Optimized Integration of Medium-Voltage Multimegawatt DC Charging Stations: Concepts, Guidelines and Analysis

Abstract

:1. Introduction

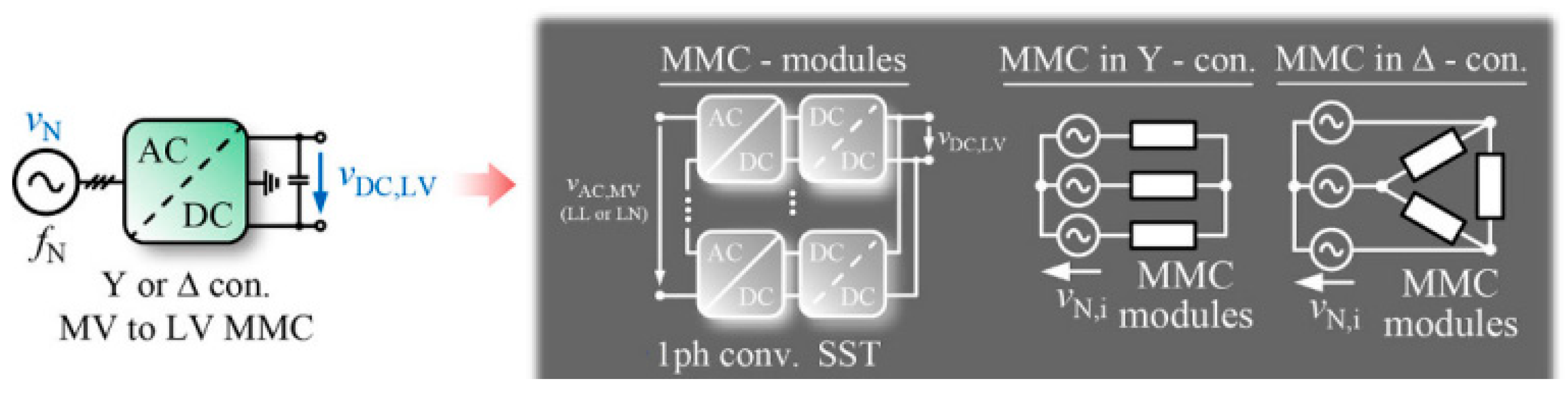

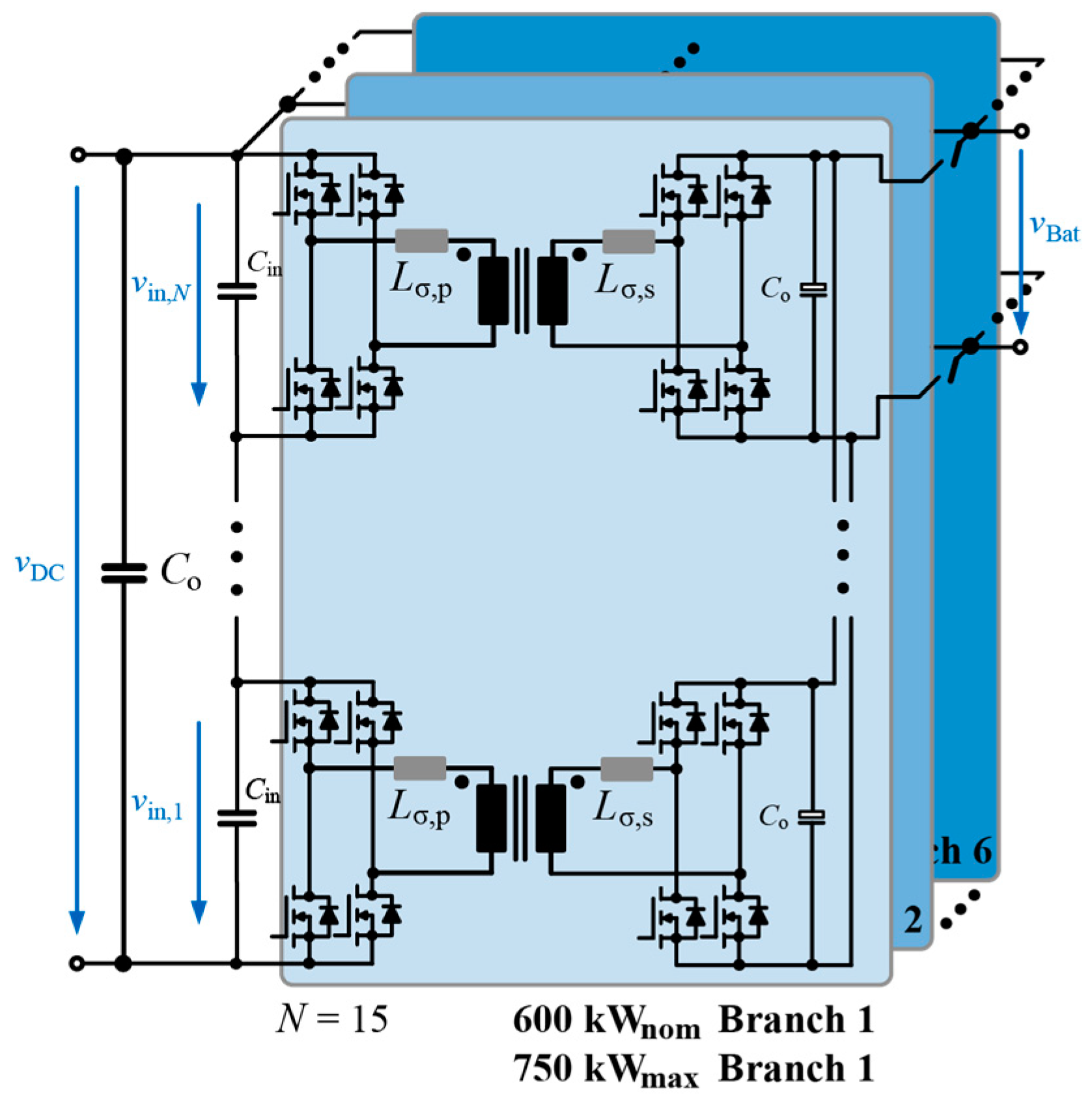

2. Power Electronics Design Guidelines and Aspects for a Medium-Voltage, Medium-Frequency Based Multimegawatt DC Charger

2.1. Key Aspects

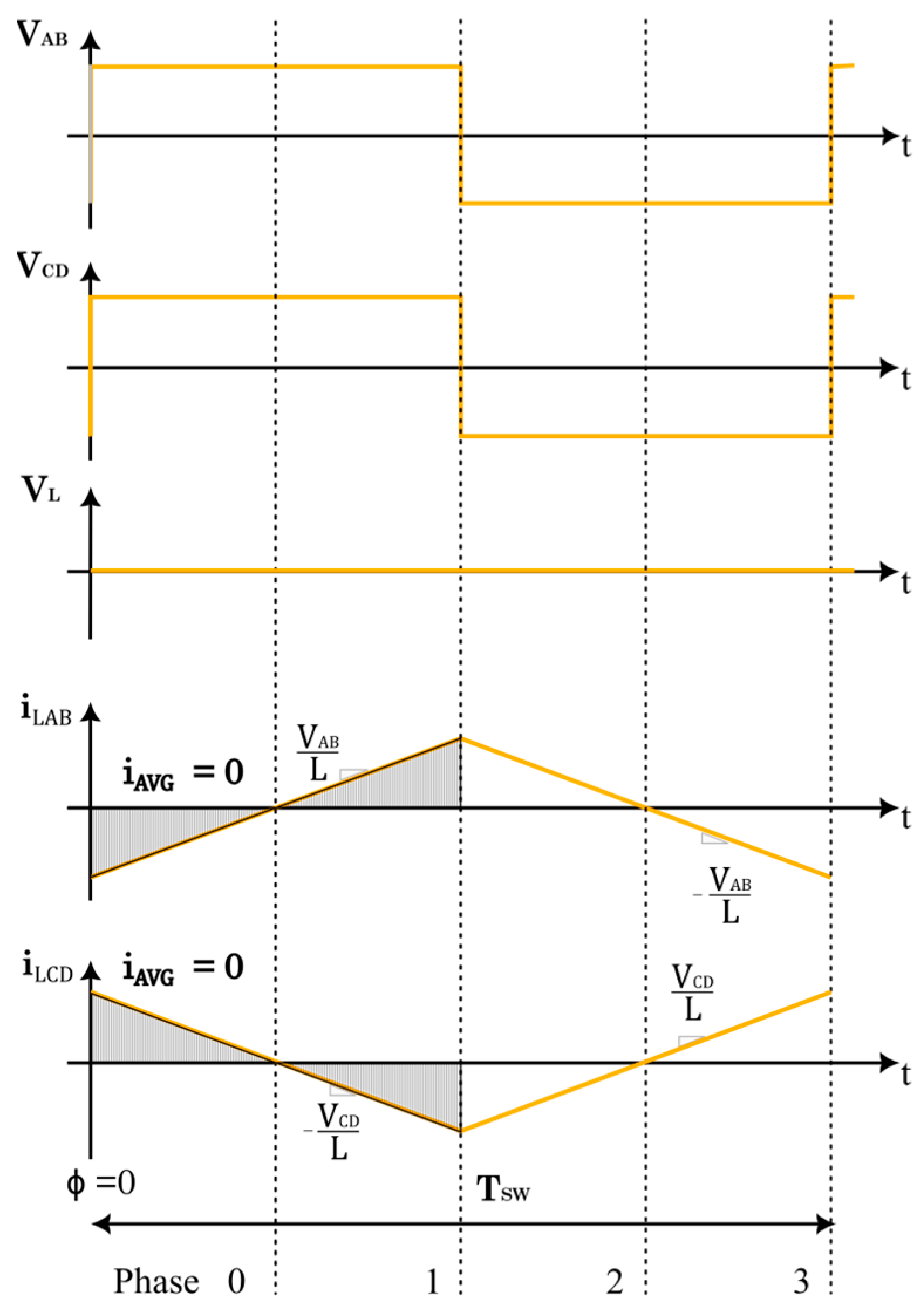

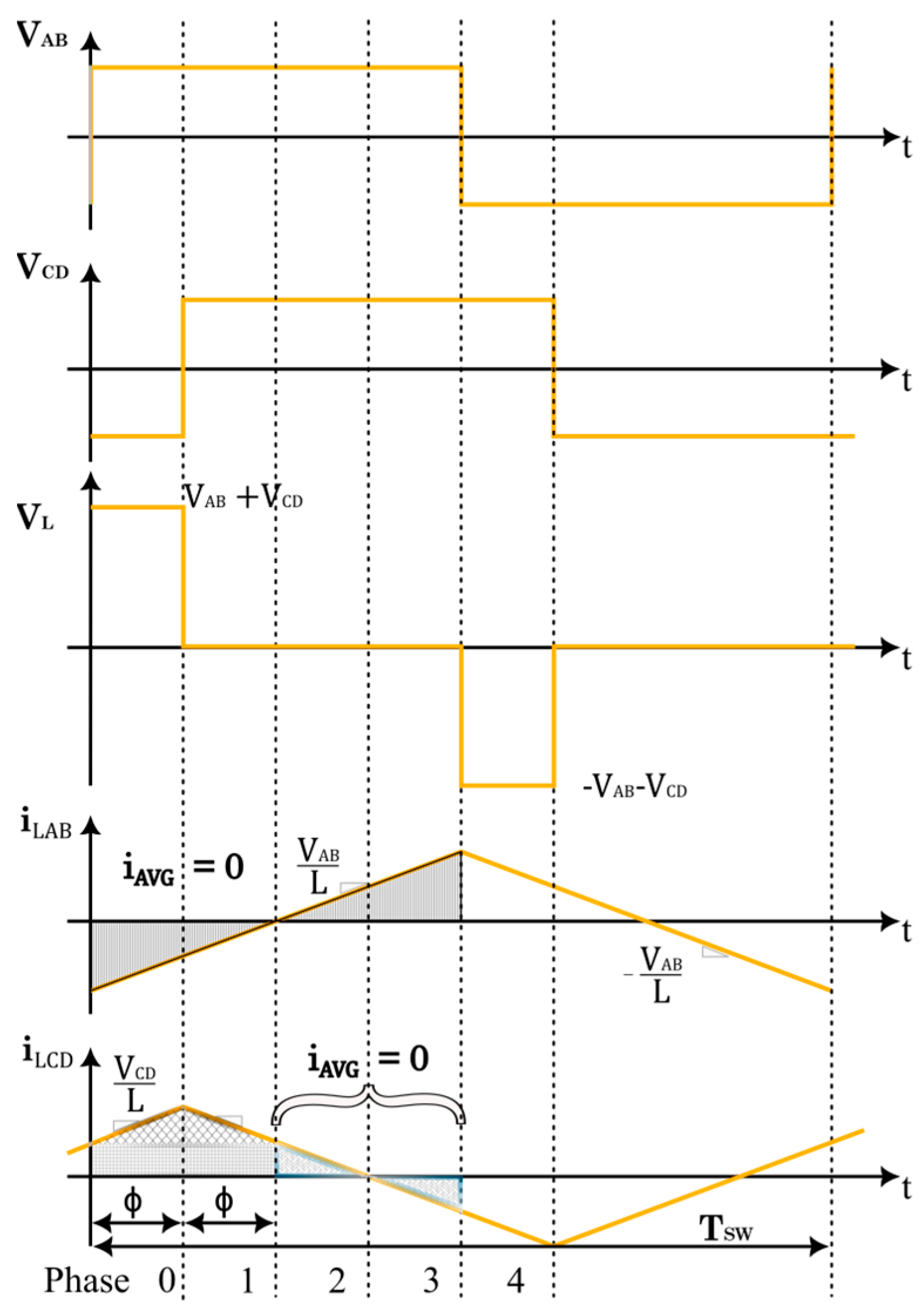

2.2. Power Transfer Mechanism in a Dual Active Bridge Converter

2.2.1. Impact of Leakage Inductance on Power Transfer

2.2.2. Impact of Output Capacitance on Power Transfer

2.3. Design Guideline for Medium-Voltage, Medium-Frequency Transformers

2.4. Design Guideline for Medium-Voltage DAB and Its SIPO Configuration

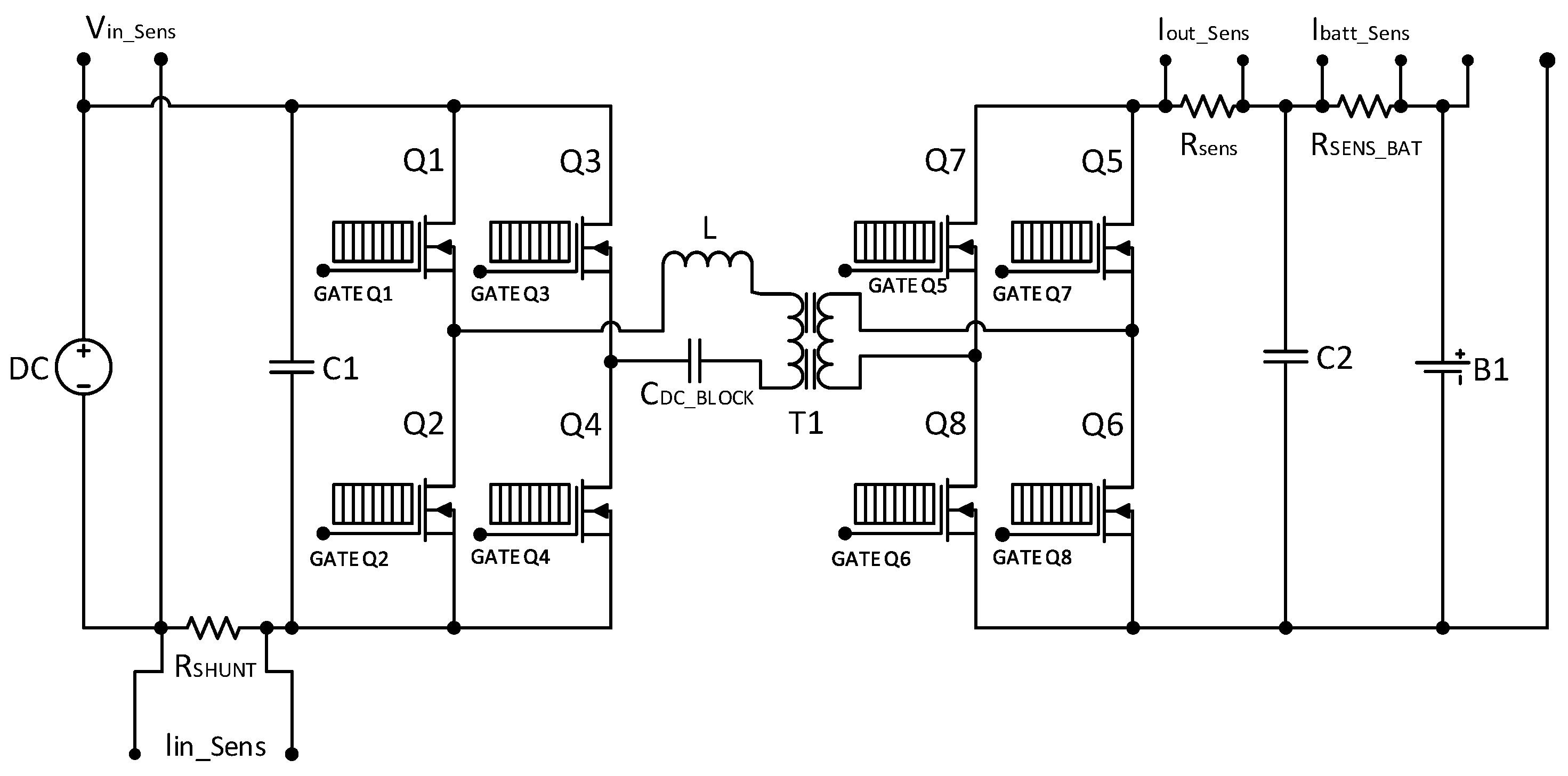

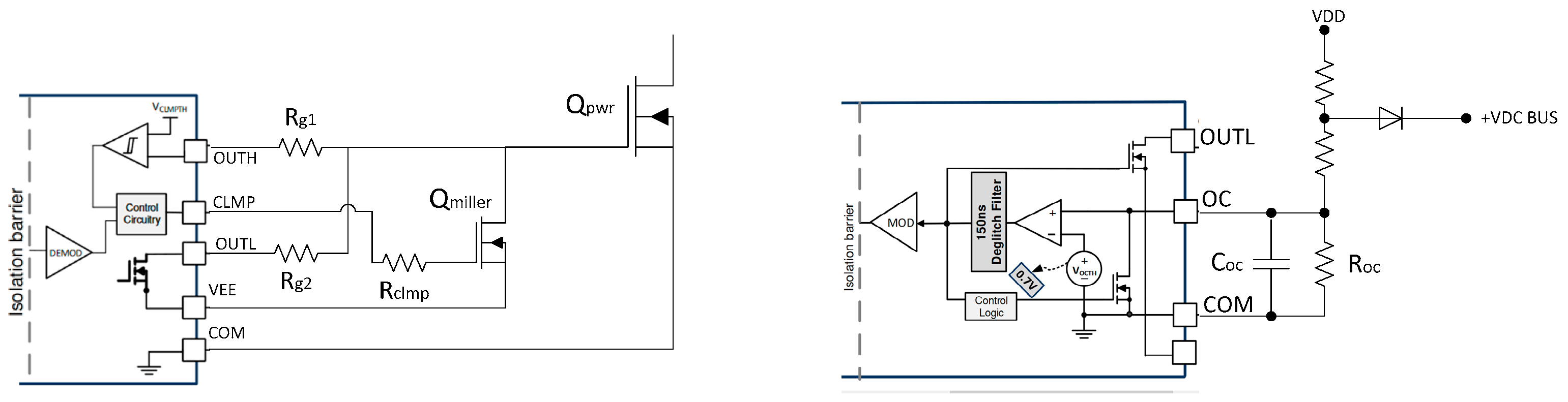

2.4.1. The Power Stage

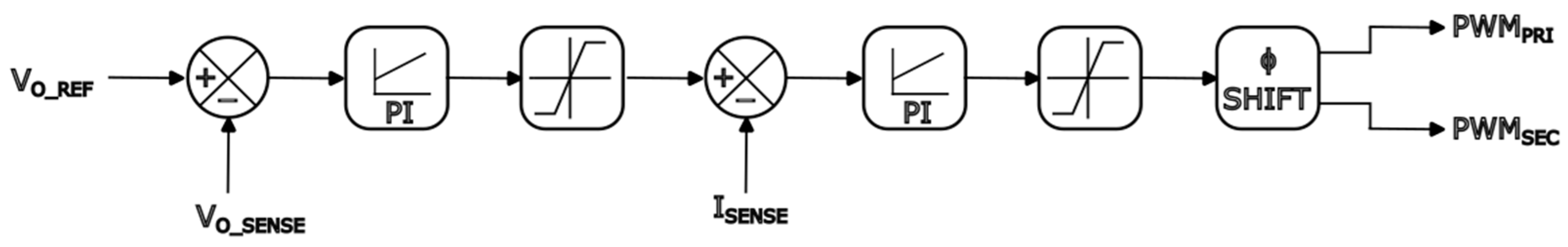

2.4.2. The Control Stage

- Phase-Shift Control: The core of DAB control is phase-shift modulation. The voltage waveforms generated by the primary and secondary H-bridge inverters are shifted relative to each other. The amount of power transferred depends on the phase shift (ϕ) between these waveforms.

- Voltage and Current Regulation: Feedback loops are implemented to regulate the output voltage and control the current. Based on the difference between the measured and desired values (i.e., error), the controller adjusts the phase shift to maintain proper power transfer.

- Bidirectional Operation: The DAB converter can transfer power in both directions, making it suitable for applications like energy storage systems. The phase-shift direction determines whether power flows from the primary to the secondary side or vice-versa.

- Current Protection: Overcurrent protection ensures the system shuts down or reduces power transfer when the current exceeds safe operating limits.

- Inputs:

- Reference output voltage (Voref): desired user/system-set output voltage;

- Reference power (Pref): desired power transfer level;

- Measured input and output voltage (Vin and Vosense): voltage sensor feedback;

- Measured current (Isense): current sensor feedback.

- Control blocks:

- Error calculation: The reference values (Vref, Pref) are compared to the measured output values (Vout, Iout), and the difference (error) is calculated;

- PI controller (Voltage Control): A proportional–integral (PI) controller processes the voltage error to generate a corrective signal for the phase-shift controller;

- PI controller (current/power Control): The power or current error is processed to determine the appropriate phase-shift adjustment;

- Phase-shift controller: This block receives signals from the voltage and power controllers and adjusts the phase-shift angle (ϕ) between the primary and secondary voltage waveforms. The phase shift determines the power flow.

- PWM Modulation:

- PWM generator: Based on the controller’s phase-shift signal, this block generates pulse-width-modulated signals to drive the MOSFET switches in the primary and secondary H bridges. The PWM signal controls the switches’ timing to generate the required square waveforms with the desired phase shift;

- Gate driver signals: The PWM signals are sent to gate drivers that provide the necessary voltage and current to control the switching of the MOSFETs in the primary and secondary H-bridge inverters.

- Power stage (h-bridges and transformer):

- Primary H bridge: Converts the input DC voltage into a high-frequency AC waveform;

- Transformer: Transfers power between the primary and secondary sides and provides galvanic isolation;

- Secondary H bridge: Converts the AC signal back into DC on the secondary side.

- Filtered output voltage: The control system regulates the output voltage to match the reference voltage.

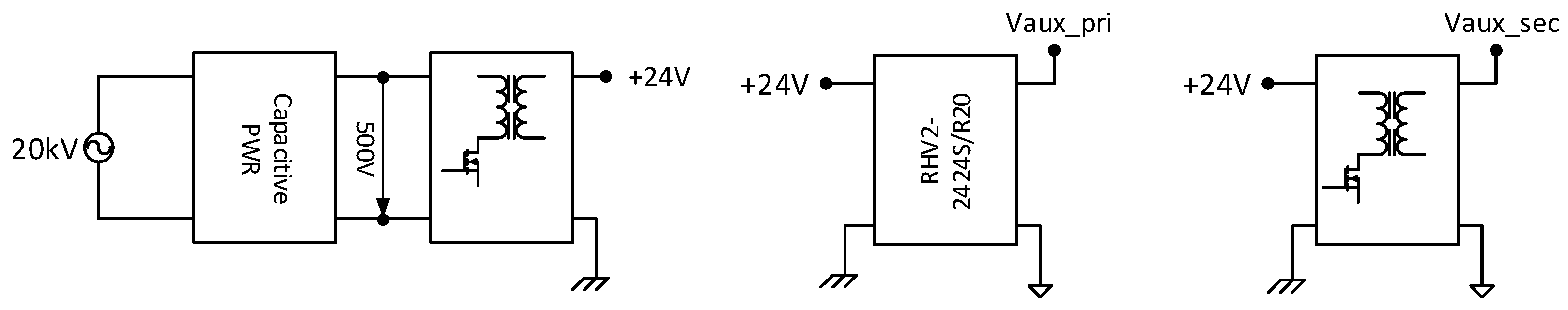

2.4.3. Auxiliary Power Supply

2.4.4. Dual Active Bridge in SIPO Configuration

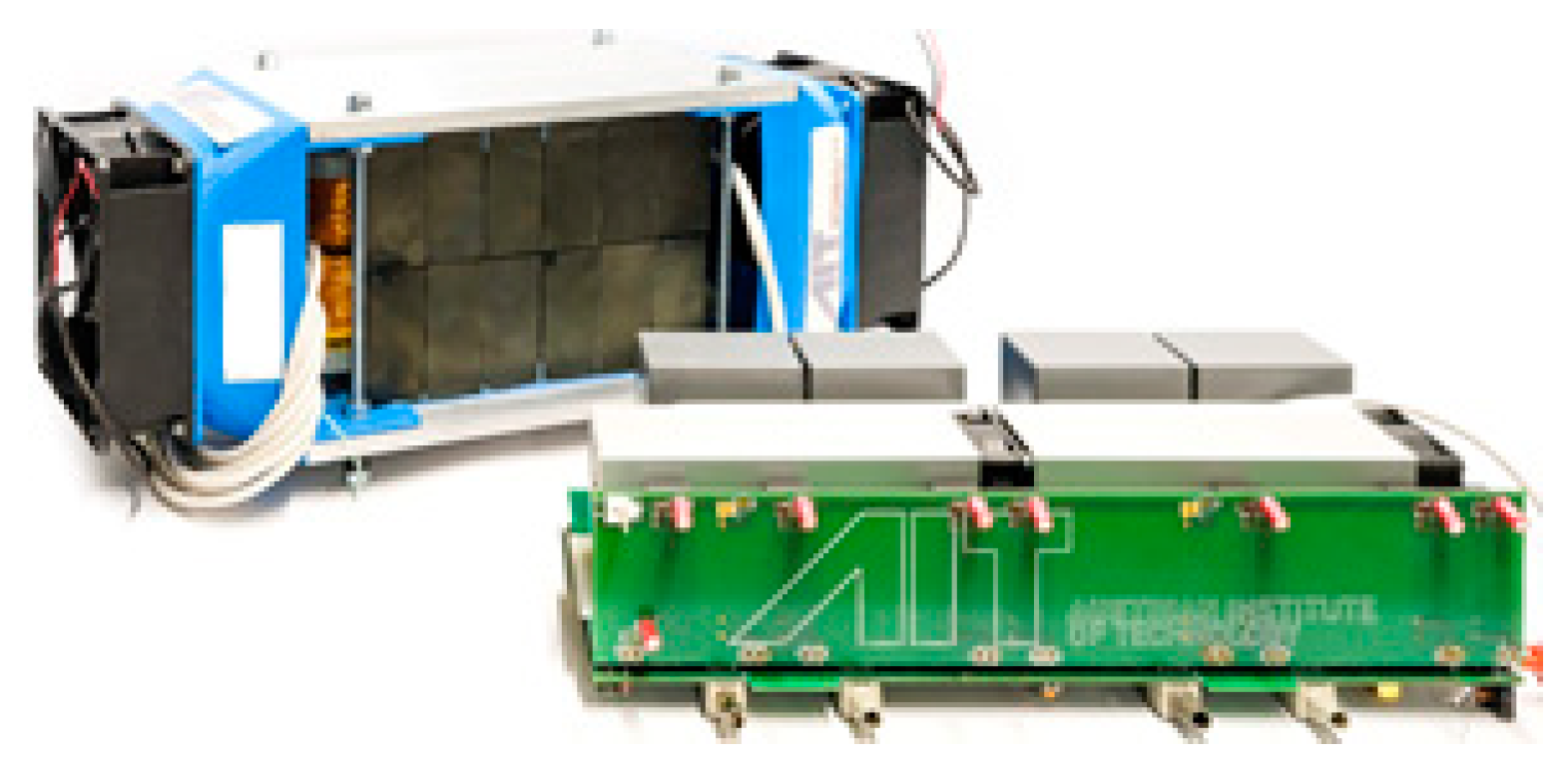

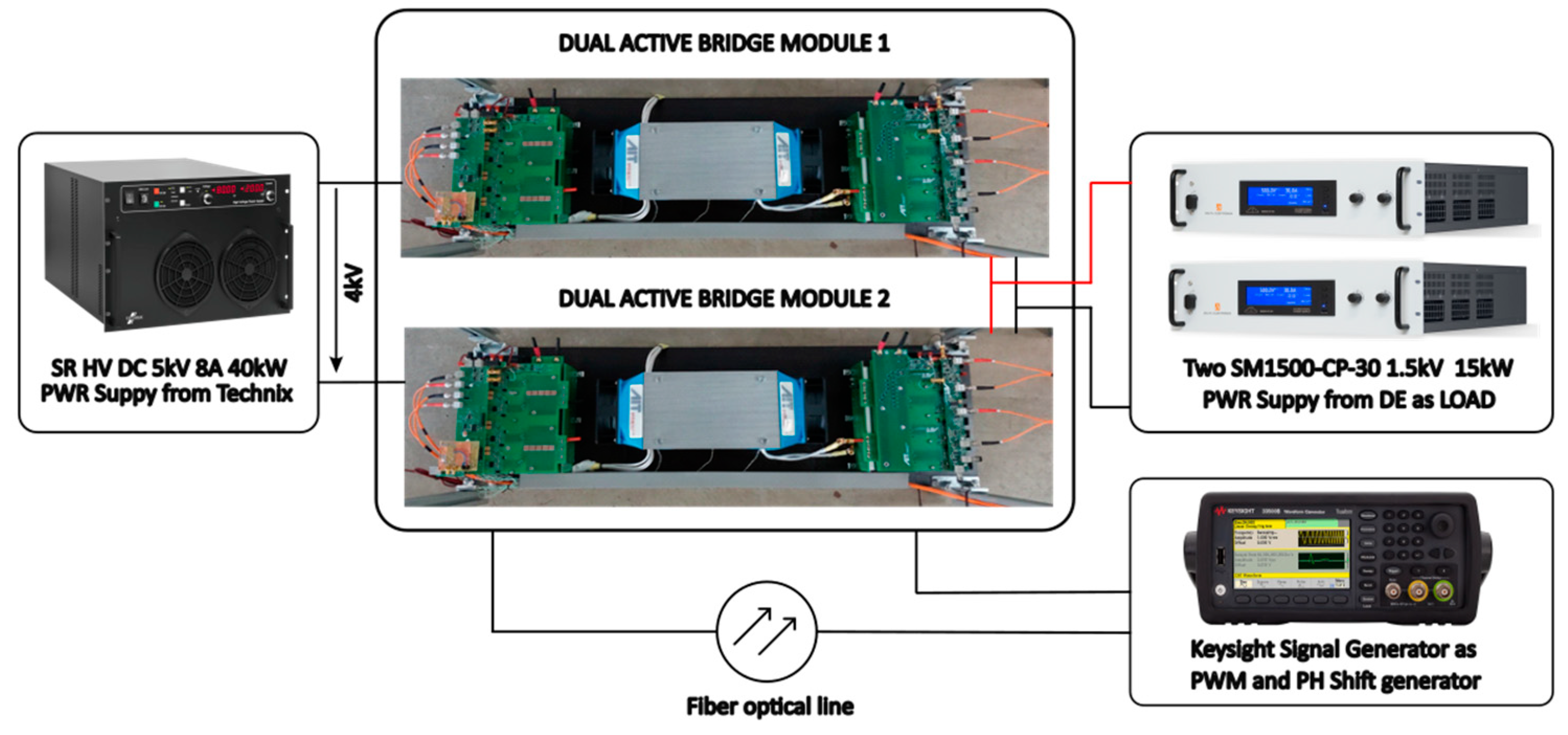

2.5. Test Setup

- Device under test (DUT): DAB is the primary device under test, comprising two full-bridge converters connected via a high-frequency transformer. For the SIPO configuration, two DAB modules should be connected in series on the primary side and in parallel on the secondary side.

- Signal generator: The signal generator creates the gate-drive signals for the switches in the DAB. It produces two sets of PWM (Pulse Width Modulation) signals with a precise phase shift between them, which controls the power transfer between the input and output sides of the DAB. For the SIPO configuration, these signals must be paralleled and provided to the modules simultaneously.

- Power supply: A DC power supply provides the input voltage to the DAB’s primary side, ensuring that it is within the converter’s design range. For dual modules, the primary side of two DABs has to be connected in series.

- Load: To simulate various load conditions, a programmable electronic load is connected to the DAB’s output side, and an appropriate load value is selected to test the converter under different load conditions. For dual modules, the converter output current increases to twice its value; hence, it has to be ensured that the programmable load is able to sink the increased output current.

- Voltage and current sensors: These sensors measure the DAB’s input voltage, input current, output voltage, and output current during operation, as well as the primary and secondary current of the transformers. The measured values help monitor and analyze the DAB’s performance.

- Temperature sensors: Temperature sensors monitor the temperature profiles of the heat sink and DC-link capacitors, providing early warnings if any component exhibits abnormal overheating.

- Oscilloscope: An oscilloscope monitors the gate signals, input/output voltages, and currents in real time, providing a visual representation of the waveforms and the timing relationships between signals.

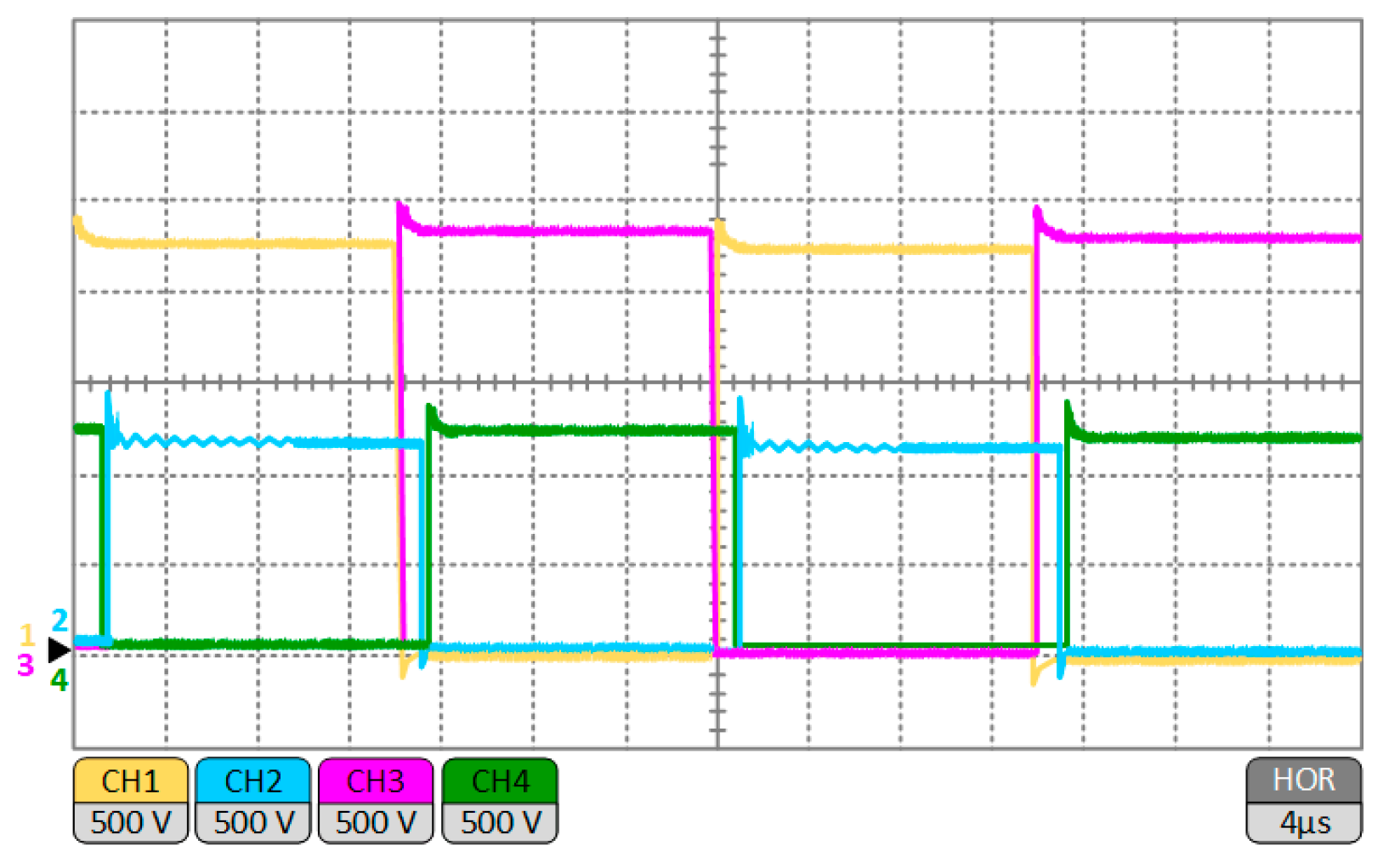

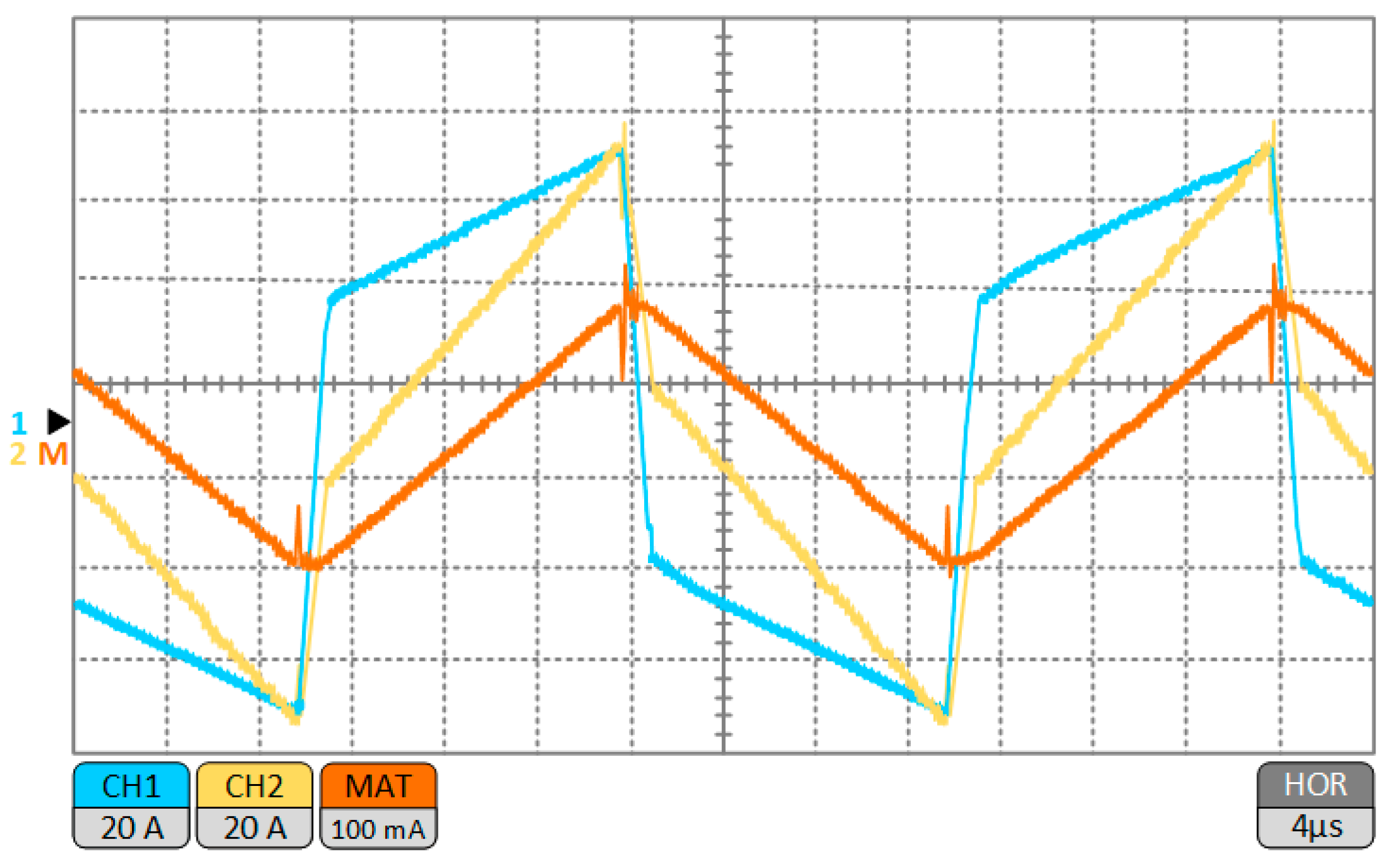

2.6. Test Results

3. Integration of Multimegawatt Charging Stations in the MV Network

3.1. Methodology for the Development of Heavy-Duty Electric Vehicle Charging Profiles

3.2. Network Simulation Methodology

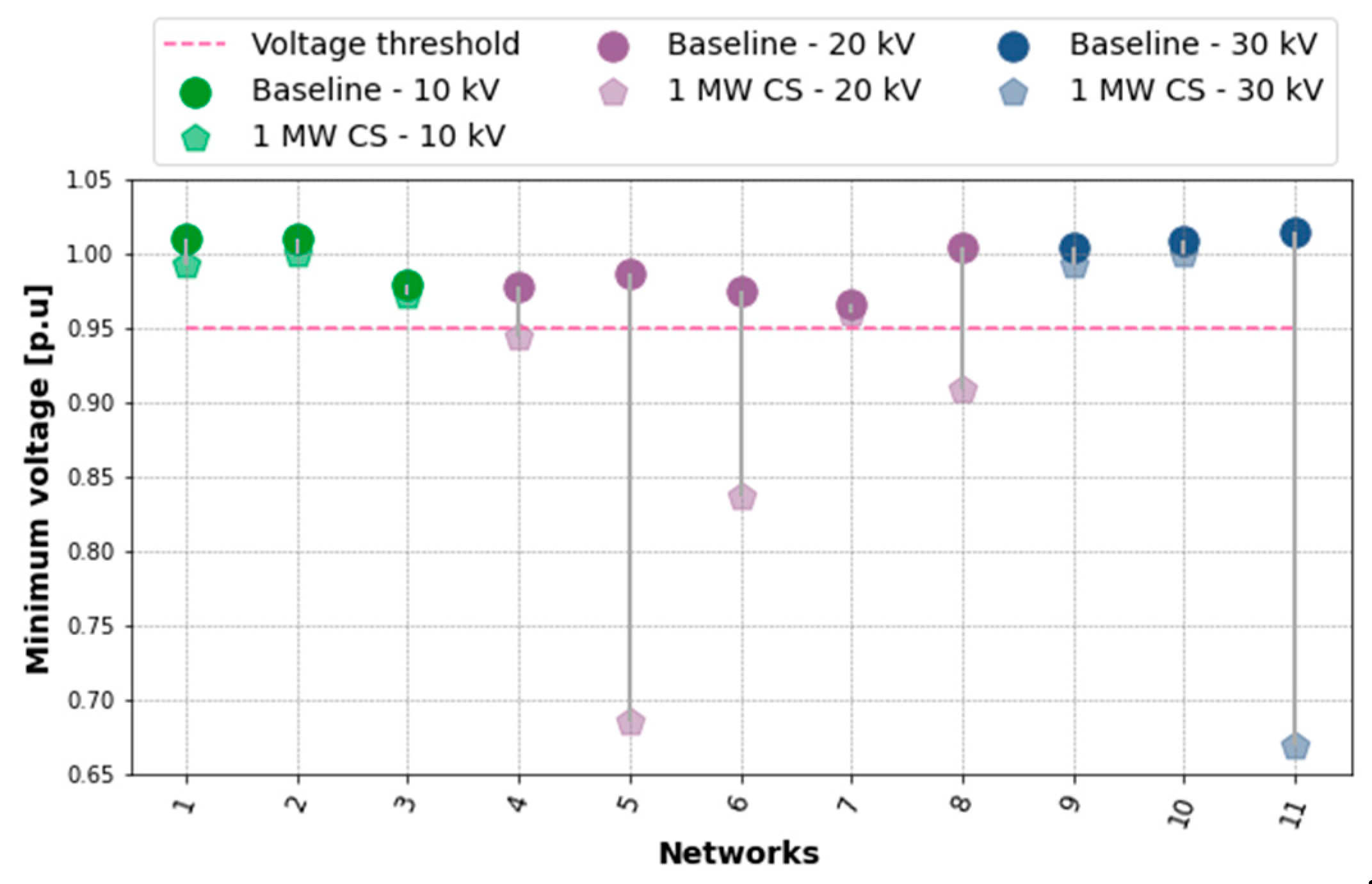

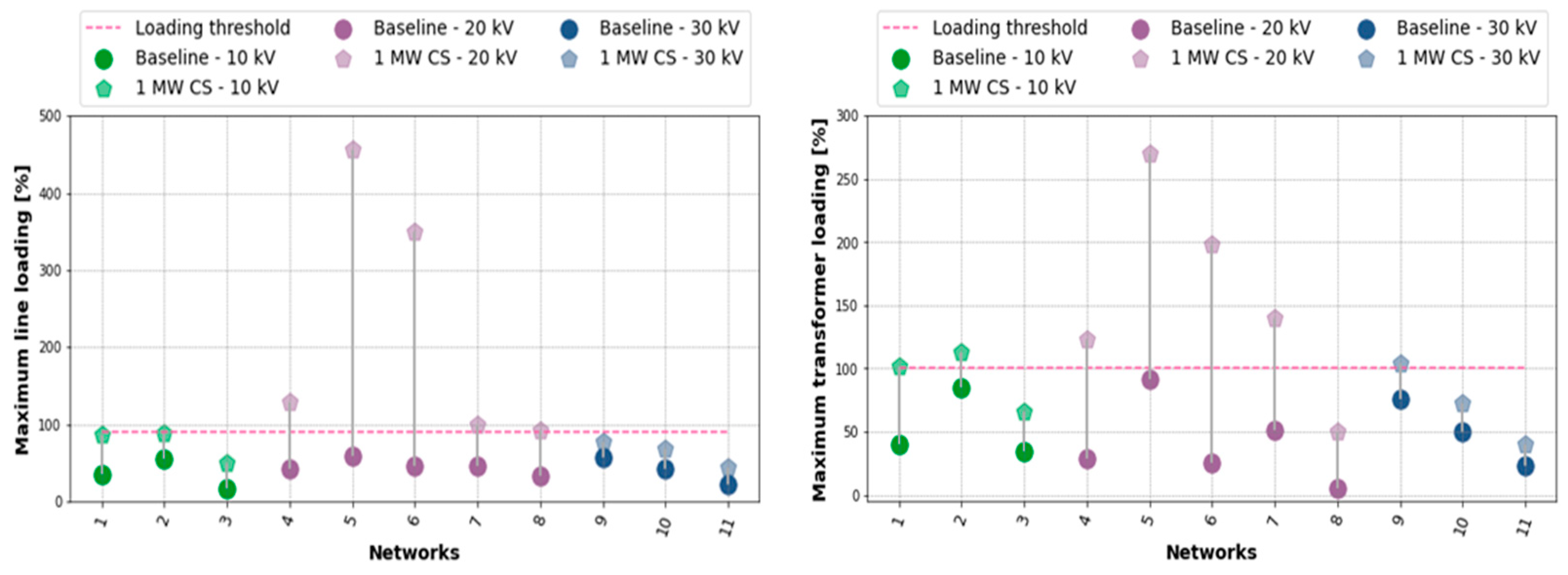

3.3. Network Simulation Results

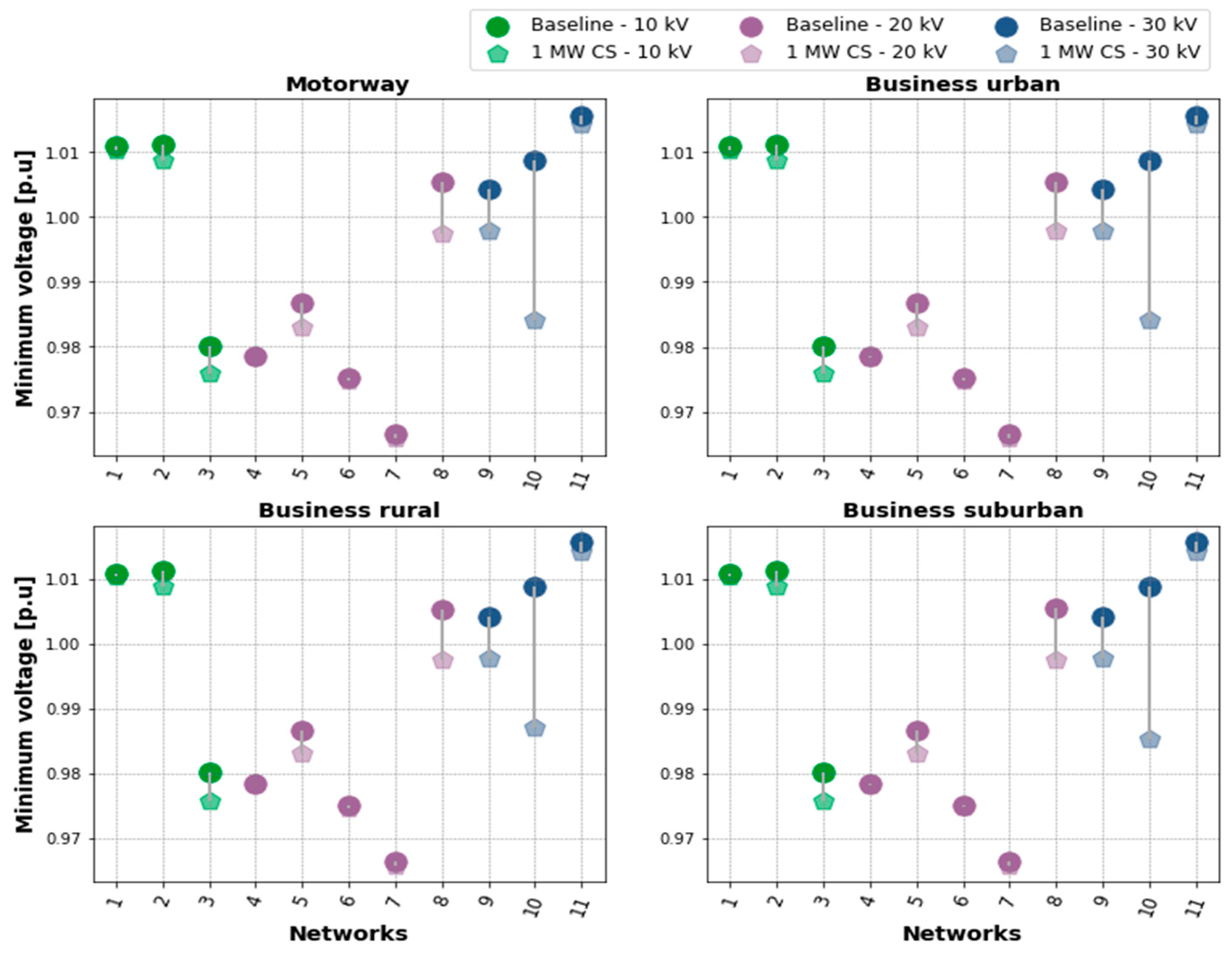

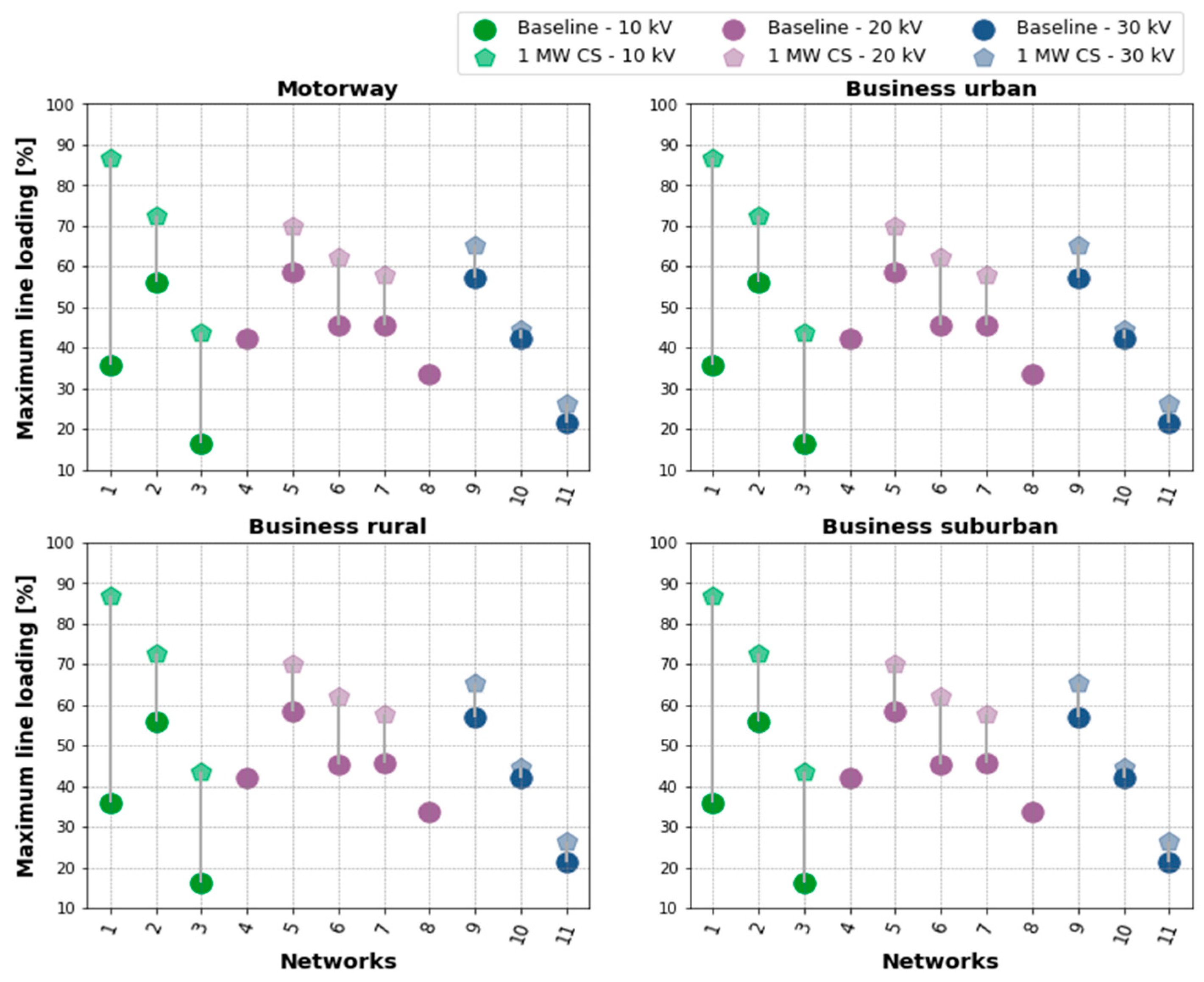

3.3.1. Megawatt Charging Station Connected to Weakest MV Node

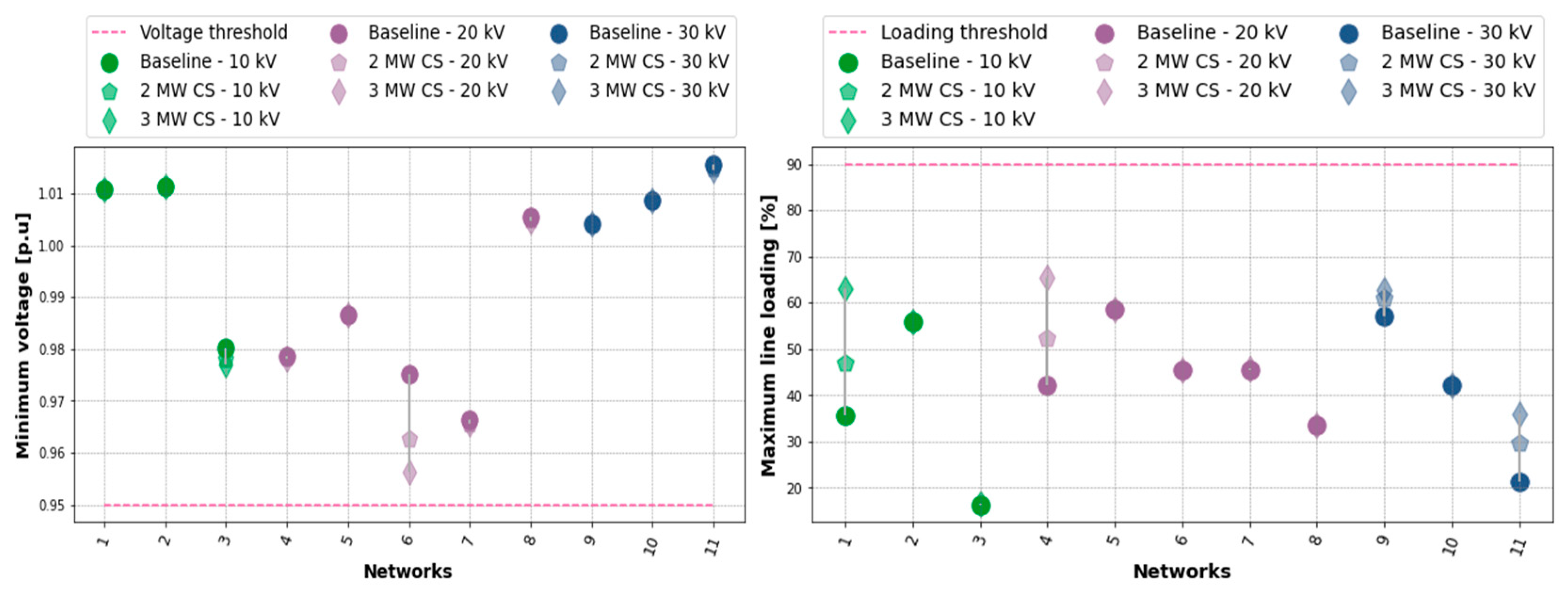

3.3.2. Scalability Analysis: Increase in Nominal Power of the Megawatt Charging Station at the Weakest Node

3.3.3. Scalability Analysis: Increase in Nominal Power of the Charging Station at the Strongest Node

3.3.4. Scalability Analysis: Increase in the Number of Charging Stations Connected within the Network

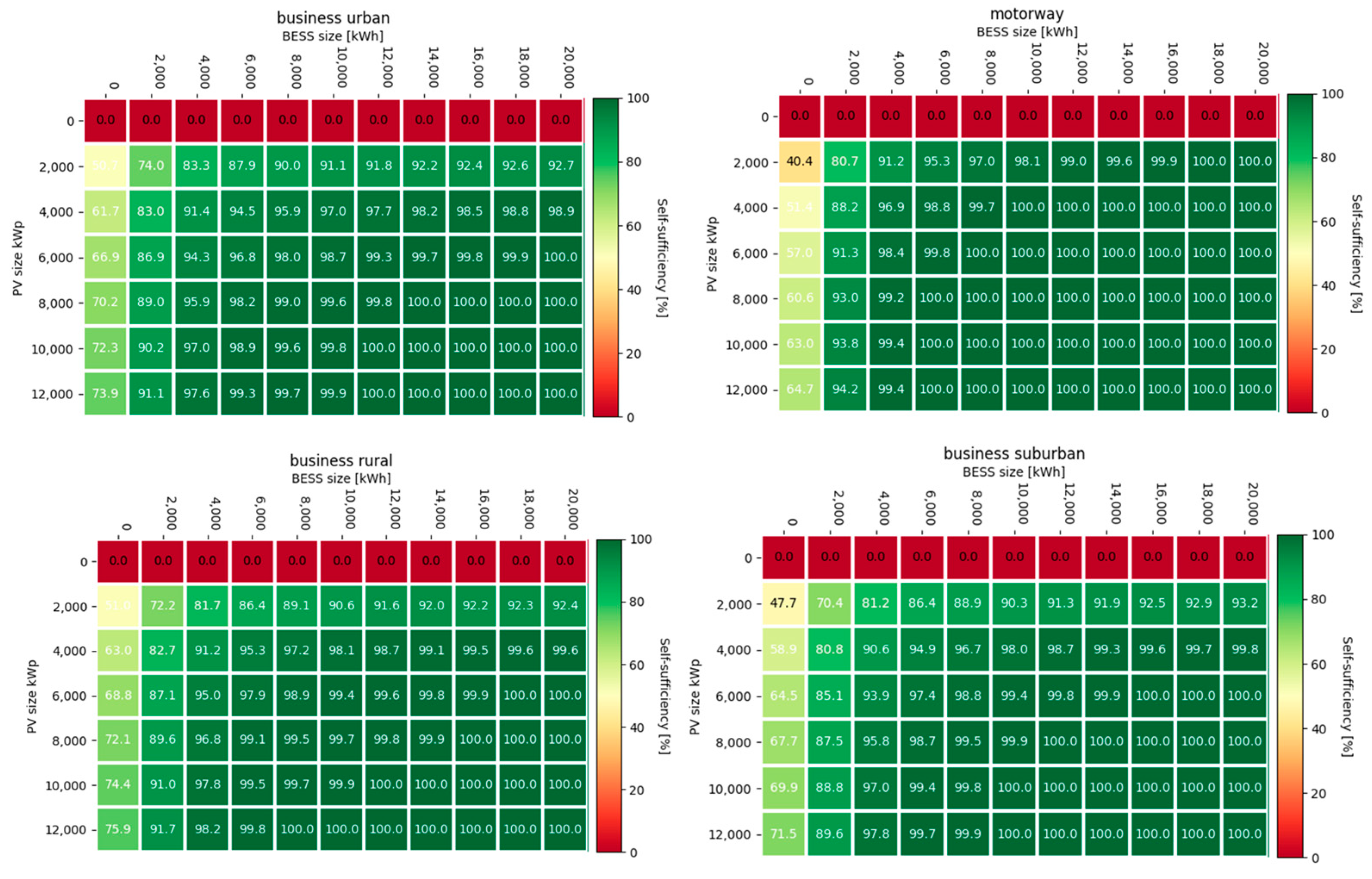

4. Photovoltaic and Battery Storage System Sizing

4.1. Self-Sufficiency

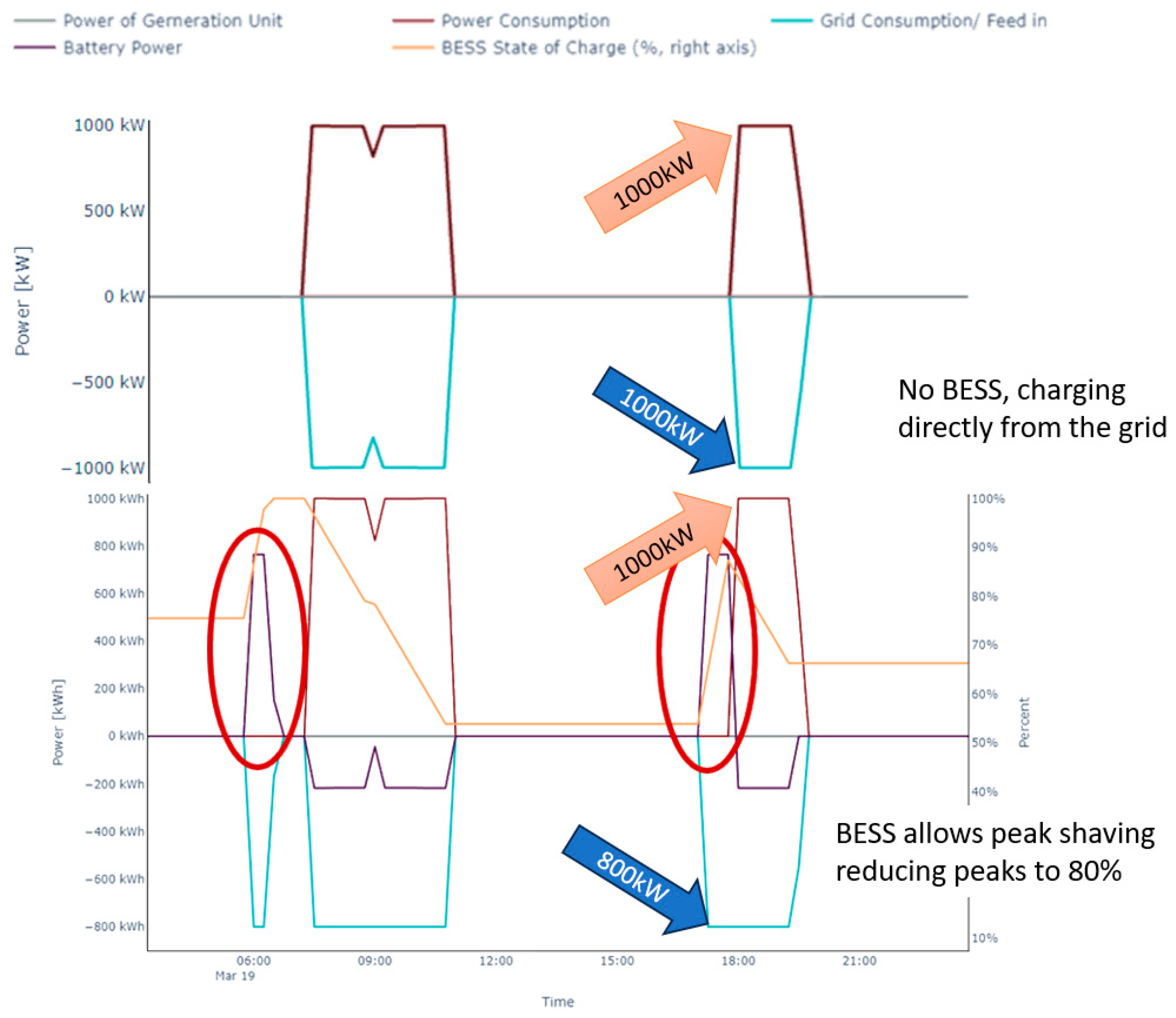

4.2. Peak Shaving

5. Development of Communication Concepts Required for a Multi Megawatt Charging Station

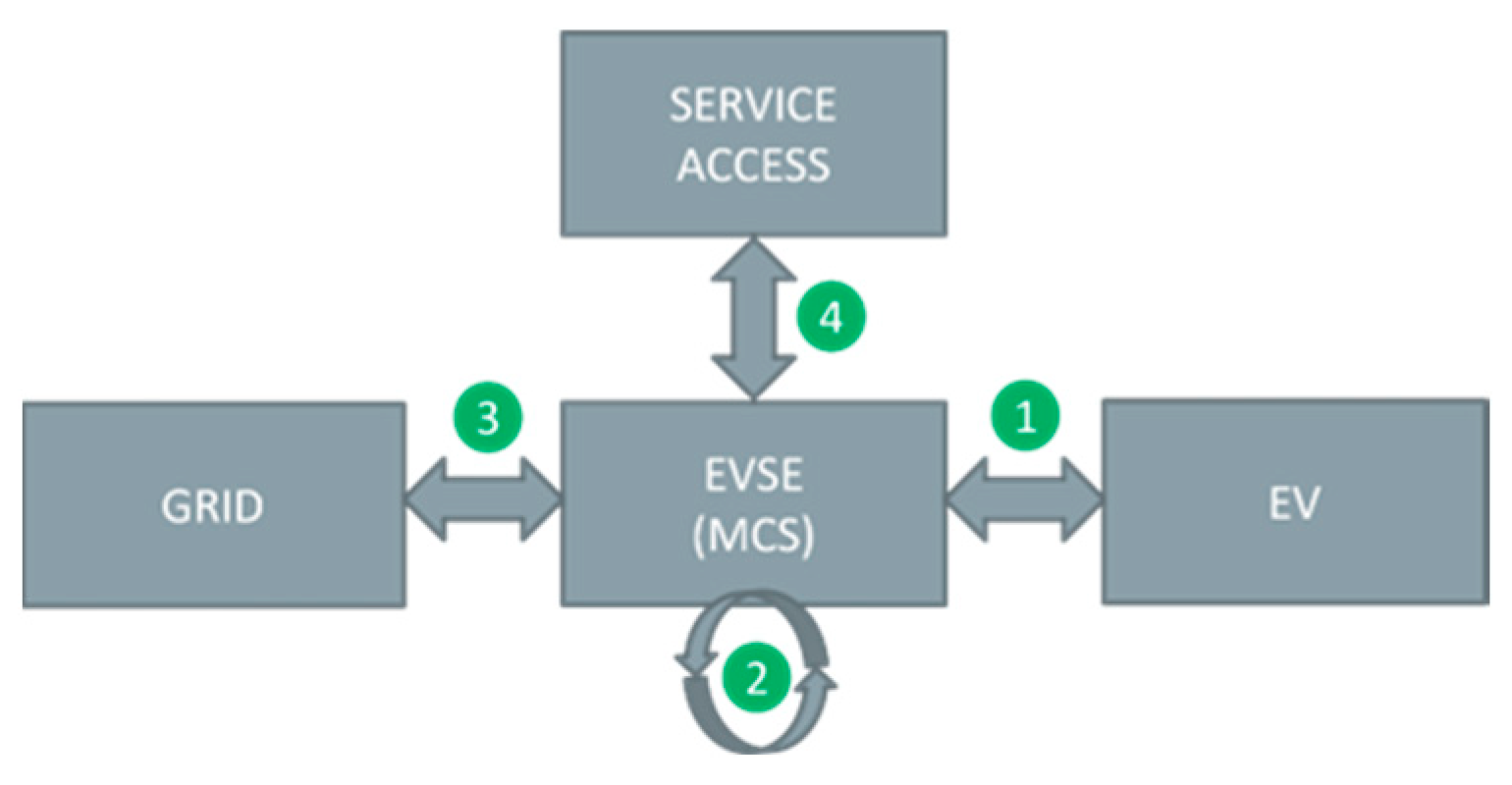

5.1. Communication Concepts between Multimegawatt Charging Station and Electric Vehicle

5.1.1. AC Charging Capabilities

5.1.2. ISO 15118 and Vehicle-to-Grid (V2G) Considerations

5.1.3. Relevant EV Charging Standards

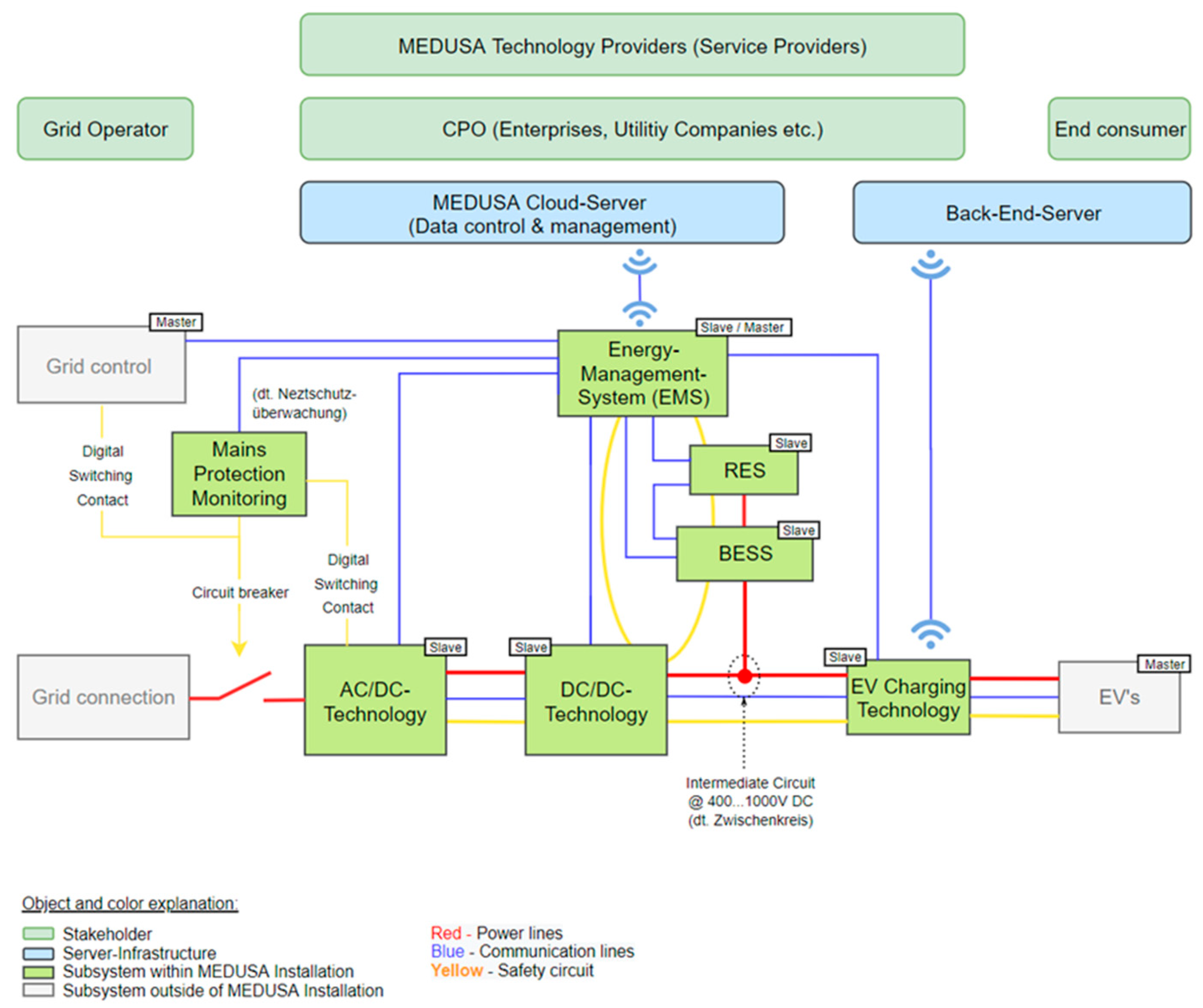

5.2. Communication within Multimegawatt Charging Station Subsystems and Involved Stakeholders

5.2.1. Energy Management System

5.2.2. Cloud Application

5.2.3. Backend Server

5.2.4. Renewable Energy Systems (RESs) and Battery Energy Storage System (BESSs)

5.2.5. DC–DC Converters and DC Link

5.2.6. EV Charging Technology

5.2.7. Further Considerations for an MCS Communication Concept

5.3. Communication between MCSs and the Distribution Grid

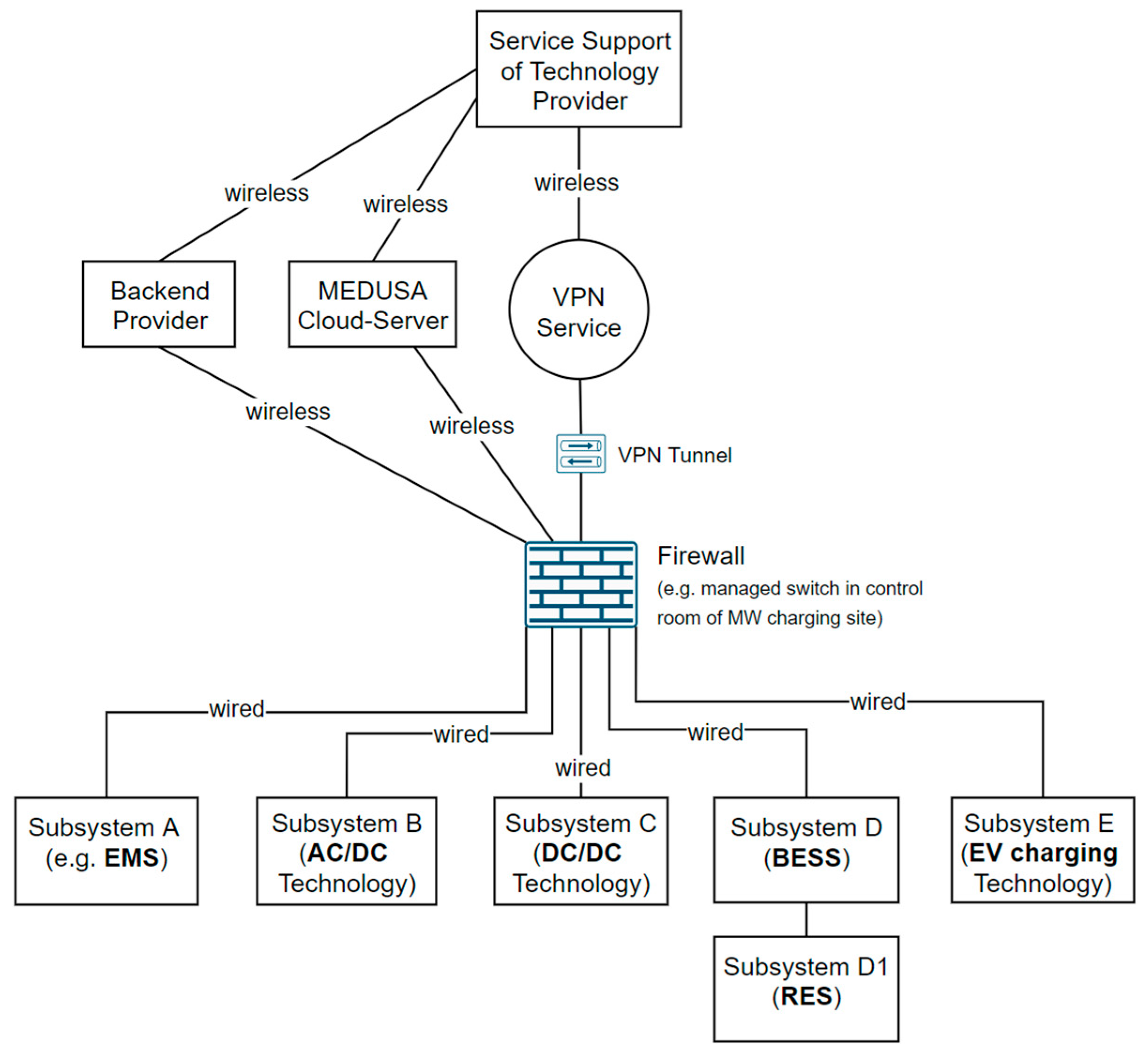

5.4. Cyber-Secure Remote Service Access

- The megawatt charging station reports an anomaly through the SCADA system or requests support.

- Operations Engineering contacts the relevant technology provider.

- A time window is scheduled for external access to the subsystem.

- The service provider connects via a VPN service.

- The system allows an OpenVPN connection to this VPN service.

- Each subsystem establishes a unique OpenVPN connection to the VPN service, with network settings configured to prevent connections to other system nodes.

- The service provider accesses and performs maintenance on the subsystem’s firmware and software.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, L.; Qin, Z.; Slangen, T.; Bauer, P.; van Wijk, T. Grid Impact of Electric Vehicle Fast Charging Stations: Trends, Standards, Issues and Mitigation Measures-An Overview. IEEE Open J. Power Electron. 2021, 2, 56–74. [Google Scholar] [CrossRef]

- Fastned. Available online: https://fastnedcharging.com/hq/why-fast-charging-stations-are-good-for-the-grid/ (accessed on 21 August 2024).

- Yuan, N.; Yu, Z.; Zhang, Y.; Chang, H.; Kang, H. Review of Electric Vehicle Ultra-Fast DC Charging Station. In Proceedings of the 2022 7th Asia Conference on Power and Electrical Engineering (ACPEE), Hangzhou, China, 15–17 April 2022. [Google Scholar]

- Statistics Austria. 22 February 2024. Available online: https://www.statistik.at/fileadmin/announcement/2024/02/20240222KfzBestand2023EN.pdf (accessed on 21 August 2024).

- Statistics Austria. July 2023. Available online: https://austriatech.at/assets/Uploads/Publikationen/PDF-Dateien/OLE_ZDF_2023_July_EN.pdf (accessed on 21 August 2023).

- Makoschitz, M. Key aspects to enable multi-megawatt fast charging. In e & i Elektrotechnik und Informationstechnik; Springer: Berlin/Heidelberg, Germany, 2022; pp. 435–448. [Google Scholar]

- Makoschitz, M. Multi-megawatt charging to foster the mobility transition. In e & i Elektrotechnik und Informationstechnik; Springer: Berlin/Heidelberg, Germany, 2022; pp. 734–736. [Google Scholar]

- Evzelman, M.; Zeltser, I.; Ben-Yaakov, S. DSP control of Gyrator-behaved switch mode converter. In Proceedings of the EDERS 2008: European DSP Education & Research Symposium, Tel-Aviv, Israel, 18 June 2008; pp. 249–256. [Google Scholar]

- IEC 60076-3:2013; Power Transformers—Part 3: Insulation Levels, Dielectric Tests and External Clearances in Air. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- Stahleder, D. EVPP-Electric Vehicle Car Park Peak Power Tool, Austrian Institute of Technology (AIT) GmbH, 2021. Available online: https://evpp.ait.ac.at/ (accessed on 22 February 2022).

- Stahleder, D.; Ubermasser, S.; Reihs, D.; Ledinger, S.; Lehfuss, F. Electric Vehicle Car Park Charging Simultaneity and Grid Connection Power Requirement Analysis. In Proceedings of the CIRED 2021—The 26th International Conference and Exhibition on Electricity Distribution, Online Conference, 20–23 September 2021. [Google Scholar]

- Synthetic Load Profiles. APCS-Power Clearing & Settlement. Available online: https://www.apcs.at/de/clearing/technisches-clearing/lastprofile (accessed on 2 November 2022).

- DIgSilent Power System Solutions. Available online: https://www.digsilent.de/en/powerfactory.html (accessed on 22 May 2023).

- Kapeller, J. zenoodo. 20 May 2021. Available online: https://zenodo.org/record/4774837#.YqnvMqHP3-h (accessed on 15 June 2022).

- Hub. European Commision-EU Science, PVGIS Photovoltaic Geographical Information System. Available online: https://joint-research-centre.ec.europa.eu/pvgis-photovoltaic-geographical-information-system_en (accessed on 21 September 2023).

- Forrest, J.; Vigerske, S.; Hafer, L.; Ralphs, T.; jpfasano; Saltzman, M.; Santos, H.G.; Hunsaker, B.; Willem, J.; tobiasachterberg; et al. Coin-or/cbc: Version 2018. Available online: https://zenodo.org/records/7820231 (accessed on 18 January 2022).

- CharIN. Megawatt Charging System. Available online: https://www.charin.global/technology/mcs/ (accessed on 3 June 2023).

- CharIN. White Paper Megawatt Charging System Recommendations and Requirements for MCS Related Standards Bodies and Solution Supplies. Available online: https://www.charin.global/media/pages/technology/knowledge-base/c708ba3361-1670238823/whitepaper_megawatt_charging_system_1.0.pdf (accessed on 30 June 2023).

- ISO 15118-20:2022; Road Vehicles—Vehicle to Grid Communication Interface—Part 20: 2nd Generation Network Layer and Application Layer Requirements. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 15118:2019; Road Vehicles—Vehicle to Grid Communication Interface. International Organization for Standardization: Geneva, Switzerland, 2019.

- IEC 61851-24:2014; Electric Vehicle Conductive Charging System—Part 24: Digital Communication between a d.c. EV Charging Station and Electric Vehicle for Control of d.c. Charging. International Electrotechnical Commission: Geneva, Switzerland, 2014.

- Control. Available online: https://www.e-control.at/documents/1785851/1811582/TOR_Verteilernetzanschluss_-_Niederspannung_V1.2.pdf (accessed on 15 May 2023).

- OCPP 2.0.1. Open Charge Point Protocol. Open Charge Alliance. 2020. Available online: https://openchargealliance.org/protocols/open-charge-point-protocol/ (accessed on 15 May 2023).

- EEBUS. Communication Standards for Smart Energy Management. Available online: https://www.eebus.org/ (accessed on 22 August 2024).

- MEDUSA-Multi-Megawatt Medium Voltage Megawatt Fast Charging-Phase 1. Available online: https://projekte.ffg.at/projekt/4032453 (accessed on 22 August 2024).

| Specification | Rating |

|---|---|

| Total output power | 50 kVA |

| Operating frequency | 50 kHz |

| Input voltage | 2500 V |

| Turns ratio | 5:3 |

| Primary current | 37 A |

| Secondary current | 61 A |

| Primary side leakage inductance | 125 µH |

| Secondary side leakage inductance | 45 µH |

| Isolation coordinate acc IEC60676-3 | 70 kV for 1 min |

| Parameter | Specification of Individual DAB Module | Specification of the SIPO DAB Module |

|---|---|---|

| Total output power | 50 kW | 100 kW |

| PWM switching frequency | 50 kHz | 50 kHz |

| Input voltage range | 2000 V–2500 V | 4000 V–5000 V |

| Secondary output current | 61 A | 120 A |

| Power density | - | - |

| Ripple voltage | <5% | <5% |

| Isolation coordinate IEC60676-3 | 70 kV for 1 min | 70 kV for 1 min |

| Parameter | Business Premises | Motorway |

|---|---|---|

| Area | Rural, urban, and suburban | Heavily frequented Austrian motorway service area in Guntramsdorf |

| Average daily mileage | 1060 km (weekdays) 840 km (Saturdays) | 1060 km (weekday) 840 km (Saturdays) |

| Maximum charging power | 1 MW | 1 MW |

| Parking duration | 2 h | 1 h |

| Battery state-of-charge threshold for plugging | 30% with a standard deviation of 15% | 30% with a standard deviation of 15% |

| Arrival time | Statistical arrival time distribution function based on a large Austrian mobility survey | Statistical arrival time distribution function extracted from publicly available data |

| Voltage Level | Network | Buses | Lowest Spare Load Capacity (MW) | Highest Spare Load Capacity (MW) |

|---|---|---|---|---|

| 10 kV | Network 1 | 40 | 1.31 | 4.10 |

| Network 2 | 100 | 1.69 | 9.52 | |

| Network 3 | 30 | 2.53 | 5.98 | |

| 20 kV | Network 4 | 300 | 3.16 | 5.20 |

| Network 5 | 510 | 1.76 | 25.15 | |

| Network 6 | 490 | 3.34 | 7.35 | |

| Network 7 | 270 | 3.28 | 13.44 | |

| Network 8 | 160 | 2.04 | 30.20 | |

| 30 kV | Network 9 | 210 | 2.64 | 11.12 |

| Network 10 | 140 | 5.28 | 16.38 | |

| Network 11 | 70 | 7.13 | 17.41 |

| Motorway Peak Shaving: 80% | Motorway Peak Shaving: 66% | |||||

|---|---|---|---|---|---|---|

| PV Size [kWp] | Grid Consumption Savings [MWh] | Grid Feed in [MWh] | CO2 Savings [t] | Grid Consumption Savings [MWh] | Grid Feed in [MWh] | CO2 Savings [t] |

| 1000 | 392 | 837 | 246 | 474 | 694 | 234 |

| 2000 | 526 | 2102 | 526 | 601 | 1868 | 494 |

| 3000 | 581 | 3435 | 803 | 653 | 3161 | 763 |

| 4000 | Not evaluated | 709 | 4386 | 1019 | ||

| Battery size [kWh] | 1000 | 1600 | ||||

| Scenario | Peak Shaving [%] | Electrical Grid Costs without Peak Shaving [k€] | Electrical Grid Costs with Peak Shaving [k€] | Savings [k€] | BESS Size [kWh] | Approx. Investment Cost [k€] |

|---|---|---|---|---|---|---|

| Business urban | 80 | −226 | −200 | 25 | 2100 | −998 |

| 66 | −225 | −182 | 44 | 3600 | −1710 | |

| Business suburban | 80 | −234 | −210 | 25 | 2900 | −1378 |

| 66 | −234 | −191 | 43 | 4900 | −2328 | |

| Motorway | 80 | −198 | −171 | 26 | 1000 | −475 |

| 66 | −198 | −152 | 46 | 1600 | −760 |

| Scenario | Business Urban | Business Suburban | Motorway | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Peak Shaving [%] | 80 | 66 | 80 | 66 | 80 | 66 | ||||||

| PV size [kWp] | Savings [k€] | Invest [−k€] | Savings [k€] | Invest [−k€] | Savings [k€] | Invest [−k€] | Savings [k€] | Invest [−k€] | Savings [k€] | Invest [−k€] | Savings [k€] | Invest [−k€] |

| 1000 | 88 | 2547 | 109 | 3438 | 90 | 3022 | 111 | 4209 | 99 | 1894 | 99 | 2250 |

| 2000 | 136 | 3847 | 156 | 4738 | 140 | 4322 | 162 | 5509 | 142 | 3194 | 142 | 3550 |

| 3000 | 180 | 5147 | 200 | 6038 | 184 | 5622 | 205 | 6809 | 184 | 4494 | 184 | 4850 |

| 4000 | 223 | 6447 | 241 | 7338 | 227 | 6922 | 245 | 8109 | 224 | 6150 | ||

| 5000 | 279 | 8638 | 270 | 8222 | 287 | 9409 | ||||||

| 6000 | 321 | 9938 | 328 | 10,709 | ||||||||

| 7000 | Not evaluated | 368 | 12,009 | Not evaluated | ||||||||

| BESS size [kWh] | 2625 | 4500 | 3625 | 6125 | 1250 | 2000 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biswas, S.; Gerald, C.K.; Herndler, B.; Stahleder, D.; Wimmer, Y.; Makoschitz, M. Optimized Integration of Medium-Voltage Multimegawatt DC Charging Stations: Concepts, Guidelines and Analysis. World Electr. Veh. J. 2024, 15, 450. https://doi.org/10.3390/wevj15100450

Biswas S, Gerald CK, Herndler B, Stahleder D, Wimmer Y, Makoschitz M. Optimized Integration of Medium-Voltage Multimegawatt DC Charging Stations: Concepts, Guidelines and Analysis. World Electric Vehicle Journal. 2024; 15(10):450. https://doi.org/10.3390/wevj15100450

Chicago/Turabian StyleBiswas, Sumanta, Cham Kpu Gerald, Barbara Herndler, Daniel Stahleder, Yannick Wimmer, and Markus Makoschitz. 2024. "Optimized Integration of Medium-Voltage Multimegawatt DC Charging Stations: Concepts, Guidelines and Analysis" World Electric Vehicle Journal 15, no. 10: 450. https://doi.org/10.3390/wevj15100450