1. Introduction

Today, environmental awareness is considered a multifaceted issue that attracted the scientific interest worldwide. Such an integrated framework upon environmental consciousness of products’ risk has been developed from Khan et al. [

1]. In this framework the participative roles of product designers, manufacturing engineers, environmental analysts, and risk experts were examined in designing and developing environmental awareness in association with varied product design choices [

1]. In another holistic framework, the environmental perspective of designing was associated with the architectural accessibility, the interior design, and the interactive technologies [

2]. Under this framework, citizen housing was promoted as healthy and enjoyable ways to be utilized by clients.

Earlier research studies examined the pronounced role of sustainability as the key-notion of a prosperous social, economic and environmental development. Specifically, sustainability can be taken into consideration toward future longevity, energy consumption, and environmental protection upon the contexts of the built environment [

3], marine environment [

4], and regulatory legislation system [

5]. The interrelationship between the entities of environment and sustainability was developed in the literature under the three interlinked framework of environmental indicators (EI) at the industrial and manufacturing contexts, sustainable production (SP) schemes, and sustainable development (SD) of environmental indicators.

In the viewpoint of environmental indicators (EI) at the sectors of industry and manufacturing, Villard et al. [

6] standardized an environmental analysis of microelectronic products upon the main indicators of resource depletion, eutrophication, water stress, and local electrical consumption, along with the features of time-sensitivity and the processes-driven microelectronic industry and its products [

6]. Another critical issue of perception environmental indicators is the decision-making problem at the industrial and manufacturing contexts, especially at cases of incomplete or vague information [

7]. Such human decision-making processes in uncertain situations are also attributed to an individual perception about pollution. Supplier selection for an environmentally friendly product is an important issue, since environmental impact can be an important criterion for supplier selection. Particularly, Sinha and Anand [

7] introduced the following five-steps environmental analysis of (1) supply, (2) logistic, (3) process analysis, (4) use, and (5) recycle. Under the methodology applied, supplier’s environmental metrics upon energy, water, emissions, and hazardous wastes were gathered and applied under a fuzzy preference modeling. The environmental impact for products was valuated under the following distinct types of global warming, ozone depletion, photochemical ozone creation, acidification, nutrient enrichment, and volatile organic compounds [

7]. At this study a multi-preference fuzzy relationship model was developed and the environmental performance of the best supplier was based on fuzzy preference approach, to handle the supplier selection problem [

7].

In the viewpoint of sustainable production (SP) schemes, Ercan and Tatari [

8] stressed out that environmentally friendly features of transportation are that of electricity and hybrid modes of fuelling. Particularly, Ercan and Tatari [

8] stressed that weighted criteria of evaluation environmentally friendly and cost-effective transportation fuels can be considered by transportation policy-makers in conjunction with multi-criteria tools of decision making and the cost-driven indicators of electricity mix and fuel economy [

9].

In the viewpoint of product users’ perception in favour of environment product sustainability is challenging aspect since it enables product designers, manufacturers, and environmentalists to follow a new product development (NPD) pattern. ]. By identifying attributes on the selection of proper suppliers among a pool of suppliers, researchers can develop an index of sustainable suppliers available, enabling the to evaluate the sustainability features among the most suitable suppliers selected [

9].

In the viewpoint of sustainable development (SD) of environmental indicators, Mariouryad et al. [

10] investigated the multifaceted adoption of health, safety, and environmental indicators and noted positive but slow changes regarding health, safety, and environmental indicators in the Iranian pharmaceutical industry. Therefore, these indicators have to be evaluated at regular time-intervals [

10]. Besides, Dobes et al. [

11] framed the management of production systems in alignment with sustainable production schemes upon resource efficiency, as follows: (i) administrative measures, (ii) eco-design of products and services, (iii) introduction of resource efficient processes and appliances, (iv) application of new and innovative business models [

11].

This study presents a systematic literature review on the evolution of the main environmental assessment tools for industry. The theoretical background upon the available environmental assessment tools for industry has been deployed at

Section 2. The development of the in-house HAPI-E industry tool proposed by authors is analyzed in

Section 3. In

Section 4, a case study in the pasta production industry is described. The underlying environmental performance took into account the management decisions on the efficiency of resources and the outputs such as energy, water, emissions, and waste strategy; all were measured and compared with the proposed improvements in alignment with environmental impact minimization. In

Section 5, the research results are discussed, along with the magnitude of the improvements, and further research orientation are deployed.

Section 6 summarized the main conclusions, stressing that the HAPI-E industry tool can be a feasible methodology for resource efficiency potential assessment and has the potential to incorporate multi-level and quantification advantages.

The novelty of this study resides on the fact of a need-driven multi-criteria decision analysis evaluation in industry, under which the Analytical Hierarchy Process (AHP) aims to assign a weight to all contributing parameters while following logical and well-structured decision processes in order to avoid possible confusion. The main objective of this study was to identify measurable aspects of the AHP as well as vulnerability aspects of the EDIT [

12]. This will enable policy makers to take appropriate measures to reduce alarming problems and to prevent environmental depletion and sustainability degradation in the examined industrial plant. Therefore, the proposed joint methodological approach of AHP and EDIT [

12] is a novel approach that has not previously been developed in the relevant literature, as far as we (the authors) know. The joint implementation of AHP and EDIT [

12] makes possible its use at the multi-business level, the quantification of data, and the external support and capacity building, which are proven developmental factors [

11].

3. HAPI-E Industry Tool—Tool Description

The modified HAPI-E industry tool used AHP supports simple and straight forward postulates in treating multi-criteria decision problems. Nevertheless, AHP is developed under a pair wise analysis of parametric attribution of weights that is based on the scale of their relative importance, but their variations should not exceed a certain threshold. Then, scaling of significance was arranged from a lowest–to-highest value. Specifically, the highest value is referred to absolute importance, while reciprocal of all scaled ratios are entered in the transpose position. Again, the lowest value is referred to the absolute triviality. Subsequently, the complete comparison matrix is formulated when the weights of the factors are calculated under normalizing the respective eigenvector by the cumulative eigenvector. Dispersion of the weight of the decision factor is allocated through the equal-interval ranging technique to different classes’ suited.

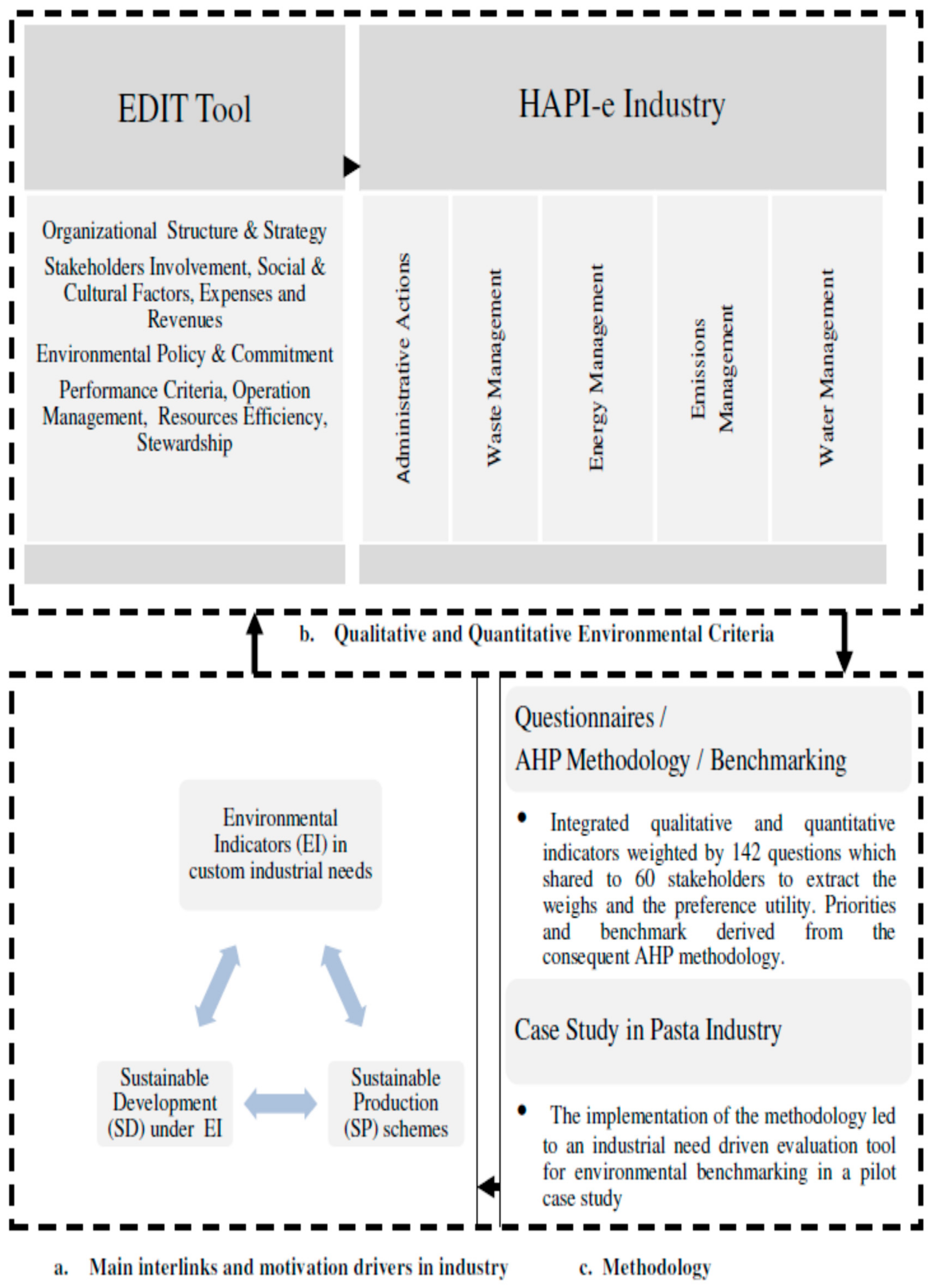

In this study, the proposed framework of industrial environmental evaluation by joint implementation of HAPI-E industry tool and EDIT is depicted at

Figure 1. This framework follows deductive logic, under which is the general process of interlinks and motivation drivers in industry (general premises given at step a) is followed by the joint applicability of the EDIT and HAPI-E industry tool (reasoning given at step b), thus reaching the logically certain conclusion of functionality in a typical pasta industry (specific conclusion drawn upon this proposed circular framework).

3.1. Questionnaires

Prior to the implementation of AHP, it is necessary to select the criteria, place them in the hierarchy levels, and formulate the pair wise comparison matrix (PCM). The core of the process is the estimation of the weights. The measurements were done by the questionnaires, in a two-stage analysis, according to the specific features in the industry and the nine EDIT indicators, in order to embed them in the HAPI-E weighting criteria.

The first stage is referred to the

Table A1 (

Appendix A) and the EDIT qualitative concepts classification in the three motivation drivers of the study. The assessment took place through weights stipulated by the distributed questionnaires. The considered qualitative criteria setting are: The EI under industry and manufacturing contexts; the SP is related with Stewardship, Operation Management, and Resources Efficiency Performance Indicators Criteria, while the SD of Environmental Indicators better related with the Organizational Structure and Strategy, Stakeholders Involvement, Social and Cultural Factors, Environmental Policy and Commitment, and Expenses and Revenues in Environmental Sponsorship and Donations. The main characteristics of the HAPI-E industry tool considering the motivation drivers are presented in

Table 3.

Following

Table 3, the second stage of the procedure refers to

Table A2 (

Appendix A), which is constituted by joint indicators, based on 142 questions distributed to the upper administration and the technical staff level via Google forms, while the analysis of the perceptions has taken into account the

Table 4 scale. In

Appendix A, the basic questionnaire of this modified HAPI-E industry tool is depicted, including the qualitative indicators that were derived from the EDIT [

12].

3.2. AHP Principles and Consistency Test

The fundamental AHP is depicted in the lines below. The development of AHP is based in the following four simple axons: reciprocal judgments, homogeneous comparisons, network structures and synthesis in a hierarchical manner, and meeting the desirable expectations [

46]. One of the key factors of the method is to estimate the priorities in terms of consistency and consideration of the principal or the largest eigenvector. Consistency means that the decision maker is exhibiting coherent judgment in specifying the pair wise comparison of the criteria or alternatives. Mathematically, it was defined that the comparison matrix

A is consistent if

That property requires all columns and rows of the comparison matrix to be linearly dependent. The consistency ratio of the aggregate matrix is defined as

where

stands for a random index of consistency

and

derives from the size of the matrix. According to Saaty (1980), the

is accepted when it is less than 0.1 in order for the matrix to be consistent. If

, the decision maker has to revise the elements of

to realize better consistency in the pair wise comparison matrix (PCM).

3.3. Weight Calculation

The relative weights (

) were found by dividing each element of the matrix with the sum of the column were it is placed. Then, the average sum of each row calculates the relative weight for each sub-criterion (

) regarding to the consistency ratio of the corresponding main criterion. Following this procedure and according to the Equations (1)–(3), above, the pair wise comparison matrix and the relative weights of the main criteria were obtained. Since,

, with

and the

equation is,

, then

That means that the

value equals to the sum of the elements of the vector column

. Following the relative weights, an AHP was used in order to quantify the weights and to indicate the main objectives of the solution, namely the tree structure of the criteria definition and its pair-wise comparison, also taking into account the reciprocal property (

) for each single pair. The analysis of the questionnaires and the data obtained for all criteria, normalized and the Pairwise Comparison Matrix (PCM) was developed according to Saaty [

54]. Particularly, Saaty [

54] classified the scale for pair-wise comparisons into 9 intensity of importance components, varying from intermediate importance (intensities 2, 4, 6, and 8), equal importance (referring to the equal contribution of two elements to the objective), moderate importance (referring to the slightly favour of one element between that of: experience or judgement, over another), up to extreme importance (referring to favouring evidence of one element over another, it is of the highest possible order of affirmation). Moreover, there are many scale functions to translate the judgments into ratios [

55].

5. Results and Discussion

The abundant approaches to sustainability have been explored for the manufacturing industry, but despite efforts that foster carbon footprint reduction, the majority of enterprises continue to operate in the traditional linear model of production and consumption which is conceptualized under the take-make-dispose rationale. Consequently, the rapid exploitation of global resources necessitates the effective use of global natural resources to sustain human activities in the future. In parallel, the implementation of holistic sustainability strategies is interlinked with products’ and services’ design, playing an influential role on the way the entire value chain is constructed and managed [

32].

The conception of the case study conducted was to investigate the adopted methodology in practice. In this research framework, an in situ visit to the factory plant in a province of Greece was made, and the questionnaire was delivered. Three visits by two persons were conducted in site to select general and process data. The results elaboration has been proceeded by using the “Business Performance Management Singapore—BPMSG AHP Excel template with multiple inputs” [

55], and the ranking (Rk) of criteria are presented at the following

Table 5, showing the HAPI-E industry tool main criteria weights and scoring. Subsequently, data collected and evaluation upon all this primary material were gathered and evaluated using the HAPI-E industry tool (

Table 5 and

Figure 3).

Data manipulation revealed that the HAPI-E industry tool is especially fitting to SMEs since it supports company personnel to unveil potential weaknesses as well specific potentials for wider company development. Subsequently, while noting threads of companies’ development, the research outcomes could also serve policy makers and company managers to stress the stakeholders’ values and to foster those corporate strategies and management tools toward mission and vision and processes to be followed upon products design and delivery. The main advantageous features of the HAPI-E industry tool directly benefit companies to be adaptable to the proposed changes that incorporate both technology and management. Moreover, collected quantitative and qualitative data support company personnel to expand the companies’ perspectives on new ways that monitor and reinforce resource efficiency, thus increasing awareness and strengthening commitment for sustainable manufacturing systems.

The valuable features of the existing methodologies can be integrated into a new holistic, prevention-oriented, need-driven system to make quantitative diagnosis to promote resources’ efficiency among SMEs. Apart from SMEs, consultancy service providers can benefited by establishing initial relationships with clients toward high-quality and need-driven services. The system is also especially supportive for multipliers/intermediaries—including SME associations—being a decisive means of identifying opportunities and fostering maximum returns of investment according to: time, money, human health, and ecological benefits.

It is also noteworthy that the high environmental policy of the pasta industry is burdened by the waste management. Indeed, these categorical indicators are proven of utmost importance among the industry professionals, according to the answers received in the questionnaire. Pasta industry can recycle, reuse, and re-sell a high portion of its waste produced. Particularly, the 30% wheat in the fermentation process is disposed as a byproduct in fodder, which then can be sold. The remaining 70% on fermentation becomes semolina, being a 100% recoverable product. Moreover, the pasta industry sustains collaborative and approved partners for paper and cellophane. From 2015 on, paper and plastic were fed recycling materials, whereas wood pallets can be repaired and reused. Finally, the oils are disposed of by the Greek Environmental Technology, where the industry studied also utilized recyclable packaging on its marketable products.

Another crucial parameter of evaluation is energy management. In the examined pasta industry, each production line is considered as autonomous since it supports its own management system (being specially focused on energy and drying). Besides, the boiler room has been facilitated with set-points of automation, whereas each machine has functioned autonomously. In parallel, the industry plant installed new-generation and low-energy consumption air conditioners, and adopted a frequent (biannual) maintenance on them and a periodic (per four months) maintenance on boilers as well as a periodic air bleeding of the radiators in working areas in order to accomplish a higher thermal efficiency.

It is also noteworthy that low scoring was reported at the categories “water management” and “emissions of gases.” In the category of “water management,” the industry was highly rated in alignment with the maintenance of the plumbing, water use reduction via battery heads with fitting low flow of water and flow restricting taps, novel technologies applied for water and energy savings, effective use and pressure regulation on the grid by operating pressure stabilizers, and water use reduction in vacuum pumps. At the category of “emissions of gases,” the industry was highly rated due to the fact of natural gas usage, being the sole fuel type for the production line and for electric vehicle motion. Besides, external associates are devoted to the marketable products transferring to and from the industry, thus indirectly affecting the gases emissions. Moreover, other externalities have not been included in calculation due to their intangible and non-countable nature. Such aspects should be the protective framework in competitive markets as well as a plethora of alternative best practices that could be exploited in processes.

6. Limitations and Future Research Perspectives

The main limitations of this study are the subjectivity in evaluating multi-criteria decision methods, the complexity of the analysis by increasing the number of experimental-designed attributes and the uncertainty of the AHP. Specifically, the proposed multi-criteria decision methods using hybrid weights may be only validated by the theoretical analysis of the case study results but not verified in a practical way. Therefore, in order to figure out whether the research outcomes work well, a long-term tracking study can be valuable, while other shortcomings—such as prejudiction, knowledge incompleteness, and uncertainty of AHP-derived assessment—can be handled by stochastic methods [

53].

Under the context of such alternative practices, administrative actions play a decisive role in energy management evaluation. Indeed, the examined pasta industry operates with a competent administrative body in order to better qualify its raw materials. Such an industrial sector supports neither an autonomous environmental department nor corporate social responsibility (CSR) policies, while there is no provision of continuing environmental education among the workforce. However, it has developed a sound collaboration partnership with an environmental consultancy office for environmental licensing, as well as research orientation toward environmental innovations. Moreover, internal audits and regularly conducted inspections can unveil potential non-compliance with the setting environmental protection standards.

Another administrative constraint that moderate the coordination among supplier selection attributes from sustainability perspective, is the subjectivity, impreciseness, and vagueness to assign score value to attributes. Indeed, while selecting the proper supplier from a pool of suppliers, the subjectivity, impreciseness, and vagueness can be reduced to a large extent by applying tools like fuzzy methodology. Another limitation is the increase of attributes included and the complexity of the analysis. To this end, Sinha and Anand [

9] introduced the concept of matrix factorization that can be utilized at industrial-based scenarios entailing the development of new products. The applicability of this framework includes a wide spectrum of industrial sectors including that of manufacturing, pharmaceutical, and automobile [

9]. Therefore, future research frameworks could enable the participation of a wider consortium of product designers, manufacturers, and environmentalists toward effective decision making upon suppliers’ selection.

7. Conclusions

Based on this study, it is noteworthy that multi-criteria decision analysis methods and tools are proven effective decision support solutions to address complex problems dealing with opposite objectives and interests, uncertainties, and non-harmonised data. The inclusion of multifaceted dimensions (technical, economic, environmental, social, and institutional) can be taken into account as a set requirement for consideration by future researchers. The proper criteria selected in the sustainability assessment of energy systems, system designers, manufacturers, risk analysts, environmentalists, and businesses ensure that the conceptual in a system design will be free from any cognitive weakness from sustainability risk point of view [

28], can play a key role in the subsequent selection and reporting of the best alternative [

70], have to be proven useful for designers and practicing engineers to compare various alternatives of a product from the life-cycle design point of view [

71] and not undermine the socio-economic determinants of sustainability accomplishment through alternative energy sources for energy production, and energy consumption especially among energy-intensified developed economies [

72,

73,

74].

Under the framework of this analysis, the novel HAPI-E industry tool was developed as a proactive environmental tool within the industrial context. It can provide early stage signaling in the inter-organizational framework, which is always less costly funded to correction actions than the post treatment. Moreover, the embedding EDIT methodology [

12] at the in-house multi-criteria tool (HAPI-E industry) expanded the functionality of the former (EDIT) by increasing the business levels, quantifying the materials, the energy, and the mass flows to specify the improvements in particular SMEs and to decrease the external technical assistance and capacity building since it utilizes internal resources, knowledge, and a robust hierarchical expertise.

Conclusively, the HAPI-E industry tool is proven an effective application in the food industry, especially in pasta production. The effectiveness of this research approach is particularly fitting to the specifications of multi-parametric industrial environments, in which the procedural complexity can be perceived and adapted to the norms, principles, and regulations of circular economy.