Depicting Flows of Embodied Water Pollutant Discharge within Production System: Case of an Undeveloped Region

Abstract

1. Introduction

2. Methodology and Data

2.1. Non-Competitive Environmentally Extended Input–Output Model

2.2. Structural Path Analysis

2.3. Depicting Flows of Embodied Discharge

2.4. Sectoral Total Consumption Attributions of Discharge

2.5. Data

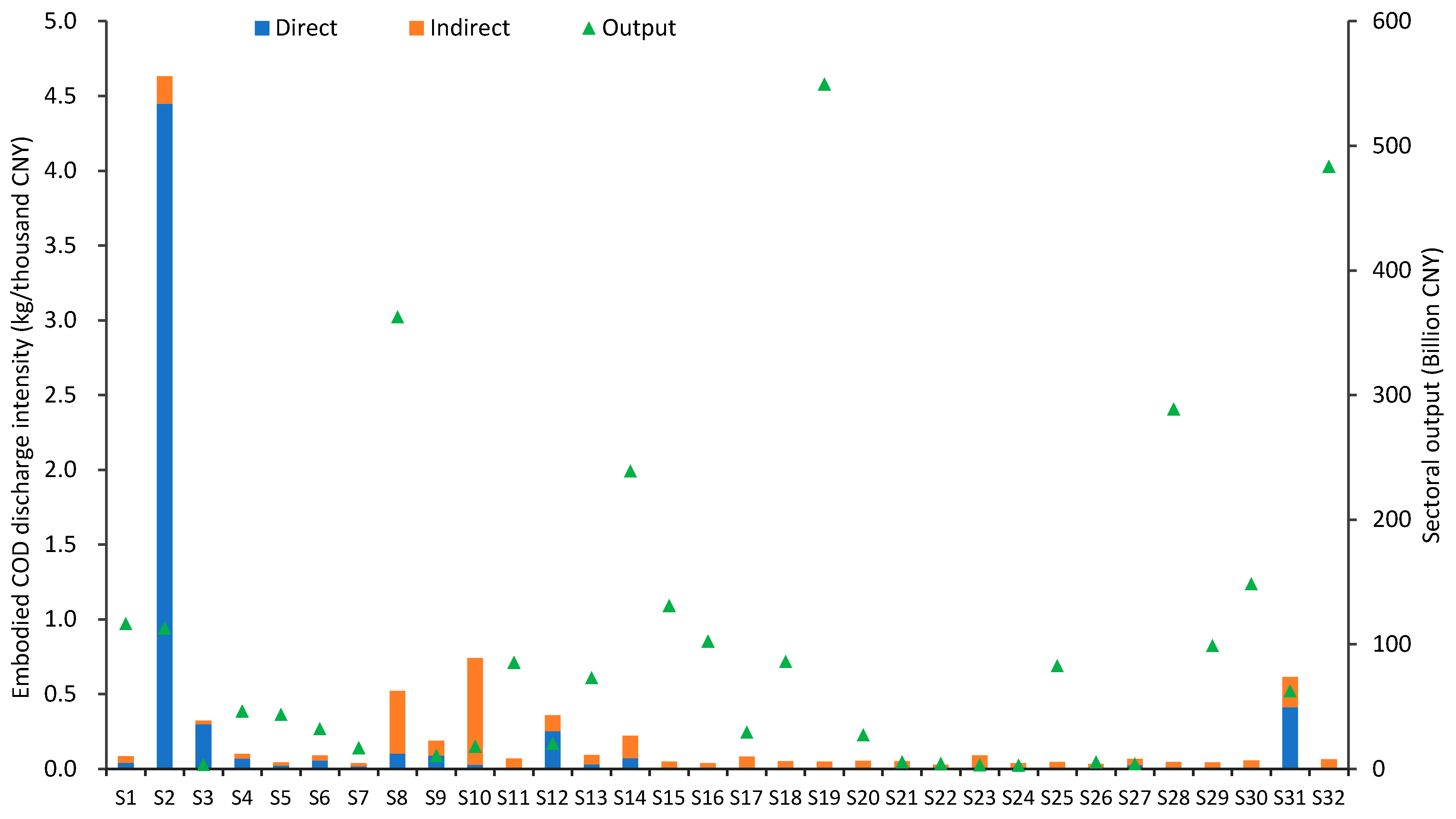

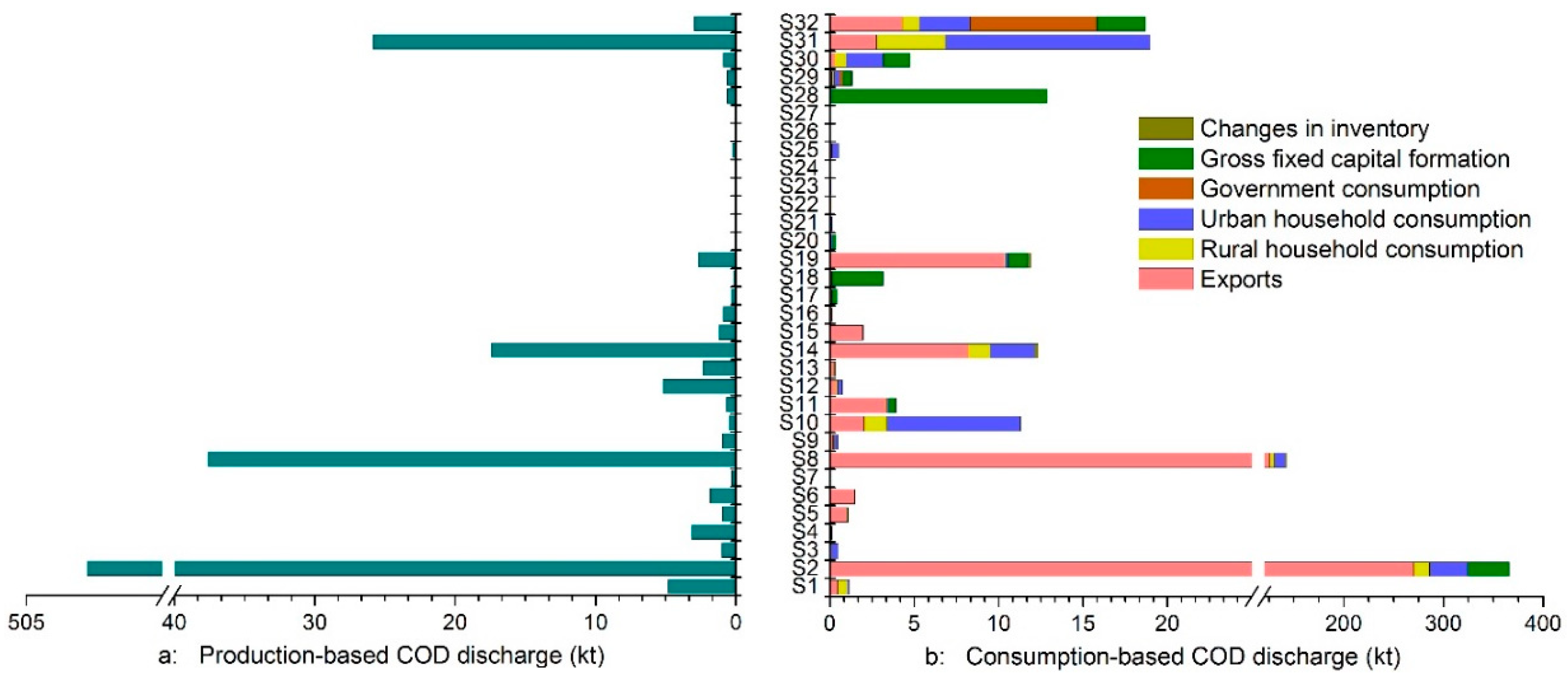

3. Results

3.1. Consumption-Based Versus Production-Based COD Discharge

3.2. Embodied Flows of COD Discharge

3.3. Normalized Evolution of Consumption and Production Attributions

4. Discussion and Policy Implications

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- World Water Assessment Programme. The United Nations World Water Development Report 2015; Water for a Sustainable World; UNESCO: Paris, France, 2015; pp. 2–6. [Google Scholar]

- Voeroesmarty, C.J.; McIntyre, P.B.; Gessner, M.O.; Dudgeon, D.; Prusevich, A.; Green, P.; Glidden, S.; Bunn, S.E.; Sullivan, C.A.; Liermann, C.R.; et al. Global threats to human water security and river biodiversity. Nature 2010, 467, 555–561. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Yang, W. Water Sustainability for China and Beyond. Science 2012, 337, 649–650. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Song, J.; Higano, Y.; Tang, J. Exploration and assessment of optimal policy combination for total water pollution control with a dynamic simulation model. J. Clean. Prod. 2015, 102, 342–352. [Google Scholar] [CrossRef]

- Yang, W.; Song, J.; Higano, Y.; Tang, J. An Integrated Simulation Model for Dynamically Exploring the Optimal Solution to Mitigating Water Scarcity and Pollution. Sustainability 2015, 7, 1774–1797. [Google Scholar] [CrossRef]

- Skelton, A.; Guan, D.; Peters, G.P.; Crawford-Brown, D. Mapping Flows of Embodied Emissions in the Global Production System. Environ. Sci. Technol. 2011, 45, 10516–10523. [Google Scholar] [CrossRef]

- Yang, W.; Song, J.; Higano, Y.; Tang, J. Combination of Assessment Indicators for Policy Support on Water Scarcity and Pollution Mitigation. Water 2016, 8, 203. [Google Scholar] [CrossRef]

- Song, J.; Yang, W.; Li, Z.; Higano, Y.; Wang, X. Discovering the energy, economic and environmental potentials of urban wastes: An input–output model for a metropolis case. Energy Convers. Manag. 2016, 114, 168–179. [Google Scholar] [CrossRef]

- Peters, G.P.; Hertwich, E.G. Structural analysis of international trade: Environmental impacts of Norway. Econ. Syst. Res. 2006, 18, 155–181. [Google Scholar] [CrossRef]

- Bagheri, M.; Guevara, Z.; Alikarami, M.; Kennedy, C.A.; Doluweera, G. Green growth planning: A multi-factor energy input-output analysis of the Canadian economy. Energy Econ. 2018, 74, 708–720. [Google Scholar] [CrossRef]

- Guan, D.; Hubacek, K.; Tillotson, M.; Zhao, H.; Liu, W.; Liu, Z.; Liang, S. Lifting China’s water spell—SDA. Environ. Sci. Technol. 2014, 48, 11048–11056. [Google Scholar] [CrossRef]

- Liang, S.; Wang, Y.; Zhang, C.; Xu, M.; Yang, Z.; Liu, W.; Liu, H.; Chiu, A.S.F. Final production-based emissions of regions in China. Econ. Syst. Res. 2018, 30, 18–36. [Google Scholar] [CrossRef]

- Leontief, W. Environmental repercussions and the economic structure: An input-output approach. Rev. Econ. Stat. 1970, 52, 262–271. [Google Scholar] [CrossRef]

- Davis, S.J.; Caldeira, K. Consumption-based accounting of CO2 emissions. Proc. Natl. Acad. Sci. USA 2010, 107, 5687–5692. [Google Scholar] [CrossRef] [PubMed]

- Erickson, P.; Allaway, D.; Lazarus, M.; Stanton, E.A. A Consumption-Based GHG Inventory for the U.S. State of Oregon. Environ. Sci. Technol. 2012, 46, 3679–3686. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.Y.; Zhang, Q.; Guan, D.B.; Davis, S.J.; Liu, Z.; Huo, H.; Lin, J.T.; Liu, W.D.; He, K.B. Assessment of China’s virtual air pollution transport embodied in trade by using a consumption-based emission inventory. Atmos. Chem. Phys. 2015, 15, 5443–5456. [Google Scholar] [CrossRef]

- Meng, J.; Liu, J.; Xu, Y.; Tao, S. Tracing Primary PM2.5 emissions via Chinese supply chains. Environ. Res. Lett. 2015, 10, 054005. [Google Scholar] [CrossRef]

- Peters, G.P.; Hertwich, E.G. Post-Kyoto greenhouse gas inventories: Production versus consumption. Clim. Chang. 2008, 86, 51–66. [Google Scholar] [CrossRef]

- Peters, G.P. From production-based to consumption-based national emission inventories. Ecol. Econ. 2008, 65, 13–23. [Google Scholar] [CrossRef]

- Huo, H.; Zhang, Q.; Guan, D.; Su, X.; Zhao, H.; He, K. Examining Air Pollution in China Using Production- And Consumption-Based Emissions Accounting Approaches. Environ. Sci. Technol. 2014, 48, 14139–14147. [Google Scholar] [CrossRef]

- Franzen, A.; Mader, S. Consumption-based versus production-based accounting of CO2 emissions: Is there evidence for carbon leakage? Environ. Sci. Technol. 2018, 84, 34–40. [Google Scholar] [CrossRef]

- Karakaya, E.; Yilmaz, B.; Alatas, S. How production-based and consumption-based emissions accounting systems change climate policy analysis: The case of CO2 convergence. Environ. Sci. Poll. Res. 2019, 26, 16682–16694. [Google Scholar] [CrossRef] [PubMed]

- Lenzen, M.; Kanemoto, K.; Moran, D.; Geschke, A. Mapping the Structure of the World Economy. Environ. Sci. Technol. 2012, 46, 8374–8381. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Cui, C.; Peng, S. Critical sectors and paths for climate change mitigation within supply chain networks. J. Environ. Manag. 2018, 226, 30–36. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Su, B.; Dasgupta, S. Structural path analysis of India’s carbon emissions using input-output and social accounting matrix frameworks. Energy Econ. 2018, 76, 457–469. [Google Scholar] [CrossRef]

- Lenzen, M. Structural path analysis of ecosystem networks. Ecol. Model. 2007, 200, 334–342. [Google Scholar] [CrossRef]

- Hanaka, T.; Kagawa, S.; Ono, H.; Kanemoto, K. Finding environmentally critical transmission sectors, transactions, and paths in global supply chain networks. Energy Econ. 2017, 68, 44–52. [Google Scholar] [CrossRef]

- Lenzen, M. Structural analyses of energy use and carbon emissions—An overview. Econ. Syst. Res. 2016, 28, 119–132. [Google Scholar] [CrossRef]

- Zhang, B.; Qu, X.; Meng, J.; Sun, X. Identifying primary energy requirements in structural path analysis: A case study of China 2012. Appl. Energy 2017, 191, 425–435. [Google Scholar] [CrossRef]

- Hong, J.; Shen, Q.; Xue, F. A multi-regional structural path analysis of the energy supply chain in China’s construction industry. Energy Policy 2016, 92, 56–68. [Google Scholar] [CrossRef]

- Zhang, B.; Guan, S.; Wu, X.; Zhao, X. Tracing natural resource uses via China’s supply chains. J. Clean. Prod. 2018, 196, 880–888. [Google Scholar] [CrossRef]

- Wang, J.; Du, T.; Wang, H.; Liang, S.; Xu, M. Identifying critical sectors and supply chain paths for the consumption of domestic resource extraction in China. J. Clean. Prod. 2019, 208, 1577–1586. [Google Scholar] [CrossRef]

- Shao, L.; Li, Y.; Feng, K.; Meng, J.; Shan, Y.; Guan, D. Carbon emission imbalances and the structural paths of Chinese regions. Appl. Energy 2018, 215, 396–404. [Google Scholar] [CrossRef]

- Oshita, Y. Identifying critical supply chain paths that drive changes in CO2 emissions. Energy Econ. 2012, 34, 1041–1050. [Google Scholar] [CrossRef]

- Gui, S.; Mu, H.; Li, N. Analysis of impact factors on China’s CO2 emissions from the view of supply chain paths. Energy 2014, 74, 405–416. [Google Scholar] [CrossRef]

- Skelton, A. EU corporate action as a driver for global emissions abatement: A structural analysis of EU international supply chain carbon dioxide emissions. Glob. Environ. Chang. Hum. Policy 2013, 23, 1795–1806. [Google Scholar] [CrossRef]

- Lenzen, M. Environmentally important paths, linkages and key sectors in the Australian economy. Struct. Chang. Econ. Dyn. 2003, 14, 1–34. [Google Scholar] [CrossRef]

- Zhang, Q.; Nakatani, J.; Shan, Y.; Moriguchi, Y. Inter-regional spillover of China’s sulfur dioxide (SO2) pollution across the supply chains. J. Clean. Prod. 2019, 207, 418–431. [Google Scholar] [CrossRef]

- Nagashima, F.; Kagawa, S.; Suh, S.; Nansai, K.; Moran, D. Identifying critical supply chain paths and key sectors for mitigating primary carbonaceous PM2.5 mortality in Asia. Econ. Syst. Res. 2016, 29, 105–123. [Google Scholar] [CrossRef]

- Llop, M.; Ponce-Alifonso, X. Identifying the role of final consumption in structural path analysis: An application to water uses. Ecol. Econ. 2015, 109, 203–210. [Google Scholar] [CrossRef]

- Wu, F.; Sun, Z.; Wang, F.; Zhang, Q. Identification of the critical transmission sectors and typology of industrial water use for supply-chain water pressure mitigation. Resour. Conserv. Recycl. 2018, 131, 305–312. [Google Scholar] [CrossRef]

- Wiedmann, T.; Lenzen, M.; Turner, K.; Barrett, J. Examining the global environmental impact of regional consumption activities—Part 2: Review of input-output models for the assessment of environmental impacts embodied in trade. Ecol. Econ. 2007, 61, 15–26. [Google Scholar] [CrossRef]

- Sonis, M.; Guilhoto, J.J.M.; Hewings, G.J.D.; Martins, E.B. Linkages, Key Sectors and Structural Change: Some New Perspectives. Dev. Econ. 1995, 33, 233–270. [Google Scholar] [CrossRef]

- Weber, C.L.; Peters, G.P.; Guan, D.; Hubacek, K. The contribution of Chinese exports to climate change. Energy Policy 2008, 36, 3572–3577. [Google Scholar] [CrossRef]

- Zhao, X.; Yang, H.; Yang, Z.; Chen, B.; Qin, Y. Applying the Input-Output Method to Account for Water Footprint and Virtual Water Trade in the Haihe River Basin in China. Environ. Sci. Technol. 2010, 44, 9150–9156. [Google Scholar] [CrossRef] [PubMed]

- Guan, D.; Su, X.; Zhang, Q.; Peters, G.P.; Liu, Z.; Lei, Y.; He, K. The socioeconomic drivers of China’s primary PM2.5emissions. Environ. Res. Lett. 2014, 9, 024010. [Google Scholar] [CrossRef]

- Editorial Committee of China Environment Book. China Environment Book 2013; Society of China Environment Book Press: Beijing, China, 2013. (In Chinese) [Google Scholar]

- National Bureau of Statistics. China Statistical Yearbook on Environment 2013; China Statistics Press: Beijing, China, 2013. (In Chinese)

- Wang, X.; Huang, K.; Yu, Y.; Hu, T.; Xu, Y. An input–output structural decomposition analysis of changes in sectoral water footprint in China. Ecol. Indic. 2016, 69, 26–34. [Google Scholar] [CrossRef]

- Statistics Bureau of Jilin. Jilin Statistical Yearbook 2013; China Statistics Press: Beijing, China, 2013. (In Chinese)

- Schmidt, M. The Sankey diagram in energy and material flow management—Part II: Methodology and current applications. J. Ind. Ecol. 2008, 12, 173–185. [Google Scholar] [CrossRef]

| Final Attributions (PL0) | Intermediate Attributions at PL1 | Intermediate Attributions at PL2 | Intermediate Attributions at PL3 | |

|---|---|---|---|---|

| Direct | ||||

| Consumption | ||||

| Production |

| to Sector i at PL0 | to Sector j at PL1 | to Sector u at PL2 | |

|---|---|---|---|

| from sector j at PL1 | |||

| from sector u at PL2 | |||

| from sector l at PL3 |

| Index | Sectors | Index | Sectors |

|---|---|---|---|

| S1 | Crop production | S17 | Metal products |

| S2 | Animal production | S18 | Machinery |

| S3 | Fishery | S19 | Transport equipment |

| S4 | Coal mining | S20 | Electrical equipment |

| S5 | Extraction of petroleum & natural gas | S21 | Electronic & telecom equipment |

| S6 | Metal ores mining | S22 | Instruments & office machinery |

| S7 | Nonmetal ores mining | S23 | Other manufacturing |

| S8 | Foods & tobacco products | S24 | Scrap and waste |

| S9 | Textiles | S25 | Electricity production & distribution |

| S10 | Clothing products | S26 | Gas production & distribution |

| S11 | Sawmills & furniture | S27 | Water production & distribution |

| S12 | Printing & paper products | S28 | Construction |

| S13 | Petroleum & coke oven products | S29 | Transport, storage & post |

| S14 | Chemical products | S30 | Wholesale & retail trades |

| S15 | Nonmetallic mineral products | S31 | Hotels & catering services |

| S16 | Smelting & pressing of metals | S32 | Other services |

| Code | Sectors | Consumption-Based COD Discharge (kt) | Output (Billion CNY) a | Distribution of Induced Direct COD Discharges (%) | |||

|---|---|---|---|---|---|---|---|

| Layer 0 | Layer 1 | Layer 2 | Layer 3→ ∞ | ||||

| S2 | Animal production | 365.47 | 113.04 | 96.04 | 2.58 | 0.93 | 0.45 |

| S8 | Foods & tobacco products | 142.58 | 362.82 | 19.91 | 61.02 | 12.92 | 6.15 |

| S31 | Hotels & catering services | 18.98 | 62.74 | 67.06 | 12.55 | 14.88 | 5.51 |

| S32 | Other services | 18.69 | 483.56 | 9.58 | 40.35 | 24.67 | 25.39 |

| S28 | Construction | 12.89 | 288.83 | 4.87 | 23.14 | 32.38 | 39.61 |

| S14 | Chemical products | 12.35 | 239.07 | 32.90 | 41.12 | 14.41 | 11.57 |

| S19 | Transport equipment | 11.89 | 549.46 | 10.08 | 26.64 | 26.42 | 36.86 |

| S10 | Clothing products | 11.28 | 18.27 | 3.72 | 80.32 | 10.61 | 5.35 |

| S30 | Wholesale & retail trades | 4.77 | 148.53 | 11.37 | 60.63 | 13.06 | 14.95 |

| S11 | Sawmills & furniture | 3.92 | 85.43 | 11.63 | 27.51 | 26.28 | 34.58 |

| ---- | Other sectors | 13.86 | 948.45 | 30.36 | 23.85 | 20.67 | 25.12 |

| Rank | Layer | Contribution | Path |

|---|---|---|---|

| 1 | 0 | 42.04% | Exports→ Animal production |

| 2 | 1 | 11.29% | Exports→ Foods & tobacco products→ Animal production |

| 3 | 0 | 6.52% | Gross fixed capital formation→ Animal production |

| 4 | 0 | 5.93% | Urban household consumption→ Animal production |

| 5 | 0 | 4.06% | Exports→ Foods & tobacco products |

| 6 | 0 | 2.48% | Rural household consumption→ Animal production |

| 7 | 2 | 2.20% | Exports→ Foods & tobacco products→ Foods & tobacco products→ Animal production |

| 8 | 0 | 1.32% | Urban household consumption→ Hotels & catering services |

| 9 | 1 | 1.01% | Urban household consumption→ Foods & tobacco products→ Animal production |

| 10 | 1 | 0.96% | Urban household consumption→ Clothing products→ Animal production |

| 11 | 1 | 0.93% | Exports→ Animal production→ Animal production |

| 12 | 0 | 0.44% | Exports→ Chemical products |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Song, J. Depicting Flows of Embodied Water Pollutant Discharge within Production System: Case of an Undeveloped Region. Sustainability 2019, 11, 3774. https://doi.org/10.3390/su11143774

Yang W, Song J. Depicting Flows of Embodied Water Pollutant Discharge within Production System: Case of an Undeveloped Region. Sustainability. 2019; 11(14):3774. https://doi.org/10.3390/su11143774

Chicago/Turabian StyleYang, Wei, and Junnian Song. 2019. "Depicting Flows of Embodied Water Pollutant Discharge within Production System: Case of an Undeveloped Region" Sustainability 11, no. 14: 3774. https://doi.org/10.3390/su11143774

APA StyleYang, W., & Song, J. (2019). Depicting Flows of Embodied Water Pollutant Discharge within Production System: Case of an Undeveloped Region. Sustainability, 11(14), 3774. https://doi.org/10.3390/su11143774