1. Introduction

The average annual total of agricultural irrigation water is very high in China, but the water use efficiency is relatively low [

1]. Similarly, China’s fertilizer use is high per year, but the utilization rate of fertilizer is low in the current season [

2]. Moreover, the excessive use of fertilizer increases the agricultural cost and causes environmental pollution. Research reported that there are many questions about cultivated land in China. For example, the area of inferior cultivated land was high, and the soil organic matter was decreased [

3]. Thus, it is greatly significant to employ both effective fertigation method and agricultural waste biomass returning field technology in China for improving the utilization efficiency of agricultural resources and for achieving the sustainable development of agriculture.

Fertigation is a new technique that combines irrigation with fertilization to fertilize through irrigation systems. This technology has the characteristics of fast fertilizer efficiency, saving water and fertilizer, and reducing production cost [

4]. At present, drip and sprinkler fertigation technology are widely used [

5,

6,

7] and there are many research results on the infiltration characteristics and distribution of soil water-fertilizer under drip fertigation [

8,

9,

10,

11]. Numerous studies revealed that the movement and distribution of nitrogen in soil were affected by various factors, such as soil properties, drip flow, fertilizer solution concentration, fertilizer type, fertilization time, and frequency under drip fertigation [

12,

13,

14,

15,

16]. Suitable drip outflow velocity and fertilization frequency reduced nitrogen leaching in soil and improved nitrogen fertilizer utilization efficiency [

17,

18].

Moistube irrigation is a new underground precision micro-irrigation technology based on micro-nano porous membrane. Moistube irrigation is driven by the water potential gradient inside and outside of membrane and soil suction. It delivers irrigation water directly into the crop root zone continuously and slowly [

19,

20], thus providing an effective carrier for agricultural fertigation technology. It has the advantages of reducing ground evaporation and of improving irrigation water use efficiency [

19,

20,

21,

22]. Several studies have shown that the soil physical properties (texture, bulk density, and initial water content), the emitter parameters (outflow velocity, length, and buried depth), the pressure head, and the salinity of irrigation water mainly influenced the infiltration and distribution of soil water under moistube irrigation [

20,

23,

24,

25,

26,

27]. The wetted soil is approximately a symmetrical ellipsoid with moistube as the axis [

20]. Soil water content reduced gradually further from the source to all around, and the maximum value appeared around the moistube [

20,

28,

29]. Currently, the infiltration characteristics of fertilizer solution and the distribution of water-fertilizer in wetted soils during moistube fertigation are not known.

Agricultural waste biomass returning technology is an effective method to improve the ecological environment of farmland and to promote the sustainable development of agriculture. It can effectively ameliorate soil physical structure, enhance soil infiltration and water retention capacity, and improve soil organic matter content and nutrient element reserves [

30,

31,

32,

33,

34]. Previous studies have shown that comminuted straw amendment rapidly improves soil structure and increases the steady infiltration rate and cumulative infiltration of soil, while mixing the long straw decreases the soil infiltration capacity [

35,

36].

Peanut is a widely cultivated edible nut in the world [

37]. The worldwide peanut planting area, yield, and shell waste were about 21 million hectares, 200 million tons, and 6 million tons, respectively, in 2010 [

38,

39]. Peanut shell returning will certainly improve soil physicochemical properties and soil fertility; however, how mixing waste biomass (peanut shell) in the soil influences the infiltration characteristics of fertilizer solution and the distribution of water-fertilizer under moistube fertigation is still unsolved and needs further investigation.

In this study, we investigated that the infiltration capacity of fertilizer solution in mixing waste biomass soil and the distribution of water-fertilizer in wetted soil under moistube fertigation. The cumulative infiltration of fertilizer solution and the distribution of water-fertilizer in wetted soil were fitted according to the model. The objective was to provide a theoretical basis and practical reference for the popularization and application of new moistube fertigation technology. It is significant to apply novel irrigation strategy and agricultural waste biomass returning field in the recycling of waste biomass resources, especially in water resource-scarce regions.

2. Materials and Methods

2.1. Experimental Materials

The experimental soil was taken from the superficial soil layer (0–20 cm) of the agricultural water-saving experimental field of Kunming University of Science and Technology (24°9′ N, 102°79′ E; 1978.9 m above sea level). The soil was air-dried and sieved in order to pass through a 2-mm sieve for reserve. Soil particle size distribution was analyzed using laser particle size analyzer (Mastersizer-2000, Malvern Panalytical, Malvern, UK), and soil type was determined to be clay loam, according to the international soil classification system [

19].

Table 1 shows the basic physicochemical properties of experimental soil.

Sieved soil was mixed uniformly with peanut shell by the design ratio. The experimental fertilizer was water-soluble fertilizers (Stanley Agriculture Group Co., Ltd., Linyi, China), and the contents of N, P2O5, and K2O were all 20%. The concentration of infiltration fertilizer solution was designed for 400 mg L−1.

2.2. Experimental Device

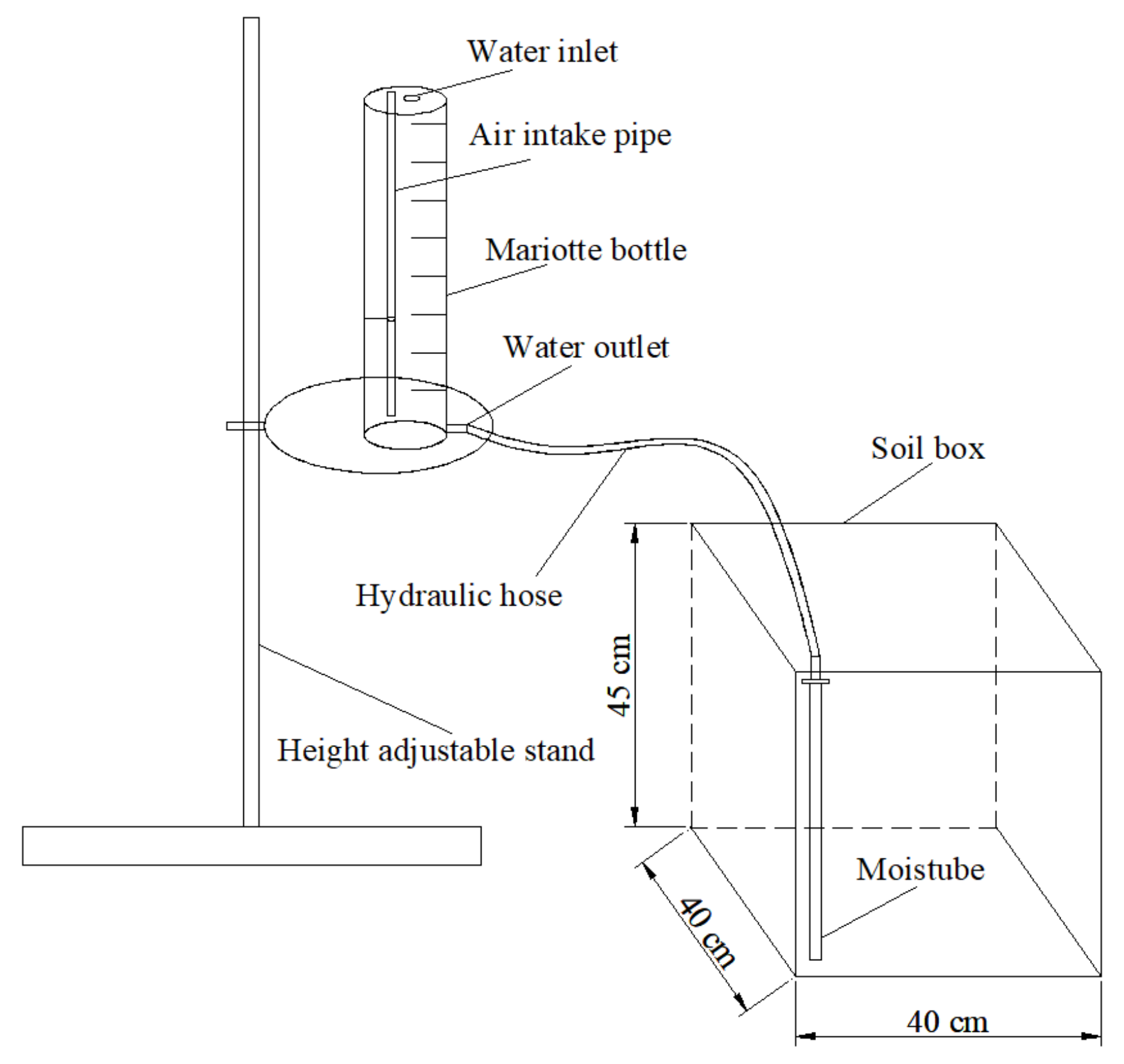

The experimental device consisted of five parts, i.e., the soil box, the height adjustable stand, the Mariotte bottle, the hydraulic hose, and the moistube (

Figure 1). The soil box (40 cm × 40 cm × 45 cm) was made of transparent acrylic with the thickness of 10 mm. The Mariotte bottle (8 cm in diameter and 60 cm in height) provided a constant pressure head. The 3rd generation moistube (Moistube Irrigation Co., Ltd., Shenzhen, China) was a four-fold double-layer structure, in which the microporous inner layer (with a density of micropores higher than 10

5 per cm

2 and a diameter ranging from 10 nm to 900 nm) was a micro-nano porous membrane with thickness of 0.06 mm, and the outer layer was a non-woven protective layer. The moistube had a 16-mm inside diameter, a folding diameter (width) of 25 ± 1.5 mm, and a thickness of 0.9 ± 0.5 mm. The moistube was arranged in a vertical inserting mode. The top of the moistube was connected to the Mariotte bottle through a joint and hydraulic hose, and the bottom was closed with a rubber plug.

2.3. Experimental Design and Method

Three waste biomass (peanut shell) mixing mass ratios were included in the experiment, and they were 1.5% (MR1.5%), 3.0% (MR3.0%), and 4.5% (MR4.5%). No mixing peanut shell (MR0%) was taken as the control (CK). This experiment consisted of 4 treatments, and each treatment was replicated 3 times. All the data in this paper are reported as means.

The experimental soil with the designed bulk density of 1.20 g·cm−3 was layered (5 cm per layer) into the soil box, and loading depth was 40 cm. The effective infiltration length of the moistube was 30 cm, and the upper joint was flush with the soil surface. The pressure head was 1.0 m in the experiment.

The fertilizer solution level of the Mariotte bottle was recorded immediately after the moistube was filled with fertilizer solution and buried in the soil. The experimental data were recorded once every hour in 0–10 h, once every 2 h in 10–24 h, once every 4 h in 24–60 h, and once every 8 h in 60–124 h. Finally, after infiltration for 124 h, the fertilizer solution supply was stopped and soil samples in wetted soil were collected instantly by the layered sampling method, with a distance between sampling points of 5 cm. The first point of each layer was taken around the moistube, and one layer was taken every 5 cm in the vertical direction. The distribution of sampling points is shown in

Figure 2.

2.4. Water-Fertilizer Content Measurement

Soil water content was calculated using oven-drying method. The measured soil nutrient is based on the method used by Wang R.S. et al. [

8]. Nitrate–N was extracted using 1 mol L

−1 KCl and measured using UV spectrophotometer. Available P was extracted using 0.5 mol L

−1 NaHCO

3 and measured using Mo–Sb colorimetry method. Available K was measured using flame photometer method.

2.5. Models Applied

The whole process of fertilizer solution infiltration was divided into three stages. We took the average infiltration rate of 0–24 h as the average infiltration rate of first stage (AIRSI); likewise, the average infiltration rate of second stage (AIRSII) and third stage (AIRSIII) were for the periods 24–60 h and 60–124 h, respectively. The average infiltration rate of the first 6 h was taken as the initial infiltration rate (IIR), the average infiltration rate of the final 24 h was taken as the steady infiltration rate (SIR), and the average infiltration rate of the 0–124 h period was taken as the overall average infiltration rate (AIR).

Kostialov infiltration model was expressed in Equation (1) as follows:

where

It is the cumulative infiltration (L),

K is infiltration coefficient (L h

−1),

α is infiltration index, and

t is infiltration time (h).

Christensen’s uniformity coefficient was calculated by Equation (2) as follows:

where

Cu is the distribution uniform coefficient of water-fertilizer (%),

is the average content of water-fertilizer (% or mg·kg

−1),

θi is the water-fertilizer content of the

ith soil sample (% or mg kg

−1), and

m is the number of sampling points.

The 4-parameter log-logistic model was expressed in Equation (3) as follows:

where

C is the fitted value of water-fertilizer content (% or mg·kg

−1),

A is the lower limit of water-fertilizer content (% or mg·kg

-1),

B is the upper limit of water-fertilizer content (% or mg·kg

−1), lg

D is the horizontal distance when the decreasing rate of water-fertilizer content begins to change (cm),

k is the decreasing rate parameter of water-fertilizer content, and

l is the horizontal distance (cm).

2.6. Statistical Analysis

The experimental data were analyzed using Microsoft Excel 2010. Variance analysis (ANOVA) was performed using Statistical Product and Service Solutions (SPSS) 21.0 (International Business Machines Corporation, Armonk, NY, USA). The distribution graphics of water-fertilizer were drawn using Surfer 11.0 (Golden Software, Golden, CO, USA), and the water-fertilizer distribution area of wetting pattern profile was calculated by programming with MATLAB 7.0 (Math Works, Natick, MA, USA).

The accuracy of the fitted model was evaluated using root mean square error (

MAE), mean relative error (

RMSE), and normalized root mean squared error (

NRMSE). These parameters are defined by the Equations (4)–(6) below:

where

Yimea is the measured value,

Yifit is the fitted value,

YM is the average of the measured value, and

n is the total number of measurements.

4. Discussion

The infiltration of fertilizer solution and the distribution characteristics of water-fertilizer affect soil fertility and root growth of crops and ultimately affect water-fertilizer use efficiency under the fertigation technology. The study on infiltration and distribution of fertilizer solution in mixing waste biomass soil under moistube fertigation can provide a theoretical basis for the popularization and application of new moistube fertigation technology.

Soil water infiltration comprises a variety of complex processes that cannot be assessed by one parameter alone but requires multiple parameters [

41,

42]. In this study, the infiltration process of fertilizer solution was divided into three stages, and six infiltration parameters (IIR, AIRSI, AIRSII, AIRSIII, SIR, and AIR) were used to evaluate the infiltration rate of fertilizer solution in the soil with different waste biomass mixing ratios. The results showed that the mixing ratio had a significant effect on the infiltration rate and that mixing waste biomass in soil could significantly increase IIR, SIR, and AIR of moistube fertigation.

The cumulative infiltration of fertilizer solution for moistube fertigation is significantly increased by mixing waste biomass in soil, probably owing to that mixing waste biomass increased the organic matter content of soil and improved the size and distribution of soil pores, which reduced soil compaction, improved soil pore connectivity, and increased the infiltration gateway of fertilizer solution. This reduced the resistance of fertilizer solution flowing between the pore, thus enhancing cumulative infiltration [

36,

43]. Obviously, mixing waste biomass in soil could effectively improve the infiltration capacity of fertilizer solution in moistube fertigation.

Kostiakov infiltration model is commonly used to describe the infiltration process in farmland irrigation and the conservation of soil and water because of the great goodness of fit between the model and actual infiltration process [

44,

45,

46,

47,

48]. In this study, this model was used to fit the infiltration process of fertilizer solution for moistube fertigation under different waste biomass mixing ratios and established the modified Kostiakov infiltration model with higher accuracy for fertilizer solution.

This study showed that the maximum content of water-fertilizer occurred just next to the moistube and that the water-fertilizer content gradually decreased further from the source, which was consistent with the results of related studies [

20,

26,

28,

29]. The distribution of soil water and nitrate–N were similar in that distribution range were larger in wetted soil, which was mainly related to the strong movement ability of nitrate–N in soil with water [

49,

50]. Simultaneously, the distribution of available P and K tended to be the same and the distribution range was smaller, which was probably related to the strong adsorption of soil to available P and K [

49,

50]. It was also found that the distribution area of water-fertilizer in wetted soil was increased by mixing waste biomass, indicating that mixing moderate waste biomass in soil could enhance the movement ability of water and nutrient to a certain extent.

Waste biomass mixing ratio had a significant effect on the average content of water-fertilizer in wetted soil of moistube fertigation, which was mainly related to the increase of cumulative infiltration of fertilizer solution by mixing waste biomass. Mixing waste biomass could improve the distribution uniformity coefficients of soil water and nitrate–N in wetted soil, perhaps due to mixing waste biomass improving soil structure, accelerating fertilizer solution infiltration, increasing cumulative infiltration [

36], and promoting the movement of water and nitrate–N far away from moistube [

49], resulting in more uniform distribution of soil water and nitrate–N. However, the distribution uniformity coefficients of available P and K were significantly reduced by mixing waste biomass, which was related to the increase of infiltration rate of fertilizer solution and the enhancement of soil adsorption of available P and available K [

51].

Logistic model is a common model for fitting the S-shaped curve, which has been widely used in many fields [

52,

53,

54]. Compared with the traditional logistic model, the 4-parameter log-logistic model adds a parameter (inflection point) to make its fitting effect better [

55,

56]. In this study, the 4-parameter log-logistic model was used to fit the relationship between the content of water-fertilizer and horizontal distance in the wetting pattern of moistube fertigation and had a good fitting result.

During intermittent fertigation (such as flood irrigation, sprinkler irrigation, and drip irrigation), the soil surface undergoes an alternate of the absorption and desorption to form a dense layer. With the increase of intermittent infiltration frequency, the soil structure tends to be compact, which reduces the infiltration capacity of fertilizer solution [

57,

58,

59]. However, moistube fertigation achieves a continuous supply of water-fertilizer with a small flow rate; thus, the infiltration of fertilizer solution is relatively uniform. According to the condition of soil and the growth characteristics of crops at different stages, moistube fertigation can effectively control the supply quantity and proportion of water and nutrient and can give full play to the coupling effect of water-fertilizer, so as to adjust water by fertilizer, to promote fertilizer by water, and to coordinate the supply of water-fertilizer. Compared with traditional fertilization methods, moistube fertigation can fulfill appropriately the crop’s demand for water and nutrients and can provide a relatively stable water and fertilizer status for root growth [

60]. It reduces the contact area between fertilizer and soil and realizes the integrated management of field moisture and nutrients, thereby improving the comprehensive utilization rate of water and fertilizer [

61,

62].

Moistube fertigation and agricultural waste biomass returning field are especially suitable for economic forest-planting areas where the distance of planting is large, soil organic matter and nutrient are poor, and drought is continual. This is mainly due to moistube fertigation being based on micro-nano porous membrane to achieve simultaneously irrigation and fertilization, and it does incompletely rely on soil suction to achieve fertigation [

19,

20]. The water-fertilizer distribution of moistube fertigation in the soil can be controlled by the pressure water head, moistube laying length, amended soil, and so on [

24,

25]. On the other hand, agricultural byproduct returning field can increase soil organic matter, can solve the problem of agricultural waste biomass, and then can realize sustainable development of agriculture. Thus, the technology will be more feasible in field application. Furthermore, the moistube fertigation system is a relatively simple structure, has low energy consumption, conveniently lays, and so on. It also can reduce the investment operation cost compared with drip and sprinkler fertilization systems [

62]. Therefore, coupling moistube fertigation and agricultural waste biomass returning field has wide application prospects in agricultural resources cyclic utilization in water resource scarce regions.

5. Conclusions

Mixing waste biomass in soil increased significantly the infiltration rate and cumulative infiltration of fertilizer solution and improved the infiltration capacity of fertilizer solution under moistube fertigation. The relationship between the cumulative infiltration of fertilizer solution and infiltration time conformed to the Kostiakov infiltration model under different waste biomass mixing ratios.

Under moistube fertigation, the contour of water-fertilizer content was approximately ellipsoid around the moistube in wetted soil. The maximum content of water-fertilizer occurred just next to the moistube, and the content of water-fertilizer gradually decreased with the increase of horizontal distance. Mixing waste biomass in soil increased the distribution area and content of water-fertilizer in wetted soil.

Mixing waste biomass in soil effectively improved the distribution uniformity coefficient of soil water and nitrate–N but reduced that of available P and K in wetted soil. The 4-parameter log-logistic model fitted well with the distribution of soil water, nitrate–N, and available P and K in wetted soil of mixing waste biomass soil under moistube fertigation.