Patent Analysis of the Electric Vehicle Battery Management Systems Based on the AHP and Entropy Weight Method

Abstract

1. Introduction

2. Research Methods

2.1. Results of the Indicator System Construction

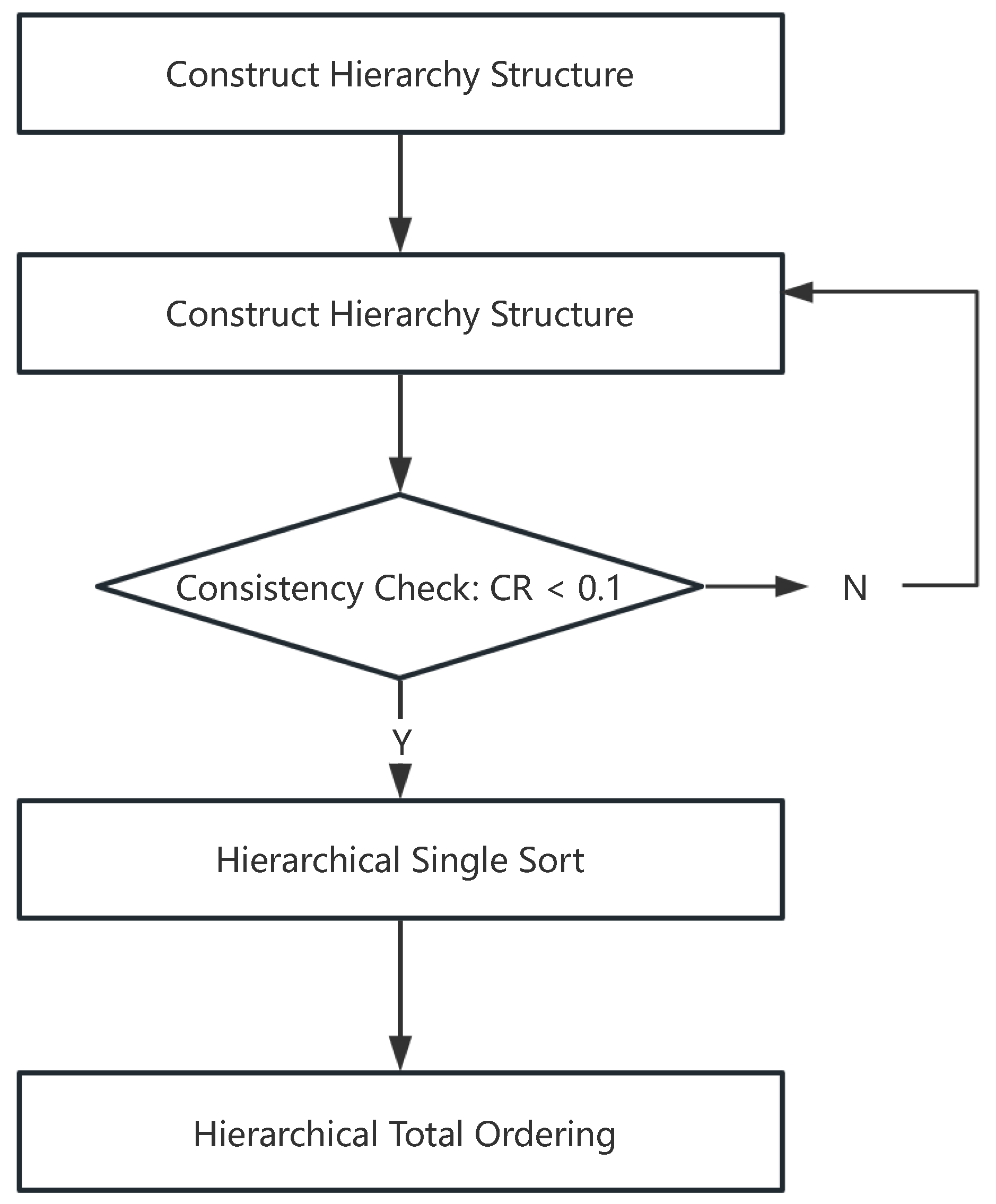

2.2. Analytic Hierarchy Process (AHP)

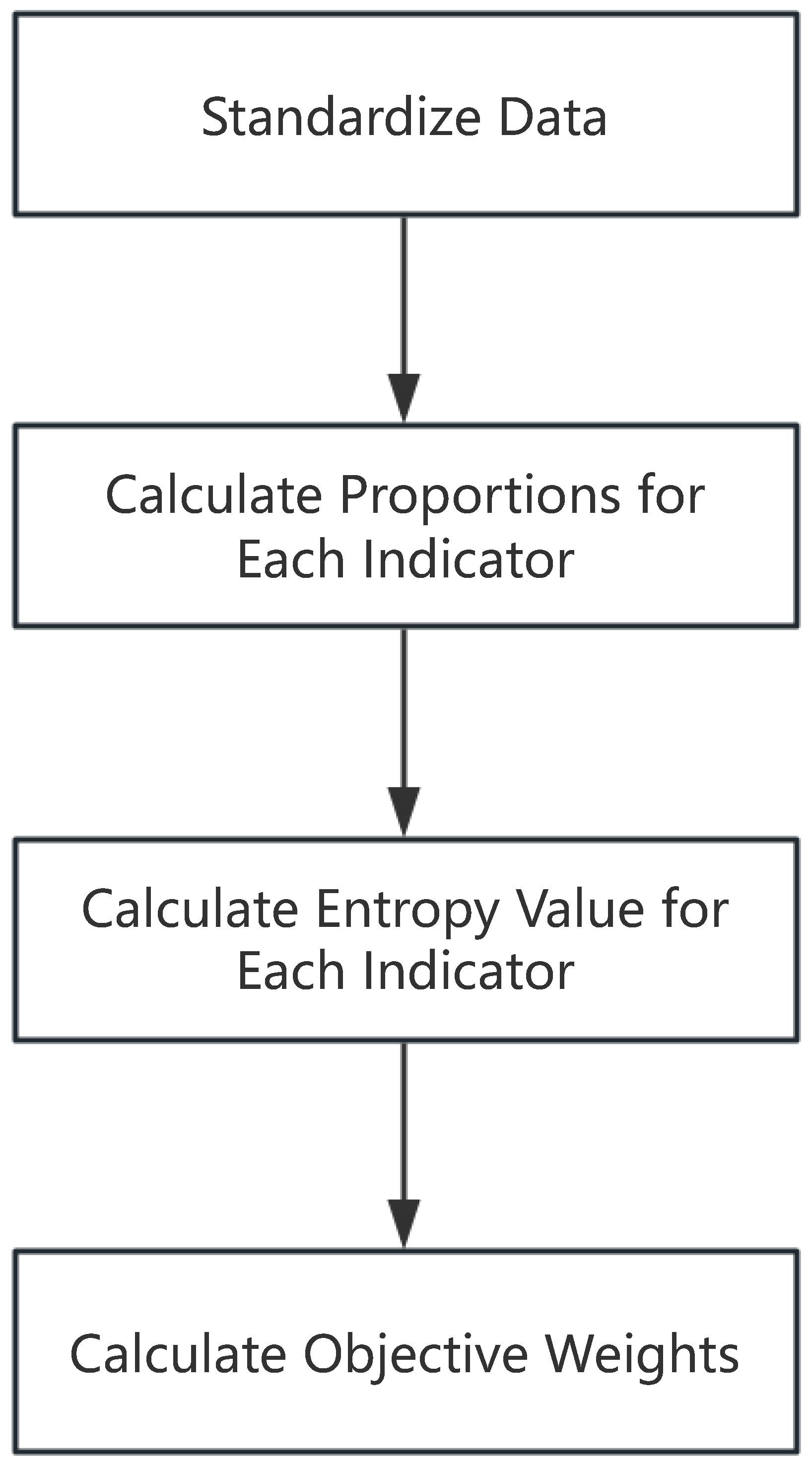

2.3. Entropy Weight Method to Determine the Objective Weight of Indicators

2.4. Determining the Combined Weight

2.5. Determining Patent Quality

3. Empirical Analysis

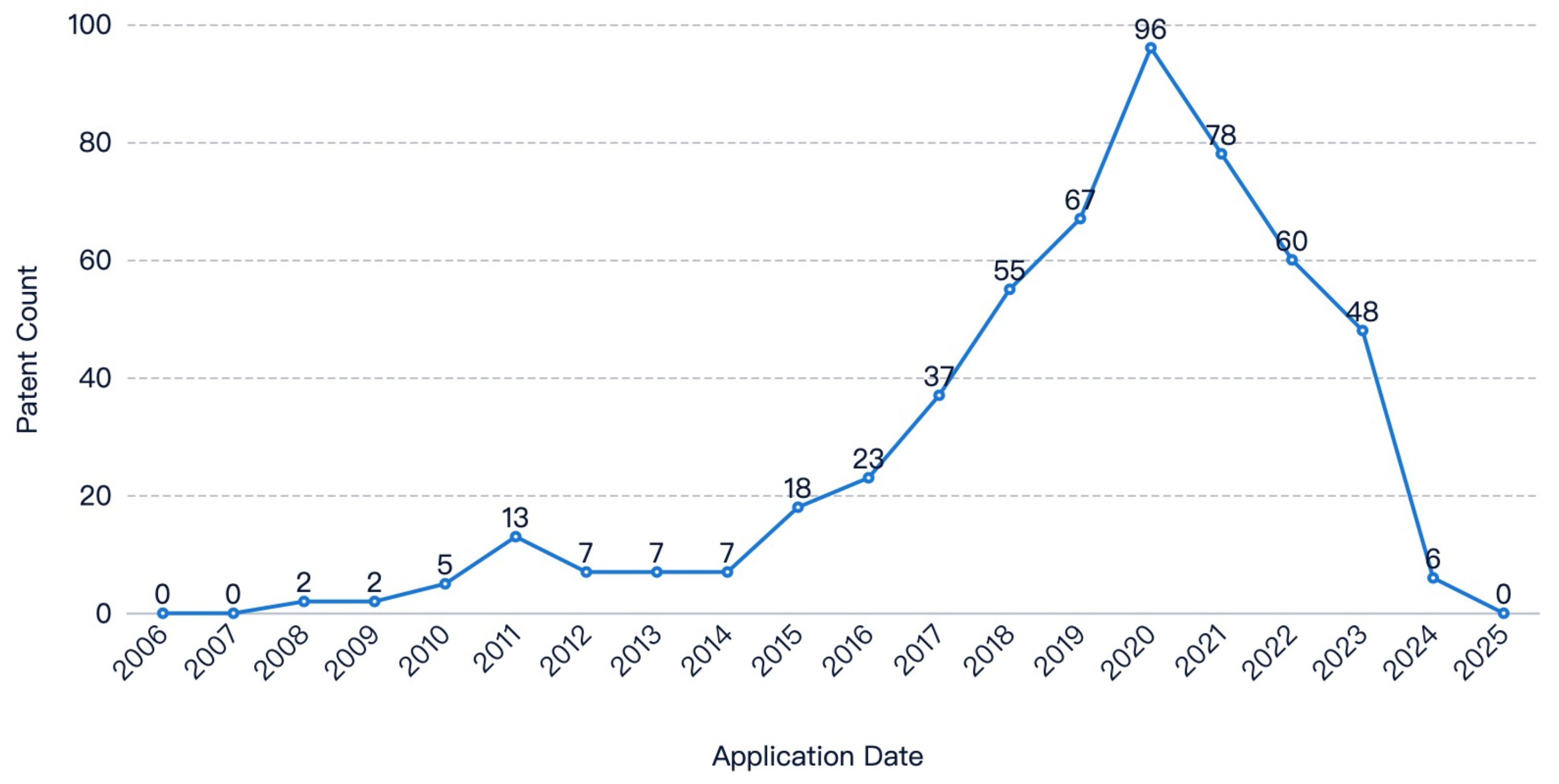

3.1. Patent Data Retrieval

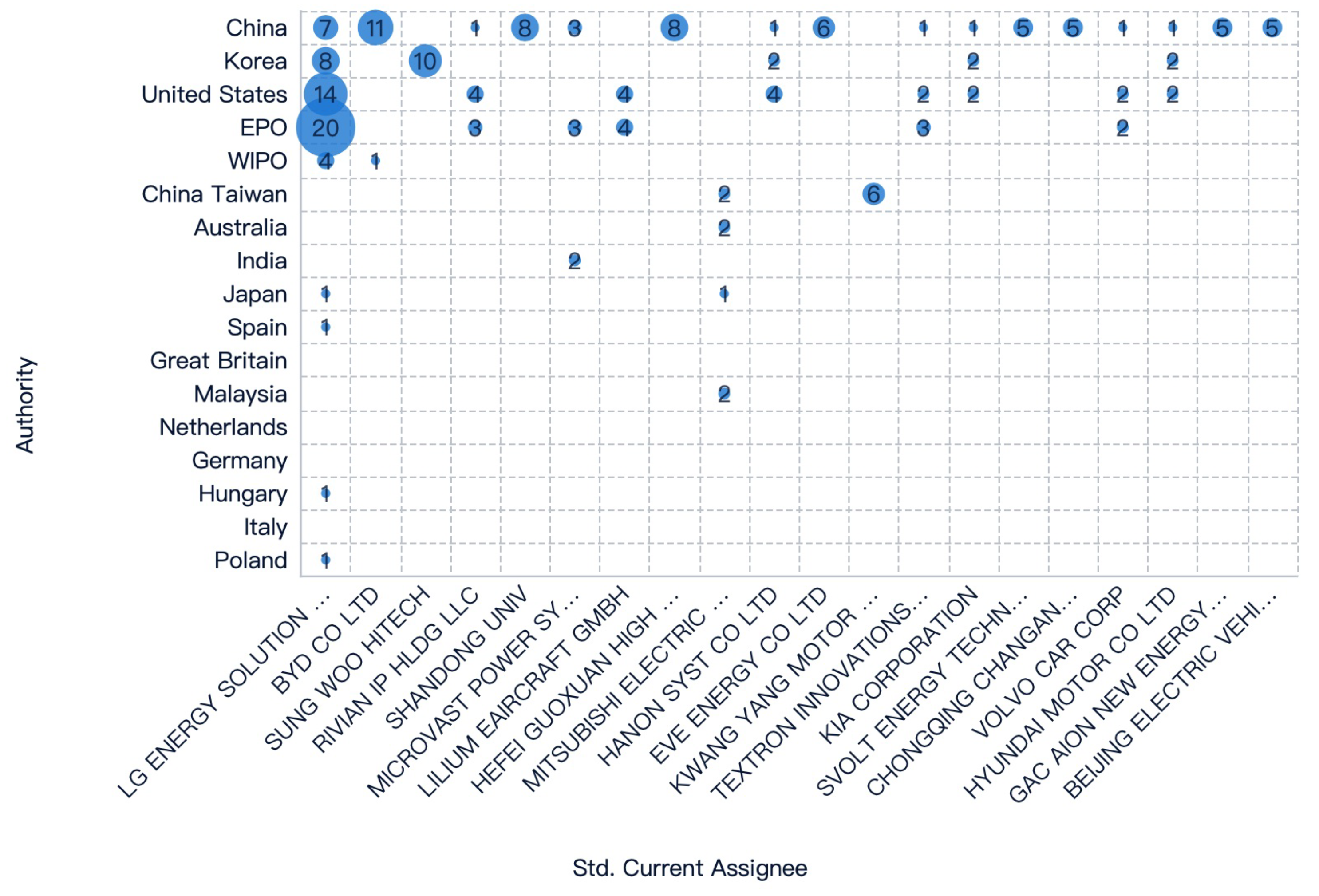

3.2. Patent Analysis

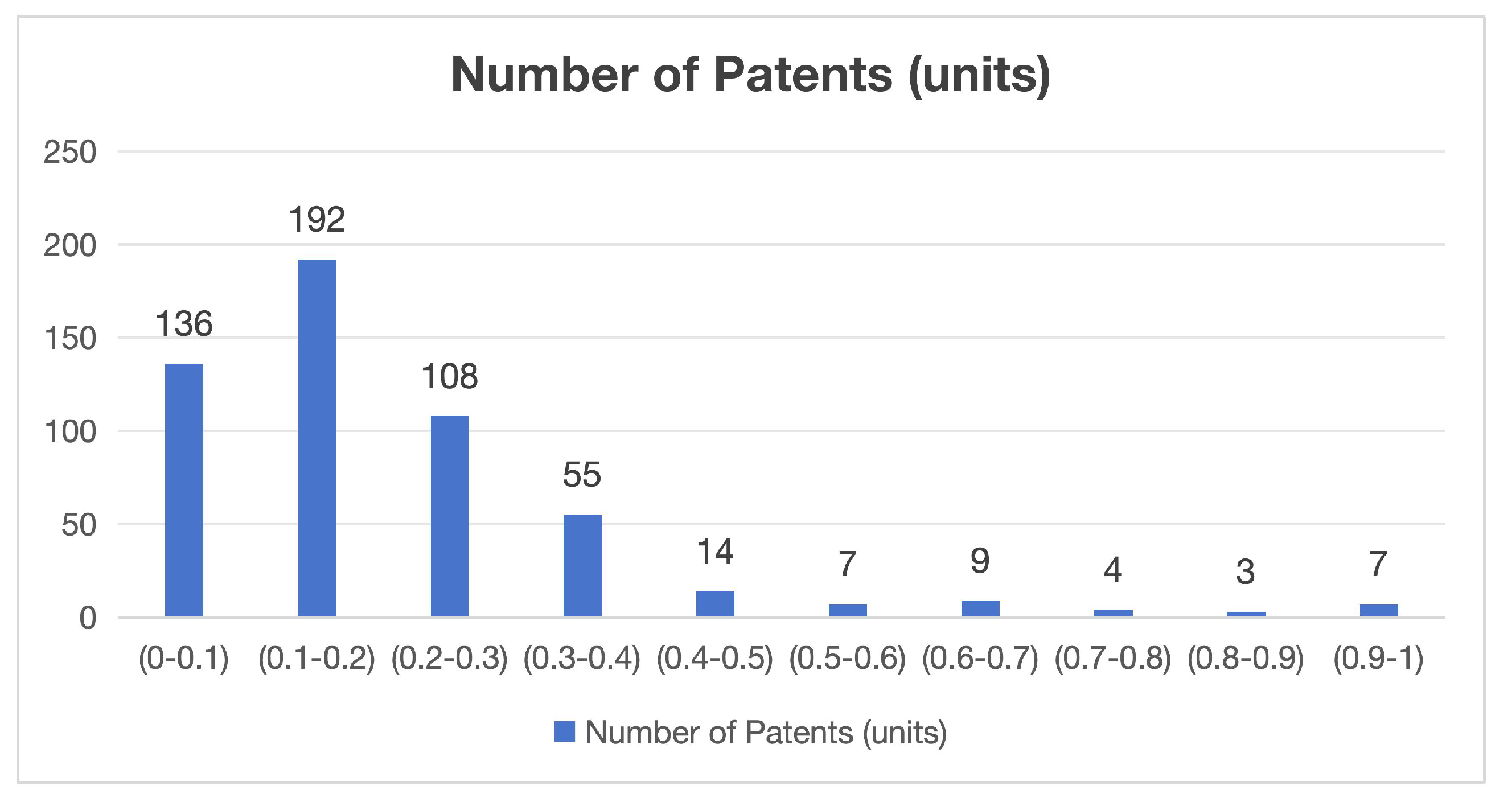

4. Identification of Electric Vehicle Battery Management System Technologies and Results Analysis

5. Conclusions and Insights

5.1. The Core Role of Electric Vehicle Companies and the Importance of BMS

5.2. Current R&D Companies and Future Development Trends

5.3. Application of the Technology Identification Indicator System

6. Limitations of the Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mahmud, M.P.; Farjana, S.H. Comparative Life Cycle Environmental Impact Assessment of Renewable Electricity Generation Systems: A Practical Approach towards Europe, North America and Oceania. Renew. Energy 2022, 193, 1106–1120. [Google Scholar] [CrossRef]

- Taylor, A.M.K.P. Science review of internal combustion engines. Energy Policy 2008, 36, 4657–4667. [Google Scholar] [CrossRef]

- US EPA, OA. EPA History: The Clean Air Act of 1970. 2016. Available online: www.epa.gov (accessed on 12 February 2025).

- Government of Canada. The Paris Agreement, Canada.ca. 2015. Available online: www.canada.ca/en/environment-climate-change/services/climate-change/paris-agreement.html (accessed on 10 February 2025).

- Pilkington, A.; Dyerson, R. Innovation in Disruptive Regulatory Environments. Eur. J. Innov. Manag. 2006, 9, 79–91. [Google Scholar] [CrossRef]

- García-Olivares, A.; Solé, J.; Osychenko, O. Transportation in a 100% Renewable Energy System. Energy Convers. Manag. 2018, 158, 266–285. [Google Scholar] [CrossRef]

- Kurucan, M.; Özbaltan, M.; Yetgin, Z.; Alkaya, A. Applications of Artificial Neural Network Based Battery Management Systems: A Literature Review. Renew. Sustain. Energy Rev. 2024, 192, 114262. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, X.; Wang, J.; Lian, Y.; Ouyang, M.; Burke, A.F. Battery Fault Diagnosis and Failure Prognosis for Electric Vehicles Using Spatio-Temporal Transformer Networks. Appl. Energy 2023, 352, 121949. [Google Scholar] [CrossRef]

- Pandise, E.; Kolodny, L. EV Drivers Wrestle with Cold Weather Sapping Their Battery Range. NBCUniversal Media, LLC. 2024. Available online: www.nbcnews.com/business/autos/ev-battery-range-cold-weather-charging-rcna134355 (accessed on 15 February 2025).

- Liu, K.; Peng, Q.; Che, Y.; Zheng, Y.; Li, K.; Teodorescu, R.; Barai, A. Transfer Learning for Battery Smarter State Estimation and Ageing Prognostics: Recent Progress, Challenges, and Prospects. Adv. Appl. Energy 2023, 9, 100117. [Google Scholar] [CrossRef]

- Gabbar, H.A.; Othman, A.M.; Abdussami, M.R. Review of Battery Management Systems (BMS) Development and Industrial Standards. Technologies 2021, 9, 28. [Google Scholar] [CrossRef]

- Barman, P.; Dutta, L.; Azzopardi, B. Electric Vehicle Battery Supply Chain and Critical Materials: A Brief Survey of State of the Art. Energies 2023, 16, 3369. [Google Scholar] [CrossRef]

- Turgut, M.; Bayir, R.; Duran, F. CAN Communication Based Modular Type Battery Management System for Electric Vehicles. Elektron. Elektrotechnika 2018, 24, 53–60. [Google Scholar] [CrossRef]

- Liu, K.; Li, K.; Peng, Q.; Zhang, C. A Brief Review on Key Technologies in the Battery Management System of Electric Vehicles. Front. Mech. Eng. 2018, 14, 47–64. [Google Scholar] [CrossRef]

- Monolithic Power Systems, Inc. EV Battery Management Systems (BMS). Monolithicpower.com. Available online: https://www.monolithicpower.com/jp/learning/mpscholar/automotive-electronics/electric-vehicles-and-hybrid-power-systems/ev-battery-management-systems?srsltid=AfmBOooPUZLlbYFgcYaP9als2-iV1envf7UN3fX51e7SVWzsX4O_8ZBe (accessed on 23 February 2025).

- Uma, S.; Eswari, R. Enhancing Electric Vehicle Battery Performance and Safety Through IoT and Machine Learning: A Fire Prevention Approach. Trans. Emerg. Telecommun. Technol. 2025, 36, 4. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, E.W.M.; Tsui, K.L.; Pecht, M. Battery Management Systems in Electric and Hybrid Vehicles. Energies 2011, 4, 1840–1857. [Google Scholar] [CrossRef]

- Conte, F.V. Battery and Battery Management for Hybrid Electric Vehicles: A Review. e i Elektrotechnik Informationstechnik 2006, 123, 424–431. [Google Scholar] [CrossRef]

- Waseem, M.; Ahmad, M.; Parveen, A.; Suhaib, M. Battery Technologies and Functionality of Battery Management System for EVs: Current Status, Key Challenges, and Future Prospects. J. Power Sources 2023, 580, 233349. [Google Scholar] [CrossRef]

- Rahmani, P.; Chakraborty, S.; Mele, I.; Katrašnik, T.; Bernhard, S.; Pruefling, S.; Hegazy, O. Driving the Future: A Comprehensive Review of Automotive Battery Management System Technologies, and Future Trend. J. Power Source 2024, 629, 235827. [Google Scholar] [CrossRef]

- Liu, J. Centralized BMS vs Distributed BMS vs Modular BMS, Which is the Main Trend? MokoEnergy—Your New Energy Solution Provider. 2023. Available online: https://www.mokoenergy.com/centralized-bms-vs-distributed-bms-vs-modular-bms/ (accessed on 16 January 2025).

- Etengoff, A. What EV Battery Management System (BMS) Architectures Are Used Today? EV Engineering. 2023. Available online: https://www.evengineeringonline.com/what-ev-battery-management-system-bms-architectures-are-used-today/ (accessed on 20 February 2025).

- Schärtel, L.; Reick, B.; Pfeil, M.; Stetter, R. Analysis and Synthesis of Architectures for Automotive Battery Management Systems. Appl. Sci. 2022, 12, 10756. [Google Scholar] [CrossRef]

- Ansari, S.; Ayob, A.; Hossain Lipu, M.S.; Hussain, A.; Saad, M.H.M. Data-Driven Remaining Useful Life Prediction for Lithium-Ion Batteries Using Multi-Charging Profile Framework: A Recurrent Neural Network Approach. Sustainability 2021, 13, 13333. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.S.H.; Hussain, A.; Saad, M.H.; Ayob, A. Neural Network Approach for Estimating State of Charge of Lithium-Ion Battery Using Backtracking Search Algorithm. IEEE Access 2018, 6, 10069–10079. [Google Scholar] [CrossRef]

- Ghazali, A.K.; Nor Hassan, M.K. Advanced Algorithms in Battery Management Systems for Electric Vehicles: A Comprehensive Review. Symmetry 2025, 17, 321. [Google Scholar] [CrossRef]

- Yuan, X.; Wu, J. Research on the Development of pure electric vehicle power battery Technology based on patent analysis. IOP Conf. Ser. Earth Environ. Sci. 2020, 615, 20–41. [Google Scholar] [CrossRef]

- Liu, Z.; Xiang, X.; Feng, J. Tracing evolutionary trajectory of charging technologies in electric vehicles: Patent citation network analysis. Environ. Dev. Sustain. 2023, 26, 12789–12813. [Google Scholar] [CrossRef]

- Basberg, B.L. Patents and the measurement of technological change: A survey of the literature. Res. Policy 1987, 16, 131–141. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development. OECD Patent Statistics Manual. 2025. Available online: https://www.oecd.org/en/publications/oecd-patent-statistics-manual_9789264056442-en.html (accessed on 16 February 2025).

- Fung, M.K.; Chow, W.W. Measuring the intensity of knowledge flow with patent statistics. Econ. Lett. 2002, 74, 353–358. [Google Scholar] [CrossRef]

- World Intellectual Property Organization. International Patent Classification (IPC). classification-ipc. 2024. Available online: https://www.wipo.int/en/web/classification-ipc (accessed on 20 February 2025).

- Vijvers, W.G. The international patent classification as a search tool. World Pat. Inf. 1990, 12, 26–30. [Google Scholar] [CrossRef]

- Liu, D.-R.; Shih, M.-J. Hybrid-patent classification based on patent-network analysis. J. Am. Soc. Inf. Sci. Technol. 2010, 62, 246–256. [Google Scholar] [CrossRef]

- Yamada, H. Identification methods and indicators of important patents. Libr. Hi Tech 2021, 40, 29–80. [Google Scholar] [CrossRef]

- Yang, G.-C.; Li, G.; Li, C.-Y.; Zhao, Y.-H.; Zhang, J.; Liu, T.; Chen, D.-Z.; Huang, M.-H. Using the comprehensive patent citation network (CPC) to evaluate patent value. Scientometrics 2015, 105, 1319–1346. [Google Scholar] [CrossRef]

- Liu, J.; Zheng, J. Identifying important nodes in complex networks based on extended degree and E-shell hierarchy decomposition. Sci. Rep. 2023, 13, 6. [Google Scholar] [CrossRef]

- Lee, C.; Kwon, O.; Kim, M.; Kwon, D. Early identification of emerging technologies: A machine learning approach using multiple patent indicators. Technol. Forecast. Soc. Change 2018, 105, 597–605. [Google Scholar] [CrossRef]

- Hofmann, S.G.; Curtiss, J.; McNally, R.J. A Complex Network. Perspect. Psychol. Sci. 2016, 11, 597–605. [Google Scholar] [CrossRef] [PubMed]

- Feng, B.; Sun, K.; Chen, M.; Gao, T. The Impact of Core Technological Capabilities of High-Tech Industry on Sustainable Competitive Advantage. Sustainability 2020, 12, 2980. [Google Scholar] [CrossRef]

- Ernst, H. Patent information for strategic technology management. World Pat. Inf. 2003, 25, 233–242. [Google Scholar] [CrossRef]

- Monolithic Power Systems, Inc. Understanding the Role of a Battery Management System (BMS) in Electric Vehicles. Monolithicpower.com. 2024. Available online: https://www.monolithicpower.com/en/learning/resources/understanding-the-role-of-a-battery-management-systems-in-electric-vehicles?srsltid=AfmBOooshbDRXgY1d4W4uH18QFbXW3ECjBJ8eC_V8IyEOD8ShGJAQUXl (accessed on 20 January 2025).

- Park, E.; Yoo, K.; Kwon, S.J.; Ohm, J.Y.; Chang, H.J. Effects of innovation cluster and type of core technology on firms’ economic performance. J. Eng. Res. 2016, 14, 12789–12813. [Google Scholar] [CrossRef]

- Torkkeli, M.; Tuominen, M. The contribution of technology selection to core competencies. Int. J. Prod. Econ. 2002, 77, 271–284. [Google Scholar] [CrossRef]

- Hsieh, C.-H. Patent value assessment and commercialization strategy. Technol. Forecast. Soc. Change 2013, 80, 307–319. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development. Measuring Patent Quality. Measuring Patent Quality. 2025. Available online: https://www.oecd.org/en/publications/measuring-patent-quality_5k4522wkw1r8-en (accessed on 28 January 2025).

- van Zeebroeck, N.; van Pottelsberghe de la Potterie, B. The vulnerability of patent value determinants. Sustainability 2011, 20, 283–308. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision-making with the AHP: Why is the principal eigenvector necessary. Eur. J. Oper. Res. 2020, 145, 85–91. [Google Scholar] [CrossRef]

- Vargas, L.G. An overview of the analytic hierarchy process and its applications. Eur. J. Oper. Res. 1990, 48, 2–8. [Google Scholar] [CrossRef]

- Munier, N. USES AND LIMITATIONS OF THE AHP METHOD: A Non-Mathematical and Rational Analysis; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Russo, R.d.F.S.M.; Camanho, R. Criteria in AHP: A Systematic Review of Literature. Procedia Comput. Sci. 2015, 55, 1123–1132. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Ameyaw, E.E.; Owusu, E.K.; Pärn, E.; Edwards, D.J. Review of application of analytic hierarchy process (AHP) in construction. Int. J. Constr. Manag. 2018, 19, 436–452. [Google Scholar] [CrossRef]

- Pathak, S.K.; Sharma, V.; Chougule, S.S.; Goel, V. Prioritization of barriers to the development of renewable energy technologies in India using integrated Modified Delphi and AHP method. Sustain. Energy Technol. Assess. 2022, 50, 101818. [Google Scholar] [CrossRef]

- Mon, D.-L.; Cheng, C.-H.; Lin, J.-C. Evaluating weapon system using fuzzy analytic hierarchy process based on entropy weight. Fuzzy Sets Syst. 1994, 62, 127–134. [Google Scholar] [CrossRef]

- Rioul, O. This is IT: A Primer on Shannon’s Entropy and Information. Inf. Theory 2011, 78, 49–86. [Google Scholar] [CrossRef]

- Nisar, U.B.; ur Rehman, W.; Saleem, S.; Taufail, K.; ur Rehman, F.; Farooq, M.; Ehsan, S.A. Assessment of water quality using entropy-weighted quality index, statistical methods and electrical resistivity tomography, Moti village, northern Pakistan. J. Contam. Hydrol. 2024, 264, 104368. [Google Scholar] [CrossRef] [PubMed]

- Hobbs, R.G.; Petkov, N.; Holmes, J.D. Semiconductor Nanowire Fabrication by Bottom-Up and Top-Down Paradigms. Chem. Mater. 2012, 24, 1975–1991. [Google Scholar] [CrossRef]

- The World Intellectual Property Organization. “PATENTSCOPE.” Patentscope. 2023. Available online: www.wipo.int/zh/web/patentscope (accessed on 12 February 2025).

- China Organizational Name Administration Center. China National Intellectual Property Administration. 2025. Available online: https://english.cnipa.gov.cn (accessed on 9 February 2025).

- PatSnap. Trusted by Top Innovators and IP Experts Worldwide. PatSnap. 2025. Available online: https://www.patsnap.com/ (accessed on 1 March 2025).

- Suganya, R.; Joseph, L.L.; Kollem, S. Understanding Lithium-Ion Battery Management Systems in Electric Vehicles: Environmental and Health Impacts, Comparative Study, and Future Trends: A Review. Results Eng. 2024, 24, 103047. [Google Scholar] [CrossRef]

- Dataintelo; Sharma, R. Electric Vehicle Battery Management System Market Research Report 2032. [Online] Dataintelo.com. 2019. Available online: https://dataintelo.com/report/electric-vehicle-battery-management-system-market?gad_source=1&gclid=EAIaIQobChMIp-i0w8ezjAMVu6RmAh2EnxRXEAAYAiAAEgIK7fD_BwE (accessed on 1 March 2025).

- Jacobsson, S.; Lindholm-Dahlstr, A.; Elg, L. Is the commercialization of European academic R&D weak?—A critical assessment of a dominant belief and associated policy responses. Res. Policy 2013, 42, 874–885. [Google Scholar] [CrossRef]

- Perry, C.; Shaw, S.; Thomson, E.; the Fastmarkets Team. Europe’s Battery Supply Chain at a Crossroads in Terms of Challenges, Opportunities. Fastmarkets. 2024. Available online: https://www.fastmarkets.com/insights/europe-battery-supply-chain-challenges-opportunities (accessed on 5 March 2025).

| Primary Indicator | Secondary Indicator |

|---|---|

| Technical Value | Patent citation frequency, patent citation count, number of IPC classifications, citation frequency within three years |

| Market Value | Patent family size, number of citations in patent families, patent license and transfer count |

| Economic Value | Patent valuation patent, growth rate of similar technologies in the past three years |

| Legal Value | Number of pages in the specification, number of Claims |

| Importance Scale | Meaning |

|---|---|

| 1:1 | Both elements are equally important |

| 3:1 | The former is slightly more important than the latter |

| 5:1 | The former is more important than the latter |

| 7:1 | The former is much more important than the latter |

| 9:1 | The former is extremely more important than the latter |

| 2, 4, 6, 8 | Intermediate values of the above judgments |

| Reciprocal of the value | The comparison of the latter to the former |

| rank of a matrix | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| RI | 0 | 0 | 0.58 | 0.89 | 1.12 | 1.24 | 1.36 | 1.41 |

| Indicator | Maximum | Minimum | Arithmetic Mean | Standard Deviation |

|---|---|---|---|---|

| Patent Citation Frequency | 118 | 0 | 4.947663551 | 11.08669738 |

| Patent citation count | 191 | 0 | 5.457943925 | 12.06123606 |

| Number of IPC Classifications | 15 | 0 | 4.347663551 | 2.872227398 |

| Citation Frequency within 3 Years | 50 | 0 | 2.994392523 | 5.88513381 |

| Patent Family Size | 20 | 1 | 2.712149533 | 3.087267263 |

| Number of Citations in Patent Families | 136 | 0 | 10.02990654 | 19.67581461 |

| Patent License and Transfer Count | 1 | 0 | 0.014953271 | 0.12147944 |

| Patent Valuation and Pricing | 2,780,000 | 3300 | 275,092.714 | 520,096.1766 |

| Patent Growth Rate of Similar Technologies in the Past Three Years | 40 | 12 | 31.61308411 | 4.110120061 |

| Number of Pages in the Specification | 102 | 4 | 16.74018692 | 13.4998187 |

| Number of Claims | 55 | 1 | 10.8953271 | 5.786484692 |

| Primary Indicators | Weight | Secondary Indicators | Weight | Combined Weight |

|---|---|---|---|---|

| Technical Value | 0.4117 | Patent citation frequency | 0.4768 | 0.1963 |

| Patent citation count | 0.174 | 0.0716 | ||

| Number of IPC classifications | 0.0795 | 0.0327 | ||

| Citation frequency within three years | 0.2696 | 0.1110 | ||

| Market Value | 0.3098 | Patent Family Size | 0.2493 | 0.0772 |

| Number of citations in patent families | 0.1571 | 0.0487 | ||

| Patent license and transfer count | 0.5939 | 0.1839 | ||

| Economic Value | 0.1800 | Patent Valuation and Pricing | 0.6667 | 0.1200 |

| Patent growth rate of similar technologies in the past three years | 0.3333 | 0.0600 | ||

| Legal Value | 0.0984 | Number of pages in the specification | 0.6667 | 0.0656 |

| Number of claims | 0.3333 | 0.0328 |

| Secondary Indicators | AHP | Entropy Weighting Method | Combined Weight |

|---|---|---|---|

| Patent Citation Frequency | 0.1963 | 0.1093 | 0.1528 |

| Patent Citation Count | 0.0716 | 0.0746 | 0.0731 |

| Number of IPC Classifications | 0.0327 | 0.0175 | 0.0251 |

| Citation Frequency within 3 Years | 0.111 | 0.1029 | 0.1070 |

| Patent Family Size | 0.0772 | 0.1090 | 0.0931 |

| Number of Citations in Patent Families | 0.0487 | 0.0904 | 0.0695 |

| Patent License and Transfer Count | 0.1839 | 0.3546 | 0.2693 |

| Patent Valuation and Pricing | 0.12 | 0.0965 | 0.1082 |

| Patent Growth Rate of Similar Technologies in the Past Three Years | 0.06 | 0.0020 | 0.0310 |

| Number of Pages in the Specification | 0.0656 | 0.0305 | 0.0481 |

| Number of Claims | 0.0328 | 0.0128 | 0.0228 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wan, D.; Peng, L.; Zhan, H. Patent Analysis of the Electric Vehicle Battery Management Systems Based on the AHP and Entropy Weight Method. World Electr. Veh. J. 2025, 16, 218. https://doi.org/10.3390/wevj16040218

Wan D, Peng L, Zhan H. Patent Analysis of the Electric Vehicle Battery Management Systems Based on the AHP and Entropy Weight Method. World Electric Vehicle Journal. 2025; 16(4):218. https://doi.org/10.3390/wevj16040218

Chicago/Turabian StyleWan, Dan, Ling Peng, and Hao Zhan. 2025. "Patent Analysis of the Electric Vehicle Battery Management Systems Based on the AHP and Entropy Weight Method" World Electric Vehicle Journal 16, no. 4: 218. https://doi.org/10.3390/wevj16040218

APA StyleWan, D., Peng, L., & Zhan, H. (2025). Patent Analysis of the Electric Vehicle Battery Management Systems Based on the AHP and Entropy Weight Method. World Electric Vehicle Journal, 16(4), 218. https://doi.org/10.3390/wevj16040218