A Comprehensive Analysis of Supercapacitors and Their Equivalent Circuits—A Review

Abstract

1. Introduction

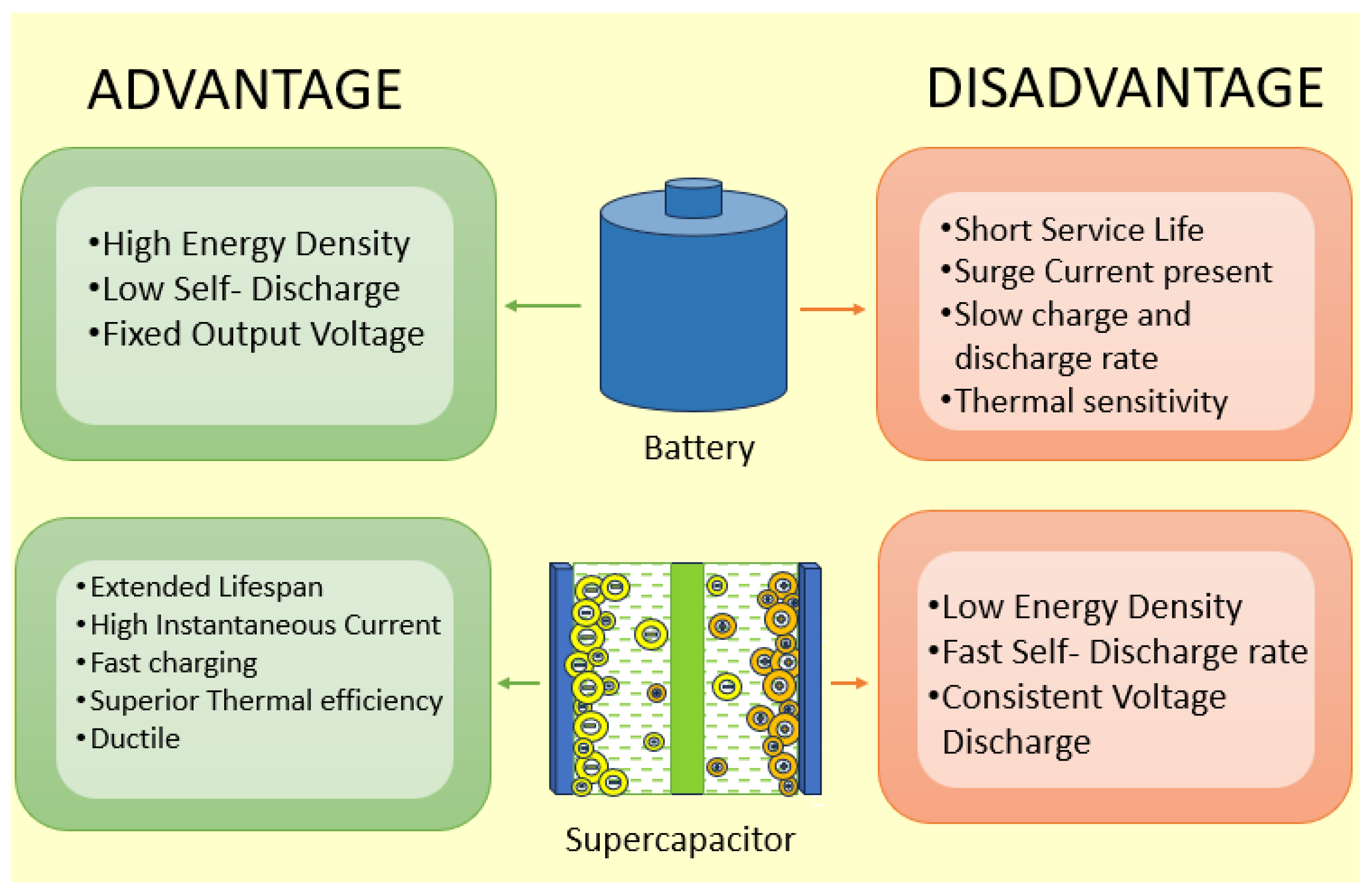

2. Background of Supercapacitors

2.1. Definition

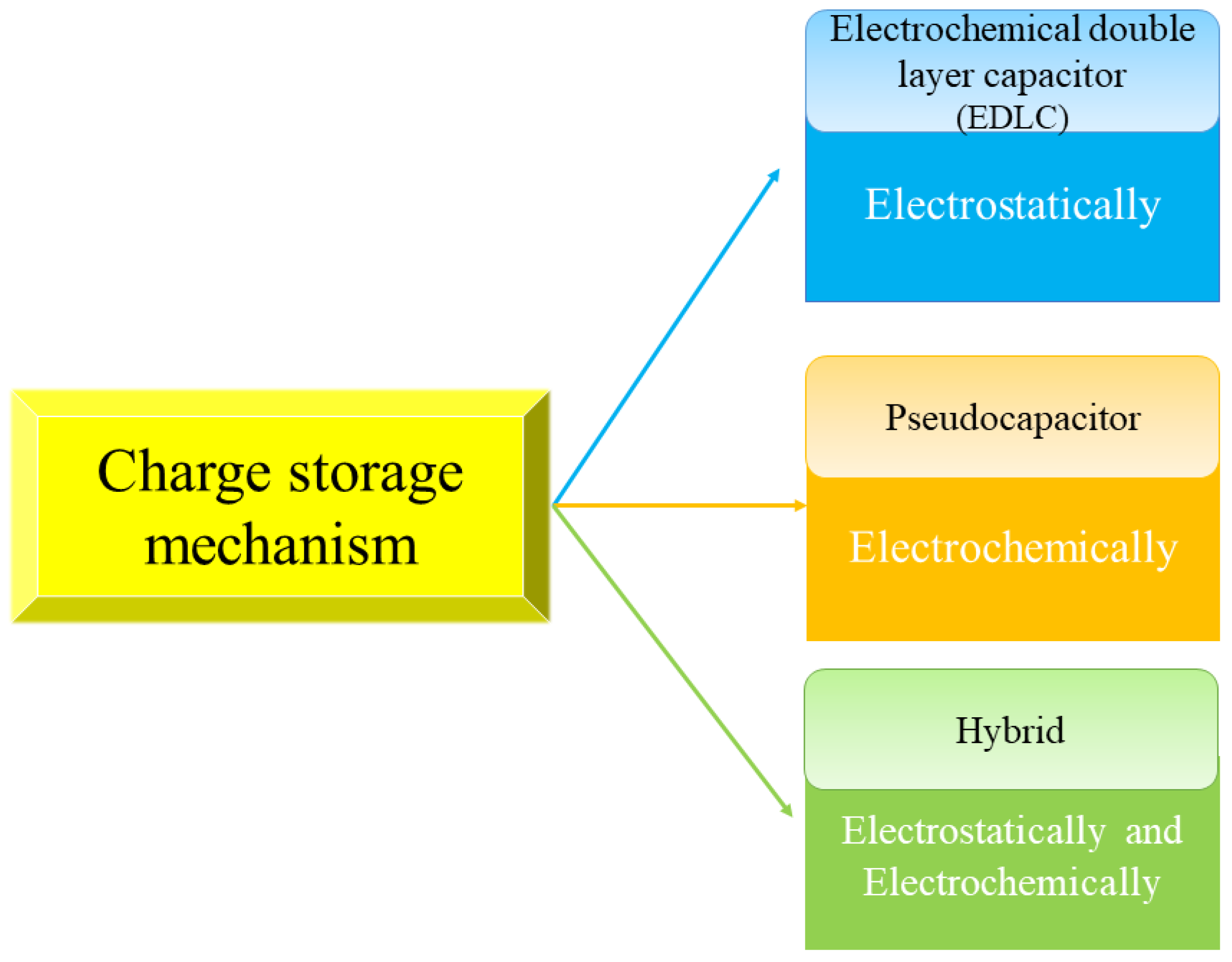

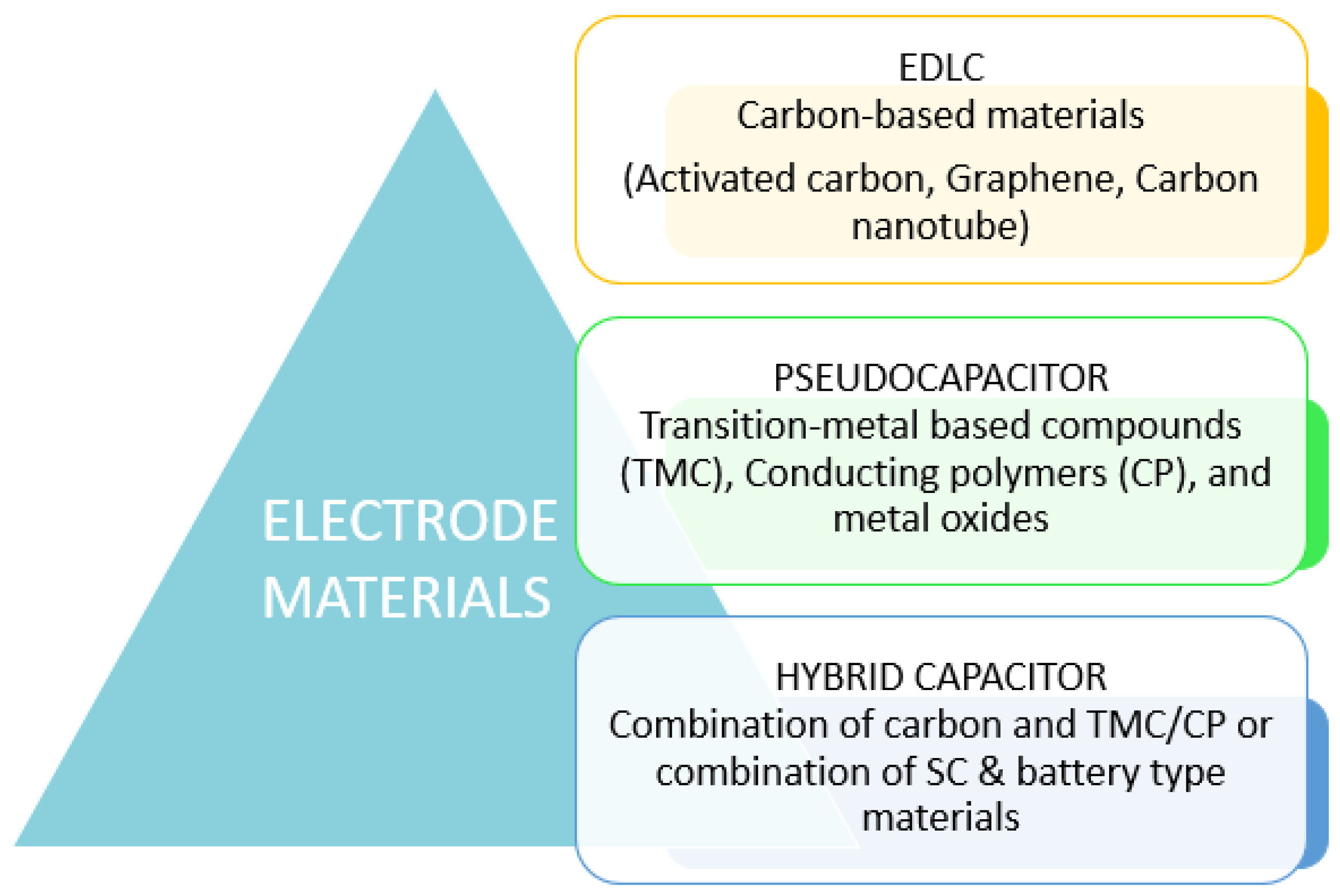

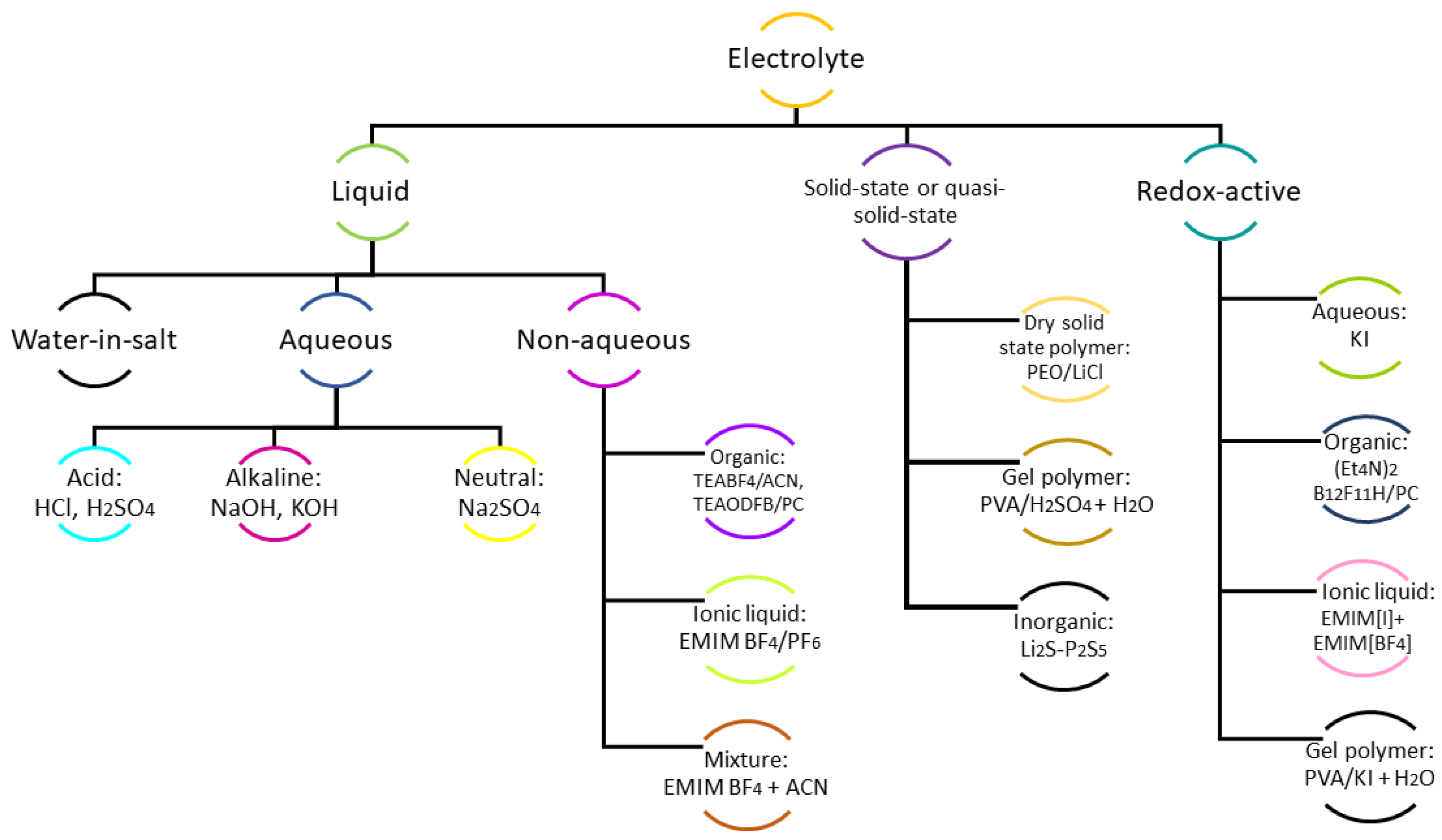

2.2. Types of Supercapacitors

2.2.1. Electrochemical Double−Layer Capacitors

2.2.2. Pseudocapacitors

2.2.3. Hybrid

2.3. Differences between Supercapacitors and Capacitors

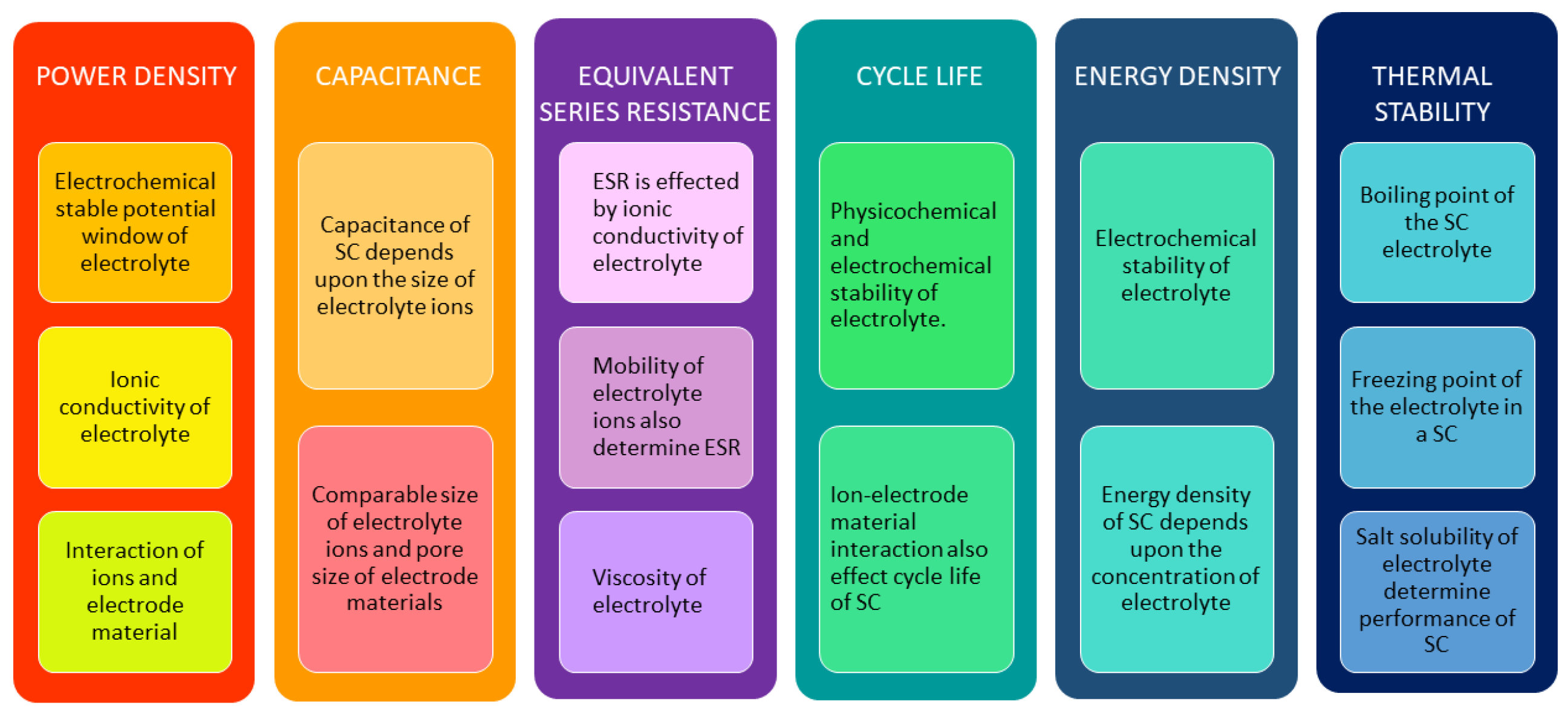

3. Equivalent Circuits

- The ability to produce high power and support high load currents due to their low resistance.

- Their charging system is easy to use, quick, and resistant to overcharging.

- SCs have superior high− and low−temperature charge and discharge performance compared to batteries.

- They offer low impedance and are very dependable.

- An equivalent RC transmission line behavior, which characterizes the dynamic response of SCs, is particularly evident in the frequency range of 0.1 Hz to 10 Hz. This behavior is a result of the porous nature of the capacitive interface.

- A self−discharge that can be represented by a high−value resistor in parallel, known as a leakage resistor.

- A phenomenon of charge redistribution that happens at low frequencies or during charge and discharge cycles longer than 1 min. It is described through two RC branches with long constant times, which are longer compared to the constant time of the RC transmission line.

- A resonance frequency (below 200 Hz) points to the transition from capacitive to inductive impedance characteristics and is identified by the impedance real part’s minimum. Beyond this resonance frequency; there is an observed increase in the minimum value of the real part of the impedance with frequency, showcasing inductive behavior.

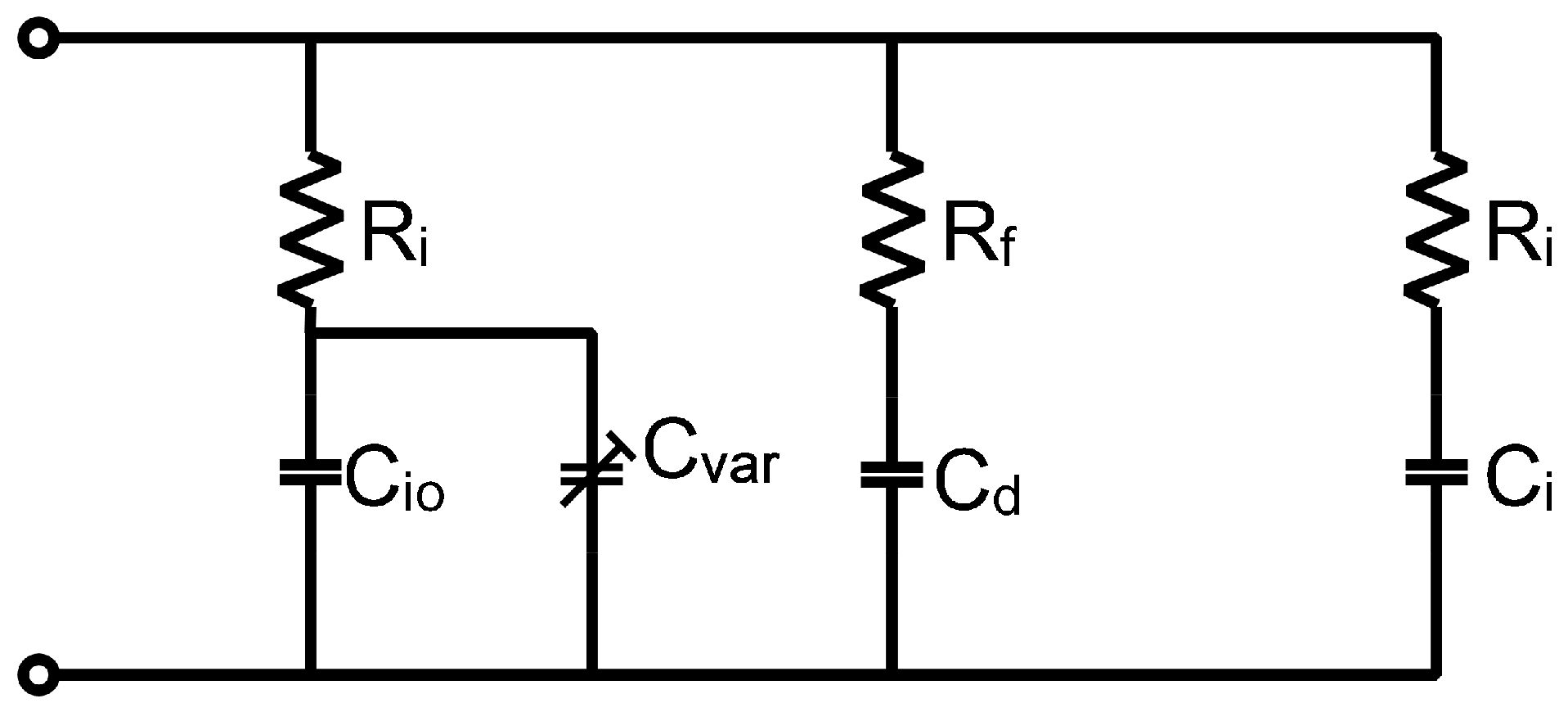

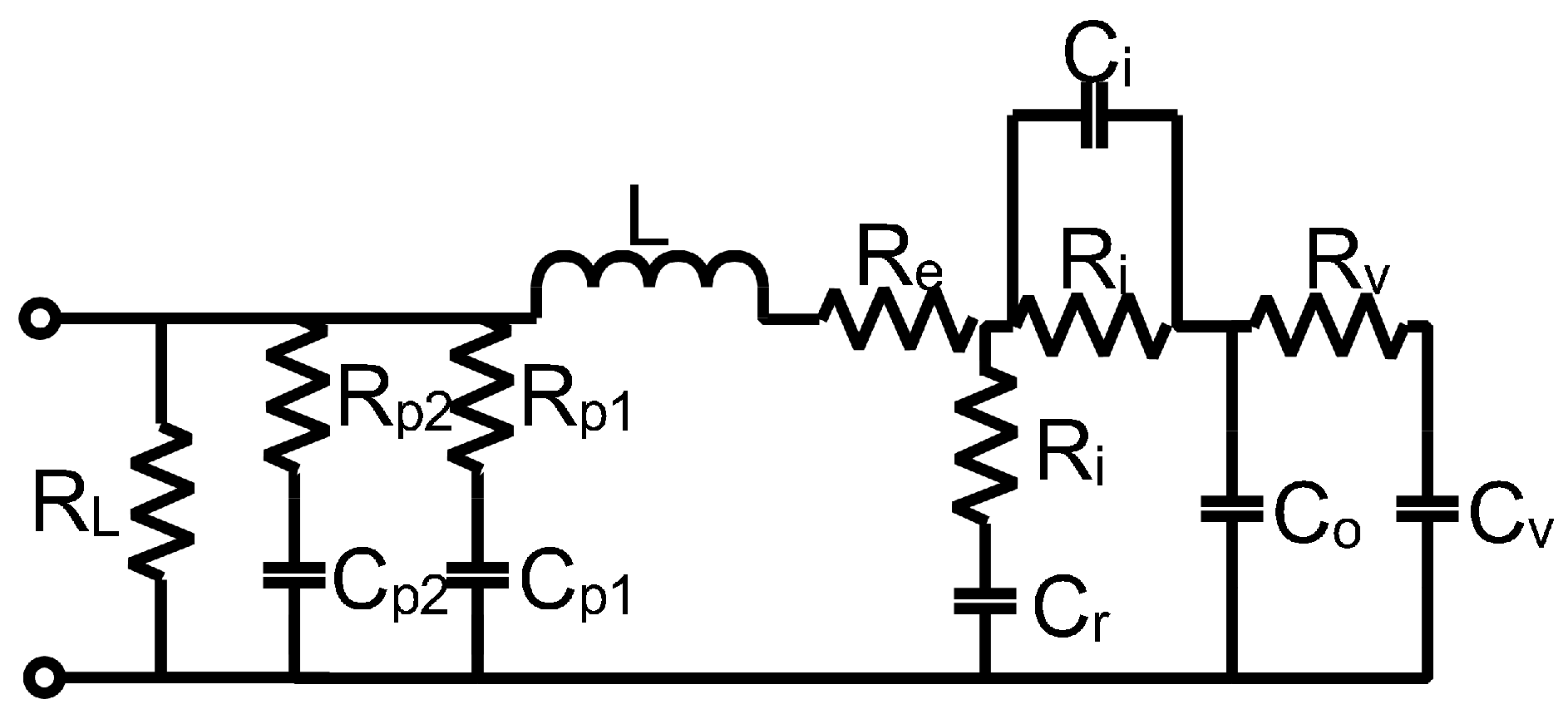

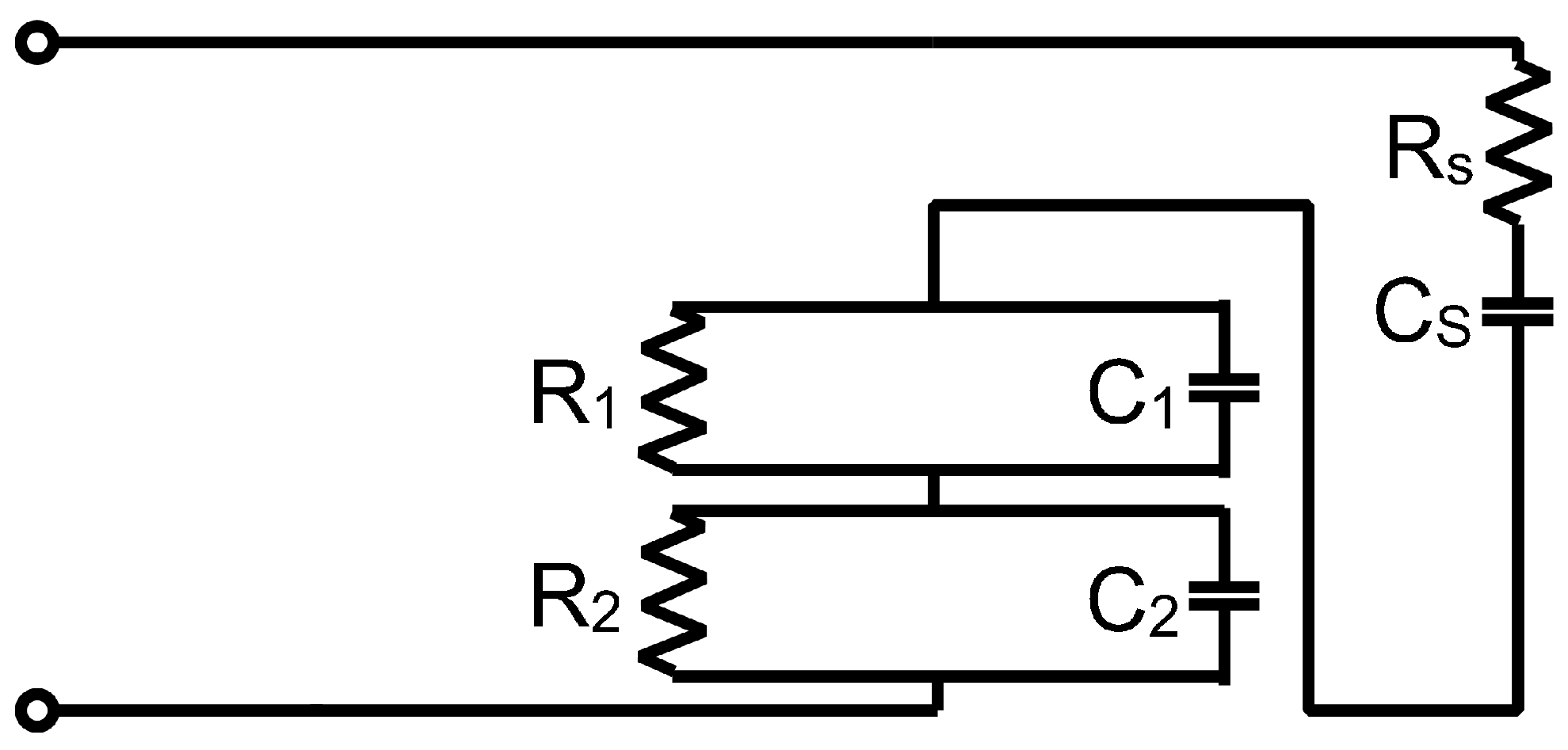

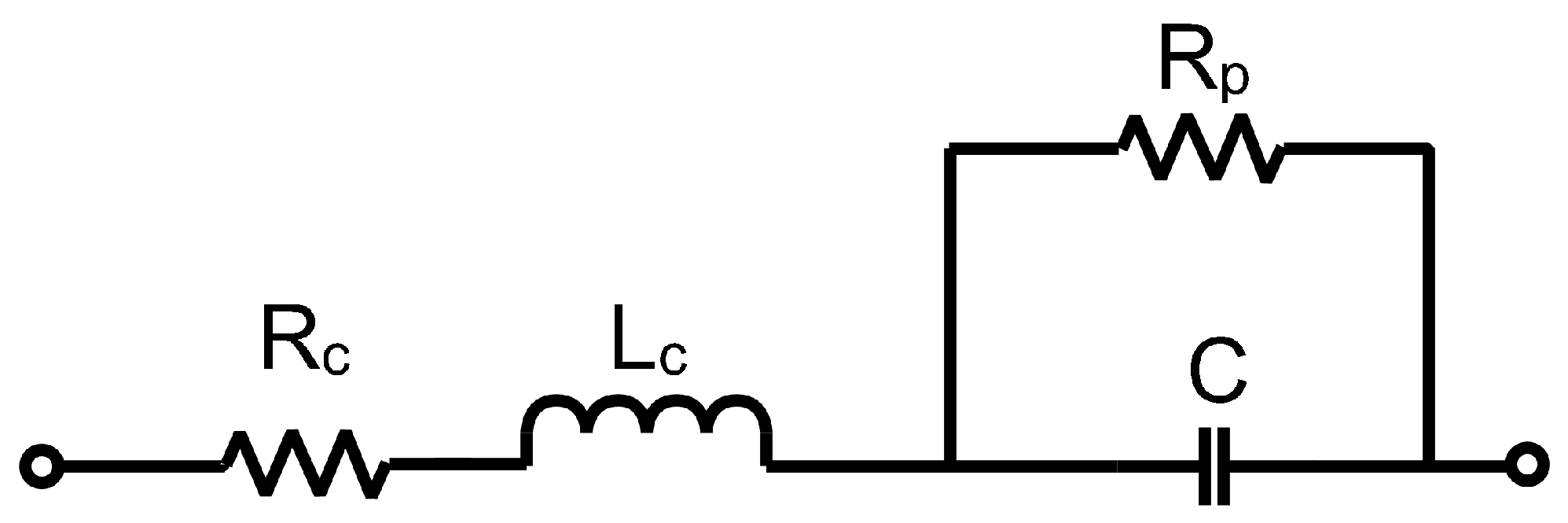

3.1. Circuit 1

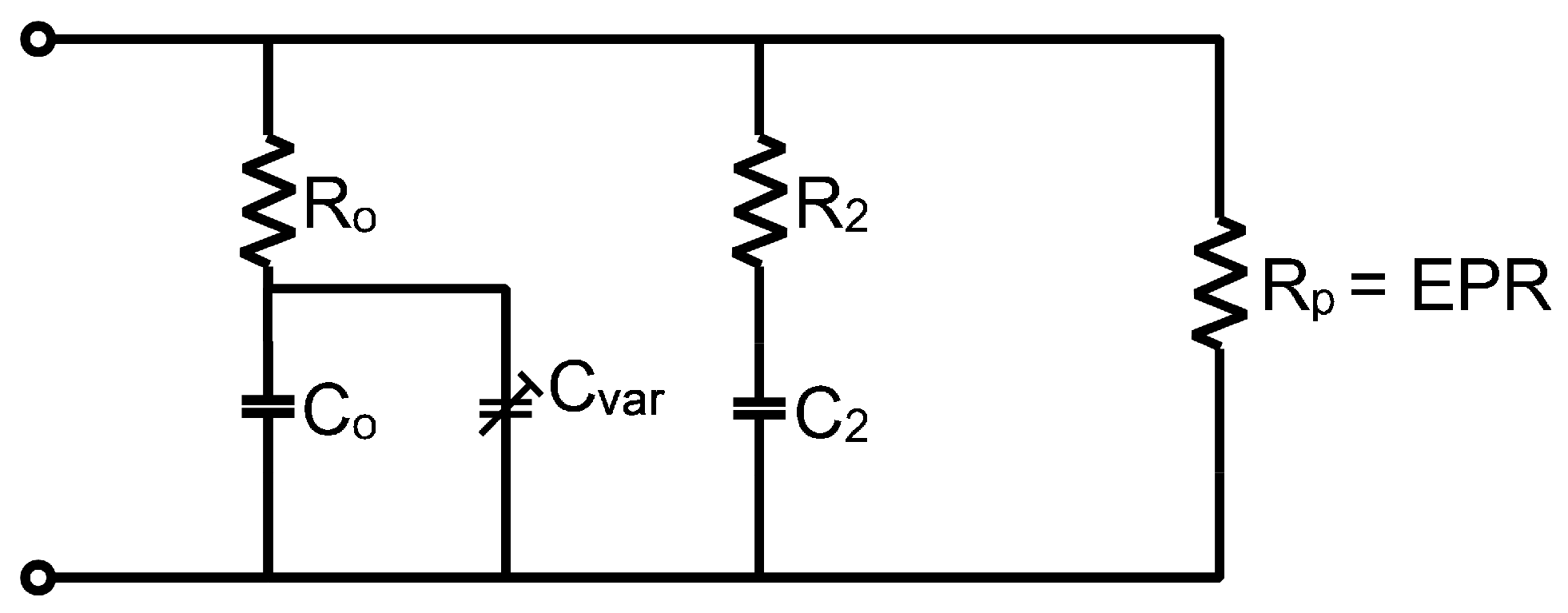

3.2. Circuit 2

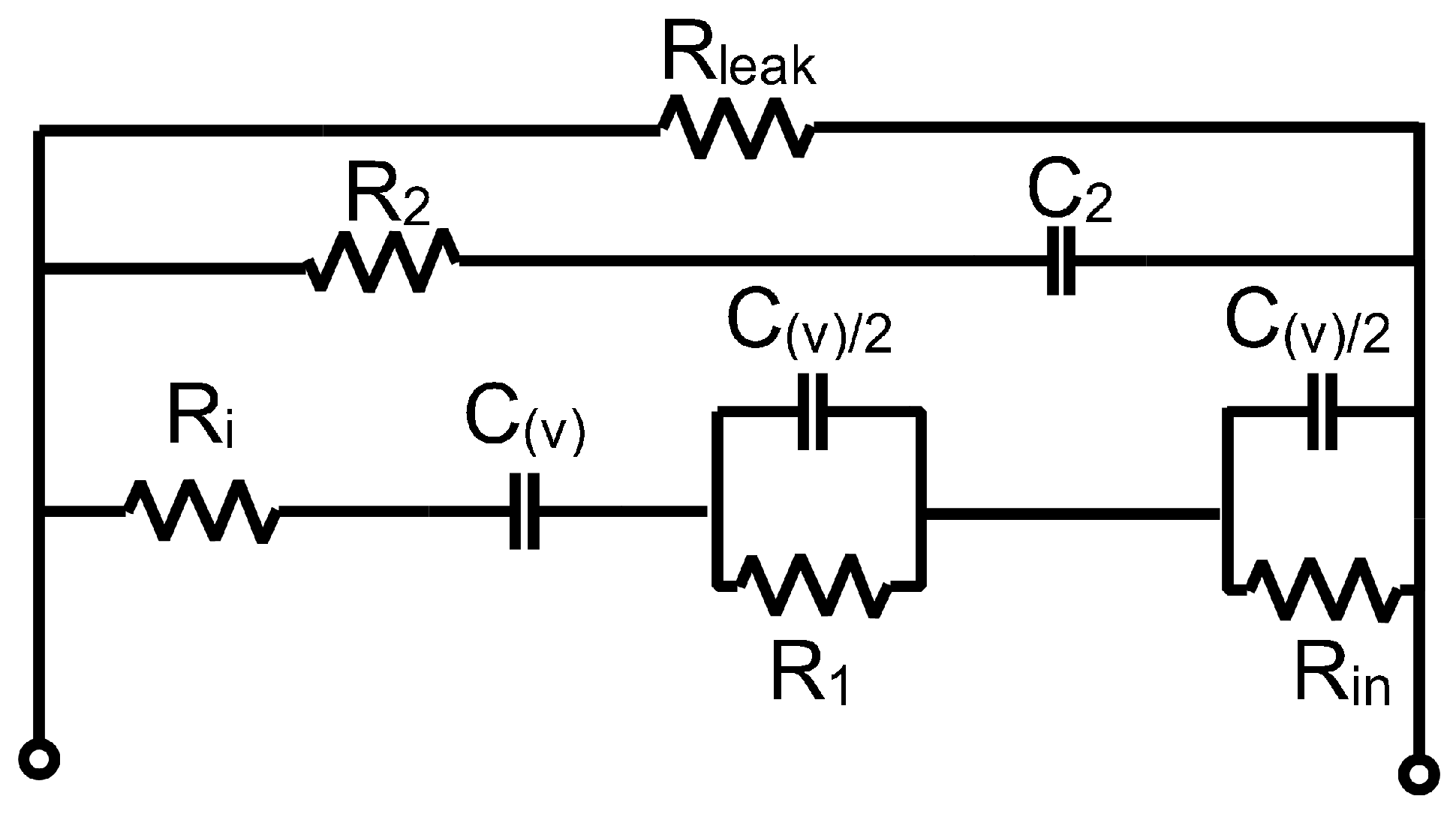

3.3. Circuit 3

3.4. Circuit 4

3.5. Circuit 5

3.6. Circuit 6

3.7. Circuit 7

3.8. Circuit 8

3.9. Circuit 9

3.10. Circuit 10

3.11. Circuit 11

3.12. Potential Uses and Benefits of EEC

- Circuit 4 is specifically tailored to assess the energy efficiency of SCs in dynamic environments like mild−hybrid vehicles [53];

- Circuit 6 is similar to the NessCap 10 F/2.7 V, Maxwell 10 F/2.5 V, and CapXX 2.4 F/2.75 V SCs in terms of capacitance and rated voltage [54];

- Circuit 7 can be easily used in various analog simulation software [3];

- Sensitivity analysis of SCs for thermal, frequency, and voltage parameters in automobiles [3].

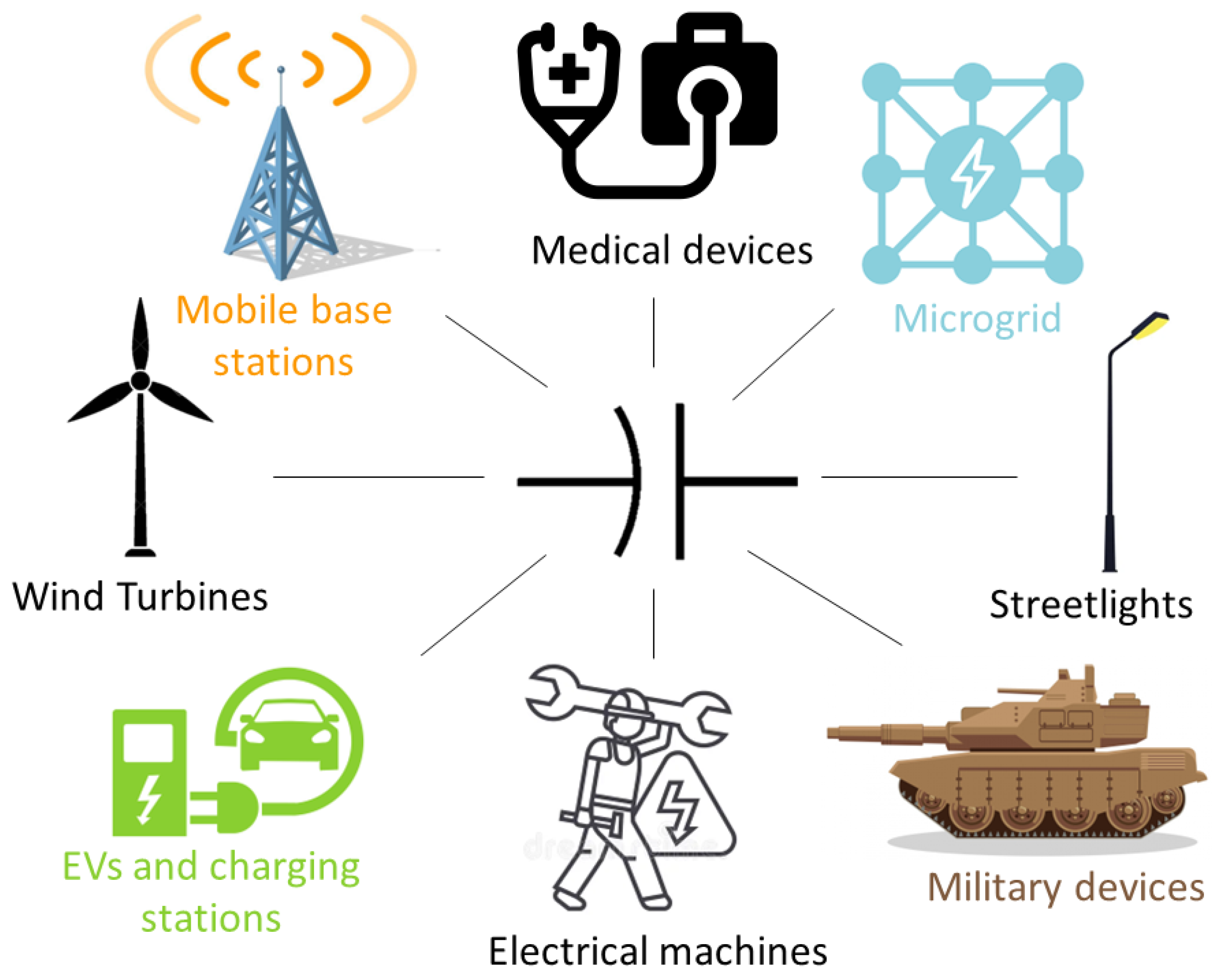

4. Supercapacitor Applications

5. Perspectives and Future Scope

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chicco, G. Sustainability challenges for future energy systems. J. Sustain. Energy 2010, 1, 6–16. [Google Scholar]

- Hammond, G.P. Engineering sustainability: Thermodynamics, energy systems, and the environment. Int. J. Energy Res. 2004, 28, 613–639. [Google Scholar] [CrossRef]

- Rafik, F.; Gualous, H.; Gallay, R.; Crausaz, A.; Berthon, A. Frequency, thermal and voltage supercapacitor characterization and modeling. J. Power Sources 2007, 165, 928–934. [Google Scholar] [CrossRef]

- Guney, M.S.; Tepe, Y. Classification and assessment of energy storage systems. Renew. Sustain. Energy Rev. 2017, 75, 1187–1197. [Google Scholar] [CrossRef]

- Hidalgo-Reyes, J.; Gómez-Aguilar, J.F.; Escobar-Jiménez, R.F.; Alvarado-Martínez, V.M.; López-López, M. Classical and fractional-order modeling of equivalent electrical circuits for supercapacitors and batteries, energy management strategies for hybrid systems and methods for the state of charge estimation: A state of the art review. Microelectron. J. 2019, 85, 109–128. [Google Scholar] [CrossRef]

- Şahin, M.E.; Blaabjerg, F.; Sangwongwanich, A. A Comprehensive Review on Supercapacitor Applications and Developments. Energies 2022, 15, 674. [Google Scholar] [CrossRef]

- Queirós, G.; Rey-Raap, N.; Pereira, C.; Pereira, M. CNT-based Materials as Electrodes for Flexible Supercapacitors. U. Porto J. Eng. 2021, 7, 151–162. [Google Scholar] [CrossRef]

- Conway, B.E. Electrochemical Supercapacitors: Scientific Fundamentals and Technological Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Frackowiak, E.; Béguin, F. Supercapacitors: Materials, Systems and Applications; Pozn. Wiley-VCH Verlag GmbH Co.: Weinheim, Germany, 2013. [Google Scholar]

- Miller, J.R.; Simon, P. Electrochemical capacitors for energy management. Science 2008, 321, 651–652. [Google Scholar] [CrossRef]

- Burke, A. Ultracapacitors: Why, how, and where is the technology. J. Power Sources 2000, 91, 37–50. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Narenthiran, B.; Sivanantham, A.; Bhatlu, L.D.; Maridurai, T. Supercapacitor: Evolution and review. Mater. Today Proc. 2021, 46, 3984–3988. [Google Scholar] [CrossRef]

- Iro, Z.S.; Subramani, C.; Dash, S. A brief review on electrode materials for supercapacitor. Int. J. Electrochem. Sci. 2016, 11, 10628–10643. [Google Scholar] [CrossRef]

- Shah, S.S.; Niaz, F.; Ehsan, M.A.; Das, H.T.; Younas, M.; Khan, A.S.; Rahman, H.U.; Nayem, S.A.; Oyama, M.; Aziz, M.A. Advanced strategies in electrode engineering and nanomaterial modifications for supercapacitor performance enhancement: A comprehensive review. J. Energy Storage 2024, 79, 110152. [Google Scholar] [CrossRef]

- Perdana, M.Y.; Johan, B.A.; Abdallah, M.; Hossain, M.E.; Aziz, M.A.; Baroud, T.N.; Drmosh, Q.A. Understanding the Behavior of Supercapacitor Materials via Electrochemical Impedance Spectroscopy: A Review. Chem. Rec. 2024, 24, e202400007. [Google Scholar] [CrossRef] [PubMed]

- Khan, H.A.; Tawalbeh, M.; Aljawrneh, B.; Abuwatfa, W.; Al-Othman, A.; Sadeghifar, H.; Olabi, A.G. A comprehensive review on supercapacitors: Their promise to flexibility, high temperature, materials, design, and challenges. Energy 2024, 295, 131043. [Google Scholar] [CrossRef]

- Reenu; Sonia; Phor, L.; Kumar, A.; Chahal, S. Electrode materials for supercapacitors: A comprehensive review of advancements and performance. J. Energy Storage 2024, 84, 110698. [Google Scholar] [CrossRef]

- Poonam; Sharma, K.; Arora, A.; Tripathi, S.K. Review of supercapacitors: Materials and devices. J. Energy Storage 2019, 21, 801–825. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Dorrell, D.G. A review of supercapacitor modeling, estimation, and applications: A control/management perspective. Renew. Sustain. Energy Rev. 2018, 81, 1868–1878. [Google Scholar] [CrossRef]

- Devillers, N.; Jemei, S.; Péra, M.C.; Bienaimé, D.; Gustin, F. Review of characterization methods for supercapacitor modelling. J. Power Sources 2014, 246, 596–608. [Google Scholar] [CrossRef]

- Catelani, M.; Ciani, L.; Corti, F.; Laschi, M.; Patriz, G.; Reatti, A.; Vangi, D. Experimental characterization of Hybrid Supercapacitor under different operating conditions using EIS Measurements. IEEE Trans. Instrum. Meas. 2023, 73, 1–10. [Google Scholar] [CrossRef]

- Yaseen, M.; Khattak, M.A.K.; Humayun, M.; Usman, M.; Shah, S.S.; Bibi, S.; Hasnain, B.S.U.; Ahmad, S.M.; Khan, A.; Shah, N.; et al. A review of supercapacitors: Materials design, modification, and applications. Energies 2021, 14, 7779. [Google Scholar] [CrossRef]

- Khalid, M. A review on the selected applications of battery-supercapacitor hybrid energy storage systems for microgrids. Energies 2019, 12, 4559. [Google Scholar] [CrossRef]

- Ates, M.; Chebil, A. Supercapacitor and battery performances of multi-component nanocomposites: Real circuit and equivalent circuit model analysis. J. Energy Storage 2022, 53, 105093. [Google Scholar] [CrossRef]

- Rouse, M. Supercapacitor. 2015. Available online: https://www.techopedia.com/definition/30407/supercapacitor (accessed on 20 October 2022).

- Sengupta, A.S.; Satpathy, S.; Mohanty, S.P.; Baral, D.; Bhattacharyya, B.K. Supercapacitors Outperform Conventional Batteries [Energy and Security]. IEEE Consum. Electron. Mag. 2018, 7, 50–53. [Google Scholar] [CrossRef]

- Capacitech Energy. Batteries vs Supercapacitors: The Answer is Both. Capacit. Energy Blog 2023. Available online: https://www.capacitechenergy.com/blog/batteries-vs-supercapacitors-the-answer-is-both (accessed on 10 June 2024).

- Namisnyk, A.; Zhu, J. A survey of electrochemical super-capacitor technology. In Proceedings of the Australian Universities Power Engineering Conference; University of Canterbury: Christchurch, New Zealand, 2003. [Google Scholar]

- Oyedotun, K. Synthesis and Characterization of Carbon-Based Nanostructured Material Electrodes for Designing Novel Hybrid Supercapacitors. Ph.D. Thesis, University of Pretoria, Hatfield, UK, 2018. [Google Scholar] [CrossRef]

- Czagany, M.; Hompoth, S.; Keshri, A.K.; Pandit, N.; Galambos, I.; Gacsi, Z.; Baumli, P. Supercapacitors: An efficient way for energy storage application. Materials 2024, 17, 702. [Google Scholar] [CrossRef] [PubMed]

- Pal, B.; Yang, S.; Ramesh, S.; Thangadurai, V.; Jose, R. Electrolyte selection for supercapacitive devices: A critical review. Nanoscale Adv. 2019, 1, 3807–3835. [Google Scholar] [CrossRef] [PubMed]

- Pan, Z.; Yang, J.; Kong, J.; Loh, X.J.; Wang, J.; Liu, Z. “Porous and Yet Dense” Electrodes for High-Volumetric-Performance Electrochemical Capacitors: Principles, Advances, and Challenges. Adv. Sci. 2021, 9, 2103953. [Google Scholar] [CrossRef] [PubMed]

- Zhong, C.; Yida, D.; Hu, W.; Qiao, J.; Zhang, L.; Zhang, J. A review of electrolyte materials and compositions for electrochemical supercapacitors. Chem. Soc. Rev. 2015, 44, 7431–7920. [Google Scholar] [CrossRef] [PubMed]

- Jalal, N.; Ibrahim, R.; Kadhim, M. A review on Supercapacitors: Types and components. J. Phys. Conf. Ser. 2021, 1973, 012015. [Google Scholar] [CrossRef]

- Minakshi, M.; Wickramaarachchi, K. Electrochemical aspects of supercapacitors in perspective: From electrochemical configurations to electrode materials processing. Prog. Solid State Chem. 2023, 69, 100390. [Google Scholar] [CrossRef]

- Watcharatharapong, T.; Minakshi Sundaram, M.; Chakraborty, S.; Li, D.; Shafiullah, G.; Aughterson, R.D.; Ahuja, R. Effect of transition metal cations on stability enhancement for molybdate-based hybrid supercapacitor. ACS Appl. Mater. Interfaces 2017, 9, 17977–17991. [Google Scholar] [CrossRef] [PubMed]

- Celzard, A.; Collas, F.; Marêché, J.; Furdin, G.; Rey, I. Porous electrodes-based double-layer supercapacitors: Pore structure versus series resistance. J. Power Sources 2002, 108, 153–162. [Google Scholar] [CrossRef]

- Sharma, P.; Bhatti, T. A review on electrochemical double-layer capacitors. Energy Convers. Manag. 2010, 51, 2901–2912. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, E.; He, W.; Deng, X.; Huang, J.; Ding, M.; Wei, X.; Liu, X.; Xu, X.J. NiCo2O4-Based Supercapacitor Nanomaterials. Nanomaterials 2017, 7, 41. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Chand, P. Supercapacitor and Electrochemical Techniques: A Brief Review. Results Chem. 2023, 5, 100885. [Google Scholar] [CrossRef]

- Prasankumar, T.; Jose, J.; Jose, S.; Balakrishnan, S.P. Pseudocapacitors. In Supercapacitors for the Next Generation; IntechOpen: London, UK, 2021. [Google Scholar]

- Everything You Need to Know about Pseudocapacitor. Available online: https://www.icrfq.net/pseudocapacitor/ (accessed on 5 February 2024).

- Hybrid Supercapacitor. Available online: https://www.sciencedirect.com/topics/materials-science/hybrid-supercapacitor (accessed on 5 February 2024).

- Muzaffar, A.; Ahamed, M.B.; Deshmukh, K.; Thirumalai, J. A review on recent advances in hybrid supercapacitors: Design, fabrication and applications. Renew. Sustain. Energy Rev. 2019, 101, 123–145. [Google Scholar] [CrossRef]

- Halper, M.S.; Ellenbogen, J.C. Supercapacitors: A Brief Overview; The MITRE Corporation: McLean, VA, USA, 2006; Volume 1. [Google Scholar]

- Saini, M.K. Difference between Capacitor and Supercapacitor. 2022. Available online: https://www.tutorialspoint.com/difference-between-capacitor-and-supercapacitor#:~:text=The%20electrodes%20of%20a%20capacitor,of%20activated%20carbon%20coated%20electrodes.&text=The%20electrical%20energy%20in%20a,electrostatically%20or%20electrochemically%20or%20hybrid (accessed on 29 October 2022).

- Lajnef, W.; Vinassa, J.M.; Briat, O.; Azzopardi, S.; Woirgard, E. Characterization methods and modelling of ultracapacitors for use as peak power sources. J. Power Sources 2007, 168, 553–560. [Google Scholar] [CrossRef]

- Zubieta, L.; Bonert, R. Characterization of double-layer capacitors for power electronics applications. IEEE Trans. Ind. Appl. 2000, 36, 199–205. [Google Scholar] [CrossRef]

- Nelms, R.; Cahela, D.; Tatarchuk, B.J. Modeling double-layer capacitor behavior using ladder circuits. IEEE Trans. Aerosp. Electron. Syst. 2003, 39, 430–438. [Google Scholar] [CrossRef]

- Logerais, P.O.; Camara, M.; Riou, O.; Djellad, A.; Omeiri, A.; Delaleux, F.; Durastanti, J. Modeling of a supercapacitor with a multibranch circuit. Int. J. Hydrogen Energy 2015, 40, 13725–13736. [Google Scholar] [CrossRef]

- Faranda, R. A new parameters identification procedure for simplified double layer capacitor two-branch model. Electr. Power Syst. Res. 2010, 80, 363–371. [Google Scholar] [CrossRef]

- Nikkhoo, M.; Farjah, E.; Ghanbari, T. A simple method for parameters identification of three branches model of supercapacitors. In Proceedings of the 2016 24th Iranian Conference on Electrical Engineering (ICEE), Shiraz, Iran, 10–12 May 2016; pp. 1586–1590. [Google Scholar]

- Buller, S.; Karden, E.; Kok, D.; De Doncker, R. Modeling the dynamic behavior of supercapacitors using impedance spectroscopy. In Proceedings of the Conference Record of the 2001 IEEE Industry Applications Conference, 36th IAS Annual Meeting (Cat. No. 01CH37248), Chicago, IL, USA, 30 September–4 October 2001; Volume 4, pp. 2500–2504. [Google Scholar]

- Sedlakova, V.; Sikula, J.; Majzner, J.; Sedlak, P.; Kuparowitz, T.; Buergler, B.; Vasina, P. Supercapacitor equivalent electrical circuit model based on charges redistribution by diffusion. J. Power Sources 2015, 286, 58–65. [Google Scholar] [CrossRef]

- Dănilă, E.; Lucache, D.D.; Livin, G. Models and modelling the supercapacitors for a defined application. Ann. Univ. Craiova-Electr. Eng. Ser. 2011, 35, 200–205. [Google Scholar]

- Wu, C.; Hung, Y.; Hong, C. On-line supercapacitor dynamic models for energy conversion and management. Energy Convers. Manag. 2012, 53, 337–345. [Google Scholar] [CrossRef]

- Njema, G.G.; Ouma, R.B.O.; Kibet, J.K. A review on the recent advances in battery development and energy storage technologies. J. Renew. Energy 2024, 2024, 2329261. [Google Scholar] [CrossRef]

- Ridden, P. Helium Bluetooth speakers powered by supercapacitors. New Atlas, 27 November 2013. [Google Scholar]

- Available online: https://hardware.slashdot.org/story/08/12/10/1821208/ultracapacitor-led-flashlight-charges-in-90-seconds (accessed on 5 February 2024).

- Lahyani, A.; Venet, P.; Guermazi, A.; Troudi, A. Battery/supercapacitors combination in uninterruptible power supply (UPS). IEEE Trans. Power Electron. 2012, 28, 1509–1522. [Google Scholar] [CrossRef]

- Schneuwly, A.; Gallay, R. Properties and applications of supercapacitors from the state-of-the-art to future trends. In Proceedings of the PCIM, Nuremberg, Germany, 7–8 July 2000; Volume 2000. [Google Scholar]

- Stepanov, A.; Galkin, I. Development of supercapacitor based uninterruptible power supply. In Proceedings of the 4th International Symposium “Topical Problems in the Field of Electrical and Power Engineering”, Estonia, Kuressaare, 15–20 January 2007. [Google Scholar]

- Murat, Ş.; Ercan, S.Ü.; Dalkın, A.; Ayvaz, E. The use of supercapacitor in smart metering gateway. Int. J. Energy Appl. Technol. 2021, 8, 53–59. [Google Scholar]

- Mangaraj, M.; Panda, A.K.; Penthia, T. Supercapacitor supported DSTATCOM for harmonic reduction and power factor correction. In Proceedings of the 2016 IEEE Students’ Conference on Electrical, Electronics and Computer Science (SCEECS), Bhopal, India, 5–6 March 2016; pp. 1–6. [Google Scholar]

- Farhadi, M.; Mohammed, O.A. Real-time operation and harmonic analysis of isolated and non-isolated hybrid DC microgrid. IEEE Trans. Ind. Appl. 2014, 50, 2900–2909. [Google Scholar] [CrossRef]

- Farhadi, M.; Mohammed, O. Adaptive energy management in redundant hybrid DC microgrid for pulse load mitigation. IEEE Trans. Smart Grid 2014, 6, 54–62. [Google Scholar] [CrossRef]

- Farhadi, M.; Mohammed, O.A. Performance enhancement of actively controlled hybrid DC microgrid incorporating pulsed load. IEEE Trans. Ind. Appl. 2015, 51, 3570–3578. [Google Scholar] [CrossRef]

- Naoi, K.; Naoi, W.; Aoyagi, S.; Miyamoto, J.i.; Kamino, T. New generation “nanohybrid supercapacitor”. Accounts Chem. Res. 2013, 46, 1075–1083. [Google Scholar] [CrossRef] [PubMed]

- Raza, W.; Ali, F.; Raza, N.; Luo, Y.; Kim, K.H.; Yang, J.; Kumar, S.; Mehmood, A.; Kwon, E.E. Recent advancements in supercapacitor technology. Nano Energy 2018, 52, 441–473. [Google Scholar] [CrossRef]

- Jiale Sun, B.L.; LRaza, H. A Review on the Conventional Capacitors, Supercapacitors, and Emerging Hybrid Ion Capacitors: Past, Present, and Future. Adv. Energy Sustain. Res. 2022, 3, 2100191. [Google Scholar]

| Specification | Unit | Supercapacitor | Capacitor |

|---|---|---|---|

| Capacitance | F | 2600 | |

| Rated Voltage | V | 2.5 | 200 |

| Maximum Energy Storage | J | 8125 | 11.2 |

| Basis of Difference | Supercapacitor | Capacitor |

|---|---|---|

| Definition | A SC is a type of capacitor that can hold charge and has a low voltage rating and high capacitance. | Electrical energy can be stored as electrostatic charge in a capacitor, a passive circuit component. |

| Constructional features | To create a SC, two conducting plates are separated by an electrolytic solution as an alternative to a dielectric. | A dielectric material is used to separate two conducting plates to create a capacitor. |

| Electrodes | Electrodes with activated carbon coating are present in a SC. | A metallic conductor makes up a capacitor’s electrodes. |

| Energy storage mechanism | Electrochemically, electrostatically, or in a hybrid fashion, a SC stores electrical energy. | A capacitor can only store electrical energy electrostatically. |

| Dielectric materials | Activated carbon is used as a SC’s interlayer between its electrodes. A double electric field is generated when an electric field is applied to the material; this double electric field serves as the SC’s dielectric. | Ceramics, polymers, mica, paper, aluminum oxides, and other materials are frequently used as capacitor dielectrics. |

| Types | Electrostatic double−layer capacitors, electrochemical pseudocapacitors, and hybrid SCs are three different types of SCs. | The most popular types of capacitors include electrolytic capacitors, film capacitors, paper capacitors, ceramic capacitors, etc., depending on the dielectric material chosen. |

| Capacitance value (F/g) | Typically 10–100 F/g, depending on the material and construction. | Much lower, typically in the range of nF to μF per gram. |

| Voltage rating | The voltage ratings of SCs are considerably lower. | An effective capacitor has a high voltage rating. |

| Energy density (in Wh/kg) | SCs have a very high energy density in comparison. Typically falls between 1 Wh/kg and 10 Wh/kg [3]. | An electrical capacitor has a low energy density. Typically ranges from 0.01 to 0.05 Wh/kg i.e., <0.1 Wh/kg [3]. |

| Power density (in Wh/kg) | SCs have power density of 10,000 Wh/kg [3]. | Capacitors have power density of more than 1,000,000 Wh/kg, which is much higher than SCs [3]. |

| Time for charging and discharging | Depending on the SC, charging and discharging can take seconds or milliseconds. Roughly around 1–30 s [3]. | A capacitor can charge or discharge between picoseconds and milliseconds approximately between and s [3]. |

| Charging and discharging efficiency | From 0.85 to 0.98 [3]. | More than 0.95 [3]. |

| Temperature of operating condition | SCs typically operate between −40 °C and +85 °C. | The operating temperature range for a capacitor is roughly −20 °C to +100 °C. |

| Lifetime (in cycle number) | SCs have a life of cycles [3]. | Capacitors also have an average life of cycles [3]. |

| Form factor | The form factor of SCs is minimal. | Capacitor form factors range from low to high. |

| Cost | SCs are expensive. | Capacitors cost less. |

| Applications | SCs are frequently used in digital camera LED flashlights, UPS, RAM, CMOS, laptops, and other portable devices to stabilize the power supply. | Capacitors are used in power factor correction, filter circuits, signal coupling and decoupling, motor starter circuits, oscillators, etc. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehra, P.; Saxena, S.; Bhullar, S. A Comprehensive Analysis of Supercapacitors and Their Equivalent Circuits—A Review. World Electr. Veh. J. 2024, 15, 332. https://doi.org/10.3390/wevj15080332

Mehra P, Saxena S, Bhullar S. A Comprehensive Analysis of Supercapacitors and Their Equivalent Circuits—A Review. World Electric Vehicle Journal. 2024; 15(8):332. https://doi.org/10.3390/wevj15080332

Chicago/Turabian StyleMehra, Pranathi, Sahaj Saxena, and Suman Bhullar. 2024. "A Comprehensive Analysis of Supercapacitors and Their Equivalent Circuits—A Review" World Electric Vehicle Journal 15, no. 8: 332. https://doi.org/10.3390/wevj15080332

APA StyleMehra, P., Saxena, S., & Bhullar, S. (2024). A Comprehensive Analysis of Supercapacitors and Their Equivalent Circuits—A Review. World Electric Vehicle Journal, 15(8), 332. https://doi.org/10.3390/wevj15080332