Sustainable Innovation Approach for Wood Quality Evaluation in Green Business

Abstract

1. Introduction

2. Materials and Methods

2.1. Reference Building with Disposition Characteristics

2.2. Quality Evaluation of Spruce Sawlogs

- Creating and processing a digital image perpendicularly to the log-end area axis with the quality mark and measuring the log-end area diameter manually;

- Image processing in the software and determining the scale (scale is the log-end area diameter in centimeters);

- Bordering the log-end area in the software;

- Bordering the area of the quality mark in the software;

- Calculating the log-end area of the quality mark.

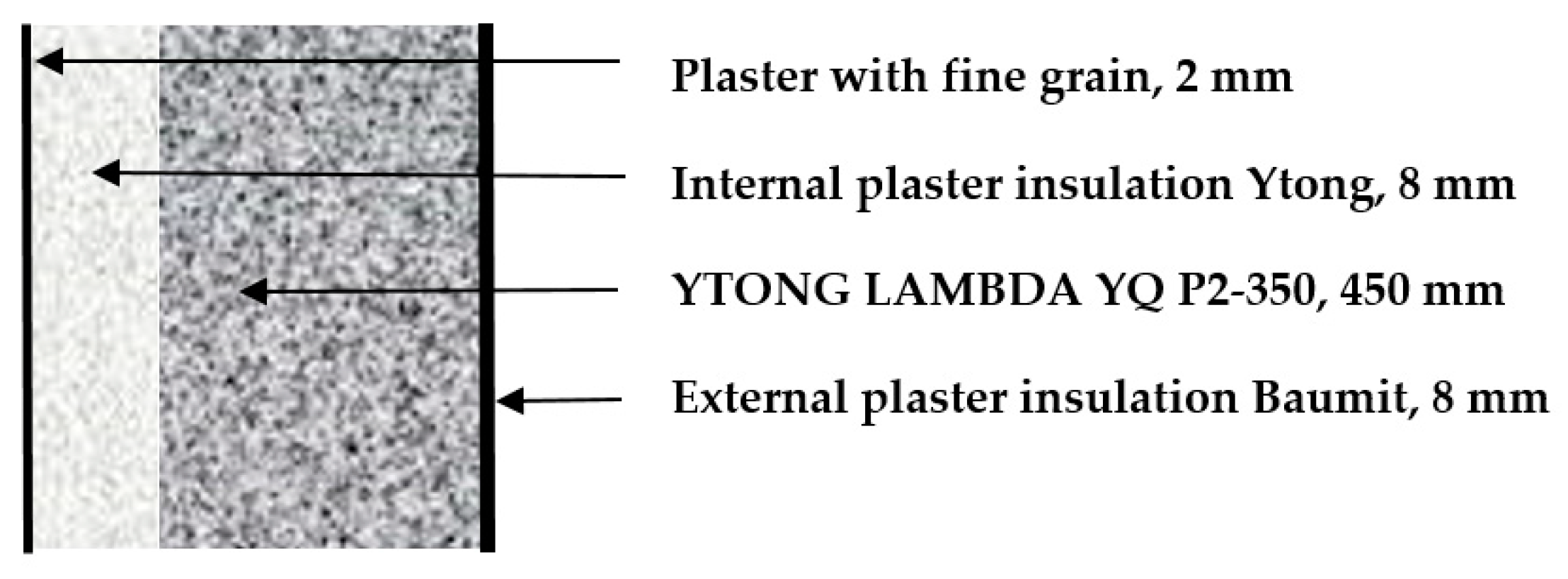

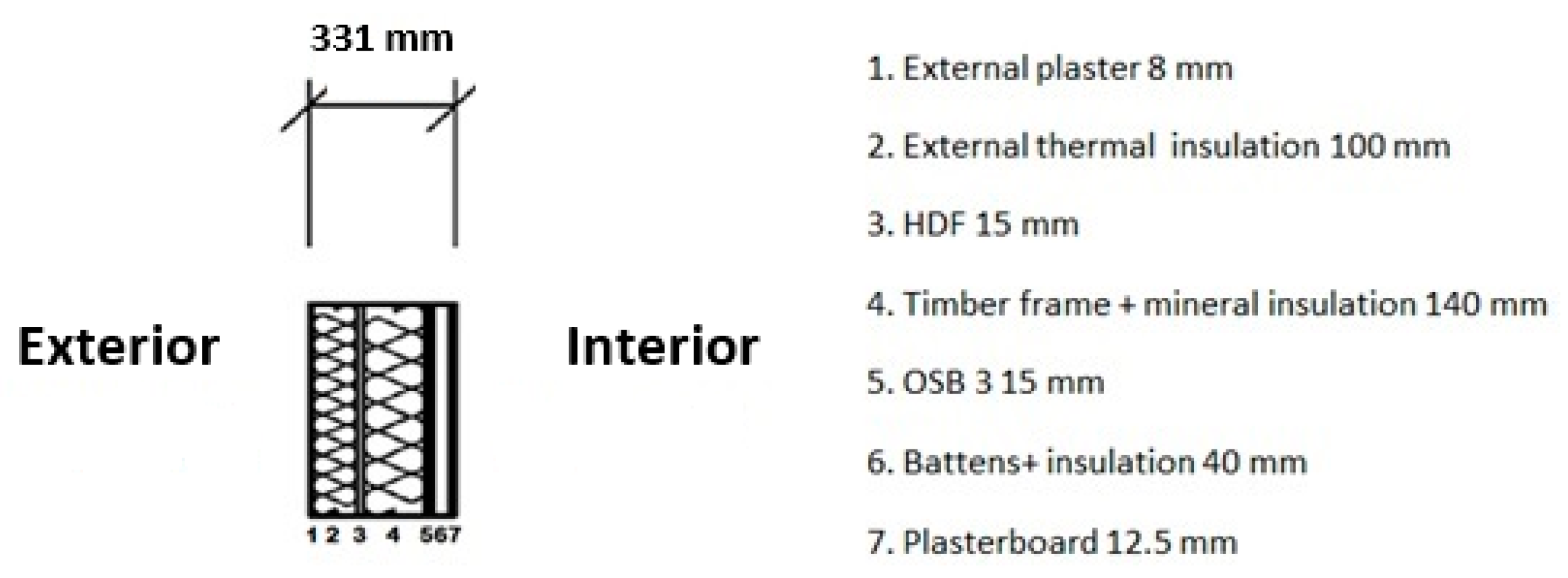

2.3. Structure of Perimeter Wall for LCA

- Primary energy input for production (PEI): This is a quantity in MJ including the amount of primary energy consumed in the given material. It is the energy spent in obtaining the raw material, production, and material transport;

- Emission CO2 ekv. (global warming potential; GWP): This figure covers emissions contributing to the greenhouse effect. Carbon dioxide was used as an equivalent due to its largest amount. The number of kilograms of CO2 released during the material production was monitored;

- Emission SO2 ekv. (acidification potential; AP): Sulfur dioxide was used as an equivalent; however, this figure also covers other gases contributing to acidification, mainly nitrogen oxides and ammonia. This figure provides information on the extent of damage to water, forest, and soil ecosystems, as well as to buildings caused by acid rain;

- Ozone depletion potential (ODP): Ozone layer depletion;

- Photochemical ozone creation potential (POCP): Creation of ground-level ozone as summer smog;

- Eutrophication potential (EP): Water, ground water, and soils.

3. Empirical Results

Results of the Qualitative Assessment of Spruce Sawlogs

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Marasová, J. Vnútorná A Vonkajšia Dimenzia Sociálnej Funkcie V Podniku; Matej Bel University: Banská Bystrica, Slovakia, 2008. (In Slovak) [Google Scholar]

- Bowen, H. Social Responsibilities of the Businessman; Harper: New York, NY, USA, 1953. [Google Scholar]

- Moura-Leite, R.; Padgett, R. Historical background of corporate social responsibility. Soc. Responsib. J. 2011, 7, 528–539. [Google Scholar] [CrossRef]

- Coombs, T.; Holladay, S. Managing Corporate Social Responsibility: A Communication Approach; Wiley-Blackwell: Oxford, UK, 2012. [Google Scholar]

- Wertjer, W.; Chandler, D. Strategic Corporate Social Responsibility: Stakeholders in a Global Environment; SAGE Publications: Thousand Oaks, CA, USA, 2010. [Google Scholar]

- Prskavcová, M.; Maršíková, K.; Řehořová, P.; Zbránková, P. Normy Z Oblasti Spoločenské Odpovědnosti Firem; Technická univerzita v Liberci: Liberec, Czech Republic, 2008. (In Czech) [Google Scholar]

- Kuldová, L. Spoločenská Odpovědnost Firem; OPS: Plzeň, Czech Republic, 2010. (In Czech) [Google Scholar]

- Kunz, V. Společenská Odpovědnost Firem; Grada Publishing: Prague, Czech Republic, 2012. (In Czech) [Google Scholar]

- Hroncová Vicianová, J. Uplatňovanie Koncepcie Spoločensky Zodpovedného Podnikania Vo Vybraných Ovetviach Národného Hospodárstva Na Slovensku; Matej Bel University: Banská Bystrica, Slovakia, 2014. (In Slovak) [Google Scholar]

- Karkkainen, L.; Kurttila, M.; Salminen, O.; Viiri, H. Effects of energy wood harvesting on timber production potential and biological diversity in North Karelia, Finland. For. Sci. 2014, 60, 1077–1088. [Google Scholar] [CrossRef]

- Verkaik, E.; Nabuurs, G.J. Wood production potentials of Fenno-Scandinavian forests under nature-orientated management. Scand. J. For. Res. 2000, 15, 445–454. [Google Scholar] [CrossRef]

- Roessiger, J.; Kulla, L.; Sedliak, M.; Kovalcik, M.; Barka, I.; Fabrika, M. Compensation payments for alternative forest management supporting nature conservation—a case study based on SIBYLA tree growth simulator and silvicultural cost model. Austrian J. For. Sci. 2017, 134, 174–204. [Google Scholar]

- Larsen, J.B.; Nielsen, A.B. Nature-based forest management—Where are we going? Elaborating forest development types in and with practice. For. Ecol. Manag. 2007, 238, 107–117. [Google Scholar] [CrossRef]

- Nabuurs, G.J.; Paivinen, R.; Schelhaas, M.J.; Pussinen, A.; Verkaik, E.; Lioubimow, A.; Mohren, F. Nature-oriented forest management in Europe—Modeling the long-term effects. J. For. 2001, 99, 28–33. [Google Scholar]

- Klopp, W.S.; Fredeen, A.L. Harvesting the dead and decaying forests: Potential carbon storage in harvested wood products. For. Chron. 2014, 90, 614–619. [Google Scholar] [CrossRef]

- Yan, Y. Integrate carbon dynamic models in analyzing carbon sequestration impact of forest biomass harvest. Sci. Total. Environ. 2018, 615, 581–587. [Google Scholar] [CrossRef] [PubMed]

- De Vries, W.; Posch, M.; Simpson, D.; Reinds, G.J. Modelling long-term impacts of changes in climate, nitrogen deposition and ozone exposure on carbon sequestration of European forest ecosystems. Sci. Total Environ. 2017, 605, 1097–1116. [Google Scholar] [CrossRef] [PubMed]

- Geng, A.X.; Yang, H.Q.; Chen, J.X.; Hong, Y.X. Review of carbon storage function of harvested wood products and the potential of wood substitution in greenhouse gas mitigation. For. Policy Econ. 2017, 85, 192–200. [Google Scholar] [CrossRef]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Modeling the carbon footprint of wood-based products and buildings. In Carbon Footprint Handbook; Muthu, S.S., Ed.; Crc Press-Taylor & Francis Group: Boca Raton, FL, USA, 2016. [Google Scholar]

- Abuzeinab, A.; Arif, M.; Qadri, M.A.; Kulonda, D. Green business models in the construction sector: An analysis of outcomes and benefits. Constr. Innov. Engl. 2018, 18, 20–42. [Google Scholar] [CrossRef]

- Meijaard, E.; Sheil, D. The dilemma of green business in tropical forests: How to protect what it cannot identify. Conserv. Lett. 2012, 5, 342–348. [Google Scholar] [CrossRef]

- Potkány, M.; Hitka, M.; Krajcirova, L. Life cycle cost calculation at the transport company in the supply of production of wooden houses—Case study. In Proceedings of the 18th International Scientific Conference-Logi 2017, České Budějovice, Czech Republic, 19 October 2017. [Google Scholar]

- Vilcekova, S.; Culakova, M.; Burdova, E.K.; Katunska, J. Energy and environmental evaluation of non-transparent constructions of building envelope for wooden houses. Energies 2015, 8, 11047–11075. [Google Scholar] [CrossRef]

- Gejdoš, M.; Potkány, M. The potential of beech wood use in selected countries of the Central Europe for valuable processing purposes. In Proceedings of the 10th Annual International Scientific Conference on More Wood, Better Management, Increasing Effectiveness: Setting Points and Perspectives, Prague, Czech Republic, 24–26 May 2017. [Google Scholar]

- Ebner, M.; Petutschnigg, A.J. Potentials of thermally modified beech (Fagus sylvatica) wood for application in toy construction and design. Mater. Des. 2007, 28, 1753–1759. [Google Scholar] [CrossRef]

- Gejdoš, M.; Suchomel, J.; Potkány, M. Software “Image J” Application in evaluating the quality of extracted raw wood assortments. Drv. Ind. 2014, 65, 105–113. [Google Scholar] [CrossRef]

- Gejdoš, M.; Teischinger, A.; Suchomel, J. Comparison of round wood sorting according to European standards and the national grading rules in Slovakia and Austria. In Proceedings of the Wood Structure and Properties ’06, Zvolen, Slovakia, 3–6 September 2006. [Google Scholar]

- Halaj, D.; Sedliačiková, M.; Malá, D. Customer behavior on the Slovakian roundwood market: A case study. BioResources 2018, 13, 6003–6020. [Google Scholar] [CrossRef]

- Wu, X.; Peng, B.; Lin, B. A dynamic life cycle carbon emission assessment on green and non-green buildings in China. Energy Build. 2017, 149, 272–281. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montanes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Weiler, V.; Harter, H.; Eicker, U. Life cycle assessment of buildings and city quarters comparing demolition and reconstruction with refurbishment. Energy Build. 2017, 134, 319–328. [Google Scholar] [CrossRef]

- Su, S.; Li, X.; Zhu, Y. Dynamic LCA framework for environmental impact assessment of buildings. Energy Build. 2017, 149, 310–320. [Google Scholar] [CrossRef]

- The International Organization for Standardization (ISO). ISO 14040 Environmental Management. Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- The International Organization for Standardization (ISO). ISO 14044 Environmental Management. Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Debnár, M.; Potkány, M. Potential of wooden houses on the Slovak market. In Microeconomics and Management: Current Problems; Croatian quality Managers Society: Zagreb, Croatia, 2016. [Google Scholar]

- British Standards Institution. EN 1310 Round and Sawn Timber. Method of Measurement of Features; BSI: London, UK, 1997. [Google Scholar]

- British Standards Institution. EN 1311 Round and Sawn Timber. Method of Measurement of Biological Degrade; BSI: London, UK, 1997. [Google Scholar]

- Slovak Office of Standards, Metrology and Testing. STN 48 0055 Qualitative Classification of Softwood Round Timber; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2007. [Google Scholar]

- Phonetip, K.; Ozarska, B.; Brodie, G.I. Comparing two internal check measurement methods for wood drying quality assessment. Eur. J. Wood Wood Prod. 2017, 75, 139–142. [Google Scholar] [CrossRef]

- Gurau, L.; Timar, M.C.; Porojan, M.; Ioras, F. Image processing method as a supporting tool for wood species identification. Wood Fiber Sci. 2013, 45, 303–313. [Google Scholar]

- Forest Market Information System. Available online: http://www.forestportal.sk/lesne-hospodarstvo/informacie-o-lesoch/trhove-spravodajstvo/Pages/informacne-listy-ltis.aspx (accessed on 25 June 2018).

- Building Testing and Research Institute. Slovak Republic—STN 73054-2:2012 Thermal Protection of Buildings. Thermal Performance of Buildings and Components. Part 2: Functional Requirements; Building Testing and Research Institute: Bratislava, Slovakia, 2012. [Google Scholar]

- The International Organization for Standardization (ISO). ISO 14025 Environmental Labels and Declarations. Type III Environmental Declarations. Principles and Procedures; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Hajdúchová, I.; Sedliačiková, M.; Halaj, D.; Krištofík, P.; Musa, H.; Viszlai, I. The Slovakian forest-based sector in the context of globalization. BioResources 2016, 11, 4808–4820. [Google Scholar] [CrossRef]

- Halaj, D.; Brodrechtová, Y. Use of marketing tools lathe Slovakian forest biomass trade. Croat. J. For. Eng. 2014, 35, 35–44. [Google Scholar]

- Zelený, J. Environmentálna Politika A Manažérstvo Organizácií. Diel Šiesty. Environmentálna Politika, Manažérstvo A Stakeholder Manažment; Matej Bel University: Banska Bystrica, Slovakia, 2010. (In Slovak) [Google Scholar]

- Dubcová, G. Nové Trendy Zodpovedného Podnikania Na Slovensku; Ekonóm: Bratislava, Slovakia, 2013. (In Slovak) [Google Scholar]

- Pavlík, M.; Bělčík, M.; Srpová, J.; Kunz, V.; Kužel, S. Spoločenská Odpovědnost Organizace: CSR V Praxi A Jak S Ním Dál; Grada Publishing: Prague, Czech Republic, 2010. (In Slovak) [Google Scholar]

- Bussard, A.; Marček, E.; Markuš, M.; Bunčák, M. Spoločensky Zodpovedné Podnikanie; Nadácia Integra: Bratislava, Slovakia, 2005. (In Slovak) [Google Scholar]

- Fernández-Guadaño, J.; Sarria-Pedroza, J.H. Impact of corporate social responsibility on value creation from a stakeholder perspective. Sustainability 2018, 10, 2062. [Google Scholar] [CrossRef]

- Choi, J.H.; Kim, S.; Dong-Hoon, Y. Small and medium enterprises and the relation between social performance and financial performance: Empirical evidence from Korea. Sustainability 2018, 10, 1816. [Google Scholar] [CrossRef]

- Charlo, M.J.; Moya, I.; Muñoz, A.M. Financial performance of socially responsible firms: The short- and long-term impact. Sustainability 2017, 9, 1622. [Google Scholar] [CrossRef]

- Yu, J.; Lee, S. The impact of greenhouse gas emissions on corporate social responsibility in Korea. Sustainability 2017, 9, 1135. [Google Scholar] [CrossRef]

- Lorincová, S.; Hitka, M.; Čambál, M.; Szabo, P.; Javorčíková, J. Motivational factors influencing senior managers in the forestry and wood-processing sector in Slovakia. BioResources 2016, 11, 10339–10348. [Google Scholar] [CrossRef]

- Lee, K.; Kim, J. Current status of CSR in the realm of supply management: The case of the Korean electronics industry. Supply Chain Manag. 2009, 14, 138–148. [Google Scholar] [CrossRef]

- Giunipero, L.; Hooker, R.; Denslow, D. Purchasing and supply management sustainability: Drivers and barriers. J. Purch. Supply Manag. 2012, 18, 258–269. [Google Scholar] [CrossRef]

- Epstein, M.; Roy, M. Making the business case for sustainability. J. Corp. Citizsh. 2003, 9, 79–96. [Google Scholar] [CrossRef]

- Ruf, B.; Muralidhar, K.; Brown, R.; Janney, J.; Paul, K. An empirical investigation of the relationship between change in corporate social performance and financial performance: A stakeholder theory perspective. J. Bus. Ethics 2001, 32, 143–156. [Google Scholar] [CrossRef]

- McWilliams, A.; Siegel, D. Corporate social responsibility: A theory of the firm perspective. Acad. Manag. Rev. 2001, 26, 117–127. [Google Scholar] [CrossRef]

- Barnea, A.; Rubin, A. Corporate social responsibility as a conflict between shareholders. J. Bus. Ethics 2010, 97, 71–86. [Google Scholar] [CrossRef]

- Lundgren, T. A microeconomic model of corporate social responsibility. Metroeconomica 2011, 62, 69–95. [Google Scholar] [CrossRef]

- Porter, M.; Kramer, M. The link between competitive advantage and corporate social responsibility. Harv. Bus. Rev. 2006, 87, 78–92. [Google Scholar]

- Balasbaneh, A.T.; Marsono, A.B. Life cycle assessment of brick and timber house and effects on climate change in Malaysia. J. Basic Appl. Sci. Res. 2013, 3, 305–310. [Google Scholar]

- Sathre, R.; Gonzales-Garcia, S. Life cycle assessment (LCA) of wood-based building materials. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; PachecoTorgal, F., Cabeza, L.F., Labrincha, J., DeMagalhaes, A., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 311–337. [Google Scholar]

- Coelho, A.C.; Branco, J.M.; Gervásio, H. Life-cycle assessment of a single-family timber house. In Proceedings of the 1st International Conference on Building Sustainability Assessment, Porto, Portugal, 23–25 May 2012. [Google Scholar]

- Ližbetinová, L.; Lorincová, S.; Caha, Z. The application of the organizational culture assessment instrument (OCAI) to logistics enterprises. Nase More 2016, 63, 170–176. [Google Scholar] [CrossRef]

| 1st Alternative Timber Structure | 2nd Alternative Brick House | |

|---|---|---|

| Base plate area (m2) | 92 (11.5 × 8) | 92 (11.5 × 8) |

| Usable floor area (m2) | 157 | 147 |

| Perimeter wall area | 148.27 | 148.27 |

| Household size (no. of people) | 4–5 | 4–5 |

| Number of bedrooms | 4 | 4 |

| Number of floors | 2 | 2 |

| Construction type | Timber frame construction | Ytong |

| Type of roof | saddle roof | saddle roof |

| Type of windows | plastic windows | plastic windows |

| Heat transfer coefficient for perimeter wall (U; W/m2K) | 0.15 | 0.18 |

| Construction Parts of House | Unit (m3) | ∑ (m3) | |

|---|---|---|---|

| 1st floor | Perimeter wall | 2.97 | 11.44 |

| Internal battens | 0.85 | ||

| Bearing wall | 1.48 | ||

| Other walls | 0.48 | ||

| Ceiling 1st floor | 5.66 | ||

| 2nd floor | Perimeter wall | 2.01 | 4.12 |

| Internal battens | 0.77 | ||

| Bearing wall | 1.18 | ||

| Other walls | 0.41 | ||

| Construction of roof | - | - | - |

| Total | 15.56 | ||

| Quality Mark | III.A | III.B | III.C |

|---|---|---|---|

| Tension/compression wood | Not allowed | Up to 30% | Allowed without restrictions |

| Rot | Not allowed | Not allowed | Dote up to 2/3 area of the end diameter |

| Stain | Not allowed | Up to 1/3 area of the end diameter | Allowed without restrictions |

| Quality Class/No. of Logs | Price 1 in €·m–3 | Number of Logs According to EN 1310, 1311 | Total Price in €·m−3 According to EN 1310, 1311 | Number of Logs According to ImageJ | Total Price in €·m−3 According to ImageJ |

|---|---|---|---|---|---|

| II. | 115.51 | 19 | 2194.69 | 25 | 2887.75 |

| III.A | 80.57 | 11 | 886.27 | 11 | 886.27 |

| III.B | 85.06 | 10 | 850.6 | 8 | 680.48 |

| III.C | 56.44 | 20 | 1128.8 | 18 | 1015.92 |

| IV. | 48.62 | 7 | 340.34 | 9 | 437.58 |

| V. | 29.28 | 23 | 673.44 | 24 | 702.72 |

| VI. | 21.98 | 10 | 219.8 | 5 | 109.9 |

| Total | 100 | 6293.94 | 100 | 6720.62 |

| Material | t (mm) | Density (kg·m–3) | GWP (kg CO2 eq. m–3) | PEI (MJ/m–3) | AP (g SO2 eq./m–3) | EP (g (PO4)3− eq. m–3) | ODP (g R-11 eq. m–3) | POCP (g C2H4 eq. m–3) | |

|---|---|---|---|---|---|---|---|---|---|

| 1. | Interior stopper with gypsum | 2 | 1000 | 0.0738 | 1.39 | 0.20 | 0.033 | 1.1286 × 10−5 | 0.009 |

| 2. | Interior plaster with gypsum | 8 | 1800 | 0.081 | 1.537 | 0.227 | 0.051 | 1.1 × 10−5 | 0.011 |

| 3. | Ytong LAMBDA YQ P2-350 | 450 | 600 | 0.225 | 2.257 | 0.308 | 0.135 | 5.18 × 10−6 | 0.014 |

| 4. | Baumit GranoporTop acrylate plast | 8 | 0.0018 | 0.7699 | 8.249 | 1.561 | 0.324 | 2.6362 × 10−5 | 0.361 |

| Material | t (mm) | Density (kg·m−3) | GWP (kg CO2 eq./kg) | PEI (MJ/kg) | AP (g SO2 eq./kg) | EP (g (PO4)3− eq./kg) | ODP (g R-11 eq./kg) | POCP (g C2H4 eq./kg) | |

|---|---|---|---|---|---|---|---|---|---|

| 1. | Plasterboard—gypsum | 12.5 | 1000 | 0.35429 | 5.74453 | 1.0976 | 0.498 | 2.56 × 10−5 | 0.046724 |

| 2. | Rockwool insulation | 40 | 32 | 1.1331 | 20.1923 | 8.3583 | 1.83 | 5.536 × 10−5 | 0.44541 |

| 3. | OSB3 | 15 | 650 | 0.481323 | 12.5057 | 2.0370 | 0.917 | 2.46 × 10−5 | 0.295185 |

| 4. | Timber frame construction | 140 | 420 | −779.00 | 97.2 | 0.118 | 0.0273 | 3.05 × 10−10 | - |

| 5. | Rockwool insulation | 140 | 32 | 1.1331 | 20.1923 | 8.3583 | 1.83 | 5.53 × 10−5 | 0.44541 |

| 6. | HDF, 15 mm | 15 | 900 | 0.650422 | 12.723 | 1.7652 | 1.366 | 6.35 × 10−5 | 0.1187 |

| 7. | Thermal insulation | 100 | 32 | 1.1331 | 20.1923 | 8.3583 | 1.83 | 5.53 × 10−5 | 0.44541 |

| 8. | Baumit | 8 | 0.0018 | 0.76995 | 8.24952 | 1.5612 | 0.324 | 2.63 × 10−5 | 0.36145 |

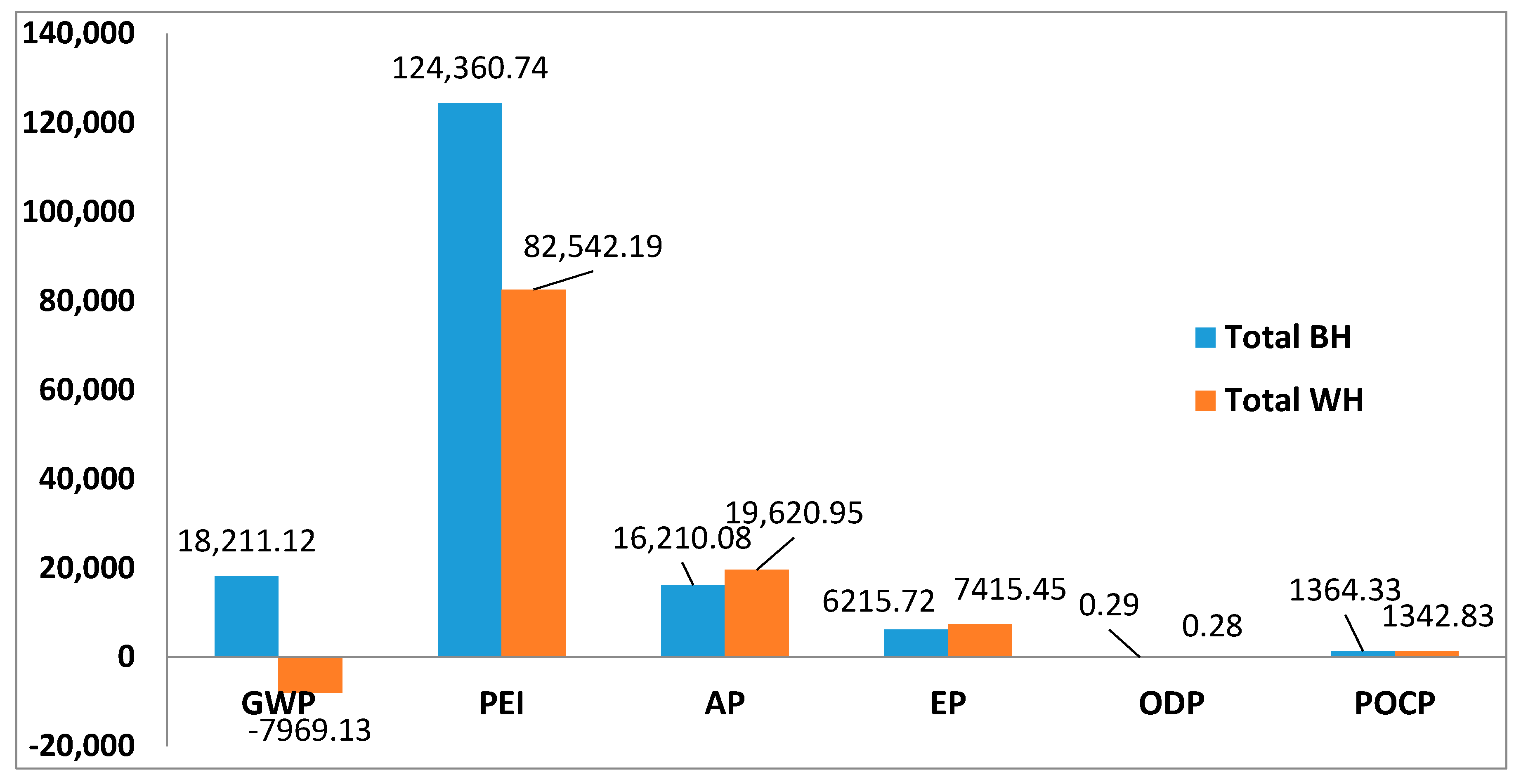

| Criteria/Envimat | Perimeter Wall of Timber Frame House | Perimeter Wall of Brick House—Ytong | Unit |

|---|---|---|---|

| Primary energy input for production (PEI) | 556.6268 | 838.632 | MJ·m−2 |

| Global warming potential (GWP) | –53.7401917 | 122.8075 | kg CO2 eq. m−2 |

| Acidification potential (AP) | 132.3148 | 109.3134 | g SO2 eq. m−2 |

| Eutrophication potential (EP) | 50.00642 | 41.916 | g (PO4)3− eq. m−2 |

| Ozone depletion potential (ODP) | 0.001914603 | 0.001959185 | g R-11 eq. m−2 |

| Photochemical ozone creation potential (POCP) | 9.055433 | 9.200427 | g C2 H4 eq. m−2 |

| Density (⍴) | 199.892 | 664.762 | kg·m−3 |

| Basic weight | 64.06 | 279.20 | kg·m−2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Potkány, M.; Gejdoš, M.; Debnár, M. Sustainable Innovation Approach for Wood Quality Evaluation in Green Business. Sustainability 2018, 10, 2984. https://doi.org/10.3390/su10092984

Potkány M, Gejdoš M, Debnár M. Sustainable Innovation Approach for Wood Quality Evaluation in Green Business. Sustainability. 2018; 10(9):2984. https://doi.org/10.3390/su10092984

Chicago/Turabian StylePotkány, Marek, Miloš Gejdoš, and Marek Debnár. 2018. "Sustainable Innovation Approach for Wood Quality Evaluation in Green Business" Sustainability 10, no. 9: 2984. https://doi.org/10.3390/su10092984

APA StylePotkány, M., Gejdoš, M., & Debnár, M. (2018). Sustainable Innovation Approach for Wood Quality Evaluation in Green Business. Sustainability, 10(9), 2984. https://doi.org/10.3390/su10092984