The Passivhaus Standard in the Spanish Mediterranean: Evaluation of a House’s Thermal Behaviour of Enclosures and Airtightness

Abstract

:1. Introduction

1.1. The Passivhaus Standard

- Annual heating demand must not exceed 15 kWh/m2;

- Annual demand for primary energy for heating, electricity and DHW must be less than or equal to 120 Kwh/m2;

- The volume of filtered air should not be greater than 0.6 air changes per hour (ACH), measured with a pressure of 50 Pa, as verified by an on-site test using the Blower Door test.

- 4.

- Annual cooling demand must not exceed 15 kWh/m2;

- 5.

- Thermal comfort must be achieved in all rooms of the house throughout the year. Therefore, the regulation allows 10% of indoor air temperature overheating, representing 10% of the total hours of a complete one-year cycle above 25 °C.

1.2. Aims and Objectives

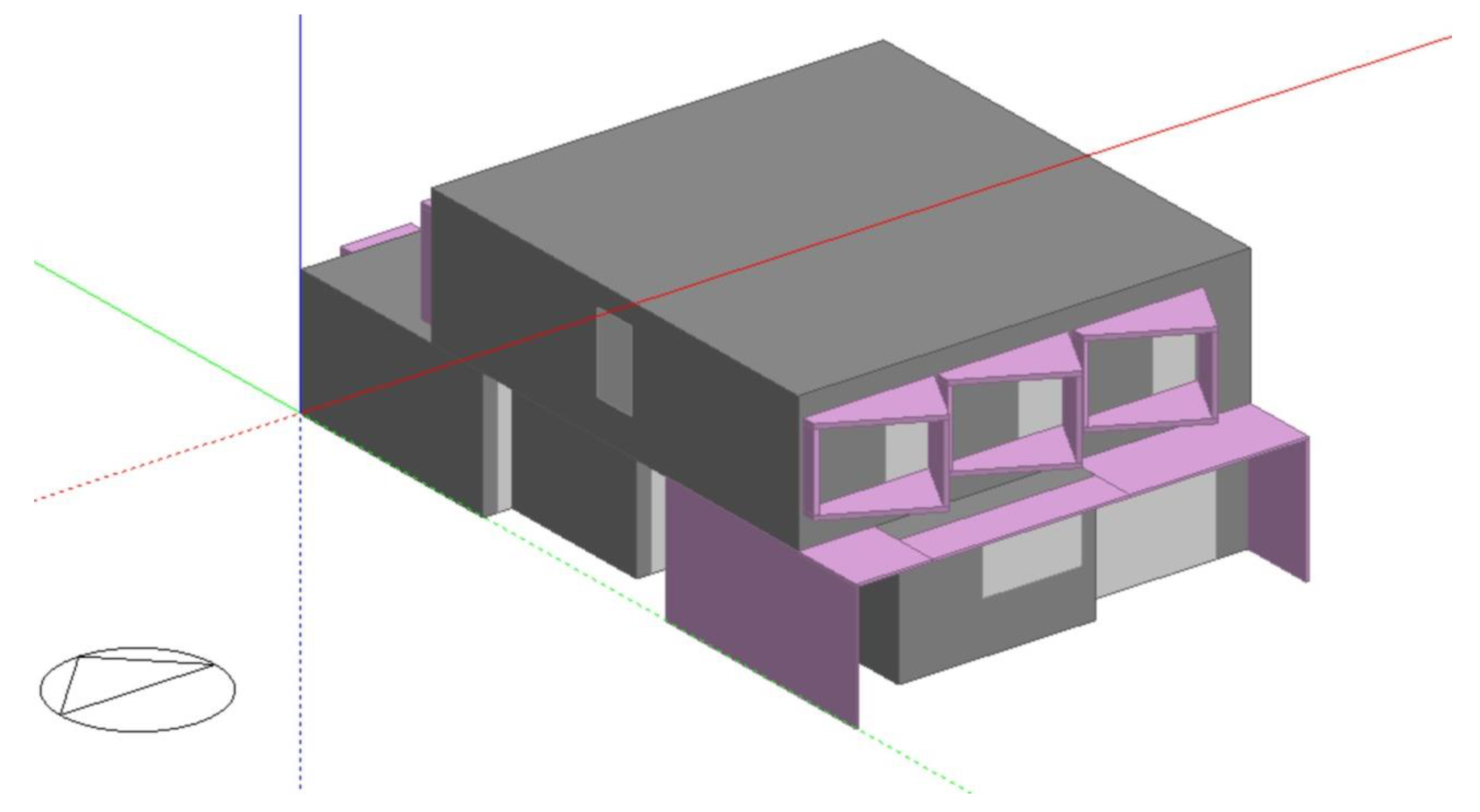

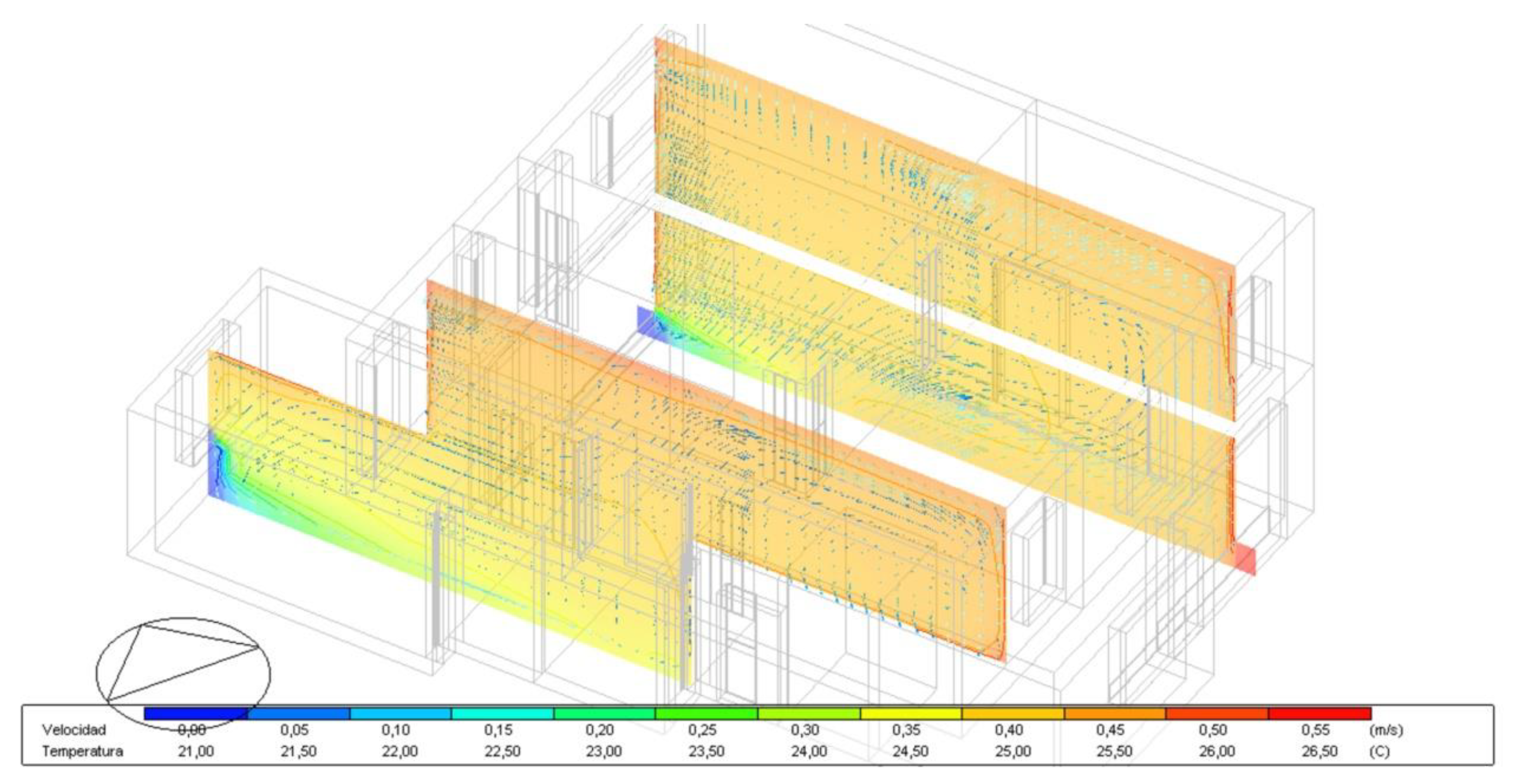

2. Description of the Case Study

2.1. Climatic and Normative Conditions

2.2. Energy Demands Obtained in the Project Phase

3. Materials and Methods

3.1. U Thermal Transmittance of the Enclosures

3.1.1. Theoretical Calculation of the U Transmittances of the Enclosures

3.1.2. In-Situ Measurements of U Transmittance

3.2. Air Infiltration Through the Envelope

- n50 renewals/hour at 50 pascals;

- ei wind protection coefficient = 0.05; and

- εi height corrector factor = 1.

3.3. Energy Impact Assessment

3.3.1. Energy Losses due to U Transmittance Values

3.3.2. Annual Energy Demand due to Air Infiltration

- Qinf is annual energy loss (kWh/yr) due to air infiltration for heating Qinf-H and cooling Qinf-C.;

- Cp is the air’s specific heat capacity, which is 0.34 Wh/m3K;

- Gt are annual degrees-days (kKh/yr); and

- Vinf is the air leak rate (m3/h).

- N is a constant;

- C is the climatic factor;

- cf1 is the building’s height correction factor, 1 (cf1 = 1) to 3 (cf1 = 0.7) floors;

- cf2 is the site screening correction factor, for well shielded cases (cf2 = 1,2), (cf2 = 1) (cf2 = 1) or exposed dwellings (cf2 = 0.9); and

- cf3 is the sealing correction factor, which depends on the value of the exponent of leak n.

- Qs is the energy impact value of the sensible heat of the air leak rate Vinf (W);

- Vinf is the air leak rate (m3/h);

- Ce is the specific heat of the air under normal conditions 0.349 Wh/kgK;

- ρ is the density of air (kg/m3);

- Te is the outside air temperature in degrees Kelvin (K), considered as the average annual value; and

- Ti is the air temperature inside the house (21 °C in winter and 24 °C in summer).

- Ql is the energetic impact value of the latent heat of the air leak rate Vinf (W);

- Cv is the heat of water vaporization (0.628 W/gvapour);

- We is the specific humidity of the external air taken as the annual average value (gvapour/kg);

- Wi is the specific humidity of the indoor air (gvapour/kg).

4. Results

4.1. Energetic Impact of Heat Flow Through the Envelope

4.2. Energetic Impact of Air Infiltration

4.3. Impact of Improvements of Thermal Transmittances and Air Infiltration on Annual Energy Demand

5. Conclusions

- Energy losses through enclosure transmittance were 11.324 kWh/m2yr, between 32% and 40% lower than those obtained in the usual homes in the region;

- Losses due to air infiltration were very low, of 5.393 kWh/m2yr, given that the Blower Door test produced a very low n50 value of 0.49 ACH. They were between 5 and 7 times lower than in conventional homes in the area;

- The annual energy demand of PH housing was 69.19% below the usual value for buildings in the Mediterranean region. Regarding the most recent buildings built under the CTE umbrella, the reduction was 60.27%.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Commission. Directive 2002/91/EC of the European Parliament andof the Council of 16 December 2002 on the energy performance of buildings. Off. J. Eur. Commun. 2003, L1, 65–70. [Google Scholar]

- European Commission. Directive 2010/31/EU of European Parliament and ofthe Council of 19 May 2010 on the energy performance of buildings (recast). Off. J. Eur. Union 2010, L153, 13–35. [Google Scholar]

- Attia, S.; Eleftheriou, P.; Xeni, F.; Morlot, R.; Ménézo, C.; Kostopoulos, V.; Betsi, M.; Kalaitzoglou, I.; Pagliano, L.; Cellura, M.; et al. Overview and future challenges of nearly zero energy buildings (nZEB) design in Southern Europe. Energy Build. 2017, 155, 439–458. [Google Scholar] [CrossRef]

- European Commission. Directive 2012/27/EU of European Parliament and of the Council of 25 October 2012 on energy efficiency, amending Directives2009/125/EC and 2010/30/EU and repealing Directives 2004/8/EC and2006/32/EC. Off. J. Eur. Union 2012, L315, 1–56. [Google Scholar]

- Technical Building Code CTE. Basic Document on Energy Savings DB-HE; Spanish Ministry of Housing: Madrid, Spain, 2006. (In Spanish) [Google Scholar]

- Orden VIV/984/2009, de 15 de abril, por la que se modifican determinados documentos básicos del Código Técnico de la Edificación aprobados por el Real Decreto 314/2006, de 17 de marzo, y el Real Decreto 1371/2007, de 19 de octubre; Spanish Ministry of Housing: Madrid, Spain, 2009. (In Spanish)

- Orden FOM/1635/2013, de 10 de septiembre, por la que se actualiza el Documento Básico DB-HE Ahorro de Energía, del Código Técnico de la Edificación, aprobado por Real Decreto 314/2006, de 17 de marzo; (Publicado en: «BOE» núm. 219, de 12 de septiembre de 2013, páginas 67137–67209); Spanish Ministry of Public Works and Transport: Madrid, Spain, 2013. (In Spanish)

- Passive House —Passivhaus Institut (PHI). Available online: http://passivehousecom/02informations/01whatisapassivehouse/01 whatisapassivehousehtm (accessed on 9 April 2019).

- Consoli, A.; Costanzo, V.; Evola, G.; Marletta, L. Refurbishing an existing apartment block in Mediterranean climate: Towards the Passivhaus standard. Energy Procedia 2017, 111, 397–406. [Google Scholar] [CrossRef]

- Taleb, H.M. Using passive cooling strategies to improve thermal performance and reduce energy consumption of residential buildings in U.A.E. buildings. Front. Arch. Res. 2014, 3, 154–165. [Google Scholar] [CrossRef] [Green Version]

- Schnieders, J.A.; Hermelink, A. CEPHEUS results: Measurements and occupants’ satisfaction provide evidence for Passive Houses being an option for sustainable building. Energy Policy 2006, 34, 151–171. [Google Scholar] [CrossRef]

- Costanzo, V.; Fabbri, K.; Piraccini, S. Stressing the passive behavior of a Passivhaus: An evidence-based scenario analysis for a Mediterranean case study. Build. Environ. 2018, 142, 265–277. [Google Scholar] [CrossRef]

- Intelligent Energy Europe, Passive-On Project: Towards Passive Homes. 2007. Available online: http://dx.doi.org/10.1017/CBO9781107415324.004 (accessed on 11 April 2019).

- Koller, C.; Talmon-Gros, M.J.; Junge, R.; Schuetze, T. Energy Toolbox—Framework for the Development of a Tool for the Primary Design of Zero Emission Buildings in European and Asian Cities. Sustainability 2017, 9, 2244. [Google Scholar] [CrossRef]

- MED-ENEC. Energy Efficiency in the Construction Sector in the Mediterranean; MED-ENEC: Cairo, Egipt, 2011; Available online: http://www.med-enec.com (accessed on 18 April 2019).

- IEEA. The Passivehaus Standard in European Warm Climates, EC Funded Project: Marketable Passive Homes for Winter and Summer Comfort. 2007. Available online: http://www.eerg.it/passive-on.org/CD/1.%20Technical%20Guidelines/Part%203/Part%203.pdf (accessed on 17 April 2019).

- Algerian Ministry of Energy and Mines. Renewable Energy and Energy Efficiency Algerian Program. Renew. Sustain. Energy Rev. 2011, 13, 1584–1591. [Google Scholar]

- Schnieders, J. Passive Houses in South West Europe: A Quantitative Investigation of Some Passive and Active Space Conditioning Techniques for Highly Energy Efficient Dwellings in the South West European. Region. Dissertation, Technical University Kaiserslautern, Kaiserslautern, Germany, 2009. [Google Scholar]

- Figueiredo, A.; Figueira, J.; Vicente, R.; Maio, R. Thermal comfort and energy performance: Sensitivity analysis to apply the Passive House concept to the Portuguese climate. Build. Environ. 2016, 103, 276–288. [Google Scholar] [CrossRef]

- Schnieders, J.; Wolfgang Feist, W.; Rongen, L. Passive Houses for different climate zones. Energy Build. 2015, 105, 71–87. [Google Scholar] [CrossRef]

- EN 15251. Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustic; European Committee for Standardization: Brussels, Belgium, 2008. [Google Scholar]

- Suárez, I.; Prieto, M.M.; Salgado, I. Dynamic evaluation of the thermal inertia of a single-family house: Scope of the retrofitting requirements to comply with Spanish regulations. Energy Build. 2017, 153, 209–218. [Google Scholar]

- Pesic, N.; Roset Calzada, J.; Muros Alcojor, A. Natural ventilation potential of the Mediterranean coastal region of Catalonia. Energy Build. 2018, 169, 236–244. [Google Scholar] [CrossRef]

- Fokaides, P.A.; Christoforou, E.; Ilic, M.; Papadopoulos, A. Performance of a Passive House under subtropical climatic conditions. Energy Build. 2016, 133, 14–31. [Google Scholar] [CrossRef]

- Ali-Toudert, F.; Weidhaus, J. Numerical assessment and optimization of a low-energy residential building for Mediterranean and Saharan climates using a pilot project in Algeria. Renew. Energy 2017, 101, 327–346. [Google Scholar] [CrossRef]

- Altan, H.; Gasperini, N.; Moshaver, S.; Frattari, A. Redesigning Terraced Social Housing in the UK for Flexibility Using Building Energy Simulation with Consideration of Passive Design. Sustainability 2015, 7, 5488–5507. [Google Scholar] [CrossRef] [Green Version]

- Mihai, M.; Tanasiev, V.; Dinca, C.; Badea, A.; Vidu, R. Passive house analysis in terms of energy performance. Energy Build. 2017, 144, 74–86. [Google Scholar] [CrossRef]

- Harkouss, F.; Fardoun, F.; Biwole, P.H. Passive design optimization of low energy buildings in different climates. Energy 2018, 165, 591–613. [Google Scholar] [CrossRef]

- Dan, D.; Tanasa, C.; Stoian, V.; Brata, S.; Stoian, D.; Nagy Gyorgy, T.; Florut, S.C. Passive house design—An efficient solution for residential buildings in Romania. Energy Sustain. Dev. 2016, 32, 99–109. [Google Scholar] [CrossRef]

- Design Builder. Design Builder EnergyPlus Simulation Documentation for Design Builder v. 4.5.; Design Builder Sortware Ltd.: Stroud, UK, 2015. [Google Scholar]

- Mlakar, J.; Strancar, J. Overheating in residential passive house: solution strategies revealed and confirmed through data analysis and simulations. Energy Build. 2011, 43, 1443–1451. [Google Scholar] [CrossRef]

- Presidencia de Gobierno. Real Decreto 2429/1979, de 6 de julio, por el que se Aprueba la Norma Básica de Edificación NBE-CT-79, sobre Condiciones Térmicas en los Edificios; Boletín Oficial del Estado: Madrid, Spain, 1979; Volume 253, pp. 24524–24550. [Google Scholar]

- Bruno, R.; Bevilacqua, P.; Cuconati, T.; Arcuri, N. Energy evaluations of an innovative multi-storey wooden near Zero Energy Building designed for Mediterranean areas. Appl. Energy 2019, 238, 929–941. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- ure(2017). World Map of the Köppen-Geiger Climate Classification Updated. High Resolution Map and Data (Version March 2017). KMZ File for Google Earth (High Res): Global_1986-2010_KG_5m.kmz. Climate Change & Infectious Diseases. Available online: http://koeppen-geiger.vu-wien.ac.at (accessed on 13 April 2019).

- Echarri, V.; Espinosa, A.; Rizo, C. Thermal Transmission through Existing Building Enclosures: Destructive Monitoring in Intermediate Layers versus Non-Destructive Monitoring with Sensors on Surfaces. Sensors 2017, 17, 2848. [Google Scholar] [CrossRef] [PubMed]

- Dong, M.N.; Lu, Z.; Mo, T.Z.; Yang, J.Y.; Leng, Y.F.; Yang, L.L. Quantitative analysis on the effect of thermal bridges on energy consumption of residential buildings in hot summer and cold winter region. J. Chongqing Jianzhu Univ. 2008, 30, 5–8. [Google Scholar]

- Garay, R.; Uriarte, A.; Apraiz, I. Performance assessment of thermal bridge elements into a full scale experimental study of a building façade. Energy Build. 2014, 85, 579–591. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Y. A simple procedure for calculating thermal response factors and conduction transfer functions of multilayer walls. Appl. Therm. Eng. 2002, 22, 333–338. [Google Scholar] [CrossRef]

- Echarri Iribarren, V.; Galiano Garrigós, A.L.; González Avilés, A.B. Ceramics and healthy heating and cooling systems: Thermal ceramic panels in buildings. Conditions of comfort and energy demand versus convective systems. Informes de la Construcción 2016, 68, 19–32. [Google Scholar]

- ISO. 13786:2007. Thermal Performance of Building Components. Dynamic Thermal Characteristics. Calculation Methods. Available online: https://www.iso.org/standard/40892.html (accessed on 19 September 2018).

- Aznar, F.; Echarri, V.; Rizo, C.; Rizo, R. Modelling the Thermal Behaviour of a Building Facade Using Deep Learning. PLoS ONE 2018, 13, e0207616. [Google Scholar] [CrossRef]

- CTE. Código Técnico de la Edificación. R/D 314/2006, de 17 de Marzo. Available online: http://www.codigotecnico.org/images/stories/pdf/realDecreto/RD3142006.pdf (accessed on 9 September 2017).

- UNE EN ISO. 10456:2012. Materiales y Productos Para la Edificación. Propiedades Higrotérmicas. Valores Tabulados de Diseño y Procedimientos Para la Determinación de los Valores Térmicos Declarados y de Diseño. 2012. Available online: http://www.aenor.es/aenor/normas/normas/fichanorma.asp?tipo=N&codigo=N0049362#.Wgbq4tThCmw (accessed on 9 October 2017).

- International Organization for Standardization. Building Components and Building Elements. Thermal Resistance and Thermal Transmittance. Calculation Method; ISO Standard 6946; International Organization for Standardization: Geneva, Switzerland, 2007; Available online: https://www.iso.org/obp/ui/#iso:std:iso:6946:ed-2:v1: en (accessed on 13 April 2019).

- Evangelisti, L.; Battista, G.; Guattari, C.; Basilicata, C.; de Lieto Vollaro, R. Influence of the thermal inertia in the European simplified procedures for the assessment of buildings’ energy performance. Sustainability 2014, 6, 4514–4524. [Google Scholar] [CrossRef]

- HULC. Herramienta unificada Lider-Calener. Orden FOM/1635/2013, de 10 de septiembre (BOE de 12 de septiembre), por la que se actualiza el Documento Básico DB HE «Ahorro de Energía», del CTE. Available online: https://www.codigotecnico.org/index.php/menu-recursos/menu-aplicaciones/282-herramientaunificada-lider-calener.html (accessed on 9 September 2017).

- Andújar Márquez, J.M.; Martínez Bohórquez, M.A.; Gómez Melgar, S. A New Metre for Cheap, Quick, Reliable and Simple Thermal Transmittance (U-Value) Measurements in Buildings. Sensors 2017, 17. [Google Scholar] [CrossRef] [PubMed]

- Deconinck, A.H.; Roels, S. Comparison of characterisation methods determining the thermal resistance of building components from onsite measurements. Energy Build. 2016, 130, 309–320. [Google Scholar] [CrossRef] [Green Version]

- ISO. 9869-1:2014. Thermal Insulation-Building Elements-In Situ Measurement of Thermal Resistance and Thermal Transmittance. Part 1.: Heat Flow Meter Method; ISO: Geneva, Switzerland, 2014; Available online: https://www.iso.org/standard/59697.html (accessed on 13 April 2019).

- Gaspar, K.; Casals, M.; Gangolells, M. A comparison of standardized calculation methods for in situ measurements of façades U-value. Energy Build. 2016, 130, 592–599. [Google Scholar] [CrossRef]

- Albatici, R.; Tonelli, A.M.; Chiogna, M. A comprehensive experimental approach for the validation of quantitative infrared thermography in the evaluation of building thermal transmittance. Appl. Energy 2015, 141, 218–228. [Google Scholar] [CrossRef]

- Tinti, A.; Tarzia, A.; Passaro, A.; Angiuli, R. Thermographic analysis of polyurethane foams integrated with phase change materials designed for dynamic thermal insulation in refrigerated transport. Appl. Therm. Eng. 2014, 70, 201–210. [Google Scholar] [CrossRef]

- Theodosiou, T.G.; Tsikaloudaki, A.G.; Kontoleon, K.J.; Bikas, D.K. Thermal bridging analysis on cladding systems for building facades. Energy Build. 2015, 109, 377–384. [Google Scholar] [CrossRef]

- Feijó-Muñoz, J.; Poza-Casado, I.; González-Lezcano, R.A.; Pardal, C.; Echarri, V.; Assiego de Larriva, R.; Fernández-Agüera, J.; Dios-Viéitez, M.J.; del Campo-Díaz, V.J.; Montesdeoca Calderín, M.; et al. Methodology for the study of the envelope airtightness of residential buildings in Spain: A case study. Energies 2018, 11, 704. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Fernández Quiñones, J.A.; Moyano, J.; Rodríguez-Jiménez, C.E. Patents Analysis of Thermal Bridges in Slab Fronts and Their Effect on Energy Demand. Energies 2018, 11, 2222. [Google Scholar] [CrossRef]

- Echarri-Iribarren, V.; Rizo-Maestre, C.; Echarri-Iribarren, F. Healthy Climate and Energy Savings: Using Termal Ceramic Panels and Solar Thermal Panels in Mediterranean Housing Blocks. Energies 2018, 11, 2707. [Google Scholar] [CrossRef]

- Younes, C.; Shdid, C.A.; Bitsuamlak, G. Air infiltration through building envelopes: a review. J. Build. Phys. 2012, 35, 267–302. [Google Scholar] [CrossRef]

- Sherman, M.H. Estimation of infiltration from leakage and climate indicators. Energy Build. 1987, 10, 81–86. [Google Scholar] [CrossRef] [Green Version]

- Echarri, V. Thermal Ceramic Panels and Passive Systems in Mediterranean Housing: Energy Savings and Environmental Impacts. Sustainability 2017, 9, 1613. [Google Scholar] [CrossRef]

- Feijó-Muñoz, J.; Pardal, C.; Echarri, V.; Fernández-Agüera, J.; Assiego de Larriva, R.; Montesdeoca Calderín, M.; Poza-Casado, I.; Padilla-Marcos, M.A.; Meiss, A. Energy impact of the air infiltration in residential buildings in the Mediterranean area of Spain and the Canary islands. Energy Build. 2019, 188–189, 226–238. [Google Scholar] [CrossRef]

- Bienvenido-Huertas, D.; Moyano, J.; Rodríguez-Jiménez, C.E.; Marín, D. Applying an artificial neural network to assess thermal transmittance in walls by means of the thermometric method. Appl. Energy 2019, 233–234, 1–14. [Google Scholar] [CrossRef]

- Echarri-Iribarren, V.; Rizo-Maestre, C.; Sanjuan-Palermo, J.L. Underfloor Heating Using Ceramic Thermal Panels and Solar Thermal Panels in Public Buildings in the Mediterranean: Energy Savings and Healthy Indoor Environment. Appl. Sci. 2019, 9, 2089. [Google Scholar] [CrossRef]

- Šadauskiene, J.; Ramanauskas, J.; Šeduikyte, L.; Daukšys, M.; Vasylius, A. A Simplified Methodology for Evaluating the Impact of Point Thermal Bridges on the High-Energy Performance of a Passive House. Sustainability 2015, 7, 16687–16702. [Google Scholar] [CrossRef] [Green Version]

- Fu, X.; Qian, X.; Wang, L. Energy Efficiency for Airtightness and Exterior Wall Insulation of Passive Houses in Hot Summer and Cold Winter Zone of China. Sustainability 2017, 9, 1097. [Google Scholar] [CrossRef]

- Johnston, D.; Siddall, M. The Building Fabric Thermal Performance of Passivhaus Dwellings—Does It Do What It Says on the Tin? Sustainability 2016, 8, 97. [Google Scholar] [CrossRef]

| Parameter | Data Introduced |

|---|---|

| Hours of operation and occupancy: Monday to Friday: 7 am to 3 pm | 25 % occupancy |

| Hours of operation and occupancy: Monday to Friday: 3 pm to 8 pm | 50 % occupancy |

| Hours of operation and occupancy: Monday to Friday: 8 pm to 7 am | 100 % occupancy |

| Hours of operation, activity and occupancy: Saturday and Sunday | 100 % occupancy |

| Climate equipment operating hours (heating) | 7 am to 10 pm |

| Climate equipment operating hours (cooling) | 9 am to 8 pm |

| Running of the air conditioning system from Monday to Sunday | 7 days/week |

| Summer period | 1 May to 30 November |

| Winter period | 1 December to 30 April |

| Occupancy density (5 people) | 0.03 person/m2 |

| Metabolic factor: "Standing/walking" option | 1.20 |

| Clothing values (CLO) | Winter CLO = 1.00 Summer CLO = 0.50 |

| Load due to general lighting | 300 lux |

| Internal air temperature setpoint Ti (cooling) | 24 °C |

| Set internal air temperature Ti (heating) | 21 °C |

| Indoor air maintenance temperature Ti (cooling) | 26 °C |

| Internal air maintenance temperature Ti (heating) | 18 °C |

| Relative humidity of the indoor air | 50% |

| Air renewal rate | 0.63 acH |

| Air infiltration through the envelope | 0,049 acH |

| Materials of the Enclosure Layers | Thickness e (cm) | Thermal Conductivity λ W/m K | Thermal Conductivity λ Mathis TCi |

|---|---|---|---|

| Multilayer coating Coteterm + Calcifin | 0.5 | 1.21 | 0.27 |

| Hollow ceramic brick | 11.5 | 0.49 | 0.52 |

| SuperPan Tech P5 water-repellent wood panel | 1.5 | 0.76 | 0.75 |

| Thermal isolation. Mineral wool | 14.8 | 0.038 | 0.0334 |

| Thermal isolation. Purone mineral wool 35 QN | 19.8 | 0.038 | 0.0361 |

| Riwega USB Tape 1 PE adhesive tape | 0.05 | 0.17 | 0.183 |

| Class 3 microcement pavement | 2.0 | 1.38 | 1.392 |

| Pieces of 90 x 60 cm porcelain stoneware | 1.0 | 2.30 | 2.21 |

| Polished concrete | 3.0 | 1.63 | 1.652 |

| Vertical Enclosure and Horizontal Flow | Thermal Resistance | |||

|---|---|---|---|---|

| LAYERS | Thickness | λ | R | |

| [m] | [W/m·K] | [m2·K/W] | ||

| 1 | Exterior environment (Rse) | 0.040 | ||

| 2 | Multilayer coating Coteterm + Calcifin | 0.005 | 1.21 | 0.004 |

| 3 | SuperPan Tech P5 water-repellent wood panel | 0.015 | 0.14 | 0.107 |

| 4 | Thermal isolation. Mineral wool type IV | 0.148 | 0.0334 | 4.428 |

| 5 | SuperPan Tech P5 water-repellent wood panel | 0.015 | 0.14 | 0.107 |

| 6 | Interior environment (Rsi) | 0.130 | ||

| RT = Sum Ri [m2·K/W] | 4.816 | |||

| UT = 1/RT [W/(m2·K)] | 0.2075 | |||

| Passivhaus House | Standard House | |||

|---|---|---|---|---|

| U Value W/m2K | U Value Testo Equipment W/m2K | 1979–2006 Period U Value W/m2K | 2006–2019 Period U Value W/m2K | |

| Opaque | 0.207 | 0.221 | 0.476 | 0.421 |

| Glazing | 2.910 | 2.932 | 3.520 | 3.450 |

| Roof | 0.208 | 0.210 | 0.508 | 0.458 |

| Ground | 0.325 | 0.307 | 0.485 | 0.465 |

| Passivhaus House | Standard House | |||

|---|---|---|---|---|

| Valor n50 (ACH) | Blower Door Test 1 21 June 2018 | Blower Door Test 2 3 October 2018 | 1979–2006 Period | 2006–2019 Period |

| Depressurization | 0.35 | 0.51 | 6.52 | 3.69 |

| Pressurization | 0.33 | 0.48 | 6.05 | 3.43 |

| Average value (ACH) | 0.34 | 0.49 | 6.23 | 3.56 |

| Surface m2 | U Value W/m2K | Annual Energy kWh/yr | Annual Energy Demand Impact kWh/m2yr | Percentage % | |

|---|---|---|---|---|---|

| Façade enclosure | 181.79 | 0.2075 | 363.72 | 2.11 | 18.55 |

| Window gap | 40.09 | 2.91 | 1,124.07 | 6.49 | 57.31 |

| Roof | 173.20 | 0.2081 | 348.13 | 2.01 | 17.75 |

| Contact with the ground | 158.30 | 0.325 | 125.39 | 0.724 | 6.39 |

| TOTAL | 553.38 | 1,961.32 | 11.324 | 100 |

| Passivhaus House | Standard House 1979–2006 | Standard House 2006–2019 | ||||

|---|---|---|---|---|---|---|

| U Value W/m2K | Annual Energy Demand Impact kWh/m2yr | U Value W/m2K | Annual Energy Demand Impact kWh/m2yr | U Value W/m2K | Annual Energy Demand Impact kWh/m2yr | |

| Opaque | 0.221 | 2.11 | 0.476 | 4.67 | 0.421 | 4.32 |

| Glazing | 2.932 | 6.49 | 3.520 | 7.85 | 3.450 | 7.21 |

| Roof | 0.210 | 2.01 | 0.508 | 4.93 | 0.458 | 4.19 |

| Ground | 0.307 | 0.724 | 0.485 | 1.27 | 0.465 | 0.98 |

| TOTAL | 11.324 | 18.72 | 16.71 | |||

| Passivhaus House | Standard House 1979–2006 | Percentage | Standard House 2006–2019 | Percentage | |

|---|---|---|---|---|---|

| Test BD n50 | 0.49 | 6.23 | 3.56 | ||

| Qs (kWh/m2yr) | 1.377 | 9.543 | 4.971 | ||

| Ql (kWh/m2yr) | 4.016 | 27.837 | 14.553 | ||

| Qt (kWh/m2yr) | 5.393 | 37.379 | 14.43% | 19.524 | 27.62% |

| PH House | Percentage | House Type 1979–2006 | Percentage | House Type 2006–2019 | Percentage | |

|---|---|---|---|---|---|---|

| Energy demand in summer (kWh/m2yr) | 14.321 | 50.64 | 42.29 | |||

| Energy demand in winter (kWh/m2yr) | 12.126 | 35.19 | 29.88 | |||

| Annual energy demand (kWh/m2yr) | 26.447 | 30.81% | 85.83 | 100% | 66.57 | 77.56% |

| Energy losses through U transmission (kWh/m2yr) | 11.324 | 42.82% | 18.72 | 21.81% | 16.71 | 25.10% |

| Energy losses through infiltration Qt (kWh/m2yr) | 5.393 | 20.39% | 37.379 | 43.05% | 19.524 | 29.33% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Echarri-Iribarren, V.; Sotos-Solano, C.; Espinosa-Fernández, A.; Prado-Govea, R. The Passivhaus Standard in the Spanish Mediterranean: Evaluation of a House’s Thermal Behaviour of Enclosures and Airtightness. Sustainability 2019, 11, 3732. https://doi.org/10.3390/su11133732

Echarri-Iribarren V, Sotos-Solano C, Espinosa-Fernández A, Prado-Govea R. The Passivhaus Standard in the Spanish Mediterranean: Evaluation of a House’s Thermal Behaviour of Enclosures and Airtightness. Sustainability. 2019; 11(13):3732. https://doi.org/10.3390/su11133732

Chicago/Turabian StyleEcharri-Iribarren, Víctor, Cristina Sotos-Solano, Almudena Espinosa-Fernández, and Raúl Prado-Govea. 2019. "The Passivhaus Standard in the Spanish Mediterranean: Evaluation of a House’s Thermal Behaviour of Enclosures and Airtightness" Sustainability 11, no. 13: 3732. https://doi.org/10.3390/su11133732

APA StyleEcharri-Iribarren, V., Sotos-Solano, C., Espinosa-Fernández, A., & Prado-Govea, R. (2019). The Passivhaus Standard in the Spanish Mediterranean: Evaluation of a House’s Thermal Behaviour of Enclosures and Airtightness. Sustainability, 11(13), 3732. https://doi.org/10.3390/su11133732