The Effect of Additional Byproducts on the Environmental Impact of the Production Stage of Concretes Containing Bottom Ash Instead of Sand

Abstract

:1. Introduction

2. Materials and Methods

2.1. Concrete Mixture Designs

2.2. Life Cycle Assessment

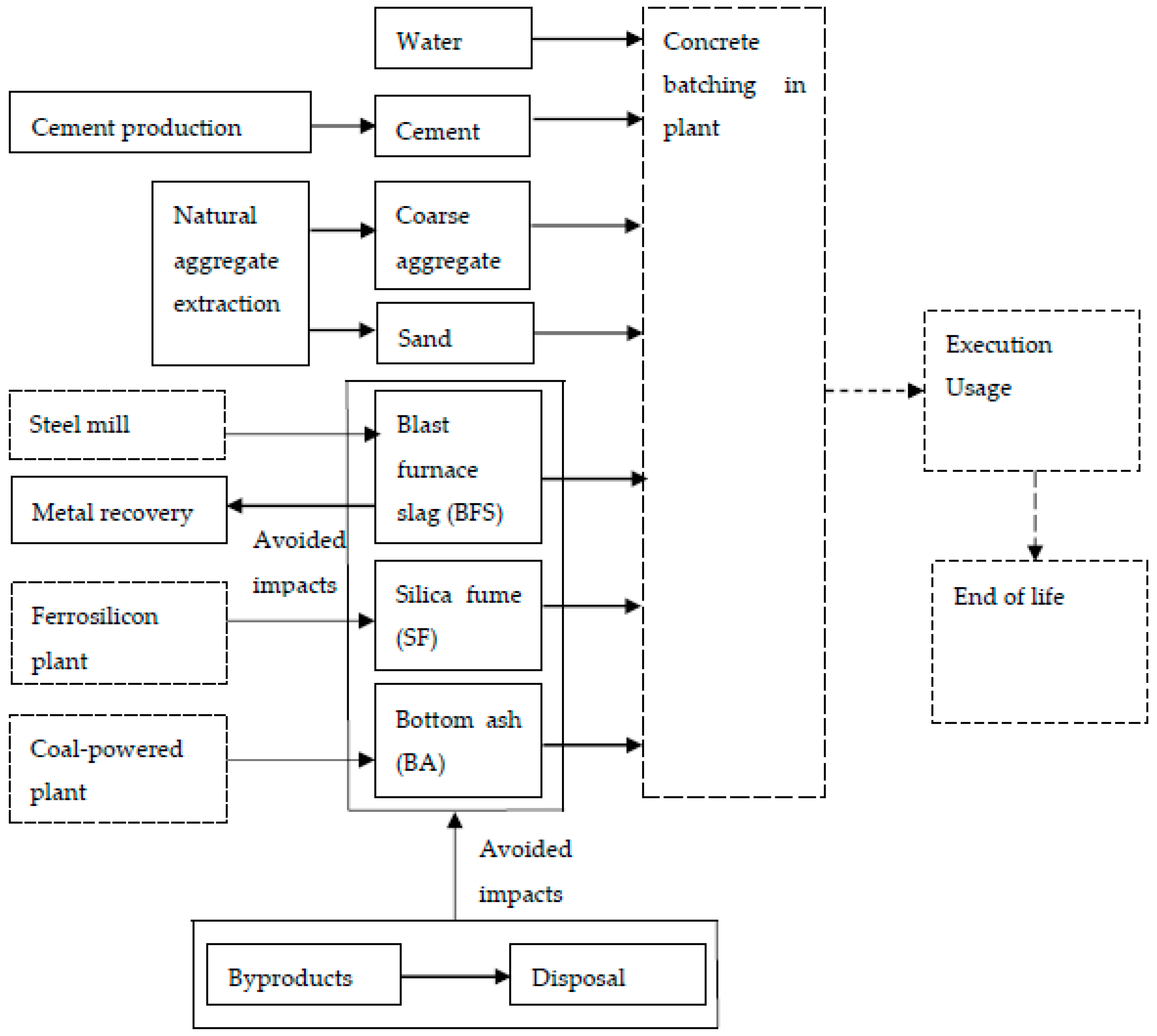

2.2.1. FU, System Boundary, and LCI

2.2.2. LCIA Method

2.2.3. The Two-stage Nested (Hierarchical) ANOVA Design Structure

2.3.4. Statistical Analysis

3. Results

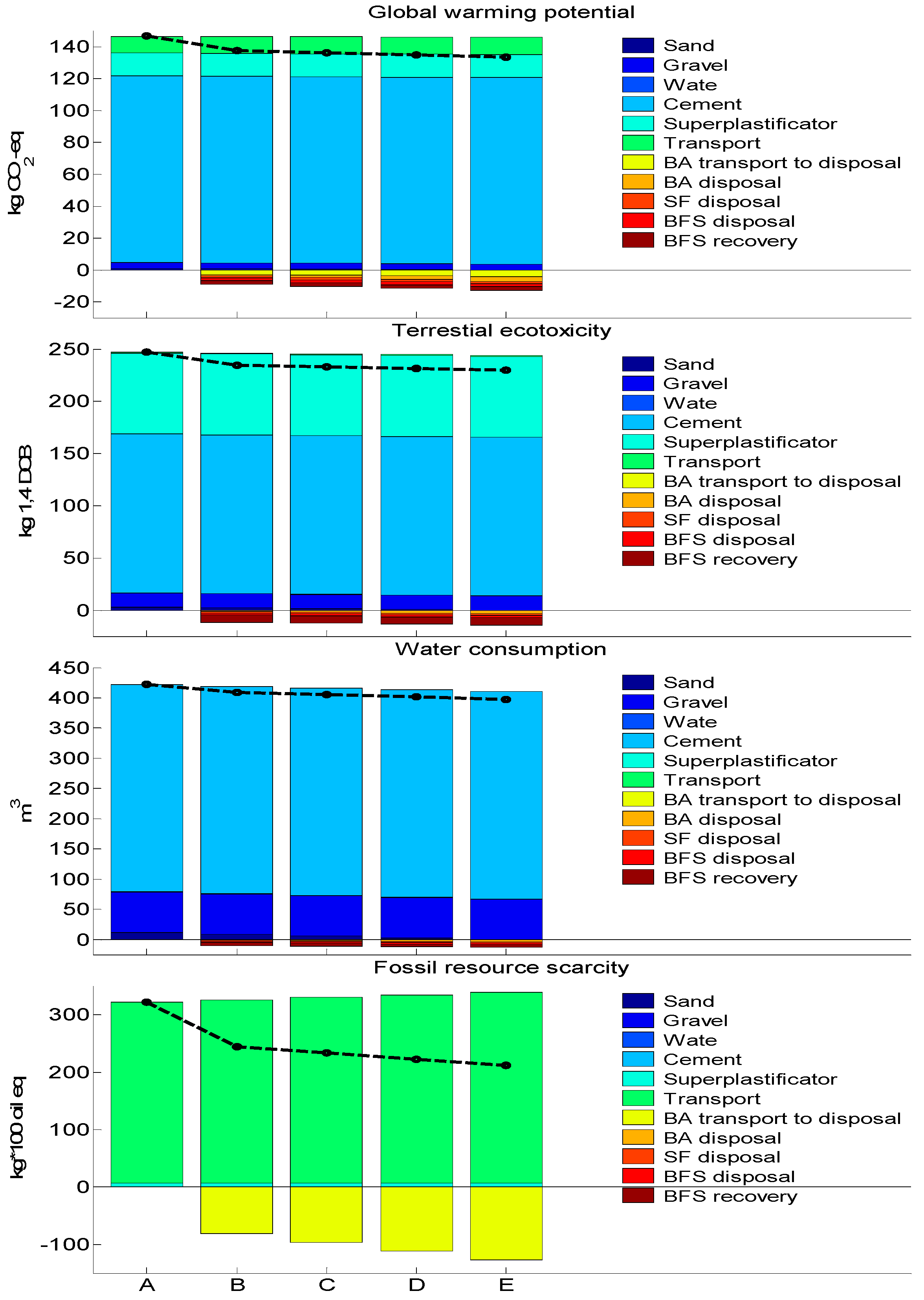

3.1. BA-Based Concrete Mixtures with SF as an Additional Binder

3.2. BA-Based Concrete Mixtures with SF and BFS as Additional Binders

4. Discussion

5. Conclusions

- According to the ReCiPe2016 midpoint H method, the increasing substitution of sand with BA in the concrete with SF as an additional binder and in the concrete with SF and BFS as additional binders led to lowered values of global warming potential, terrestrial ecotoxicity, water consumption, and especially, fossil resource scarcity. The BA-based concrete with more byproducts (SF and BFS) as additional binders brought more environmental benefits than the BA-based concrete with fewer byproducts (SF) as additional binders.

- According to the six methodological options of the ReCiPe2016 single-score method, for the BA-based concretes with SF as an additional binder and SF and BFS as additional binders, the concretes with 40–100 and 75–100 wt % of sand replacement, respectively, seemed to cause the least environmental damage.

Funding

Conflicts of Interest

References

- Hossain, M.U.; Poon, C.S.; Dong, Y.H.; Xuan, D.X. Evaluation of environmental impact distribution methods for supplementary cementitious materials. Renew. Sustain. Energy Rev. 2018, 82, 597–608. [Google Scholar] [CrossRef]

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of concrete prepared with crushed fine stone, furnace bottom ash and fine recycled aggregate as fine aggregates. Construct. Build. Mater. 2009, 23, 2877–2886. [Google Scholar] [CrossRef]

- Kua, H.W. The consequences of substituting sand with used copper slag in construction—An embodied energy and global warming potential analysis using life cycle approach and different allocation methods. J. Ind. Ecol. 2013, 17, 869–879. [Google Scholar] [CrossRef]

- Lim, S.K.; Tan, C.S.; Li, B.; Ling, T.C.; Hossain, M.U.; Poon, C.S. Utilizing high volumes quarry wastes in the production of lightweight foamed concrete. Construct. Build. Mater. 2017, 151, 441–448. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended Portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Gursel, A.P.; Ostertag, C.P. Impact of Singapore’s importers on life-cycle assessment of concrete. J. Clean. Prod. 2016, 118, 140–150. [Google Scholar] [CrossRef]

- Pushkar, S. Modeling the substitution of natural materials with industrial byproducts in green roofs using life cycle assessments. J. Clean. Prod. 2019, 227, 652–661. [Google Scholar] [CrossRef]

- ISO 14040 (International Organization for Standardization). Environmental Management Life Cycle Assessment Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Van den Heede, P.; De Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental evaluation of green concretes versus conventional concrete by means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef]

- Prem, P.R.; Verma, M.; Ambily, P.S. Sustainable cleaner production of concrete with high volume copper slag. J. Clean. Prod. 2018, 193, 43–58. [Google Scholar] [CrossRef]

- Gursel, A.P.; Ostertag, C. Life-cycle assessment of high-strength concrete mixtures with copper slag as sand replacement. Adv. Civ. Eng. 2019, 2019, 13. [Google Scholar] [CrossRef]

- Kim, H.K.; Lee, H.K. Use of power plant bottom ash as fine and coarse aggregates in high-strength concrete. Construct. Build. Mater. 2011, 25, 1115–1122. [Google Scholar] [CrossRef]

- Kadam, M.P.; Patil, Y.D. Strength, durability, and micro structural properties of concrete incorporating MS and GCBA as sand substitube. J. Sci. Ind. Res. 2017, 76, 644–653. [Google Scholar]

- ISO 13315-1 (International Organization for Standardization). Environmental Management for Concrete and Concrete Structures 2012, Part 1: General Principles; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Habert, G.; de Lacaillerie, J.B.D.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Brand, S. How Buildings Learn; Viking Press: New York, NY, USA, 1994. [Google Scholar]

- Gursel, A.P.; Masanet, E.; Horvath, A.; Stadel, A. Life-cycle inventory analysis of concrete production: A critical review. Cem. Concr. Compos. 2014, 51, 38–48. [Google Scholar] [CrossRef]

- Napolano, L.; Menna, C.; Asprone, D.; Prota, A.; Manfredi, G. Life cycle environmental impact of different replacement options for a typical old flat roof. Int. J. Life Cycle Assess. 2015, 20, 694–708. [Google Scholar] [CrossRef]

- PRé Consultants. SimaPro, Version 9.0; PRé Consultants: Amersfoort, The Netherlands, 2019. [Google Scholar]

- Ekvall, T.; Weidema, B.P. System boundaries and input data in consequential life cycle inventory analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Thompson, M.; Ellis, R.; Wildavsky, A. Political cultures. In Cultural Theory; Westview Press: Boulder, CO, USA, 1990. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Picquelle, S.J.; Mier, K.L. A practical guide to statistical methods for comparing means from two-stage sampling. Fish. Res. 2011, 107, 1–13. [Google Scholar] [CrossRef]

- Hurlbert, S.H.; Lombardi, C.M. Final collapse of the Neymane-Pearson decision theoretic framework and rise of the neoFisherian. Ann. Zool. Fenn. 2009, 46, 311–349. [Google Scholar] [CrossRef]

- Gotelli, N.J.; Ellison, A.M. A Primer of Ecological Statistics; Sinauer Associates Inc.: Sunderland, MA, USA, 2004. [Google Scholar]

- Verbitsky, O.; Pushkar, S. Eco-Indicator 99, ReCiPe, and ANOVA for evaluating building technologies under LCA uncertainties. Environ. Eng. Manag. J. 2018, 17, 2549–2559. [Google Scholar] [CrossRef]

- Pushkar, S.; Verbitsky, O. LEED-NCv3 silver and gold certified projects in the US: An observational study. J. Green Build. 2018, 13, 67–83. [Google Scholar] [CrossRef]

- Pushkar, S.; Verbitsky, O. LEED-NC 2009 silver to gold certified projects in the US in 2012–2017: An appropriate statistical analysis. J. Green Build. 2019, 14, 83–107. [Google Scholar] [CrossRef]

- Pushkar, S.; Verbitsky, O. Silver and gold LEED commercial interiors: Certified projects. J. Green Build. 2019, 14, 95–113. [Google Scholar] [CrossRef]

| Material | BA0SF 2 | BA40SF 2 | BA60SF 2 | BA80SF 2 | BA100SF 2 |

|---|---|---|---|---|---|

| Portland cement (kg/m3) | 438 | 438 | 438 | 438 | 438 |

| SF (kg/m3) | 0 | 35.36 | 35.36 | 35.36 | 35.36 |

| Water content (kg/m3) | 197 | 197 | 197 | 197 | 197 |

| Sand (kg/m3) 1 | 678.47 | 407.08 | 271.39 | 135.69 | 0 |

| BA (kg/m3) 1 | 0 | 199.92 | 299.88 | 399.83 | 499.79 |

| Coarse aggregate (kg/m3) | 1097 | 1097 | 1097 | 1097 | 1097 |

| Superplastificator (kg/m3) | 0 | 0 | 0 | 0.795 | 0.884 |

| Material | BA0SF-BFS 2 | BA25SF-BFS 2 | BA50SF-BFS 2 | BA75SF-BFS 2 | BA100SF-BFS 2 |

|---|---|---|---|---|---|

| Portland cement (kg/m3) | 607 | 607 | 607 | 607 | 607 |

| SF (kg/m3) | 0 | 143 | 143 | 143 | 143 |

| BFS (kg/m3) | 0 | 186 | 186 | 186 | 186 |

| Water content (kg/m3) | 187 | 187 | 187 | 187 | 187 |

| Sand (kg/m3) 1 | 437 | 328 | 219 | 109 | 0 |

| BA (kg/m3) 1 | 0 | 76 | 152 | 227 | 303 |

| Coarse aggregate (kg/m3) | 824 | 824 | 824 | 824 | 824 |

| Superplastificator (kg/m3) | 14 | 14 | 14 | 14 | 14 |

| Process | Reference |

|---|---|

| Water treatment | Tap water, at user/CH U |

| Cement production | Cement mortar, at plant/CH U |

| Aggregate extraction | Gravel, crushed, at mine/CH U |

| Sand extraction | Sand, at mine/CH U |

| Transport | Lorry transport, Euro 0, 1, 2, 3, 4 mix, 22 t total weight, 17.3 t |

| BA landfilling | Disposal, concrete, 5% water, to inert material landfill/CH U |

| SF landfilling | Disposal, slag from silicon production, 0% water, to inert landfill/CH U |

| BFS landfilling | Disposal, steel, % water, to inert material landfill/CH U |

| Steel production | Reinforcing steel, at plant/RER U |

| Conventional Concrete | BA40SF 2 | BA60SF 2 | BA80SF 2 | BA100SF 2 |

|---|---|---|---|---|

| BA0SF 2 | 0.1462 1 | 0.07381 | 0.08871 | 0.05471 |

| Conventional Concrete | BA25SF-BFS 2 | BA50SF-BFS 2 | BA75SF-BFS 2 | BA100SF-BFS 2 |

|---|---|---|---|---|

| BA0SF 2 | 0.1443 1 | 0.1148 1 | 0.09611 | 0.07791 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pushkar, S. The Effect of Additional Byproducts on the Environmental Impact of the Production Stage of Concretes Containing Bottom Ash Instead of Sand. Sustainability 2019, 11, 5037. https://doi.org/10.3390/su11185037

Pushkar S. The Effect of Additional Byproducts on the Environmental Impact of the Production Stage of Concretes Containing Bottom Ash Instead of Sand. Sustainability. 2019; 11(18):5037. https://doi.org/10.3390/su11185037

Chicago/Turabian StylePushkar, Svetlana. 2019. "The Effect of Additional Byproducts on the Environmental Impact of the Production Stage of Concretes Containing Bottom Ash Instead of Sand" Sustainability 11, no. 18: 5037. https://doi.org/10.3390/su11185037