Standardization Framework for Sustainability from Circular Economy 4.0

Abstract

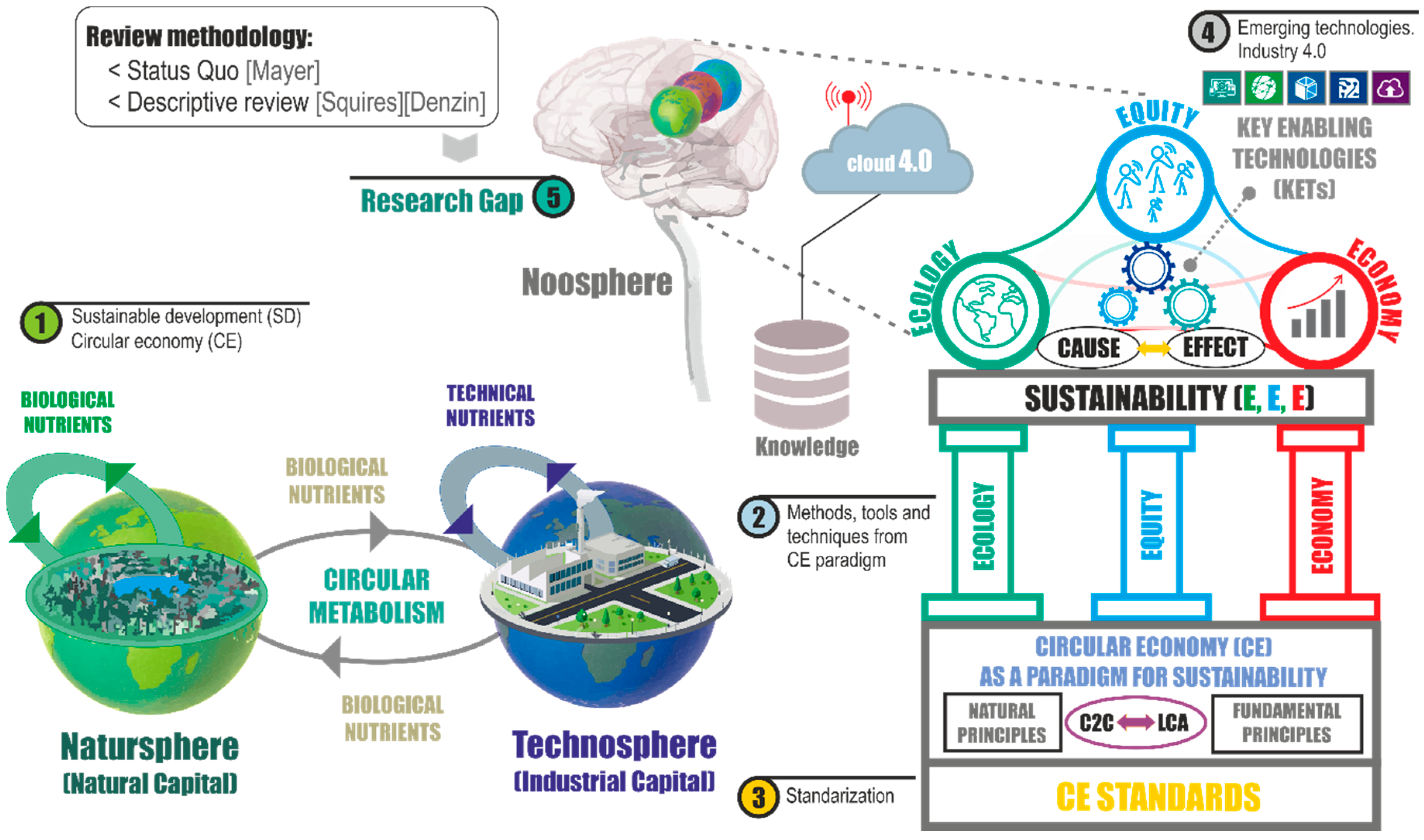

:1. Introduction

2. Literature Review

2.1. Sustainable Development and Circular Economy

2.2. Circular Economy Methods, Techniques, and Tools from the TBL

2.3. Circular Economy Standardization

2.4. Emerging Technologies in Industry 4.0

2.5. Research Gap

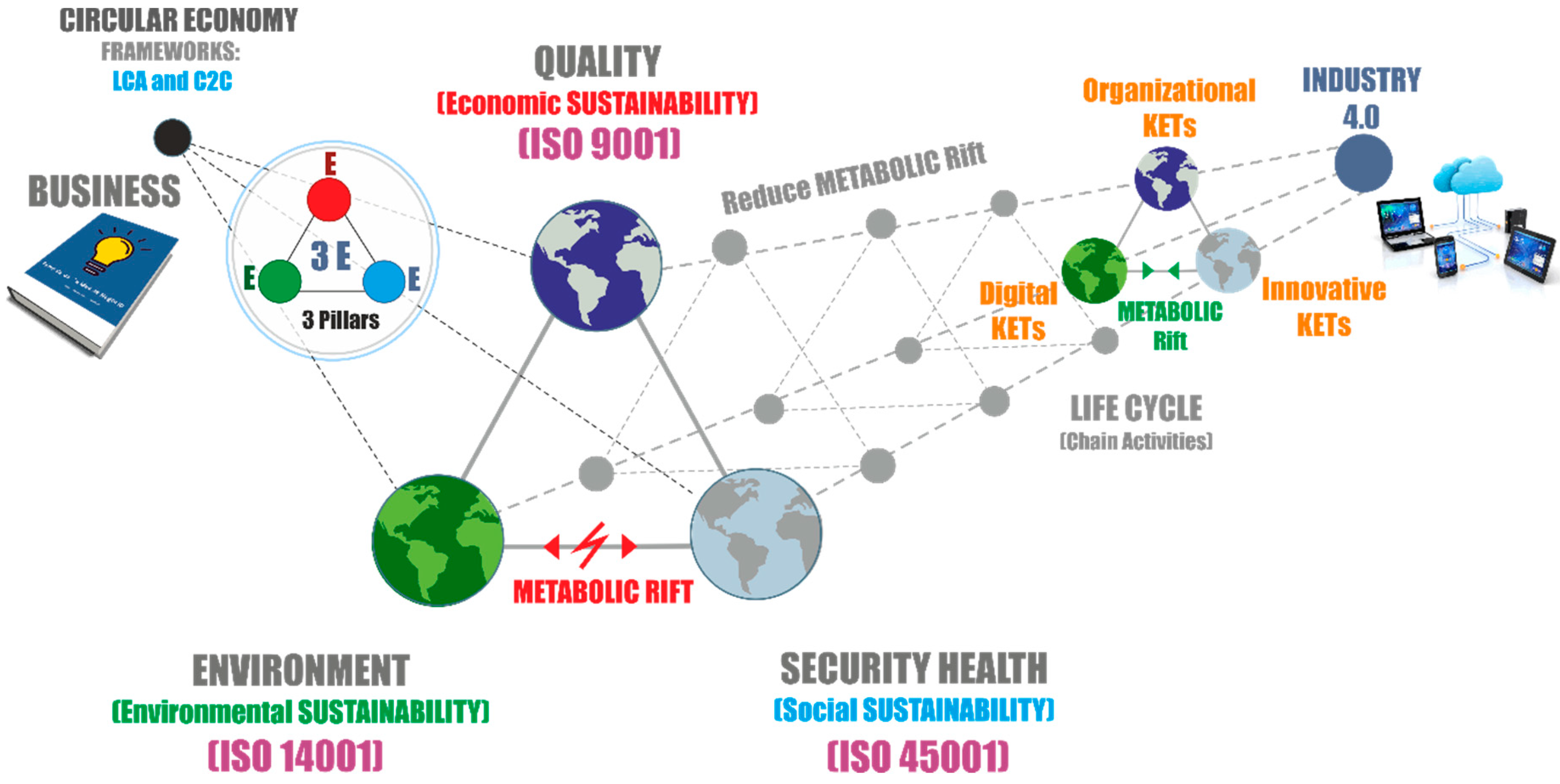

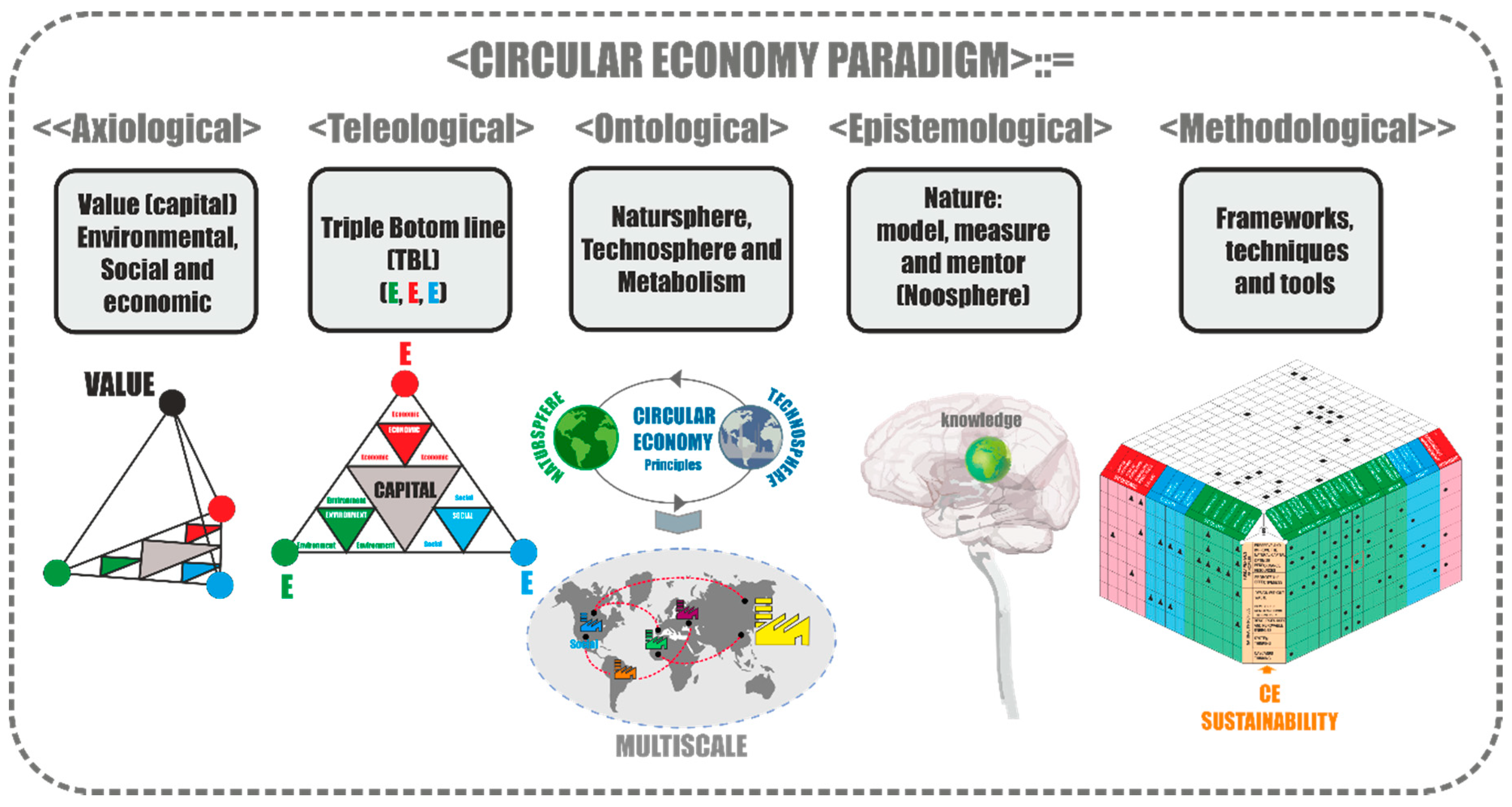

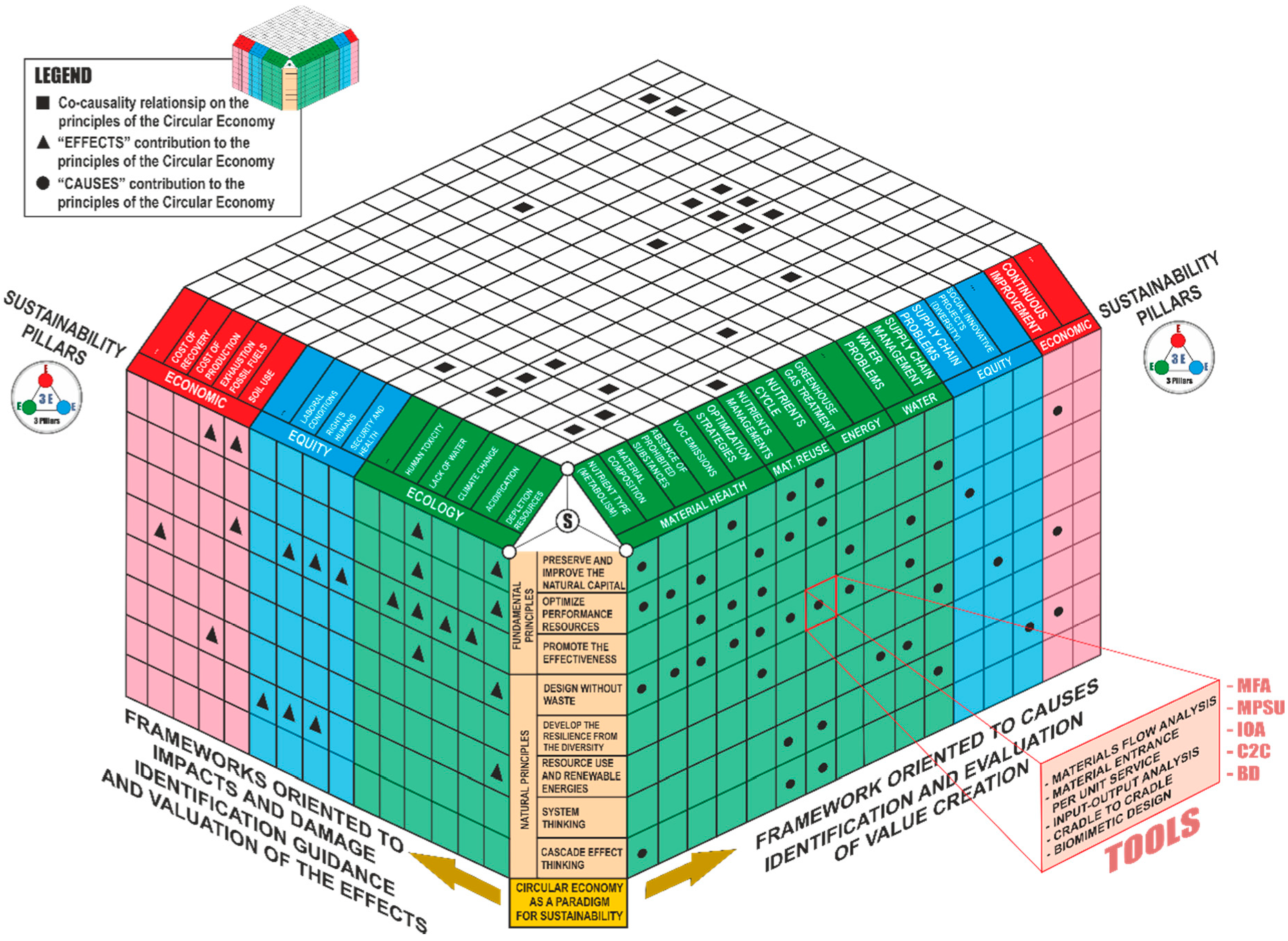

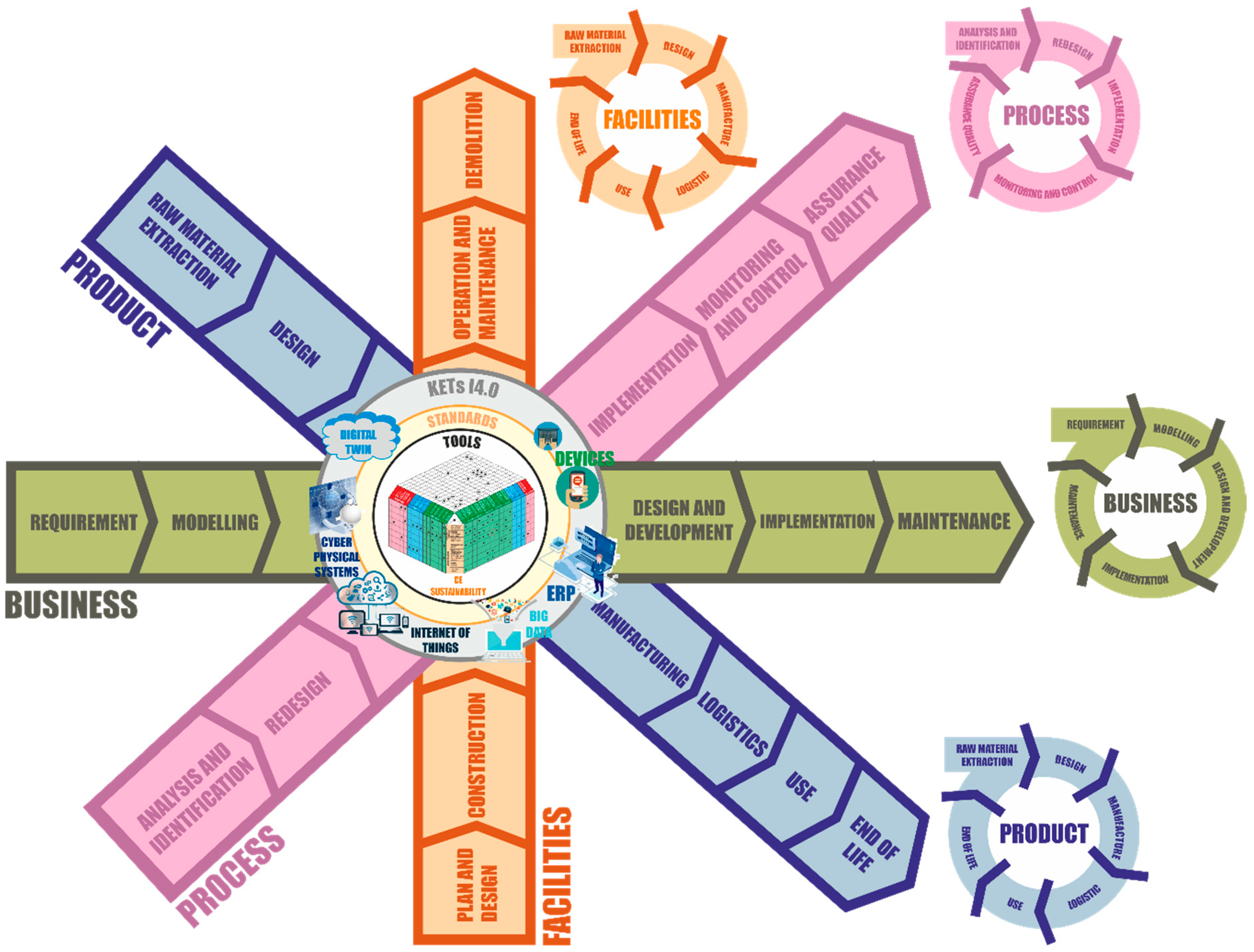

3. Conceptual Framework

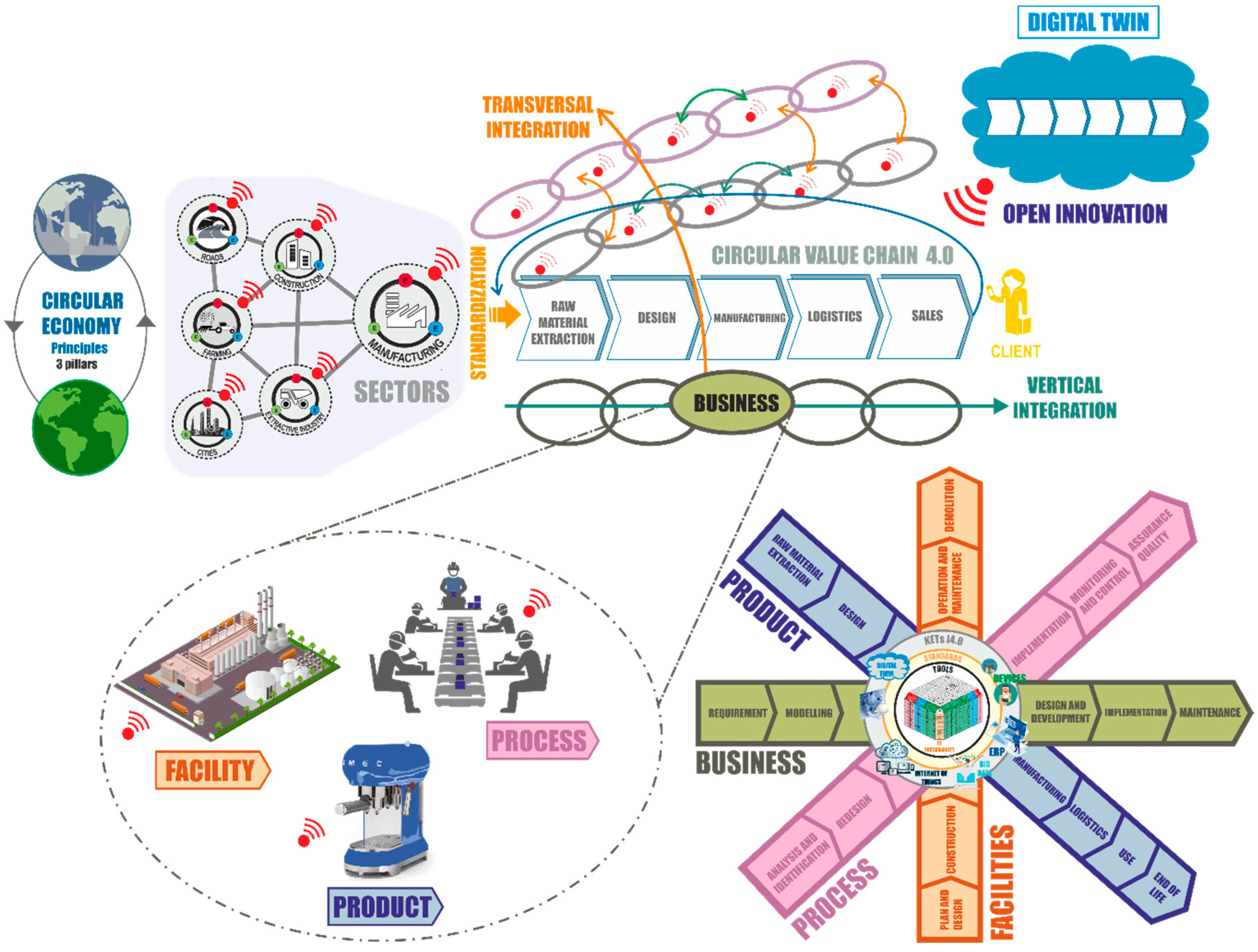

4. Case Study

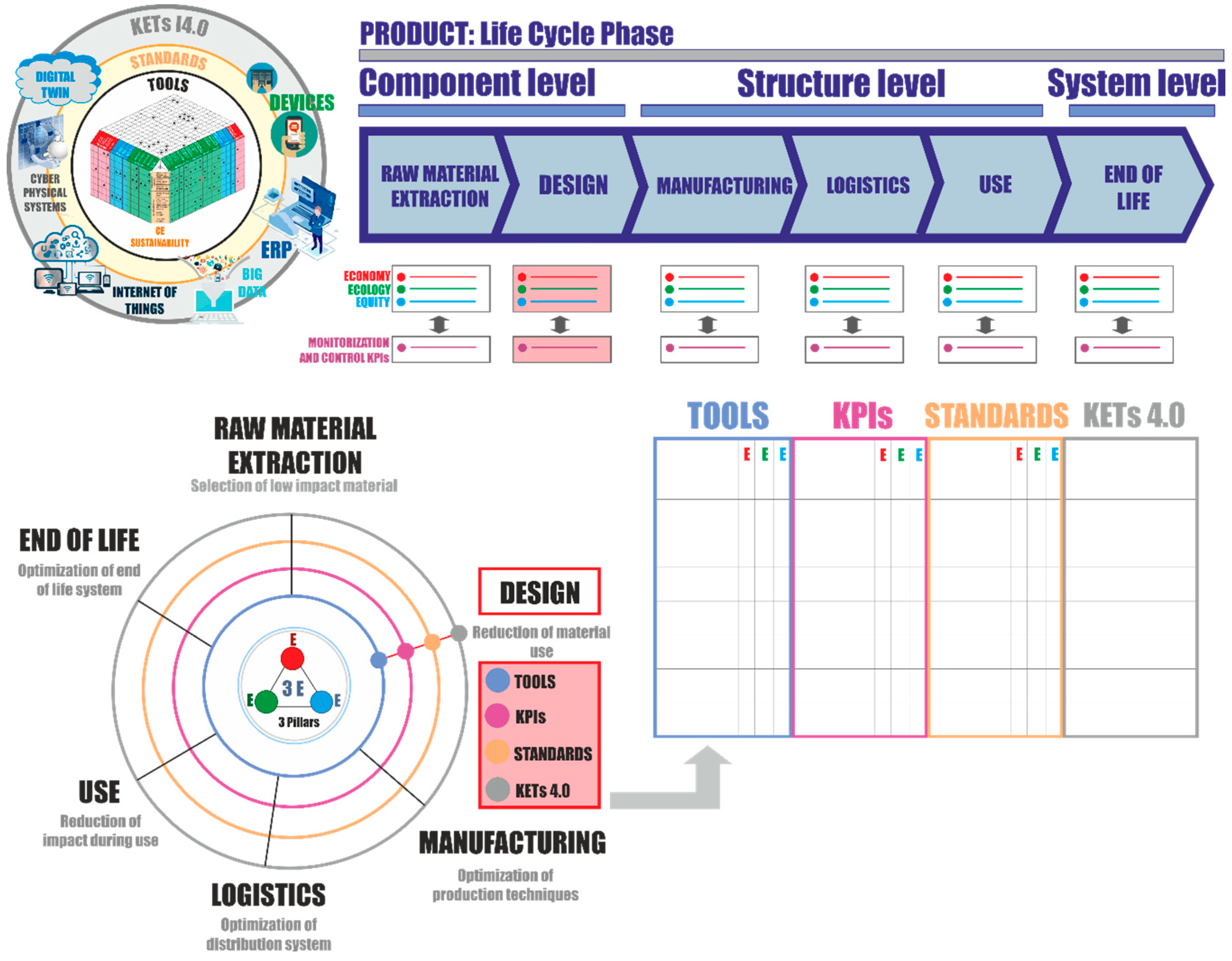

4.1. Methodological Framework for a Product

4.2. Result and Discussion

4.2.1. Product Design Phase for Tools

4.2.2. Product Design Phase for Key Performance Index

4.2.3. Product Design Phase for Standard

4.2.4. Product Design Phase for Key Enabling Technologies (KETs)

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- González de Molina, M.; Toledo, V.M. The Social Metabolism—A Socio-Ecological Theory of Historical Change; Springer: Berlin, Germany, 2014; Volume 3, ISBN 978-3-319-06357-7. [Google Scholar]

- Esposito, M.; Tse, T.; Soufani, K. Introducing a circular economy: New Thinking with new managerial and policy implications. Calif. Manage. Rev. 2018, 60, 5–19. [Google Scholar] [CrossRef]

- Kalmykova, Y.; Sadagopan, M.; Rosado, L. Circular economy—From review of theories and practices to development of implementation tools. Resour. Conserv. Recycl. 2018, 135, 190–201. [Google Scholar] [CrossRef]

- Loiseau, E.; Saikku, L.; Antikainen, R.; Droste, N.; Hansjürgens, B.; Pitkänen, K.; Leskinen, P.; Kuikman, P.; Thomsen, M. Green economy and related concepts: An overview. J. Clean. Prod. 2016, 139, 361–371. [Google Scholar] [CrossRef]

- Zinck, S.; Ayed, A.-C.; Niero, M.; Head, M.; Wellmer, F.-W.; Scholz, R.W.; Morel, S. Life cycle management approaches to support circular economy. In Designing Sustainable Technologies, Products and Policies; Springer International Publishing: Cham, Switzerland, 2018; pp. 3–9. [Google Scholar]

- Niero, M.; Rivera, X.C.S. The role of life cycle sustainability assessment in the implementation of circular economy principles in organizations. Procedia CIRP 2018, 69, 793–798. [Google Scholar] [CrossRef]

- Jensen, J.P.; Prendeville, S.M.; Bocken, N.M.P.; Peck, D. Creating sustainable value through remanufacturing: Three industry cases. J. Clean. Prod. 2019, 218, 304–314. [Google Scholar] [CrossRef]

- Ryen, E.G.; Gaustad, G.; Babbitt, C.W.; Babbitt, G. Ecological foraging models as inspiration for optimized recycling systems in the circular economy. Resour. Conserv. Recycl. 2018, 135, 48–57. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M.; Anastas, P.T.; Zimmerman, J.B. Applying the principles of green engineering to cradle-to-cradle design: Industry is using these tenets and principles to work toward sustainability. Environ. Sci. Tech. 2003, 37, 434A–441A. [Google Scholar] [CrossRef]

- Gamage, A.; Hyde, R. A model based on Biomimicry to enhance ecologically sustainable design. Archit. Sci. Rev. 2012, 55, 224–235. [Google Scholar] [CrossRef]

- Mi, Z.; Coffman, D.M. The sharing economy promotes sustainable societies. Nat. Commun. 2019, 10, 1214. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Kuhn, T.S. The Structure of Scientific Revolutions, 3rd ed.; University of Chicago Press: Chicago, IL, USA, 1962; ISBN 9781912281589. [Google Scholar]

- Kivunja, C.; Kuyini, A.B. Understanding and applying research paradigms in educational contexts. Int. J. High. Educ. 2017, 6, 26. [Google Scholar] [CrossRef]

- Bjørn, A.; Hauschild, M.Z. Cradle to cradle and LCA. In Life Cycle Assessment: Theory and Practice; Springer International Publishing: Cham, Switzerland, 2017; pp. 605–631. ISBN 9783319564753. [Google Scholar]

- Halbe, J.; Adamowski, J.; Pahl-Wostl, C. The role of paradigms in engineering practice and education for sustainable development. J. Clean. Prod. 2015, 106, 272–282. [Google Scholar] [CrossRef]

- Pauliuk, S.; Hertwich, E.G. Socioeconomic metabolism as paradigm for studying the biophysical basis of human societies. Ecol. Econ. 2015, 119, 83–93. [Google Scholar] [CrossRef]

- Reich-Weiser, C.; Vijayaraghavan, A.; Dornfeld, D. Appropriate use of green manufacturing frameworks. In Proceedings of the 17th CIRP LCE Conference, Hefei, China, 19–21 May 2010; pp. 196–201. [Google Scholar]

- Korhonen, J.; Nuur, C.; Feldmann, A.; Birkie, S.E. Circular economy as an essentially contested concept. J. Clean. Prod. 2018, 175, 544–552. [Google Scholar] [CrossRef]

- Vanhamaki, S.; Medkova, K.; Malamakis, A.; Kontogianni, S.; Marisova, E.; Dellago, D.H.; Moussiopoulos, N. Bio-based circular economy in European national and regional strategies. Int. J. Sustain. Dev. Plan. 2019, 14, 31–43. [Google Scholar] [CrossRef]

- Pauliuk, S. Critical appraisal of the circular economy standard BS 8001:2017 and a dashboard of quantitative system indicators for its implementation in organizations. Resour. Conserv. Recycl. 2018, 129, 81–92. [Google Scholar] [CrossRef]

- Escrig-Tena, A.B.; Garcia-Juan, B.; Segarra-Ciprés, M. Drivers and internalisation of the EFQM excellence model. Int. J. Qual. Reliab. Manag. 2019, 36, 398–419. [Google Scholar] [CrossRef]

- Pohle, A.; Blind, K.; Neustroev, D. The impact of international management standards on academic research. Sustain. 2018, 10, 4656. [Google Scholar] [CrossRef]

- Veugelers, R.; Cincera, M.; Frietsch, R.; Rammer, C.; Schubert, T.; Pelle, A.; Renda, A.; Montalvo, C.; Leijten, J. The impact of Horizon 2020 on innovation in Europe. Intereconomics 2015, 50, 4–30. [Google Scholar] [CrossRef]

- Mayer, P. Guidelines for Writing a Review Article; Zurich-Basel Plant Science Center: Zurich, Switzerland, 2009; Volume 82, pp. 443–446. [Google Scholar]

- Squires, J.E.; Estabrooks, C.A.; Gustavsson, P.; Wallin, L. Individual determinants of research utilization by nurses: A systematic review update. Implement. Sci. 2011, 6, 1. [Google Scholar] [CrossRef] [PubMed]

- Denzin, N.K.; Lincoln, Y.S. Handbook of Qualitative Research; SAGE Publications: Los Angeles, CA, USA, 2011; ISBN 978-1-4129-7417-2. [Google Scholar]

- Pearce, D.W.; Turner, R. Economics of Natural Resources and the Environment; Johns Hopkins University Press: Baltimore, MD, USA, 1989. [Google Scholar]

- Ellen MacArthur Foundation. Growth Within: A Circular Economy Vision for a Competitive Europe; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Ellen MacArthur Foundation. Towards the Circular Economy; Ellen MacArthur Foundation: Cowes, UK, 2013; pp. 1–96. [Google Scholar]

- Kobza, N.; Schuster, A. Building a responsible Europe—The value of circular economy. IFAC-PapersOnLine 2016, 49, 111–116. [Google Scholar] [CrossRef]

- Oliveira Neto, G.C.D.; Pinto, L.F.R.; Amorim, M.P.C.; Giannetti, B.F.; Almeida, C.M.V.B. de A framework of actions for strong sustainability. J. Clean. Prod. 2018, 196, 1629–1643. [Google Scholar] [CrossRef]

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Elia, V.; Gnoni, M.G.; Tornese, F. Measuring circular economy strategies through index methods: A critical analysis. J. Clean. Prod. 2017, 142, 2741–2751. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Tóth Szita, K. The application of life cycle assessment in circular economy. Hungarian Agric. Eng. 2017, 31, 5–9. [Google Scholar] [CrossRef]

- Spangenberg, J.H.; Omann, I.; Hinterberger, F. Sustainable growth criteria: Minimum benchmarks and scenarios for employment and the environment. Ecol. Econ. 2002, 42, 429–443. [Google Scholar] [CrossRef]

- Daozhong, C.; Qingli, Z.; Jie, W.; Xiaozhi, Z. Comparative analysis of ecological rucksack between open-pit and underground coal mine. Energy Procedia 2011, 5, 1116–1120. [Google Scholar] [CrossRef] [Green Version]

- Suh, S.; Kagawa, S. Industrial ecology and input-output economics: An introduction. Econ. Syst. Res. 2005, 17, 349–364. [Google Scholar] [CrossRef]

- Liwarska-Bizukojc, E.; Bizukojc, M.; Marcinkowski, A.; Doniec, A. The conceptual model of an eco-industrial park based upon ecological relationships. J. Clean. Prod. 2009, 17, 732–741. [Google Scholar] [CrossRef]

- Jacobsen, N.B. Industrial symbiosis in Kalundborg, Denmark: A quantitative assessment of economic and environmental aspects. J. Ind. Ecol. 2008, 10, 239–255. [Google Scholar] [CrossRef]

- Hannon, B. The structure of ecosystems. J. Theor. Biol. 1973, 41, 535–546. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Li, Y.; Zheng, H. Ecological network analysis of energy metabolism in the Beijing-Tianjin-Hebei (Jing-Jin-Ji) urban agglomeration. Ecol. Modell. 2017, 351, 51–62. [Google Scholar] [CrossRef]

- Rosen, M.A.; Dincer, I. Exergy as the confluence of energy, environment and sustainable development. Exergy 2001, 1, 3–13. [Google Scholar] [CrossRef]

- Odum, H.T. Environmental Accounting. Emergy and Environmental Decision Making; John Wiley Sons: Hoboken, NJ, USA, 1996; p. 370. [Google Scholar]

- Loiseau, E.; Junqua, G.; Roux, P.; Bellon-Maurel, V. Environmental assessment of a territory: An overview of existing tools and methods. J. Environ. Manag. 2012, 112, 213–225. [Google Scholar] [CrossRef]

- De Pauw, I.; Kandachar, P.; Karana, E.; Peck, D.; Wever, R. Nature inspired design: Strategies towards sustainability. In Proceedings of the Knowledge Collaboration & Learning for Sustainable Innovation ERSCP-EMSU Conference, Delft, The Netherlands, 25–28 October 2010; pp. 1–21. [Google Scholar]

- Andersen, M.S. An introductory note on the environmental economics of the circular economy. Sustain. Sci. 2007, 2, 133–140. [Google Scholar] [CrossRef]

- Norris, G.A. Integrating life cycle cost analysis and LCA. Int. J. Life Cycle Assess. 2001, 6, 118–120. [Google Scholar]

- Vygotsky, L. Mind in Society: The Development of Higher Psychological Processes; Harvard University Press: Cambridge, MA, USA, 1980. [Google Scholar]

- Weidema, B.P. The integration of economic and social aspects in life cycle impact assessment. Int. J. Life Cycle Assess. 2006, 11, 89–96. [Google Scholar] [CrossRef]

- Boons, F.; Howard-Grenville, J.A. The Social Embeddedness of Industrial Ecology; Edward Elgar: Cheltenham, UK, 2009; ISBN 9781848449060. [Google Scholar]

- Moya, I. Escenario de Estandarización en Economía Circular; UNE Normalización Española: Madrid, Spain, 2018. [Google Scholar]

- Pagoropoulos, A.; Pigosso, D.C.A.; McAloone, T.C. The emergent role of digital technologies in the circular economy: A Review. Procedia CIRP 2017, 64, 19–24. [Google Scholar] [CrossRef] [Green Version]

- Dujin, A.; Geissler, C.; Horstkötter, D. Industry 4.0. The New Industrial Revolution. How Europe Will Succeed; Roland Berger: Munich, Germany, 2014; pp. 1–24. [Google Scholar]

- Wang, L.; Törngren, M.; Onori, M. Current status and advancement of cyber-physical systems in manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Uhlemann, T.H.-J.; Lehmann, C.; Steinhilper, R. The digital twin: Realizing the cyber-physical production system for industry 4.0. Procedia CIRP 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Gligoric, N.; Krco, S.; Hakola, L.; Vehmas, K.; De, S.; Moessner, K.; Jansson, K.; Polenz, I.; Van Kranenburg, R. Smarttags: IoT product passport for circular economy based on printed sensors and unique item-level identifiers. Sensors 2019, 19, 586. [Google Scholar] [CrossRef] [Green Version]

- Liebel, G.; Marko, N.; Tichy, M.; Leitner, A.; Hansson, J. Model-based engineering in the embedded systems domain: An industrial survey on the state-of-practice. Softw. Syst. Model. 2018, 17, 91–113. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Khajavi, S.H.; Partanen, J. The direct digital manufacturing (r)evolution: Definition of a research agenda. Oper. Manag. Res. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Marina, L.A.; Trasnea, B.; Grigorescu, S.M. A multi-platform framework for artificial intelligence engines in automotive systems. In Proceedings of the 22nd International Conference on System Theory, Control and Computing, ICSTCC 2018, Sinaia, Romania, 10–12 October; pp. 559–564.

- Posada, J.; Toro, C.; Barandiaran, I.; Oyarzun, D.; Stricker, D.; Amicis, R.; Pinto, E.; Eisert, P.; Döllner, J.; Vallarino, I. Visual computing as key enabling technology for industry 4.0 & industrial internet. IEEE Comput. Graph. Appl. 2015, 35, 26–40. [Google Scholar]

- Halenar, I.; Juhas, M.; Juhasova, B.; Borkin, D. Virtualization of production using digital twin technology. In Proceedings of the 20th International Carpathian Control Conference (ICCC), Kraków-Wieliczka, Poland, 26–29 May 2019; pp. 1–5. [Google Scholar]

- Verhoef, P.C.; Stephen, A.T.; Kannan, P.K.; Luo, X.; Abhishek, V.; Andrews, M.; Bart, Y.; Datta, H.; Fong, N.; Hoffman, D.L.; et al. Consumer connectivity in a complex, technology-enabled, and mobile-oriented world with smart products. J. Interact. Mark. 2017, 40, 1–8. [Google Scholar] [CrossRef]

- Jiang, P.; Leng, J. The configuration of social manufacturing: A social intelligence way toward service-oriented manufacturing. In Proceedings of the International Conference on Innovative Design and Manufacturing ICIDM 2016, Auckland, New Zealand, 24–26 January 2016. [Google Scholar]

- Tao, F.; Cheng, Y.; Zhang, L.; Nee, A.Y.C. Advanced manufacturing systems: Socialization characteristics and trends. J. Intell. Manuf. 2017, 28, 1079–1094. [Google Scholar] [CrossRef]

- Zhu, K.; Kraemer, K.L. E-commerce metrics for net-enhanced organizations: Assessing the value of e-commerce to firm performance in the manufacturing sector. Inf. Syst. Res. 2002, 13, 275–295. [Google Scholar] [CrossRef] [Green Version]

- He, M.; Devine, L.; Zhuang, J. Perspectives on cybersecurity information sharing among multiple stakeholders using a decision-theoretic approach. Risk Anal. 2018, 38, 215–225. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Z.H.; Liu, X.F.; Gong, Y.J.; Zhang, J.; Chung, H.S.H.; Li, Y. Cloud computing resource scheduling and a survey of its evolutionary approaches. ACM Comput. Surv. 2015, 47, 63. [Google Scholar] [CrossRef] [Green Version]

- Laborie, F.; Røed, O.C.; Engdahl, G.; Camp, A. Extracting value from data using an industrial data platform to provide a foundational digital twin. In Proceedings of the Annual Offshore Technology Conference 2019, Houston, TX, USA, 6–9 May 2019. [Google Scholar]

- De Marchi, V.; Di Maria, E. Sustainability Strategies, Investments in Industry 4.0 and Circular Economy Results; “Marco Fanno” Working Papers; Dipartimento di Scienze Economiche “Marco Fanno”: Padova, Italy, 2019. [Google Scholar]

- Cheutet, V.; Sekhari, A.; Corbeaux, N. PLM and BIM approach to support information management in nuclear decommissioning: A synthesis. In Proceedings of the IFIP Advances in Information and Communication Technology; Springer: Berlin, Germany, 2018; pp. 104–114. [Google Scholar]

- Martín Gómez, A.M.; Aguayo González, F.; Marcos Bárcena, M. Smart eco-industrial parks: A circular economy implementation based on industrial metabolism. Resour. Conserv. Recycl. 2018, 135, 58–69. [Google Scholar] [CrossRef]

- Fer, I.; Kelly, R.; Moorcroft, P.R.; Richardson, A.D.; Cowdery, E.M.; Dietze, M.C. Linking big models to big data: Efficient ecosystem model calibration through Bayesian model emulation. Biogeosciences 2018, 15, 5801–5830. [Google Scholar] [CrossRef] [Green Version]

- Loconto, A.; Barbier, M. Creating actionable knowledge for sustainability: A case of “Standards in the making”. Res. Rural Sociol. Dev. 2017, 24, 115–133. [Google Scholar]

- Sales, B.; Darmois, E.; Papadimitriou, D.; Bourse, D. A systematic approach for closing the research to standardization gap. In The Future Internet Assembly; Springer: Berlin/Heidelberg, Germany, 2012; pp. 18–29. [Google Scholar]

- Mauser, W.; Klepper, G.; Rice, M.; Schmalzbauer, B.S.; Hackmann, H.; Leemans, R.; Moore, H. Transdisciplinary global change research: The co-creation of knowledge for sustainability. Curr. Opin. Environ. Sustain. 2013, 5, 420–431. [Google Scholar] [CrossRef] [Green Version]

- Tecchio, P.; McAlister, C.; Mathieux, F.; Ardente, F. In search of standards to support circularity in product policies: A systematic approach. J. Clean. Prod. 2017, 168, 1533–1546. [Google Scholar] [CrossRef]

- Folmer, E.; Berends, W.; Luttighuis, P.O.; Van Hillegersberg, J. Top is research on quality of transaction standards: A structured literature review to identify a research gap. In Proceedings of the 6th International Conference on Standardization and Innovation in Information Technology SIIT 2009, Tokyo, Japan, 8–10 September 2009; pp. 65–78. [Google Scholar]

- Ding, A.Y.; Korhonen, J.; Savolainen, T.; Kojo, M.; Ott, J.; Tarkoma, S.; Crowcroft, J. Bridging the gap between internet standardization and networking research. Comput. Commun. Rev. 2013, 44, 56–62. [Google Scholar] [CrossRef]

- Fomin, V.; Keil, T. Standardization: Bridging the gap between economic and social theory. In Proceedings of the International Conference on Information Systems, Brisbane, Australia, 10—13 December 2000; pp. 206–217. [Google Scholar]

- Le May, A.; Mulhall, A.; Alexander, C. Bridging the research-Practice gap: Exploring the research cultures of practitioners and managers. J. Adv. Nurs. 1998, 28, 428–437. [Google Scholar] [CrossRef] [PubMed]

- Lanfang, L.; Issam, S.; Chong, W.K.; Christopher, H. Integrating G2G, C2C and resource flow analysis into life cycle assessment framework: A case of construction steel′s resource loop. Resour. Conserv. Recycl. 2015, 102, 143–152. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W.; Bollinger, A. Cradle-to-cradle design: Creating healthy emissions—A strategy for eco-effective product and system design. J. Clean. Prod. 2007, 15, 1337–1348. [Google Scholar] [CrossRef]

- Reijnders, L. Are emissions or wastes consisting of biological nutrients good or healthy? J. Clean. Prod. 2008, 16, 1138–1141. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M.; Anastas, P.T.; Zimmerman, J.B. Applying the principles of green engineering to Cradle-To-Cradle design. Environ. Sci. Technol. 2003, 37, 434A–441A. [Google Scholar] [CrossRef] [Green Version]

- Bach, V.; Minkov, N.; Finkbeiner, M. Assessing the ability of the Cradle to Cradle CertifiedTM Products Program to reliably determine the environmental performance of products. Sustainability 2018, 10, 1562. [Google Scholar] [CrossRef] [Green Version]

- Niero, M.; Hauschild, M.Z. Closing the loop for packaging: Finding a framework to operationalize circular economy strategies. Procedia CIRP 2017, 61, 685–690. [Google Scholar] [CrossRef] [Green Version]

- Scheepens, A.E.; Vogtländer, J.G.; Brezet, J.C. Two life cycle assessment (LCA) based methods to analyse and design complex (regional) circular economy systems. Case: Making water tourism more sustainable. J. Clean. Prod. 2016, 114, 257–268. [Google Scholar] [CrossRef]

- Despeisse, M.; Ball, P.D.; Evans, S.; Levers, A. Industrial ecology at factory level—A conceptual model. J. Clean. Prod. 2012, 31, 30–39. [Google Scholar] [CrossRef] [Green Version]

- Huang, A. A Framework and Metrics for Sustainable Manufacturing Performance Evaluation at the Production Line, Plant and Enterprise Levels. Ph.D. Thesis, University of Kentucky, Lexington, KY, USA, July 2017. [Google Scholar]

- Nosratabadi, S.; Mosavi, A.; Keivani, R.; Aram, F. State of the art survey of deep learning and machine learning models for smart cities and urban sustainability. Preprints 2019. [Google Scholar] [CrossRef] [Green Version]

- Bertoni, A.; Dasari, S.K.; Hallstedt, S.I.; Petter, A. Model-based decision support for value and sustainability assessment: Applying machine learning in aerospace product development. In Proceedings of the 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; pp. 2585–2596. [Google Scholar]

| Tools for Circular Product: Design Phase |  | Key | CE Principles * | Triple Bottom Line (TBL) | Value Creation (+) | Reduced Damage (-) | ||

|---|---|---|---|---|---|---|---|---|

| E | E | E | ||||||

| Material Flow Analysis | MFA | (1) (2) | X | X | ||||

| Life Cycle Assessment | LCA | (1) (2) (3) | X | X | ||||

| Material input per service unit | MIPSU | (1) (2) | X | X | ||||

| Ecological rucksack | ER | (1) | X | X | ||||

| Water circularity (water footprint) | WC | (2) | X | X | ||||

| Longevity Indicator | LI | (2) | X | X | ||||

| Input–Output Analysis | IOA | (2) | X | X | X | |||

| Ecological Networks Analysis | ENA | (1) (3) | X | X | ||||

| Embedded Energy Analysis | EEA | (2) | X | X | ||||

| Emergy Analysis | EA | (2) | X | X | ||||

| Exergy Analysis | ExA | (2) | X | X | ||||

| Analysis of Social Exergy | ASEx | (2) | X | X | X | |||

| Sankey diagram | SD | (2) | X | X | ||||

| Substance Flow Analysis | SFA | (2) | X | X | ||||

| Substance Analysis from C2C | SA | (2) | X | X | ||||

| Bioinspired or Biomimetic Design | BD | (1) | X | X | ||||

| Life cycle cost analysis | LCCA | (2) (3) | X | X | ||||

| Economic Network Analysis | EcNA | (2) (3) | X | X | ||||

| Cost-Benefit Analysis | CBA | (2) | X | X | X | |||

| Eco-costs/Relationship | Ec | (2) | X | X | X | |||

| Eco-efficient Value Creation | EcVC | (1) (2) | X | X | ||||

| Actor Network Theory | ANT | (1) (2) | X | X | X | X | ||

| Socio-constructivism | SC | (1) (3) | X | X | ||||

| Social Life Cycle Assessment | S-LCA | (2) (3) | X | X | ||||

| Social Network Analysis (SNA) | SNA | (1) (2) | X | X | ||||

| Cradle to Cradle (C2C) | C2C | (1) (2) (3) | X | X | X | X | X | |

| Product Component Level | Product Structure Level | Product System Level | |||

|---|---|---|---|---|---|

| Raw material extraction | Design | Manufacturing | Logistics | Use | End of life |

| Transversal tools (E, E, E) * | |||||

| Life Cycle Assessment (LCA) (E, E, E) | |||||

| Cradle to Cradle (C2C) (E, E, E) | |||||

| Ecological Network Analysis (ENA) (E, E, E) | |||||

| Material Flow Analysis (MFA)/ Substance Flow Analysis (SFA) (E, E, E) | |||||

| Embedded Energy Analysis (EEA)/ Emergy Analysis (EA)/ Exergy Analysis (ExA) (E, E, E) | |||||

| Particular tools (E, E, E) * | |||||

| ● Bioinspired or biomimetic design | ● Actor Network Theory | ● Input–Output Analysis | |||

| ● Material input per service unit | ● Cost-benefit analysis | ● Longevity indicator | |||

| ● Socio-constructivism | ● Social Network Analysis | ● Social Life Cycle Assessment | |||

| ● Life cycle cost analysis | ● Eco-efficient Value Creation | ||||

| Id. | Indicator for Circular Product: Design Phase | Triple Bottom Line (TBL) * | ||

|---|---|---|---|---|

| E | E | E | ||

| KPI01 | Total weight of the use of raw material in the product [kg] | X | ||

| KPI02 | Raw material use efficiency in the packaging [%] | X | ||

| KPI03 | Total weight of the packaging material used [kg material] | X | ||

| KPI04 | Mass of restricted material used [kg] | X | ||

| KPI05 | Energy consumption [kWh] | X | ||

| KPI06 | Use of renewable energy [MJ eq] | X | ||

| KPI07 | Number of projects carried out [n] | X | X | |

| KPI08 | CAD-drawing received on time [weeks] | X | ||

| KPI09 | On-time delivery [weeks] | X | ||

| KPI10 | Consideration of real costs: externalities [€] | X | ||

| KPI11 | Efficiency in energy use [%] | X | ||

| KPI12 | Total amount of water consumed [m3] | X | ||

| KPI13 | Water use efficiency [%] | X | ||

| KPI14 | Returned material to the product [%] | X | ||

| KPI15 | Consumables recovered [%] | X | ||

| KPI16 | Used packaging material recovered [%] | X | ||

| KPI17 | Used raw material/recovered scrap parts [%] | X | ||

| KPI18 | Recovered energy returned to the product [%] | X | ||

| KPI19 | Use of recycled water returned to the product [%] | X | ||

| KPI20 | Waste generation intensity [kg/h] | X | ||

| KPI21 | Amount of greenhouse gases generated [kgCO2] | X | ||

| KPI22 | Biological nutrients, supra-recycled technicians [kg] | X | X | |

| KPI23 | Learning cost [€] | X | X | |

| KPI24 | Operating costs [€] | X | ||

| KPI25 | Patent application [n] | X | ||

| KPI26 | Value added and job [projects realized/month] | X | ||

| KPI27 | Corporate Social Responsibility (CSR Brand value) | X | X | |

| KPI28 | Worker safety and health [nº accident] | X | ||

| KPI29 | Adaptation of jobs for people with special needs | X | ||

| KPI30 | Worker efficiency (Ratio of personal work time/defined assistance time) | X | X | |

| Product Component Level | Product Structure Level | Product System Level | |||

|---|---|---|---|---|---|

| Raw material extraction | Design | Manufacturing | Logistics | Use | End of life |

| Transversal KPIs (E, E, E) * | |||||

| Raw material use efficiency in product [%] (E, E, E) | |||||

| Energy consumption [kWh] (E, E, E) | |||||

| Water use efficiency [%] (E, E, E) | |||||

| Corporate Social Responsibility (CSR Brand value) (E, E, E) | |||||

| Patent application [n] (E, E, E) | |||||

| Particular KPIs (E, E, E) * | |||||

| ● Number of projects carried out [n] | ● On-time delivery [weeks] | ● Efficiency in the packaging [%] | |||

| ● Learning cost [€] | ● Operating costs [€] | ● Waste generation intensity [kg/h] | |||

| ● Worker efficiency [%] | ● Adaptation of jobs for people with special needs [competency profile] | ● Consumables recovered [%] | |||

| ● CAD-drawing received on time [weeks] | ● Amount of greenhouse gases generated [kgCO2] | ● Biological nutrients, supra-recycled technicians [kg] | |||

| ● Worker safety and health [nº accident] | ● Waste generation intensity [kg/h] | ||||

| Standards for Circular Product: Design Phase | Type | Triple Bottom Line (TBL) | Value Creation (+) | Reduced Damage (-) | ||

|---|---|---|---|---|---|---|

| E | E | E | ||||

| ISO/TC Circular Economy | T | X | X | X | X | X |

| ISO/TC 207 Environmental Management | T | X | X | |||

| CEN/CLC/JTC 10 Efficiency in the use of materials | T | X | X | X | X | |

| PNE-prEN IEC 62959:2018. Environmentally Conscious Design (ECD) | T | X | X | |||

| ISO 8887-1:2017 Technical product documentation | T | X | X | X | ||

| ISO 10303—the STEP Standard for Product Data Exchange | T | X | X | |||

| ISO/TC 176. Quality management and quality assurance | T | X | X | |||

| ISO/TC 279. Innovation management | T | X | X | |||

| ISO/TC 324. Sharing Economy | T | X | X | X | ||

| Directive 2009/125/CE (RD 187/2011) Eco-design | P | X | X | |||

| ANSI/AAMI HE74:2001 Human Factors Design Process | T | X | X | X | ||

| ISO/TC 260. Human Resource Management (ISO 30400, ISO 30405, ISO 30408, ISO 30409) | T | X | X | |||

| ISO/TC 283. Occupational health and safety management (ISO 45001:2018) | T | X | X | |||

| ISO/TC159/SC4. Ergonomics of human-system interaction | T | X | X | |||

| M/495 Energy efficiency ErP | P | X | X | |||

| IEC/TC 111. Environmental standardization for electrical and electronic products and systems | P | X | X | |||

| UNE-EN 62430 Ecological design of electrical and electronic products | P | X | X | |||

| Cradle to Cradle Certified™ Product Standard | P | X | X | X | ||

| ASTM D6400-04 Standard specification for compostable plastics. | P | X | X | |||

| UNE-EN 13428. Containers and packaging. Specific requirements for manufacturing and composition. Prevention by reduction in origin | P | X | X | X | ||

| Directive 2008/98/EC Waste Framework Directive// protect the environment and human health | T | X | X | X | ||

| UNE-CEN ISO/TS 14027 Environmental labels and declarations. Development of product category rules | P | X | X | |||

| ISO 14001. Environmental management systems. Requirements with guidance for use | T | X | X | |||

| ISO 14004. Environmental management systems—General guidelines on implementation | T | X | X | |||

| ISO 14006. Environmental management systems—Guidelines for incorporating eco-design | P | X | X | |||

| ISO 14015. Environmental management—Environmental assessment of sites and organizations (EASO) | T | X | X | |||

| ISO 14020-14025. Environmental labels and declarations | P | X | X | |||

| ISO/NP 14030. Green bonds. Environmental performance of nominated projects and assets; discussion of post-production environmental assessment | T | X | X | |||

| ISO 14031. Environmental management—Environmental performance evaluation—Guidelines | T | X | X | X | ||

| ISO 14040 to 14049. Environmental management—Life cycle assessment; discussion of pre-production planning and environment goal setting. | T | X | X | X | ||

| ISO 14050. Environmental management—Vocabulary; terms and definitions | T | X | X | |||

| ISO/TR 14062. Environmental management—Integrating environmental aspects into product design and development | T | X | X | X | ||

| ISO 14063. Environmental management. Environmental communication. Guidelines and examples | T | X | X | X | ||

| ISO 14064. Greenhouse gases; measuring, quantifying, and reducing greenhouse gas emissions | T | X | X | |||

| ISO 9001:2015. Quality Management Systems (QMS). Requirements. | T | X | X | X | ||

| ISO 9004:2008. Guidelines for performance improvement. | T | X | X | X | ||

| ISO 10006. Quality management. Guidelines to quality management in projects | T | X | X | |||

| ISO 19011. Guidelines for quality management systems auditing and environmental management systems auditing | T | X | X | X | ||

| ISO/IEC 27001. Information security management | T | X | X | X | ||

| ISO 50001. Energy Audit | T | X | X | X | ||

| Product Component Level | Product Structure Level | Product System Level | |||

|---|---|---|---|---|---|

| Raw material extraction | Design | Manufacturing | Logistics | Use | End of life |

| Transversal Standards (E, E, E) * | |||||

| Bioinspired Metabolism Principles (E, E, E) (BD, LCA, C2C, ENA, EA, SNA) | |||||

| Circular Metabolism Material (E, E, E) (MFA, MIPSU, ER, SFA, IOA, SA) | |||||

| Circular Metabolism Water (E, E, E) (WC, LI, SA) | |||||

| Circular Metabolism Energy (E, E, E) (EEA, EA, ExA, ASEx, SD) | |||||

| Circular Metabolism Toxicity (E, E, E) (SFA, SA, C2C) | |||||

| Circular Industrial Symbiosis (E, E, E) (ANT, ENA, SNA) | |||||

| Circular Metabolism Supplier System (E, E, E) (ENA, LCCA, EcNA) Circular adaptation of Standard for Product Data Exchange—ISO 10303 (E, E, E) | |||||

| Particular Standards (E, E, E) * | |||||

| ● Design for innovative concept development | ● Design for Modular product structure | ● Design for Share use of the product | |||

| ● Design for Dematerialization | ● Design for Optimization production techniques | ● Design for Reuse of the product | |||

| ● Design for Functional component optimization | ● Design for Efficient logistics | ● Design for Remanufacturing of product | |||

| ● Design for Easier maintenance and repair | ● Design for Lean manufacturing | ● Design for Recycling of materials | |||

| Product Component Level | Product Structure Level | Product System Level | |||

|---|---|---|---|---|---|

| Raw material extraction | Design | Manufacturing | Logistic | Use | End of life |

| KETs (E, E, E) * | |||||

| ● Digitalization | ● Sensor and actuator | ● Cloud computing | |||

| ● Simulation | ● CyberPhysical systems | ● Fog | |||

| ● Machine learning | ● Ubiquous computation | ● Big data | |||

| ● Big data | ● Virtual and augmented Reality | ● Online platforms | |||

| ● Data mining | ● Balanced scorecard | ● Digital twin | |||

| ● Surrogate models | ● Smart robotic | ||||

| ● Virtual and augmented reality 3D printing | ● Aditive manufacturing ● Collaborative robotic | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ávila-Gutiérrez, M.J.; Martín-Gómez, A.; Aguayo-González, F.; Córdoba-Roldán, A. Standardization Framework for Sustainability from Circular Economy 4.0. Sustainability 2019, 11, 6490. https://doi.org/10.3390/su11226490

Ávila-Gutiérrez MJ, Martín-Gómez A, Aguayo-González F, Córdoba-Roldán A. Standardization Framework for Sustainability from Circular Economy 4.0. Sustainability. 2019; 11(22):6490. https://doi.org/10.3390/su11226490

Chicago/Turabian StyleÁvila-Gutiérrez, María Jesús, Alejandro Martín-Gómez, Francisco Aguayo-González, and Antonio Córdoba-Roldán. 2019. "Standardization Framework for Sustainability from Circular Economy 4.0" Sustainability 11, no. 22: 6490. https://doi.org/10.3390/su11226490

APA StyleÁvila-Gutiérrez, M. J., Martín-Gómez, A., Aguayo-González, F., & Córdoba-Roldán, A. (2019). Standardization Framework for Sustainability from Circular Economy 4.0. Sustainability, 11(22), 6490. https://doi.org/10.3390/su11226490