Sustainable Supply Chain Management in the Automotive Industry: A Process-Oriented Review

Abstract

:1. Introduction

2. The Background of the Study

3. Research Methodology

3.1. Defining the Relevant Keywords for Searching Databases

3.2. Database Selection and the First Search Phase

3.3. Filtration

3.4. Snowball Approach

3.5. Final Filtration

3.6. Descriptive Analysis of the Sample

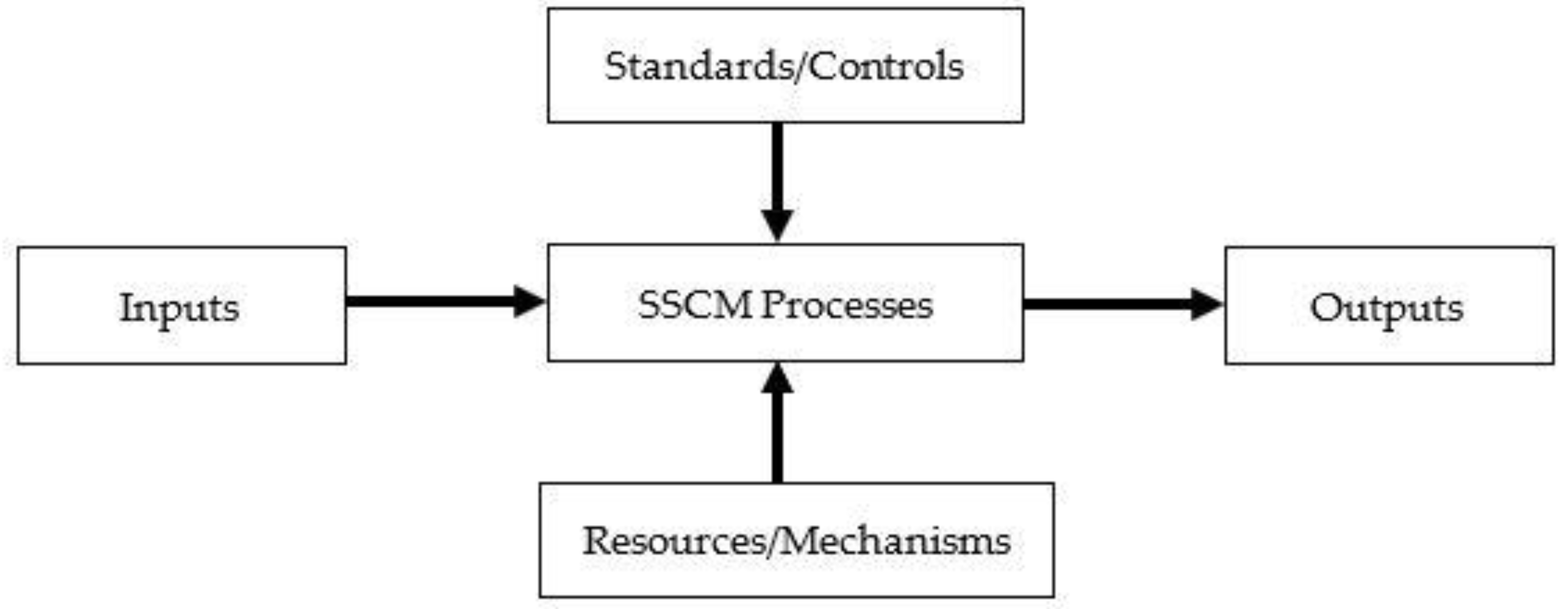

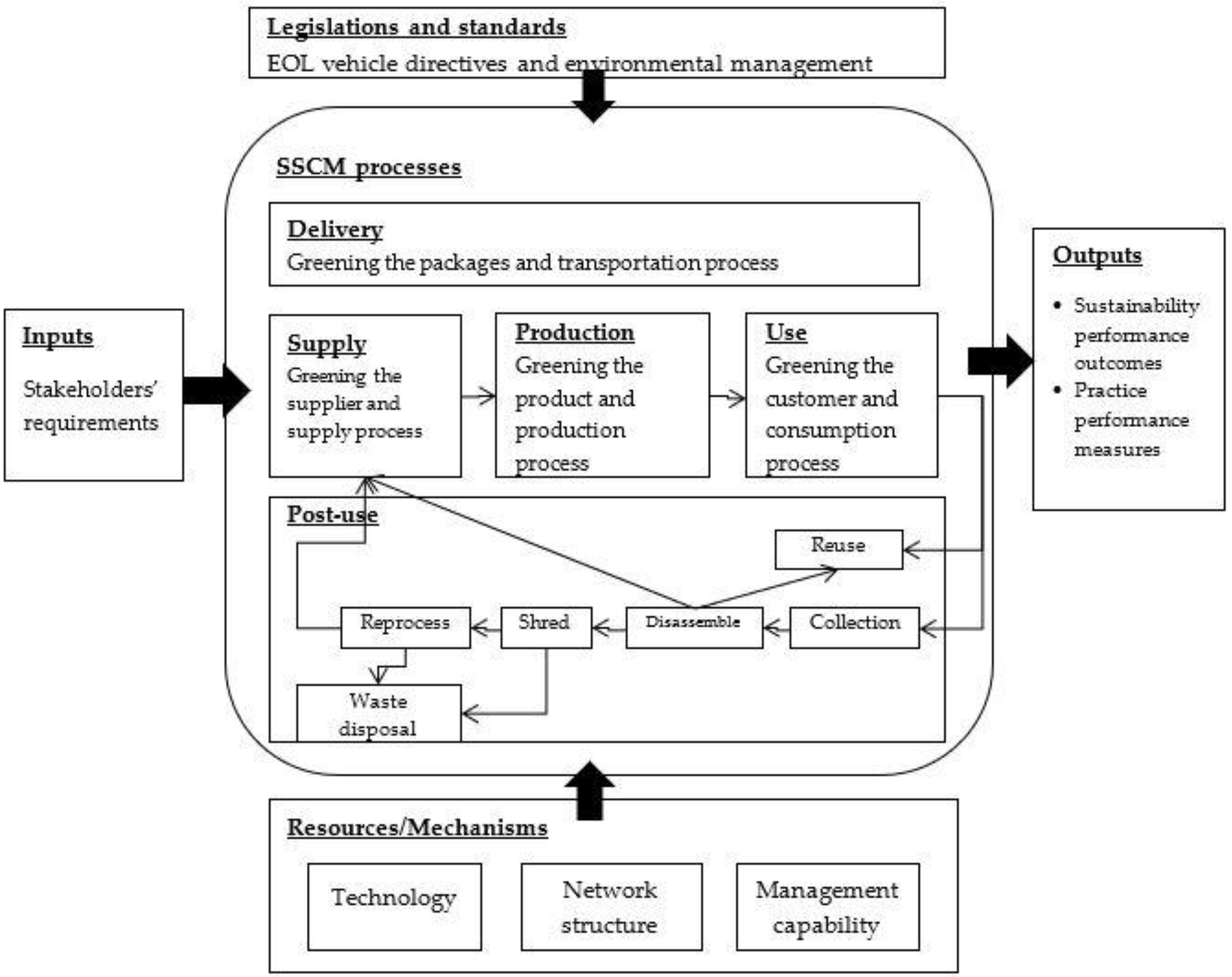

3.7. The Content Classification Scheme

4. Classification and Review of Studies in Auto-SSCM

4.1. Descriptive Analysis of the Literature Based on Their Content

4.2. Key Findings from the Previous Research on Auto-SSCM

4.2.1. Legislation and Standards

4.2.2. Inputs (Stakeholder Requirements)

4.2.3. SSCM Processes

4.2.4. Resources/Mechanisms

4.2.5. Outputs (Performance)

5. Implications for Designing an Auto-SSCM

6. Research Gaps and Recommendations for Future Research

- ➢

- The automotive industry is an industry that is highly influenced and shaped by its stakeholders’ (e.g., investors, governments, employees, consumers, competitors) demands. As our study shows, investigating the stakeholders’ requirements is one of the less studied areas in the literature. Specially, we discovered that a few studies available in this literature have mainly focused on the effect of stakeholders’ pressure on performance or adoption of environmental policies of a single firm. The automotive industry has a complex supply chain network with many tiers, where environmental degradation happens mostly within the supply chain network. Future studies should be directed toward how stakeholders’ requirements may affect the collaboration of supply chain tiers in the automotive industry in responding to the pressure.

- ➢

- Discussing the stakeholders’ pressure further, future research needs to catch up with the fast growth of the industry and changing stakeholders’ expectations. Given the globalization of the industry and the universal growth of car manufacturing, the stakeholders’ demands are constantly changing, putting more pressure on the industry to ensure that the sustainable requirements of the stakeholders are met. For instance, the industry is moving toward zero emissions and clean cities through renewable energies for electricity and alternative fuels by 2050 [186]. In this regard, it is crucial for the automotive industry to respond effectively to the complex and evolving needs of its stakeholders. To help the industry in tackling this issue, more academic research is required. For example, identifying the most influential stakeholders and investigating the change in their needs and expectations with growth of technology can be a promising research area. Furthermore, the growth in technology also increases the challenges of making the balance between environmental expectations of stakeholders and the economic benefit of the industry. These are some of the main challenges that leave a substantial room for future studies.

- ➢

- Concerning the aforementioned matter, it is further observed that the effect of stakeholders’ requirements on the relationship between different tiers in SC is largely unexplored. For instance, it is still not clear how different tiers in the automotive supply chain work collaboratively to address the environmental concern or regulations in the industry. Furthermore, the relationship between the tiers can additionally be joined to performance indicators of an SSC to explore how stakeholders’ requirements and the relationship between different tiers may affect the performance of an SSC.

- ➢

- Legislation and standards is another area that is not deeply studied. The studies have thus far investigated the problem across only one emerging economy (i.e., China) and in a few automobile sectors (i.e., plastic industry). There is not much knowledge about the effect of legislation and standards on the automobile sectors of several countries, particularly on the world’s major automobile manufacturers (i.e., India, Brazil). In addition, further research is required to study the impact of legislation and standards on reprocessing activities of various components in the automotive industry.

- ➢

- As to the sub-categories of SSCM processes, far more studies have been done on the post-use process compared with other sub-categories. Thus, more researches are needed to be conducted in the sub-categories of delivery, supply, production, and use to make a balance between the number of research in all sub-groups. Future studies in these sub-classes of SSCM processes would also lead to the development of the field.

- ➢

- In spite of the strategic importance of management capabilities for developing an SSCM, this topic is observed to be an under-researched area. Although the importance role of management capabilities including information management, relatiohnship and collaboration management, risk and knowledge management, and human resource management in the supply chain has been already very well researched in the literature of traditional SCM, it is certainly less investigated in the auto SSCM literature.

- ➢

- Despite the growing body of literature in the field of performance analysis, little effort has been made to discuss the intangible values that could be created by sustainability-conscious practices in the automotive industry. Studying the latent cost or intangible values of SSCM practices would provide a better understanding of the link between SSCM implementation and organizational performance, which could encourage proactive adoption of SSCM practices beyond the legislation.

- ➢

- The sustainability reports of the top-ranking car manufacturers are valuable secondary resources presenting the best sustainability-conscious practices in addition to the performance outcomes of the practices. These valuable sources have rarely been investigated in the reviewed literature. Future studies can develop further practical studies in this area relying on the useful information provided in these reports. Designing expert systems for measuring the environmental performance of automotive SCs and benchmarking with the best practices in this industry is an example.

- ➢

- Reviewing the available studies discloses that they have only discussed the selected stages of auto-SSCM. However, more studies should be conducted to develop an integrated perspective that resembles several processes of SSCM (or ideally even the whole processes). Doing so not only can boost the potential of designing a more sustainable SCM, but also would allow researchers to analyze the interaction between the processes and stages to make a transition toward a more sustainable SC.

- ➢

- The focus of studies in the automotive industry has only been on single countries so far. The practices and lessons learned from every country are different and comparing countries may shed more light on the establishment of a more sustainable automotive industry.

- ➢

- There is a growing concern on the social aspects of supply chains in the literature. We found only nine papers in our sample addressed a social issue. The social aspects of an automotive supply chain such as safety, health, training, education of the employees and their satisfaction, community development, and public policy of companies are understudied to a great extent.

- ➢

- The concentration of the studies in the literature has mostly been on large to medium size companies. The supply chain of automotive companies may include many small-sized companies’ employees and the level of adaptation of sustainability may be different for these companies compared with the large to medium sized ones. So, future studies should investigate the adaptation of sustainability by small companies.

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| No. | Source | Area of Study | Objective | Industry-Oriented |

|---|---|---|---|---|

| 1 | [187] | SSCM | Reviewing the studies applied system dynamic approach in renewable energy in SSCM | × |

| 2 | [188] | SSCM | Reviewing and classifying the whole area in order to find research gaps, and building a theoretical framework to define world-class SSCM | × |

| 3 | [189] | SSCM | Reviewing the themes and challenges of social sustainability in the context of SCs | × |

| 4 | [190] | SSCM | Tracking the integration of sustainable dimensions of automated guided vehicles into SCs | × |

| 5 | [24] | SSCM | Analyzing the advancement of sustainability issue for mineral SC | ✓ |

| 6 | [25] | SSCM | Presenting an overview of the studies addressed social issues in SSCM in the textile industry | ✓ |

| 7 | [26] | SSCM | Review of the studies related to sustainable management and optimization of biorefinery SC | ✓ |

| 8 | [191] | SSCM | A systematic literature review of the role of information systems in supporting SSCM | × |

| 9 | [192] | GSCM | Building a conceptual framework on GSCM and proposing future research opportunities | × |

| 10 | [22] | SSCM | Tracking the emergence of SSCM topic in the literature | × |

| 11 | [27] | SSCM | Deriving the key elements of SSCM implementation in the oil and gas industry and their relationship | ✓ |

| 12 | [17] | GSCM | Review of the practices and aspect of GSCM | × |

| 13 | [193] | GSCM | Drivers and barriers of adopting GSCM practices in Asian emerging economies | × |

| 14 | [194] | GSCM | Identifying the factors affecting GSCM in small and medium enterprises (SMEs) | × |

| 15 | [28] | GSCM | Investigating the effect of GSCM practices on U.K. food SMEs | ✓ |

| 16 | [195] | GSCM | Analyzing and classifying past studies in the area of GSCM | × |

| 17 | [196] | GSCM | Review of the models in SC dealing with optimizing CO2 emission | × |

| 18 | [197] | GSCM | Investigating the interaction between GSCM and green SC performance | × |

| 19 | [198] | GSCM | Giving an overview of the drivers and barriers of SSCM | × |

| 20 | [199] | SSCM | Deriving energy-related measurements in SSCM | × |

| 21 | [200] | SSCM | Review of the studies pertained to sustainable SC innovation | × |

| 22 | [29] | SSCM | Reviewing the development of SSCM in the fashion industry | ✓ |

| 23 | [201] | GSCM | Reviewing and classification of GSCM models and concepts | × |

| Journal | 1995–2000 | 2001–2005 | 2006–2010 | 2011–2015 | 2016–2017 | Total |

|---|---|---|---|---|---|---|

| Journal of Cleaner Production | 1 | 4 | 12 | 20 | 37 | |

| Journal of Material Cycles and Waste Management | 5 | 6 | 1 | 12 | ||

| International Journal of Production Economics | 3 | 2 | 4 | 9 | ||

| Resources, Conservation and Recycling | 2 | 1 | 2 | 1 | 3 | 9 |

| Waste Management | 3 | 1 | 3 | 2 | 9 | |

| The International Journal of Advanced Manufacturing Technology | 6 | 2 | 8 | |||

| Journal of Remanufacturing | 4 | 4 | 8 | |||

| Benchmarking: An International Journal | 1 | 4 | 2 | 7 | ||

| Production Planning & Control | 2 | 4 | 6 | |||

| Sustainability | 1 | 1 | 4 | 6 | ||

| The International Journal of Life Cycle Assessment | 1 | 2 | 3 | 6 | ||

| Jom | 1 | 2 | 1 | 1 | 5 | |

| International Journal of Production Research | 2 | 2 | 4 | |||

| Business Strategy and the Environment | 1 | 1 | 1 | 1 | 4 | |

| Journal of Manufacturing Technology Management | 1 | 1 | 1 | 3 | ||

| Computers & Industrial Engineering | 1 | 2 | 3 | |||

| Transportation Research Part E: Logistics and Transportation Review | 1 | 1 | 1 | 3 | ||

| International Journal of Operations & Production Management | 1 | 2 | 3 | |||

| Global Business Review | 1 | 2 | 3 | |||

| Supply Chain Management: An International Journal | 2 | 1 | 3 | |||

| Chemosphere | 2 | 2 | ||||

| Flexible Services and Manufacturing Journal | 1 | 1 | 2 | |||

| Ecological Economics | 1 | 1 | 2 | |||

| European Journal of Operational Research | 2 | 2 | ||||

| Journal of Hazardous Materials | 2 | 2 | ||||

| Technovation | 2 | 2 | ||||

| Annals of Operations Research | 2 | 2 | ||||

| International Journal of Sustainable Engineering | 2 | 2 | ||||

| Expert Systems with Applications | 1 | 1 | 2 | |||

| Others * | 5 | 6 | 4 | 17 | 31 | 63 |

| Total | 11 | 18 | 36 | 70 | 94 | 229 |

References

- Orsato, R.; Wells, P. The automobile industry & sustainability. J. Clean. Prod. 2007, 15, 989–993. [Google Scholar]

- Mathivathanan, D.; Haq, A.N. Comparisons of sustainable supply chain management practices in the automotive sector. Int. J. Bus. Perform. Supply Chain Model. 2017, 9, 18–27. [Google Scholar] [CrossRef]

- Adams, W.J. The automobile industry. In The Structure of European Industry; Springer: Dordrecht, Netherlands, 1981; pp. 187–207. [Google Scholar]

- Binder, A.; Rae, J. Encyclopedia Britannica. Last Update 4th August. Available online: http://global.britannica.com/EBchecked/topic/45050/automotive-industry 2013 (accessed on 4 June 2017).

- Xia, X.; Govindan, K.; Zhu, Q. Analyzing internal barriers for automotive parts remanufacturers in China using grey-DEMATEL approach. J. Clean. Prod. 2015, 87, 811–825. [Google Scholar] [CrossRef]

- Larsson, A. The development and regional significance of the automotive industry: Supplier parks in Western Europe. Int. J. Urban Reg. Res. 2002, 26, 767–784. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J. Purch. Supply Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Govindan, K.; Azevedo, S.; Carvalho, H.; Cruz-Machado, V. Lean, green and resilient practices influence on supply chain performance: Interpretive structural modeling approach. Int. J. Environ. Sci. Technol. 2015, 12, 15–34. [Google Scholar] [CrossRef]

- Mathivathanan, D.; Kannan, D.; Haq, A.N. Sustainable supply chain management practices in Indian automotive industry: A multi-stakeholder view. Resour. Conserv. Recycl. 2018, 128, 284–305. [Google Scholar] [CrossRef]

- Brundtland, G. World Commission on Environment and Development; Oxford University Press: Oxford, UK, 1987. [Google Scholar]

- Ashby, A.; Leat, M.; Hudson-Smith, M. Making connections: A review of supply chain management and sustainability literature. Supply Chain Manag. Int. J. 2012, 17, 497–516. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Beamon, B.M. Designing the green supply chain. Logist. Inf. Manag. 1999, 12, 332–342. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Fleischmann, M.; Bloemhof-Ruwaard, J.M.; Dekker, R.; Van der Laan, E.; Van Nunen, J.A.; Van Wassenhove, L.N. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Guide, V.D.R., Jr.; Van Wassenhove, L.N. Closed-loop supply chains: An introduction to the feature issue (part 1). Prod. Oper. Manag. 2006, 15, 345–350. [Google Scholar] [CrossRef]

- Islam, S.; Karia, N.; Fauzi, F.B.A.; Soliman, M. A review on green supply chain aspects and practices. Manag. Mark. 2017, 12, 12–36. [Google Scholar] [CrossRef] [Green Version]

- Carter, C.R.; Liane Easton, P. Sustainable supply chain management: evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- Machi, L.A.; McEvoy, B.T. The literature review: Six steps to success; Corwin Press: Sauzen Oaks, CA, USA, 2016. [Google Scholar]

- Creswell, J.W.; Creswell, J.D. Research Design: Qualitative, Quantitative, and Mixed Methods Approaches; Sage publications: Thousand oaks, CA, USA, 2017. [Google Scholar]

- Govindan, K.; Soleimani, H. A review of reverse logistics and closed-loop supply chains: A Journal of Cleaner Production focus. J. Clean. Prod. 2017, 142, 371–384. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of sustainability in supply chain management: A literature review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Beske, P.; Land, A.; Seuring, S. Sustainable supply chain management practices and dynamic capabilities in the food industry: A critical analysis of the literature. Int. J. Prod. Econ. 2014, 152, 131–143. [Google Scholar] [CrossRef]

- Sauer, P.C.; Seuring, S. Sustainable supply chain management for minerals. J. Clean. Prod. 2017, 151, 235–249. [Google Scholar] [CrossRef]

- Köksal, D.; Strähle, J.; Müller, M.; Freise, M. Social Sustainable Supply Chain Management in the Textile and Apparel Industry—A Literature Review. Sustainability 2017, 9, 100. [Google Scholar] [CrossRef]

- Pérez, A.T.E.; Camargo, M.; Rincón, P.C.N.; Marchant, M.A. Key challenges and requirements for sustainable and industrialized biorefinery supply chain design and management: A bibliographic analysis. Renew. Sustain. Energy Rev. 2017, 69, 350–359. [Google Scholar] [CrossRef]

- Ahmad, N.K.W.; de Brito, M.P.; Rezaei, J.; Tavasszy, L.A. An integrative framework for sustainable supply chain management practices in the oil and gas industry. J. Environ. Plan. Manag. 2017, 60, 577–601. [Google Scholar] [CrossRef]

- Ali, A.; Bentley, Y.; Cao, G.; Habib, F. Green supply chain management–food for thought? Int. J. Logist. Res. Appl. 2017, 20, 22–38. [Google Scholar] [CrossRef]

- Khurana, K.; Ricchetti, M. Two decades of sustainable supply chain management in the fashion business, an appraisal. J. Fash. Mark. Manag. 2016, 20, 89–104. [Google Scholar] [CrossRef]

- Fahimnia, B.; Sarkis, J.; Davarzani, H. Green supply chain management: A review and bibliometric analysis. Int. J. Prod. Econ. 2015, 162, 101–114. [Google Scholar] [CrossRef]

- Abedinnia, H.; Glock, C.H.; Schneider, M.; Grosse, E.H. Machine scheduling problems in production: A tertiary study. Comput. Ind. Eng. 2017, 111, 403–416. [Google Scholar] [CrossRef]

- Hochrein, S.; Glock, C.H. Systematic literature reviews in purchasing and supply management research: A tertiary study. Int. J. Integr. Supply Manag. 2013, 7, 215–245. [Google Scholar] [CrossRef]

- Saunders, M.N. Research Methods for Business Students, 5/e; Pearson Education Edinburgh: London, UK, 2011. [Google Scholar]

- Marasco, A. Third-party logistics: A literature review. Int. J. Prod. Econ. 2008, 113, 127–147. [Google Scholar] [CrossRef]

- Abedinnia, H.; Glock, C.H.; Schneider, M.D. Machine scheduling in production: A content analysis. Appl. Math. Model. 2017, 50, 279–299. [Google Scholar] [CrossRef]

- Shekarian, E.; Rashid, S.H.A.; Bottan, E.; De, S.K. Fuzzy inventory models: A comprehensive review. Appl. Soft Comput. 2017. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Cooper, H. Research Synthesis and Meta-Analysis: A Step-by-Step Approach; Sage publications: Thousand Oaks, CA, USA, 2015. [Google Scholar]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Yong-Hak, J. Web of Science; Thomson Reuters: Eagan, MN, USA, 2013. [Google Scholar]

- Chicksand, D.; Watson, G.; Walker, H.; Radnor, Z.; Johnston, R. Theoretical perspectives in purchasing and supply chain management: An analysis of the literature. Supply Chain Manag. Int. J. 2012, 17, 454–472. [Google Scholar] [CrossRef]

- Cheng-Leong, A.; Li Pheng, K.; Keng Leng, G.R. IDEF*: A comprehensive modelling methodology for the development of manufacturing enterprise systems. Int. J. Prod. Res. 1999, 37, 3839–3858. [Google Scholar] [CrossRef]

- Woolridge, A.; Morrissey, A.; Phillips, P.S. The development of strategic and tactical tools, using systems analysis, for waste management in large complex organisations: A case study in UK healthcare waste. Resour. Conserv. Recycl. 2005, 44, 115–137. [Google Scholar] [CrossRef]

- Fenech, C.; Nolan, K.; Rock, L.; Morrissey, A. Development of a decision-support tool for identifying the most suitable approach to achieve nitrate source determination. Environ. Sci. Process. Impacts 2014, 16, 2564–2570. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.-H.; Jang, K.-J. Designing performance analysis and IDEF0 for enterprise modelling in BPR. Int. J. Prod. Econ. 2002, 76, 121–133. [Google Scholar] [CrossRef]

- Commission, E. Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on end-of-life vehicles. Off. J. Eur. Communities 2000, 269, 34–269. [Google Scholar]

- Zorpas, A.A.; Inglezakis, V.J. Automotive industry challenges in meeting EU 2015 environmental standard. Technol. Soc. 2012, 34, 55–83. [Google Scholar] [CrossRef]

- Ferrao, P.; Amaral, J. Assessing the economics of auto recycling activities in relation to European Union Directive on end of life vehicles. Technol. Forecast. Soc. Chang. 2006, 73, 277–289. [Google Scholar] [CrossRef]

- Johnson, M.; Wang, M. Evaluation policies and automotive recovery options according to the European Union directive on end-of-life vehicles (ELV). Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2002, 216, 723–739. [Google Scholar] [CrossRef]

- Coates, G.; Rahimifard, S. Cost Models for Increased Value Recovery from End-of-Life Vehicles; CIRP Life Cycle Engineering Conference; Loughborough University: Loughborough, UK, 2006. [Google Scholar]

- Zhang, H.; Chen, M. Current recycling regulations and technologies for the typical plastic components of end-of-life passenger vehicles: A meaningful lesson for China. J. Mater. Cycles Waste Manag. 2014, 16, 187–200. [Google Scholar] [CrossRef]

- Zhang, J.-H.; Chen, M. Assessing the impact of China’s vehicle emission standards on diesel engine remanufacturing. J. Clean. Prod. 2015, 107, 177–184. [Google Scholar] [CrossRef]

- Nawrocka, D.; Brorson, T.; Lindhqvist, T. ISO 14001 in environmental supply chain practices. J. Clean. Prod. 2009, 17, 1435–1443. [Google Scholar] [CrossRef]

- Mazzanti, M.; Zoboli, R. Economic instruments and induced innovation: The European policies on end-of-life vehicles. Ecol. Econ. 2006, 58, 318–337. [Google Scholar] [CrossRef]

- Kumar, S.; Yamaoka, T. System dynamics study of the Japanese automotive industry closed loop supply chain. J. Manuf. Technol. Manag. 2007, 18, 115–138. [Google Scholar] [CrossRef]

- Xiang, W.; Ming, C. Implementing extended producer responsibility: vehicle remanufacturing in China. J. Clean. Prod. 2011, 19, 680–686. [Google Scholar] [CrossRef]

- Roh, J.J.; Yang, M.G.; Park, K.; Hong, P. Stakeholders’ pressure and managerial responses: lessons from hybrid car development and commercialisation. Int. J. Bus. Inf. Syst. 2015, 18, 506–529. [Google Scholar] [CrossRef]

- Seles, B.M.R.P.; de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Dangelico, R.M. The green bullwhip effect, the diffusion of green supply chain practices, and institutional pressures: Evidence from the automotive sector. Int. J. Prod. Econ. 2016, 182, 342–355. [Google Scholar] [CrossRef]

- Sarkis, J.; Gonzalez-Torre, P.; Adenso-Diaz, B. Stakeholder pressure and the adoption of environmental practices: The mediating effect of training. J. Oper. Manag. 2010, 28, 163–176. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Green supply chain management: Pressures, practices and performance within the Chinese automobile industry. J. Clean. Prod. 2007, 15, 1041–1052. [Google Scholar] [CrossRef]

- Lin, L.-H.; Lan, J.-F. Green supply chain management for the SME automotive suppliers. Int. J. Automot. Technol. Manag. 2013, 13, 372–390. [Google Scholar] [CrossRef]

- Vanalle, R.M.; Ganga, G.M.D.; Godinho Filho, M.; Lucato, W.C. Green supply chain management: An investigation of pressures, practices, and performance within the Brazilian automotive supply chain. J. Clean. Prod. 2017, 151, 250–259. [Google Scholar] [CrossRef]

- Sutherland, J.; Gunter, K.; Allen, D.; Bauer, D.; Bras, B.; Gutowski, T.; Murphy, C.; Piwonka, T.; Sheng, P.; Thurston, D. A global perspective on the environmental challenges facing the automotive industry: State-of-the-art and directions for the future. Int. J. Veh. Des. 2004, 34, 86–110. [Google Scholar] [CrossRef]

- Dyckhoff, H.; Souren, R.; Keilen, J. The expansion of supply chains to closed loop systems: A conceptual framework and the automotive industry’s point of view. In Supply Chain Management and Reverse Logistics; Springer: Berlin, Germany, 2004; pp. 13–34. [Google Scholar]

- Olugu, E.U.; Wong, K.Y.; Shaharoun, A.M. Development of key performance measures for the automobile green supply chain. Resour. Conserv. Recycl. 2011, 55, 567–579. [Google Scholar] [CrossRef]

- Glock, C.H.; Grosse, E.H.; Ries, J.M. Decision support models for supplier development: Systematic literature review and research agenda. Int. J. Prod. Econ. 2017, 193, 798–812. [Google Scholar] [CrossRef]

- Kannan, D.; Khodaverdi, R.; Olfat, L.; Jafarian, A.; Diabat, A. Integrated fuzzy multi criteria decision making method and multi-objective programming approach for supplier selection and order allocation in a green supply chain. J. Clean. Prod. 2013, 47, 355–367. [Google Scholar] [CrossRef]

- Kumar, A.; Jain, V.; Kumar, S. A comprehensive environment friendly approach for supplier selection. Omega 2014, 42, 109–123. [Google Scholar] [CrossRef]

- Kumar Sahu, N.; Datta, S.; Sankar Mahapatra, S. Green supplier appraisement in fuzzy environment. Benchmarking Int. J. 2014, 21, 412–429. [Google Scholar] [CrossRef]

- Hashemi, S.H.; Karimi, A.; Tavana, M. An integrated green supplier selection approach with analytic network process and improved Grey relational analysis. Int. J. Prod. Econ. 2015, 159, 178–191. [Google Scholar] [CrossRef]

- Yu, Q.; Hou, F. An approach for green supplier selection in the automobile manufacturing industry. Kybernetes 2016, 45, 571–588. [Google Scholar] [CrossRef]

- Neumüller, C.; Lasch, R.; Kellner, F. Integrating sustainability into strategic supplier portfolio selection. Manag. Decis. 2016, 54, 194–221. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Jauhar, S.K.; Pant, M. Integrating DEA with DE and MODE for sustainable supplier selection. J. Comput. Sci. 2017, 21, 299–306. [Google Scholar] [CrossRef]

- Ghadimi, P.; Dargi, A.; Heavey, C. Making sustainable sourcing decisions: practical evidence from the automotive industry. Int. J. Logist. Res. Appl. 2017, 20, 297–321. [Google Scholar] [CrossRef]

- Kumar, D.; Rahman, Z.; Chan, F.T. A fuzzy AHP and fuzzy multi-objective linear programming model for order allocation in a sustainable supply chain: A case study. Int. J. Comput. Integr. Manuf. 2017, 30, 535–551. [Google Scholar] [CrossRef]

- Datta, S.; Samantra, C.; Sankar Mahapatra, S.; Mandal, G.; Majumdar, G. Appraisement and selection of third party logistics service providers in fuzzy environment. Benchmarking Int. J. 2013, 20, 537–548. [Google Scholar] [CrossRef]

- Khodaverdi, R.; Hashemi, S.H. A grey–based decision–making approach for selecting a reverse logistics provider in a closed loop supply chain. Int. J. Manag. Decis. Mak. 2015, 14, 32–43. [Google Scholar] [CrossRef]

- Basu, R.J.; Subramanian, N.; Gunasekaran, A.; Palaniappan, P. Influence of non-price and environmental sustainability factors on truckload procurement process. Ann. Oper. Res. 2017, 250, 363–388. [Google Scholar] [CrossRef]

- Ghadimi, P.; Dargi, A.; Heavey, C. Sustainable supplier performance scoring using audition check-list based fuzzy inference system: A case application in automotive spare part industry. Comput. Ind. Eng. 2017, 105, 12–27. [Google Scholar] [CrossRef] [Green Version]

- Govindan, K.; Jafarian, A.; Nourbakhsh, V. Bi-objective integrating sustainable order allocation and sustainable supply chain network strategic design with stochastic demand using a novel robust hybrid multi-objective metaheuristic. Comput. Oper. Res. 2015, 62, 112–130. [Google Scholar] [CrossRef]

- Koplin, J.; Seuring, S.; Mesterharm, M. Incorporating sustainability into supply management in the automotive industry – the case of the Volkswagen AG. J. Clean. Prod. 2007, 15, 1053–1062. [Google Scholar] [CrossRef]

- Akman, G. Evaluating suppliers to include green supplier development programs via fuzzy c-means and VIKOR methods. Comput. Ind. Eng. 2015, 86, 69–82. [Google Scholar] [CrossRef]

- Villalba, G.; Segarra, M.; Chimenos, J.M.; Espiell, F. Using the recyclability index of materials as a tool for design for disassembly. Ecol. Econ. 2004, 50, 195–200. [Google Scholar] [CrossRef]

- Mat Saman, M.Z.; Zakuan, N.; Blount, G. Design for End-of-Life Value Framework for Vehicles Design and Development Process. J. Sustain. Dev. 2012, 5. [Google Scholar] [CrossRef]

- Yang, S.; Nasr, N.; Ong, S.; Nee, A. Designing automotive products for remanufacturing from material selection perspective. J. Clean. Prod. 2015, 153, 570–579. [Google Scholar] [CrossRef]

- Kumar, S.; Luthra, S.; Govindan, K.; Kumar, N.; Haleem, A. Barriers in green lean six sigma product development process: An ISM approach. Prod. Plan. Control 2016, 27, 604–620. [Google Scholar] [CrossRef]

- Pechancová, V. Renewable energy potential in the automotive sector: Czech regional case study. J. Secur. Sustain. Issues 2017. [Google Scholar] [CrossRef]

- Granovskii, M.; Dincer, I.; Rosen, M.A. Economic and environmental comparison of conventional, hybrid, electric and hydrogen fuel cell vehicles. J. Power Sources 2006, 159, 1186–1193. [Google Scholar] [CrossRef]

- Jones, C.T. Another look at US passenger vehicle use and the rebound effect from improved fuel efficiency. Energy J. 2010, 99–110. [Google Scholar]

- Sivak, M.; Tsimhoni, O. Fuel efficiency of vehicles on US roads: 1923–2006. Energy Policy 2009, 37, 3168–3170. [Google Scholar] [CrossRef]

- Hollos, D.; Blome, C.; Foerstl, K. Does sustainable supplier co-operation affect performance? Examining implications for the triple bottom line. Int. J. Prod. Res. 2012, 50, 2968–2986. [Google Scholar] [CrossRef]

- White, G.R.; Wang, X.; Li, D. Inter-organisational green packaging design: A case study of influencing factors and constraints in the automotive supply chain. Int. J. Prod. Res. 2015, 53, 6551–6566. [Google Scholar] [CrossRef]

- Staš, D.; Lenort, R.; Wicher, P.; Holman, D. Green Transport balanced scorecard model with analytic network process support. Sustainability 2015, 7, 15243–15261. [Google Scholar] [CrossRef]

- Nunes, B.; Bennett, D. Green operations initiatives in the automotive industry: An environmental reports analysis and benchmarking study. Benchmarking Int. J. 2010, 17, 396–420. [Google Scholar] [CrossRef]

- Krikke, H.; le Blanc, I.; van Krieken, M.; Fleuren, H. Low-frequency collection of materials disassembled from end-of-life vehicles. Int. J. Prod. Econ. 2008, 111, 209–228. [Google Scholar] [CrossRef]

- Sundin, E.; Dunbäck, O. Reverse logistics challenges in remanufacturing of automotive mechatronic devices. J. Remanuf. 2013, 3, 2. [Google Scholar] [CrossRef] [Green Version]

- Abdulrahman, M.D.; Gunasekaran, A.; Subramanian, N. Critical barriers in implementing reverse logistics in the Chinese manufacturing sectors. Int. J. Prod. Econ. 2014, 147, 460–471. [Google Scholar] [CrossRef]

- Shaharudin, M.R.; Govindan, K.; Zailani, S.; Tan, K.C. Managing product returns to achieve supply chain sustainability: An exploratory study and research propositions. J. Clean. Prod. 2015, 101, 1–15. [Google Scholar] [CrossRef]

- Colledani, M.; Battaïa, O. A decision support system to manage the quality of end-of-life products in disassembly systems. CIRP Ann. 2016, 65, 41–44. [Google Scholar] [CrossRef]

- Hwang, I.; Yokono, S.; Matsuto, T. Pretreatment of automobile shredder residue (ASR) for fuel utilization. Chemosphere 2008, 71, 879–885. [Google Scholar] [CrossRef] [Green Version]

- Vermeulen, I.; Van Caneghem, J.; Block, C.; Baeyens, J.; Vandecasteele, C. Automotive shredder residue (ASR): Reviewing its production from end-of-life vehicles (ELVs) and its recycling, energy or chemicals’ valorisation. J. Hazard. Mater. 2011, 190, 8–27. [Google Scholar] [CrossRef]

- Khodier, A.; Williams, K.; Dallison, N. Challenges around automotive shredder residue production and disposal. Waste Manag. 2017, 73, 566–573. [Google Scholar] [CrossRef]

- Saavedra, Y.M.; Barquet, A.P.; Rozenfeld, H.; Forcellini, F.A.; Ometto, A.R. Remanufacturing in Brazil: Case studies on the automotive sector. J. Clean. Prod. 2013, 53, 267–276. [Google Scholar] [CrossRef]

- Yusop, N.; Wahab, D.A.; Saibani, N. Realising the automotive remanufacturing roadmap in Malaysia: challenges and the way forward. J. Clean. Prod. 2016, 112, 1910–1919. [Google Scholar] [CrossRef]

- Chaowanapong, J.; Jongwanich, J.; Ijomah, W. Factors influencing a firm’s decision to conduct remanufacturing: evidence from the Thai automotive parts industry. Prod. Plan. Control 2017, 28, 1139–1151. [Google Scholar] [CrossRef]

- Ramoni, M.O.; Zhang, H.-C. End-of-life (EOL) issues and options for electric vehicle batteries. Clean Technol. Environ. Policy 2013, 15, 881–891. [Google Scholar] [CrossRef]

- Đorđević, M.; Kokić, M. Concept for management of end of life vehicles recycling system. Int. J. Qual. Res. 2008, 2, 179–184. [Google Scholar]

- Ahmed, S.; Ahmed, S.; Shumon, M.R.H.; Quader, M.A.; Cho, H.M.; Mahmud, M.I. Prioritizing strategies for sustainable end-of-life vehicle management using combinatorial multi-criteria decision making method. Int. J. Fuzzy Syst. 2016, 18, 448–462. [Google Scholar] [CrossRef]

- Keivanpour, S.; Ait-Kadi, D.; Mascle, C. Automobile manufacturers’ strategic choice in applying green practices: joint application of evolutionary game theory and fuzzy rule-based approach. Int. J. Prod. Res. 2017, 55, 1312–1335. [Google Scholar] [CrossRef]

- Kuik, S.S.; Nagalingam, S.; Samaranayake, P.; McLean, M.W. Evaluation of recovery configuration options by product utilisation value. J. Manuf. Technol. Manag. 2017, 28, 686–710. [Google Scholar] [CrossRef]

- Subramoniam, R.; Huisingh, D.; Chinnam, R.B. Remanufacturing for the automotive aftermarket-strategic factors: Literature review and future research needs. J. Clean. Prod. 2009, 17, 1163–1174. [Google Scholar] [CrossRef]

- Anthony, C.; Cheung, W.M. Cost evaluation in design for end-of-Life of automotive components. J. Remanuf. 2017, 7, 97–111. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Bai, H.; Yin, J.; Xu, H. Life cycle assessment of end-of-life vehicle recycling processes in China—take Corolla taxis for example. J. Clean. Prod. 2016, 117, 176–187. [Google Scholar] [CrossRef]

- Chavez, R.; Sharma, M. Profitability and environmental friendliness of a closed-loop supply chain for PET components: A case study of the Mexican automobile market. Resour. Conserv. Recycl. 2017. [Google Scholar] [CrossRef]

- Bellmann, K.; Khare, A. European response to issues in recycling car plastics. Technovation 1999, 19, 721–734. [Google Scholar] [CrossRef]

- Fleischmann, M.; Krikke, H.R.; Dekker, R.; Flapper, S.D.P. A characterisation of logistics networks for product recovery. Omega 2000, 28, 653–666. [Google Scholar] [CrossRef]

- Zarei, M.; Mansour, S.; Husseinzadeh Kashan, A.; Karimi, B. Designing a reverse logistics network for end-of-life vehicles recovery. Math. Probl. Eng. 2010. [Google Scholar] [CrossRef]

- Jayant, A. REVERSE LOGISTICS: PERSPECTIVES, EMPIRICAL STUDIES AND RESEARCH DIRECTIONS. Int. J. Ind. Eng. Theoryappl. Pract. 2012, 19. [Google Scholar]

- Kannegiesser, M.; Günther, H.-O. Sustainable development of global supply chains—part 1: Sustainability optimization framework. Flex. Serv. Manuf. J. 2014, 26, 24–47. [Google Scholar] [CrossRef]

- Kannegiesser, M.; Günther, H.-O.; Gylfason, Ó. Sustainable development of global supply chains—part 2: Investigation of the European automotive industry. Flex. Serv. Manuf. J. 2014, 26, 48–68. [Google Scholar] [CrossRef]

- Ene, S.; Öztürk, N. Network modeling for reverse flows of end-of-life vehicles. Waste Manag. 2015, 38, 284–296. [Google Scholar] [CrossRef]

- Tognetti, A.; Grosse-Ruyken, P.T.; Wagner, S.M. Green supply chain network optimization and the trade-off between environmental and economic objectives. Int. J. Prod. Econ. 2015, 170, 385–392. [Google Scholar] [CrossRef]

- Özceylan, E.; Demirel, N.; Çetinkaya, C.; Demirel, E. A closed-loop supply chain network design for automotive industry in Turkey. Comput. Ind. Eng. 2017, 113, 727–745. [Google Scholar] [CrossRef]

- Demirel, E.; Demirel, N.; Gökçen, H. A mixed integer linear programming model to optimize reverse logistics activities of end-of-life vehicles in Turkey. J. Clean. Prod. 2016, 112, 2101–2113. [Google Scholar] [CrossRef]

- Boks, C.; Tempelman, E. Future disassembly and recycling technology: results of a Delphi study. Futures 1998, 30, 425–442. [Google Scholar] [CrossRef]

- Pickering, S. Recycling technologies for thermoset composite materials—current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Günther, H.-O.; Kannegiesser, M.; Autenrieb, N. The role of electric vehicles for supply chain sustainability in the automotive industry. J. Clean. Prod. 2015, 90, 220–233. [Google Scholar] [CrossRef]

- Butler, E.; Devlin, G.; McDonnell, K. Waste polyolefins to liquid fuels via pyrolysis: review of commercial state-of-the-art and recent laboratory research. Waste Biomass Valorization 2011, 2, 227–255. [Google Scholar] [CrossRef]

- Schmidt, W.-P.; Dahlqvist, E.; Finkbeiner, M.; Krinke, S.; Lazzari, S.; Oschmann, D.; Pichon, S.; Thiel, C. Life cycle assessment of lightweight and end-of-life scenarios for generic compact class passenger vehicles. Int. J. Life Cycle Assess. 2004, 9, 405–416. [Google Scholar] [CrossRef]

- MacLean, H.L.; Lave, L.B. Evaluating automobile fuel/propulsion system technologies. Prog. Energy Combust. Sci. 2003, 29, 1–69. [Google Scholar] [CrossRef]

- Uruburu, Á.; Ponce-Cueto, E.; Cobo-Benita, J.R.; Ordieres-Meré, J. The new challenges of end-of-life tyres management systems: A Spanish case study. Waste Manag. 2013, 33, 679–688. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Chen, M. End-of-life vehicle dismantling and recycling enterprises: developing directions in China. JOM 2013, 65, 1015–1020. [Google Scholar] [CrossRef]

- Freiberger, S.; Albrecht, M.; Käufl, J. Reverse engineering technologies for remanufacturing of automotive systems communicating via CAN bus. J. Remanuf. 2011, 1, 6. [Google Scholar] [CrossRef]

- Mamalis, A.; Spentzas, K.; Mamali, A. The impact of automotive industry and its supply chain to climate change: Somme techno-economic aspects. Eur. Transp. Res. Rev. 2013, 5, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Tian, G.; Chu, J.; Hu, H.; Li, H. Technology innovation system and its integrated structure for automotive components remanufacturing industry development in China. J. Clean. Prod. 2014, 85, 419–432. [Google Scholar] [CrossRef]

- Förster, B. Technology foresight for sustainable production in the German automotive supplier industry. Technol. Forecast. Soc. Chang. 2015, 92, 237–248. [Google Scholar] [CrossRef]

- Ferguson, N.; Browne, J. Issues in end-of-life product recovery and reverse logistics. Prod. Plan. Control 2001, 12, 534–547. [Google Scholar] [CrossRef]

- Rahimifard, A.; Newman, S.T.; Rahimifard, S. A web-based information system to support end-of-life product recovery. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2004, 218, 1047–1057. [Google Scholar] [CrossRef] [Green Version]

- Vachon, S.; Klassen, R.D. Extending green practices across the supply chain—The impact of upstream and downstream integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Simpson, D.; Power, D.; Samson, D. Greening the automotive supply chain: A relationship perspective. Int. J. Oper. Prod. Manag. 2007, 27, 28–48. [Google Scholar] [CrossRef]

- Liu, Y.; Srai, J.S.; Evans, S. Environmental management: the role of supply chain capabilities in the auto sector. Supply Chain Manag. Int. J. 2016, 21, 1–19. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, Q.; Seuring, S. Linking capabilities to green operations strategies: The moderating role of corporate environmental proactivity. Int. J. Prod. Econ. 2017, 187, 182–195. [Google Scholar] [CrossRef]

- Xie, G. Cooperative strategies for sustainability in a decentralized supply chain with competing suppliers. J. Clean. Prod. 2016, 113, 807–821. [Google Scholar] [CrossRef]

- Rehman, M.A.A.; Aneyrao, T.A.; Shrivastava, R. Identification of critical success factors in Indian automobile industry: A GSCM approach. Int. J. Process Manag. Benchmarking 2015, 5, 229–245. [Google Scholar] [CrossRef]

- Graham, I.; Goodall, P.; Peng, Y.; Palmer, C.; West, A.; Conway, P.; Mascolo, J.E.; Dettmer, F.U. Performance measurement and KPIs for remanufacturing. J. Remanuf. 2015, 5, 10. [Google Scholar] [CrossRef]

- Vasanthakumar, C.; Vinodh, S.; Ramesh, K. Application of interpretive structural modelling for analysis of factors influencing lean remanufacturing practices. Int. J. Prod. Res. 2016, 54, 7439–7452. [Google Scholar] [CrossRef]

- Habidin, N.F.; Mohd Zubir, A.F.; Mohd Fuzi, N.; Md Latip, N.A.; Azman, M.N.A. Critical success factors of sustainable manufacturing practices in Malaysian automotive industry. Int. J. Sustain. Eng. 2017, 1–6. [Google Scholar] [CrossRef]

- Tyagi, M.; Kumar, P.; Kumar, D. Analysis of interactions among the drivers of green supply chain management. Int. J. Bus. Perform. Supply Chain Model. 2015, 7, 92–108. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Vafadarnikjoo, A. Intuitionistic fuzzy based DEMATEL method for developing green practices and performances in a green supply chain. Expert Syst. Appl. 2015, 42, 7207–7220. [Google Scholar] [CrossRef]

- Ravi, V.; Ravi, V.; Shankar, R.; Shankar, R. An ISM-based approach analyzing interactions among variables of reverse logistics in automobile industries. J. Model. Manag. 2017, 12, 36–52. [Google Scholar] [CrossRef]

- Brent, A.C.; Visser, J.K. An environmental performance resource impact indicator for life cycle management in the manufacturing industry. J. Clean. Prod. 2005, 13, 557–565. [Google Scholar] [CrossRef] [Green Version]

- Sellitto, M.A.; Bittencourt, S.A.; Reckziegel, B.I. Evaluating the implementation of GSCM in industrial supply chains: Two cases in the automotive industry. Chem. Eng. Trans. 2015, 43, 1315–1320. [Google Scholar]

- Schöggl, J.-P.; Fritz, M.M.; Baumgartner, R.J. Toward supply chain-wide sustainability assessment: A conceptual framework and an aggregation method to assess supply chain performance. J. Clean. Prod. 2016, 131, 822–835. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. LARG index: A benchmarking tool for improving the leanness, agility, resilience and greenness of the automotive supply chain. Benchmarking Int. J. 2016, 23, 1472–1499. [Google Scholar] [CrossRef]

- Azevedo, S.G.; Govindan, K.; Carvalho, H.; Cruz-Machado, V. Ecosilient Index to assess the greenness and resilience of the upstream automotive supply chain. J. Clean. Prod. 2013, 56, 131–146. [Google Scholar] [CrossRef]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Impact of supply chain management practices on sustainability. J. Clean. Prod. 2014, 85, 212–225. [Google Scholar] [CrossRef]

- Chavez, R.; Yu, W.; Feng, M.; Wiengarten, F. The Effect of Customer-Centric Green Supply Chain Management on Operational Performance and Customer Satisfaction. Bus. Strategy Environ. 2016, 25, 205–220. [Google Scholar] [CrossRef]

- Chiappetta Jabbour, C.J.; Mauricio, A.L.; Jabbour, A.B.L.D.S. Critical success factors and green supply chain management proactivity: shedding light on the human aspects of this relationship based on cases from the Brazilian industry. Prod. Plan. Control 2017, 28, 671–683. [Google Scholar] [CrossRef] [Green Version]

- Maria Vanalle, R.; Blanco Santos, L. Green supply chain management in Brazilian automotive sector. Manag. Environ. Qual. Int. J. 2014, 25, 523–541. [Google Scholar] [CrossRef]

- Tian, Y.; Govindan, K.; Zhu, Q. A system dynamics model based on evolutionary game theory for green supply chain management diffusion among Chinese manufacturers. J. Clean. Prod. 2014, 80, 96–105. [Google Scholar] [CrossRef]

- Drohomeretski, E.; Gouvea da Costa, S.; Pinheiro de Lima, E. Green supply chain management: drivers, barriers and practices within the Brazilian automotive industry. J. Manuf. Technol. Manag. 2014, 25, 1105–1134. [Google Scholar] [CrossRef]

- Luthra, S.; Qadri, M.A.; Garg, D.; Haleem, A. Identification of critical success factors to achieve high green supply chain management performances in Indian automobile industry. Int. J. Logist. Syst. Manag. 2014, 18, 170–199. [Google Scholar] [CrossRef]

- Zailani, S.; Govindan, K.; Iranmanesh, M.; Shaharudin, M.R.; Chong, Y.S. Green innovation adoption in automotive supply chain: The Malaysian case. J. Clean. Prod. 2015, 108, 1115–1122. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Critical success factors of green supply chain management for achieving sustainability in Indian automobile industry. Prod. Plan. Control 2015, 26, 339–362. [Google Scholar]

- Govindan, K.; Shankar, K.M.; Kannan, D. Application of fuzzy analytic network process for barrier evaluation in automotive parts remanufacturing towards cleaner production–a study in an Indian scenario. J. Clean. Prod. 2016, 114, 199–213. [Google Scholar] [CrossRef]

- Tippayawong, K.Y.; Niyomyat, N.; Sopadang, A.; Ramingwong, S. Factors Affecting Green Supply Chain Operational Performance of the Thai Auto Parts Industry. Sustainability 2016, 8, 1161. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. The impacts of critical success factors for implementing green supply chain management towards sustainability: An empirical investigation of Indian automobile industry. J. Clean. Prod. 2016, 121, 142–158. [Google Scholar] [CrossRef]

- Tian, G.; Zhang, H.; Feng, Y.; Jia, H.; Zhang, C.; Jiang, Z.; Li, Z.; Li, P. Operation patterns analysis of automotive components remanufacturing industry development in China. J. Clean. Prod. 2017, 164, 1363–1375. [Google Scholar] [CrossRef]

- Kumar, D.; Garg, C.P. Evaluating sustainable supply chain indicators using Fuzzy AHP: Case of Indian automotive industry. Benchmarking Int. J. 2017, 24, 1742–1766. [Google Scholar] [CrossRef]

- Ferreira, M.A.; Jabbour, C.J.C.; de Sousa Jabbour, A.B.L. Maturity levels of material cycles and waste management in a context of green supply chain management: An innovative framework and its application to Brazilian cases. J. Mater. Cycles Waste Manag. 2017, 19, 516–525. [Google Scholar] [CrossRef]

- Schöggl, J.-P.; Fritz, M.; Baumgartner, R.J. Sustainability Assessment in Automotive and Electronics Supply Chains—A Set of Indicators Defined in a Multi-Stakeholder Approach. Sustainability 2016, 8, 1185. [Google Scholar] [CrossRef]

- Mauricio, A.L.; Jabbour, A.B.L.D.S. Critical success factors for GSCM adoption: case studies in the automotive battery industry. Gestão Produção 2017, 24, 78–94. [Google Scholar] [CrossRef]

- DiMaggio, P.J.; Powell, W.W. The iron cage revisited institutional isomorphism and collective rationality in organizational fields. Adv. Strateg. Manag. 2000, 17, 143–166. [Google Scholar]

- Sarkis, J.; Zhu, Q.H.; Lai, K.H. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- DiMaggio, P.J.; Powell, W.W. The iron cage revisited: Institutional isomorphism and collective rationality in organizational fields. Am. Sociol. Rev. 1983, 147–160. [Google Scholar] [CrossRef]

- Delmas, M.; Toffel, M.W. Stakeholders and environmental management practices: An institutional framework. Bus. Strategy Environ. 2004, 13, 209–222. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. The moderating effects of institutional pressures on emergent green supply chain practices and performance. Int. J. Prod. Res. 2007, 45, 4333–4355. [Google Scholar] [CrossRef]

- González-Benito, J.; González-Benito, Ó. The role of stakeholder pressure and managerial values in the implementation of environmental logistics practices. Int. J. Prod. Res. 2006, 44, 1353–1373. [Google Scholar] [CrossRef]

- Walker, H.; Di Sisto, L.; McBain, D. Drivers and barriers to environmental supply chain management practices: Lessons from the public and private sectors. J. Purch. Supply Manag. 2008, 14, 69–85. [Google Scholar] [CrossRef]

- Min, H.; Galle, W.P. Green purchasing strategies: Trends and implications. Int. J. Purch. Mater. Manag. 1997, 33, 10–17. [Google Scholar] [CrossRef]

- Bloemhof-Ruwaard, J.M.; Van Beek, P.; Hordijk, L.; Van Wassenhove, L.N. Interactions between operational research and environmental management. Eur. J. Oper. Res. 1995, 85, 229–243. [Google Scholar] [CrossRef]

- Rao, P.; Holt, D. Do green supply chains lead to competitiveness and economic performance? Int. J. Oper. Prod. Manag. 2005, 25, 898–916. [Google Scholar] [CrossRef]

- Thierry, M.C.; Salomon, M.; Nunen, J.; Wassenhove, L.N. Strategic issues in product recovery management. Calif. Manag. Rev. 1995, 37, 114–135. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Hendrick, T.E. Purchasing’s involvement in environmental issues: A multi-country perspective. Ind. Manag. Data Syst. 1998, 98, 313–320. [Google Scholar] [CrossRef]

- Cornet, A.; Deubener, H.; Möller, T.; Schaufuss, P.; Tschiesner, A. A Long-term Vision for The European Automotive Industry. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/a-long-term-vision-for-the-european-automotive-industry (accessed on 16 June 2019).

- Fontes, C.H.D.O.; Freires, F.G.M. Sustainable and renewable energy supply chain: A system dynamics overview. Renew. Sustain. Energy Rev. 2018, 82, 247–259. [Google Scholar]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Fosso Wamba, S. World class sustainable supply chain management: Critical review and further research directions. Int. J. Logist. Manag. 2017, 28, 332–362. [Google Scholar] [CrossRef]

- Abbasi, M. Towards socially sustainable supply chains–themes and challenges. Eur. Bus. Rev. 2017, 29. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Iakovou, E. Sustainable supply chain management in the digitalisation era: The impact of Automated Guided Vehicles. J. Clean. Prod. 2017, 142, 3970–3984. [Google Scholar] [CrossRef] [Green Version]

- de Camargo Fiorini, P.; Jabbour, C.J.C. Information systems and sustainable supply chain management towards a more sustainable society: Where we are and where we are going. Int. J. Inf. Manag. 2017, 37, 241–249. [Google Scholar] [CrossRef] [Green Version]

- Dubey, R.; Dubey, R.; Gunasekaran, A.; Gunasekaran, A.; Papadopoulos, T.; Papadopoulos, T. Green supply chain management: Theoretical framework and further research directions. Benchmarking Int. J. 2017, 24, 184–218. [Google Scholar] [CrossRef]

- Geng, R.; Mansouri, S.A.; Aktas, E.; Yen, D.A. The role of Guanxi in green supply chain management in Asia’s emerging economies: A conceptual framework. Ind. Mark. Manag. 2017. [Google Scholar] [CrossRef]

- Choudhary, A.; Mondal, S.; Mukherjee, K. Analysis of critical factors influencing the management of green supply chain practice in small and medium enterprises. Int. J. Logist. Syst. Manag. 2017, 28, 200–224. [Google Scholar] [CrossRef]

- Singh, A.; Singh, A.; Trivedi, A.; Trivedi, A. Sustainable green supply chain management: trends and current practices. Compet. Rev. 2016, 26, 265–288. [Google Scholar] [CrossRef]

- Memari, A.; Rahim, A.R.A.; Ahmad, R.; Hassan, A. A literature review on green supply chain modelling for optimising CO2 emission. Int. J. Oper. Res. 2016, 26, 509–525. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, S.; Gandhi, M.A.; Gandhi, M.A. Exploring correlations in components of green supply chain practices and green supply chain performance. Compet. Rev. 2016, 26, 332–368. [Google Scholar] [CrossRef]

- Dhull, S.; Narwal, M. Drivers and barriers in green supply chain management adaptation: A state-of-art review. Uncertain Supply Chain Manag. 2016, 4, 61–76. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C.; Jaber, M.Y. Energy-related performance measures employed in sustainable supply chains: A bibliometric analysis. Sustain. Prod. Consum. 2016, 7, 1–15. [Google Scholar] [CrossRef]

- Gao, D.; Xu, Z.; Ruan, Y.Z.; Lu, H. From a systematic literature review to integrated definition for sustainable supply chain innovation (SSCI). J. Clean. Prod. 2016, 142, 1518–1538. [Google Scholar] [CrossRef]

- Soda, S.; Sachdeva, A.; Garg, R.K. Literature review of multi-aspect research works carried out on the concept and implementation of GSCM. Int. J. Ind. Syst. Eng. 2016, 23, 223–253. [Google Scholar] [CrossRef]

- Darnall, N.; Jolley, G.J.; Handfield, R. Environmental management systems and green supply chain management: Complements for sustainability? Bus. Strategy Environ. 2008, 17, 30–45. [Google Scholar] [CrossRef]

- Blount, G.N. End of life vehicles recovery: process description, its impact and direction of research. J. Mek. 2006, 21, 40–52. [Google Scholar]

- Mathiyazhagan, K.; Haq, A.N. Analysis of the influential pressures for green supply chain management adoption—an Indian perspective using interpretive structural modeling. Int. J. Adv. Manuf. Technol. 2013, 68, 817–833. [Google Scholar] [CrossRef]

- Miemczyk, J. An exploration of institutional constraints on developing end-of-life product recovery capabilities. Int. J. Prod. Econ. 2008, 115, 272–282. [Google Scholar] [CrossRef] [Green Version]

- Chandra Shukla, A.; Deshmukh, S.; Kanda, A. Environmentally responsive supply chains: Learnings from the Indian auto sector. J. Adv. Manag. Res. 2009, 6, 154–171. [Google Scholar] [CrossRef]

- Shibin, K.; Dubey, R.; Gunasekaran, A.; Hazen, B.; Roubaud, D.; Gupta, S.; Foropon, C. Examining sustainable supply chain management of SMEs using resource based view and institutional theory. Ann. Oper. Res. 2017, 1–26. [Google Scholar] [CrossRef]

- Bansal, P.; Bogner, W.C. Deciding on ISO 14001: Economics, institutions, and context. Long Range Plan. 2002, 35, 269–290. [Google Scholar] [CrossRef]

- Castro, M.B.; Remmerswaal, J.A.; Reuter, M.A. Life cycle impact assessment of the average passenger vehicle in the Netherlands. Int. J. Life Cycle Assess. 2003, 8, 297–304. [Google Scholar] [CrossRef]

- Granovskii, M.; Dincer, I.; Rosen, M.A. Life cycle assessment of hydrogen fuel cell and gasoline vehicles. Int. J. Hydrog. Energy 2006, 31, 337–352. [Google Scholar] [CrossRef]

- Kumar, S.; Putnam, V. Cradle to cradle: Reverse logistics strategies and opportunities across three industry sectors. Int. J. Prod. Econ. 2008, 115, 305–315. [Google Scholar] [CrossRef]

- Sakai, S.-I.; Noma, Y.; Kida, A. End-of-life vehicle recycling and automobile shredder residue management in Japan. J. Mater. Cycles Waste Manag. 2007, 9, 151–158. [Google Scholar] [CrossRef]

- Coates, G.; Rahimifard, S. Assessing the economics of pre-fragmentation material recovery within the UK. Resour. Conserv. Recycl. 2007, 52, 286–302. [Google Scholar] [CrossRef]

- Cote, R.P.; Lopez, J.; Marche, S.; Perron, G.M.; Wright, R. Influences, practices and opportunities for environmental supply chain management in Nova Scotia SMEs. J. Clean. Prod. 2008, 16, 1561–1570. [Google Scholar] [CrossRef]

- Das, S.; Curlee, T.R.; Rizy, C.G.; Schexnayder, S.M. Automobile recycling in the United States: energy impacts and waste generation. Resour. Conserv. Recycl. 1995, 14, 265–284. [Google Scholar] [CrossRef]

- Diabat, A.; Khodaverdi, R.; Olfat, L. An exploration of green supply chain practices and performances in an automotive industry. Int. J. Adv. Manuf. Technol. 2013, 68, 949–961. [Google Scholar] [CrossRef]

- Duval, D.; MacLean, H.L. The role of product information in automotive plastics recycling: A financial and life cycle assessment. J. Clean. Prod. 2007, 15, 1158–1168. [Google Scholar] [CrossRef]

- Forton, O.; Harder, M.; Moles, N. Value from shredder waste: Ongoing limitations in the UK. Resour. Conserv. Recycl. 2006, 46, 104–113. [Google Scholar] [CrossRef] [Green Version]

- Fuse, M.; Kashima, S. Evaluation method of automobile recycling systems for Asia considering international material cycles: Application to Japan and Thailand. J. Mater. Cycles Waste Manag. 2008, 10, 153–164. [Google Scholar] [CrossRef]

- Guo, Q.; Zhang, X.; Li, C.; Liu, X.; Li, J. TG–MS study of the thermo-oxidative behavior of plastic automobile shredder residues. J. Hazard. Mater. 2012, 209, 443–448. [Google Scholar] [CrossRef]

- Hammond, R.; Amezquita, T.; Bras, B. Issues in the automotive parts remanufacturing industry: A discussion of results from surveys performed among remanufacturers. Eng. Des. Autom. 1998, 4, 27–46. [Google Scholar]

- Harder, M.K.; Forton, O.T. A critical review of developments in the pyrolysis of automotive shredder residue. J. Anal. Appl. Pyrolysis 2007, 79, 387–394. [Google Scholar] [CrossRef] [Green Version]

- Hu, S.; Kurasaka, H. Projection of end-of-life vehicle (ELV) population at provincial level of China and analysis on the gap between the future requirements and the current situation of ELV treatment in China. J. Mater. Cycles Waste Manag. 2013, 15, 154–170. [Google Scholar] [CrossRef]

- Joung, H.-T.; Cho, S.-J.; Seo, Y.-C.; Kim, W.-H. Status of recycling end-of-life vehicles and efforts to reduce automobile shredder residues in Korea. J. Mater. Cycles Waste Manag. 2007, 9, 159–166. [Google Scholar] [CrossRef]

- Joung, H.T.; Seo, Y.C.; Kim, K.H.; Hong, J.H.; Yoo, T.W. Distribution and characteristics of pyrolysis products from automobile shredder residue using an experimental semi-batch reactor. Korean J. Chem. Eng. 2007, 24, 996–1002. [Google Scholar] [CrossRef]

- Kameda, T.; Fukuda, Y.; Park, K.-S.; Grause, G.; Yoshioka, T. Efficient dehalogenation of automobile shredder residue in NaOH/ethylene glycol using a ball mill. Chemosphere 2009, 74, 287–292. [Google Scholar] [CrossRef] [PubMed]

- Kanari, N.; Pineau, J.-L.; Shallari, S. End-of-life vehicle recycling in the European Union. Jom 2003, 55, 15–19. [Google Scholar] [CrossRef]

- Kandelaars, P.P.; van Dam, J.D. An analysis of variables influencing the material composition of automobiles. Resour. Conserv. Recycl. 1998, 24, 323–333. [Google Scholar] [CrossRef] [Green Version]

- Keoleian, G.A. Is environmental improvement in automotive component design highly constrained? An instrument panel case study. J. Ind. Ecol. 1998, 2, 103–118. [Google Scholar] [CrossRef]

- Kim, K.-H.; Joung, H.-T.; Nam, H.; Seo, Y.-C.; Hong, J.H.; Yoo, T.-W.; Lim, B.-S.; Park, J.-H. Management status of end-of-life vehicles and characteristics of automobile shredder residues in Korea. Waste Manag. 2004, 24, 533–540. [Google Scholar] [CrossRef]

- Koffler, C.; Rohde-Brandenburger, K. On the calculation of fuel savings through lightweight design in automotive life cycle assessments. Int. J. Life Cycle Assess. 2010, 15, 128. [Google Scholar] [CrossRef]

- Martínez, J.D.; Puy, N.; Murillo, R.; García, T.; Navarro, M.V.; Mastral, A.M. Waste tyre pyrolysis–A review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Osada, M.; Tanigaki, N.; Takahashi, S.; Sakai, S.-I. Brominated flame retardants and heavy metals in automobile shredder residue (ASR) and their behavior in the melting process. J. Mater. Cycles Waste Manag. 2008, 10, 93–101. [Google Scholar] [CrossRef]

- Pineau, J.-L.; Kanari, N.; Menad, N. Representativeness of an automobile shredder residue sample for a verification analysis. Waste Manag. 2005, 25, 737–746. [Google Scholar] [CrossRef] [PubMed]

- Roy, C.; Chaala, A. Vacuum pyrolysis of automobile shredder residues. Resour. Conserv. Recycl. 2001, 32, 1–27. [Google Scholar] [CrossRef]

- Sakai, S.-I.; Yoshida, H.; Hiratsuka, J.; Vandecasteele, C.; Kohlmeyer, R.; Rotter, V.S.; Passarini, F.; Santini, A.; Peeler, M.; Li, J. An international comparative study of end-of-life vehicle (ELV) recycling systems. J. Mater. Cycles Waste Manag. 2014, 16, 1–20. [Google Scholar] [CrossRef]

- Schultmann, F.; Zumkeller, M.; Rentz, O. Modeling reverse logistic tasks within closed-loop supply chains: An example from the automotive industry. Eur. J. Oper. Res. 2006, 171, 1033–1050. [Google Scholar] [CrossRef]

- Seitz, M.A.; Wells, P.E. Challenging the implementation of corporate sustainability: The case of automotive engine remanufacturing. Bus. Process Manag. J. 2006, 12, 822–836. [Google Scholar] [CrossRef]

- Simpson, D.F.; Power, D.J. Use the supply relationship to develop lean and green suppliers. Supply Chain Manag. Int. J. 2005, 10, 60–68. [Google Scholar] [CrossRef]

- Yano, J.; Hirai, Y.; Okamoto, K.; Sakai, S.-I. Dynamic flow analysis of current and future end-of-life vehicles generation and lead content in automobile shredder residue. J. Mater. Cycles Waste Manag. 2014, 16, 52–61. [Google Scholar] [CrossRef]

- Zah, R.; Hischier, R.; Leão, A.L.; Braun, I. Curauá fibers in the automobile industry–a sustainability assessment. J. Clean. Prod. 2007, 15, 1032–1040. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Initiatives and outcomes of green supply chain management implementation by Chinese manufacturers. J. Environ. Manag. 2007, 85, 179–189. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Green supply chain management implications for “closing the loop”. Transp. Res. Part E Logist. Transp. Rev. 2008, 44, 1–18. [Google Scholar] [CrossRef]

- Zolezzi, M.; Nicolella, C.; Ferrara, S.; Iacobucci, C.; Rovatti, M. Conventional and fast pyrolysis of automobile shredder residues (ASR). Waste Manag. 2004, 24, 691–699. [Google Scholar] [CrossRef]

- Errington, M.; Childe, S.J. A business process model of inspection in remanufacturing. J. Remanuf. 2013, 3, 7. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Sanchez, J.F.; Njuguna, J. Cost modelling to support optimised selection of End-of-Life options for automotive components. Int. J. Adv. Manuf. Technol. 2014, 73, 399–407. [Google Scholar] [CrossRef] [Green Version]

- Lind, S.; Olsson, D.; Sundin, E. Exploring inter-organizational relationships in automotive component remanufacturing. J. Remanuf. 2014, 4, 5. [Google Scholar] [CrossRef]

- Elo, M.; Kareila, T. Management of remanufacturing–strategic challenges from intellectual property rights. Int. J. Manuf. Technol. Manag. 2014, 28, 306–335. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.-H. Supply chain-based barriers for truck-engine remanufacturing in China. Transp. Res. Part E Logist. Transp. Rev. 2014, 68, 103–117. [Google Scholar] [CrossRef]

- Ridley, S.J.; Ijomah, W. A novel pre-processing inspection methodology to enhance productivity in automotive product remanufacture: An industry-based research of 2196 engines. J. Remanuf. 2015, 5, 8. [Google Scholar] [CrossRef]

- D’Adamo, I.; Rosa, P. Remanufacturing in industry: Advices from the field. Int. J. Adv. Manuf. Technol. 2016, 86, 2575–2584. [Google Scholar] [CrossRef]

- van Loon, P.; Van Wassenhove, L.N. Assessing the economic and environmental impact of remanufacturing: A decision support tool for OEM suppliers. Int. J. Prod. Res. 2017, 1–13. [Google Scholar] [CrossRef]

- Zhang, J.-H.; Yang, B.; Chen, M. Challenges of the development for automotive parts remanufacturing in China. J. Clean. Prod. 2017, 140, 1087–1094. [Google Scholar] [CrossRef]

- Kumar, A.; Chinnam, R.B.; Murat, A. Hazard rate models for core return modeling in auto parts remanufacturing. Int. J. Prod. Econ. 2017, 183, 354–361. [Google Scholar] [CrossRef]

- McKenna, R.; Reith, S.; Cail, S.; Kessler, A.; Fichtner, W. Energy savings through direct secondary reuse: An exemplary analysis of the German automotive sector. J. Clean. Prod. 2013, 52, 103–112. [Google Scholar] [CrossRef]

- DeRousseau, M.; Gully, B.; Taylor, C.; Apelian, D.; Wang, Y. Repurposing Used Electric Car Batteries: A Review of Options. JOM 2017, 69, 1575–1582. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I.; Rosa, P.; Terzi, S. Scrap automotive electronics: A mini-review of current management practices. Waste Manag. Res. 2016, 34, 3–10. [Google Scholar] [CrossRef]

- Parry, G.; Roehrich, J. Automotive enterprise transformation: Build to order as a sustainable and innovative strategy for the automotive industry? J. Enterp. Transform. 2013, 3, 33–52. [Google Scholar] [CrossRef]

- Nakamichi, K.; Hanaoka, S.; Kawahara, Y. Estimation of cost and CO2 emissions with a sustainable cross-border supply chain in the automobile industry: A case study of Thailand and neighboring countries. Transp. Res. Part D Transp. Environ. 2016, 43, 158–168. [Google Scholar] [CrossRef]

- Zimmer, K.; Fröhling, M.; Breun, P.; Schultmann, F. Assessing social risks of global supply chains: A quantitative analytical approach and its application to supplier selection in the German automotive industry. J. Clean. Prod. 2017, 149, 96–109. [Google Scholar] [CrossRef]

- Yazdani, M. An integrated MCDM approach to green supplier selection. Int. J. Ind. Eng. Comput. 2014, 5, 443–458. [Google Scholar] [CrossRef]

- Martin, D.M.; Väistö, T. Reducing the Attitude-Behavior Gap in Sustainable Consumption: A Theoretical Proposition and the American Electric Vehicle Market. In Marketing in and for a Sustainable Society; Emerald Group Publishing Limited: London, UK, 2016; pp. 193–213. [Google Scholar]

- Patala, S.; Jalkala, A.; Keränen, J.; Väisänen, S.; Tuominen, V.; Soukka, R. Sustainable value propositions: Framework and implications for technology suppliers. Ind. Mark. Manag. 2016, 59, 144–156. [Google Scholar] [CrossRef]

- Pallaro, E.; Subramanian, N.; Abdulrahman, M.D.; Liu, C.; Tan, K.H. Review of sustainable service-based business models in the Chinese truck sector. Sustain. Prod. Consum. 2017, 11, 31–45. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Mangla, S.K. Structural model for sustainable consumption and production adoption—A grey-DEMATEL based approach. Resour. Conserv. Recycl. 2017, 125, 198–207. [Google Scholar] [CrossRef]

- Cruz-Rivera, R.; Ertel, J. Reverse logistics network design for the collection of end-of-life vehicles in Mexico. Eur. J. Oper. Res. 2009, 196, 930–939. [Google Scholar] [CrossRef]

- Karakayali, I.; Emir-Farinas, H.; Akcali, E. An analysis of decentralized collection and processing of end-of-life products. J. Oper. Manag. 2007, 25, 1161–1183. [Google Scholar] [CrossRef]

- Zarandi, M.H.F.; Sisakht, A.H.; Davari, S. Design of a closed-loop supply chain (CLSC) model using an interactive fuzzy goal programming. Int. J. Adv. Manuf. Technol. 2011, 56, 809–821. [Google Scholar] [CrossRef]

- Sharma, M. The role of employees’ engagement in the adoption of green supply chain practices as moderated by environment attitude: An empirical study of the Indian automobile industry. Glob. Bus. Rev. 2014, 15, 25S–38S. [Google Scholar] [CrossRef]

- Daaboul, J.; Le Duigou, J.; Penciuc, D.; Eynard, B. An integrated closed-loop product lifecycle management approach for reverse logistics design. Prod. Plan. Control 2016, 27, 1062–1077. [Google Scholar] [CrossRef]

- Vaz, C.R.; Rauen, T.R.S.; Lezana, Á.G.R. Sustainability and Innovation in the Automotive Sector: A Structured Content Analysis. Sustainability 2017, 9, 880. [Google Scholar] [Green Version]

- Azevedo, S.G.; Carvalho, H.; Machado, V.C. The influence of green practices on supply chain performance: A case study approach. Transp. Res. Part E Logist. Transp. Rev. 2011, 47, 850–871. [Google Scholar] [CrossRef]

- Azzone, G.; Noci, G. Identifying effective PMSs for the deployment of “green” manufacturing strategies. Int. J. Oper. Prod. Manag. 1998, 18, 308–335. [Google Scholar] [CrossRef]

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4, 024008. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Hoffmann, R. Application of life cycle assessment for the environmental certificate of the Mercedes-Benz S-Class (7 pp). Int. J. Life Cycle Assess. 2006, 11, 240–246. [Google Scholar] [CrossRef]

- Gerrard, J.; Kandlikar, M. Is European end-of-life vehicle legislation living up to expectations? Assessing the impact of the ELV Directive on ‘green’innovation and vehicle recovery. J. Clean. Prod. 2007, 15, 17–27. [Google Scholar] [CrossRef]

- Giannouli, M.; de Haan, P.; Keller, M.; Samaras, Z. Waste from road transport: development of a model to predict waste from end-of-life and operation phases of road vehicles in Europe. J. Clean. Prod. 2007, 15, 1169–1182. [Google Scholar] [CrossRef]

- Hussain, M.; Dincer, I.; Li, X. A preliminary life cycle assessment of PEM fuel cell powered automobiles. Appl. Therm. Eng. 2007, 27, 2294–2299. [Google Scholar] [CrossRef]

- Kasai, J. Experiences and thoughts about life cycle assessment in the automotive industry in Japan. Int. J. Life Cycle Assess. 2000, 5, 313–316. [Google Scholar] [CrossRef]

- MacLean, H.L.; Lave, L.B. Life cycle assessment of automobile/fuel options. Environ. Sci. Technol. 2003, 37, 5445–5452. [Google Scholar] [CrossRef]

- Olugu, E.U.; Wong, K.Y. Evaluation of green supply chain management practices in the Malaysian automotive industry. Int. J. Serv. Oper. Manag. 2011, 9, 245–258. [Google Scholar] [CrossRef]

- Olugu, E.U.; Wong, K.Y. An expert fuzzy rule-based system for closed-loop supply chain performance assessment in the automotive industry. Expert Syst. Appl. 2012, 39, 375–384. [Google Scholar] [CrossRef]

- Olugu, E.U.; Wong, K.Y.; Shaharoun, A.M. A comprehensive approach in assessing the performance of an automobile closed-loop supply chain. Sustainability 2010, 2, 871–889. [Google Scholar] [CrossRef]

- Martínez, C.I.P. Energy efficiency in the automotive industry evidence from Germany and Colombia. Environ. Dev. Sustain. 2011, 13, 367–383. [Google Scholar] [CrossRef]

- Puri, P.; Compston, P.; Pantano, V. Life cycle assessment of Australian automotive door skins. Int. J. Life Cycle Assess. 2009, 14, 420–428. [Google Scholar] [CrossRef]

- Gopal, P.; Thakkar, J. Development of composite sustainable supply chain performance index for the automobile industry. Int. J. Sustain. Eng. 2015, 8, 366–385. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. Empirical analysis of green supply chain management practices in Indian automobile industry. J. Inst. Eng. (India): Ser. C 2014, 95, 119–126. [Google Scholar] [CrossRef]

- Hunke, K.; Prause, G. SUSTAINABLE SUPPLY CHAIN MANAGEMENT IN GERMAN AUTOMOTIVE INDUSTRY: EXPERIENCES AND SUCCESS FACTORS. J. Secur. Sustain. Issues 2014, 3. [Google Scholar] [CrossRef]

- Salvado, M.F.; Azevedo, S.G.; Matias, J.C.; Ferreira, L.M. Proposal of a sustainability index for the automotive industry. Sustainability 2015, 7, 2113–2144. [Google Scholar] [CrossRef]

- Balon, V.; Sharma, A.K.; Barua, M.K. Assessment of barriers in green supply chain management using ISM: A case study of the automobile industry in India. Glob. Bus. Rev. 2016, 17, 116–135. [Google Scholar] [CrossRef]

- Kumar, D.; Rahman, Z. Buyer supplier relationship and supply chain sustainability: empirical study of Indian automobile industry. J. Clean. Prod. 2016, 131, 836–848. [Google Scholar] [CrossRef]

- Kushwaha, G.S.; Sharma, N.K. Green initiatives: A step towards sustainable development and firm’s performance in the automobile industry. J. Clean. Prod. 2016, 121, 116–129. [Google Scholar] [CrossRef]

- Rehman, M.A.A.; Aneyrao, T.A.; Pachchhao, A.; Shrivastava, R. Identification of performance measures in Indian automobile industry: A green supply chain management approach. Int. J. Bus. Perform. Manag. 2016, 17, 30–43. [Google Scholar] [CrossRef]

- Gopal, P.; Thakkar, J. Sustainable supply chain practices: An empirical investigation on Indian automobile industry. Prod. Plan. Control 2016, 27, 49–64. [Google Scholar] [CrossRef]

- Khairani, N.S.; Kasim, E.S.; Rajamanoharan, I.D.; Misman, F.N. Green Supply Chain Management in the Malaysian Automotive Industry: A Systems Thinking Perspective. Int. J. Supply Chain Manag. 2017, 6, 38–48. [Google Scholar]

- Malviya, R.K.; Kant, R. Modeling the enablers of green supply chain management: An integrated ISM–fuzzy MICMAC approach. Benchmarking Int. J. 2017, 24, 536–568. [Google Scholar] [CrossRef]

- Carvalho, H.; Govindan, K.; Azevedo, S.G.; Cruz-Machado, V. Modelling green and lean supply chains: An eco-efficiency perspective. Resour. Conserv. Recycl. 2017, 120, 75–87. [Google Scholar] [CrossRef]

- Fritz, M.M.; Schöggl, J.-P.; Baumgartner, R.J. Selected sustainability aspects for supply chain data exchange: Towards a supply chain-wide sustainability assessment. J. Clean. Prod. 2017, 141, 587–607. [Google Scholar] [CrossRef]

- Handfield, R.; Sroufe, R.; Walton, S. Integrating environmental management and supply chain strategies. Bus. Strategy Environ. 2005, 14, 1–19. [Google Scholar] [CrossRef]

- Van Hoek, R.I. Case studies of greening the automotive supply chain through technology and operations. Int. J. Environ. Technol. Manag. 2001, 1, 140–163. [Google Scholar] [CrossRef]

- Wells, P.; Seitz, M. Business models and closed-loop supply chains: A typology. Supply Chain Manag. Int. J. 2005, 10, 249–251. [Google Scholar] [CrossRef]

- Wu, H.-J.; Dunn, S.C. Environmentally responsible logistics systems. Int. J. Phys. Distrib. Logist. Manag. 1995, 25, 20–38. [Google Scholar] [CrossRef]

- Xia, Y.; Li-Ping Tang, T. Sustainability in supply chain management: Suggestions for the auto industry. Manag. Decis. 2011, 49, 495–512. [Google Scholar] [CrossRef]

| Main Category | Process Sub-Categories | |||||||

|---|---|---|---|---|---|---|---|---|

| Content Category | Fre. * | Perc. ** | Content Category | Fre. | Perc. | Content Category | Fre. | Perc. |

| Input | 12 | 3.87% | Delivery | 3 | 2.27% | Management Capabilities | 7 | 17.07% |

| Legislation and Standards | 18 | 5.81% | Supply | 26 | 19.70% | Network Structure | 16 | 39.03% |

| Processes | 130 | 41.93% | Production | 15 | 11.36% | Technology | 18 | 43.90% |

| Resources/Mechanisms | 36 | 11.62% | Use | 8 | 6.06% | Total | 41 | 100% |

| Output | 102 | 32.9% | Post-use | 80 | 60.61% | |||

| Overall Review | 12 | 3.87% | Total | 132 | 100% | |||

| Total | 310 | 100% | ||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masoumi, S.M.; Kazemi, N.; Abdul-Rashid, S.H. Sustainable Supply Chain Management in the Automotive Industry: A Process-Oriented Review. Sustainability 2019, 11, 3945. https://doi.org/10.3390/su11143945

Masoumi SM, Kazemi N, Abdul-Rashid SH. Sustainable Supply Chain Management in the Automotive Industry: A Process-Oriented Review. Sustainability. 2019; 11(14):3945. https://doi.org/10.3390/su11143945

Chicago/Turabian StyleMasoumi, S. Maryam, Nima Kazemi, and Salwa Hanim Abdul-Rashid. 2019. "Sustainable Supply Chain Management in the Automotive Industry: A Process-Oriented Review" Sustainability 11, no. 14: 3945. https://doi.org/10.3390/su11143945

APA StyleMasoumi, S. M., Kazemi, N., & Abdul-Rashid, S. H. (2019). Sustainable Supply Chain Management in the Automotive Industry: A Process-Oriented Review. Sustainability, 11(14), 3945. https://doi.org/10.3390/su11143945