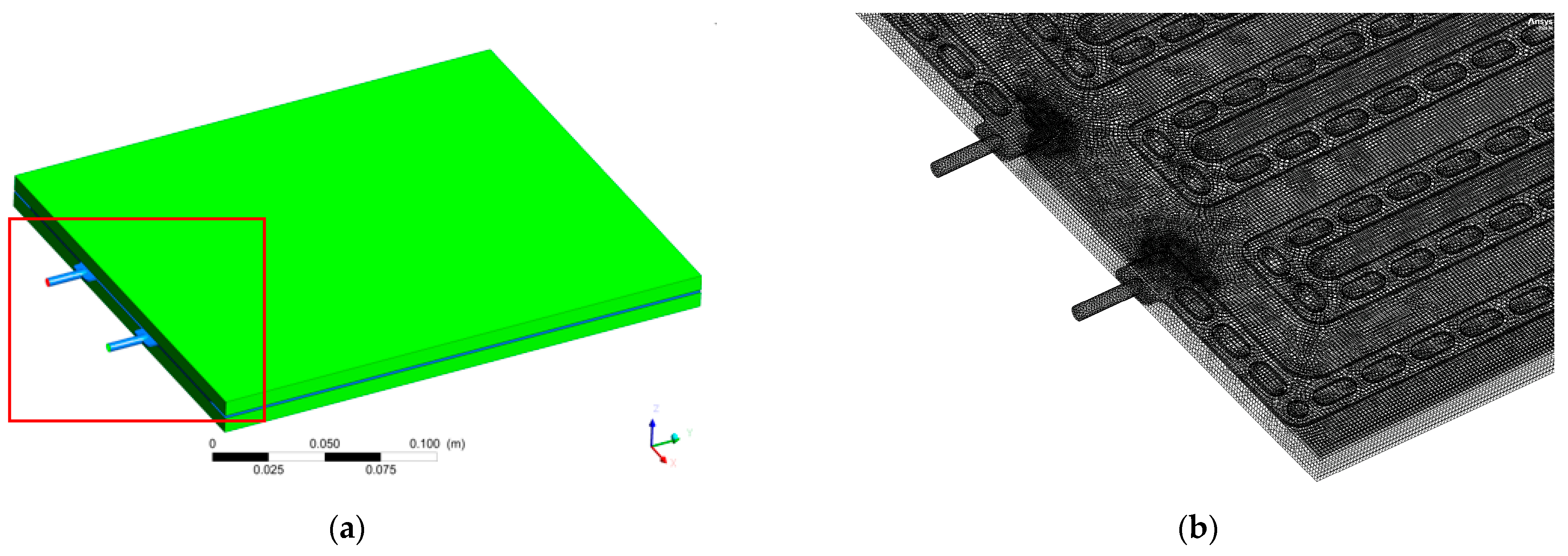

2.1. Geometric Models

2.2. Mathematical Models

2.3. Basic Control Equations

- (1)

- Reynolds number

- (2)

- Continuity equation

- (3)

- Momentum equation

- (4)

- Energy equation

2.4. Boundary Conditions and Material Properties

3. Results Analysis

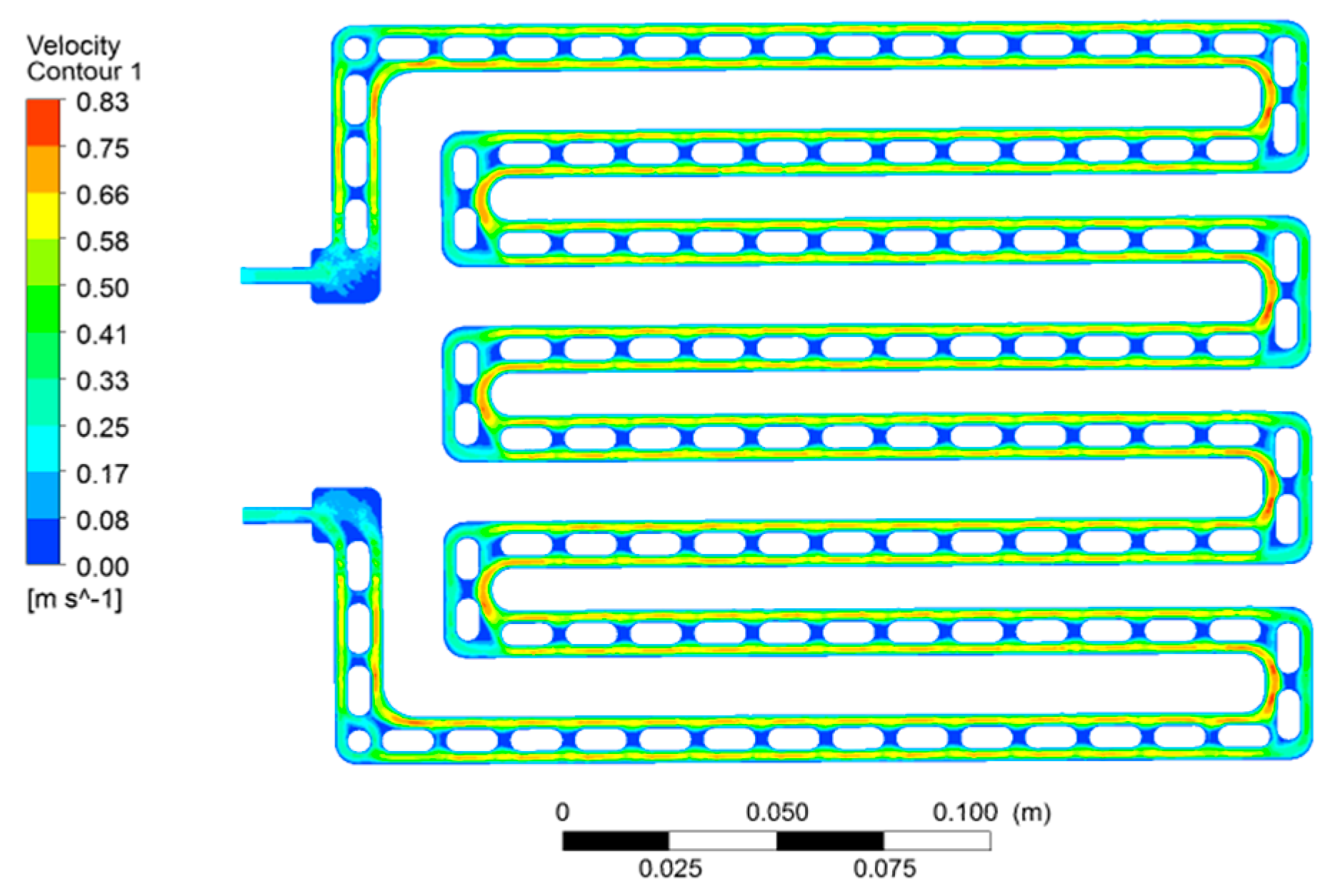

3.1. Flow Field Simulation Analysis

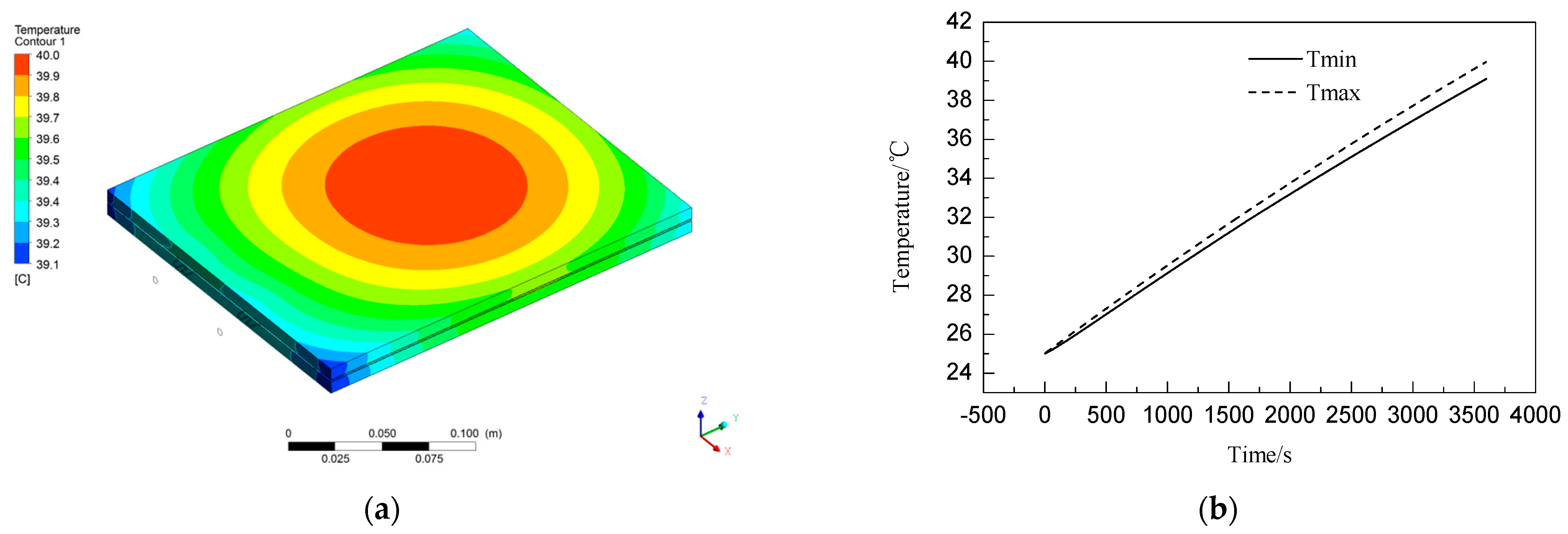

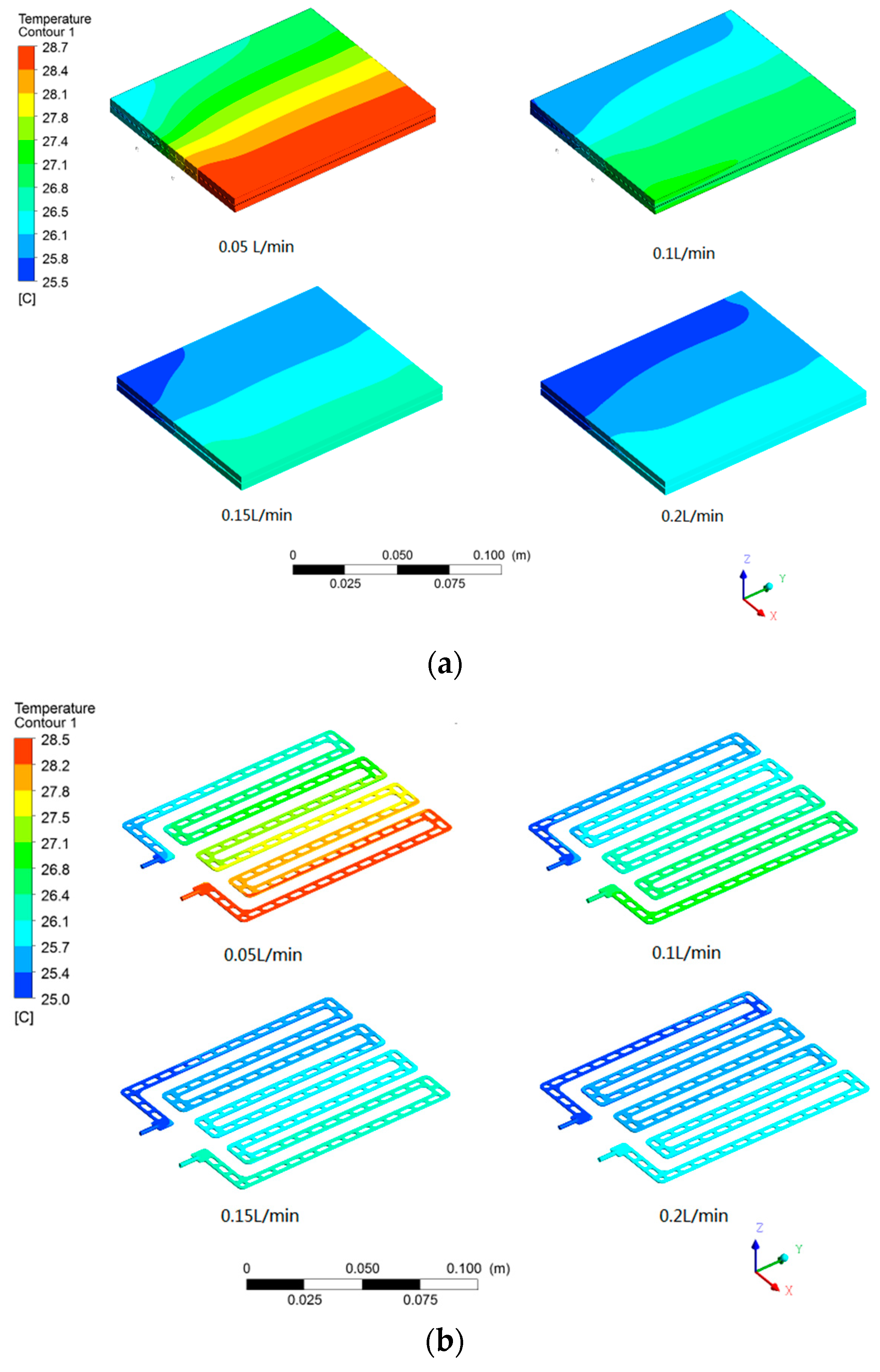

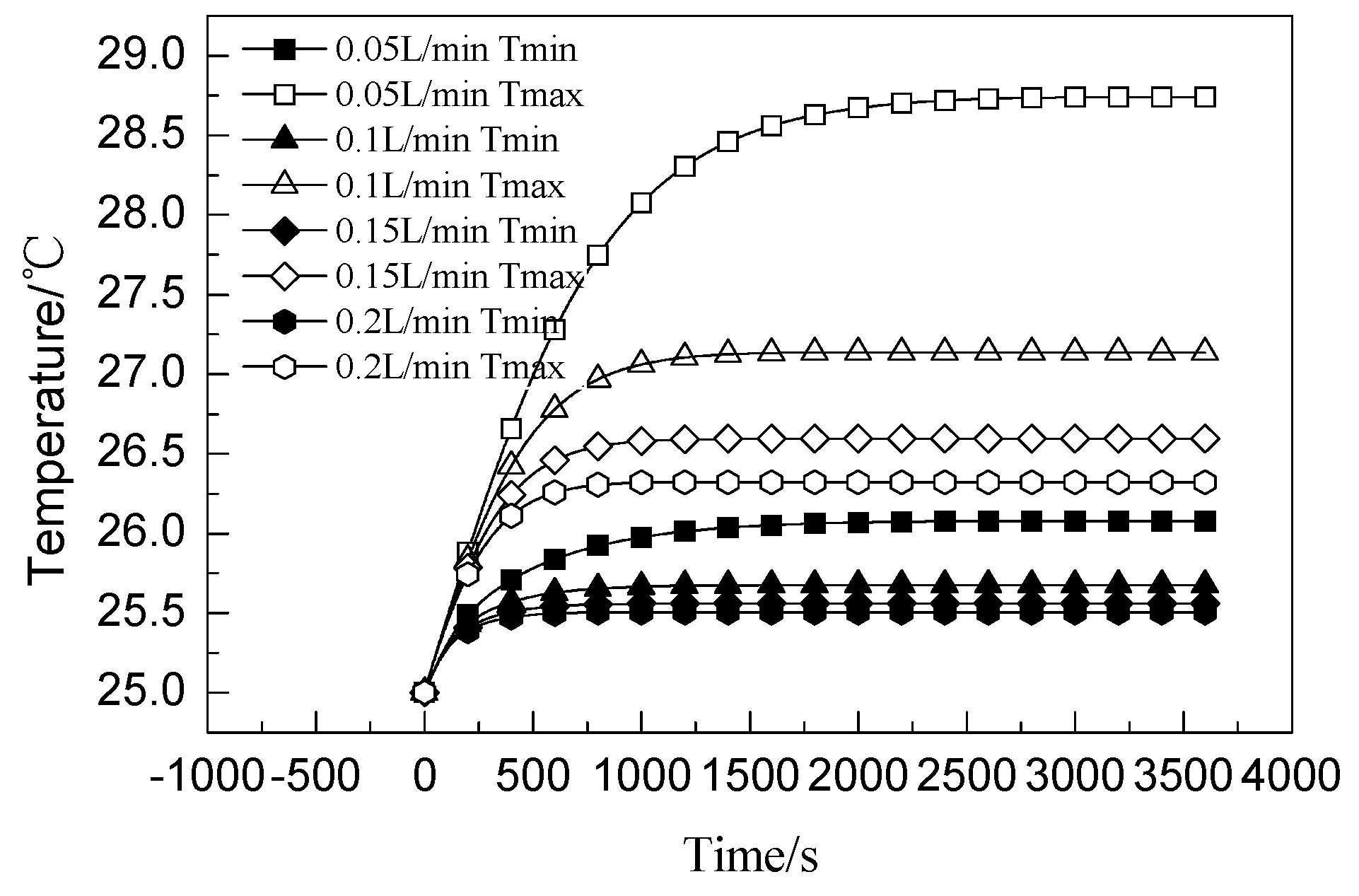

3.2. Simulation Analysis of Cooling of Electric Cell by Cold Plate

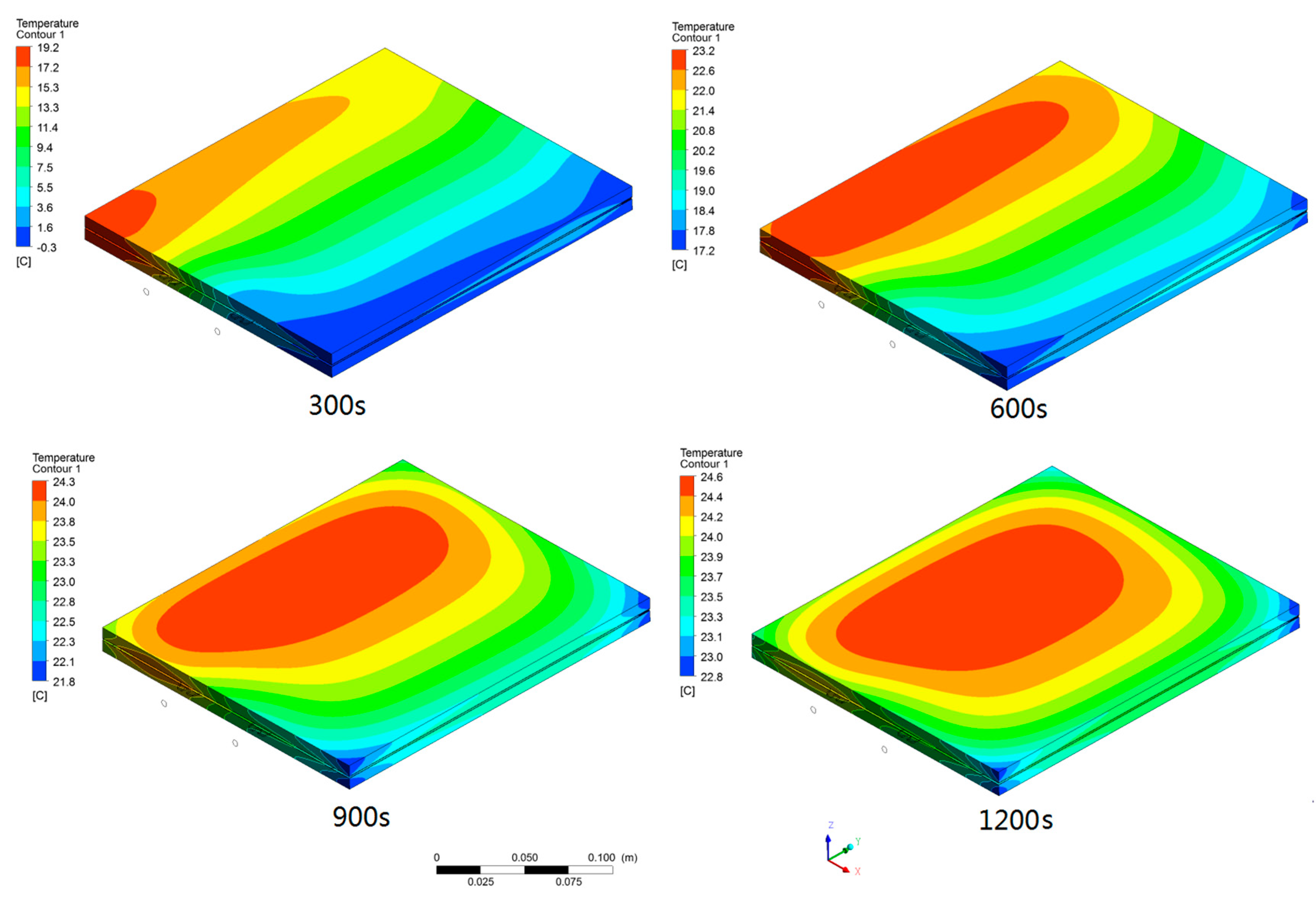

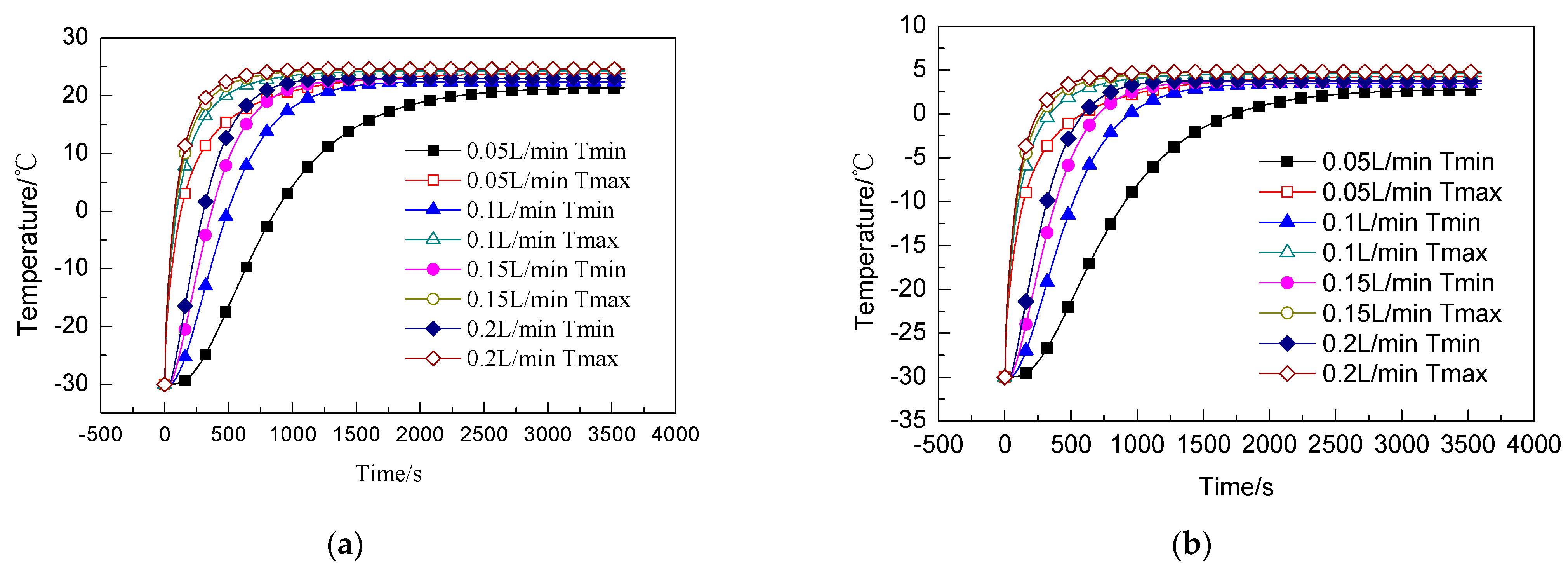

3.3. Simulation Analysis of the Heating of the Core by the Cold Plate

4. Conclusions

- (1)

- For the cold plate used in this study, the flow resistance is a quadratic function of the flow rate,. Under the condition that the flow rate is less than 0.2 L/min, the general design requirement of flow resistance < 50 kPa is satisfied.

- (2)

- The large surface thermal management technology of pouch cells can effectively and quickly control the temperature rise of the core when the core is charged and discharged. The greater the flow rate, the slower the temperature rise rate of the core, and the lower the maximum temperature. The temperature difference of the core is below 3 °C.

- (3)

- When heating the core at low temperature, the temperature of the core gradually increases. The result is that the higher the flow rate, the faster the temperature rise rate of the core that finally reaches close to the temperature of the antifreeze. The higher the temperature of the antifreeze, the faster the temperature rise of the core, but the greater the temperature difference. The temperature difference of the core rises first and then decreases. Under the same condition of antifreeze temperature, the smaller the flow rate, the larger the temperature difference.

- (4)

- When setting the heating strategy for the low temperature heating method in this study, the antifreeze temperature should be set with a design target temperature difference higher than the minimum temperature allowed for charging as a reference.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, Y.B.; Jin, Y.L.; Liu, Y.C. National institute for environmental health and related product safety. J. Hyg. Res. 2003, 32, 504–507. (In Chinese) [Google Scholar]

- Lang, C.Y.; Luo, B. Research on cryogenic properties of NCM batteries. Mach. Electron. 2016, 34, 7–12. (In Chinese) [Google Scholar]

- Deng, Y.W.; Feng, C.L.; Jiaqiang, E.; Zhu, H.; Chen, J.; Wen, M.; Yin, H. Effects of different coolants and cooling strategies on the cooling performance of the power lithium ion battery system: A review. Appl. Therm. Eng. 2018, 142, 10–29. [Google Scholar] [CrossRef]

- Li, J.Q.; Wu, P.E.; Zhang, C.N. Study and implementation of thermal management technology for the power batteries of electric vehicles. Automot. Eng. 2016, 38, 22–27+35. (In Chinese) [Google Scholar]

- Deng, T.; Ran, Y.; Yin, Y.L.; Chen, X.; Liu, P. Multi-objective optimization design of double-layered reverting cooling plate for lithium-ion batteries. Int. J. Heat Mass Transf. 2019, 143, 118580. [Google Scholar] [CrossRef]

- Zhao, G.Z.; Li, L.; Zhao, X.H.; Zhou, T.B. Lithium battery thermal management system for hybrid electric vehicles. Energy Storage Sci. Technol. 2018, 7, 1146–1151. (In Chinese) [Google Scholar]

- Du, M.H.; Zheng, X.W.; Jiang, Z.W.; Du, H.D. Analysis on the influence factors of liquid cooling performance of electric vehicle battery pack. Guangdong Chem. Ind. 2018, 45, 48–50+23. (In Chinese) [Google Scholar]

- Wang, Y.H.; Zhang, C.L.; Yu, H.G.; Sheng, J.; Song, J.; Cao, Y.J. The progress of phase change materials applied in battery thermal management. J. Funct. Mater. 2013, 44, 3213–3218. (In Chinese) [Google Scholar]

- Lian, L.L. Based on COMSOL Multiphysics platform, simulation of heat dissipation structure of power lithium ion battery module. Autom. Instrum. 2017, 37, 170–172+175. (In Chinese) [Google Scholar]

- Li, K.J.; Tan, X.J.; Chu, Y.Y.; Fan, Y.T. A research on the air cooling thermal management system of lithium-ion traction battery pack in electric vehicles. Chin. J. Power Sources 2019, 43, 1975–1978+2035. (In Chinese) [Google Scholar]

- Sheng, L.; Su, L.; Zhang, H.; Li, K.; Fang, Y.; Ye, W.; Fang, Y. Numerical investigation on a lithiumion battery thermal management utilizing a serpentine-channel liquid cooling plate exchanger. Int. J. Heat Mass Transf. 2019, 141, 658–668. [Google Scholar] [CrossRef]

- Lai, Y.X.; Wu, W.X.; Chen, K.; Wang, S.; Xin, C. A compact and lightweight liquid-cooled thermal management solution for cylindrical lithium-ion power battery pack. Int. J. Heat Mass Transf. 2019, 144, 118581. [Google Scholar] [CrossRef]

- Liu, Q. Performance Optimization of Lithium-Ion Battery Thermal Management System Based on Phase Change Materials. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2017. (In Chinese). [Google Scholar]

- Xu, X.M.; Zhao, Y.Q. Experimental Research on Heat Dissipation Performance of Cold Plate Liquid Cooling System for Electric Vehicle under Different Working Conditions. Automot. Eng. 2014, 36, 1057–1062+1092. (In Chinese) [Google Scholar]

- Wang, X.S.; Liang, J.; Wang, D.P. Numerical Simulation and Structural Optimization of Liquid-Cooled Modules for Electric Vehicle Battery Packs. In Proceedings of the 19th Asia-Pacific Automotive Engineering Annual Conference and 2017 China Automotive Engineering Society Annual Conference, Shanghai, China, 24–26 October 2017. (In Chinese). [Google Scholar]

- Xue, L. Simulation of Liquid Cooling for Power Lithium Battery Pack. Sci. Technol. Wind. 2018, 31, 162+168. (In Chinese) [Google Scholar]

- Lv, M.; Chen, C.; Chen, Z.X.; Jin, B.H.; Luo, H.R.; Fan, Y.T. Research on Optimization of Water Cooling System for lithium iron phosphate Power Battery. Automot. Electr. Appl. 2017, 58, 5–8. (In Chinese) [Google Scholar]

- Deng, Y.W.; Zhang, S.A.; Zhong, J.F.; Wang, B.J. Structure design of Liquid Cooling Radiator for Lithium Battery for Hybrid Electric Vehicle. Power Supply Technol. 2015, 39, 454–457. (In Chinese) [Google Scholar]

- Xing, Z.B. Engineering Simulation and Verification of Molten—Glass Stirring and Forming Behavior of Float Glass. Ph.D. Thesis, Yanshan University, Qinhuangdao, China, 2017. (In Chinese). [Google Scholar]

- Zhang, P.F. Optimization Design Research of Mine Submersible Pump Impeller Based on CFD Technology and Orthogonal Test Method. Master’s Thesis, Henan Polytechnic University, Jiaozuo, China, 2014. (In Chinese). [Google Scholar]

- Kang, B.C.; Guo, Z.J.; Feng, L.N. Hydrodynamic parameters calculation and trajectory simulation of aircraft. Ordnance Ind. Autom. 2019, 38, 29–34. (In Chinese) [Google Scholar]

- Liu, B.T. Research on Control System of Arc Spraying Marking Equipment Based on Siemens PLC. Master’s Thesis, Tianjin University of Science & Technology, Tianjin, China, 2017. (In Chinese). [Google Scholar]

| Aluminum Plate | Cell | Antifreeze (50% Ethylene Glycol Aqueous Solution) | |

|---|---|---|---|

| Density/kg·m−3 | 2719 | 2365 | ρ = −0.0024T2 − 0.3381T + 1081.1 |

| Specific heat/J·(kg·K)−1 | 871 | 1140 | C = 0.0039T + 3.2034 |

| Thermal conductivity/W·(m·K)−1 | 202.4 | λx = λy = 19.6; λz = 3.9 | λ = 0.0009T + 0.3624 |

| Viscosity/mPa·s | —— | —— | μ = 9.1954e − 0.044T |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Ding, F.; Zhang, Q.; Liu, M.; Tian, M. Application of Simulation Analysis for Thermal Management Technology on Main Parts of Pouch Cells. World Electr. Veh. J. 2023, 14, 124. https://doi.org/10.3390/wevj14050124

Wang B, Ding F, Zhang Q, Liu M, Tian M. Application of Simulation Analysis for Thermal Management Technology on Main Parts of Pouch Cells. World Electric Vehicle Journal. 2023; 14(5):124. https://doi.org/10.3390/wevj14050124

Chicago/Turabian StyleWang, Bo, Fang Ding, Qianbin Zhang, Mingyan Liu, and Miaofa Tian. 2023. "Application of Simulation Analysis for Thermal Management Technology on Main Parts of Pouch Cells" World Electric Vehicle Journal 14, no. 5: 124. https://doi.org/10.3390/wevj14050124

APA StyleWang, B., Ding, F., Zhang, Q., Liu, M., & Tian, M. (2023). Application of Simulation Analysis for Thermal Management Technology on Main Parts of Pouch Cells. World Electric Vehicle Journal, 14(5), 124. https://doi.org/10.3390/wevj14050124