Greenhouse materials (such as plastic films) that possess ideal optical properties allow plants to absorb ultraviolet B (UV-B) radiation. UV-B radiation is beneficial because it triggers the release of secondary metabolites beneficial to human health. Metabolites such as polyphenols, carotenoids, lycopene, and anthocyanins have been proven useful in the prevention of cancer and cardiovascular diseases [

31]. Moreover, plants grown under a greenhouse are exposed to fewer pathogens and fungal infections [

15]. A lower exposure to pathogens translates to higher agricultural yields. On the downside, the benefits afforded by UV-B radiation involve a tradeoff between the stimulation of the metabolites and delayed crop time.

The customization of the optical properties of greenhouse covering remains an issue of interest in research. According to Mormile and co-researchers, a UV amount of 0.5–10 KJm2 d1 is theoretically ideal. However, experimental evidence is required to validate the theoretical propositions. The standard types of greenhouse covering materials are critiqued in the main body of the article to determine the most appropriate material from an environmental sustainability perspective.

According to Hao and Papadopoulos, the exploration of alternative and new cladding materials for greenhouses beyond the glass was triggered by the oil crisis in the 1970s and the 1980s [

4]. The energy crisis motivated researchers to investigate materials whose production process was energy efficient. Research on greenhouse cladding materials has also been informed by sustainability considerations, namely CO

2 emissions and the need to conserve energy due to the depletion of fossil fuel reserves. Recent research suggests that plastic films and sheets are effective in the conservation of energy in greenhouses, given they utilize minimal energy compared to heating, ventilation, and air conditioning (HVAC) systems [

25]. The claims concerning low energy use are further validated by the life-cycle assessment of plastic sheets and films.

Higher energy is conserved through the utilization of multiple layers of plastic films. However, the adoption of this approach involves a tradeoff between heat retention and loss of light—the incorporation of each additional sheet translates into a 10 percent loss of light [

4]. The loss of light might compromise photosynthetic processes and impact plant growth. Sustainability concerns in crop production and the need for ideal pest control management systems and organic cultivation [

15] have informed the development of greenhouse materials with customized properties such as higher photo-selectivity and slow insecticide release capabilities [

32,

33]. Other properties associated with modern greenhouse materials are limited droplet formation, reduced heat losses, accumulation of dust, and transmission of a particular wavelength of light [

14,

31,

32,

34].

2.1. Impact of North Wall Materials for Chinese-Type Greenhouses and Mulching on Greenhouse Microclimate

Even though cladding materials influence plant growth rates and the quantity of PAR and UV-A radiation, the performance of the greenhouse materials and microclimate is also predicted by the usage of plastic-based mulching or bio-based mulches [

30,

35]. Heat retention in greenhouse structures is dependent on the type of materials used in the construction of the greenhouses. According to [

30], the performance of wall materials varies depending on locality—greenhouses in arid and semi-arid areas require better insulation from heat, while pure and bioplastics have different levels of susceptibility to UV degradation. Plastic films experience the least deterioration (1.5.to. 4.5 percent) while bio-based films are degraded 100 percent.

The Chinese prefer fired clay blocks and compacted clay as shown in

Figure 1 [

21] while the construction of greenhouse walls and roofs using one material such as glass or plastic films and sheets is common in other countries [

14,

34,

36]. Zhang and co-researchers reported low conductivity in the clay bricks constructed with agricultural waste (0.280 W m

−1k

−1) compared to porous clay blocks. The surface and cross-sectional morphology of glass straw-clay and porous clay blocks are depicted in

Figure 2. The incorporation of plant materials to the clay yielded better performance in heat storage and heat absorption from the ambient. In general, the clay blocks have higher thermal conductivity compared to polystyrene boards (0.04 W m

−1C

−1). A lower thermal conductivity is an essential requirement in heat conservation, especially during winter.

A comparative analysis of bio-based, plastic and biodegradable paper mulching materials by Zhang and co-researchers [

30], Briassoulis and Giannoulis [

35] in China and Greece, respectively confirmed the impact of mulching materials on plant growth (root to shoot ratio, plant biomass, root morphology, and fruit quality) and the greenhouse microclimate (electrical conductivity, pH, moisture, temperature), and presence of nutrients and enzyme.

2.3. Additives, Fillers, Reinforcements, and Colorants

The properties of plastics such as heat resistance, heat loss, droplet formation, and dust forming on the film can be improved through the integration of functional additives, fillers, air bubbles [

44], reinforcements (glass or carbon fibers), and colorants as illustrated in

Table 4. Functional additives include stabilizers and UV absorbers whose core function is to prevent damage to plants; UV-B above 40 KJm

2 dcauses radiation damage to greenhouse plants [

31]. The additive also predicts the UV and IR transmission rates - commercially available materials have transmission rates of between 0.7 and 0.9 [

24]. Ethyl-vinyl-acetate, anti-fog, and infrared additives are also integrated into the plastics to prevent fog formation and transmission of harmful IR radiation [

15]. Even though the stabilizers improve the optical and mechanical properties of the cladding materials for greenhouses, selected stabilizers contain heavy metals such as lead and cadmium, which are toxic to human health (cytotoxicity) [

2,

45]. Nonetheless, heavy metal stabilizers do not pose any direct risk to plants grown under greenhouses covered with PVC materials in-situ—the risk emerges during recycling. Even though there is a minimal risk in-situ, concerns about cytotoxicity and heavy metal contamination of plants have informed the synthesis of biopolymers-based photo-catalysts made of gelatin, agar, or chitosan [

2].

In addition to the customization of the optical properties of the cladding materials, additives and stabilizers such as carbon black reduce the risk of photo-degradation and UV damage on plastic films and sheets, and by extension, the durability of the greenhouse structures [

9]. Standard reinforcements for greenhouse covering materials and walls include fiber textiles (hemp linen, jute burlap, and hemp burlap), which are integrated into bio-based plastics to form composites. Mechanical tests established that hemp line composites had the highest ultimate tensile strength (UTS) 83.5 MPa [

13], percentage elongation, and resistance to creep deformation. Reinforced hemp linen composites can be employed as substitute materials to straw fibers and porous clay blocks [

21] or concrete in the construction of greenhouse walls based on the mechanical properties.

Apart from preventing the radiation damage of plants, the additives and UV absorbers prevent the growth of pathogens (pest and disease) [

3]. Additionally, the infrared light absorbers (generally in the range between 700 and 2500 nm) suppress heat losses and prevent longwave radiation. Similarly, the long wave absorbers (2500–40,000 nm) suppress heat losses from the plants shielded by the greenhouse while the light diffusers facilitate the dispersion of light within the greenhouse, which prevents the light burn phenomenon. The surfactant and antistatic agents help to reduce the accumulation of dust on the plastic film and the surface tension, respectively [

12]. Other additives that are employed to augment the performance of greenhouse plastic additives include red light emission enhances, glossy surfaces, and color pigments. However, the latter have minimal benefits in greenhouse cladding and are briefly reviewed below.

As illustrated in

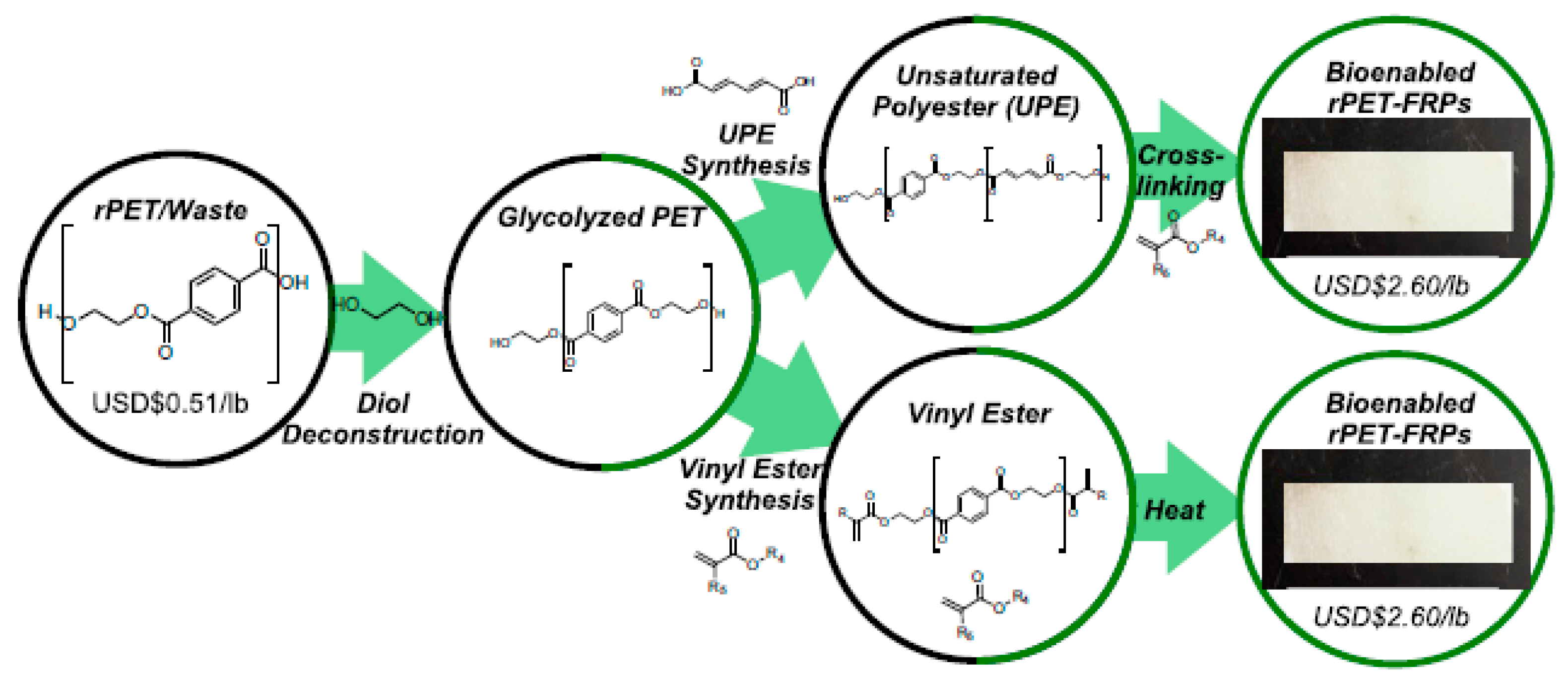

Table 5, the functionality of the materials for greenhouses is also augmented by pigments (pigment volume fraction). Aldaftari and co-researchers reported the effectiveness of diamond particle-based pigment in radiation control in greenhouse cladding materials [

20]. The use of pigments in radiation control offers a low-cost alternative compared to the utilization of air conditioning systems (HVAC). In contrast to the pigments, diamond particle-based and TiO

2 pigment possessed unique optical properties—the coatings facilitated the reflection of incident radiation in the near-infrared region (800 to 2500 nm) but transmitted shorter visible wavelength [

20].

The mechanism of action of the diamond-based pigments yielded the following benefits. First, it reduced the quantity of heat in circulation within the greenhouse. Second, it provides sufficient light for photosynthesis. Beyond diamond particles, there are other materials employed in the development of radiation protection pigments for greenhouse materials, as shown in

Table 4. Following the comparison of diamond particles with TiO

2 particles (the standard), the former material possessed the best properties - transmittance was highest in the shorter visible wavelength (VIS). In contrast, the reflectance of light was most pronounced in the near-infrared region [

20]. In place of diamond-particles, TiO

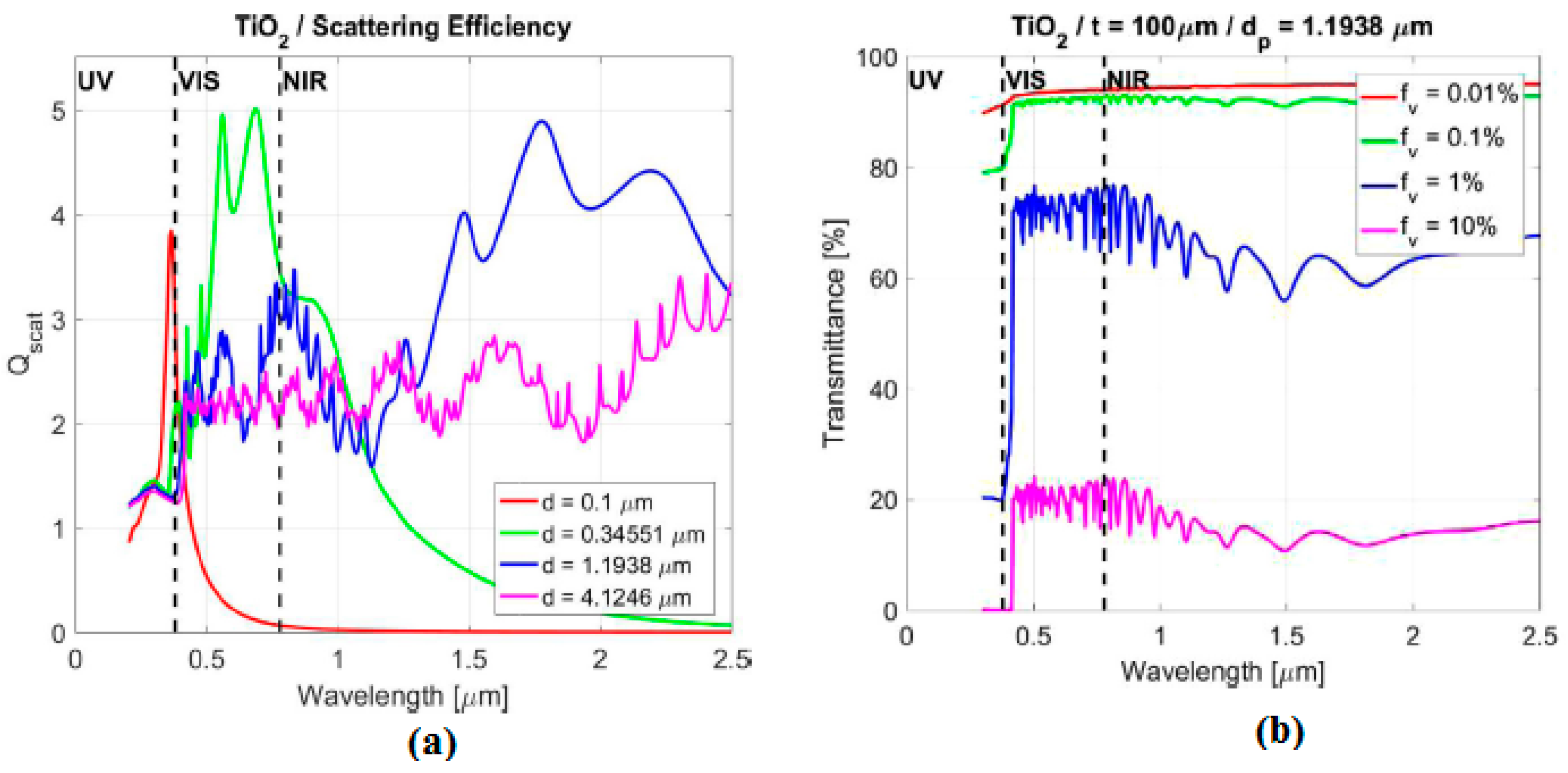

2 can be employed in low-cost applications because the material also exhibits significant scattering efficiency (d = 1.19 μm) in the NIR and pronounced transmittance (~95%) in the VIS region for particles with a diameter of 0.1 μm as shown in

Figure 3 [

20]. The only challenge is the impact of particle sizes on scattering efficiency and transmittance—higher particle diameters led to more significant scattering efficient but lower transmittance. The mechanism through which the black body emissions schematics illustrate the particle sizes influence transmittance and scattering efficiency in the VIS and NIR regions in

Figure 3 and

Figure 4.

Apart from acting as pigments for greenhouse cladding materials, TiO

2 nanoparticles have been used to develop nano-based coats for transparent solar distillers (TSD), which are multipurpose greenhouse cladding materials that are also used to harness solar energy to desalinate water [

46]. Rabhy and co-researchers note that the application of the TiO

2 nanoparticle-based coat improved the optical and thermal properties of the absorber layer—precisely the rate of condensate formation and daily yield.

Beyond the modification of the optical properties of polymers, TiO

2 has biocompatible antimicrobial properties [

2], which are essential for plant growth, considering fungal and bacterial infections retard plant growth. Additionally, novel polymers such as LLDPE with slow-releasing capabilities for pesticides have been developed to suppress the spread of insect-vector diseases in plants such as tomato yellow leaf curl disease [

33,

47]. The mobile release capabilities are augmented by halloysite nano-composite films [

33]. However, the development of novel polymers introduces new health challenges for humans as noted by Seven and co-researchers [

4]. Such health concerns have not been effectively addressed.

2.4. Distillers

Apart from the incorporation of the pigments, the performance of the greenhouse materials for greenhouses can be modified through the incorporation of the solar distillers [

6] and organic PVs. Standard materials for solar cells are phenyl-C61-butyric acid methyl ester (PCBM) and are poly (3-hexylthiophene) (P3HT) and fullerene-conjugated polymer derivatives. The organic materials are preferred due to suitable charge transfer and optical absorption properties compared to silicon materials [

7]. The roll-to-roll process can address the cost barriers in organic PV materials.

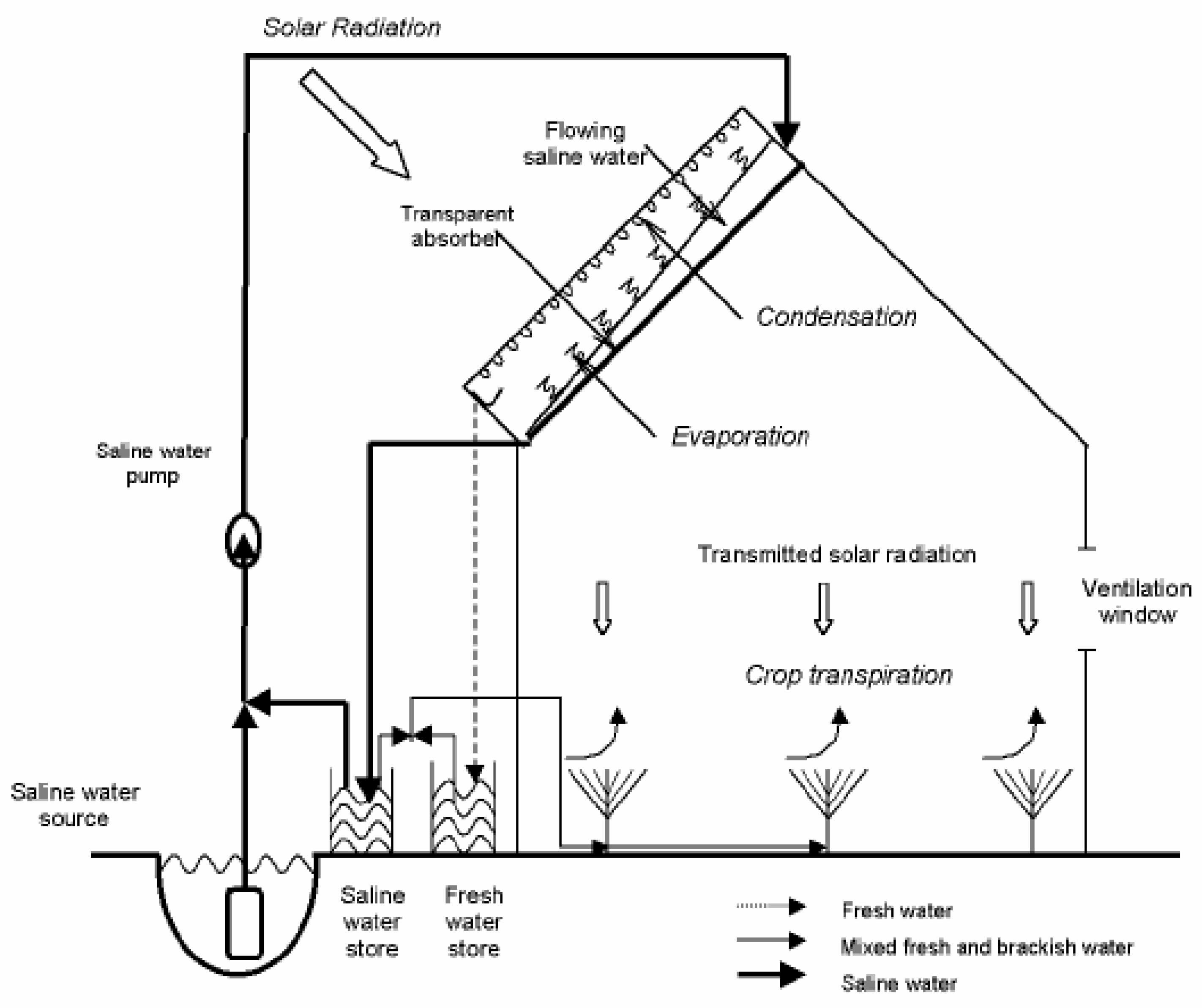

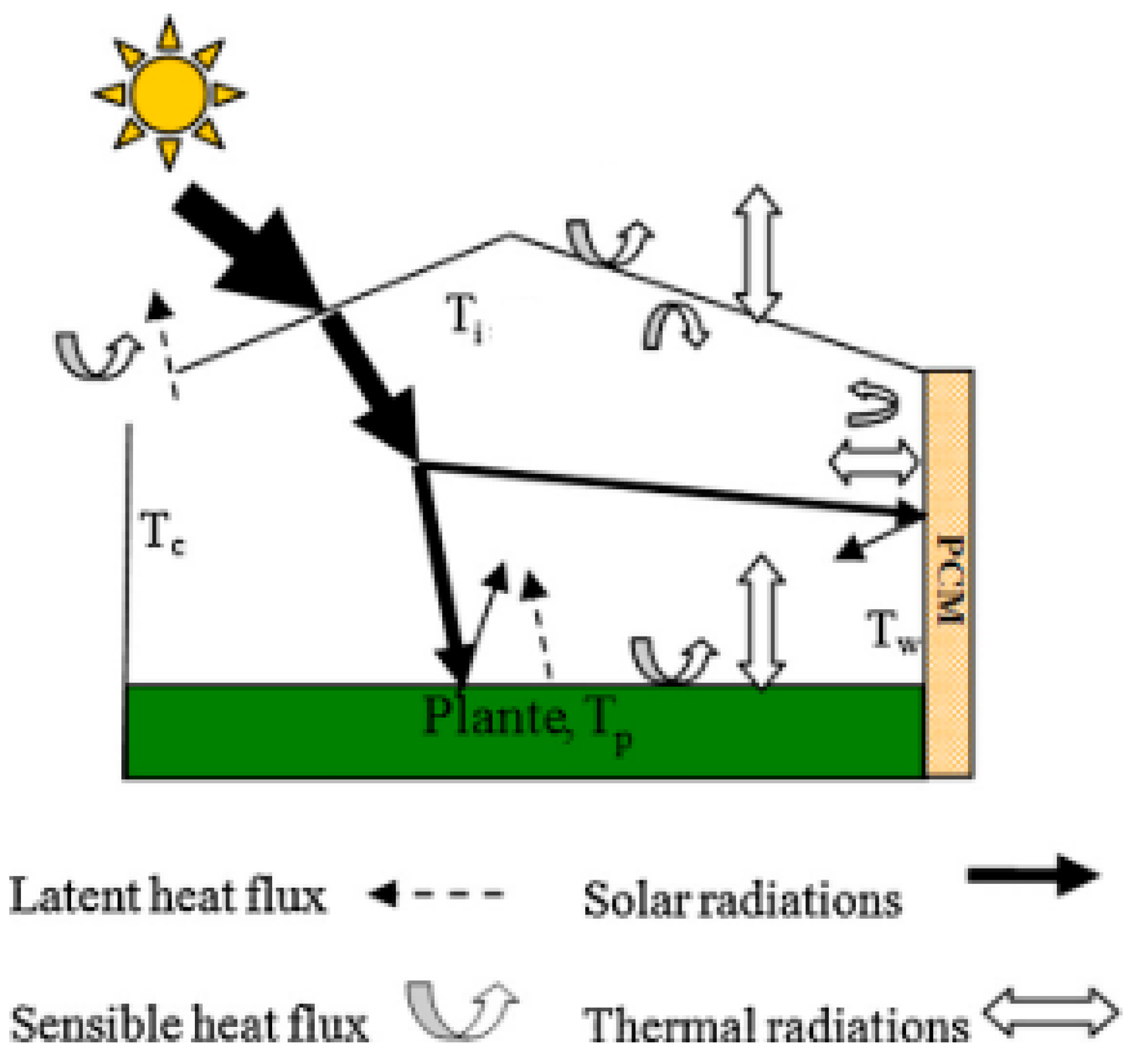

The solar distillers feature photovoltaic solar cells, which convert solar radiation to energy. The energy is consequently used to generate desalinated water for commercial agriculture. In addition to the distillation of water, the distillers reduce the in-house temperatures and the incident solar radiation through condensation and evaporation as shown in

Figure 5 [

11]; it is of note that there are three layers namely the cover glass, water layer, and the absorber glass and insulation layer. The second layer poses a challenge due to the high levels of transmission—a phenomenon that is regulated by absorber glasses with low transmittance of infra-red radiation. In principle, the distillers achieve the same function as pigments and additives in the transmission and reflection of infrared and UV radiation [

11]. However, in contrast to the traditional systems, the performance (transmittance and reflectance) of the solar distillers is influenced by the rate of plant transpiration, mass flux, which are calculated using the governing equations below. The ideal roof pitch angle varies between 15 and 42 °C [

8]. However, the pitch can be influenced by latitude. Low altitude areas are warmer and therefore require higher roof pitches to control internal air temperatures.

2.4.1. Mass Flux

The mass flux of the solar distillers is influenced by the parameters outlined in Equation (1), where pw and pg denote partial pressures of water vapor at saturation for the water and the glass; hc denotes heat transfer coefficient for convention and L is the latent heat of vaporization of the water [

11]. Mass flux is also influenced by the ambient temperature, given that there is a direct link between ambient temperature and partial pressures.

2.4.2. Transpiration Rate

The following parameters in Equation (2) define the transpiration rate of the crops; Iabs - the amount of long and short wave radiation absorbed by the crop canopy per unit area. S—the thermal energy generated or stored by the plant canopy as a result of biochemical reactions such as photosynthesis. However, the role of thermal energy can be disregarded in transpiration calculations. LAI, re, and ri -denotes the leaf area index. External canopy resistance, internal canopy resistance to vapor flow, respectively. In addition, ea and eas denote the true vapor pressure of air and the saturated vapor pressure, respectively. The green symbols γ and δ denote psychrometric constant and the “slope of saturation vapor pressure curve” [

11].

2.4.3. Reflectance and Total Transmittance

Apart from the transpiration rates and the mass flux, the performance of the solar distillers is influenced by the reflectance coefficient, as demonstrated in Equations (3) and (4); it is of note that the wavelength impacts stomata opening and plant transpiration. The symbol τ

g,w denotes the cumulative transmission coefficient for the water and glass layers. The reflectance coefficients for the glass and water are represented by r

g and r

w, respectively [

11]. The transmittance of the glass and water layers is calculated using the formula in Equation (4).

Even though the impact of all other variables has been addressed, the performance of the solar distillers is influenced by the following assumptions; the mass of air within the greenhouse is negligible, the transfer of heat from the floor to the ground is negligible [

11], there is an envelope in the greenhouse temperatures, there is uniform mixing of air, and adequate moisture is present on the plant canopy. Such assumptions might not always hold depending on the season and the types of plants; it is hypothesized that during winter, there would be significant heat losses from the floor of the greenhouse to the ground. Heat losses from the floor are also influenced by the type of flooring material; concrete versus gravel or soil, and if a plastic mulch/film is on the floor, and the color of the flooring (white versus black). The claims made above are validated by the data in

Table 6, which illustrates that the maximum temperatures were highest in June and July [

46].