2. Methodology

The LCA presented here examines the effect of a gradual but complete adoption of either electric vehicles or biofuels by 2050 in Brazilian (urban) passenger transport. This means 100% of vehicles would be BEVs, or 100% of all fuel sold would be biofuel (sugarcane ethanol or soy-based biodiesel) in conjunction with 100% biofuel-capable vehicles, respectively, in 2050. The results are calculated in terms of CO2 emissions, urban air pollution (nitrous oxides (NOx) and particulate matter (PM)), electricity consumption and the land area required to grow sufficient biofuel feedstocks.

The LCA considers passenger cars, urban buses and bus rapid transit (BRT) buses. However, because the magnitude of results of BRT buses is negligible in comparison to the other modes (see Figure 4), the results for BRT are omitted for brevity. The LCA is calculated in a spreadsheet for the years 2015–2050 in five-year steps. The results for each year are for only the year in question as a ‘snapshot’ (i.e., the intervening years are ignored). An overview of the aspects and life phases considered in the LCA is shown in

Figure 1, and further described in the section below. The spreadsheet is structured to allow for the comparison of sets of five scenarios, allowing a comparison of the BAU scenario with four alternatives.

Appendix A contains tables of the input values used in the LCA.

2.1. Vehicle Use and Characteristics

2.1.1. Total National Vehicle Use

To allow free selection of various powertrain types (see below) in the scenarios, the total distance driven in Brazil by all vehicles of each mode (cars, urban buses) (

Figure 2) per year in vehicle kilometers (vkm) must be calculated. It is calculated from the total projected vehicle stock of each mode multiplied by the corresponding average distance driven per vehicle, using figures for both from International Energy Agency (IEA) modeling [

47,

48] (

Table A4 and

Table A5).

2.1.2. Fleet and Fuel Composition

In each scenario, for each year (

Table A2 and

Table A3), the composition of the fleets (cars and urban buses) is defined from the following powertrain types: flex, flex hybrid, diesel, diesel hybrid, compressed natural gas (CNG) and electric. Hybrids are assumed to be ‘standard’ hybrids without the facility to be charged from external sources, while electric is assumed to mean fully electric vehicles with only onboard batteries as energy storage. In parallel, for each year, the proportion of biofuels sold is defined from 0%–100% (

Table A1). Values for the volume of fuels sold are available for 2015 and 2018 [

49,

50]; the 2020 values are calculated by extrapolating the development from 2015 to 2018. For ethanol, both hydrated and anhydrous are considered together; hence, the proportion in 2015 (49.6%) being significantly greater than the 27% ethanol as mandated in pump petrol (‘gasohol’). For biodiesel, the extrapolated 2020 value was above the mandated 10%; so, 10% has been used from 2020 onwards under the assumption that there would be no overshoot.

This model assumes all relevant vehicles are able to run on any proportion of bio or fossil fuel. For petrol, flex vehicles are near ubiquitous in new registrations in Brazil [

41] (and ethanol is sold in similar volumes to petrol in 2015) and so this assumption is almost already reality. For diesel, however, Brazil’s pump diesel currently contains only 10% biodiesel, so this assumption must be considered more speculative, though it is assumed to be possible given sufficient research and development for the purposes of this LCA.

2.2. Fuel Production and Use Phase

2.2.1. Total Fuel Use Per Vehicle Type and Fuel Type

The total vkm per mode and powertrain type is calculated based on the overall vkm per mode and the powertrain proportions as entered in the scenarios. The total use-phase energy, and thus fuel, consumed by each vehicle type is calculated from the vkm and the corresponding on-road average fuel economy for each type. All relevant values here are provided by the IEA [

47] (

Table A4 and

Table A5). The total amounts of fuel used are multiplied by emission factors for well-to-tank (WtT) (including electricity) and tank-to-wheel (TtW) emissions (more details of both below) to determine the emissions of each vehicle (and fuel) type and thus scenario. For electric vehicles, the round-trip efficiency for electric vehicles (buses) of 88%, from Lajunen [

51], is applied to the stated fuel economy to reflect the inefficiency in charging and discharging the battery.

2.2.2. Well-to-Tank (WtT) Emissions

For each fuel type, the well-to-tank CO

2 emissions (per liter) are given by Edwards et al. [

52] (

Table A7). The figures provided are calculated for Europe and modified for Brazil (see below), as consistent figures for all fuel types for Brazil could not be found. For fossil fuels, the figures have been used as found. For biofuels, the European figures for Brazilian-produced ethanol and biodiesel are modified by deducting the value listed for ‘transport to Europe’. These figures do not contain land-use emissions. The WtT factor for electric vehicles is provided by the relevant average emission intensity of the electricity system in that year (see below).

2.2.3. Tank-to-Wheels (TtW) Emissions

TtW emissions are calculated using the energy and CO

2 content of each fuel type [

47,

53], along with NOx and PM exhaust emissions intensities from Agência Nacional de Transportes Terrestres [

54], supplemented with NOx exhaust emissions intensities for LPG/CNG vehicles from Murrells and Pang [

55] (

Table A7). The TtW CO

2 exhaust emission intensity of ethanol and biodiesel is considered to be zero as this carbon is considered to have been sequestered in the production phase. For NO

x and PM, the values for 2012 (the latest year available) are applied for all years (

Table A6), or an annual reduction in air pollution emission intensity of 8.67% (from 2012), derived from Miller et al. [

56] is applied.

2.2.4. Electricity System

Best- (mostly renewables) and worst-case (mostly fossil fuels) scenarios for both total generation (in TWh) and CO

2 emission intensity (in kilotonne/TWh) are provided by the online calculator provided by the Energy Research Office [

57] (EPE in Portuguese) for decadal years (2020, 2030, etc.) (

Table A8), extrapolated to other years. The worst-case scenario is the default used in the scenarios. The model does not account for any effects of large additional loads in the short or long term, and the total generation capacity is used only as a comparison; a more complicated model accounting for the characteristics of the electricity generation system is beyond the scope of this study.

2.2.5. Land-Use Change Emissions

A direct land-use change (LUC) emission model is used to calculate the LUC emissions. It is assumed that the land area for all other crops remains the same, with all changes in biofuel use directly affecting the land used to grow the feedstocks, and that this land comes from (or returns to) various forest types or Cerrado/savannah according to the volume of biofuel needed in each year. A more complicated model involving intermediate steps and economic elasticities is beyond the scope of this analysis.

Firstly, the land area required to grow the requisite fuel feedstocks is calculated using figures for the yield of ethanol (sugarcane) or biodiesel (assumed to be all derived from soyabeans) per land area, using values from Valin et al. [

58] (

Table A10). The values used are constant for all land types and locations. From this and the volume of fuel required each year, the yearly change in cropland area from the previous period is calculated.

The National Energy Policy Council (CNPE) has mandated, as part of the RenovaBio programme, a decrease in the CO

2 emissions of each unit of energy consumed by Brazilians from 74.3 g/MJ (2017) to 66.1 g/MJ in 2029; 1.07% per year [

59], assumed to be achieved through increased biofuel yields (L/ha) and from increasing the proportion of biofuels used in fuels, though no statement of how much each contributes is given, and so it is assumed that each contributes half of the 1.07% (0.535% pa). The improved biofuel yields are thus increased at the rate of 0.535% per annum, although even this may be overly favorable to biofuels as the possibility of increased yields is questioned by Bernardo, Lourenzani, Satolo, and Caldas [

60]. Furthermore, this would almost certainly cause the embedded CO

2 in biofuel to increase through, e.g., increased tractor and fertilizer use, and because these changes cannot be quantified, they are assumed to be negligible. The assumption that increased biofuel use decreases emissions presents a difficulty, as this is the opposite finding to this LCA, and so must be assumed to be based on a different methodology; as such, the other half of the mandated 1.07% decrease from increased biofuel use is omitted.

For biodiesel, 20% of the land-use change emissions are attributed to transport use, according to the ≈20% oil portion of the beans which can be used to make biodiesel: the other 80% would be attributed to the other uses of the soyabeans (e.g., soyameal for animal feed), outside this LCA.

Secondly, the carbon dioxide emitted (or absorbed) from the change in land-use is calculated using values of the carbon content of various Brazilian forest types (including plantation) and Cerrado (Brazilian Savannah) (

Table A9). The values for plantation forest and Cerrado are used as found, whereas a numerical mean and standard deviation is calculated for the forest values, with the low and high values representing one standard deviation from the mean value. The conversion from biomass carbon to CO

2 emissions is performed using the average ratio between “Average forest AGB [Above Ground Biomass]” and “Primary forest (instantaneous, non-process) emissions” (primary is selected assuming that the recropping of the land for biofuel is part of the secondary stage), from Aguiar et al. [

61], giving a value for CO

2 emissions for each hectare of land changed.

The emissions from land-use change are spread over a 20 year period. LUC emissions in 2015 are zero as the LCA captures only change in biofuel use (and thus land use) to generate LUC emissions, and so for example the 2020 value includes any change from 2015 to 2020.

2.3. Vehicle and Battery Manufacturing Phase

For computational efficiency and because of a lack of equivalent model data pre-2015, a fleet model could not be implemented, so the number of vehicles manufactured per year is calculated by assuming each year is closed regarding vehicles, i.e., all vehicles used in a year would be manufactured in that year and disposed of at the end of the same year. The scenarios thus prescribe a fleet proportion, not sales proportions of the various powertrain types. The number of vehicles for each year is calculated by dividing the total vkm for each powertrain type by the total lifetime (in km) of that type. The emissions for vehicle manufacturing are constant per vehicle, independent of changes to the electricity emission intensity applied elsewhere in the LCA. In addition, the values are accounted for in Brazil, even if the parts actually originate elsewhere.

For cars, the lifetime (200,000 km) is provided by Messagie [

14] and assumed to be the same for all vehicle types (see

Table A11). In addition, with the exception of the batteries for hybrid and electric vehicles, the non-battery components are assumed to result in the same CO

2 emissions (≈3.2 tonnes); see

Table A12. For buses, the lifetimes (different by powertrain type) are provided by Lajunen [

51] with a correction factor for the lifetime of non-diesel buses in line with the calculations by WRI [

62] (

Table A13 and

Table A14).

Battery manufacturing emissions are calculated from the overall capacity of batteries required for all hybrid and electric vehicles and their respective battery capacities (and the rate of battery replacement) as shown in

Table A11 and

Table A13. A range of current battery manufacturing emissions intensities (in g/kWh) is provided in Hall and Lutsey [

16], from which the average (default) minimum or maximum values (see

Table A15) can be applied. The default assumption for the battery and vehicle manufacturing calculations is that both are manufactured from raw materials and disposed of without reuse or recycling at the end of life. As such, if the scenarios dictate that the materials (and thus CO

2 emissions) are recovered or reused at the end of life, this results in a ‘credit’, covered in more detail in the end-of-life section, below.

2.4. End-of-Life Phase

As mentioned above, the LCA treats each year as a closed system, so all vehicles used in any year also come to the end of their lives in that year. Five aspects of the end of life are considered: non-battery recycling emissions, non-battery materials credit, battery recycling emissions and materials credit and a battery reuse credit (values and sources given in

Table A16). Reusing batteries and recovering materials through recycling effectively reduces the manufacturing emissions, but they are considered as credits in this manner to allow separate (calculation) and presentation of these and the default manufacturing emissions.

Recycling emissions considers the energy required to recycle the respective parts and is calculated by multiplying the total mass of vehicles and capacity of batteries to be recycled by the respective factors for the energy required to recycle them. It is assumed the energy for this comes from the electricity network, so the relevant CO2 emission intensity of the electricity system for that year is applied.

The vehicle recycling materials credit is included at current levels of recycling and use of recycled materials. The credit is zero as it is assumed to be included in current calculations of vehicle manufacturing emissions.

The battery recycling materials credit is calculated according to the 10%–17% and 23%–43% reductions (

Table A16) given for the use of recycled materials in battery manufacturing. The base assumed reduction is 26.5%—the mid-point between the 10% and 43% outer figures. The actual emission credit figure is calculated from the total battery manufacturing emissions in the relevant year, multiplied by the 26.5% and the assumed proportion of battery recycling (details below).

The battery reuse credit is calculated using the assumed extra life (72%) batteries can be used for after their vehicular use, i.e., they are used for 58.1% of their lives in vehicles and, as such, the remaining 41.9% counted as a credit for this LCA, as that proportion of the manufacturing emissions can be attributed to subsequent use.

The calculation of end-of-life credits applies an assumed proportion of battery reuse and recycling. Both are assumed to increase linearly to 100% by 2050, from 5% and 0% in 2015 for recycling and reuse, respectively (see

Table A17). This assumes that the greater use of batteries as per the scenarios will create an ever-greater economic and environmental imperative on the more efficient use of batteries and materials. As batteries can be both reused and recycled, both credits can be applied.

4. Results

The following contains an overview of the results of the various LCAs tested as described above. First, the main LCA results are shown, split into separate sections for cars and urban buses. This is followed by a section for the relevant results of each of the sensitivity analysis for both modes combined.

4.1. Main LCA

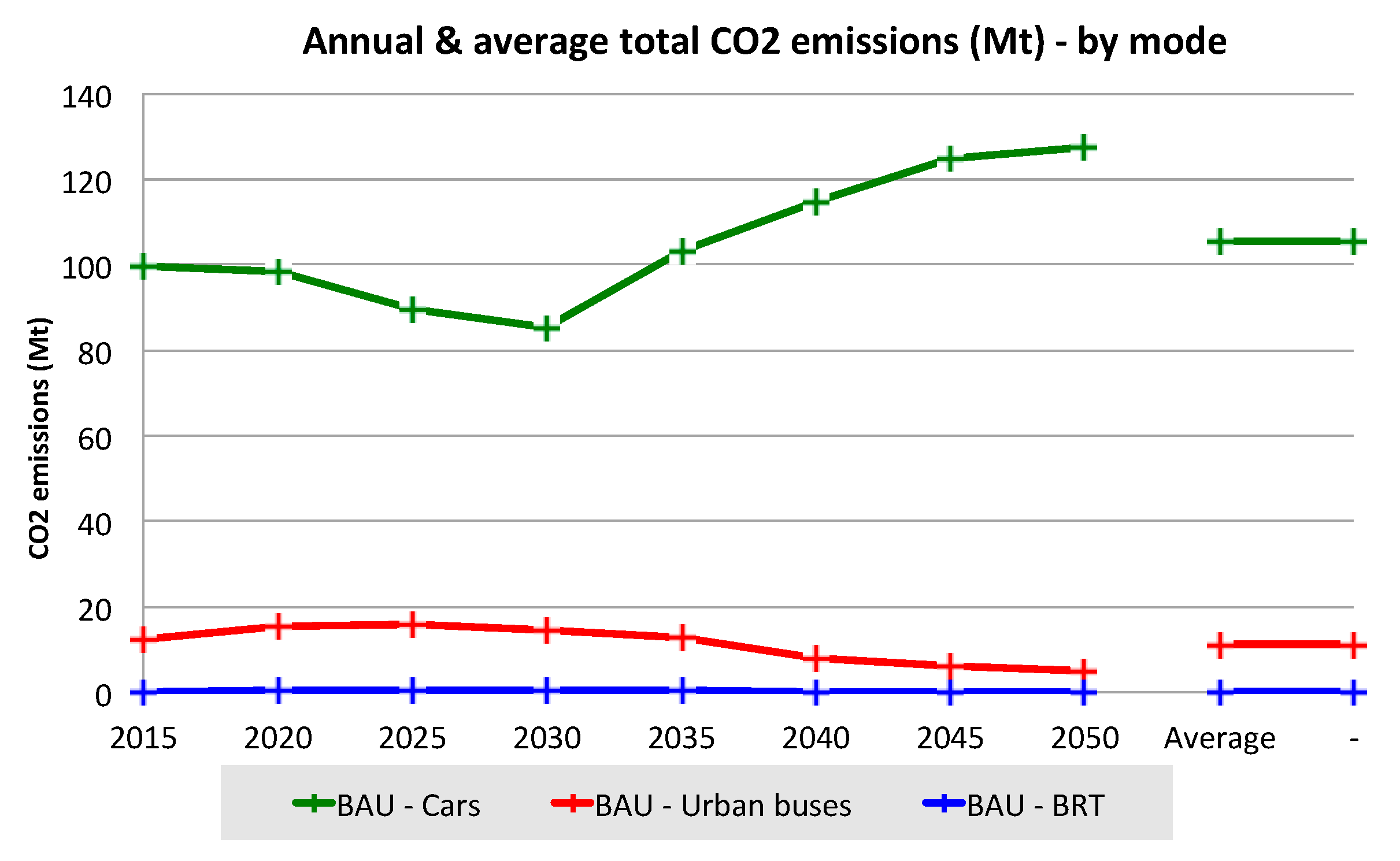

Figure 4 shows the CO

2 emissions of the BAU scenarios of cars, urban buses and BRT buses, respectively, in the main LCA. Cars are by far the dominant mode, while BRT buses are insignificant.

4.1.1. Cars

The results for the main LCA scenarios in

Figure 5 show that the biofuel scenario without hybridization of the fleet has greater emissions than BAU on average, while biofuel with hybrid is approximately equal on average. Both electrification scenarios (best and worst case) have lower emissions than BAU throughout and on average.

Figure 6 shows the composition of the scenarios in the main LCA according to the different life phases in 2020, 2035 and 2050. The BAU scenario is predominated by exhaust emissions (grey), while the biofuel scenarios have large portions from LUC emissions (red), especially in 2035 and 2050. The electrification scenarios have large portions for manufacturing emissions (blue) in 2050, but in the best-case scenario, a great deal of those would be offset by the end-of-life credit for increased reuse and recycling of the parts and materials (black). In addition, this scenario is notable for the large

negative portion of LUC emissions as the use of biofuel decreases and the land is switched to sequestration. In the worst-case electrification scenario, electricity generation (green) is a significant contributor to the overall emissions in 2050 due to the greater emission intensity of electricity generation in this scenario. For the same reason the end-of-life credit is diminished.

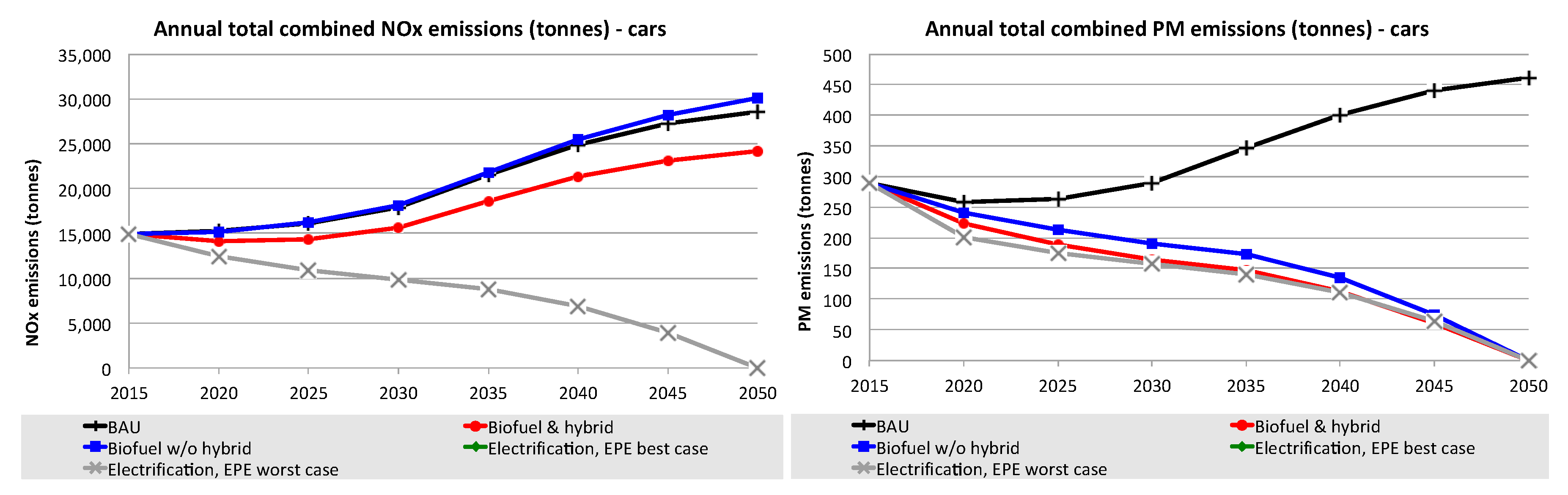

Figure 7 shows the result for air pollutant emissions in the main LCA scenarios. It shows electrification has a clear advantage over BAU. For NO

x, the biofuel scenarios have similar emissions to the (fossil-dominated) BAU scenario, while the air pollutant emissions for the electrification scenarios reduce to zero. For PM emissions, all alternatives to BAU have lower emissions. However, as shown in

Figure 8, if policies and technologies are applied which contribute to an 8.67% annual improvement, as suggested by Miller et al. [

56], the differences in powertrain technology become much less pronounced and all scenarios reduce to much lower levels by 2050.

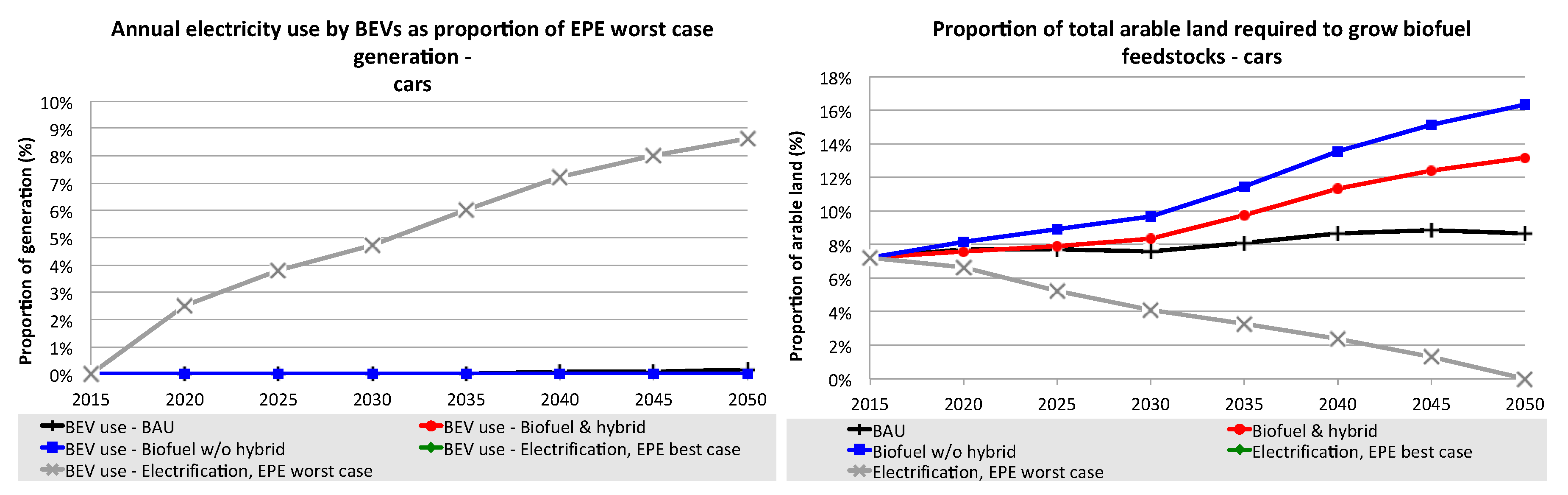

Figure 9 shows the results of the electricity consumption (left) and land use (right). The amount of electricity consumed steadily increases, approaching 9% of the worst-case generation capacity. The proportion of the arable land area required to meet the demand for ethanol increases steadily to over 13% and 16% in 2050 for the hybrid and non-hybrid scenarios, respectively.

4.1.2. Urban Buses

The results of the main LCA for urban buses (

Figure 10) follow a similar pattern (between scenarios) as for cars, above. The electrification of urban buses would result in the lowest CO

2 emissions, with the two biofuel scenarios resulting in the greatest emissions. However, on a yearly basis, the hybrid biofuel scenario becomes lower than BAU by 2050, as the overall use of fuel reduces and much of the land previously used to grow biofuel feedstocks switches to sequestration. The biofuel scenarios are sensitive to the gradient of vehicle use. This holds for cars also, but there are several differences which account for the greater variation for urban buses.

Urban bus use increases in the early stages of the analysis, where car use does not.

Biodiesel results in greater LUC emissions per liter because of the lower yield per hectare of land.

The scenarios dictate a greater increase per slot for biodiesel, which starts at zero and increases to 100% (≈14% per 5-year slot), whereas ethanol starts from ≈50%.

The composition of the total emissions according to life phases for urban buses (

Figure 11) is also similar in pattern to cars. The biofuel scenarios have large land-use change emissions, especially in 2035, and the worst-case electrification scenario has large electricity generation emissions. Manufacturing and end-of-life emissions make only very small or insignificant contributions. This figure also shows the source of the negative overall emissions calculated for the best-case electrification scenario: primarily, the large negative emissions from LUC, as biofuel use is reduced.

Also regarding air pollutant emissions, the same pattern emerges as for cars, as shown in

Figure 12. The results and expected trends are similar to those of the car scenarios, with the biofuel scenarios without and with hybrid close to, but above and below, BAU, respectively, while the electrification scenarios steadily decrease to zero. However, as shown in

Figure 13, if policies and technologies are applied which contribute to a 8.67% annual improvement, as suggested by Miller et al. [

56], the differences in powertrain technology become much less pronounced and the emissions from all scenarios diminish to much lower levels by 2050.

Figure 14 shows the results of proportional electricity consumption (left) and proportional land use (right). Regarding electricity use, electric urban bus electricity consumption peaks at below 0.5%, presumably an irrelevant amount from a grid-operational perspective. The amount of land required to grow sufficient biofuel feedstocks for urban buses peaks at below 1% for the highest scenario: biofuels without hybrid, while the biofuel with hybrid scenario peaks at below 0.8%.

4.2. Sensitivity Analysis #1: Land-Use Change Emissions (Biofuel)

The total annual CO

2 emissions for the sensitivity analysis of various LUC emission scenarios are shown in

Figure 15, below. Also included, for perspective, are the results for BAU if the LUC emissions were disregarded.

For both cars and urban buses, the results are quite sensitive to the LUC scenario selected, with a considerable difference between the biofuel scenarios with no-LUC (blue, left) and high-density forest (grey, right), in line with the overall contribution of LUC emissions to the overall result and the CO2 embedded in the various biomes (values in t/ha), Cerrado (122, green, left), plantation forest (212, grey, left), then low- (284, blue, right), average- (459, green, right) and high-density forest (635, grey, right).

For cars, on average, the plantation forest, Cerrado and low-density forest biomes result in lower overall emissions than BAU; the average- and high-density forest biomes result in greater overall emissions than BAU.

For buses, if the land for biofuel feedstocks is assumed to come from/return to Cerrado or plantation forest, on average, the results are lower than BAU, with all remaining forest biomes resulting in greater emissions than BAU.

Furthermore, the difference between BAU with (black) and without (red) LUC emissions can be seen; for cars, BAU without LUC is consistently below BAU, but for urban buses, the same holds until between 2035 and 2040, where the lines cross due to the LUC emissions switching to sequestration in the BAU scenario.

In addition, in general, it can be seen that the results are also quite sensitive to year-to-year changes of fuel use.

4.3. Sensitivity Analysis #2: Battery Manufacturing Emissions

This sensitivity analysis examines the effect of battery manufacturing emissions on a CO

2 per kWh of battery capacity basis. The results are shown in

Figure 16, showing that the overall results are not particularly sensitive to this change for cars, and practically not at all for urban buses.

4.4. Sensitivity Analysis #3: Vehicle and Battery Lives

This sensitivity analysis examines the effect of a this change in the life-length (both expressed in km) of both vehicles and their batteries in the electrification scenarios. For example, in the −20% scenario, the life of a car is reduced from 200,000 km to 160,000 km, in conjunction with a decrease in battery life from ≈133,000 km to ≈107,000 km. This has the effect of needing a greater (or lower) number of vehicles and batteries to be manufactured each year, with a corresponding change in the overall proportion of manufacturing emissions.

Figure 17 shows the results for CO

2 emissions with a ±20% change in the assumed vehicle and battery life. For cars, this has a comparatively small effect, especially when compared to the difference to the BAU and biofuel scenarios shown. For urban buses, the effect is even smaller; it is practically invisible.

The final sensitivity analysis compares a best-case biofuel scenario with the three electrification scenarios, the results of which are shown in

Figure 18. As this shows, all alternative scenarios have lower emissions than BAU, throughout and on average. Furthermore, on average, for cars the worst-case electrification scenario results in lower emissions than the best-case biofuel scenario, though the two do converge somewhat by 2050. For urban buses, all electrification scenarios initially rise above the best-case biofuel scenario but subsequently drop below.

4.5. Sensitivity Analysis #4: Best-Case Biofuel vs. Electricity System Development

Overall, this sensitivity analysis shows the advantage of the electrification scenarios over biofuels: even in what could be regarded as extreme and unrealistic scenarios, (biofuel disregarding LUC emissions altogether, and electrification dominated by fossil fuels), for cars, electrification still has lower emissions on average and throughout, and for urban buses, on average the result is only slightly in favor of the biofuel scenario. As such, under more realistic scenarios, it could be expected that electrification would have lower emissions.

Finally, the results presented here show that if the current overall CO2 emission intensity of Brazilian electricity generation is maintained into the future (i.e., as per the 2015/17 scenario), the resulting emissions would be between the EPE scenarios, but closer to the best case, i.e., the worst-case scenario is significantly more CO2 emission-intensive than the current scenario, and the best-case scenario is somewhat less CO2 emission-intensive.

5. Findings and Discussion

1. Cars are the largest contributor to the effects examined in this LCA

Overall, of the modes examined in this LCA, cars have the greatest effect on the results—CO2 emissions, air pollutant emissions, electricity consumption and land-use for biofuel feedstocks—albeit to differing degrees: the results for air pollutant emissions, for example, between cars and urban buses are comparatively close. Despite cars being smaller and having lower emissions per distance driven than buses, their collective total distance driven is much, much higher, accounting for their greater overall effect.

2. Electrification results in the lowest CO2 emissions

This LCA finds that the lowest CO

2 emissions would be reached in the electrification scenarios examined. Even if the worst-case electrification scenario is compared to the best-case biofuel scenario—both of which are probably unlikely given the extremity of their underlying premises—the electrification scenario results in lower (cars) or only slightly higher (urban buses) emissions. In the main LCA, the electrification scenarios offer 65%–89% CO

2 savings over BAU on average (note that the electrification scenarios include negative LUC emissions). A comparison of this finding with the other electrification-biofuel comparison found [

34] is near-impossible due to the very different methodologies applied (including an apparent exclusion of LUC emissions) and the different countries in question.

Not shown above is a further expansion of sensitivity analysis #4, in which the electrification scenarios were calculated without LUC emissions. For cars, the average CO2 emissions were almost identical between the biofuel (with hybrid) and electrification (2015/17) scenarios. For urban buses, the biofuel scenario resulted in near-identical CO2 emissions to the worst-case electrification scenario, i.e., without LUC at all, the BEVs offer improved CO2 emissions, assuming the overall generation profile remains similar to the present. While there is controversy regarding the methodology of including LUC emissions, we consider it unlikely that LUC would be zero; however, even if it were, BEVs under reasonable assumptions would result in similar CO2 emissions to biofuel with full hybridization.

3. Electrification results in lower air pollutant emissions

As with the CO2 emissions, the results suggest that the electrification of cars and buses would be the ideal path as it would lead to the highest reduction in both NOx and PM emissions. Biofuels, on the other hand, in most cases, do not reduce air pollution significantly from BAU (except for car PM emissions from ethanol). The magnitude of this result is greatly diminished; however, if a yearly improvement of ≈9% in emission intensity is achieved, the difference between scenarios becomes much smaller.

4. Land-use change emissions are a major contributor to the results for the biofuel scenarios

LUC emissions as calculated here are a major contributor to the overall CO2 emissions of the biofuel scenarios, and there is a great difference between the carbon content of the biomes selected, making the results very sensitive to whether LUC emissions are included or how they are calculated, and the rate of change of vehicle/biofuel use. If the Cerrado or plantation forest biomes are used to calculate LUC emissions, the result is emissions below BAU level, while using average- or high-density forest results in higher-than-BAU emissions, with low-density forest being below BAU for cars, above for urban buses.

LUC emissions are delayed and for a limited time (20 years), but the other emissions occur on a year-by-year basis. An interesting aspect of this analysis, covering a long timeframe, is that it shows the way in which LUC emissions fluctuate in relation to the other emissions that occur on a year-to-year basis, which LCAs of a single point in time would be unable to show well.

Related to this point is the land that would be required to grow sufficient feedstocks for biofuels. For cars, assuming the worst case of the full use of biofuels (without hybridization), up to 16% of Brazil’s arable land would be required to grow sufficient sugarcane.

5. Electrification is sensitive to electricity system characteristics

While the electrification scenarios can potentially yield significant benefits in terms of emission reduction, the amount of benefit depends greatly on the electricity system’s average emission intensity. However, the analysis suggests capacity can be added with higher than current emission intensity (as per the EPE worst case) while still maintaining a significant benefit over BAU. This is in line with the findings of previous studies described in the introduction.

Another characteristic of the electricity system of note is the total generation capacity. This analysis shows that cars would result in significant electricity demand: the full-scale electrification of cars is calculated to require up to ≈9% (in 2050) of the projected total generation capacity of Brazil (38% of 2017-level generation capacity). Intuitively, this would also be significant in terms of peak loads. The electrification of urban buses is calculated to result in urban bus electricity demand that would remain below 0.6% of the total expected national generation capacity.

Other aspects

Similar patterns were found for the sensitivity of the results to battery manufacturing emission factors and the lifetime of vehicles and batteries. Namely, for cars, the overall result was not particularly sensitive to changes, while for urban buses, the overall result was hardly sensitive at all. Presumably, this is due to the relatively lower proportion of the manufacturing phase for urban buses. This is particularly interesting because it is in contrast to many sources in the introduction, suggesting both of these factors are strong determinants of the overall result.

The other effects listed in the literature review: charging time of day, noise, and other effects were beyond the scope of this study.

5.1. Policy Recommendations

Cars

From a CO2 and air pollutant emissions standpoint, ideally, Brazil should implement policies to encourage the increased adoption of electric cars. These could include taxation or feebate schemes based on exhaust CO2 emissions, subsidies on the purchase of electric vehicles, or free parking or use of carpooling lanes. As included in Rota 2030, manufacturers could be forced to include and encourage EVs by setting average emission levels targets (which decrease year by year) for all vehicles they sell each year, such as applies in the EU. Subsidies on locally manufactured fuels (including biofuels) should be removed or reduced

If electrification is not pursued, the use of ethanol should not be increased, by (at least) maintaining the current ≈50% proportion of ethanol (to petrol) sold.

Urban buses

The recommended course of action for urban buses is, superficially, the same as for cars: from a CO2 and air pollution emissions standpoint, urban buses should be electrified. Electrification of urban buses may be easier than cars because biodiesel is not as well established or widespread in Brazil, and there are far fewer vehicles, and those vehicles tend to be owned and operated by organizations with many vehicles each, limiting the number of affected stakeholders. Given the far lower consumption of urban buses combined, less regard needs to be paid to considerations of the grid or overall generation capacity; though given that buses may need (very) high power, some local improvements may be necessary. Electrification of urban buses could be encouraged by providing direct funding to operators or local authorities to buy electric buses or the necessary charging infrastructure. Furthermore, where routes are put to tender, these could have the condition of being operated by electric vehicles.

General

Several aspects not covered directly by this LCA are nevertheless important regarding the discussion on reducing the emissions from the transport sector. These include measures to reduce the per km fuel consumption (and air pollution emissions) of individual vehicles, reducing the use of vehicles through improved urban planning and improved cycling and walking infrastructure and encouraging public transport use rather than individual vehicles, which would have positive effects on all aspects considered in this LCA, as well as in other dimensions not covered (e.g., health, noise, economics, etc.).

Another aspect to consider is the international aspect of technological development. Brazil’s biofuel system is very well developed, with arguably significantly better environmental outcomes than other countries, especially those using corn-ethanol. If all other countries shift away from liquid-fueled, internal-combustion vehicles to electric vehicles, this could make Brazil a technology island; potentially cut off from foreign sources of major developments such as autonomous vehicles, forcing Brazil to either develop those technologies themselves or adapt them to local vehicles.

Moreover, it is important to bear in mind the economic relevance of the biofuel industry in Brazil and its linkages to other sectors such as automotive. As such, if an electrification strategy for the automotive sector were implemented, consideration should be paid to the associated conversion of the biofuel industry.

Biofuel feedstocks and land

In all cases, but especially where the policy focus remains on biofuels, it should be ensured that any additional land used to grow biofuel feedstocks should not have high stored carbon, i.e., should be Cerrado or plantation forest, or similar biomes, or even better that it must come from already cleared land, such as farmland used for other crops, degraded pastureland or brownfield sites. However, steps must be taken to ensure any resulting pressure on farmland does not result in land cleared for other crops, and thus indirect land-use change emissions and productive ecosystems and the services they offer are not degraded.

As included in the yearly increase in biofuel feedstock yields, efforts to increase the yield of biofuels per area of land should be undertaken, such as investing in technological and capacity building. It must be noted though that this study does not include the assessment of impacts on other parameters such as soil biodiversity and sustainability, which might be important to consider if higher yield intensities are sought for existing areas of feedstock cultivation.

Electricity system

If electrification is pursued, especially for cars, the country’s electricity generation capacity should be increased in line with the consumption of BEVs. This added capacity should be as low emission as possible. Additionally, policies to address the possible high load on the grid of vehicles being charged should be implemented. At their simplest, these could involve simple grid/generation capacity upgrades. Preferential tariffs for off-peak charging could be introduced, possibly also in conjunction with technologies to allow vehicles to take advantage of those tariffs and also potentially for them to be utilized for grid balancing. Furthermore, the availability of charging infrastructure away from home would encourage people to buy EVs in the first place by easing their range anxiety, but also to charge their cars during the day away from the morning and evening peaks.

5.2. Suggested Improvements to the LCA Methodology Applied

The following areas have been identified as areas that would improve the LCA.

A more complicated LUC calculation including the agricultural land-use elasticities and yields of biofuels differentiated by land type.

Inclusion of modal/behavioral shift aspects to allow the effects of reduced travel or modal shifts to be included in scenarios.

Inclusion of electricity emissions intensities in all aspects of the LCA (e.g., manufacturing) to better reflect changes to the system, along with better representation of the place of manufacture (and CO2 emissions) of vehicle components.

Consideration of the economic effects of hybrids and BEVs in Brazil, and of the expansion in electricity generation necessary for the electrification scenarios.

Include a fleet model for vehicles.

Inclusion of further effects such as water use (especially for biofuel feedstock production), toxicity, and the use of other key materials