Simulating Noise, Vibration, and Harshness Advances in Electric Vehicle Powertrains: Strategies and Challenges

Abstract

1. Introduction

- ⚬

- Section 2: Key Contributors to NVH in EV Powertrains: This section explores the primary sources of NVH in EV powertrains, including the electric motor, power inverter, and transmission. It examines how these components contribute to the overall NVH profile and the challenges they pose when integrated into a complete system.

- ⚬

- Section 3: Noise Reduction Methods: Various methods for mitigating NVH in EV powertrains are discussed here. The section covers strategies for reducing mechanical noise, electromagnetic noise from electric motors and inverters, and aerodynamic and fluid flow noise, emphasizing advanced design techniques and material selection.

- ⚬

- Section 4: Development of Simulation Models for NVH Analysis: This section focuses on the development of computational models for NVH analysis. It details the methodologies and tools used, such as multi-body dynamics (MBD), the finite element method (FEM), and the boundary element method (BEM), and the integration of these models to analyze the dynamic behavior and acoustic characteristics of the powertrain.

- ⚬

- Section 5: Acoustic Analysis Setup and Results: The setup and results of acoustic simulations are presented in this section. It includes details on microphone placement, modeling of acoustic sources, and the interpretation of simulation results, providing insights into the acoustic behavior of the powertrain and guiding noise control solutions.

- ⚬

- Section 6: Conclusions: The manuscript concludes with a summary of the findings and their implications for NVH management in EV powertrains. It underscores the necessity of a holistic system-level approach and the application of advanced simulation techniques to effectively address NVH challenges in electric vehicles.

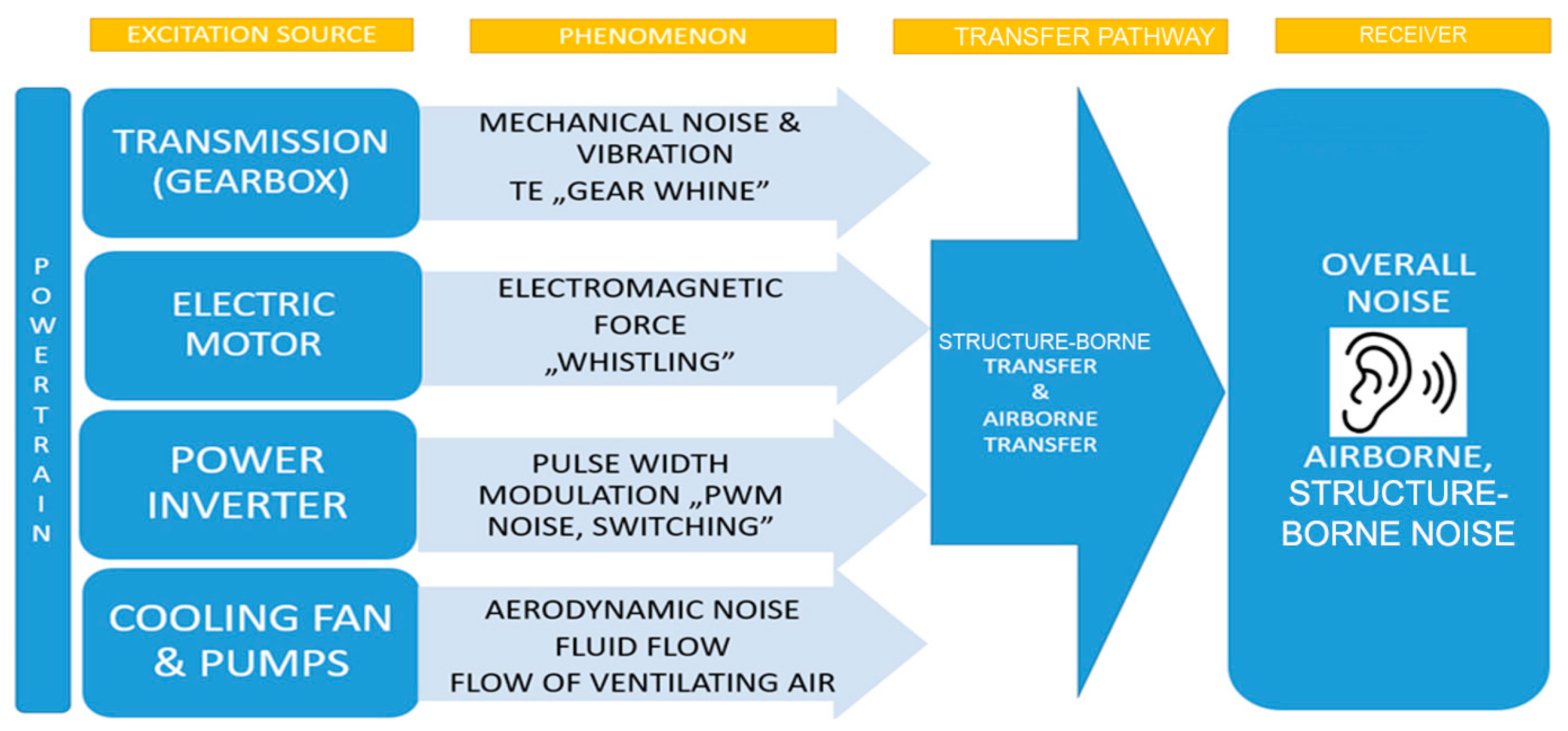

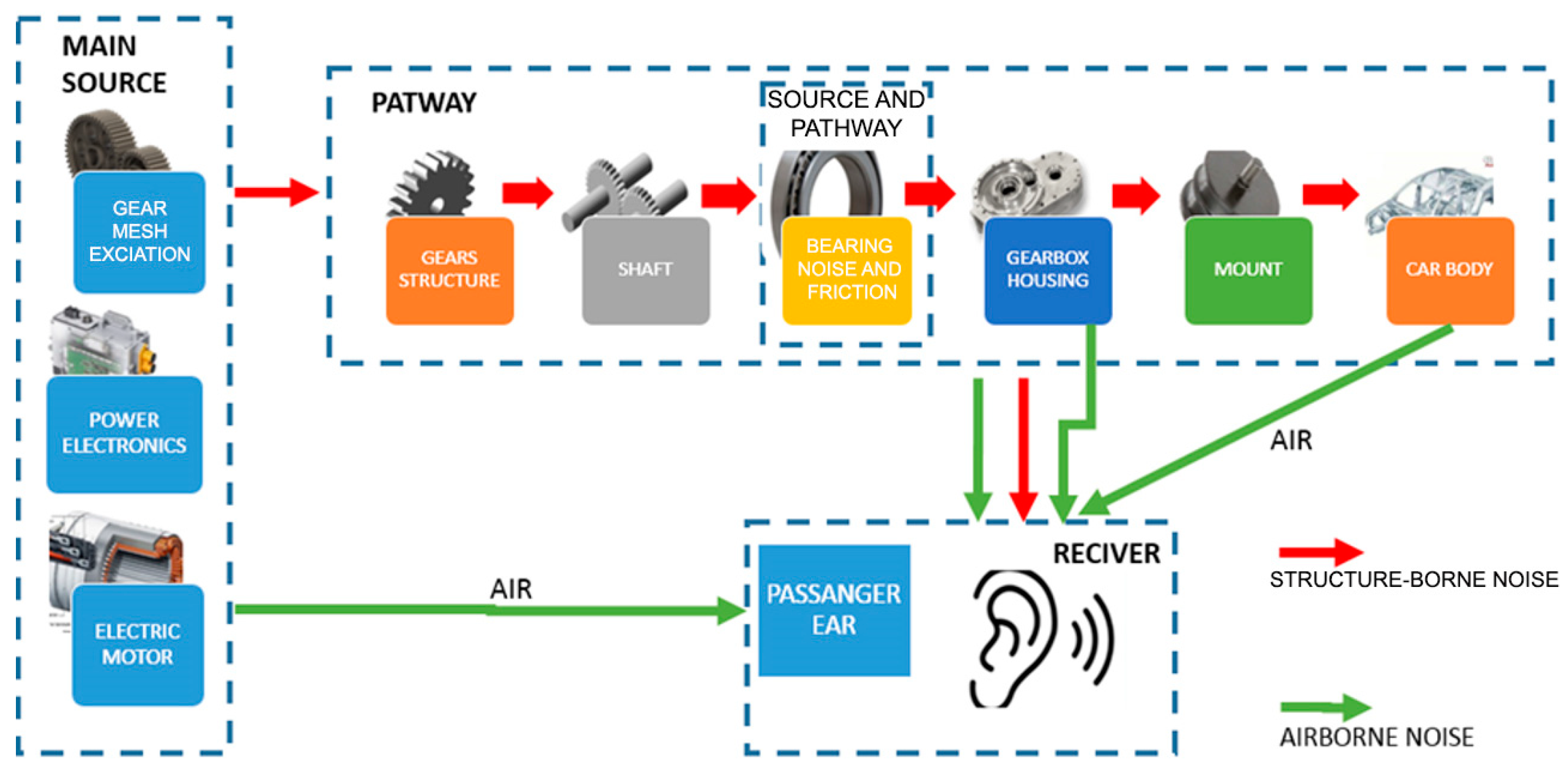

2. Key Contributors to NVH in EV Powertrains

- Transmission and gear reducer (gearbox): mechanical ooise (commonly known as ‘gear whine’): this occurs due to vibrations caused by gear transmission error (TE), excitable mechanically [13].

- Electric Motor: generates excitations via electromagnetic forces, causing what is commonly known as “whistling” or slot/pole noise (also referred to as ‘slotting’).

- Power Inverter and Electronics: include components that contain higher-order harmonics, leading to pulse width modulation (PWM noise), (‘switching’).

- Cooling Fan and Pumps: Produce aerodynamic noise and fluid flow noise.

2.1. Contributors to Mechanical Noise

2.2. Noise from Electric Motors

2.3. Noise from Inverters

2.4. Contributors to Aerodynamic Noises and Fluid Flow

2.5. Factors Influencing Noise from Electromagnetic Components

- Mechanical Deformations and Vibrations: These arise from various factors including the slot design, winding distributions, current waveform distortions, air gap variations, rotor eccentricity, and phase imbalances. These contribute to mechanical deformations and vibrations through complex harmonic forces and torques [20].

- Stator-Frame Resonance: The stator frame structure acts as the primary noise radiator of the machine. Resonance can occur when the radial force frequency aligns with the stator frame’s natural frequencies, leading to significant noise [21].

- Magnetostrictive Noise: This is due to the periodic elongation or contraction of the core material, which, in high-power applications like in EVs and HEVs, can contribute substantially to the overall noise [21].

- Parasitic Oscillation Torque: In inverter-fed motors, parasitic oscillating torques arise from time harmonics in the stator currents and can be exacerbated by voltage ripples from the rectifier [21].

3. Noise Reduction Methods

3.1. Preventing Mechanical Noise

- Selection and Environmental Dependence on Material: The use of materials with natural damping properties is important to help control mechanical noise. For example, vibrations may be absorbed, and the transmission of noise would be reduced when using rubber or Polyurethane (PU) mounts or pads. Foams and composites also work well in areas where lots of noise is absorbed [23].

- Optimization of Design: Designing components and systems with minimal noise production will reduce mechanical noise. Tightening and designing assemblies to not rattle (meaning they no longer vibrate or create noise) is crucial. Design techniques, such as finite element analysis (FEA), are particularly useful in detecting and addressing possible noise problems [24].

- Noise Source Isolation: It should be ensured that machinery or other noise-generating components are isolated from the rest of the structure. This is possible when sound transmission is prevented, such as through isolation mounts, enclosures, or barriers. Isolating sensitive components from vibration sources is particularly important [25].

- Precision Engineering and Manufacturing: A high level of precision provided in engineering and manufacturing processes equals lower mechanical noise. This is achieved by keeping tolerances tight, ensuring proper alignment, and balancing moving parts. Regular checks are necessary to prevent noise development caused by excessive wear [26].

- Application of Damping Techniques: It may be easier to reduce noise from a vibration source than to reduce the vibration itself. Selective damping of the machinery or structure may be considered. This could include damping coatings or layers in mechanical systems and actively or passively moving tuned mass dampers that absorb certain vibration frequencies [27].

- Adjusting Operational Parameters: Adjusting parameters like speed, torque, and load can help reduce mechanical operation noise. Running machines at speeds that do not hit resonances is a great idea, as is stepping into and out of new operations smoothly [28].

- Active Noise Control (ANC): ANC reduces noise by using electronic means. It uses microphones to listen to the sound and speakers to create a counter-noise that effectively cancels the original noise, especially where conventional noise reduction methods are unsuitable [29].

- Tailored Gear and Bearing Design: Gear design profoundly affects NVH risks in mechanical systems. Eliminating stiffness variation and optimizing the contact ratio can be achieved through the modification of macro- and micro-geometry of gears to minimize gear TE. Noise can be reduced through strategies such as raising the helix angle of gear sets, though this may also increase the axial loads placed on bearings and reduce efficiency. Similarly, an augmented contact ratio due to an inclined tooth addendum can increase frictional losses [30]. Key among these design considerations are reducing NVH while preserving efficiency and handling bearing loads.

3.2. Preventing Electric Motor Noise

- Pole Shaping: Refining the shape of magnetic poles to optimize the magnetic field distribution.

- Modulation of Pole and Slot Width/Position: Adjusting poles and slots can influence the magnetic field’s harmonics and, consequently, the noise and vibrations produced.

- Notches and Flux Barriers: Introducing notches or flux barriers to disrupt magnetic flux paths and control flux flow.

- Airgap Increase: Expanding the airgap between the rotor and stator to lower magnetic forces, while carefully considering the potential effects on motor efficiency and torque.

3.3. Preventing Electromagnetic Noise in Power Inverter:

- High-Frequency Adjustment: By increasing the inverter’s switching frequency above the audible range, the noise becomes imperceptible to the human ear.

- Control Strategies: These highlight the role of control strategies in balancing vibroacoustic and electrical performances, especially in induction and synchronous machines, to optimize for either efficiency or noise reduction [35].

- Vibration Isolation: Integrating the inverter into the motor’s isolation system can diminish the vibration transmitted from the inverter [36].

3.4. Preventing Aerodynamic and Fluid Flow Noise

- Water Pump Noise: Focusing on strategic mounting and location is crucial to prevent aerodynamic and fluid flow noise in powertrains, especially from water pumps in HEVs/EVs. Additionally, minimizing pulsation transmission through organized fluid conductor layouts, stiffening large flat metal areas, and selecting pumps with low noise ratings are key strategies. These approaches address the root causes of noise and offer practical solutions for engineers designing quieter and more efficient vehicle systems [19].

- Cooling Fan Noise: Utilized for vehicle cooling or dedicated HEV component cooling, these fans’ noise should be masked by other sources. Controlling noise levels at low speeds and in idle conditions is vital [19].

4. Development of Simulation Models for NVH Analysis

4.1. EM Simulation

4.2. Multi-Body Dynamic Simulation Using Flexible Bodies

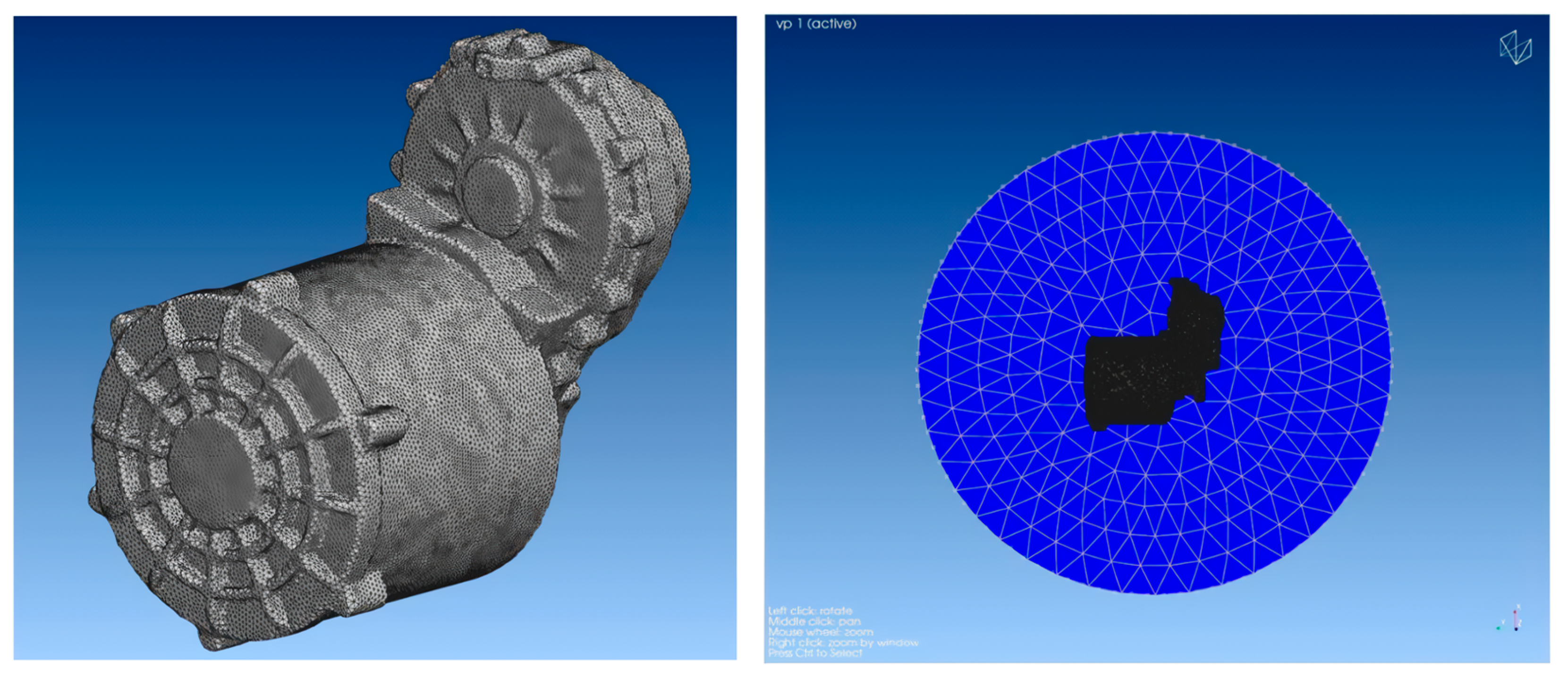

4.3. Structural Analysis

4.4. Acoustic Radiation Calculations

4.5. Common Workflow in Fully Numerical CAE Software

- Defining Objectives and Requirements: Establish goals of the simulation, focusing on NVH aspects like noise source identification, noise level evaluation, and noise reduction strategies. Define key parameters and performance indicators, including NVH-specific metrics.

- Gathering and Preparing Data: Collect necessary data on the powertrain’s physical properties, operational characteristics, and environmental factors from various sources.

- Modeling the Powertrain Components (Incorporating MBD and Flexibility): Develop detailed models of powertrain components using FEM and integrate MBD modeling, including flexible components such as motor and gearbox housings, shafts, bearings, and gear tooth contacts.

- Integrating Electromagnetic and Mechanical Models: Combine electromagnetic simulations with mechanical models for a comprehensive analysis of electromagnetic-induced vibrations.

- Setting Up Acoustic Models: Develop acoustic models using methods like BEM for predicting sound wave generation from powertrain vibrations and defining the acoustic environment.

- Validating Component Models: Independently validate each component model against experimental data for accuracy.

- Assembling the Complete Powertrain Model: Integrate individual component models, ensuring accurate representation of interfaces and dynamic interactions.

- Simulating Operational Conditions: Simulate various operational scenarios to understand the noise behavior under different EV conditions.

- Analyzing NVH Simulation Results: Use Equivalent Radiated Power (ERP) to quantify the energy emitted as sound. Use Sound Pressure Level (SPL) to measure the acoustic energy perceived. Use Campbell diagrams (both 2D and 3D) to visualize the frequency response and identify critical speeds. Evaluate individual modes in both time and frequency domains for detailed analysis. Obtain results for casing, including stress, displacement, and insights for optimization.

- Refining the Model: Based on NVH analysis, refine the model for accuracy, adjusting material properties, boundary conditions, or geometry.

- Iterative Testing and Optimization: Iterate the simulation process, adjusting the model based on NVH findings and retesting for noise reduction or design improvements. Final validation and reporting: validate the final model against known data or experimental results.

- NVH Result Interpretation and Application: Interpret NVH results such as ERP, SPL, and Campbell diagrams to understand the acoustic behavior of the powertrain. Use time domain and frequency domain analyses to identify and evaluate specific vibration modes and their impact on noise and harshness. Analyze casing stress and displacement results to inform structural optimization for reducing noise and improving durability.

- Design Recommendations Based on NVH Analysis: Based on the comprehensive NVH analysis, make design recommendations aimed at reducing noise and vibration, while enhancing the overall sound quality of the powertrain. Propose modifications to the powertrain design.

5. Acoustic Analysis Setup and Results

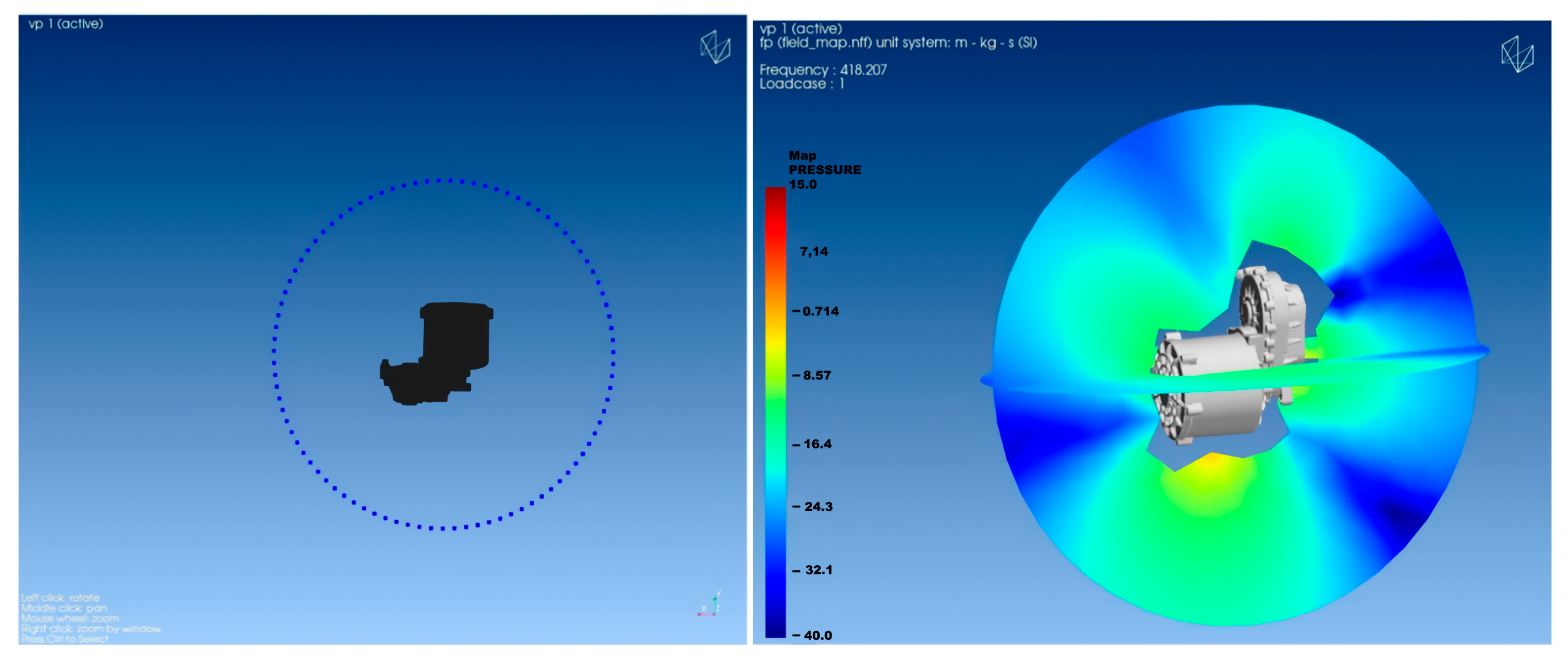

- Microphone Placement: The process begins with placing virtual microphones around the powertrain model. Positioning is crucial to correctly capture sound emanating from different parts of the system. This involves considering factors like the distance to the noise source, the recording location on the car, and the directionality of the microphones [58,59] (Figure 6).

- Simulation Environment: Acoustic analysis is conducted in a simulated environment that accurately reflects real-world conditions. This includes specifying the acoustic properties of the environment, such as air density and temperature, which affect sound propagation [60].

- Modeling Acoustic Sources: The powertrain components are modeled as sound sources. This requires understanding which components are most likely to generate noise, at what frequencies, and under what operating conditions [61].

Interpretation of Acoustic Results

- Radiation Patterns: Understanding the acoustic radiation patterns of the powertrain can reveal how sound waves emanate from the noise source. These patterns fluctuate continuously, and by graphically representing them, engineers can precisely locate areas of high noise emission [62]. This knowledge is essential for designing countermeasures to contain or deflect the sound away from sensitive areas, such as the passenger cabin.

- Sound Pressure Levels (SPLs): SPL measurements provide quantitative data on the loudness of noise at various locations around the powertrain. Areas with the highest SPL readings are of particular concern as they directly impact the comfort of the vehicle’s occupants [63]. SPL data also ensure that the vehicle meets legal noise regulations and industry standards for both interior and exterior noise levels.

- Frequency Analysis: Identifying the principal and problematic frequencies is crucial for recognizing entrenched NVH issues. Some frequencies may be more perceptible and annoying to the human ear, making them prime targets for reduction strategies. Frequency analysis facilitates the development of noise control solutions, such as damping materials or active noise control systems, tailored to suppress specific frequencies [64].

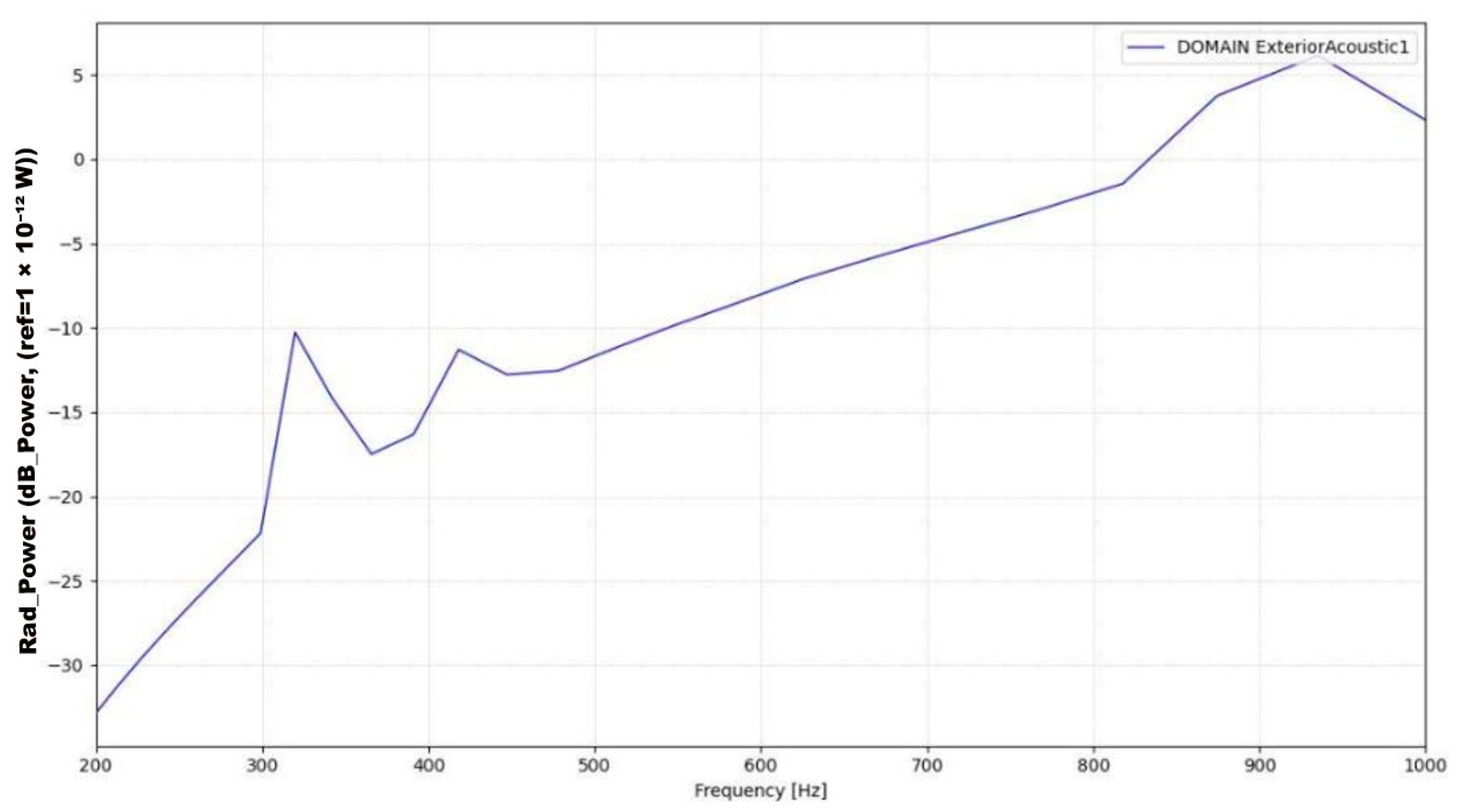

- Equivalent Radiated Power: This metric quantifies the total sound power produced by the powertrain. It is important to assess the overall noise contribution of the powertrain and evaluate the relative impact of different noise reduction strategies [65]. Figure 7 illustrates the variation in radiated acoustic power across different frequencies, highlighting significant peaks.

6. Conclusions

7. Future Research Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wennmo, M. Helping Electric Vehicle Manufacturers Compete. Gear Technology Magazine. 29 September 2022. Available online: https://www.geartechnology.com/articles/30078-helping-electric-vehicle-manufacturers-compete (accessed on 12 January 2020).

- EV-Volumes. Global EV Sales for February 2022; EV-Volumes: Trollhättan, Sweden; Available online: https://www.ev-volumes.com/ (accessed on 12 January 2020).

- Virta. 1.06 Million New EVs Registered in Europe. Virta Global EV Charging Report. Available online: https://www.virta.global/ (accessed on 12 January 2020).

- European Environment Agency. New Registrations of Electric Vehicles in Europe. Available online: https://www.eea.europa.eu/ (accessed on 2 February 2024).

- Weber, J. Technological trends. In Moving Times; Springer: Wiesbaden, Germany, 2022; pp. 27–159. [Google Scholar] [CrossRef]

- Kosuru, V.S.R.; Venkitaraman, A.K. Trends and challenges in electric vehicle motor drivelines—A review. Int. J. Electr. Comput. Eng. Syst. 2023, 14, 485–495. [Google Scholar] [CrossRef]

- NAGASE. NVH Reduction in EVs. NAGASE Whitepaper. Available online: https://www.nagase.com/content/dam/nagase-www/en/resources/nvh-reduction/NAM%20NVH%20Reduction%20in%20EVs%20WP%200323.pdf (accessed on 1 March 2024).

- Fuchs, A.; Nijman, E.; Priebsch, H.-H. (Eds.) Automotive NVH Technology, 1st ed.; Springer: Cham, Switzerland, 2015; Volume XVIII. [Google Scholar] [CrossRef]

- James, B.M.; Hofmann, A. Simulating and reducing noise excited in an EV powertrain by a switched reluctance machine. In Proceedings of the 8th International Styrian Noise, Vibration & Harshness Congress: The European Automotive Noise Conference, Graz, Austria, 2–4 July 2014. [Google Scholar] [CrossRef]

- Meek, B.; Van der Auwear, H.; De Langhe, K. Challenges in NVH for electric vehicles. In Proceedings of the FISITA 2012 World Automotive Congress; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2013; Volume 191, pp. 56–72. [Google Scholar] [CrossRef]

- Mehrgou, M.; Garcia de Madinabeitia, I.; Graf, B.; Zieher, F.; Priestner, C. NVH Aspects of Electric Drives-Integration of Electric Machine, Gearbox, and Inverter; SAE Technical Paper 2018-01-1556; SAE: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Furness, M.; Craven, J. Silencing the Future—A System Level Approach to NVH. In Proceedings of the 32nd Electric Vehicle Symposium (EVS32), Lyon, France, 19–22 May 2019; Available online: https://mobex.io/webinar-library/silencing-the-future-dsds-approach-to-electrified-powertrain-nvh/ (accessed on 1 March 2024).

- Magliacano, D.; Viscardi, M.; Ciminello, M.; Dimino, I.; Concilio, A. Feasibility study for a tonal vibration control system of a mounting bracket for automotive gearboxes. Int. J. Mech. 2016, 10, 403–410. [Google Scholar]

- Le Besnerais, J.; Toubin, H.; Gning, P.; Devillers, E. Electromagnetic Noise & Vibrations in Electrical Machines Webinar 7/8: Noise and Vibrations in Electrical Machines Application with MANATEE [Webinar Presentation]; EOMYS Engineering: Lille, France, 2 June 2020. [Google Scholar]

- Zhang, J.; Lv, C.; Li, Z. Investigation of high-speed dynamic transmission error testing using gear strain. Machines 2023, 11, 956. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, T. Vibroacoustic characterization of a permanent magnet synchronous motor powertrain for electric vehicles. IEEE Trans. Energy Convers. 2018, 33, 272–280. [Google Scholar] [CrossRef]

- Deng, C.; Deng, Q.; Liu, W.; Yu, C.; Hu, J.; Li, X. Analysis of vibration and noise for the powertrain system of electric vehicles under speed-varying operating conditions. Math. Probl. Eng. 2020, 2020, 6617291. [Google Scholar] [CrossRef]

- Sarrazin, M.; Janssens, K.; Van der Auweraer, H. Influence of inverter PWM control schemes on noise signature of electric powertrains. In Proceedings of the 4th International Conference on Biomedical Ontology, Montreal, QC, Canada, 7–12 July 2013; pp. 2899–2906. [Google Scholar]

- Cherng, J.G. Noise and vibration of cooling fan and accessory components. In ME 570 Powertrain NVH of Electrified Vehicles; Mechanical Engineering Department, University of Michigan-Dearborn: Dearborn, MI, USA, 2013; p. 48128. [Google Scholar]

- Ermolaev, A.; Erofeev, V.; Plekhov, A.; Titov, D. Magnetic vibration in induction motor caused by supply voltage distortion. Energies 2022, 15, 9600. [Google Scholar] [CrossRef]

- Li, J.; Yang, S.; Yang, J.; Li, F.; Zeng, Q.; Shao, J.; Chang, C.; Wu, N.; Chen, Y.; Li, K. Low-order radial modal test and analysis of drive motor stator. Machines 2021, 9, 97. [Google Scholar] [CrossRef]

- Bučinskas, V.; Mirzaei, S.; Kirchner, K. Some aspects of bearing noise generation. Solid State Phenom. 2010, 164, 278–284. [Google Scholar] [CrossRef]

- Hazra, S.; Reddy, K.J. A comparative study of properties of natural rubber and polyurethane-based powertrain mount on electric vehicle NVH performance. Int. J. Veh. Noise Vib. 2022, 18, 22–40. [Google Scholar] [CrossRef]

- Kumar, D.; Kottalgi, S.; Sambharam, T.; Mandloi, P. A multiphysics optimization approach to design low noise and light weight electric powertrain noise, vibration and harshness (NVH) prediction of electric powertrain using finite element analysis (FEA) and optimization. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 1692–1697. [Google Scholar] [CrossRef]

- Dylejko, P.; MacGillivray, I.; Moore, S.; Skvortsov, A. The Influence of Internal Resonances from Machinery Mounts on Radiated Noise from Ships. IEEE J. Ocean. Eng. 2017, 42, 399–409. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, J.; Kuriyagawa, T. Manufacturing technologies toward extreme precision. Int. J. Extrem. Manuf. 2019, 1, 022001. [Google Scholar] [CrossRef]

- Thelen, D.; Burkert, W. How to achieve lower tolerances in production balancing machines. In Proceedings: Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Technology Conference (Cat. No.03CH37480); IEEE: New York, NY, USA, 2003; pp. 339–342. [Google Scholar] [CrossRef]

- Ayana, E.; Plahn, P.; Wejrzanowski, K.; Mohan, N. Active Torque Cancellation for transmitted vibration reduction of low cylinder count engines. In Proceedings of the 2009 IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–10 September 2009; pp. 325–329. [Google Scholar] [CrossRef]

- Schirmacher, R. Active noise control and active sound design—Enabling factors for new powertrain technologies. In Proceedings of the 6th International Styrian Noise, Vibration & Harshness Congress—Sustainable NVH Solutions Inspired by Ecology and Economy, Graz, Austria, 22–24 June 2022. [Google Scholar] [CrossRef]

- Åkerblom, M. Gear Geometry for Reduced and Robust Transmission Error and Gearbox Noise, Report, Maskinkonstruktion; School of Industrial Engineering and Management. Machine Design, Trita-MMK. 2008. Available online: https://kth.diva-portal.org/smash/record.jsf?pid=diva2%3A139890&dswid=281 (accessed on 12 March 2024).

- Hosseini, S.; Alinejad-Beromi, Y. Noise reduction in switched reluctance motor by modifying the structures. IET Electr. Power Appl. 2021, 14, 2863–2872. [Google Scholar] [CrossRef]

- Humbert, L.; Pellerey, P.; Cristaudo, S. Electromagnetic and structural coupled simulation to investigate NVH behavior of an electrical automotive powertrain. SAE Int. J. Altern. Powertrains 2012, 1, 395–404. [Google Scholar] [CrossRef]

- Liu, G.; Gao, A.; Chen, Q.; Mao, Y.; Xu, G. Vibration and noise optimization of new asymmetric modular PMaSynRM. Chin. J. Electr. Eng. 2023, 9, 57–70. [Google Scholar] [CrossRef]

- Pyrhönen, J.; Jokinen, T.; Hrabovcová, V. Design of Rotating Electrical Machines, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2014; pp. 167–491. [Google Scholar] [CrossRef]

- Subramaniam, U.; Bhaskar, S.M.; Almakhles, D.J.; Padmanaban, S.; Leonowicz, Z. Investigations on EMI mitigation techniques: Intent to reduce grid-tied PV inverter common mode current and voltage. Energies 2019, 12, 3395. [Google Scholar] [CrossRef]

- Henderson, J.; Plummer, A.; Johnston, N. An electro-hydrostatic actuator for hybrid active-passive vibration isolation. Int. J. Hydromechatronics 2018, 1, 47–71. [Google Scholar] [CrossRef]

- Salmani, H.; Khalkhali, A.; Mohsenifar, A. A practical procedure for vehicle sound package design using statistical energy analysis. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 237, 3054–3069. [Google Scholar] [CrossRef]

- Law, H.; Law, J.; Kierzkowski, M. Absorptive noise barrier development. J. Acoust. Soc. Am. 2023, 154, A351. [Google Scholar] [CrossRef]

- Kim, S.; Altinsoy, M.E. Active control of road noise considering the vibro-acoustic transfer path of a passenger car. Appl. Acoust. 2022, 192, 108741. [Google Scholar] [CrossRef]

- Horváth, K.; Ambrus, Z. Vibro-acoustic simulation of gearboxes—A literature review. In Proceedings of the 26th International Ph.D. Conference (PEME XXVI), Debrecen, Hungary, 9–10 November 2023; Professzorok az Európai Magyarországért: Budapest, Hungary; Miskolc, Hungary, 2023; pp. 73–81. [Google Scholar]

- Duda, T.; Mülder, C.; Jacobs, G.; Hameyer, K.; Bosse, D.; Cardaun, M. Integration of electromagnetic finite element models in a multibody simulation to evaluate vibrations in direct-drive generators. Originalarbeiten/Originals 2021, 85, 257–264. [Google Scholar] [CrossRef]

- Ansys, Inc. Ansys Maxwell. Available online: https://www.ansys.com/products/electronics/ansys-maxwell (accessed on 16 February 2024).

- JSOL Corporation. JMAG: Simulation Technology for Electromechanical Design. Available online: https://www.jmag-international.com/ (accessed on 3 February 2024).

- Siemens Digital Industries Software. Simcenter MAGNET: Electromagnetics Simulation. Available online: https://plm.sw.siemens.com/en-US/simcenter/electromagnetics-simulation/magnet/ (accessed on 3 February 2024).

- FunctionBay, Inc. RecurDyn Overview: Multibody Dynamics Software for Flexible and Rigid Body Analysis. Available online: https://functionbay.com/en/page/single/2/recurdyn-overview (accessed on 3 February 2024).

- Hexagon. Adams: Multibody Dynamics and Motion Analysis Software for Simulating the Behavior of Mechanical Systems. Available online: https://hexagon.com/products/product-groups/computer-aided-engineering-software/adams (accessed on 16 February 2024).

- Ansys, Inc. Ansys Mechanical: Finite Element Analysis Software for Structural Analysis and Simulation. Available online: https://www.ansys.com/products/structures/ansys-mechanical (accessed on 16 February 2024).

- Hexagon. MSC Nastran: Finite Element Analysis Software for Structural Analysis, Including Linear and Nonlinear Static and Dynamic Analysis. Available online: https://hexagon.com/products/product-groups/computer-aided-engineering-software/msc-nastran (accessed on 16 February 2024).

- Bilgin, B.; Liang, J.; Terzic, M.V.; Dong, J.; Rodriguez, R.; Trickett, E.; Emadi, A. Modeling and analysis of electric motors: State-of-the-art review. IEEE Trans. Transp. Electrif. 2019, 5, 602–617. [Google Scholar] [CrossRef]

- Xu, X.; Han, Q.; Chu, F. Review of electromagnetic vibration in electrical machines. Energies 2018, 11, 1779. [Google Scholar] [CrossRef]

- Levent, A.H.; Lordoglu, A.; Aydeniz, M.G. Design and optimization of permanent magnet synchronous motor for electric vehicle applications. In Proceedings of the 2020 2nd Global Power, Energy and Communication Conference (GPECOM), Izmir, Turkey, 20–23 October 2020. [Google Scholar] [CrossRef]

- Rahnejat, H.; Johns-Rahnejat, P.M.; Dolatabadi, N.; Rahmani, R. Multi-body dynamics in vehicle engineering. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2023, 238, 3–25. [Google Scholar] [CrossRef]

- Pellerey, P.; Lanfranchi, V.; Friedrich, G. Coupled numerical simulation between electromagnetic and structural models. Influence of the supply harmonics for synchronous machine vibrations. IEEE Trans. Magn. 2012, 48, 983–986. [Google Scholar] [CrossRef]

- Reeves, D. Electric motor noise modeling with Actran. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo, Dearborn, MI, USA, 27–29 June 2016. [Google Scholar]

- Holehouse, R.; Shahaj, A.; Michon, M.; James, B. Integrated approach to NVH analysis in electric vehicle drivetrains. J. Eng. 2019, 2019, 3842–3847. [Google Scholar] [CrossRef]

- dos Santos, F.L.M.; Anthonis, J.; Naclerio, F.; Gyselinck, J.J.C.; Van der Auweraer, H.; Góes, L.C.S. Multiphysics NVH modeling: Simulation of a switched reluctance motor for an electric vehicle. IEEE Trans. Ind. Electron. 2014, 61, 469–476. [Google Scholar] [CrossRef]

- Kumar, D.; Sambharam, T.; Kottalgi, S.; Mandloi, P.; Kesarkar, O. Electric vehicle powertrain multiphysics NVH simulation. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018. [Google Scholar] [CrossRef]

- COMSOL Blog. How to Model Gearbox Vibration and Noise in COMSOL Multiphysics®. Available online: https://www.comsol.com/blogs/how-to-model-gearbox-vibration-and-noise-in-comsol-multiphysics/ (accessed on 26 June 2024).

- Choi, J.; Ha, T.; Chung, E.C.; Jeong, H.S.; Jung, K.; Harris, O.; Gale, A.; Harvey, T.; Kim, S. Development of Rumble Noise Analysis Method for Electric Powertrain; SAE Technical Paper 2023-01-0459; SAE: Warrendale, PA, USA, 2023. [Google Scholar] [CrossRef]

- Aghaei, S. Acoustic Radiation of an Automotive Component Using Multi-Body Dynamics. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2020. [Google Scholar]

- Shiozaki Shiozaki, H.; Iwanaga, Y.; Ito, H. Interior Noise Evaluation of Electric Vehicle: Noise Source Contribution Analysis; SAE Technical Paper 2011-39-7229; SAE: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Gagliardini, L.; Hamdi, M.A.; Defosse, H. Noise radiation model of a powertrain using an inverse boundary element method and projection on wave-envelope vectors. In Proceedings of the SAE 2003 Noise and Vibration Conference, Traverse City, MI, USA, 5–8 May 2003. [Google Scholar] [CrossRef]

- Pennig, S.; Quehl, J.; Rolny, V. Effects of aircraft cabin noise on passenger comfort. Ergonomics 2012, 55, 1252–1265. [Google Scholar] [CrossRef]

- Caprile, J.; Chaufour, C.; Chartrain, P. Efficient methodology for automotive powertrain acoustic radiation analysis. In Proceedings of the 9th International Styrian Noise, Vibration & Harshness Congress: The European Automotive Noise Conference, Graz, Austria, 22–24 June 2016. SAE Technical Paper 2016-01-1794. [Google Scholar] [CrossRef]

- Luegmair, M.; Münch, H. Advanced equivalent radiated power (ERP) calculation for early vibro-acoustic product optimization. In Proceedings of the 22nd International Congress on Sound and Vibration, Florence, Italy, 12–16 July 2015; pp. 1–8. [Google Scholar]

- Müller, J.; Jacobs, G.; Ramm, M.; Wischmann, S.; Jagla, P.; Berroth, J. Model-based NVH optimization of a tractor drivetrain during different phases of a design adaptation. Forsch. Ingenieurwesen 2023, 87, 363–373. [Google Scholar] [CrossRef]

- Skill-lync. Real-Time Simulation of the HEV Powertrain Using MATLAB & Simulink. Available online: https://skill-lync.com/blogs/real-time-simulation-of-the-hev-powertrain-using-matlab-simulink (accessed on 26 June 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Horváth, K.; Zelei, A. Simulating Noise, Vibration, and Harshness Advances in Electric Vehicle Powertrains: Strategies and Challenges. World Electr. Veh. J. 2024, 15, 367. https://doi.org/10.3390/wevj15080367

Horváth K, Zelei A. Simulating Noise, Vibration, and Harshness Advances in Electric Vehicle Powertrains: Strategies and Challenges. World Electric Vehicle Journal. 2024; 15(8):367. https://doi.org/10.3390/wevj15080367

Chicago/Turabian StyleHorváth, Krisztián, and Ambrus Zelei. 2024. "Simulating Noise, Vibration, and Harshness Advances in Electric Vehicle Powertrains: Strategies and Challenges" World Electric Vehicle Journal 15, no. 8: 367. https://doi.org/10.3390/wevj15080367

APA StyleHorváth, K., & Zelei, A. (2024). Simulating Noise, Vibration, and Harshness Advances in Electric Vehicle Powertrains: Strategies and Challenges. World Electric Vehicle Journal, 15(8), 367. https://doi.org/10.3390/wevj15080367