A Scalable Joint Estimation Algorithm for SOC and SOH of All Individual Cells within the Battery Pack and Its HIL Implementation

Abstract

1. Introduction

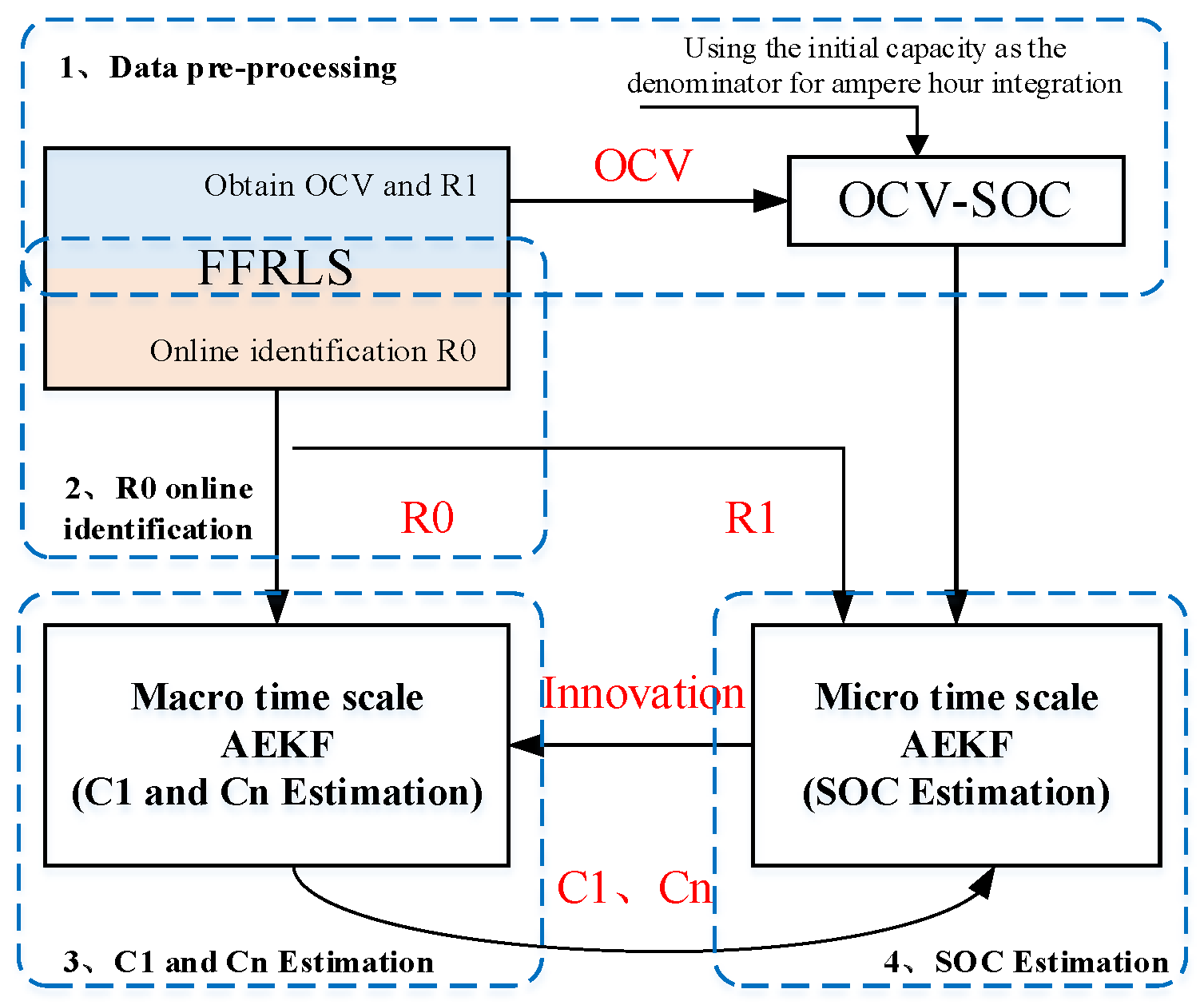

2. SOC and SOH Joint Estimation Scheme and Pre-Data Processing

2.1. SOC and SOH Joint Estimation Scheme

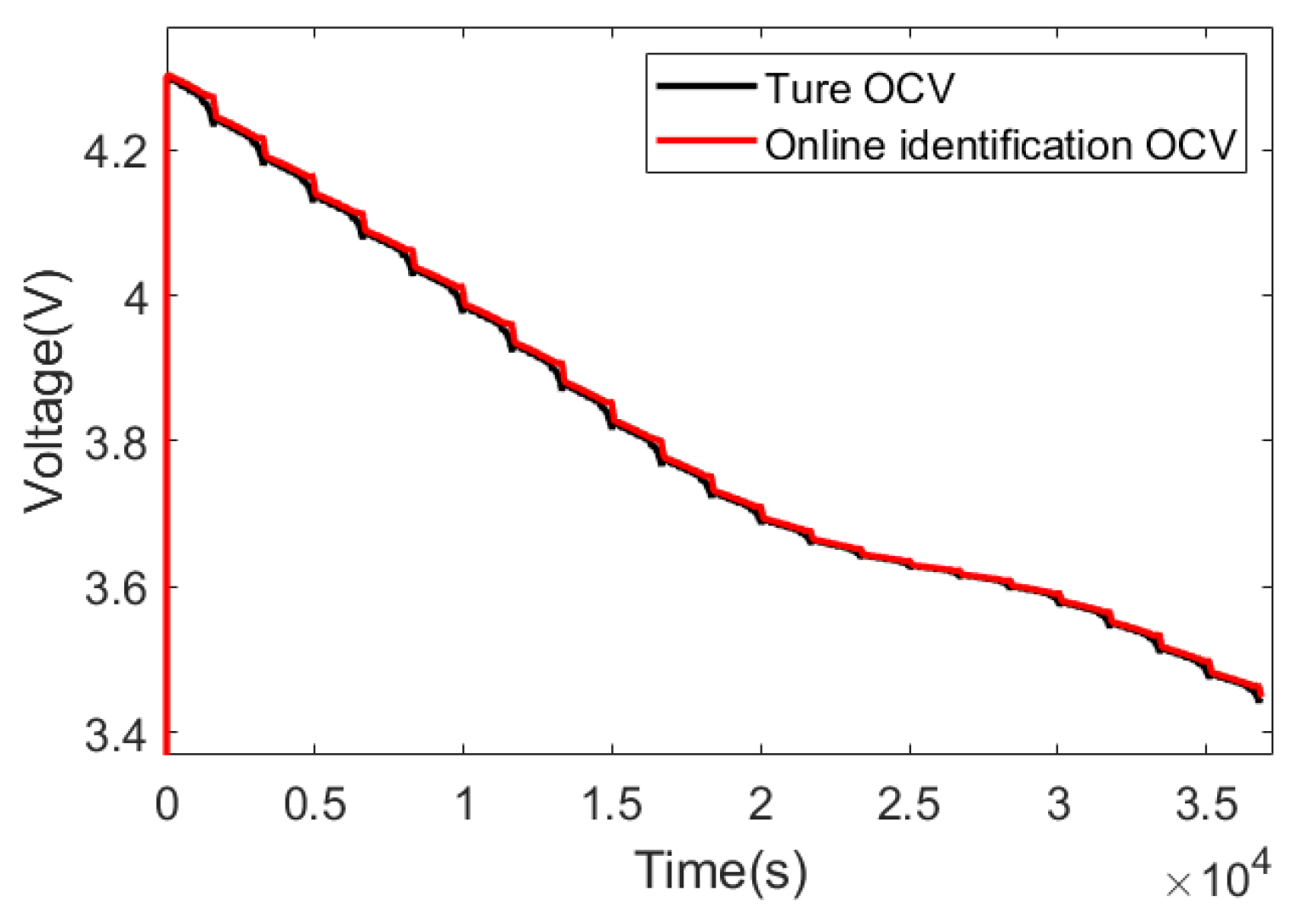

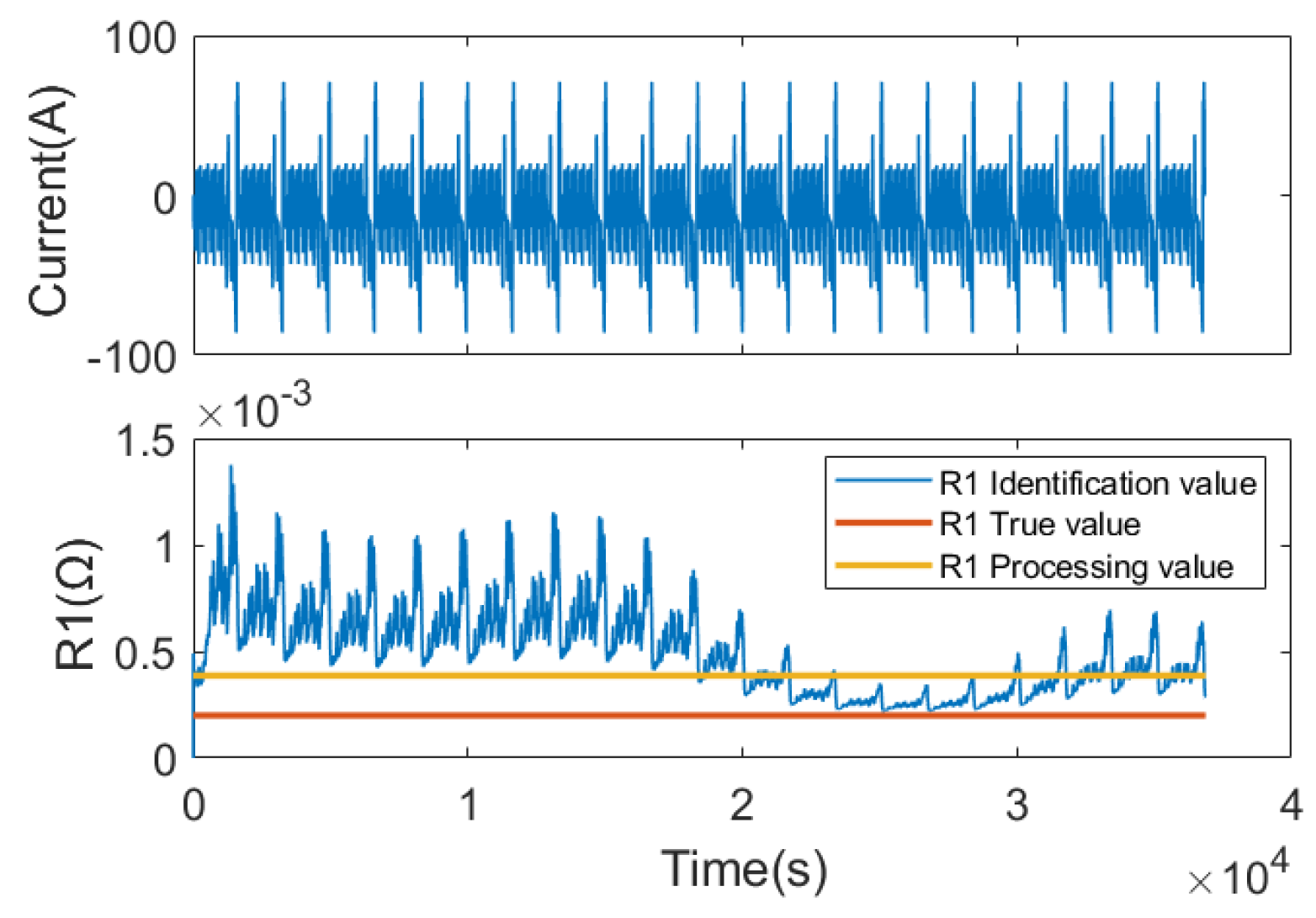

2.2. Early Data Processing Based on FFRLS to Obtain OCV, R1

| Algorithm 1: FFRLS to obtain OCV-SOC, R1 and R0 |

| Input: Output: , // The calculation process of FFRLS // Parameter initialization θ0, P0 for k = 1:N // Determine the input and parameter vectors |

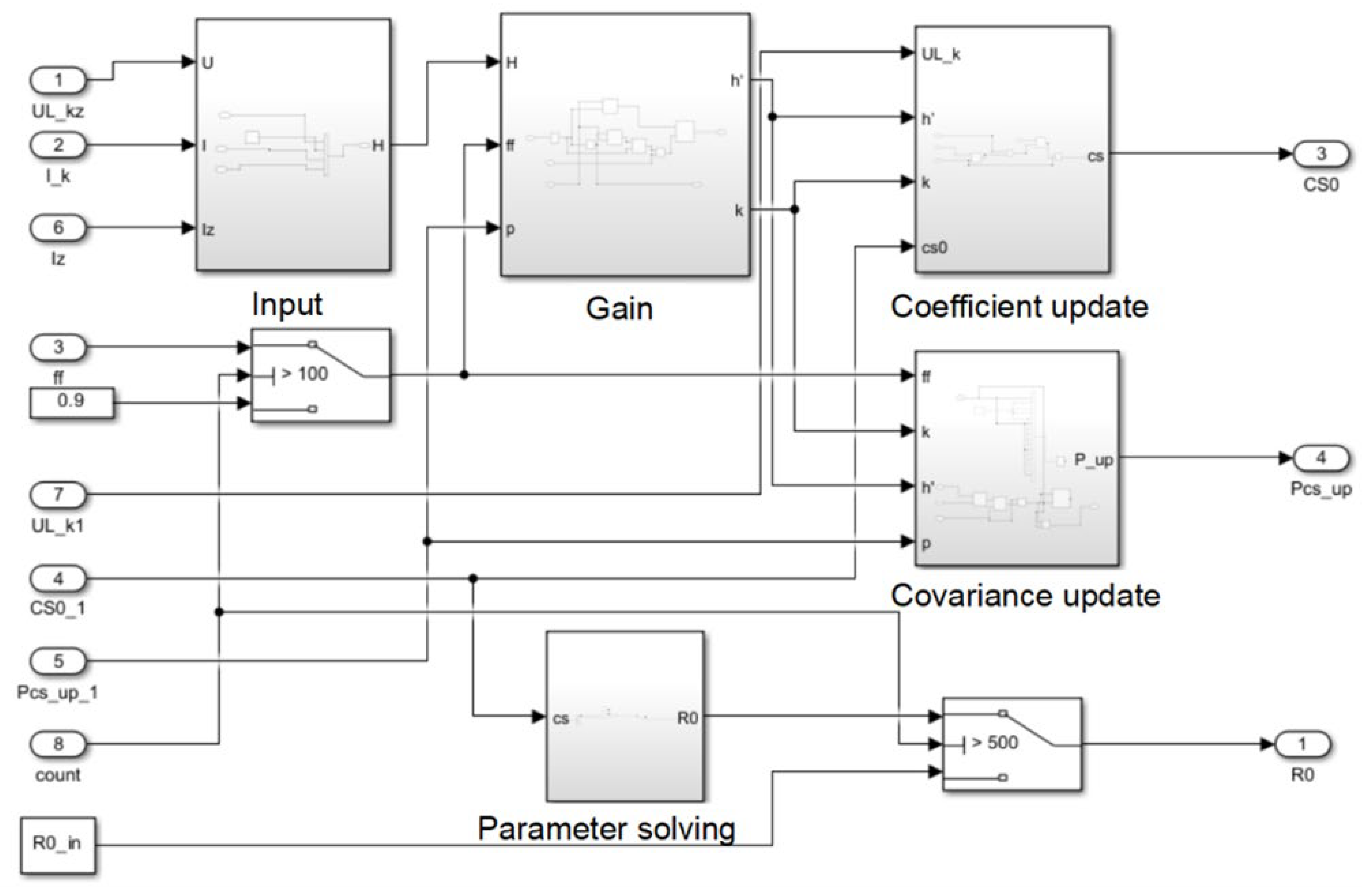

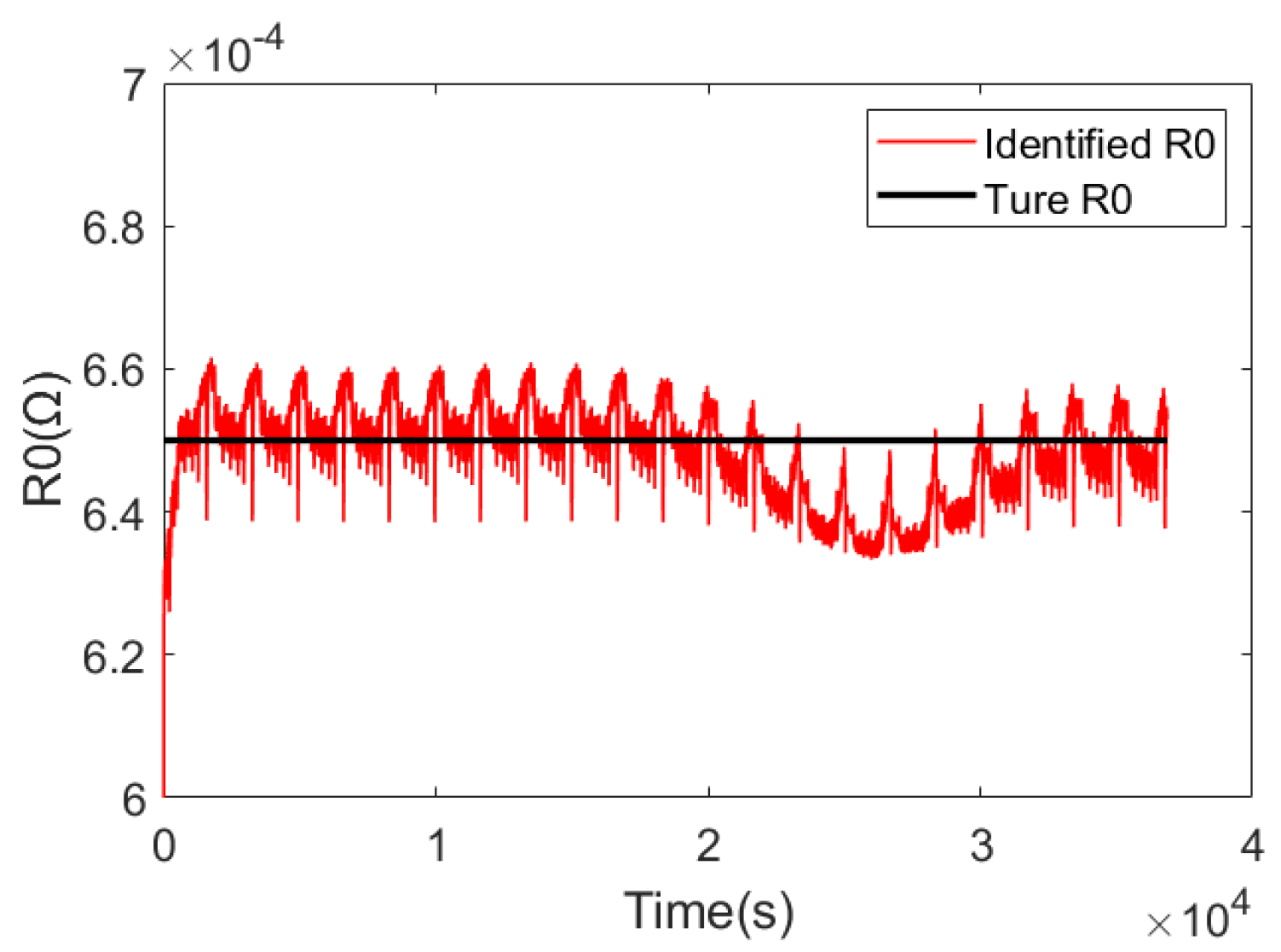

2.3. Online Real-Time Calculation Based on FFRLS Algorithm to Obtain R0

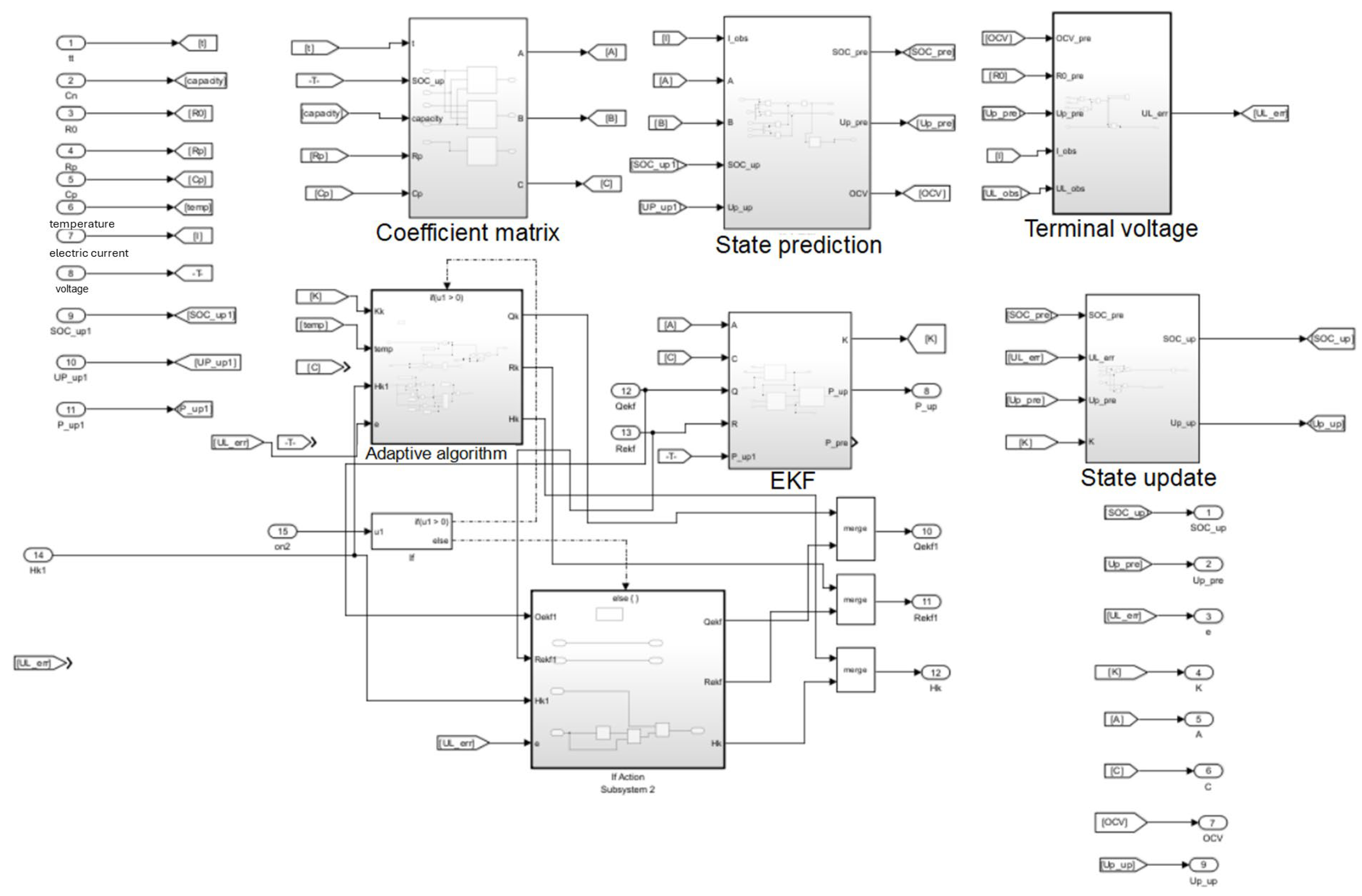

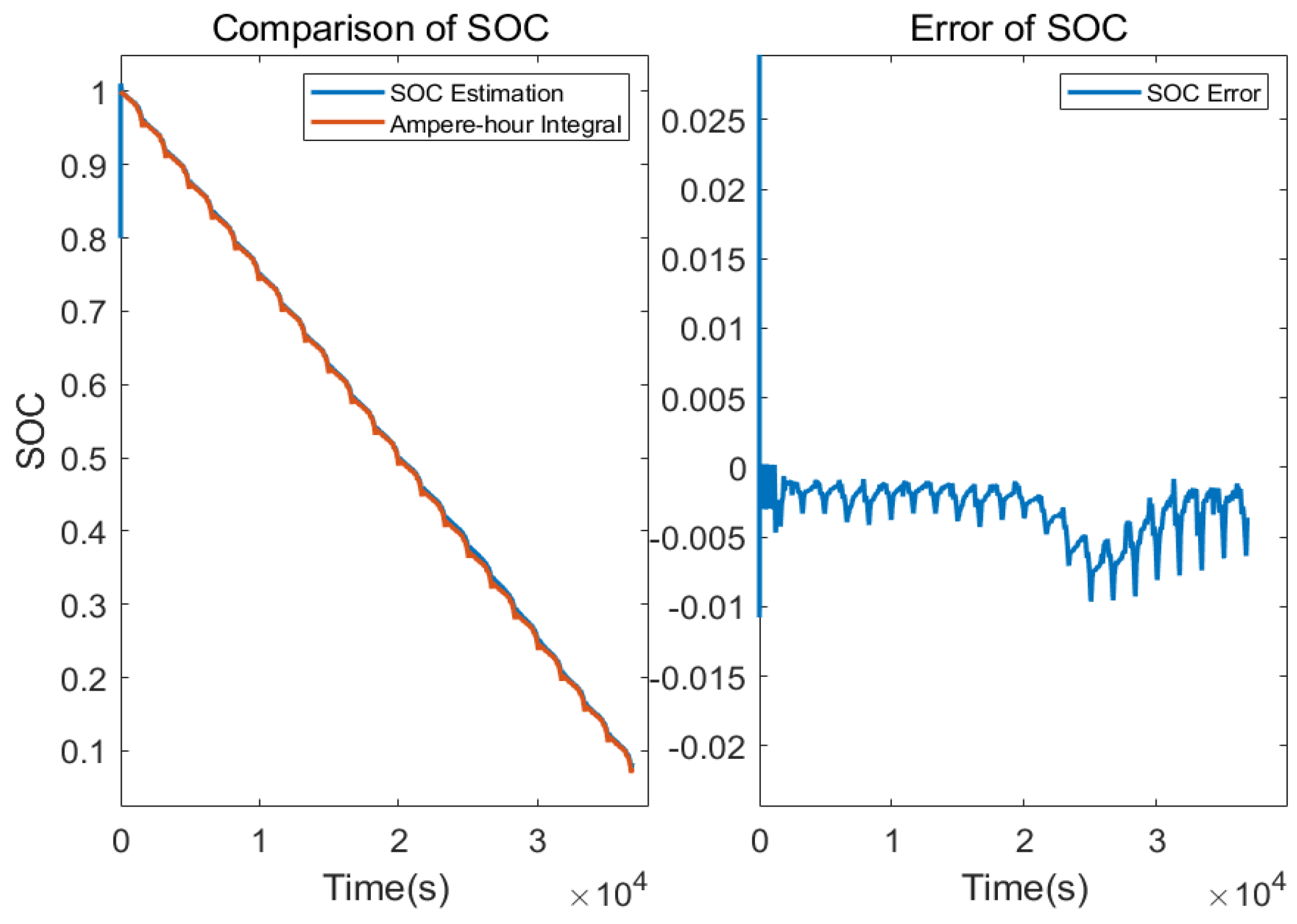

2.4. Micro-Time-Scale SOC Estimation and Simulink Implementation

| Algorithm 2: Micro-time scale SOC estimation |

| Input: Output: // Initialize the micro-time-scale SOC estimator . for k = 1:L // Prior estimate of the state quantities, State error covariance and terminal voltage |

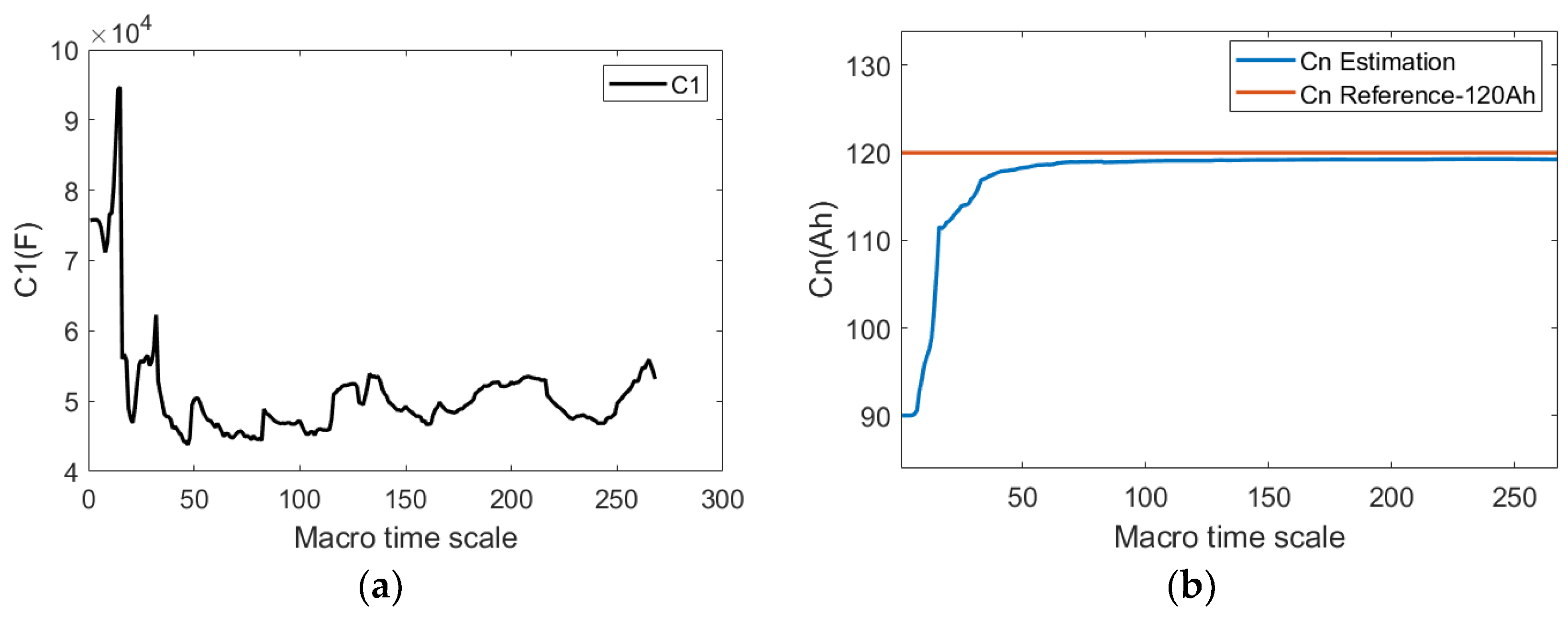

2.5. Macro-Time-Scale C1 and Cn Estimation and Simulink Implementation

| Algorithm 3: Macro-time-scale C1 and Cn estimation |

| Input: Output: // Initialize the macro-time-scale parameter estimator . // The calculation of parameters and parameter error covariance prior estimates. |

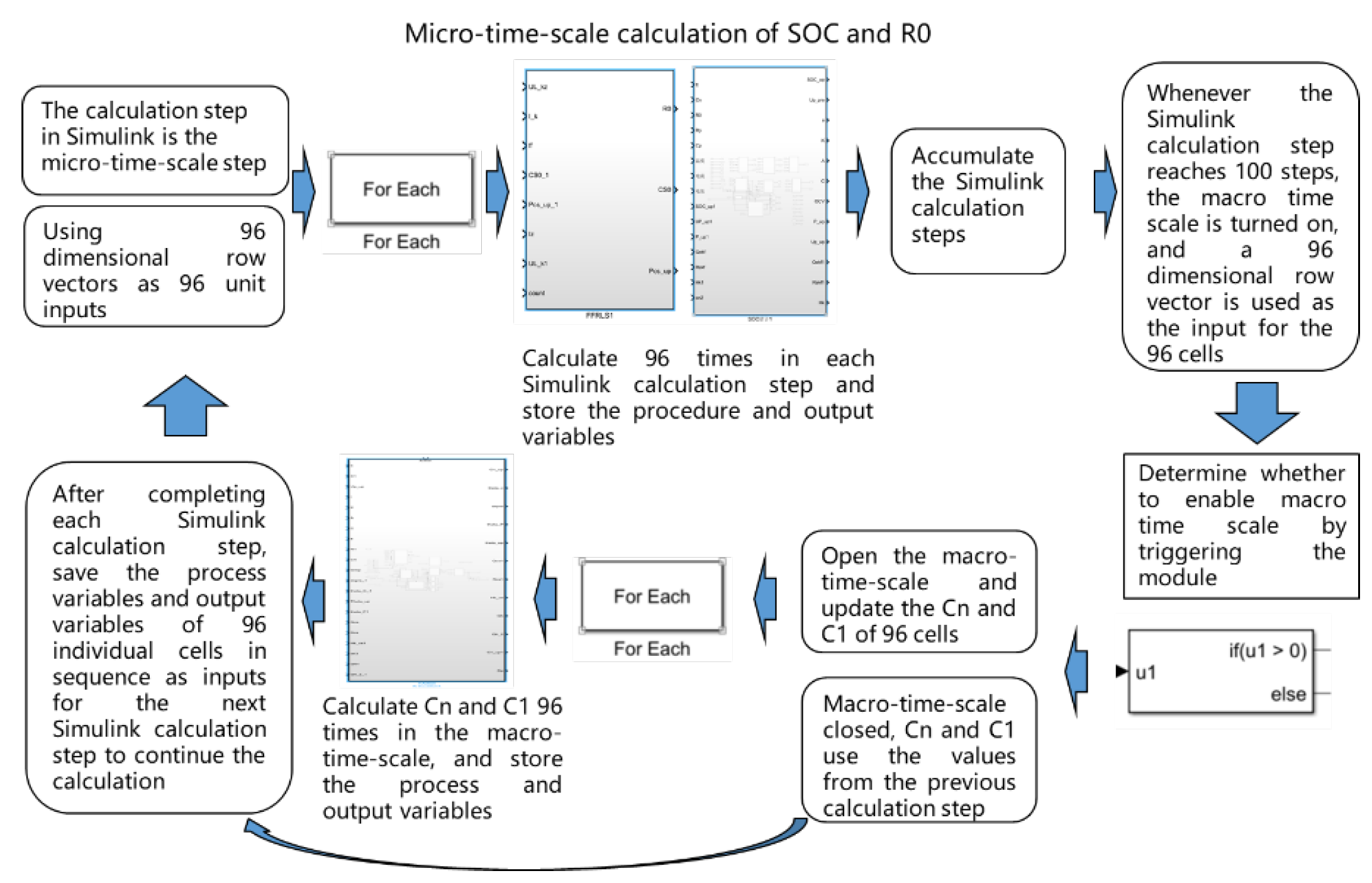

2.6. Sequential Cycle Calculation of 96 Series Connected Cells of Simulink Implementation

3. HIL Experimental Testing and Result Analysis

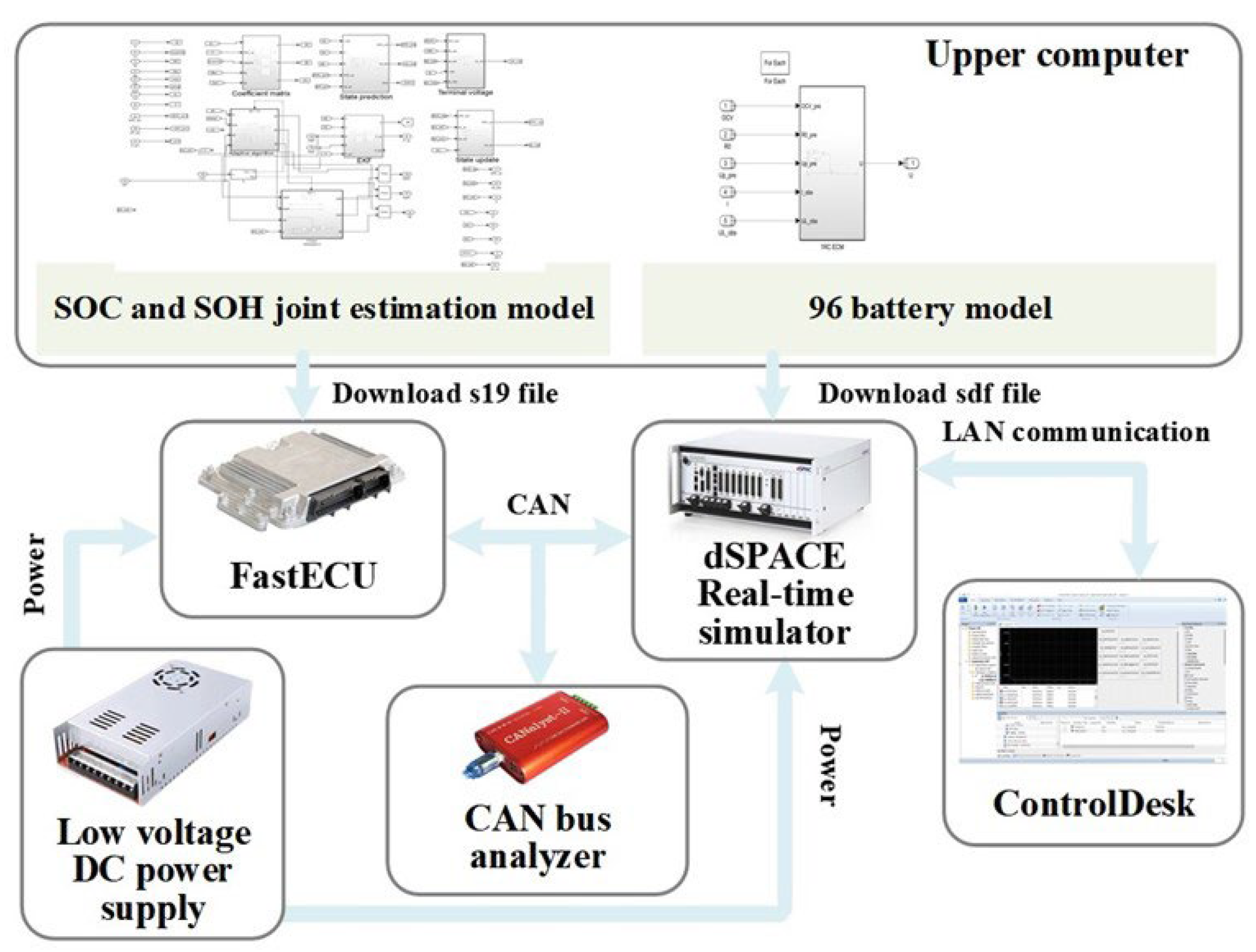

3.1. Introduction to Hardware Implementation Scheme of HIL

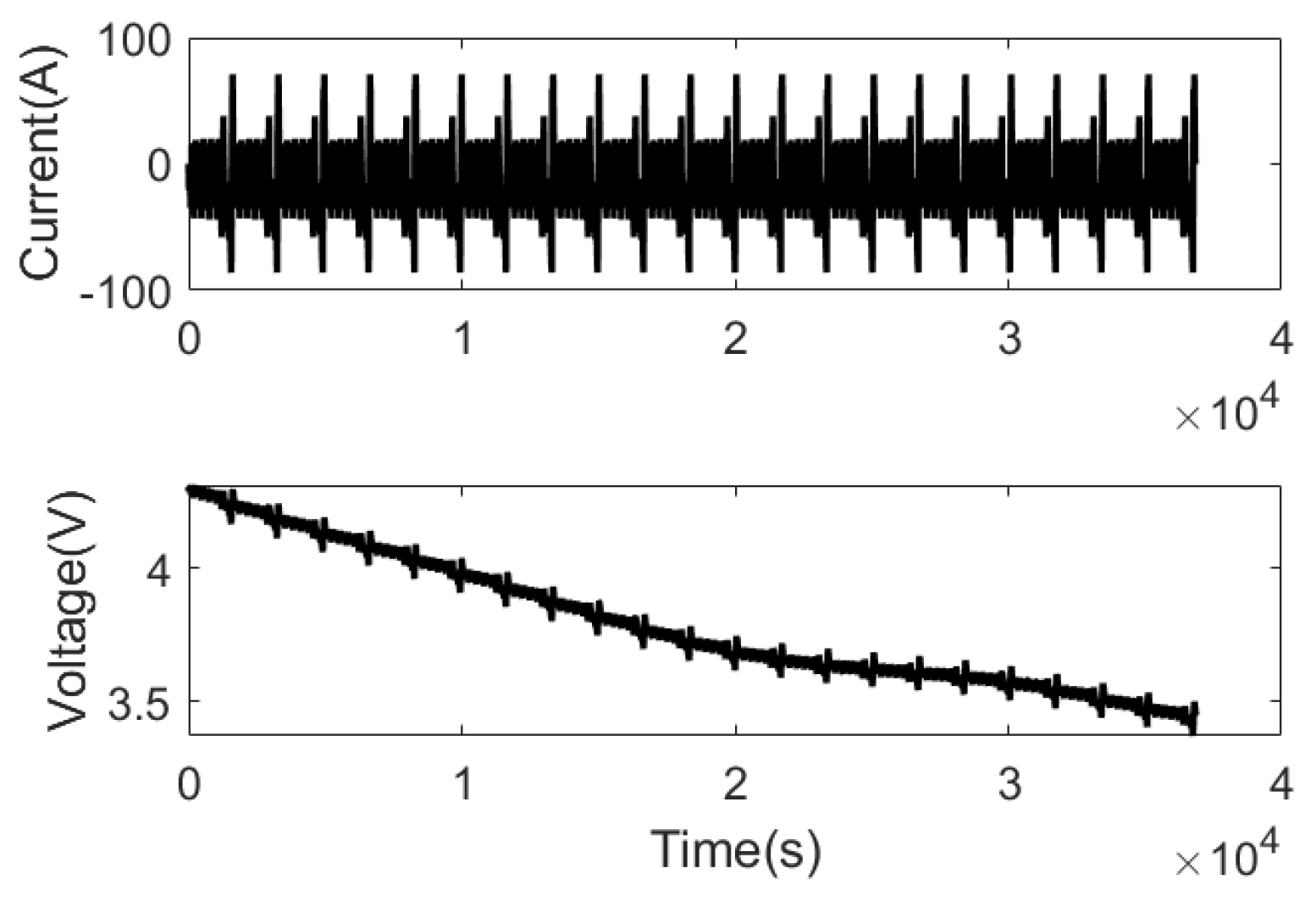

3.2. Multi-Scenarios Testing Scheme

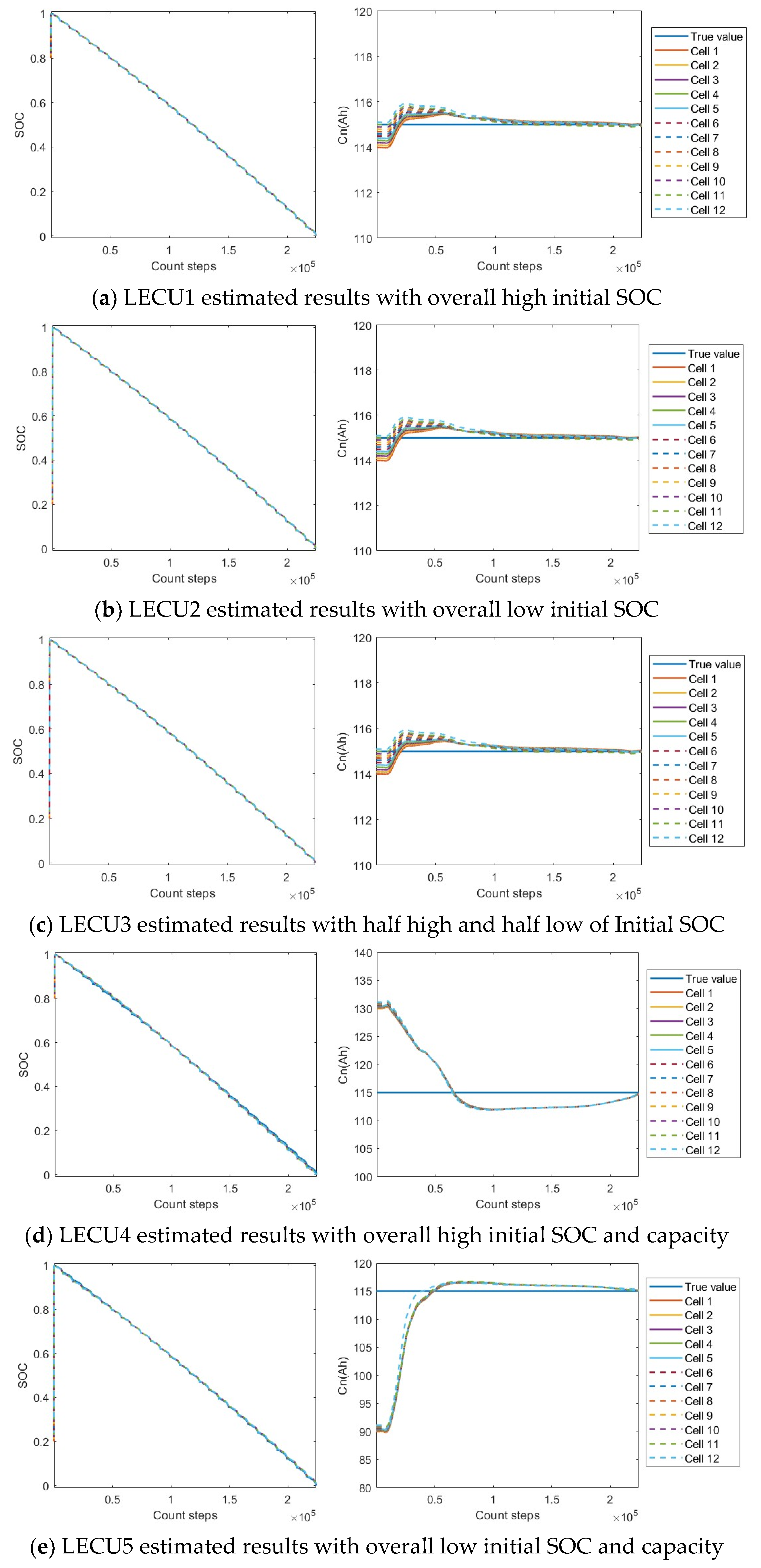

3.3. Real Time Estimation Result Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khan, F.N.U.; Rasul, M.G.; Sayem, A.S.M.; Mandal, N.K. Design and optimization of lithium-ion battery as an efficient energy storage device for electric vehicles: A comprehensive review. J. Energy Storage 2023, 71, 108033. [Google Scholar] [CrossRef]

- Chen, Y.; Li, R.; Sun, Z.; Zhao, L.; Guo, X. SOC estimation of retired lithium-ion batteries for electric vehicle with improved particle filter by H-infinity filter. Energy Rep. 2023, 9, 1937–1947. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Zhang, L. Co-estimation of capacity and state-of-charge for lithium-ion batteries in electric vehicles. Energy 2019, 174, 33–44. [Google Scholar] [CrossRef]

- Shen, P.; Ouyang, M.; Lu, L.; Li, J.; Feng, X. The Co-Estimation of State of Charge, State of Health, and State of Function for Lithium-ion Batteries in Electric Vehicles. IEEE Trans. Veh. Technol. 2017, 67, 92–103. [Google Scholar] [CrossRef]

- Guo, F.; Hu, G.; Xiang, S.; Zhou, P.; Hong, R.; Xiong, N. A multi-scale parameter adaptive method for state of charge and parameter estimation of lithium-ion batteries using dual Kalman filters. Energy 2019, 178, 79–88. [Google Scholar] [CrossRef]

- Shuzhi, Z.; Xu, G.; Xiongwen, Z. A novel one-way transmitted co-estimation framework for capacity and state-of-charge of lithium-ion battery based on double adaptive extended Kalman filters. J. Energy Storage 2021, 33, 102093. [Google Scholar] [CrossRef]

- Arora, S.; Shen, W.; Kapoor, A. Critical analysis of open circuit voltage and its effect on estimation of irreversible heat for Li-ion pouch cells. J. Power Sources 2017, 350, 117–126. [Google Scholar] [CrossRef]

- Yun, X.; Zhang, X.; Wang, C.; Fan, X. Online parameters identification and state of charge estimation for lithium-ion batteries based on improved central difference particle filter. J. Energy Storage 2023, 70, 107987. [Google Scholar] [CrossRef]

- Zheng, Y.; Cui, Y.; Han, X.; Dai, H.; Ouyang, M. Lithium-ion battery capacity estimation based on open circuit voltage identification using the iteratively reweighted least squares at different aging levels. J. Energy Storage 2021, 44, 103487. [Google Scholar] [CrossRef]

- Dai, H.; Xu, T.; Zhu, L.; Wei, X.; Sun, Z. Adaptive model parameter identification for large capacity Li-ion batteries on separated time scales. Appl. Energy 2016, 184, 119–131. [Google Scholar] [CrossRef]

- Plett, G.L. Efficient battery pack state estimation using Bar-delta filtering. In Proceedings of the EVS24 International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Stavanger, Norway, 13–16 May 2009. [Google Scholar]

- Dai, H.; Wei, X.; Sun, Z.; Wang, J.; Gu, W. Online cell SOC estimation of Li-ion battery packs using a dual time-scale Kalman filtering for EV applications. Appl. Energy 2012, 95, 227–237. [Google Scholar] [CrossRef]

- Jiang, B.; Dai, H.; Wei, X. A Cell-to-Pack State Estimation Extension Method Based on a Multilayer Difference Model for Series-Connected Battery Packs. IEEE Trans. Transp. Electrif. 2021, 8, 2037–2049. [Google Scholar] [CrossRef]

- Pai, H.Y.; Liu, Y.H.; Ye, S.P. Online estimation of lithium-ion battery equivalent circuit model parameters and state of charge using time-domain assisted decoupled recursive least squares technique. J. Energy Storage 2023, 62, 106901. [Google Scholar] [CrossRef]

- Tran, M.-K.; Mathew, M.; Janhunen, S.; Panchal, S.; Raahemifar, K.; Fraser, R.; Fowler, M. A comprehensive equivalent circuit model for lithium-ion batteries, incorporating the effects of state of health, state of charge, and temperature on model parameters. J. Energy Storage 2021, 43, 103252. [Google Scholar] [CrossRef]

- Multithreaded Simulation Using For Each Subsystem. Available online: https://ww2.mathworks.cn/help/simulink/ug/multithreaded-simulation-using-for-each-subsystem.html (accessed on 9 April 2024).

- Haupt, H.; Plöger, M.; Bracker, J. Hardware-in-the-Loop Test of Battery Management Systems. IFAC Proc. Vol. 2013, 46, 658–664. [Google Scholar] [CrossRef]

- Dai, H.; Zhang, X.; Wei, X.; Sun, Z.; Wang, J.; Hu, F. Cell-BMS validation with a hardware-in-the-loop simulation of lithium-ion battery cells for electric vehicles. Int. J. Electr. Power Energy Syst. 2013, 52, 174–184. [Google Scholar] [CrossRef]

| Initial Deviations/Corresponding LECU and Subfigures of Figure 13 | Verification Purposes | ||

|---|---|---|---|

| Overall high initial SOC/LECU1-Figure 13a | Overall low initial SOC/LECU2-Figure 13b | Initial SOC half high and half low /LECU3-Figure 13c | Deviation cell and amplitude do not affect the accuracy of SOC estimation |

| Overall high initial SOC and high initial capacity/LECU4-Figure 13d | Overall low initial SOC and low initial capacity/LECU5-Figure 13e | Initial SOC and capacity are both half high and half low/LECU6-Figure 13f | The combination deviation of initial SOC and capacity does not affect the accuracy of SOC estimation and capacity regression |

| High initial SOC and high model parameters/LECU7-Figure 13g | Low initial SOC and low model parameters/LECU8-Figure 13h | / | The combination deviation of initial SOC and model parameters does not affect the accuracy of SOC estimation and capacity regression |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhang, D.; Wang, F.; Huang, T.; Yu, Y.; Sun, F. A Scalable Joint Estimation Algorithm for SOC and SOH of All Individual Cells within the Battery Pack and Its HIL Implementation. World Electr. Veh. J. 2024, 15, 236. https://doi.org/10.3390/wevj15060236

Liu Y, Zhang D, Wang F, Huang T, Yu Y, Sun F. A Scalable Joint Estimation Algorithm for SOC and SOH of All Individual Cells within the Battery Pack and Its HIL Implementation. World Electric Vehicle Journal. 2024; 15(6):236. https://doi.org/10.3390/wevj15060236

Chicago/Turabian StyleLiu, Yongshan, Di Zhang, Fan Wang, Tengfei Huang, Yuanbin Yu, and Fangjie Sun. 2024. "A Scalable Joint Estimation Algorithm for SOC and SOH of All Individual Cells within the Battery Pack and Its HIL Implementation" World Electric Vehicle Journal 15, no. 6: 236. https://doi.org/10.3390/wevj15060236

APA StyleLiu, Y., Zhang, D., Wang, F., Huang, T., Yu, Y., & Sun, F. (2024). A Scalable Joint Estimation Algorithm for SOC and SOH of All Individual Cells within the Battery Pack and Its HIL Implementation. World Electric Vehicle Journal, 15(6), 236. https://doi.org/10.3390/wevj15060236