Evaluation of Chinese Enterprise Safety Production Resilience Based on a Combined Gray Relevancy and BP Neural Network Model

Abstract

:1. Introduction

2. Theory

2.1. Proposed Definition of Enterprise Safety Production Resilience

2.2. The Change Law of Enterprise Safety Production Resilience

3. Methods

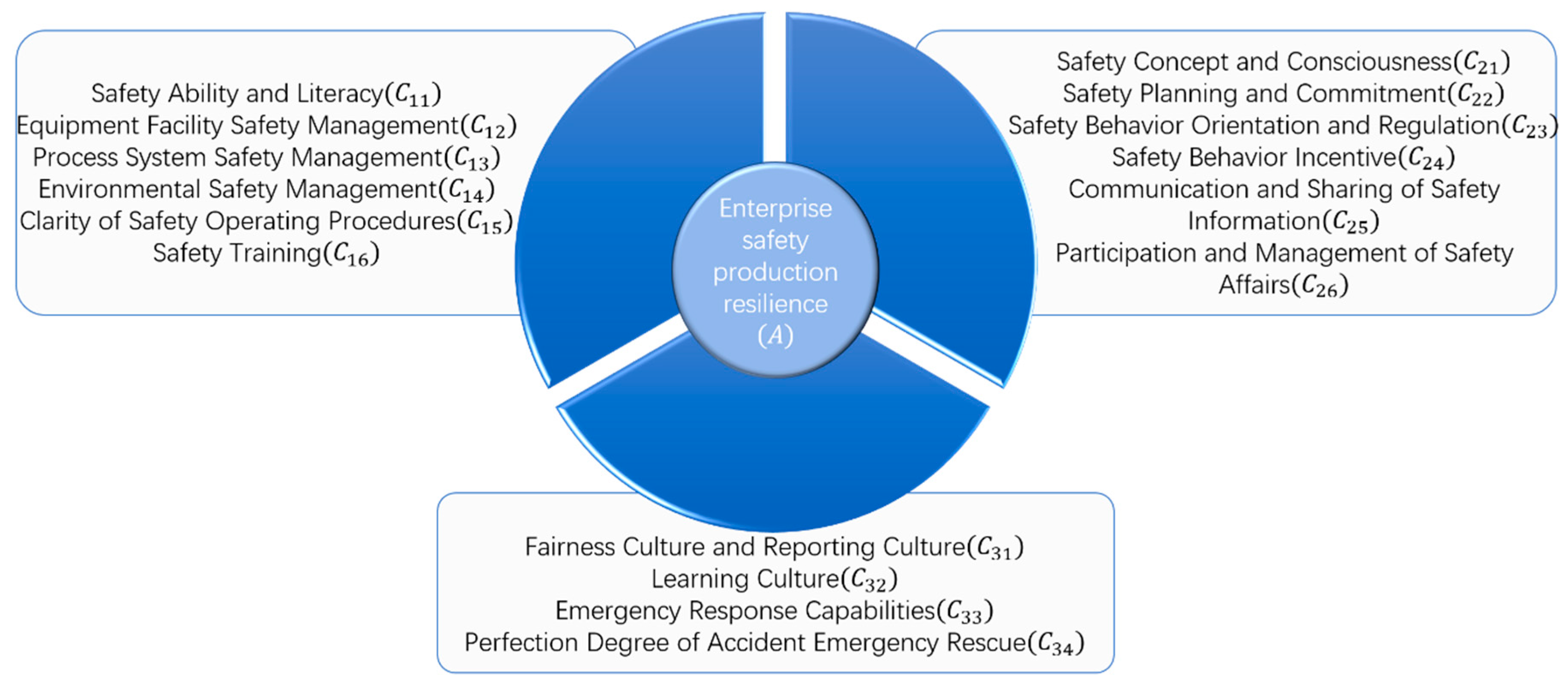

3.1. Analysis of Factors Affecting the Resilience of Safety Production

3.2. Gray Correlation Degree Verification Factors Affecting the Recovery Ability of Enterprise Safety Production

- Step 1.

- Find the difference sequence of index and − .

- Step 2.

- Find the maximum difference and the minimum difference between the two poles.

- Step 3.

- Step 4.

- Calculate the degree of association −.

3.3. Construction of the Enterprise Safety Production Resilience Model Based on a BP Neural Network

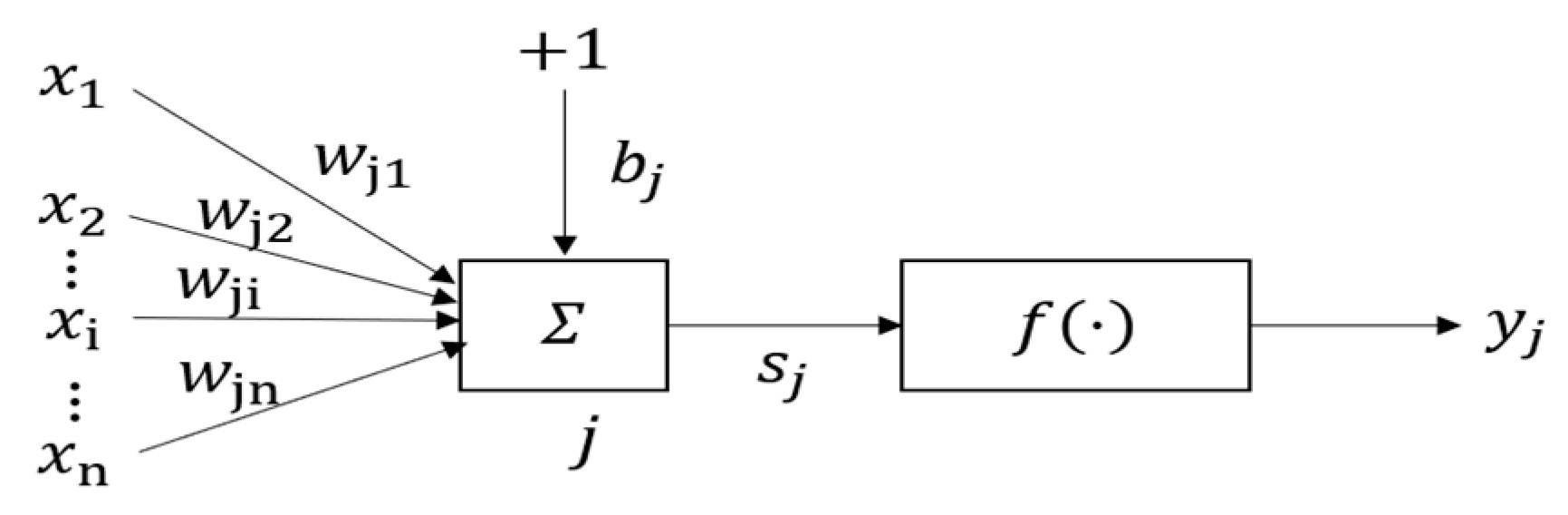

3.3.1. BP Neuron

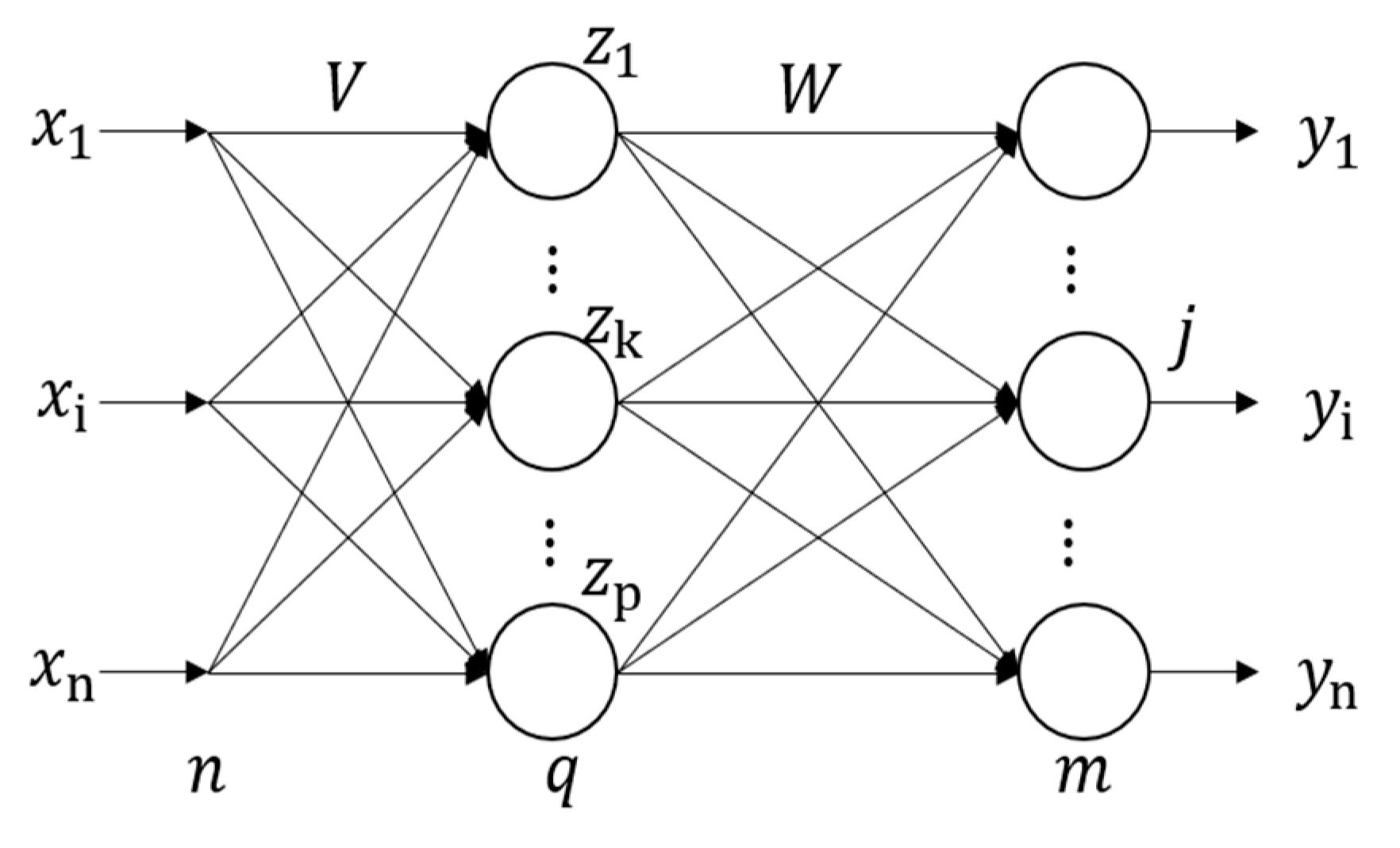

3.3.2. BP Neural Network

4. Empirical Analysis

4.1. Data Collection

4.2. Data Processing

4.2.1. Gray Correlation Analysis Results

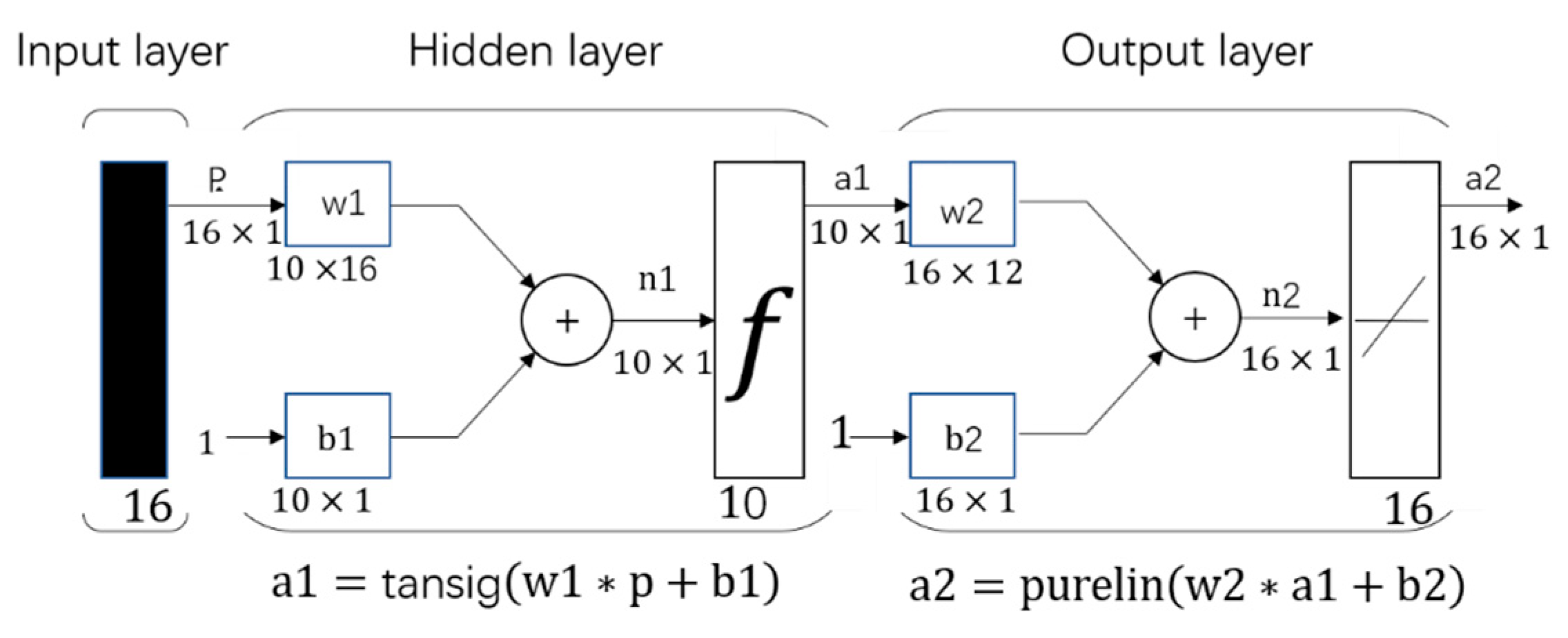

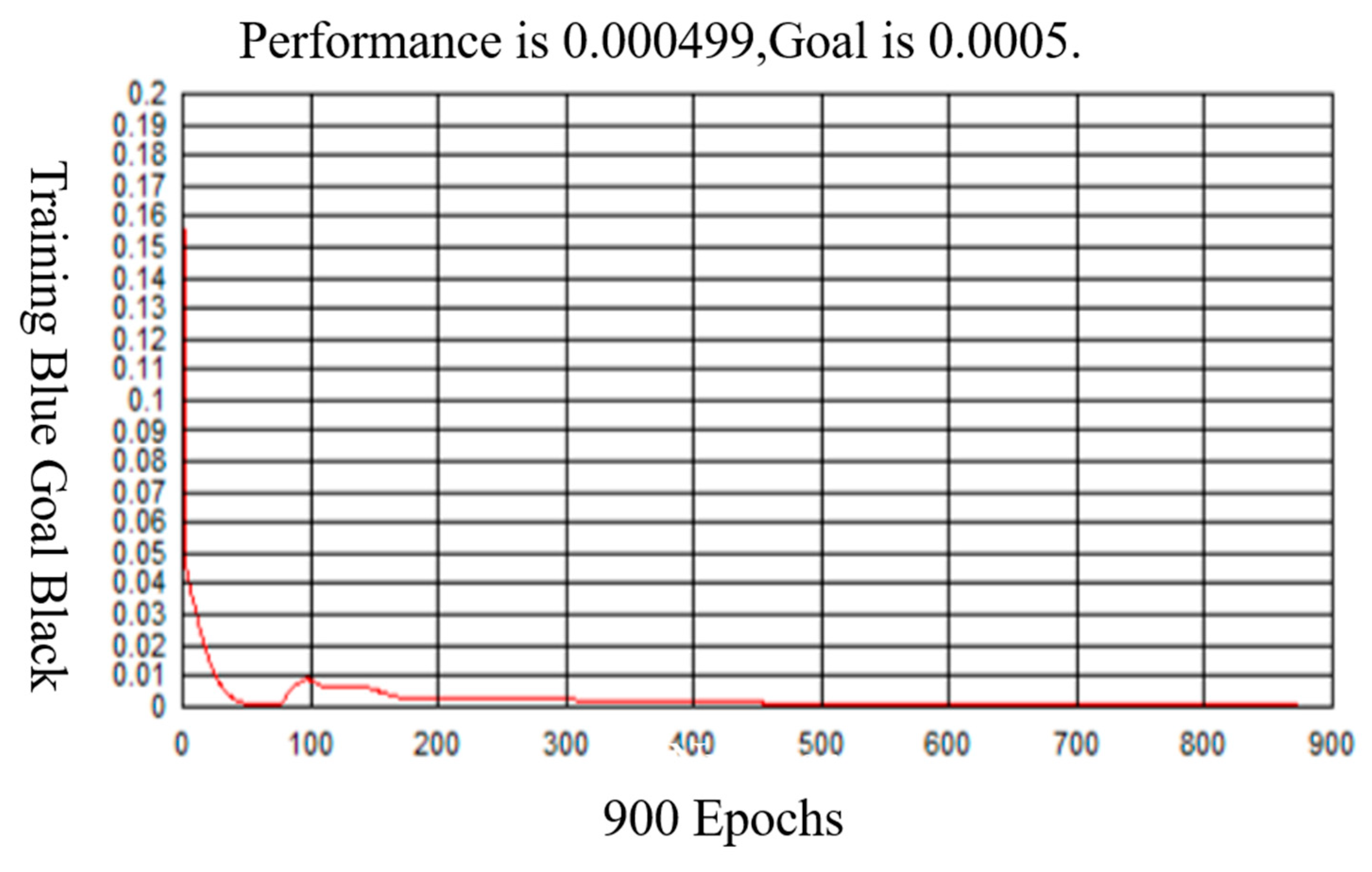

4.2.2. BP Neural Network Model Analysis Results

4.3. Model Application

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bergström, J.; van Winsen, R.; Henriqson, E. On the rationale of resilience in the domain of safety: A literature review. Reliab. Eng. Syst. Saf. 2015, 141, 131–141. [Google Scholar] [CrossRef] [Green Version]

- Dekker, S. Drift into Failure: From Hunting Broken Components to Understanding Complex. Systems; Ashgate Publishing Ltd.: Farnham, UK, 2012. [Google Scholar]

- Pęciłło, M. The resilience engineering concept in enterprises with and without occupational safety and health management systems. Saf. Sci. 2016, 82, 190–198. [Google Scholar] [CrossRef]

- Woods, D.D. Creating Foresight: How Resilience Engineering Can Transform NASA’s Approach to Risky Decision Making. Testimony on the Future of NASA for Committee on Commerce. Science and Transportation, John Mc Cain, Chair. 2003. Available online: https://www.researchgate.net/publication/237353911_Creating_Foresight_How_Resilience_Engineering_Can_Transform_NASA’s_Approach_to_Risky_Decision_Making (accessed on 15 April 2019).

- Tveiten, C.K.; Albrechtsen, E.; Wærø, I.; Wahl, A.M. Building resilience in to emergency management. Saf. Sci. 2012, 50, 1960–1966. [Google Scholar] [CrossRef]

- Huber, G.J.; Gomes, J.O.; de Carvalho, P.V. A program to support the construction and evaluation of resilience indicators. Work 2012, 41 (Suppl. 1), 2810–2816. [Google Scholar] [Green Version]

- Huang, L.; Wu, C.; Wang, B. Modeling on shaping and assessment of system safety resilience. J. Saf. Sci. Technol. 2016, 12, 15–21. [Google Scholar]

- Pimm, S.L. The complexity and stability of ecosystems. Nature 1984, 307, 321–326. [Google Scholar] [CrossRef]

- Holling, C.S. Resilience and stability of ecological systems. Annu. Rev. Ecol. Syst. 1973, 4, 12–23. [Google Scholar] [CrossRef]

- Ge, Y.; Shi, P.; Xu, W.; Liu, J.; Qian, Y.; Chen, L. New progress and review on resilience research. J. Catastrophol. 2010, 25, 119–124. [Google Scholar]

- Hollnagel, E.; Woods, D. Epilogue: Resilience Engineering-Concept Sand Precepts; Ashgate Publishing: Aldershot, UK, 2006; pp. 347–358. [Google Scholar]

- Speranze, C.I.; Wiesmann, U.; Rist, S. An indicator framework for assessing livelihood resilience in the context of social-ecological dynamics. Glob. Environ. Chang. 2004, 28, 109–119. [Google Scholar] [CrossRef]

- Hollnagel, E. IO07 presentation: Resilience Engineering and Proactive Safety Management, presentation held at the IO07. In Proceedings of the 3rd International Conference on Integrated Operations in the Petroleum Industry, Trondheim, Norway, 2–3 October 2007. [Google Scholar]

- The White House. Presidential Policy Directive (PDD)-21: Critical in Frastructure Security and Resilience; The White House: Washington, DC, USA, 2003.

- United Nations Office for Disaster Risk Reduction (UNISDR). Disaster Risk and Resilience. U N System Task Force on the Post-2015 UN Development Agenda; UNISDR: Geneva, Switzerland, 2012. [Google Scholar]

- Xu, R.; Liu, M.; Yao, W. Systemic risk from the perspective of financial ecological resilience. Syst. Eng. 2017, 35, 30–35. [Google Scholar]

- Shi, Y.; Li, J. MATLAB Language TOOLBOX—TOOLBOX Practical Guide; Northwestern Polytechnical University Press: Xi’an, China, 1999. [Google Scholar]

- Liu, S. Grey System Theory and Its Application; Science Press: Beijing, China, 1999. [Google Scholar]

- Deng, J. Grey Prediction and Grey Decision; Huazhong University of Science and Technology Press: Wuhan, China, 2002. [Google Scholar]

| Source | Definition | Typical Characteristics | Research Object |

|---|---|---|---|

| Holling, C.S. [9] | The system withstands and absorbs the amount of disturbance, and maintains the stability of the system | Withstand, absorb | Ecosystem |

| Hollnagel, E. [13] | The system recognizes and adapts to the function of absorbing external disturbances and damages | Identify, adapt, absorb | Industrial system |

| US Presidential Policy Directive 21 [14] | The system is able to prepare, withstand, adapt, resist, and recover quickly from terrorist attacks, cyber-attacks, and natural disasters | Prepare in advance, defend, recover | Critical infrastructure system |

| United Nations Office for Disaster Reduction [15] | The system, community, and society are able to resist, absorb, adapt, and recover quickly and efficiently | Resist, absorb, adapt, recover | Infrastructure, society, economy |

| First Level | A | Total | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Second Level | B1 | B2 | B3 | ||||||||||||||

| Third Level | C11 | C12 | C13 | C14 | C15 | C16 | C21 | C22 | C23 | C24 | C25 | C26 | C31 | C32 | C33 | C34 | |

| 1 | 80 | 93 | 91 | 82 | 79 | 90 | 89 | 91 | 90 | 88 | 93 | 90 | 80 | 50 | 93 | 77 | 88 |

| 2 | 57 | 69 | 65 | 67 | 49 | 59 | 71 | 72 | 64 | 74 | 72 | 67 | 70 | 79 | 92 | 80 | 63 |

| 3 | 76 | 72 | 73 | 67 | 68 | 67 | 83 | 77 | 70 | 79 | 72 | 77 | 80 | 80 | 92 | 79 | 73 |

| 4 | 76 | 72 | 70 | 67 | 68 | 64 | 76 | 67 | 70 | 74 | 72 | 77 | 80 | 80 | 92 | 82 | 70 |

| 5 | 76 | 71 | 71 | 67 | 71 | 64 | 79 | 72 | 67 | 74 | 67 | 81 | 82 | 82 | 92 | 82 | 71 |

| 6 | 81 | 88 | 87 | 84 | 81 | 88 | 91 | 89 | 91 | 84 | 89 | 88 | 83 | 80 | 93 | 83 | 87 |

| 7 | 78 | 74 | 73 | 68 | 70 | 70 | 87 | 80 | 74 | 79 | 71 | 79 | 84 | 80 | 91 | 82 | 77 |

| 8 | 79 | 83 | 83 | 83 | 79 | 84 | 86 | 83 | 89 | 83 | 86 | 84 | 80 | 83 | 90 | 81 | 83 |

| 9 | 76 | 70 | 66 | 62 | 56 | 59 | 73 | 62 | 73 | 72 | 70 | 71 | 75 | 68 | 90 | 78 | 68 |

| 10 | 76 | 76 | 75 | 79 | 77 | 80 | 81 | 80 | 84 | 81 | 83 | 82 | 81 | 80 | 89 | 81 | 80 |

| 11 | 80 | 91 | 93 | 88 | 84 | 88 | 92 | 93 | 92 | 90 | 92 | 90 | 87 | 83 | 92 | 82 | 89 |

| 12 | 90 | 91 | 93 | 88 | 88 | 88 | 92 | 93 | 92 | 90 | 92 | 92 | 87 | 89 | 92 | 89 | 92 |

| 13 | 57 | 67 | 65 | 67 | 49 | 59 | 71 | 70 | 64 | 67 | 69 | 67 | 70 | 79 | 82 | 77 | 60 |

| 14 | 59 | 65 | 65 | 67 | 59 | 56 | 70 | 65 | 64 | 67 | 64 | 67 | 72 | 70 | 85 | 75 | 58 |

| 15 | 67 | 67 | 64 | 67 | 69 | 59 | 78 | 72 | 64 | 75 | 73 | 68 | 79 | 73 | 90 | 80 | 66 |

| 16 | 61 | 65 | 65 | 63 | 52 | 56 | 70 | 65 | 64 | 67 | 60 | 67 | 57 | 70 | 73 | 75 | 55 |

| 17 | 79 | 73 | 71 | 69 | 73 | 67 | 79 | 74 | 65 | 74 | 69 | 83 | 80 | 84 | 93 | 83 | 75 |

| 18 | 90 | 91 | 93 | 90 | 88 | 91 | 92 | 93 | 92 | 91 | 92 | 93 | 88 | 89 | 95 | 89 | 93 |

| 19 | 57 | 69 | 65 | 67 | 49 | 59 | 71 | 72 | 64 | 74 | 72 | 67 | 70 | 79 | 92 | 80 | 85 |

| 20 | 59 | 69 | 69 | 65 | 67 | 69 | 71 | 72 | 62 | 72 | 71 | 67 | 82 | 79 | 88 | 80 | 66 |

| Enterprise | Early June 2017 | End of August 2017 | ||

|---|---|---|---|---|

| Resilience Value | Resilience level | Resilience Value | Resilience level | |

| 1 | 89 | High | ||

| 2 | 63 | Low | 75 | Medium |

| 3 | 69 | Medium | ||

| 4 | 59 | Low | 68 | Medium |

| 5 | 78 | Medium | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pei, J.; Liu, W. Evaluation of Chinese Enterprise Safety Production Resilience Based on a Combined Gray Relevancy and BP Neural Network Model. Sustainability 2019, 11, 4321. https://doi.org/10.3390/su11164321

Pei J, Liu W. Evaluation of Chinese Enterprise Safety Production Resilience Based on a Combined Gray Relevancy and BP Neural Network Model. Sustainability. 2019; 11(16):4321. https://doi.org/10.3390/su11164321

Chicago/Turabian StylePei, Jingjing, and Wen Liu. 2019. "Evaluation of Chinese Enterprise Safety Production Resilience Based on a Combined Gray Relevancy and BP Neural Network Model" Sustainability 11, no. 16: 4321. https://doi.org/10.3390/su11164321