Evaluation on Strength Properties of Lime–Slag Stabilized Loess as Pavement Base Material

Abstract

1. Introduction

2. Experiment

2.1. Materials

2.2. Preparation of Specimens

2.2.1. Compaction Tests

2.2.2. Unconfined Compression Tests

3. Results and Discussion

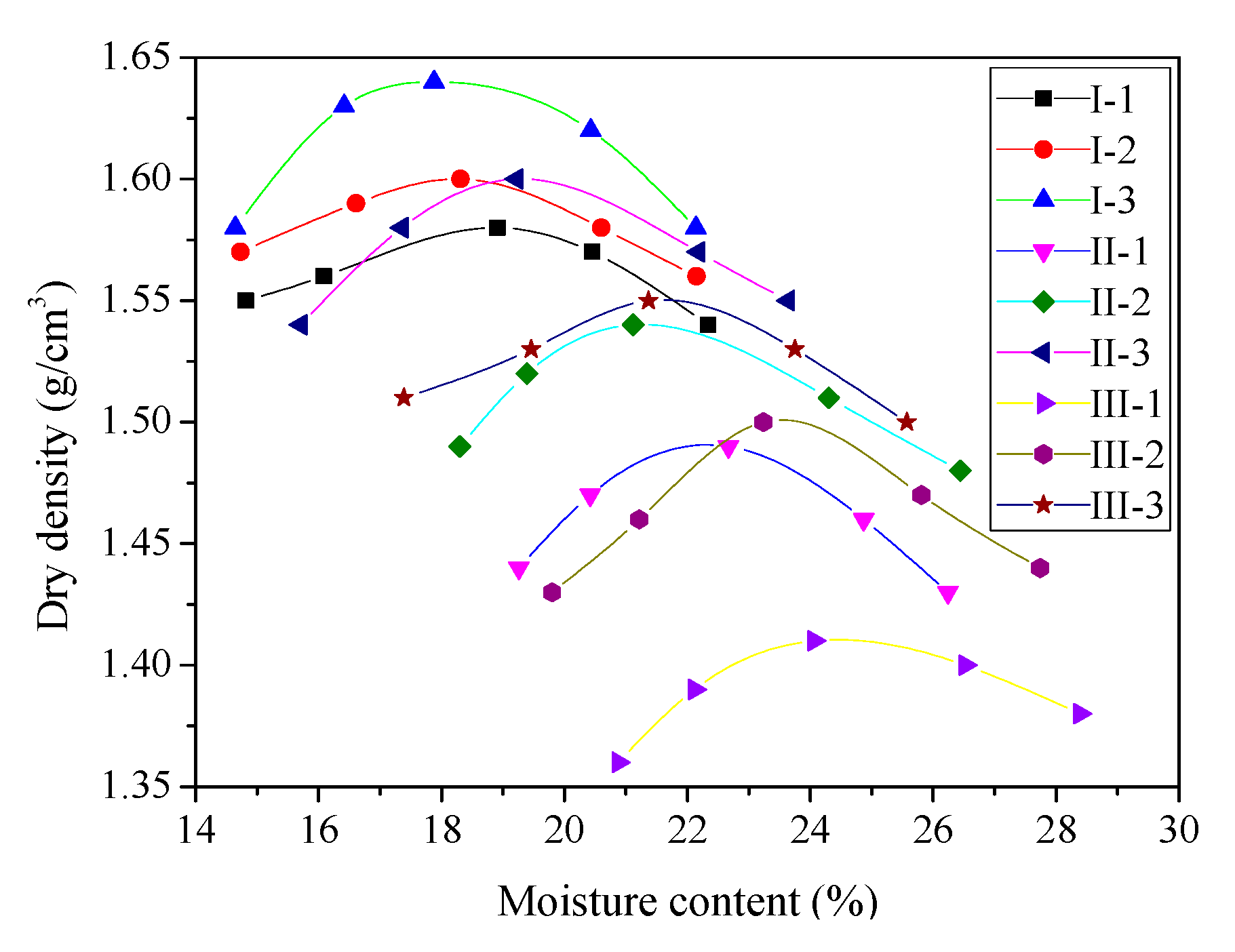

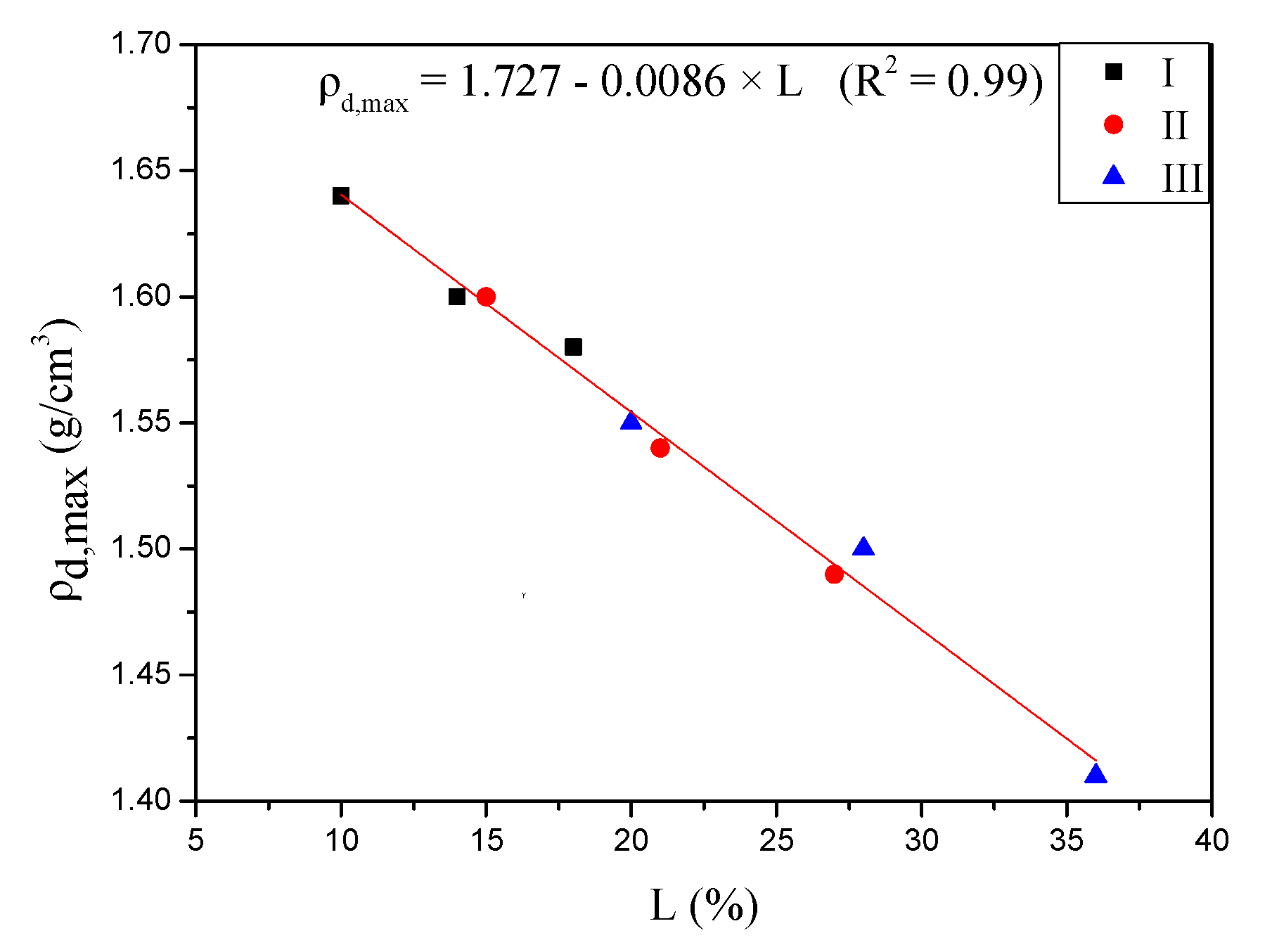

3.1. Standard Compaction Tests

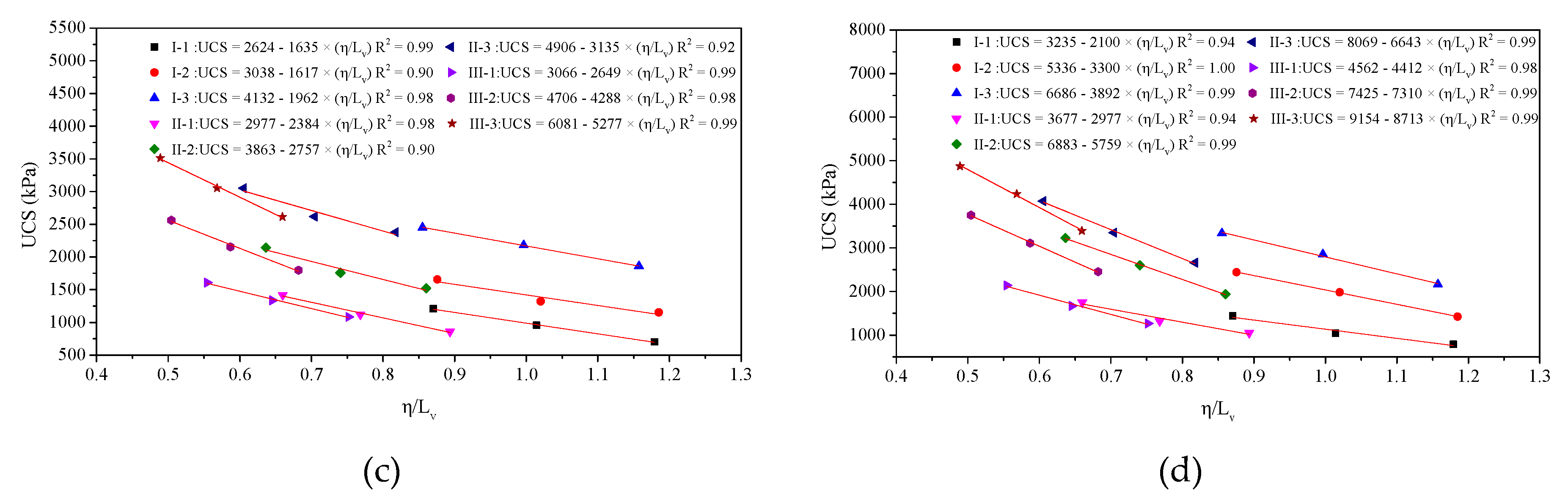

3.2. Unconfined Compression Tests

3.2.1. Effect of the Slag Content, L/S Ratio, and Porosity

3.2.2. Effect of Porosity-Volumetric Binder Content Ratio

4. Conclusions

Author Contributions

Acknowledgments

Funding

Conflicts of Interest

Abbreviations

| UCS | unconfined compression strength (kPa) |

| ρd | dry density (g/mm3) |

| ρd,max | maximum dry density(g/mm3) |

| ωopt | optimum water contents (%) |

| L | lime content (%) |

| GsLo | specific gravity of loess |

| GsS | specific gravity of slag |

| S | slag content (%) |

| R2 | coefficient of determination |

| Lo | loess content (%) |

| GsL | specific gravity of lime |

| Lv | volumetric binder content (mm3) |

References

- Derbyshire, E.; Mellors, T. Geological and geotechnical characteristics of some loess and loessic soils from China and Britain: A comparison. Eng. Geol. 1988, 25, 135–175. [Google Scholar] [CrossRef]

- Rogers, C.D.F.; Dijkstra, T.A.; Smalley, I.J. Hydroconsolidation and subsidence of loess: Studies from China, Russia, North America and Europe: In memory of Jan Sajgalik. Eng. Geol. 1994, 37, 83–113. [Google Scholar] [CrossRef]

- Jefferson, I.; Mavlyanova, N.; O’Hara-Dhand, K.; Smalley, I. The engineering geology of loess ground: 15 tasks for investigators—The Mavlyanov programme of loess research. Eng. Geol. 2004, 74, 33–37. [Google Scholar] [CrossRef]

- Ma, F.; Yang, J.; Bai, X. Water sensitivity and microstructure of compacted loess. Transp. Geotech. 2017, 11, 41–56. [Google Scholar] [CrossRef]

- Pei, X.; Zhang, F.; Wu, W.; Liang, S. Physicochemical and index properties of loess stabilized with lime and fly ash piles. Appl. Clay Sci. 2015, 114, 77–84. [Google Scholar] [CrossRef]

- Zhang, Y.; Ye, W.; Wang, Z. Study on the Compaction Effect Factors of Lime-treated Loess Highway Embankments. Civ. Eng. J. 2017, 3, 1008. [Google Scholar] [CrossRef]

- Gao, Y.; Qian, H.; Li, X.; Chen, J.; Jia, H. Effects of lime treatment on the hydraulic conductivity and microstructure of loess. Environ. Earth Sci. 2018, 77, 529. [Google Scholar] [CrossRef]

- Bakir, N.; Abbeche, K.; Panczer, G. Experimental study of the effect of the glass fibers on reducing collapse of a collapsible soil. Géoméch. Eng. 2017, 12, 71–83. [Google Scholar] [CrossRef]

- Li, Y.; He, S.; Deng, X.; Xu, Y. Characterization of macropore structure of Malan loess in NW China based on 3D pipe models constructed by using computed tomography technology. J. Asian Earth Sci. 2018, 154, 271–279. [Google Scholar] [CrossRef]

- Zhang, F.; Pei, X.; Yan, X. Physicochemical and mechanical properties of lime-treated loess. Geotech. Geol. Eng. 2018, 36, 685–696. [Google Scholar] [CrossRef]

- Xie, W.-L.; Li, P.; Zhang, M.-S.; Cheng, T.-E.; Wang, Y. Collapse behavior and microstructural evolution of loess soils from the Loess Plateau of China. J. Mt. Sci. 2018, 15, 1642–1657. [Google Scholar] [CrossRef]

- Kavak, A.; Akyarlı, A. A field application for lime stabilization. Environ. Geol. 2007, 51, 987–997. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, F.; Hu, H.; Cui, Y.; Peng, J. Structural characterization of natural loess and remolded loess under triaxial tests. Eng. Geol. 2014, 181, 249–260. [Google Scholar] [CrossRef]

- Yao, K.; Xiao, H.; Chen, D.H.; Liu, Y. A direct assessment for the stiffness development of artificially cemented clay. Géotechnique 2018, 69, 741–747. [Google Scholar] [CrossRef]

- Yao, K.; Chen, Q.; Ho, J.; Xiao, H.; Lee, F.H. Strain-dependent shear stiffness of cement-treated marine clay. J. Mater. Civ. Eng. 2018, 30, 04018255. [Google Scholar] [CrossRef]

- Yao, K.; Li, N.; Chen, D.-H.; Wang, W. Generalized hyperbolic formula capturing curing period effect on strength and stiffness of cemented clay. Constr. Build. Mater. 2019, 199, 63–71. [Google Scholar] [CrossRef]

- Yao, K.; Wang, W.; Li, N.; Zhang, C.; Wang, L. Investigation on strength and microstructure characteristics of nano-MgO admixed with cemented soft soil. Constr. Build. Mater. 2019, 206, 160–168. [Google Scholar] [CrossRef]

- Yao, K.; Pan, Y.; Jia, L.; Yi, J.T.; Hu, J.; Wu, C. Strength evaluation of marine clay stabilized by cementitious binder. Mar. Georesour. Geotechnol. 2019, 1–14. [Google Scholar] [CrossRef]

- Jia, L.; Guo, J.; Zhou, Z.; Fu, Y.; Yao, K. Experimental investigation on strength development of lime stabilized loess. RSC Adv. 2019, 9, 19680–19689. [Google Scholar] [CrossRef]

- Goni, S.; Guerrero, A.; Luxan, M.P.; Macías, A. Activation of the fly ash pozzolanic reaction by hydrothermal conditions. Cem. Concr. Res. 2003, 33, 1399–1405. [Google Scholar] [CrossRef]

- Cuisinier, O.; Masrouri, F.; Pelletier, M.; Villieras, F.; Mosser-Ruck, R. Microstructure of a compacted soil submitted to an alkaline PLUME. Appl. Clay Sci. 2008, 40, 159–170. [Google Scholar] [CrossRef]

- Lorca, P.; Calabuig, R.; Benlloch, J.; Soriano, L.; Payá, J. Microconcrete with partial replacement of Portland cement by fly ash and hydrated lime addition. Mater. Des. 2014, 64, 535–541. [Google Scholar] [CrossRef]

- Vitale, E.; Deneele, D.; Paris, M.; Russo, G. Multi-scale analysis and time evolution of pozzolanic activity of lime treated clays. Appl. Clay Sci. 2017, 141, 36–45. [Google Scholar] [CrossRef]

- Bicalho, K.V.; Boussafir, Y.; Cui, Y.-J. Performance of an instrumented embankment constructed with lime-treated silty clay during four-years in the Northeast of France. Transp. Geotech. 2018, 17, 100–116. [Google Scholar] [CrossRef]

- Silva, J.; Azenha, M.; Correia, A.G.; François, B. Two-staged kinetics of moduli evolution with time of a lime treated soil under different curing temperatures. Transp. Geotech. 2018, 17, 133–140. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Value-added utilization of marine clay as cement replacement for sustainable concrete production. J. Clean. Prod. 2018, 198, 867–873. [Google Scholar] [CrossRef]

- Wang, S.-D.; Scrivener, K.L.; Pratt, P. Factors affecting the strength of alkali-activated slag. Cem. Concr. Res. 1994, 24, 1033–1043. [Google Scholar] [CrossRef]

- Xi, Y.; Siemer, D.; Scheetz, B. Strength development, hydration reaction and pore structure of autoclaved slag cement with added silica fume. Cem. Concr. Res. 1997, 27, 75–82. [Google Scholar] [CrossRef]

- Pal, S.; Mukherjee, A.; Pathak, S. Investigation of hydraulic activity of ground granulated blast furnace slag in concrete. Cem. Concr. Res. 2003, 33, 1481–1486. [Google Scholar] [CrossRef]

- Holzer, L.; Figi, R.; Gruskovnjak, A.; Lothenbach, B.; Winnefeld, F. Hydration of alkali-activated slag: Comparison with ordinary Portland cement. Adv. Cem. Res. 2006, 18, 119–128. [Google Scholar]

- Yang, K.-H.; Cho, A.-R.; Song, J.-K.; Nam, S.-H. Hydration products and strength development of calcium hydroxide-based alkali-activated slag mortars. Constr. Build. Mater. 2012, 29, 410–419. [Google Scholar] [CrossRef]

- Abo-El-Enein, S.; Heikal, M.; Amin, M.; Negm, H. Reactivity of dealuminated kaolin and burnt kaolin using cement kiln dust or hydrated lime as activators. Constr. Build. Mater. 2013, 47, 1451–1460. [Google Scholar] [CrossRef]

- Kim, M.S.; Jun, Y.; Lee, C.; Oh, J.E. Use of CaO as an activator for producing a price-competitive non-cement structural binder using ground granulated blast furnace slag. Cem. Concr. Res. 2013, 54, 208–214. [Google Scholar] [CrossRef]

- Ayeldeen, M.; Negm, A.; El-Sawwaf, M.; Kitazume, M. Enhancing mechanical behaviors of collapsible soil using two biopolymers. J. Rock Mech. Geotech. Eng. 2017, 9, 329–339. [Google Scholar] [CrossRef]

- Wang, J.; Lyu, X.; Wang, L.; Cao, X.; Liu, Q.; Zang, H. Influence of the combination of calcium oxide and sodium carbonate on the hydration reactivity of alkali-activated slag binders. J. Clean. Prod. 2018, 171, 622–629. [Google Scholar] [CrossRef]

- Kwon, Y.-H.; Kang, S.-H.; Hong, S.-G.; Moon, J. Enhancement of Material Properties of Lime-Activated Slag Mortar from Intensified Pozzolanic Reaction and Pore Filling Effect. Sustainability 2018, 10, 4290. [Google Scholar] [CrossRef]

- Prietto, P.D.M.; Carraro, J.A.H.; Consoli, N.C.; Heineck, K.S. Behavior of Compacted Soil-Fly Ash-Carbide Lime Mixtures. J. Geotech. Geoenviron. Eng. 2001, 127, 774–782. [Google Scholar]

- Consoli, N.C.; Rosa, F.D.; Fonini, A. Plate Load Tests on Cemented Soil Layers Overlaying Weaker Soil. J. Geotech. Geoenviron. Eng. 2009, 135, 1846–1856. [Google Scholar] [CrossRef]

- Donato, M.; Thomé, A.; Consoli, N.C.; Graham, J. Circular footings on a cemented layer above weak foundation soil. Can. Geotech. J. 2005, 42, 1569–1584. [Google Scholar]

- Sharma, R.S.; Phanikumar, B.R.; Rao, B.V. Engineering Behavior of a Remolded Expansive Clay Blended with Lime, Calcium Chloride, and Rice-Husk Ash. J. Mater. Civ. Eng. 2008, 20, 509–515. [Google Scholar] [CrossRef]

- Yokohama, S.; Miura, S.; Matsumura, S. Change in the hydromechanical characteristics of embankment material due to compaction state conditions. Soils Found. 2014, 54, 731–747. [Google Scholar] [CrossRef]

- Cabrera, J.; Rojas, M.F. Mechanism of hydration of the metakaolin–lime–water system. Cem. Concr. Res. 2001, 31, 177–182. [Google Scholar] [CrossRef]

- Bougara, A.; Lynsdale, C.; Milestone, N. Reactivity and performance of blastfurnace slags of differing origin. Cem. Concr. Compos. 2010, 32, 319–324. [Google Scholar] [CrossRef]

- Velandia, D.F.; Lynsdale, C.J.; Provis, J.L.; Ramírez, F. Effect of mix design inputs, curing and compressive strength on the durability of Na2SO4-activated high volume fly ash concretes. Cem. Concr. Compos. 2018, 91, 11–20. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Dispersion and stability of graphene nanoplatelet in water and its influence on cement composites. Constr. Build. Mater. 2018, 167, 403–413. [Google Scholar] [CrossRef]

- ASTM D854-4. Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- GB/T 50123-1999. Standard for Soil Test Method; Ministry of Construction, P.R. China: Beijing, China, 1999. (In Chinese)

- ASTM D 698. Standard Test METHODS for Laboratory Compaction Characteristics of Soil Using Standard Effort [12,400 ft-lbf/ft3 (600 kN · m/m3)]; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ISO, STC. TS 17892-4: 2004: Geotechnical Investigation and Testing-Laboratory Testing of Soil–Part 4: Determination of Particle Size Distribution (ISO/TS 17892-4: 2004); Inštitut za standardizacijo: Ljubljana, Slovenija, 2014. [Google Scholar]

- Jayasinghe, C.; Kamaladasa, N. Compressive strength characteristics of cement stabilized rammed earth walls. Constr. Build. Mater. 2007, 21, 1971–1976. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z. Influence Factor Analysis on Strength of Lime-Fly Ash Loess. Engineering 2013, 5, 561–565. [Google Scholar] [CrossRef][Green Version]

- Zhao, Z.; Qu, X.; Li, F.; Wei, J. Effects of steel slag and silica fume additions on compressive strength and thermal properties of lime-fly ash pastes. Constr. Build. Mater. 2018, 183, 439–450. [Google Scholar] [CrossRef]

- Consoli, N.C.; da Silva Lopes, L., Jr.; Heineck, K.S. Key parameters for the strength control of lime stabilized soils. J. Mater. Civ. Eng. 2009, 21, 210–216. [Google Scholar] [CrossRef]

- Abdi, M.R. Effect of Calcium Sulphate on Lime-Stabilised Kaolinite. Ph.D. Thesis, Polytechnic of Wales, Treforest, UK, 1992. [Google Scholar]

- Regourd, M. Structure and behavior of slag Portland cement hydrates. In Proceedings of the 7th International Congress on the Chemistry of Cement, Paris, France, 30 June–4 July 1980; p. III-2. [Google Scholar]

- Criado, M.; Walkley, B.; Ke, X.; Provis, J.L.; Bernal, S.A. Slag and Activator Chemistry Control the Reaction Kinetics of Sodium Metasilicate-Activated Slag Cements. Sustainability 2018, 10, 4709. [Google Scholar] [CrossRef]

- Wu, C.; Chu, J.; Wu, S.; Hong, Y.; Chuangzhou, W.; Shifan, W. 3D characterization of microbially induced carbonate precipitation in rock fracture and the resulted permeability reduction. Eng. Geol. 2019, 249, 23–30. [Google Scholar] [CrossRef]

- Consoli, N.C.; Rotta, G.V.; Prietto, P.D.M. Yielding-compressibility-strength relationship for an artificially cemented soil cured under stress. Géotechnique 2006, 56, 69–72. [Google Scholar] [CrossRef]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key Parameters for Strength Control of Artificially Cemented Soils. J. Geotech. Geoenviron. Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Consoli, N.C.; Rosa, A.D.; Saldanha, R.B. Variables governing strength of compacted soil-fly ash-lime mixtures. J. Mater. Civ. Eng. 2010, 23, 432–440. [Google Scholar] [CrossRef]

- Consoli, N.C.; Dalla Rosa, A.; Corte, M.B.; Lopes, L.D.S., Jr.; Consoli, B.S. Porosity-cement ratio controlling strength of artificially cemented clays. J. Mater. Civ. Eng. 2011, 23, 1249–1254. [Google Scholar] [CrossRef]

- Merzouki, T.; Bouasker, M.; Khalifa, N.E.H.; Mounanga, P. Contribution to the modeling of hydration and chemical shrinkage of slag-blended cement at early age. Constr. Build. Mater. 2013, 44, 368–380. [Google Scholar] [CrossRef]

- Consoli, N.C.; Samaniego, R.A.Q.; Villalba, N.M.K. Durability, Strength, and Stiffness of Dispersive Clay-Lime Blends. J. Mater. Civ. Eng. 2016, 28, 4016124. [Google Scholar] [CrossRef]

- Du, H. Properties of ultra-lightweight cement composites with nano-silica. Constr. Build. Mater. 2019, 199, 696–704. [Google Scholar] [CrossRef]

- Prabakar, J.; Dendorkar, N.; Morchhale, R. Influence of fly ash on strength behavior of typical soils. Constr. Build. Mater. 2004, 18, 263–267. [Google Scholar] [CrossRef]

- Consoli, N.C.; Rosa, A.D.; Saldanha, R.B. Parameters controlling strength of industrial waste-lime amended soil. Soils Found. 2011, 51, 265–273. [Google Scholar] [CrossRef]

- Abo-El-Enein, S.; Hashem, F.; Amin, M.; Sayed, D. Physicochemical characteristics of cementitious building materials derived from industrial solid wastes. Constr. Build. Mater. 2016, 126, 983–990. [Google Scholar] [CrossRef]

- Bougara, A.; Lynsdale, C.; Milestone, N.B. The influence of slag properties, mix parameters and curing temperature on hydration and strength development of slag/cement blends. Constr. Build. Mater. 2018, 187, 339–347. [Google Scholar] [CrossRef]

| Properties | Values |

|---|---|

| Liquid limit (%) | 26.44 |

| Plastic limit (%) | 17.31 |

| Plasticity index (%) | 9.13 |

| Specific gravity | 2.71 |

| Particle size (mm) | ≤0.5 |

| Compounds | SiO2 | Al2O3 | CaO | MgO | K2O | Fe2O3 |

|---|---|---|---|---|---|---|

| Values (%) | 50 | 8~15 | 10 | 2~3 | 2 | 4~5 |

| Compounds | Binder (%) | |

|---|---|---|

| Slag | Lime | |

| CaO | 43.18 | - |

| SiO2 | 31.57 | ≤2 |

| Al2O3 | 15.27 | - |

| MgO | 6.68 | ≤2 |

| S | 1.08 | - |

| TiO2 | 0.742 | - |

| K2O | 0.448 | - |

| Fe2O3 | 0.431 | - |

| Na2O | 0.212 | - |

| Ca(OH)2 | - | ≥94 |

| CaCO3 | - | ≤4 |

| Pb | - | ≤3ppm |

| As | - | ≤0.4ppm |

| Free moisture | - | ≤1.0 |

| Properties | Measured |

|---|---|

| Specific gravity | 2.89 |

| Specific surface area(m2/kg) | 425 |

| Moisture content (%) | 0.28 |

| Strength grade | S95 |

| Mobility ratio (%) | 102 |

| Chloride (%) | 0.036 |

| Category | Mix Ratio by Mass Lime: Slag:Loess | Binder (Lime + Slag) Content (%) | Lime Content (%) | Slag Content (%) | Lime to Slag (L/S) Ratio | Slag Ratio in Binder (%) | Maximum Dry Density ρd,max (g/cm3) | Average ρd,ma (g/cm3) | Optimum Moisture Content ωopt (%) | ωopt − 1 (%) | ωopt − 2(%) | Average ωopt (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| I-1 | 18:2:80 | 20 | 18 | 2 | 9 | 10 | 1.58 | 1.61 | 18.91 | 17.91 | 16.91 | 18.37 |

| I-2 | 14:6:80 | 14 | 6 | 2.33 | 30 | 1.60 | 18.31 | 17.31 | 16.31 | |||

| I-3 | 10:10:80 | 10 | 10 | 1 | 50 | 1.64 | 17.88 | 16.88 | 15.88 | |||

| II-1 | 27:3:70 | 30 | 27 | 3 | 9 | 10 | 1.49 | 1.54 | 22.67 | 21.67 | 20.67 | 21.00 |

| II-2 | 21:9:70 | 21 | 9 | 2.33 | 30 | 1.54 | 21.12 | 20.12 | 19.12 | |||

| II-3 | 15:15:70 | 15 | 15 | 1 | 50 | 1.60 | 19.22 | 18.22 | 17.22 | |||

| III-1 | 36:4:60 | 40 | 36 | 4 | 9 | 10 | 1.41 | 1.49 | 24.06 | 23.06 | 22.06 | 22.89 |

| III-2 | 28:12:60 | 28 | 12 | 2.33 | 30 | 1.50 | 23.24 | 22.24 | 21.24 | |||

| III-3 | 20:20:60 | 20 | 20 | 1 | 50 | 1.55 | 21.37 | 20.37 | 19.37 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, L.; Zhang, L.; Guo, J.; Yao, K.; Lim, S.M.; Li, B.; Xu, H. Evaluation on Strength Properties of Lime–Slag Stabilized Loess as Pavement Base Material. Sustainability 2019, 11, 4099. https://doi.org/10.3390/su11154099

Jia L, Zhang L, Guo J, Yao K, Lim SM, Li B, Xu H. Evaluation on Strength Properties of Lime–Slag Stabilized Loess as Pavement Base Material. Sustainability. 2019; 11(15):4099. https://doi.org/10.3390/su11154099

Chicago/Turabian StyleJia, Liang, Li Zhang, Jian Guo, Kai Yao, Sin Mei Lim, Bin Li, and Hui Xu. 2019. "Evaluation on Strength Properties of Lime–Slag Stabilized Loess as Pavement Base Material" Sustainability 11, no. 15: 4099. https://doi.org/10.3390/su11154099

APA StyleJia, L., Zhang, L., Guo, J., Yao, K., Lim, S. M., Li, B., & Xu, H. (2019). Evaluation on Strength Properties of Lime–Slag Stabilized Loess as Pavement Base Material. Sustainability, 11(15), 4099. https://doi.org/10.3390/su11154099