Constructing the Embodied Carbon Flows and Emissions Landscape from the Perspective of Supply Chain

Abstract

:1. Introduction

2. Material and Methods

2.1. Data Source

2.2. Research Methods

2.2.1. Supply Chain and Its Multi-Level Division

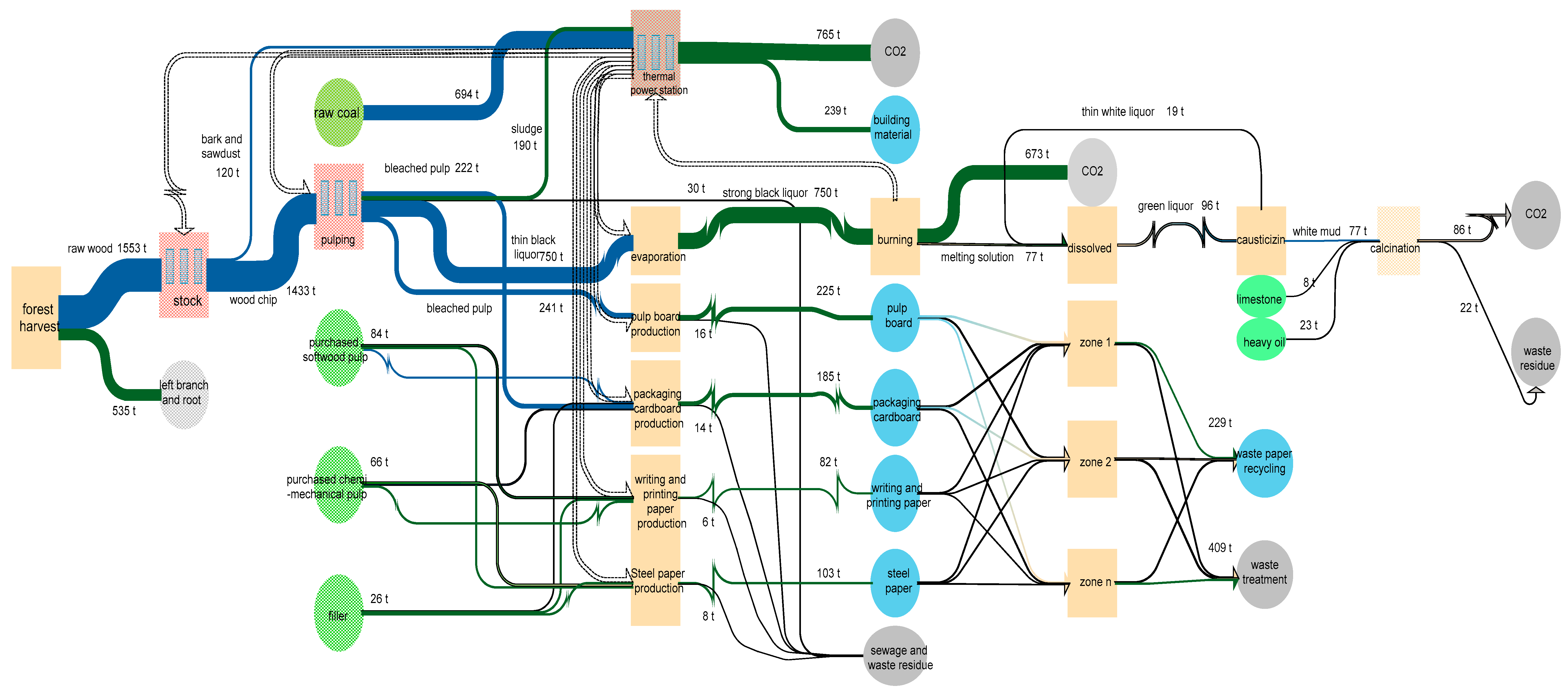

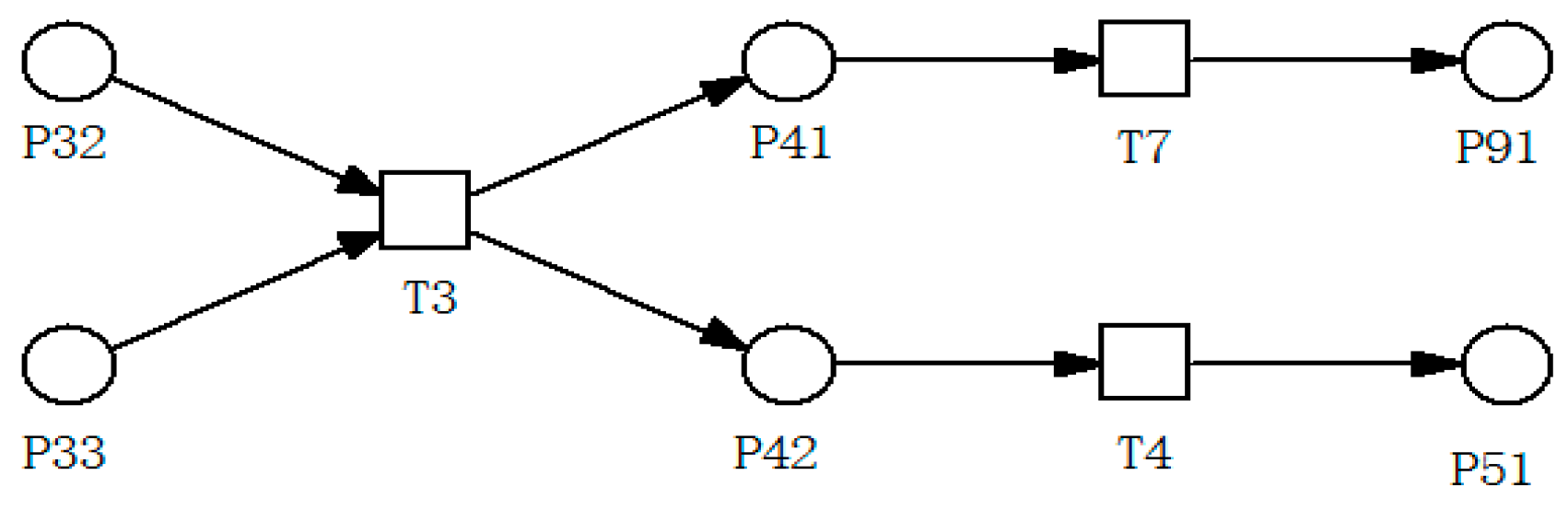

2.2.2. Multi-Level Modeling of Embodied Carbon Flows and Carbon Emissions

3. Results

4. Discussion

4.1. Processing of Complex Carbon Landscape Network

4.2. Looking for Hot-Spot Carbon Emission Sources and Hot-Spot Carbon Emissions Paths

4.3. Low-Carbon Development Path

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Paulraj, A. Environmental motivations: A classification scheme and its impact on environmental strategies and practices. Bus. Strategy Environ. 2009. [Google Scholar] [CrossRef]

- Acquaye, A.; Barrett, P.; Topi, C.; Glew, D.; Kuylenstierna, J.; Koh, SC.L.; Barrett, J.; McQueen-Masonet, S. Greening the Supply Chain: The Development of Supply Chain Carbon Maps. Int. J. Eng. Manag. Econ. 2012. [Google Scholar] [CrossRef]

- Geels, F.W.; Sovacool, B.K.; Schwanen, T.; Sorrell, S. Sociotechnical transitions for deep decarbonization. Science 2017. [Google Scholar] [CrossRef] [PubMed]

- Ambec, S.; Cohen, M.A.; Elgie, S.; Lanoie, P. The Porter Hypothesis at 20: Can Environmental Regulation Enhance Innovation and Competitiveness? Rev. Environ. Econ. Policy 2013. [Google Scholar] [CrossRef]

- Laroche, M.; Bergeron, J.; Barbaro-Forleo, G. Targeting consumers who are willing to pay more for environmentally friendly products. J. Consum. Mark. 2013. [Google Scholar] [CrossRef]

- Raghavendra, T.V.S.; Hema, K.; Omkar, A.M.B.; Manideep, B.; Sam Preetish, G.; Anudeep, K. Estimation of carbon footprint in a transport network of supply chain. Int. J. Appl. Eng. Res. 2015, 108, 19011–19032. [Google Scholar]

- Wilson, J.B. Life-cycle inventory of formaldehyde-based resins used in wood composites in terms of resources, emissions, energy and carbon. Wood Fiber Sci. J. Soc. Wood Sci. Technol. 2010, 423, 125–143. [Google Scholar]

- Wang, Q.; Zhao, D.; He, L. Contracting emission reduction for supply chains considering market low-carbon preference. J. Clean. Prod. 2016. [CrossRef]

- Das, C.; Jharkharia, S. Low carbon supply chain: A state-of-the-art literature review. J. Manuf. Technol. Manag. 2018. [Google Scholar] [CrossRef]

- Sarkis, J. A boundaries and flows perspective of green supply chain management. Supply Chain Manag. Int. J. 2012. [Google Scholar] [CrossRef]

- Elhedhli, S.; Merrick, R. Green supply chain network design to reduce carbon emissions. Transp. Res. Part D-Transp. Environ 2012. [Google Scholar] [CrossRef]

- Convery, F. The global carbon market-mechanism landscape: Pre and post 2020 perspectives. Clim. Policy 2015. [Google Scholar] [CrossRef]

- Glendell, M.; Brazier, R.E. Accelerated export of sediment and carbon from a landscape under intensive agriculture. Sci. Total Environ. 2014. [Google Scholar] [CrossRef] [PubMed]

- Koh, S.C.L.; Genovese, A.; Acquaye, A.A.; Barratt, P.; Rana, N.; Kuylenstierna, J.; Gibbs, D. Decarbonising product supply chains: design and development of an integrated evidenced-based Decision Support System. Int. J. Prod. Res. 2013. [Google Scholar] [CrossRef]

- Cruz, J.M.; Wakolbinger, T. Multiperiod effects of corporate social responsibility on supply chain networks, transaction costs, emissions, and risk. Int. J. Prod. Econ. 2008. [Google Scholar] [CrossRef]

- Liang, S.; Feng, Y.; Xu, M. Structure of the global virtual carbon network--Revealing important sectors and communities for emission reduction. J. Ind. Ecol. 2015. [Google Scholar] [CrossRef]

- Cheng, H.; Dong, S.C.; Li, F.J.; Yang, Y.; Li, S.T.; Li, Y. Multiregional input-output analysis of spatial-temporal evolution driving force for carbon emissions embodied in Interprovincial trade and optimization policies: Case study of northeast industrial district in China. Environ. Sci. Technol. 2018. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Sharma, C.; Mullick, S.C.; Kandpal, T.C. Carbon mitigation potential of solar industrial process heating: paper industry in India. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- D’Amato, D.; Wan, M.; Li, N.; Rekola, M.; Toppinen, A. Managerial views of corporate impacts and dependencies on ecosystem services: A case of international and domestic forestry companies in China. J. Bus. Eth. 2018. [CrossRef]

- Carlsson, D.; D’Amours, S.; Martel, A.; Rönnqvist, M. Supply chain management in the pulp and paper industry. Inf. Syst. Oper. Res. 2006. [Google Scholar] [CrossRef]

- Ramudhin, A.; Chaabane, A.; Paquet, M. Carbon market sensitive sustainable supply chain network design. Int. J. Manag. Sci. Eng. Manag. 2010. [Google Scholar] [CrossRef]

- Hearnshaw, E.J.S.; Wilson, M.M.J. A complex network approach to supply chain network theory. Int. J. Oper. Prod. Manag. 2013. [Google Scholar] [CrossRef]

- Ulanowicz, R.T.E. Identifying the structure of cycling in ecosystem. Math. Biosci. 1983. [Google Scholar] [CrossRef]

- Lenzen, M.; Crawford, R. The path exchange method for hybrid LCA. Environ. Sci. Technol. 2009. [Google Scholar] [CrossRef] [PubMed]

- Genovese, A.; Koh, S.C.L.; Acquaye, A.; Barrett, J. Benchmarking carbon emissions performance in supply chains. Supply Chain Manag. 2014. [Google Scholar] [CrossRef]

- Skelton, A.; Guan, D.; Peters, G.P.; Crawford-Brown, D. Mapping Flows of Embodied Emissions in the Global Production System. Environ. Sci. Technol. 2011. [Google Scholar] [CrossRef] [PubMed]

- Bringezu, S.; Schütz, H.; Moll, S. Rationale for and Interpretation of Economy—Wide Materials Flow Analysis and Derived Indicators. J. Ind. Ecol. 2010. [Google Scholar] [CrossRef]

- Kang, C.Q.; Zhou, T.R.; Chen, Q.; Wang, J.H.; Sun, Y.L.; Xia, Q.; Yan, H.G. Carbon emission flow from generation to demand: A network-based model. IEEE Trans. Smart Grid 2017. [Google Scholar] [CrossRef]

- Atkinson, G.; Hamilton, K.; Ruta, G.; Mensbrugghe, D.V.D. Trade In ‘Virtual Carbon’: Empirical results and implications for policy. Glob. Environ. Chang. Hum. Policy Dimens. 2010. [Google Scholar] [CrossRef]

- Liu, X.; Klemeš, J.J.; Varbanov, P.S.; Čuček, L.; Qian, Y. Virtual carbon and water flows embodied in international trade: Areview on consumption-based analysis. J. Clean. Prod. 2017. [Google Scholar] [CrossRef]

- Heymans, J.J.; Baird, D. A carbon flow model and network analysis of the northern Benguela upwelling system, Namibia. Ecol. Model. 2000. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, B.; Feng, K.; Hubacek, K. Ecological network analysis for carbon metabolism of eco-industrial parks: A case study of a typical eco-industrial park in Beijing. Environ. Sci. Technol. 2015. [Google Scholar] [CrossRef] [PubMed]

- Odum, E.P. The strategy of ecosystem development. Science 1969. [Google Scholar] [CrossRef]

- Kuo, T.C.; Chen, Y.H.G.; Wang, M.L.; Ho, W.M. Carbon footprint inventory route planning and selection of hot spot suppliers. Int. J. Prod. Econ. 2014. [Google Scholar] [CrossRef]

- He, Y.J.; Zhang, Y.; Ma, Z.F.; Sahinidis, N.V.; Tan, R.R.; Foo, D.C.Y. Optimal source–sink matching in carbon capture and storage systems under uncertainty. Ind. Eng. Chem. Res. 2014. [Google Scholar] [CrossRef]

- Wesseling, J.H.; Lechtenböhmer, S.; Åhman, M.; Nilsson, L.J.; Worrell, E.; Coenen, L. The transition of energy intensive processing industries towards deep decarbonization: Characteristics and implications for future research. Renew. Sustain. Energy Rev. 2017, 79. [Google Scholar] [CrossRef]

- Mcdowall, W.; Rodriguez, B.S.; Usubiaga, A.; Fernández, J.A. Is the optimal decarbonization pathway influenced by indirect emissions? Incorporating indirect life-cycle carbon dioxide emissions into a European TIMES model. J. Clean. Prod. 2017. [Google Scholar] [CrossRef]

- Feng, W.; Ji, G.; Pardalos, P.M. Effects of government regulations on Manufacturer’s behaviors under carbon emission reduction. Environ. Sci. Pollut. Res. 2017. [Google Scholar] [CrossRef] [PubMed]

- Chao, O.Y.; Chen, H.W.; Ho, C.H.; Chou, J.C.; Yuan, Y.T.; Ho, C.L.; Hsueh, H.T.; Chen, S.T.; Liao, P.C.; Chao, L.K.P. Value chain analysis of algal bioenergy and carbon capture integrated with a biotechnology innovation. J. Clean. Prod. 2018. [Google Scholar] [CrossRef]

- Bi, K.; Huang, P.; Ye, H. Risk identification, evaluation and response of low-carbon technological innovation under the global value chain: A case of the Chinese manufacturing industry. Technol. Forecast. Soc. Chang. 2015. [Google Scholar] [CrossRef]

| Level | Output |

|---|---|

| Models | Direct Carbon Emissions for Product Output | Embodied Carbon Flows | Total Emissions for Product Output |

|---|---|---|---|

| Innovation Type | Technology Type | Technology Measures | TRL | Carbon Emission Reduction Potential | Main Obstacles | |

|---|---|---|---|---|---|---|

| Internal operations innovation | Energy efficiency innovation | Increasing energy efficiency | Reduce energy consumption of heat pump | all | 0~33% | Technology innovation and cost input |

| Cogeneration | all | 0~33% | Cost input | |||

| Adopt CCS | Integrate carbon capture facilities into process design | Up to 6 | 33~66% | Facility input & extra energy demand | ||

| Operations innovation | New production process | New separation and drying process | all | 33~66% | Facility input & cost input | |

| New alkali recovery process | all | 33~66% | Facility input and cost input | |||

| Development and utilization of new products | Low quantitative paper product design and production | Up to 6 | 33~66% | Technology research and development, facility input, cost input | ||

| Efficient recycling of waste paper | all | 33~66% | Facility input and cost input | |||

| Supply Chain innovation | Cooperation innovation | Forestry-pulp and paper integration | Raw material plantations construction | all | 0~33% | Land property, land leasing, source of international capital |

| Introduction of new species of tree | all | 0~33% | Technology research and development, cost input | |||

| Materials and technology innovation | Biomass refining research and development | Biochemical raw materials | 4–6 | more than 66% | New materials and technology research and development | |

| New paper-based materials and filler development | 4–6 | more than 66% | New materials and technology research and development | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Wen, Z.; Toppinen, A. Constructing the Embodied Carbon Flows and Emissions Landscape from the Perspective of Supply Chain. Sustainability 2018, 10, 3865. https://doi.org/10.3390/su10113865

Zhao Q, Wen Z, Toppinen A. Constructing the Embodied Carbon Flows and Emissions Landscape from the Perspective of Supply Chain. Sustainability. 2018; 10(11):3865. https://doi.org/10.3390/su10113865

Chicago/Turabian StyleZhao, Qingjian, Zuomin Wen, and Anne Toppinen. 2018. "Constructing the Embodied Carbon Flows and Emissions Landscape from the Perspective of Supply Chain" Sustainability 10, no. 11: 3865. https://doi.org/10.3390/su10113865