Green Supplier Selection Criteria: From a Literature Review to a Comprehensive Knowledge Base

Abstract

1. Introduction

- to bring a gap between classical assumption of decision making and knowledge-based problem structuring;

- to obtain a high accuracy of and quality of collected papers for data aggregation about criteria determining green-oriented supplier selection;

- to address the lack of knowledge issue in the scattered criteria determining green-oriented supplier selection.

2. Literature Review

2.1. State-of-the-Art of the Suppliers’ Selection Approaches

2.2. State-of-the-Art of Knowledge Management Approaches for Supplier Selection

3. Materials and Methods

3.1. Methodological Overview

3.2. Search Strategy

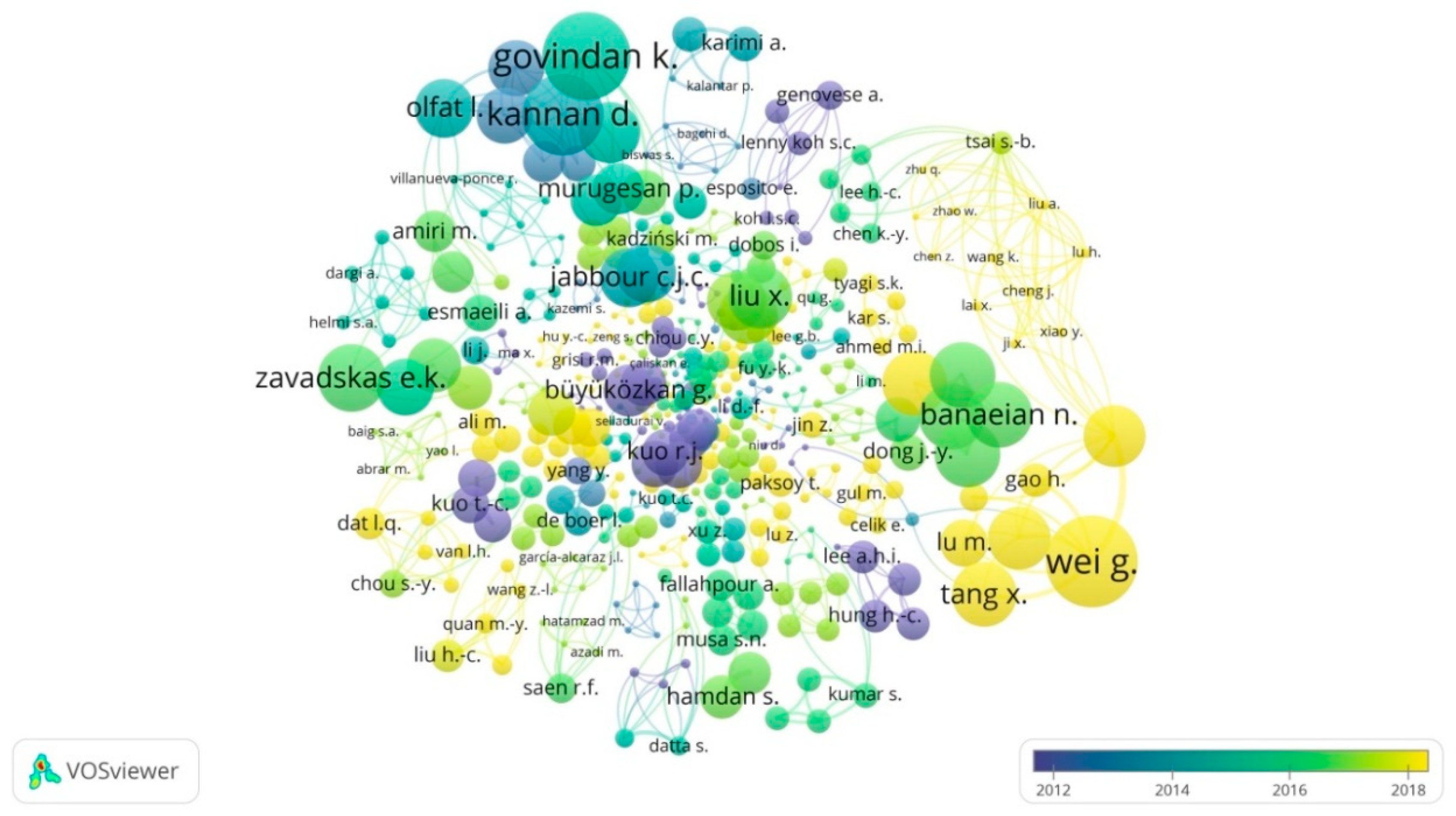

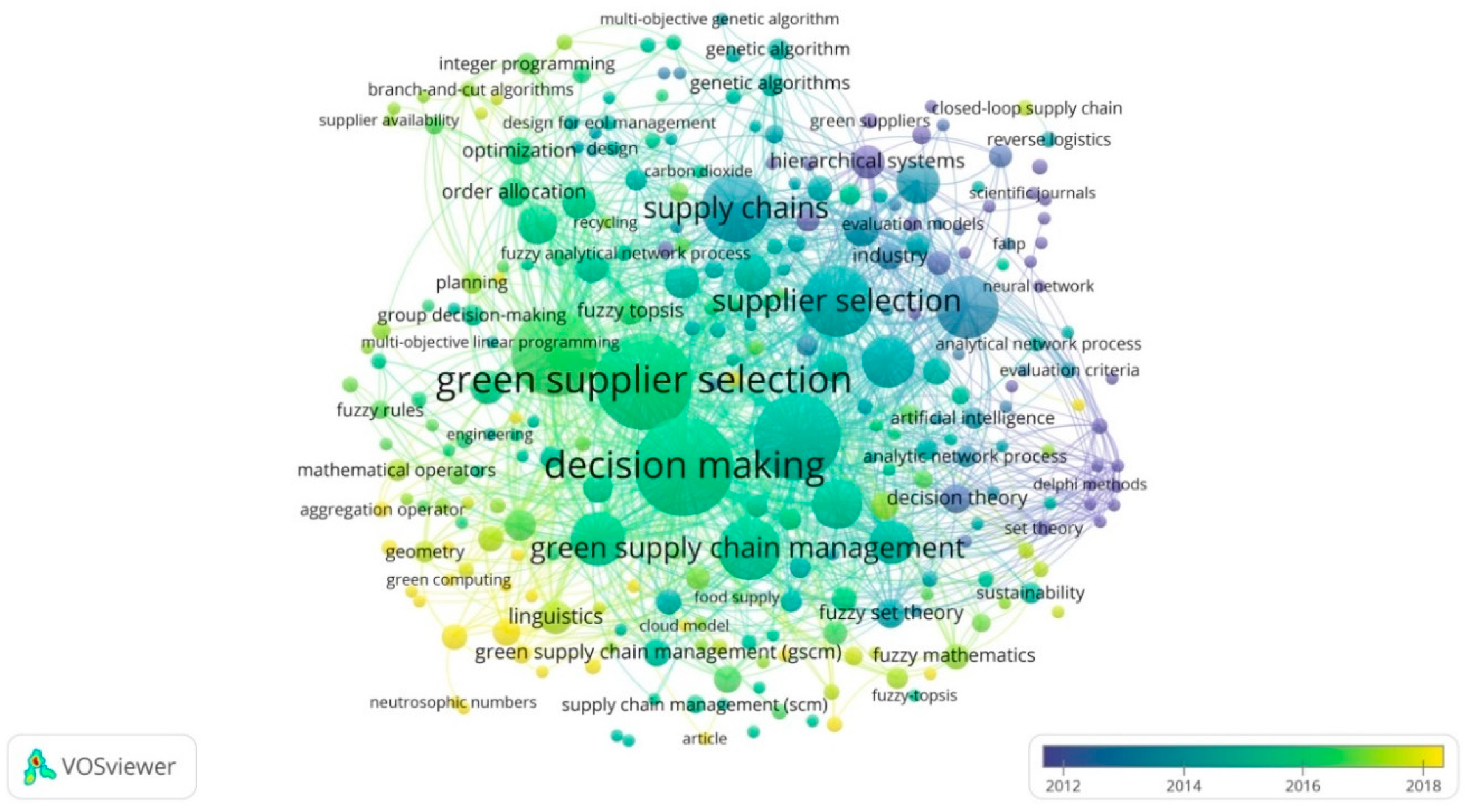

3.3. Preparation of a Set of Criteria Using Bibliometric Analysis

3.4. Filtering Results and Data Cleaning

4. An Ontology for Green-Oriented Supplier Selection

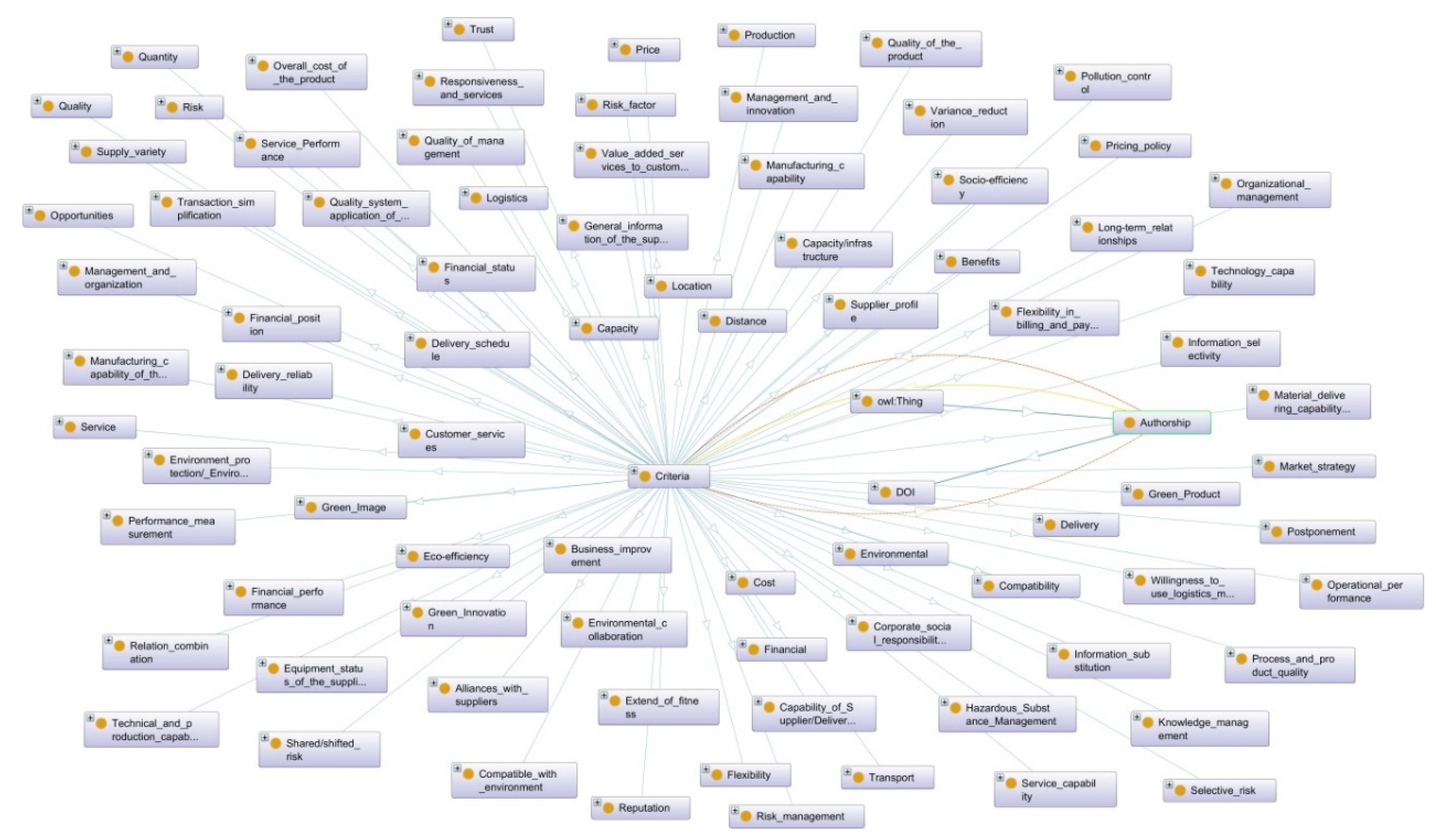

4.1. Taxonomy Construction

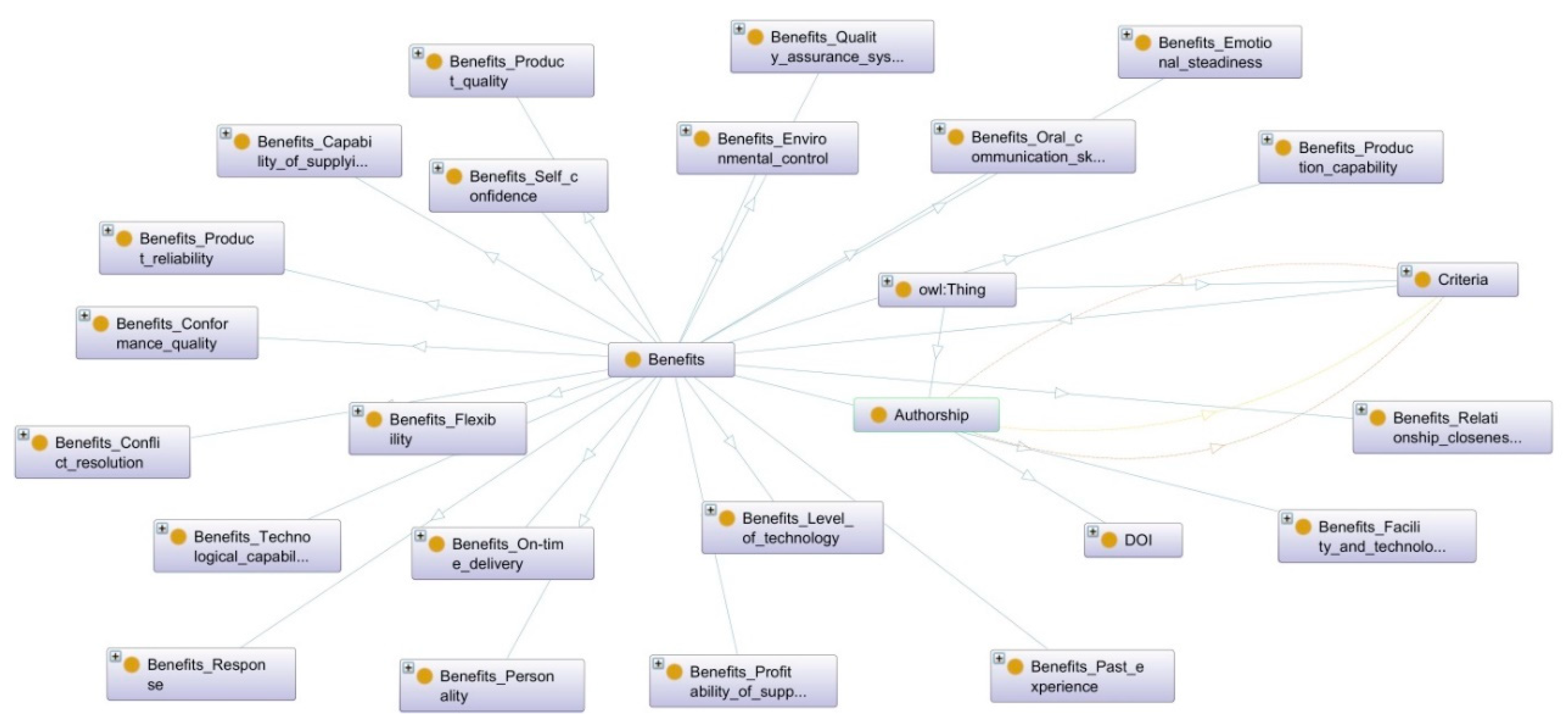

4.2. Ontology

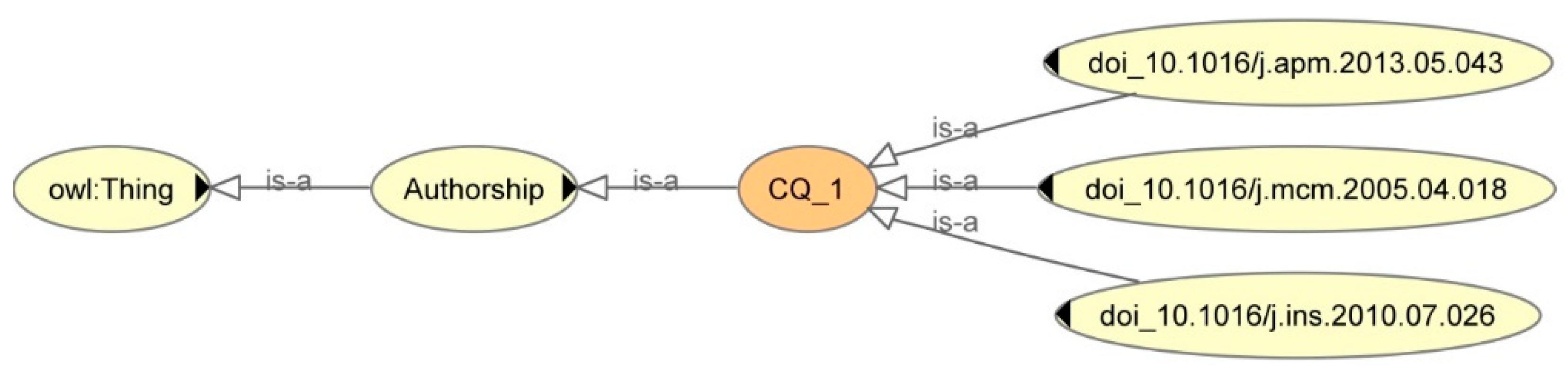

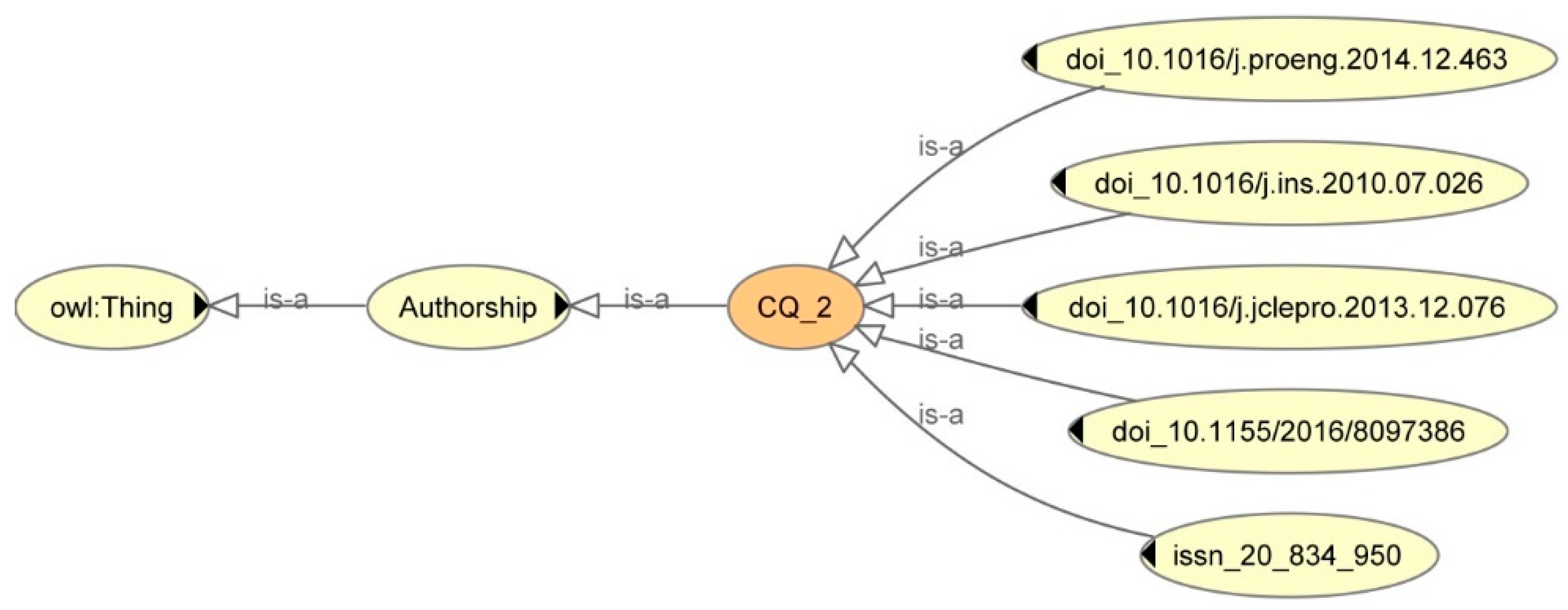

4.3. Validation Process Using Competency Questions

4.4. Practical Implications of the Proposed Solution

- semantic connection with existing ontologies of particular supplier selection methods and automatic application of algorithms used;

- integration with repositories containing scientific papers of green supplier selection domain and information systems supporting decision-making processes and evaluation.

5. Conclusions

- the systematic and formal procedure of analysis of the available documents related to green-oriented supplier selection, with methodological background;

- the encapsulation of unstructured, semi-structured and structured knowledge about criteria determining green-oriented supplier selection;

- filling a gap between classical assumption of decision making and knowledge-based problem structuring by using the ontology as a form of problem solving in the scattered criteria determining green-oriented supplier selection;

- obtaining high accuracy of and quality of collected papers for data aggregation about criteria determining green-oriented supplier selection;

- elaboration of complete domain knowledge of criteria determining green-oriented supplier selection, with ease of expanding, reusing, multi-usage, sharing and handling, and publicly available;

- verification and consistency checking of the obtained ontology using competency questions.

Supplementary Materials

Funding

Conflicts of Interest

Appendix A. Classification of Selected Criteria

- B is defined as a separated set of Benefits, with formal presentation presented below:where the subsequent abbreviations were used as follows: Bp Profitability of supplier, Brc—Relationship closeness, Btc—Technological capability, Bcq—Conformance quality, Bcr—Conflict resolution, Bes—Emotional steadiness, Boc—Oral communication skill, Bps—Personality, Bpe—Past experience, Bpr—Product reliability, Bec—Environmental control, Br—Response, Bsc—Self-confidence, Bf—Flexibility, Bpq—Product quality, Botd—On-time delivery, Bpc—Production capability, Bqas—Quality assurance system, Blt—Level of technology, Bco—Capability of supplying the urgent orders, Bft—Facility and technology).B = {Bp, Brc, Btc, Bcq, Bcr, Bes, Boc, Bps, Bpe, Bpr, Bec, Br, Bsc, Bf, Bpq, Botd, Bpc, Bqas, Blt, Bco, Bft},

- C represents a separated set of Cost formally presented as:where the symbols mean as follows: Cc—Cost, Cpc—Product cost, Coc—Ordering cost, Clc—Logistics costs, Cprc—Price/Cost, Casc—After sales costs, Cpp—Product price, Ctcd—Tariff and custom duties, Cp—Price, Ccl—Cost level, Cphc—Purchase costs, Cspp—Suppliers production pauses, Ccd—Customers dissatisfaction, Cce—Capital expenditure, Coe—Operating expenditure, Csc—Sunk cost, Cdc—Direct cost, Cic—Indirect cost, Cgpr—Gross profit rate, Cqdr—Quantity discount rate, Capp—Appropriateness of the product price to the market price, Ccrc—Cost reduction capability.C = {Cc, Cpc, Coc, Clc, Clc, Cprc, Casc, Cpp, Ctcd, Cp, Ccl, Cphc, Cspp, Ccd, Cce, Coe, Csc, Cdc, Cic, Cgpr, Cqdr, Capp, Ccrc},

- Mc refers to one-element set of Manufacturing capability:where Mcm refers to Manufacturing capability.Mc = {Mcm},

- Dr represents a set of Delivery reliability with formal presentation as follows:where Drl refers to Lead time, and Drt means On time delivery.Dr = {Drl, Drt},

- Q is defined as a separated set of Quality, with proper presentation as follows:where the subsequent abbreviations were used: Qa—Quality assurance, Qrr—Rejection ratio, Qrrp—Rejection rate of the product, Qild—Increased lead time, Qas—Quality assessment, Qrqp—Remedy for quality problems, Qqi—Quality image, Qpq—Product quality, Qvs—Vendor specific, Qo—Operational, Qt—Technical, Qqp—Quality of product, Qqm—Quality of manufacturing, Qpq—Product quality, Qprb—Performance about quality rejections before delivery, Qpra—Performance about quality rejections after delivery, Qrt—Return rate, Qdt—Discount rate, Qq—Quality, Qldt—Low defect rate, Qcq—Commitment to quality, Qipc—Improved process capability, Qrjr—Quality Systems, Reject Rate, Qwcp—Warranties and Claim Policies, Qchq—Capability of handling abnormal quality, Qcq—Commitment to quality).Q = {Qa, Qrr, Qrrp, Qild, Qas, Qrqp, Qqi, Qpq, Qvs, Qo, Qt, Qqp, Qqm, Qpq, Qprb, Qpra, Qrt, Qdt, Qq, Qldt, Qcq, Qipc, Qqs, Qrjr, Qwcp, Qchq, Qcq},

- Tc represents a set of Technology capability defined as follows:where Tcl refers to Technology level, Tcrd shows Capability of R&D, and Tcc represents Capability of design.Tc = {Tcl, Tcrd, Tcc},

- Cs is a separated set of Customer services, formally defined as follows:where Csrs refers to Response to complaints, Csws represents Warranty support, and Cscs denotes Communication system.Cs = {Csrs, Csws, Cscs},

- O is defined as a separated set of Opportunities, with formal presentation as follows:where the abbreviations represent the resulting elements: Osc—Supplier collaboration, Osd—Supplier development, Oimc—Increase in manufacturing capacity, Ofg—Financial growth, Oiec—Improvement and ease of communication, Ossi—Service support improvement, Ojg—Joint growth, Oti—Technological improvement.O = {Osc, Osd, Oimc, Ofg, Oiec, Ossi, Ojg, Oti},

- R is defined as a separated set of Risk, with appropriate presentation as follows:where the subsequent abbreviations were used as follows: Rcd—Changes in demand, Rcc—Customer complaints, Rfr—Field return, Rfs—Financial strength, Rmb—Machine break down, Rls—Labour strikes, Rod—Order delays, Ripf—Inability of production flexibility, Rgl—Geographical location, Rps—Political stability, Recc—Equipment capacity change, Rcr—Country risk, Rfri—Financial risk, Rnd—Natural disasters, Rtr—Technology risk, Rdr—Delivery risk, Rsc—Supply constraint, Rbsc—Buyer supplier constraint, Ri—Inconsistency, Rvp—Variation in price, Rspi—Suppliers production imitations, Rcc—Cutting cooperation, Ruo—Uncompleted order, Rsp—Suppliers profile.R = {Rcd, Rcc, Rfr, Rfs, Rmb, Rls, Rod, Ripf, Rgl, Rps, Recc, Rcr, Rfri, Rnd, Rtr, Rdr, Rsc, Rbsc, Ri, Rvp, Rspi, Rcc, Ruo, Rsp},

- Sp represents a set of Service performance defined as follows:where Spd refers to Delivery schedule, Spt represents Technological R&D support, Spr means Response to change, and Spe denotes Ease of communication.Sp = {Spd, Spt, Spr, Spe},

- Spp is defined as a separated set of Supplier profile, with appropriate presentation as follows:where the subsequent abbreviations were used as follows: Sppf—Financial status, Sppc—Customer base, Performance history, Production facility and capacity, Organization structure, The number of personnel, Education status of the personnel).Spp = {Sppf, Sppc, Sppp, Sppf, Sppo, Sppn, Spps},

- Rf reflects to a set of Risk factor, presented below:where Rfg means Geographical location, Rfp denotes Political stability, Rfe presents Economy, and Rft depicts Terrorism.Rf = {Rfg, Rfp, Rfe, Rft},

- F is defined as a separated set of Financial, with specified presentation as follows:where the following subsets are shown as consequent: Ft—Turnover, Fd—Distance, Ffm—Financial of manufacturing, Ffp—Financial of product, Ffs—Financial strength, Ffp—Financial position, Fcs—Cost saving, Frv—Recapturing value, Fuo—Unit operation cost, Ffc—Fixed cost of maintaining a warehouse, Fce—Cost of establishing a warehouse, Fcw—Fixed cost of expanding a warehouse, Fvc—Variable cost of expanding a warehouse Fixed cost of maintaining a repair facility, Fcer—Cost of establishing a repair facility, Ffce—Fixed cost of expanding a repair, Fsw—Savings from the use of an existing warehouse as a repair facility, Frl—Reverse logistics cost, Ftc—Total cost of shipments, Frs—Revenue from the sale of recyclables, Ffst—Financial stability).F = {Ft, Fd, Ffm, Ffp, Ffs, Ffp, Fcs, Frv, Fuo, Ffc, Fcw, Ffc, Fvc, Fcer, Ffce, Fsw, Frl, Ftc, Frs, Ffst},

- S is defined as a separated set of Service with itemized presentation as follows:where the following subsets are shown as consequent: Sd—Delivery on time, Src—Responsiveness to customer needs, Sp—Professionalism of sales person, Sq—Quality of relationship with vendor, Sr—Response to demand, Si—Information acquisition, Sa—After-sales service, Ss—Service, Ssd—Service standard, Sr—Responsiveness, Sic—Improvement capability, Sod—On time delivery, Sqr—Quick responsiveness, Ssc—Supplier capacity, Sro—Rate of processing order form, Srd—Rate of delivery in time, Sdi—Degree of information modernized, Spu—Punctuality, Sfl—Flexibility, Spf—Price Fairness, Ssq—Service quality).S = {Sd, Src, Sp, Sq, Sr, Si, Sa, Ss, Ssd, Sr, Sic, Sod, Sqr, Ssc, Sro, Srd, Sdi, Spu, Sfl, Spf, Ssq},

- Gis refers to a set representing General information of the supplier, with the specified elements:where Gisf presents Facility location, Gisw means The number of working years in this sector, Gisr shows References, Giss refers to The service capability, and Gisc denotes Communication capability.Gis = {Gisf, Gisw, Gisr, Giss, Gisc},

- Fs represents a set of Financial status defined as follows:where the following subsets are noted as particulars: Fsp—The last term profit, Fse—Exporting status, Fsa—Appropriateness of the materials price to the market price.Fs = {Fsp, Fse, Fsa},

- Ess represents a set of Equipment status of the supplier, defined subsequently:where Essm means Machine capacity and capability, and Esst presents Manufacturing technology;Ess = {Essm, Esst},

- Mcs presents a set of Manufacturing capability of the supplier defined as follows:where Mcsf means Facilities manufacturing capacity, Mcst represents Technical capability, Mscp shows Manufacturing planning capability, and Msch refers to Handling and packaging capability.Mcs = {Mcsf, Mcst, Mcsp, Msch},

- Mdc refers to a subset of Material delivering capability of the supplier defined subsequently:where Mdcq presents Appropriateness of the quantity, Mdcd means Appropriateness of the delivery date, Mdcp denotes Appropriateness of the packaging standards, and Mdcm shows The period of procuring materials.Mdc = {Mdcq, Mdcd, Mdcp, Mdcm},

- Qsc is defined as a set of Quality system certificate of the supplier with specified subsets:where the following subsets are shown as consequent: Qscs—Quality system certificate of the supplier, Qscm—Quality manual, Qscd—Documentation control, Qsca—Archive of quality records, Qscu—Usage of worth instructions, Qscp—Process control capability, Qsci—Product identification, Qscr—Receiving Inspection, Qscc—Calibration control, Qscn—Non-conforming material control system, Qscp—Corrective and preventive action system, Qscau—Audit mechanism, Qsct—Training.Qsc = {Qscs, Qscm, Qscd, Qsca, Qscu, Qscp, Qsci, Qscr, Qscc, Qscn, Qscp, Qscau, Qsct},

- Sr represents a set of Selective risk, specified as follows:where the following subsets are shown using the symbols: Srk—Knowledge about customer, Srkc—Knowledge about competition, Srks—Service range capabilities, Srki—Inventory management system flexibility.Sr = {Srk, Srkc, Srks, Srki},

- Is contains a set of elements of Information selectivity, which is formally describes as:where Isf means Flexibility of data linkages, Isa represents Accuracy of data, Isd denotes Accuracy of data needs, and Iss refers to Data search capability.Is = {Isf, Isa, Isd, Iss},

- Isb refers to a set of Information substitution, formally defined as a set of elements:where the elements are noted as follows: Isbc—Coverage of information linkages, Isca—Accuracy of data, Isbl—Level of system integration, Isbf—Forecasting capabilities.Isb = {Isbc, Isca, Isbl, Isbf},

- Ts represents a set of Transaction simplification, with specified subsets formally described as:where Tsu refers to User–interface friendliness, Tsd means Data available to user, Tsl shows Level of system integration, and Tss points at Supplier access to information.Ts = {Tsu, Tsd, Tsl, Tss},

- Vr contains a set of elements referred to Variance reduction, represented as follows:where Vrd shows Demand forecasting tools, Vrc means Communication with customer/supplier, Vrs depicts Statistical process control, and Vri represents Internal system integration.Vr = {Vrd, Vrc, Vrs, Vri},

- Iv represents a set of Inventory velocity, formally defined as follows:where the subsets are noted using abbreviations: Ive—Efficient third party relationship, Ivj—Just in time support, Ivf—Flexible manufacturing operations, Ivd—Flexible distribution options.Iv = {Ive, Ivj, Ivf, Ivd},

- P refers to a set of Postponement, represented as follows:where the following subsets are included: Pm—Modular product design, Pf—Flexible packaging design, Pr—Retail/distribution site data.P = {Pm, Pf, Pr},

- Ssr is a set of Shared/shifted risk, formally noted as:where the subsets mean as follows: Ssrc—Creation of standards, Ssro—Outsourcing agreements, Ssrs—Supplier customization.Ssr = {Ssrc, Ssro, Ssrs},

- Ce represents a set of Compatible with environment, formally defined as follows:where the following subsets are included: Cep—Pollution control initiatives, Cet—The use of green technology and materials, Ceg—Participation in green projects, Ceq—Quality of Service, Cedv—Delivery, Cee—Environmental certification, Cec—Cooperating with green organization, Cepr—The profitability and financial position, Cef—Flexibility in the demand changes, Cea—Product life cycle assessment, Ceet—Employee training.Ce = {Cep, Cet, Ceg, Ceq, Cedv, Cee, Cec, Cepr, Cef, Ced, Cea, Ceet},

- T is defined as a set of Trust, formally defined as:where the following subsets are included: Tf—Inter-firm trust, Tt—Interpersonal trust.T = {Tf, Tt},

- Mo represents a set of Management and organization, specified as follows:where the subsets are formalized as follows: Mor—Responsiveness, Mod—Discipline, Moe—Environment, Mot—Technical capability, Mof—Facility and capacity, Mop—Performance history.Mo = {Mor, Mod, Moe, Mot, Mof, Mop},

- Csd refers to a set of Capability of Supplier/Delivery, formalized in the form of:where the subsets are as follows: Csdt—Technological capability, Csdp—Production capability, Csde—Electronic transaction capability.Csd = {Csdt, Csdp, Csde},

- Sc is defined as a set of Service capability, formally defined as:where the following subsets are included: Scf—Flexibility, Sce—Ease of communication, Scp—Production facility and capacity, Scr—Response to changes).Sc = {Scf, Sce, Scp, Scr},

- Pp represents a set of Pricing policy, with formal presentation presented below:where the following subsets are specified: Ppf—Fair price, Ppq—Quantity discount rate, Ppp—Price fluctuation, Ppt—Total price);Pp = {Ppf, Ppq, Ppp, Ppt},

- Rs is defined as a set of Responsiveness and services, formally represented as:where the subsets refer to consecutive elements: Rsa—After sales service, Rsw—Warranty, Rsp—Packaging capacity, Rsm—Mutual trust and ease of communication, Rsr—Responsiveness and attitude.Rs = {Rsa, Rsw, Rsp, Rsm, Rsr},

- Fx represents a set of Flexibility, with formal presentation presented below:where the subsets are defined as follows: Fxp—Having new production technology, Fxit—IT and automation usage, Fxt—Technical capacity.Fx = {Fxp, Fxit, Fxt},

- Tpc refers to a set of Technical and production capability, formalized in the form of:where Tpcr means R&D rate, Tpcp refers to Process capability, and Tpcs poins at Supplier’s technical level.Tpc = {Tpcr, Tpcp, Tpcs},

- Rc contains a set of Relation combination, formally defined as:where the subsets are specified as follows: Rct—Technique cooperation, Rcm—Market cooperation, Rcc—Cooperative time.Rc = {Rct, Rcm, Rcc},

- Om is defined as a set of Organizational management, formally defined as:where the subsets are represented by the specified abbreviations: Omi—Inventory turnover ratio, Ome—Operating expense rate.Om = {Omi, Ome},

- Ee represents a set of Eco-efficiency, with formal presentation presented below:where the subsets are defined as follows: Eegd—Green design, Eep—Pollution prevention, Eegi—Green image, Eegc—Green capability, Eeem—Environmental management system.Ee = {Eegd, Eep, Eegi, Eegc, Eeem},

- Pr contains a set of Price, formally described as:where the subsets reflect the following elements: Prp—Price, Pre—The estimated price level offered by a supplier as compared to the average market price, Prpp—Purchasing price, Prpv—Price performance value, Prt—Transportation cost.Pr = {Prp, Pre, Prpp, Prpv, Prt},

- Ci is defined as a set of Capacity/infrastructure, formally defined as:where the subsets are described as: Cir—Reserve capacity, Circ—Capacity usage ratio, Cipc—Production capacity of the client plant, Cimw—Maximum capacity per warehouse, Cimr—Maximum capacity per repair center, Cime—Maximum capacity of expansion per warehouse, Cimf—Maximum capacity of expansion per repair facility, Cit—Technical/Engineering Capability, Cii—Inability to meet future requirement.Ci = {Cir, Cicr, Cicp, Cimw, Cimr, Cime, Cimf, Cit, Cii},

- L represents a single element set of Location, defined as follows:where Lg refers to Geographical location.L = {Lg},

- Se is defined as a set of Socio-efficiency, formally defined as:where the subsets are described as: Sel—Long term relationship, Sec—Communication openness, Sea—Reciprocal arrangement, Sep—Physical facilities, Sei—Relationship intensity, See—Effort to establish cooperation, Ser—Reputation, Sed—Decrease customer response time, Ses—Increase employee’s skills).Se = {Sel, Sec, Sea, Sep, Sei, See, Ser, Sed, Ses},

- Km is defined as a set of Knowledge management, with formal presentation as follows:where the subsets are noted as: Kmw—Willingness to share information, Kmi—Increase order information sharing, Kme—Expand accessibility of information, Kms—Information sharing.Km = {Kmw, Kmi, Kme, Kms},

- D contains a set of Delivery, formally described as:where the subsets represent the following elements: Dd—Delivery, Ddt—Compliance delivery with due time, Dq—Compliance delivery with quantity, Dot—Delivery on time, Dp—Price, Dt—Transport, Dds—Conformance to delivery schedule, Dcq—Conformance to quantity, Dc—Choice of transportation, Ds—Supplier’s delay on delivery, Dr—Defect rate (return rate), Dqs—Quality system certificate of the supplier, Drq—Reliability of quality, Drr—Rejection rate, Dl—Lead time, Dod—On-time delivery rate, Dlf—Delivery flexibility, Dse—Supplier’s effort in promoting JIT principles, Dotd—On time delivery, Dmp—Measures the percentage of on-time delivery.D = {Dd, Ddt, Dq, Dot, Dp, Dt, Dds, Dcq, Dc, Ds, Dr, Dqs, Drq, Drr, Dl, Dod, Ddf, Dse, Djt, Dotd, Dmp},

- Ds represents a set of Delivery schedule, defined formally as:where the subsets refer to the following elements: Dss—Shortest lead time, Dst—Delivery on time rate, Dsd—Serious delivery delay rate.Ds = {Dss, Dst, Dsd},

- Qp is defined as a separated set of Quality of the product, formalized as:where the subsets mean: Qpi—Ingredient consistency, Qpp—Process capability, Qpy—Yield rate.Qp = {Qpi, Qpp, Qpy},

- Ocp covers a set of Overall cost of the product, formally noted as:where the subsets refer to the following items: Ocpr—Recycled material price, Ocph—Handling cost, Ocpl—Process loss cost.Ocp = {Ocpr, Ocph, Ocpl},

- Ec represents a set of Environmental collaboration, defined as follows:where the subsets cover as follows: Ect—Technology for recycling products and process, Ecg—Green manufacturing policy.Ec = {Ect, Ecg},

- Cd is defined as a separated set of Capability of Supplier/Delivery, formalized as:where the following subsets are included: Cdl—Logistic capabilities, Cds—Supplying capability, Cdt—Level of Technique, Cdpd—Capability of Product Development, Cdo—Order fulfil rate, Cdlt—Lead time, Cdr—Capability of R&D, Cdtc—Technology Level, Cdf—Flexibility of the Supplier, Cdss—Supplier Stock Management, Cdtf—Technical capability and facility, Cdsd—Service and delivery.Cd = {Cdl, Cds, Cdt, Cdpd, Cdo, Cdlt, Cdr, Cdtc, Cdf, Cdss, Cdtf, Cdsd},

- Po represents a subsequent set of Production, defined as follows:where the subsets point at specifically: Pol—Product line, Pob—Product bundle, Poi—Improve production efficiency.Po = {Pol, Pob, Poi},

- Ms is defined as a separated set of Market strategy, formalized as:where the subsets cover: Msc—Market coverage, Mse—Marketing experience, Msa—Management ability, Msi—Identify market innovative opportunities.Ms = {Msc, Mse, Msa, Msi},

- Bi is a separated set of Business improvement, formalized in the form of:where Bir means Reputation of industry, Bif refers to Financial strength, Bim presents Managing ability, and Bio points at Organizations customers.Bi = {Bir, Bif, Bim, Bio},

- Ef represents a subsequent set of Extend of fitness, defined as follows:where the subsets are as follows: Efs—Sharing of expertise, Eff—Flexible practices, Efd—Diversified customers.Ef = {Efs, Eff, Efd},

- Qt represents a single element set of Quantity, formalized as:where Qtq refers to Quantity.Qt = {Qtq},

- L is a separated set of Logistics, formalized in the form of:where the subsets cover the following items: Lw—Warehouse management, Lt—Transportation management, Lit—IT management, Ltd.—On time delivery ratio, Lcf—Confirmed fill rate, Lsq—Service quality level, Lto—Total order cycle time, Lsf—System flexibility index, Litl—Integration technologies level, Lim—Increment in market share, Lr—Research and development ratio, Ld—Demand forecast for each client, product, Lrf—Return forecast for each client, product, Lrr—Rejection rate, Lp—Procurement.L = {Lw, Lt, Lit, Ltd., Lcf, Lsq, Lto, Lsf, Litl, Lim, Lr, Ld, Lrf, Lrr, Lp},

- Va represents a subsequent set of Value added services to customers, defined as follows:where the subsets cover as follows: Vac—Convenience, Vas—Customer service, Vag—Green products, Vacs—Customer satisfaction, Vaar—Assembly/reassembly, Varr—Repackaging/re-labeling, Varm—Remanufacturing, Varf—Refurbishment, Vad—Disposal, Vacc—Call-center operation, Vaas—After sales service, Vam—Management/performance reports.Va = {Vac, Vas, Vag, Vacs, Vaar, Varr, Varm, Varf, Vad, Vacc, Vaas, Vam},

- As is a separated set of Alliances with suppliers, defined in the form of:where the following subsets are included: Asc—Competitiveness, Asm—Mentoring of suppliers, Asf—Formation of strategic alliances, Ask—Knowledge management.As = {Asc, Asm, Asf, Ask},

- Ev represents a single element set of Environmental, formalized as:where Evp refers to Product recovery options and green products.Ev = {Evp},

- Ppr is a separated set of Process and product quality, defined as:where the subsets cover the elements as: Ppqn—Non defect rate, Ppqc—Corrective actions, Ppqt—Throughput time.Ppq = {Ppqn, Ppqc, Ppqt},

- Mi represents a subsequent set of Management and innovation, defined as follows:where the subsets include the items as follows: Mih—Human Resources, Mir—Relationships with large enterprises, Mid—R&D investment.Mi = {Mih, Mir, Mid},

- Fp is defined as a set of Financial position, formally noted as:where Fpp means to Profit margin, Fpa refers to Assets, and Fpl presents Liquidity.Fp = {Fpp, Fpa, Fpl},

- Cp represents a single element set of Capacity, formalized as:where Cppc presents Production capacity.Cp = {Cppc},

- Tr presents a single element set of Transport, formalized as:where Tre refers to Enhance transportation tool utilization.Tr = {Tre},

- Epm is defined as a set of Environment protection/Environment management, formally noted as:where the subsets are defined as: Epms—Environment protection system certification, Epme—Environment efficiency, Epmu—EUP, Epmh—RoHS, Epmp—Environmental protection policies/plans.Epm = {Epms, Epme, Epmu, Epmh, Epmp},

- Csr is a separated set of Corporate social responsibility, formalized as follows:where the subsets include the following items: Csri—The interests and rights of employee, Csrs—The rights of stakeholder, Csrd—Information disclosure, Csrr—Respect for the policy.Csr = {Csri, Csrs, Csrd, Csrr}

- Pc is defined as a set of Pollution control, represented in the form of:where the subsets cover as follows: Pca—Air Emissions, Pcw—Waste water, Pcpi—Pollution control Initiatives, Pcpr—Pollution reduction capability.Pc = {Pca, Pcw, Pcpi, Pcpr},

- Gp is a separated set of Green Product, formalized as:where the subsets refer to: Gpr—Recycle, Gpp—Green packaging, Gpc—Cost of component disposal, Gpg—Green certifications, Gpgp—Green production, Gpr—Reuse, Gpm—Re-Manufacture, Gpd—Disposal.Gp = {Gpr, Gpp, Gpc, Gpg, Gpgp, Gpr, Gpm, Gpd},

- Gi refers to a set of Green Image, formalized as:where the subsets include: Gim—Materials used in the supplied components that reduce the impact on natural resources, Gia—Ability to alter process and product for reducing the impact on natural resources, Gir—Ratio of green customers to total customers, Gic—Green customers’ market share, Gisr—Stakeholder’s relationship, Gimc—Green materials coding and recording.Gi = {Gim, Gia, Gir, Gic, Gisr, Gimc},

- Gin is a separated set of Green Innovation, defined as follows:where the subsets reflect to: Gint—Green Technology Capabilities, Gind—Green design, Ginp—Green process/Production planning, Ginr—Recycling product design, Ginrp—Renewable product design, Ginrd—Green R&D project, Ginre—Redesign of product.Gin = {Gint, Gind, Ginp, Ginr, Ginrp, Ginrd, Ginre},

- Hms represent a subsequent set of Hazardous Substance Management, formalized as follows:where the subsets are defined as follows: Hsmm—Management for hazardous substances, Hsmp—Prevention of mixed material, Hsma—Process auditing, Hsmw—Warehouse management, Hsmi—Inventory of hazardous substances.Hms = {Hsmm, Hsmp, Hsma, Hsmw, Hsmi},

- Cmp is a single set of Compatibility, defined as follows:where Cmpc refers to Compatibility.Cmp = {Cmpc},

- Rp is a single set of Reputation, formalized as follows:where Rpr denotes Reputation.Rp = {Rpr},

- Ltr is a single set of Long-term relationships, presented formally as:where Ltrr means Long-term relationships.Ltr = {Ltrr},

- Fpr is a single set of Financial performance, presented below as:where Fprf points at Financial performance.Fpr = {Fprf},

- Rm is a single set of Risk management, formalized as:where Rmrm refers to Risk management.Rm = {Rmrm},

- Pm is a single set of Performance measurement, defined as:where Pmpm points at Performance measurement.Pm = {Pmpm},

- Wlm is a single set of Willingness to use logistics manpower, described formally as:where Wlml covers Willingness to use logistics manpower.Wlm = {Wlml},

- Flexibility in billing and payment;where Fbpf refers to Flexibility in billing and payment.Fbp = {Fbpf},

- Qm is a single set of Quality of management, presented below in the form of:where Qmq refers to Quality of management.Qm = {Qmq},

- Sv is a single set of Supply variety, formalized as:where Svn codes Number of parts supplied by the supplier.Sv = {Svn},

- D is a single set of Distance, formally defined as:where Dde presents The distance is related to delivery efficiency.D = {Dde},

References

- Akman, G. Evaluating suppliers to include green supplier development programs via fuzzy c-means and VIKOR methods. Comput. Ind. Eng. 2015, 86, 69–82. [Google Scholar] [CrossRef]

- Nielsen, I.E.; Banaeian, N.; Golińska, P.; Mobli, H.; Omid, M. Green Supplier Selection Criteria: From a Literature Review to a Flexible Framework for Determination of Suitable Criteria. In Logistics Operations, Supply Chain Management and Sustainability; Golinska, P., Ed.; Springer International Publishing: Cham, Switzerland, 2014; pp. 79–99. ISBN 978-3-319-07286-9. [Google Scholar]

- Ng, W.L. An efficient and simple model for multiple criteria supplier selection problem. Eur. J. Oper. Res. 2008, 186, 1059–1067. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Kumar, N. Global supplier development considering risk factors using fuzzy extended AHP-based approach. Omega 2007, 35, 417–431. [Google Scholar] [CrossRef]

- de Boer, L.; Labro, E.; Morlacchi, P. A review of methods supporting supplier selection. Eur. J. Purch. Supply Manag. 2001, 7, 75–89. [Google Scholar] [CrossRef]

- Gurel, O.; Acar, A.Z.; Onden, I.; Gumus, I. Determinants of the Green Supplier Selection. Procedia Soc. Behav. Sci. 2015, 181, 131–139. [Google Scholar] [CrossRef]

- Min, S.; Mentzer, J.T. Developing and Measuring Supply Chain Management Concepts. J. Bus. Logist. 2004, 25, 63–99. [Google Scholar] [CrossRef]

- Chan, F.T.S.; Kumar, N.; Tiwari, M.K.; Lau, H.C.W.; Choy, K.L. Global supplier selection: A fuzzy-AHP approach. Int. J. Prod. Res. 2008, 46, 3825–3857. [Google Scholar] [CrossRef]

- Kuo, R.J.; Wang, Y.C.; Tien, F.C. Integration of artificial neural network and MADA methods for green supplier selection. J. Clean. Prod. 2010, 18, 1161–1170. [Google Scholar] [CrossRef]

- Lee, A.H.I.; Kang, H.Y.; Hsu, C.F.; Hung, H.C. A green supplier selection model for high-tech industry. Expert Syst. Appl. 2009, 36, 7917–7927. [Google Scholar] [CrossRef]

- Sancha, C.; Gimenez, C.; Sierra, V. Achieving a socially responsible supply chain through assessment and collaboration. J. Clean. Prod. 2016, 112, 1934–1947. [Google Scholar] [CrossRef]

- Shaw, K.; Shankar, R.; Yadav, S.S.; Thakur, L.S. Global supplier selection considering sustainability and carbon footprint issue: AHP multi-objective fuzzy linear programming approach. Int. J. Oper. Res. 2013, 17, 215–247. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. The PRISMA Group Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

- Smith, B. Ontology (Science); IOS Press: Amsterdam, The Netherlands, 2008; pp. 21–35. [Google Scholar]

- Luciano, F. (Ed.) Blackwell Guide to the Philosophy of Computing and Information; Blackwell: Oxford, UK, 2003; pp. 155–166. [Google Scholar]

- Obrst, L. Ontologies for semantically interoperable systems. In Proceedings of the twelfth International Conference on Information and Knowledge Management—CIKM ’03, New Orleans, LA, USA, 3–8 November 2003; ACM Press: New York, NY, USA, 2003; p. 366. [Google Scholar]

- Fox, M.S.; Grüninger, M. Ontologies for Enterprise Modelling. In Enterprise Engineering and Integration; Kosanke, K., Nell, J.G., Eds.; Springer: Berlin/Heidelberg, Germany, 1997; pp. 190–200. ISBN 978-3-540-63402-7. [Google Scholar]

- Lee, C.H.; Wang, Y.H.; Trappey, A.J.C. Ontology-based reasoning for the intelligent handling of customer complaints. Comput. Ind. Eng. 2015, 84, 144–155. [Google Scholar] [CrossRef]

- Chu, C.C.; Cheng, Y.F.; Tsai, F.S.; Tsai, S.B.; Lu, K.H. Open Innovation in Crowdfunding Context: Diversity, Knowledge, and Networks. Sustainability 2019, 11, 180. [Google Scholar] [CrossRef]

- Maedche, A.; Staab, S. Ontology learning for the Semantic Web. IEEE Intell. Syst. 2001, 16, 72–79. [Google Scholar] [CrossRef]

- Mankovskii, S.; Gogolla, M.; Urban, S.D.; Dietrich, S.W.; Urban, S.D.; Dietrich, S.W.; Yang, M.H.; Dobbie, G.; Ling, T.W.; Halpin, T.; et al. Ontology. In Encyclopedia of Database Systems; Liu, L., Özsu, M.T., Eds.; Springer: Boston, MA, USA, 2009; pp. 1963–1965. ISBN 978-0-387-35544-3. [Google Scholar]

- Wang, S.; Noe, R.A. Knowledge sharing: A review and directions for future research. Hum. Resour. Manag. Rev. 2010, 20, 115–131. [Google Scholar] [CrossRef]

- Kanter, J. Knowledge Management, Practically Speaking. Inf. Syst. Manag. 1999, 16, 7–15. [Google Scholar] [CrossRef]

- Uschold, M. Knowledge level modelling: Concepts and terminology. Knowl. Eng. Rev. 1998, 13, 5–29. [Google Scholar] [CrossRef]

- Gruber, T. Ontology; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 0-387-35544-8. [Google Scholar]

- Dhaouadi, R.; Benmiled, A.; Ghédira, K. Ontology based Multi Agent System for Improved Procurement Process: Application for the Handicraft Domain. Procedia Comput. Sci. 2014, 35, 251–260. [Google Scholar] [CrossRef]

- Konys, A. An Ontology-Based Knowledge Modelling for a Sustainability Assessment Domain. Sustainability 2018, 10, 300. [Google Scholar] [CrossRef]

- Fensel, D.; McGuiness, D.L.; Schulten, E.; Ng Keong, W.; Lim, G.P.; Yan, G.H. Ontologies and electronic commerce. IEEE Intell. Syst. 2001, 16, 8–14. [Google Scholar] [CrossRef]

- Corrente, S.; Greco, S.; Słowiński, R. Multiple Criteria Hierarchy Process with ELECTRE and PROMETHEE. Omega 2013, 41, 820–846. [Google Scholar] [CrossRef]

- Corso, M.; Dogan, S.F.; Mogre, R.; Perego, A. The role of knowledge management in supply chains: Evidence from the Italian food industry. Int. J. Netw. Virtual Organ. 2010, 7, 163–183. [Google Scholar] [CrossRef]

- Smith, B. FOIS introduction: Ontology—Towards a new synthesis. In Proceedings of the international conference on Formal Ontology in Information Systems—FOIS ’01, Ogunquit, ME, USA, 17–19 October 2001. [Google Scholar]

- Gene Ontology Consortium. The Gene Ontology (GO) database and informatics resource. Nucleic Acids Res. 2004, 32, 258–261. [Google Scholar] [CrossRef]

- Konys, A. A Framework for Analysis of Ontology-Based Data Access. In Computational Collective Intelligence; Nguyen, N.T., Iliadis, L., Manolopoulos, Y., Trawiński, B., Eds.; Springer International Publishing: Cham, Switzerland, 2016; Volume 9876, pp. 397–408. ISBN 978-3-319-45245-6. [Google Scholar]

- Cai, M.; Zhang, W.Y.; Zhang, K. ManuHub: A Semantic Web System for Ontology-Based Service Management in Distributed Manufacturing Environments. IEEE Trans. Syst. Man Cybern. Part Syst. Hum. 2011, 41, 574–582. [Google Scholar] [CrossRef]

- Lin, H. Knowledge sharing and firm innovation capability: An empirical study. Int. J. Manpow. 2007, 28, 315–332. [Google Scholar] [CrossRef]

- Wu, I.L.; Chen, J.L. Knowledge management driven firm performance: The roles of business process capabilities and organizational learning. J. Knowl. Manag. 2014, 18, 1141–1164. [Google Scholar] [CrossRef]

- Cruz, J.M.; Matsypura, D. Supply chain networks with corporate social responsibility through integrated environmental decision-making. Int. J. Prod. Res. 2009, 47, 621–648. [Google Scholar] [CrossRef]

- Young, A. Sustainable Supply Network Management. Corp. Environ. Strategy 2001, 8, 260–268. [Google Scholar] [CrossRef]

- Kovács, G. Corporate environmental responsibility in the supply chain. J. Clean. Prod. 2008, 16, 1571–1578. [Google Scholar] [CrossRef]

- Sharfman, M.P.; Shaft, T.M.; Anex, R.P. The road to cooperative supply-chain environmental management: Trust and uncertainty among pro-active firms. Bus. Strategy Environ. 2009, 18, 1–13. [Google Scholar] [CrossRef]

- Min, H.; Galle, W.P. Green Purchasing Strategies: Trends and Implications. Int. J. Purch. Mater. Manag. 1997, 33, 10–17. [Google Scholar] [CrossRef]

- Günther, E.; Scheibe, L. The hurdle analysis. A self-evaluation tool for municipalities to identify, analyse and overcome hurdles to green procurement. Corp. Soc. Responsib. Environ. Manag. 2006, 13, 61–77. [Google Scholar] [CrossRef]

- Carter, C.R. Purchasing social responsibility and firm performance: The key mediating roles of organizational learning and supplier performance. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 177–194. [Google Scholar] [CrossRef]

- Zsidisin, G.A.; Siferd, S.P. Environmental purchasing: A framework for theory development. Eur. J. Purch. Supply Manag. 2001, 7, 61–73. [Google Scholar] [CrossRef]

- González-Benito, J.; González-Benito, Ó. The role of stakeholder pressure and managerial values in the implementation of environmental logistics practices. Int. J. Prod. Res. 2006, 44, 1353–1373. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable supply chains: An introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Bai, C.; Sarkis, J. Integrating sustainability into supplier selection with grey system and rough set methodologies. Int. J. Prod. Econ. 2010, 124, 252–264. [Google Scholar] [CrossRef]

- Erkman, S. Industrial ecology: An historical view. J. Clean. Prod. 1997, 5, 1–10. [Google Scholar] [CrossRef]

- Jelinski, L.W.; Graedel, T.E.; Laudise, R.A.; McCall, D.W.; Patel, C.K. Industrial ecology: Concepts and approaches. Proc. Natl. Acad. Sci. USA 1992, 89, 793–797. [Google Scholar] [CrossRef]

- Bhote, K.R. Strategic Supply Management: A Blueprint for Revitalizing the Manufacturer-Supplier Partnership; American Management Association: New York, NY, USA, 1989; ISBN 978-0-8144-5925-6. [Google Scholar]

- Kraljic, P. Purchasing must become supply management. Harv. Bus. Rev. 1983, 61, 109–117. [Google Scholar]

- Gelderman, C.J.; van Weele, A.J. Purchasing Portfolio Models: A Critique and Update. J. Supply Chain Manag. 2005, 41, 19–28. [Google Scholar] [CrossRef]

- Gungor, A.; Gupta, S.M. Issues in environmentally conscious manufacturing and product recovery: A survey. Comput. Ind. Eng. 1999, 36, 811–853. [Google Scholar] [CrossRef]

- Bras, B.; McIntosh, M.W. Product, process, and organizational design for remanufacture—An overview of research. Robot. Comput. Integr. Manuf. 1999, 15, 167–178. [Google Scholar] [CrossRef]

- Fleischmann, M.; Krikke, H.R.; Dekker, R.; Flapper, S.D.P. A characterisation of logistics networks for product recovery. Omega 2000, 28, 653–666. [Google Scholar] [CrossRef]

- Jayaraman, V.; Patterson, R.A.; Rolland, E. The design of reverse distribution networks: Models and solution procedures. Eur. J. Oper. Res. 2003, 150, 128–149. [Google Scholar] [CrossRef]

- Beamon, B.M. Measuring supply chain performance. Int. J. Oper. Prod. Manag. 1999, 19, 275–292. [Google Scholar] [CrossRef]

- Rezaei, J.; Ortt, R. A multi-variable approach to supplier segmentation. Int. J. Prod. Res. 2012, 50, 4593–4611. [Google Scholar] [CrossRef]

- Segura, M.; Maroto, C. A multiple criteria supplier segmentation using outranking and value function methods. Expert Syst. Appl. 2017, 69, 87–100. [Google Scholar] [CrossRef]

- Rezaei, J.; Ortt, R. Multi-criteria supplier segmentation using a fuzzy preference relations based AHP. Eur. J. Oper. Res. 2013, 225, 75–84. [Google Scholar] [CrossRef]

- Day, M.; Magnan, G.M.; Moeller, M.M. Evaluating the bases of supplier segmentation: A review and taxonomy. Ind. Mark. Manag. 2010, 39, 625–639. [Google Scholar] [CrossRef]

- Ip, W.H.; Huang, M.; Yung, K.L.; Wang, D. Genetic algorithm solution for a risk-based partner selection problem in a virtual enterprise. Comput. Oper. Res. 2003, 30, 213–231. [Google Scholar] [CrossRef]

- Virolainen, V.M. A survey of procurement strategy development in industrial companies. Int. J. Prod. Econ. 1998, 56–57, 677–688. [Google Scholar] [CrossRef]

- Wątróbski, J.; Jankowski, J.; Ziemba, P.; Karczmarczyk, A.; Zioło, M. Generalised framework for multi-criteria method selection. Omega 2019, 86, 107–124. [Google Scholar] [CrossRef]

- Govindan, K.; Khodaverdi, R.; Jafarian, A. A fuzzy multi criteria approach for measuring sustainability performance of a supplier based on triple bottom line approach. J. Clean. Prod. 2013, 47, 345–354. [Google Scholar] [CrossRef]

- Chai, J.; Liu, J.N.K.; Ngai, E.W.T. Application of decision-making techniques in supplier selection: A systematic review of literature. Expert Syst. Appl. 2013, 40, 3872–3885. [Google Scholar] [CrossRef]

- Lee, D.M.; Drake, P.R. A portfolio model for component purchasing strategy and the case study of two South Korean elevator manufacturers. Int. J. Prod. Res. 2010, 48, 6651–6682. [Google Scholar] [CrossRef]

- Huang, G.Q.; Mak, K.L. WeBid: A web-based framework to support early supplier involvement in new product development. Robot. Comput. Integr. Manuf. 2000, 16, 169–179. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.H. Compromise solution by MCDM methods: A comparative analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Rezaei, J.; Wang, J.; Tavasszy, L. Linking supplier development to supplier segmentation using Best Worst Method. Expert Syst. Appl. 2015, 42, 9152–9164. [Google Scholar] [CrossRef]

- Chang, B.; Chang, C.W.; Wu, C.H. Fuzzy DEMATEL method for developing supplier selection criteria. Expert Syst. Appl. 2011, 38, 1850–1858. [Google Scholar] [CrossRef]

- Ameri, F.; Dutta, D. A Matchmaking Methodology for Supply Chain Deployment in Distributed Manufacturing Environments. J. Comput. Inf. Sci. Eng. 2008, 8, 011002. [Google Scholar] [CrossRef]

- Yang, D.; Dong, M.; Miao, R. Development of a product configuration system with an ontology-based approach. Comput. Aided Des. 2008, 40, 863–878. [Google Scholar] [CrossRef]

- Jang, J.; Jeong, B.; Kulvatunyou, B.; Chang, J.; Cho, H. Discovering and integrating distributed manufacturing services with semantic manufacturing capability profiles. Int. J. Comput. Integr. Manuf. 2008, 21, 631–646. [Google Scholar] [CrossRef]

- Lee, J.; Jung, K.; Kim, B.H.; Peng, Y.; Cho, H. Semantic web-based supplier discovery system for building a long-term supply chain. Int. J. Comput. Integr. Manuf. 2015, 28, 155–169. [Google Scholar] [CrossRef]

- Camarinha-Matos, L.M.; Cardoso, T. Selection of Partners for a Virtual Enterprise. In Infrastructures for Virtual Enterprises; Camarinha-Matos, L.M., Afsarmanesh, H., Eds.; Springer: Boston, MA, USA, 1999; Volume 27, pp. 259–278. ISBN 978-1-4757-5499-5. [Google Scholar]

- Baldo, F.; Rabelo, R.J.; Vallejos, R.V. An Ontology-Based Approach for Selecting Performance Indicators for Partners Suggestion. In Establishing the Foundation of Collaborative Networks; Camarinha-Matos, L.M., Afsarmanesh, H., Novais, P., Analide, C., Eds.; Springer: Boston, MA, USA, 2007; pp. 187–196. ISBN 978-1-4757-0564-5. [Google Scholar]

- Baldo, F.; Rabelo, R.J.; Vallejos, R.V. Modeling Performance Indicators’ Selection Process For Vo Partners’ Suggestions. In Innovation in Manufacturing Networks; Azevedo, A., Ed.; Springer: Boston, MA, USA, 2008; Volume 266, pp. 67–76. ISBN 978-0-387-09491-5. [Google Scholar]

- Chen, Y.J. Structured methodology for supplier selection and evaluation in a supply chain. Inf. Sci. 2011, 181, 1651–1670. [Google Scholar] [CrossRef]

- Karczmarczyk, A.; Jankowski, J.; Wątróbski, J. Multi-criteria decision support for planning and evaluation of performance of viral marketing campaigns in social networks. PLoS ONE 2018, 13, e0209372. [Google Scholar] [CrossRef]

- Dickson, G.W. An Analysis of Vendor Selection Systems And Decisions. J. Purch. 1966, 2, 5–17. [Google Scholar] [CrossRef]

- Weber, C.A.; Current, J.R.; Benton, W.C. Vendor selection criteria and methods. Eur. J. Oper. Res. 1991, 50, 2–18. [Google Scholar] [CrossRef]

- Cheraghi, S.H.; Dadashzadeh, M.; Subramanian, M. Critical Success Factors For Supplier Selection: An Update. J. Appl. Bus. Res. JABR 2011, 20, 91–108. [Google Scholar] [CrossRef][Green Version]

- Thiruchelvam, S.; Tookey, J.E. Evolving Trends of Supplier Selection Criteria and Methods. Int. J. Automot. Mech. Eng. 2011, 4, 437–454. [Google Scholar] [CrossRef]

- Irani, Z.; Kamal, M.M.; Sharif, A.; Love, P.E. Enabling sustainable energy futures: Factors influencing green supply chain collaboration. Prod. Plan. Control 2017, 28, 684–705. [Google Scholar] [CrossRef]

- Luo, X.; Wu, C.; Rosenberg, D.; Barnes, D. Supplier selection in agile supply chains: An information-processing model and an illustration. J. Purch. Supply Manag. 2009, 15, 249–262. [Google Scholar] [CrossRef]

- Fernie, J.; Fernie, S.; Moore, C.M. Principles of Retailing, 2nd ed.; Routledge: Abington Thames, UK, 2015; ISBN 978-1-315-76243-2. [Google Scholar]

- Cheng, J.; Yeh, C.; Tu, C. Trust and knowledge sharing in green supply chains. Supply Chain Manag. Int. J. 2008, 13, 283–295. [Google Scholar] [CrossRef]

- Sharif, A.M.; Irani, Z. Supply Chain Leadership. Int. J. Prod. Econ. 2012, 140, 57–68. [Google Scholar] [CrossRef]

- Sodhi, M.S.; Son, B.G. Supply-chain partnership performance. Transp. Res. Part E Logist. Transp. Rev. 2009, 45, 937–945. [Google Scholar] [CrossRef]

- Qian Li, Z.; Chen Tan, H.; Anumba, C.; Choy Chia, F. Development of a web-based system for managing suppliers’ performance and knowledge sharing in construction project. Built Environ. Proj. Asset Manag. 2017, 7, 117–129. [Google Scholar] [CrossRef]

- Jankowski, J.; Hamari, J.; Wątróbski, J. A gradual approach for maximising user conversion without compromising experience with high visual intensity website elements. Internet Res. 2019, 29, 194–217. [Google Scholar] [CrossRef]

- Konys, A. Knowledge-Based Approach to Question Answering System Selection. In Computational Collective Intelligence; Núñez, M., Nguyen, N.T., Camacho, D., Trawiński, B., Eds.; Springer International Publishing: Cham, Switzerland, 2015; Volume 9329, pp. 361–370. ISBN 978-3-319-24068-8. [Google Scholar]

- Hashim, K.F.; Tan, F.B. The mediating role of trust and commitment on members’ continuous knowledge sharing intention: A commitment-trust theory perspective. Int. J. Inf. Manag. 2015, 35, 145–151. [Google Scholar] [CrossRef]

- Desouza, K.C.; Chattaraj, A.; Kraft, G. Supply chain perspectives to knowledge management: Research propositions. J. Knowl. Manag. 2003, 7, 129–138. [Google Scholar] [CrossRef]

- Desouza, K.; Evaristo, R. Global Knowledge Management Strategies. Eur. Manag. J. 2003, 21, 62–67. [Google Scholar] [CrossRef]

- Kazemargi, N.; Cerruti, C.; Appolloni, A. Adopting open innovation in supply networks. Int. J. Manag. Enterp. Dev. 2016, 15, 174–190. [Google Scholar] [CrossRef]

- Giannakis, M. Facilitating learning and knowledge transfer through supplier development. Supply Chain Manag. Int. J. 2008, 13, 62–72. [Google Scholar] [CrossRef]

- Chong, A.Y.L.; Chan, F.T.; Goh, M.; Tiwari, M.K. Do interorganisational relationships and knowledge-management practices enhance collaborative commerce adoption? Int. J. Prod. Res. 2013, 51, 2006–2018. [Google Scholar] [CrossRef]

- Zahay, D.L.; Handfield, R.B. The role of learning and technical capabilities in predicting adoption of B2B technologies. Ind. Mark. Manag. 2004, 33, 627–641. [Google Scholar] [CrossRef]

- Mentzas, G.; Apostolou, D.; Kafentzis, K.; Georgolios, P. Inter-organizational networks for knowledge sharing and trading. Inf. Technol. Manag. 2006, 7, 259–276. [Google Scholar] [CrossRef]

- Arslan, G.; Kivrak, S.; Birgonul, M.T.; Dikmen, I. Improving sub-contractor selection process in construction projects: Web-based sub-contractor evaluation system (WEBSES). Autom. Constr. 2008, 17, 480–488. [Google Scholar] [CrossRef]

- Desai, A.; Rai, S. Knowledge Management for Downstream Supply Chain Management of Indian Public Sector Oil Companies. Procedia Comput. Sci. 2016, 79, 1021–1028. [Google Scholar] [CrossRef]

- Rodríguez-Enríquez, C.A.; Alor-Hernández, G.; Mejia-Miranda, J.; Sánchez-Cervantes, J.L.; Rodríguez-Mazahua, L.; Sánchez-Ramírez, C. Supply chain knowledge management supported by a simple knowledge organization system. Electron. Commer. Res. Appl. 2016, 19, 1–18. [Google Scholar] [CrossRef]

- Wu, Y.C.; Goh, M.; Yuan, C.H.; Huang, S.H. Logistics management research collaboration in Asia. Int. J. Logist. Manag. 2017, 28, 206–223. [Google Scholar] [CrossRef]

- Mollahosseini, A.; Barkhordar, M. Supplier Knowledge Management For Supplier Development. Rev. Bus. Inf. Syst. RBIS 2010, 14, 17–25. [Google Scholar] [CrossRef]

- Stock, J.R.; Boyer, S.L.; Harmon, T. Research opportunities in supply chain management. J. Acad. Mark. Sci. 2010, 38, 32–41. [Google Scholar] [CrossRef]

- Ang, C.L.; Gay, R.; Sourina, O. Data integration for virtual enterprise in cyberworlds. In Proceedings of the 2005 International Conference on Cyberworlds (CW’05), Singapore, 23–25 November 2005. [Google Scholar]

- Maamar, Z.; Faci, N.; Mostéfaoui, S.K.; Akhter, F. Towards a Framework for Weaving Social Networks Into Mobile Commerce. Int. J. Syst. Serv. Oriented Eng. 2011, 2, 32–46. [Google Scholar] [CrossRef]

- Lee, S.; Choi, K.; Suh, Y. A personalized trustworthy seller recommendation in an open market. Expert Syst. Appl. 2013, 40, 1352–1357. [Google Scholar] [CrossRef]

- Chen, C.T.; Lin, C.T.; Huang, S.F. A fuzzy approach for supplier evaluation and selection in supply chain management. Int. J. Prod. Econ. 2006, 102, 289–301. [Google Scholar] [CrossRef]

- Chen, C.T. Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst. 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Roszkowska, E.; Wachowicz, T. Metoda Topsis i Jej Rozszerzenia—Studium Metodologiczne; University of Economics in Katowice: Katowice, Poland, 2013; pp. 11–40. [Google Scholar]

- Grzegorzewski, P.; Mrówka, E. Trapezoidal approximations of fuzzy numbers—Revisited. Fuzzy Sets Syst. 2007, 158, 757–768. [Google Scholar] [CrossRef]

- Ban, A. Approximation of fuzzy numbers by trapezoidal fuzzy numbers preserving the expected interval. Fuzzy Sets Syst. 2008, 159, 1327–1344. [Google Scholar] [CrossRef]

- Abbasbandy, S.; Amirfakhrian, M. The nearest trapezoidal form of a generalized left right fuzzy number. Int. J. Approx. Reason. 2006, 43, 166–178. [Google Scholar] [CrossRef]

- Khodaverdi, R.; Olfat, L. A fuzzy MCDM approach for supplier selection and evaluation: A case study in an automobile manufacturing company. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Singapore, 6–9 December 2011. [Google Scholar]

- Palanisamy, P.; Abdul Zubar, H. Hybrid MCDM approach for vendor ranking. J. Manuf. Technol. Manag. 2013, 24, 905–928. [Google Scholar] [CrossRef]

- de Boer, L.; van der Wegen, L.; Telgen, J. Outranking methods in support of supplier selection. Eur. J. Purch. Supply Manag. 1998, 4, 109–118. [Google Scholar] [CrossRef]

- Shyur, H.J.; Shih, H.S. A hybrid MCDM model for strategic vendor selection. Math. Comput. Model. 2006, 44, 749–761. [Google Scholar] [CrossRef]

- Gencer, C.; Gürpinar, D. Analytic network process in supplier selection: A case study in an electronic firm. Appl. Math. Model. 2007, 31, 2475–2486. [Google Scholar] [CrossRef]

- Tam, M.C.Y.; Tummala, V.M.R. An application of the AHP in vendor selection of a telecommunications system. Omega 2001, 29, 171–182. [Google Scholar] [CrossRef]

- Malmir, R.; Hamzehi, E.; Farsijani, H. A Multi Stage Decision Making Model to Evaluate Suppliers by Using MOLP and ANP in a Strategic Approach. Int. J. Appl. Innov. Eng. Manag. 2013, 2, 563–577. [Google Scholar]

- Meade, L.; Sarkis, J. Strategic analysis of logistics and supply chain management systems using the analytical network process. Transp. Res. Part E Logist. Transp. Rev. 1998, 34, 201–215. [Google Scholar] [CrossRef]

- Shemshadi, A.; Toreihi, M.; Shirazi, H.; Tarokh, M.J. Supplier selection based on supplier risk: An ANP and fuzzy TOPSIS approach. J. Math. Comput. Sci. 2011, 2, 111–121. [Google Scholar] [CrossRef]

- Dehghani, M.; Esmaeilian, M.; Tavakkoli-Moghaddam, R. Employing fuzzy ANP for green supplier selection and order allocations: A case study. Int. J. Econ. Manag. Soc. Sci. 2013, 2, 565–575. [Google Scholar]

- Tahriri, F.; Osman, M.R.; Ali, A.; Yusuff, R.; Esfandiary, A. AHP approach for supplier evaluation and selection in a steel manufacturing company. J. Ind. Eng. Manag. 2008, 1, 54–76. [Google Scholar]

- Pani, A.K.; Kar, A.K. A Study to Compare Relative Importance of Criteria for Supplier Evaluation in e-Procurement. In Proceedings of the 2011 44th Hawaii International Conference on System Sciences, Kauai, HI, USA, 4–7 January 2011; pp. 1–8. [Google Scholar]

- Sivrikaya, B.T.; Kaya, A.; Dursun, M.; Çebi, F. Fuzzy AHP—Goal Programming Approach For a Supplier Selection Problem. Res. Logist. Prod. 2015, 5, 271–285. [Google Scholar]

- Roshandel, J.; Miri-Nargesi, S.S.; Hatami-Shirkouhi, L. Evaluating and selecting the supplier in detergent production industry using hierarchical fuzzy TOPSIS. Appl. Math. Model. 2013, 37, 10170–10181. [Google Scholar] [CrossRef]

- Bas, E. The integrated framework for analysis of electricity supply chain using an integrated SWOT-fuzzy TOPSIS methodology combined with AHP: The case of Turkey. Int. J. Electr. Power Energy Syst. 2013, 44, 897–907. [Google Scholar] [CrossRef]

- Wang, C.H. Using quality function deployment to conduct vendor assessment and supplier recommendation for business-intelligence systems. Comput. Ind. Eng. 2015, 84, 24–31. [Google Scholar] [CrossRef]

- Hsu, C.H.; Wang, F.K.; Tzeng, G.H. The best vendor selection for conducting the recycled material based on a hybrid MCDM model combining DANP with VIKOR. Resour. Conserv. Recycl. 2012, 66, 95–111. [Google Scholar] [CrossRef]

- Zou, Z.; Tseng, T.L.; Sohn, H.; Song, G.; Gutierrez, R. A rough set based approach to distributor selection in supply chain management. Expert Syst. Appl. 2011, 38, 106–115. [Google Scholar] [CrossRef]

- Vinodh, S.; Anesh Ramiya, R.; Gautham, S.G. Application of fuzzy analytic network process for supplier selection in a manufacturing organisation. Expert Syst. Appl. 2011, 38, 272–280. [Google Scholar] [CrossRef]

- Shemshadi, A.; Shirazi, H.; Toreihi, M.; Tarokh, M.J. A fuzzy VIKOR method for supplier selection based on entropy measure for objective weighting. Expert Syst. Appl. 2011, 38, 12160–12167. [Google Scholar] [CrossRef]

- Yu, C.; Wong, T.N. An agent-based negotiation model for supplier selection of multiple products with synergy effect. Expert Syst. Appl. 2015, 42, 223–237. [Google Scholar] [CrossRef]

- Guarnieri, P.; Sobreiro, V.A.; Nagano, M.S.; Marques Serrano, A.L. The challenge of selecting and evaluating third-party reverse logistics providers in a multicriteria perspective: A Brazilian case. J. Clean. Prod. 2015, 96, 209–219. [Google Scholar] [CrossRef]

- Bruno, G.; Esposito, E.; Genovese, A.; Passaro, R. AHP-based approaches for supplier evaluation: Problems and perspectives. J. Purch. Supply Manag. 2012, 18, 159–172. [Google Scholar] [CrossRef]

- Dargi, A.; Anjomshoae, A.; Galankashi, M.R.; Memari, A.; Tap, M.B.M. Supplier Selection: A Fuzzy-ANP Approach. Procedia Comput. Sci. 2014, 31, 691–700. [Google Scholar] [CrossRef]

- Tyagi, M.; Kumar, P.; Kumar, D. A Hybrid Approach using AHP-TOPSIS for Analyzing e-SCM Performance. Procedia Eng. 2014, 97, 2195–2203. [Google Scholar] [CrossRef]

- Kannan, D.; Govindan, K.; Rajendran, S. Fuzzy Axiomatic Design approach based green supplier selection: A case study from Singapore. J. Clean. Prod. 2015, 96, 194–208. [Google Scholar] [CrossRef]

- Jharkharia, S.; Shankar, R. Selection of logistics service provider: An analytic network process (ANP) approach. Omega 2007, 35, 274–289. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. VOS: A New Method for Visualizing Similarities Between Objects. In Advances in Data Analysis; Decker, R., Lenz, H.J., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 299–306. ISBN 978-3-540-70980-0. [Google Scholar]

- Peters, H.P.F.; van Raan, A.F.J. Co-word-based science maps of chemical engineering. Part I: Representations by direct multidimensional scaling. Res. Policy 1993, 22, 23–45. [Google Scholar] [CrossRef]

- Rip, A.; Courtial, J.P. Co-word maps of biotechnology: An example of cognitive scientometrics. Scientometrics 1984, 6, 381–400. [Google Scholar] [CrossRef]

- Konys, A.; Wątróbski, J.; Różewski, P. Approach to Practical Ontology Design for Supporting COTS Component Selection Processes. In Intelligent Information and Database Systems; Selamat, A., Nguyen, N.T., Haron, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 7803, pp. 245–255. ISBN 978-3-642-36542-3. [Google Scholar]

- Guarino, N. Formal ontology, conceptual analysis and knowledge representation. Int. J. Hum. Comput. Stud. 1995, 43, 625–640. [Google Scholar] [CrossRef]

- Gruber, T.R. A translation approach to portable ontology specifications. Knowl. Acquis. 1993, 5, 199–220. [Google Scholar] [CrossRef]

- Sure, Y.; Staab, S.; Studer, R. On-To-Knowledge Methodology (OTKM). In Handbook on Ontologies; Staab, S., Studer, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; pp. 117–132. ISBN 978-3-662-11957-0. [Google Scholar]

- Corcho, O.; Fernández-López, M.; Gómez-Pérez, A.; López-Cima, A. Building Legal Ontologies with METHONTOLOGY and WebODE. In Law and the Semantic Web; Benjamins, V.R., Casanovas, P., Breuker, J., Gangemi, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2005; Volume 3369, pp. 142–157. ISBN 978-3-540-25063-0. [Google Scholar]

- Musen, M.A. The protégé project: A look back and a look forward. AI Matters 2015, 1, 4–12. [Google Scholar] [CrossRef]

| Research Questions | Motivations | Outcomes |

|---|---|---|

| RQ1: How to select the optimal green supplier | Focusing on development and improvement of new methods by most of the research. Limited attention has been paid to the identifying sets of criteria and capturing of the domain knowledge. A gap between classical assumption of decision making and knowledge-based problem structuring. | Presenting a methodological and practical background for capturing and handling knowledge about green supplier selection criteria, supported by a formal guideline for their appropriate acquisition. |

| RQ2: What are most pertinent criteria determining green supplier selection? | Providing a macroscopic overview of global research trends of green supplier selection based on a bibliometric analysis. | Providing meta-analysis to reveal a collection of key data supported by a formal and trustworthiness bibliometric analysis. |

| RQ2.1: What are the most influential keywords determining green supplier selection? | An attempt to extend prior research by yielding heterogeneous informative overview within the past twelve-year period with a focus on keyword occurrence analysis. | Providing an overview of the development of the field of green supplier selection and analysis of collected data. |

| RQ2.2: What are the correlations, properties and inclusion scheme among the criteria indicated by cluster analysis? | Visible lack of the classification and systematization of used criteria. Visible lack of a broad and multifaceted view of criteria determining green supplier selection in the form of roadmap. Highlighting the most prominent fields based on the collection of investigated keywords/criteria. | Providing a new deep insight for the underpinning building blocks to allow properly adapting within each criterion and to show how these criteria correlate with each other. A descriptive summary of existing correlations and a clustering analysis, and also multidimensional scaling of properties between the criteria. |

| RQ3: How to gather knowledge about the criteria for choosing a green supplier and manage it effectively | A visible lack of complete knowledge base about green supplier selection criteria. A visible lack of publicly available knowledge about green supplier selection criteria, collected in a one place. | Capturing knowledge in one place in the form of ontology for enabling selection and evaluation criteria of green suppliers at the same time providing interoperability of collected knowledge. |

| RQ3.1: How to prepare relatively trustworthiness set of criteria | A need for comprehensive elaboration of available criteria determining green supplier selection. | Condensing large amounts of bibliographic information and revising and elaborating of harvested data by affixture of rules and limitations. Analyzing and cleaning the data to create relevant and comprehensive information in the form of a set of clusters with assigned criteria. |

| RQ3.2: How to ensure access to the valuable knowledge of green-oriented suppliers and how to effectively capture the learning knowledge | A visible lack of advanced technological solutions to acquire and share knowledge to successfully support supply chains. | Knowledge sharing and best practice between partners to accomplish collective goals. Independent knowledge about criteria for green-oriented supplier selection proved by scientific analysis of literature. Obtained knowledge can be incorporated into any database, knowledge base or information system holding knowledge associated to green or sustainability domain. Possibility of a machine-readable access and handling semantic data can improve the searching capacity and knowledge sharing of the proposed ontology. The proposed ontology is featured by multi-usage, reusing, and also knowledge sharing and dissemination. The possible extension of the current collection of criteria and expansion of this ontology of other domains, closely related with green and sustainability. |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Konys, A. Green Supplier Selection Criteria: From a Literature Review to a Comprehensive Knowledge Base. Sustainability 2019, 11, 4208. https://doi.org/10.3390/su11154208

Konys A. Green Supplier Selection Criteria: From a Literature Review to a Comprehensive Knowledge Base. Sustainability. 2019; 11(15):4208. https://doi.org/10.3390/su11154208

Chicago/Turabian StyleKonys, Agnieszka. 2019. "Green Supplier Selection Criteria: From a Literature Review to a Comprehensive Knowledge Base" Sustainability 11, no. 15: 4208. https://doi.org/10.3390/su11154208

APA StyleKonys, A. (2019). Green Supplier Selection Criteria: From a Literature Review to a Comprehensive Knowledge Base. Sustainability, 11(15), 4208. https://doi.org/10.3390/su11154208