Abstract

Good quality sleep is a prerequisite for regenerating the human body, hence, beds should be optimized for specific group of users, taking into consideration their size or age. Current research studies show similar trends in adult populations around the world, where increases in height as well as in weight can be observed. Not only the ergonomics but also the safety of beds, which is determined by the quality and dimensions of structural elements, must be taken into account in bed design. Designing the structural elements for users with a high body weight is presented in the paper. The properties of a bed’s structural elements, which ensure comfort as well as the safety of a bed are affected by the excess weight of users. New requirements for cross sections, suitable materials and construction of structural elements were set in accordance with the standard EN 1725:1998. Also, an analysis of stresses was done using the finite element method (FEM) and the calculation of allowable stresses related to a user weighing 150 kg. The results of our research provide complete standards and regulations associated with the safety requirements of bedroom furniture for users with a weight more than 110 kg to ensure that the manusfacture of quality products in Slovakia.

1. Introduction

High quality and uninterrupted sleep is essential for the well-being of any individual, an is needed to regenerate parts of the brain. Changes in sleep duration depend upon age. Children need to sleep 10 to 14 h a day on average. The average sleep duration of adults is 6 to 8 hours and at higher ages, people report shorter sleep duration. The quality of sleep and relaxation is affected mainly by the quality of bed.

Of all the factors that impact sleep quality, external factors can especially be changed. The “sleep system” includes the mattress, bed base and pillow, and it is an essential component of the sleep environment. As such, it has the highest demands placed on it. The combination of the elements mentioned above determines the overall behavior of the sleep system in terms of body support and thermal regulation, both of which should be adapted as much as possible to personal needs, preferably in an objective way [1]. The bed itself is created by the frame, legs or base, mattress and headboard. The bed frame is an essential part of the bed construction and it determines the size and shape of the bed. The solidity of the bed is associated with the ability to support the correct curvature of the spine while sleeping on the back, side or stomach [2,3,4,5]. A bed that is too small to allow users to turn from a supine to a side lying position increases the difficulty of mobilizing patients. Subsequently, the risk of musculoskeletal injury to caregivers can increase along with the risk of pressure injuries to users. The comfort of users is also reduced [6].

In terms of anthropometry, the length, width and height of the lying area are the most important bed parameters. The length and width affect the size of the lying area, whereas the height of the bed provides comfort when sitting on the edge or getting up. The general requirements for bedroom furniture defined in terms of anthropometry, physiology and hygiene are as follows: the bed size must fit the human measurements and changes in sleeping positions during sleep. In terms of ergonomics, product dimensions are generally created by the sum of the size of an individual plus additional factors (each separately), so, for the width of the bed we get P99 + room for turning left and/or right and for different positions. For these reasons anthropometric information should be used in the design of bedroom furniture (and other furniture), and may improve well-being, health, comfort and safety [mm].

Secular trends in human growth are a global phenomenon [7,8]. Since the early 19th century, the army has played a major role in research into trends in human physical growth [9]. Hauspie et al. [10] studied secular trends in Europe over the last decades of the 20th century and found increases in height of 3 mm/decade in Scandinavia with increases of 30 mm/decade in some countries of Southern and Eastern Europe. Data gathered since 1990, have reported a plateau in some countries, for example, in the Netherlands [11], and in Norway and Finland. In other countries, especially in Belgium, Spain and Portugal, the height of the population has increased at a constant rate of about 2–3 cm over each decade since 1990 [12]. With the exception of some countries, the increase in the height of adult populations can be observed all over the world. This is confirmed by the results of research studies conducted in countries all around the world: (i) in the USA and in North America [13,14,15], (ii) in Northern Europe [16,17,18], (iii) in Southern and Southeastern Europe [19,20,21,22,23], (iv) in Western Europe [24], (v) in Asia [25,26,27,28,29], (vi) in Australia [30] and (vii) in Africa [31,32].

Weight gain is reported as well. Population-based studies measuring the body weight of the adult population are based on BMI (body mass index). Categories are selected according to the rules associated with the determination of the BMI: 25 kg/m2 < 30 kg/m2 (overweight), > 30 kg/m2 (obese), and > 35 kg/m2 (severely obese). In many countries, weight has continued to increase as part of global obesity epidemic [33,34,35,36,37,38]. In 2015, the BMI value of one third of all inhabitants in the USA was higher than 30 [39]. Based on data from 369 national and 591 local research studies [40], the trends in BMI changes throughout the world from 1980 to 2008 were defined. Another study used 450 national studies to determine the trends in childhood obesity and excess weight from 1990 to 2020 [41]. Data from both studies, as well as many others, show overall weight gain in recent decades [42,43,44,45,46].

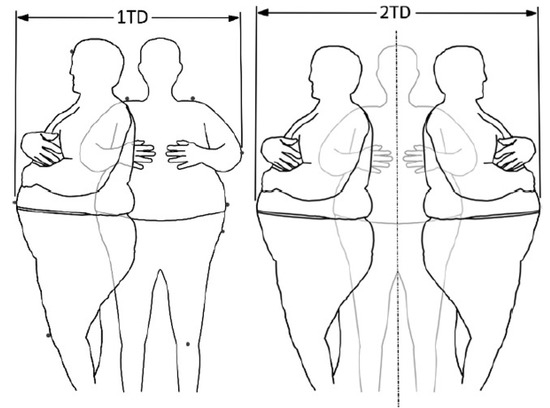

From the viewpoint of a user with a high weight, there are very few scientific publications about appropriate furniture dimensions [47,48,49] including the dimensions for beds and the bed’s components [50]. Some are based only on the weight of users. The use of wider beds is recommended in case of patients weighing more than 159 kg [51]. Other authors [52] suggest the use of special beds for users who weigh more than 147 kg or with a BMI score higher than 55 kg/m2. A scientific study [6] determined how much space individuals occupy when turning from supine to side lying (Figure 1) as predicted by their anthropometric attributes (i.e., waist circumference). The relationship between anthropometric attributes and the space occupied when turning was then used to establish guidelines for selecting an appropriate hospital bed width based on the size of the users. The findings from this study suggest that, when lying in the centre of a 910 mm wide hospital bed, a patient with a BMI greater than 35 kg/m2 would have insufficient space to be turned in either direction without lateral repositioning. Furthermore, a patient with a BMI greater than 45 kg/m2 would have insufficient space to be turned at all, even if repositioned to one edge of the surface before being turned.

Figure 1.

1TD represents the minimum space required for people who are able to slide side-to-side in bed or lift their hips to turn while staying centred in bed. 2TD represents the amount of space required to allow a patient who is centred in the bed to be turned both directions without lateral repositioning [5].

Two other ways to determine the width of bed can be found in scientific papers [53,54]. Prokopec [53] determined the width of lying area b according to the shoulder width (Bi-deltoid width) extended by 50% and two standard deviations. Each human individual changes their sleeping position many times during the night. Therefore, the minimum width of a bed must be extended by 20–25%. The final width of the bed lying area is determined according to the formula (where w—average shoulder breadth, and sx—standard deviation of the average):

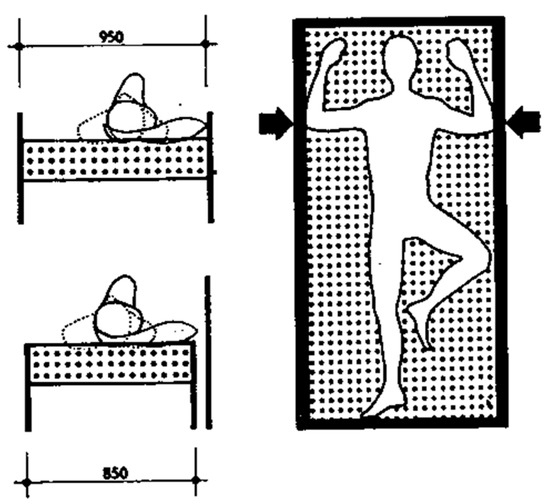

The second way used to determine the bed width [2] is based on the sleeping position on the back with relaxed arms (Figure 2), where elbow span is considered to be the maximum width. Therefore, the width of the lying area has to be extended by 25%. The basic width resulting from the aforementioned calculation is 85–95 cm.

Figure 2.

Sleeping on back, with relaxed arms [1].

Various types of bed bases have been developed to support mattresses. The most commonly used bed bases are rigid bases, slatted bases, spiral bases and box springs. A slatted base consists of a frame on which slats are fixed perpendicular to the cranio-caudal direction. Slats are traditionally fabricated in solid wood or laminated wood [1,55,56,57]. Slats made of solid wood are attached to the frame separately using screws, or slats are loosely laid. Slats made from laminated wood are attached to the frame separately by means of synthetic slat suspension. Extensive space for further experimental research in furniture design is offered using wood composite materials [58,59,60]. The ergonomic design of sleep systems (i.e., the mattress, bed base and head cushion) aims to optimize bed properties to achieve maximum recovery during sleep. This is very important for the health of users with excess weight.

Various simulation tools can be used by furniture makers and designers in the process of designing optimum construction for specific users. The most frequent method applied in the literature to calculate the stress and strain in wood furniture is the FEM (finite element method) [61,62,63,64]. Critical stress points can be determined using this method. The literature shows agreement between the data collected by calculation and experimental testing [65,66]. The studies by Gustafsson [67,68] are considered interesting because of their structural analysis of furniture using modern software tools.

Furniture design of all types of furniture (bedroom, seating furniture, cabinets, tables and multi-functional furniture) has to correspond with the dimensions and weight of current as well as future populations. Valid standard EN and Slovak laws are currently based on a human body weight of 110 kg. At the present time, overweight users are not taken into consideration in the process of designing and making furniture construction in Slovakia. For furniture makers, this problem must be resolved on an individual basis. Therefore, the need to put the principles associated with furniture design and construction for users who weigh more than 110 kg into practice, is considered to be essential. For that reason, we consider this paper beneficial and supportive of the innovation required in this area. A wider group of users will be able to use the furniture due to its functional properties, and this innovation in furniture making will also help to lead the furniture industry towards sustainability.

Therefore, the aim of the paper is to define up-to-date mechanical properties (especially strength) for single bed construction for users with excess weight in Slovakia, mainly bed bases and bed frames. The research is aimed at using a calculation method based on limited states and evaluating it by simulating the FEM in the ANSYS program.

2. Analysis Approach

2.1. Experimental Subjects

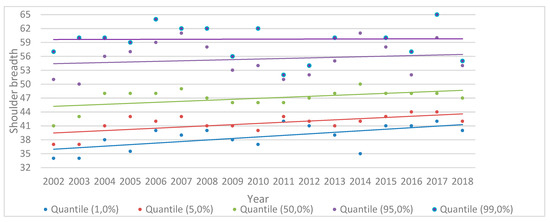

Research on the secular trends in human growth have been carried out in the Slovak Republic since 1993. The sampling unit consists of the Slovak adult population. 71.816 male respondents were used to analyze secular trends in Slovak men from 1993 to 2017. The data were collected from the Public Health Authority of the Slovak Republic and other available sources [69,70,71]. Third-degree polynomials were used to analyze the trends (Figure 3 and Figure 4).

Figure 3.

Average shoulder breadth of adult male population in Slovakia in years 2002–2018.

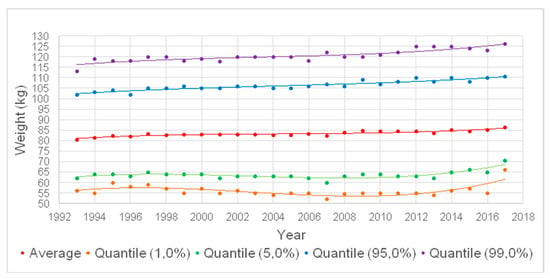

Figure 4.

Development of the average body weight and percentiles for men in 1993–2017 [51].

The current average shoulder breadth in the adult male population is 47.87 cm ± 6.06 cm. Following the data, the calculated width of bed b is according to (1) 104.91 cm (Figure 3).

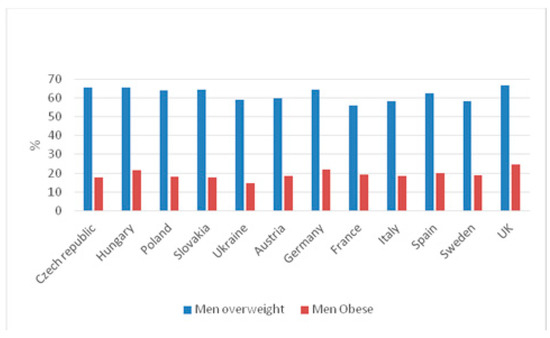

Regarding the weight of users, an increase in the average weight of the Slovak male population of more than 6 kg has been observed over the last 25 years. In 2017, the weight of more than 113,000 Slovak men was higher than 110 kg. Moreover, the weight of 11% of these men was more than 130 kg. Regional and national estimates of BMI in other European countries show that the situation is very similar (Figure 5) [72,73]. Following the BMI data, 400,000 men in Slovakia suffered from obesity and 90,000 suffered from severe obesity in 2017. The weight of approximately 46,000 men with severe obesity was more than 110 kg [74,75,76,77].

Figure 5.

Regional and national estimates of the prevalence of overweight and obese men in European countries in 2016.

2.2. Static Load Test of Beds

Following these findings, it can be concluded that individual parameters of bedroom furniture are not consistent with the standards and do not meet the needs of the current population. Therefore, these standards need to be updated. Modification of the standard dimensions requires cooperation from designers, furniture makers, anthropologists, ergonomists as well as doctors. Only the cooperation of a team of multidisciplinary professionals can produce changes in the manufacturing of furniture that supports the development of a healthy population. For the reasons mentioned above, the use of 110 kg in current standards associated with the load bearing capacity of beds (EN 1725:1998) [78] is considered inadequate. Following the weight analysis of men in Slovakia and other European countries, and to improve the existing standards it is necessary to up-to-date the standards to include people weighing over 150 kg. Similarly, standard bed sizes of 800 mm and 900 mm are not considered to be adequate and it seems advisable to use a bed width of 1050 mm as the standard.

Mechanical properties, especially the strength, of furniture are evaluated using tests mentioned in European standards. Experiments and testing are usually carried out using real constructions with real dimensions to simulate situations where changes in structure as well as breakages can occur. In addition, structural analysis with reduced size and material is conducted to evaluate the construction of the furniture. Although the structural analysis of most furniture is a complex process requiring considerable technical skill and involving substantial numbers of tedious computations, assumptions about the structural behavior of the furniture can often be made. The difficulty of analysis is reduced significantly. In the case of frame construction, for example, it is often assumed that slender members that can only carry modest bending loads owing to their geometry, may be treated as though they were pinned at each end when, in fact, they may be fixed. This assumption substantially reduces the amount of time required to analyze a frame and the accuracy of the solution is usually only affected in a minimal way [79].

Furniture can be customized to individual needs to implement space management. Aesthetic, ergonomic and safety are the main criteria in furniture design. A significant number of benefits can be gained during the development phase. This study involves designing the dimensions of the structural elements of a bed for users with high body weight. Standards associated with testing beds take into account an individual weight of 110 kg. Therefore, static and cyclic loading conditions during testing are based on the weight of 110 kg. However, the question is, what will happen to the construction when the weight of the user is more than 150 kg, as this means changing the loading conditions?

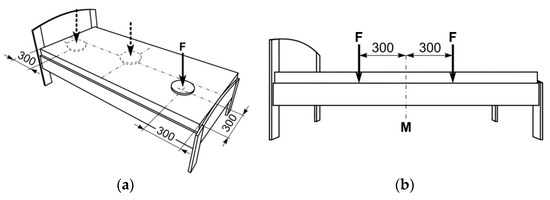

Modeling the bed-load was based on the standard EN 1725:1998. Distribution of stresses and deformations in structural elements corresponding to the vertical static load test of the edge (Figure 6a) and the strength of the lying area in case of static loading (Figure 6b) were evaluated. The diameter of the circular plate used during the plate bearing test was 200 mm.

Figure 6.

Bed strength testing with static load EN 1725:1998; (a) testing the strength of the lying area; (b) vertical static load test of the edge.

In general, bed tests are based on the weight of individuals of 110 kg. The following forces are used to describe the load. F = 1200 N (Figure 6b) is used for the vertical static load test of the edge and F = 1400 N is used for testing the strength of the lying area (Figure 6a). The stresses and deformation associated with a user weight of 150 kg are not defined in the standards. Therefore, the values corresponding to the weight of users of 150 kg were set using the linear extrapolation as follows: F = 1800 N (Figure 6b) for the vertical static load test of the edge and F = 2100 N for testing the strength of the lying area (Figure 6a).

2.3. Designing in Accordance with the Limit State

2.3.1. Strength of Elements

The standard stress of material varies linearly across the thickness. The maximum value of compression is on one side and an equal maximum value of tension is located on the other side of the thickness and passes through zero at the mid-plane. When designing the support beam, the following conditions must be met for (2) and (4):

where:

- σt,0,d—design tensile stress parallel to grains

- ft,0,d—design tensile strength of timber parallel (perpendicular) to grains, at which

- ft,0,k—typical tensile strength of timber parallel to grains (for spruce wood ft,0,k = 24 MPa, for beech wood ft,0,k = 42 MPa)

- γM—partial safety factor, γM = 1.3 for wood and wood materials

- kmod—modification factor dealing with the impact of the time of applying the load and the moisture content on the strength of material kmod = 1.10 for immediate load [55]

- σc,0,d—design compressive stress,

- fc,0,d—design compressive strength, at which

Further, σc and σT denote compressive and tensile normal stresses, respectively. For strength, typically coniferous sawn timber is graded to strength classes C40 or D70, which means the sawn timber almost without defects. This corresponds with the values calculated from the average strengths (using elements with no defects) provided that the number of elements is higher than 30 and the coefficient of variation is 20%.

2.3.2. Element Bending

The bed sideboard is also used to test for fitness for use in terms of deformation. The afore-mentioned deformation meets the condition that the bend of a beam is ymax < L/333, while L is the length of a beam. The condition associated with the reliability of bending is expressed as):

ymax < y

2.4. Methodology for Static Loading Testing of Bed Slats

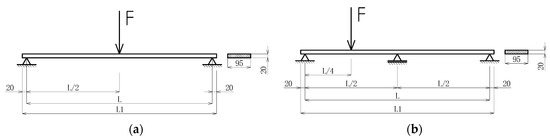

The width and length of the lying area are essential in terms of evaluating the strength and deformation of structural elements (w × l). The width of the lying area results from the ergonomic requirements for the lying area. We opted for the basic size of 800 mm and two sizes suitable for users with excess weight, w = 900 mm and 1050 mm. The bed base was designed in accordance with the standard EN 1725:1998. The bearing slat cross section is (b × h) 95 × 20 mm, the distance between slats is 65 mm. The support beam of the bed slats is made of Norway spruce sawn timber. According to the standards, the bed slats with a width more than 1000 mm must be supported. Bed slats were supported with spruce prisms measuring 20 × 45 mm, which means that 20 mm is the width used to support the bearing slat. Following the analysis of anthropometric data associated with the excess weight and dimensions of users, two extended lengths of bed base, L1 = 900 mm and 1050 mm were used. The bed sideboard is designed from beech wood sawn timber. The standard minimum cross section of the sideboard (b × h) 25 × 200 mm, l = 2000 mm was used for load testing. Stresses and deformations were evaluated using the FEM software.

In terms of safety specifications for furniture, the strength of the lying area must be evaluated. As mentioned, the evaluation was carried out using the FEM software ANSYS. Figure 7 shows the load applied. Two wood species commonly used in bed making were analyzed—Norway spruce and European beech [80,81]. Material constants associated with these wood species are mentioned in Table 1.

Figure 7.

Static load scheme of support beam of bed slats; (a) unsupported (b) supported.

Table 1.

Material constants used in the calculation using the FEM.

A 3D volume model with orthotropic wood properties taken into consideration was used in the analysis of the support beam by means of the ANSYS program. A Cartesian coordinate system was used to simulate the phenomenon. Direction X is along the grains, direction Y is perpendicular to the grain radial, and direction Z is perpendicular to the grains tangential. A material is defined by its material constants (Table 1 and Table 2). Every element has to be assigned a particular material. The element type was 3D element SOLID 95 with 20 nodes. The boundary conditions applied in this simulation are the same as in experimental tests, according to the standard EN 1725. They are shown in Figure 7 and Figure 8. These conditions are: symmetry boundary conditions, restriction of the displacement in the support (UX = UY = UZ = 0), and loading applied at the top surface of wood beam.

Table 2.

Design strength of timber f0,d (MPa).

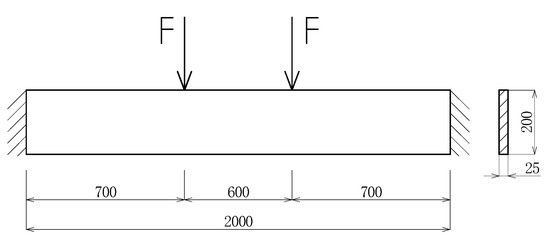

Figure 8.

Static load scheme of the edge of the bed.

2.5. Methodology for Static Loading Testing of Sideboard

The vertical static load test of the edge was carried out in accordance with the static scheme shown in Figure 8 and the load was applied on the bed sideboard. The cross section of the bed sideboard of 25 mm × 200 mm with a length of 2000 mm was simulated as an orthogonally anisotropic material, that is, beech wood ρ = 684 kg·m−3, and the material constants are mentioned in Table 1. The direction along the grain is described by the x-axis and the radial direction perpendicular to the grain is described by y-axis. The tangential direction perpendicular to the grain is described by z-axis.

3. Results

The evaluation of the strength of the bed base was based on the design tensile strength ft,0,d and a compression strength of fc,0,d along the grain for the wood species of Norway spruce and European beech, as mentioned in Table 2.

The values for the stresses measured on the spruce support beam of the bed slats collected using the FEM method are shown in Table 3.

Table 3.

Values of stresses in the spruce support beam of the bed slats at standard and higher load.

When the load is 1400 N, the length of the support beam of bed slats is 800 mm. However, when the load is higher, 2100 N, the beam tension exceeds the compressive strength by 75% and the tensile strength by 60%, so, it cannot be used. A beam measuring 900 or 1050 mm is not fit for use when the load is normal or higher, that is 2100 N. When the load is normal, the tension of the beam with a length of 900 mm exceeds the compressive strength by 18% and tensile strength by 29%.

Changes in materials and structure must be incorporated into the design in order for standard bed slats to be used with excess weight. In terms of material changes we think beech wood is stronger and therefore, it is more suitable for this purpose. In terms of changes in structure, we propose that the beam be supported in the centre, the place with the highest stress concentration (Figure 2b). The stress values gathered using the FEM method are shown in Table 4 and are compared to the design strength of timber f0,d according to Table 2.

Table 4.

Values of stresses in the support beam of bed slats at standard and higher load after changes in structure or material.

The calculated values show that the beam must be supported in the centre in case of normal load and the length increased to 900 mm and 1050 mm. When the mentioned change in structure cannot be done, beech wood should be used as a material. When the load increases to 2100 N, which corresponds to a user weight of 150 kg, a beam of beech wood fits for the length of 900 mm, even though the tensile stress is equal to the design strength of timber f0,d. In the case of the length of 1050 mm, only a supported beech beam can be used. The development of stresses in suitable beams is shown in Figure 9.

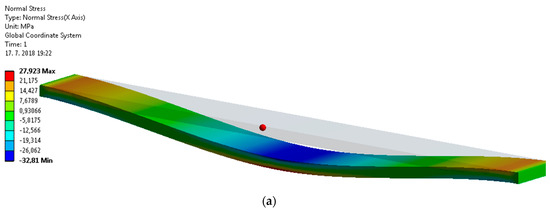

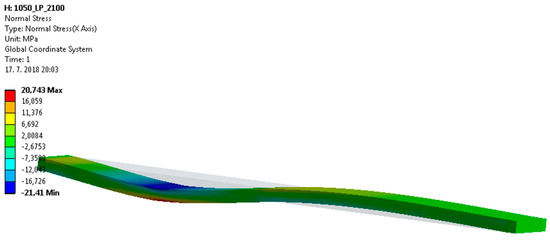

Figure 9.

Development of normal stresses measured on the height of the support beam of bed slats, L1 = 1050 mm from European beech 90 × 25 mm; (a) load 1400 N, unsupported beam; (b) load 2100 N, supported beam.

In some cases, not only safety but also material expenditures were taken into account. Therefore, a choice has to be made between the use of Norway spruce material recommended by the standard EN 1725:1998 or European beech. In the case of the Norway spruce wood, if the support beam of bed slats is 1500 mm and the applied load is 2100 N, a cross section of 95 mm × 24 mm has to be used; this means the cross-sectional area increases by 20%. The maximum compressive stress σc,0,d = 21.41 MPa and tensile stress σt,0,d = 20.743 MPa (Figure 10) corresponds to the design strength of spruce sawn timber [83] (Table 2).

Figure 10.

Development of normal stresses measured on the height of the spruce support beam with a cross section of 90 mm × 24 mm and a length of L1 = 1050 mm.

Table 5 shows the normal stresses and deformations of a bed sideboard with a length of l = 2000 mm in the case of normal and increased load.

Table 5.

Evaluation of stresses and deformations in the bed sideboard.

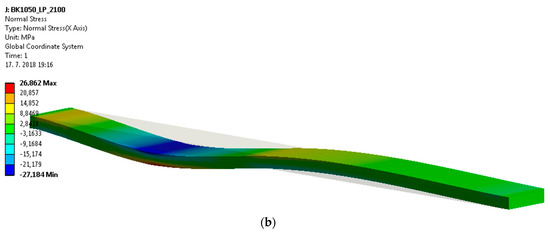

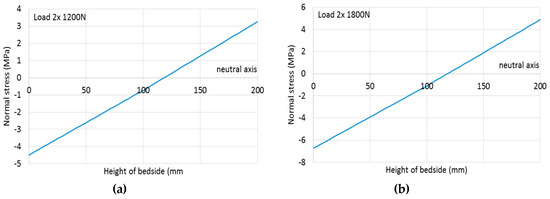

Development of normal stresses (y-axis) along the length of the cross section (x-axis) is shown in Figure 11. The bed sideboard with the standard cross section of 25 mm × 200 mm, made from the beech wood is suitable for use in terms of normal and increased stresses. The maximum values of normal and shear stress were not exceeded in the process of simulation. The design tensile strength of beech wood along the grain is ft,0,d = 35.53 MPa and the design compressive strength of beech wood along the grain is fc,0,d = 18.32 MPa. Calculated values show that the edge of bed described by the sideboard is fit for the load resulting from the excess weight of a user of 150 kg.

Figure 11.

Tensile stress, σt and compressive stress, σc in the sideboard of the beam; (a) load 1200 N; (b) load 1800 N.

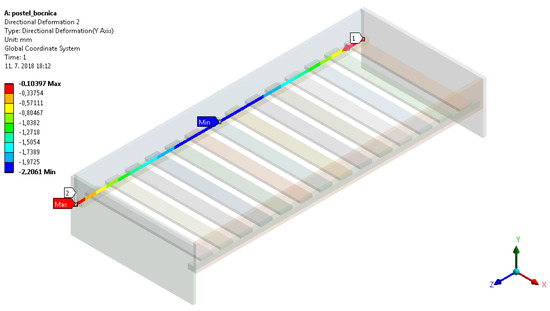

The bed sideboard is also fit for the use in terms of deformation. The maximum deformation with the increased load is ymax = 2.2061 mm. The deformation meets the condition that the bend of a beam is ymax < L/333 while L is the length of a beam. In our case, y = L/333 = 2000/333 = 6.006 mm, which means the condition ymax < y is met. The development of the deformation of the bed sideboard is illustrated in Figure 12.

Figure 12.

Deformation of the bed sideboard when the load increases.

4. Discussion and Conclusions

An increase in weight of the population in the Slovak Republic (as well as in other countries) has occurred recently. For example, the 95th percentile for weight has increased from 102 kg to 110 kg (more than 130 thousand men weigh more than 110 kg) over the last 25 years in Slovakia. Not only weight but other anthropometric data, such as height, shoulder breadth, and waistband width has increased as well. The design of furniture of all types (bedroom, seating furniture, cabinets, tables and multi-functional furniture) has to correspond with the dimensions and weight of current as well as future populations. Structural proposals for safe beds are based on standard dimensions and weight; which results in beds measuring 80 cm × 200 cm and 90 cm × 200 cm for the users weighing up to 110 kg. Following our analysis, these parameters are considered to be inadequate. We propose that the size of beds should be extended to 105 cm × 200 cm with a load capacity up to 150 kg. Therefore, it is necessary to improve the existing standards for testing beds; new standards for people weighing over 150 kg must be developed. In the case of a support beam with a length of more than 1000 mm, it must be supported. This should also be included in suggestions for the construction of safe beds. Our research shows that the spruce beam for bed slats with a length of 800 mm without support fits for use with a normal load (the 1400 N corresponds with the users’ weight of 110 kg). Spruce beams of 900 mm and 1050 mm cannot be used when the load is normal, which is inconsistent with the suggestions for the construction of safe beds. In the case of spruce beams and increased load (2100 N corresponds with the weight of 150 kg), no length of spruce beam is fit for use (800 mm, 900 mm, 1050 mm). Changes in material and structure must be designed in order to use standard bed slats by users with excessive weight. In terms of material changes, we think beech wood, which is stronger in comparison to commonly used spruce wood, is more suitable for use. Following the results of our research, we can state that the beech beam, with a length of 900 mm and 1050 mm, is fit for use with normal load with no support. In case of changes in structure and the normal load, a spruce beam of 900 mm and 1050 mm, can only be used when supported in the centre. The results show that the spruce beam must also be also supported in the case of the standard bed width of 800 mm when the weight of the user is 150 kg. The stress in the slats extend the design strength f0,d by 13%. Only bed slats made of beech wood supported in the centre can be used when the width of bed slats is 1050 mm, which means it is suitable for users with excess weight. If the beech sawn timber cannot be used to make the bed slats, the slats made of spruce with dimensions of 95 × 20 mm must be replaced by those higher in cross section. In our case, when the load is 2100 N and the length of the bed slats is 1050 mm, a cross section of 90 × 24 mm, and of course supported, must be used.

Following the results of the research, it can be concluded that changes in the material and dimensions of the supporting construction parts of beds must correspond with the requirements of overweight users. Moreover, the standards associated with the safety requirements of bedroom furniture for users who weigh more than 110 kg must be created in Slovakia.

In the future, we suggest expanding this research into other products that have to carry increasing body weight like (airplane) chairs, surgery tables, toilet seats, etc., similar to the research into chairs [48]. In addition to that, anthropometric measurements and the dimensions of furniture for current generation must be updated regularly. Modification of the standard dimensions for furniture requires interdisciplinary collaboration between anthropologists, ergonomists, developers and health professionals. This is the only way that a multidisciplinary approach can deliver results in the production of health-conscious consumer products.

A wider group of users will be able to use the furniture due to its functional properties, and more innovation in furniture making will help to lead the furniture industry towards sustainability. Sustainability, that is, development that meets the needs of the present without compromising the ability of future generations to meet their own needs includes attention to natural and physical resources (the planet), but also attention to human and social resources (people), in combination with economic sustainability (profit) [84,85,86,87,88,89,90]. In this way, we will achieve the sustainability of standards and their timeliness.

Author Contributions

Conceptualization, R.R., Ľ.K., M.H., N.L. and P.J.; Data curation, Ľ.K., M.H., N.L. and M.C.; Visualization, R.R., Ľ.K., M.H. and N.L.; Writing—original draft, R.R., Ľ.K., M.H. and P.J.

Funding

This research was funded by APVV 16-0297 Updating of anthropometric database of Slovak population.

Acknowledgments

This research was supported by the Slovak Research and Development Agency under the contract No. APVV-16-0297 “Updating the Anthropometric Database of Slovak population” and No. APVV-14-0506 “Lowering the Formaldehyde Emission from Wood-based Panels by Environmental Progressive Modification of Polycondensation Adhesives with Biopolymers from Leather Waste, Natural Nanofillers, Additives and Activators” and VEGA No. 1/0626/16 “Mechanical Resistance of Glued Wooden Composites Against Dynamic Stress”.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Verhaert, V. Ergonomic analysis of integrated bed measurements: Towards smart sleep systems. Ergonomics 2011, 54, 169–178. [Google Scholar] [CrossRef]

- Navrátil, V. Čalunenie; Technical University in Zvolen: Zvolen, Slovakia, 2001. [Google Scholar]

- Camden, S.G. Nursing care of the bariatric patient. Bariatr. Nurs. Surg. Patient Care 2006, 1, 21–30. [Google Scholar] [CrossRef]

- Kornoš, P. Analýza Čaluneného Nábytku z Pohľadu Konštrukcie; Technical University in Zvolen: Zvolen, Slovakia, 2009. [Google Scholar]

- Hitka, M.; Hajduková, A. Antropometrická optimalizácia rozmerov lôžkového nábytku. Acta Facultatis Xylologiae Zvolen 2013, 55, 101–109. [Google Scholar]

- Wiggermann, N.; Smith, K.; Kumpar, D. What bed size does a patient need? The relationship between body mass index and space required to turn in bed. Nurs. Res. 2017, 66, 483–489. [Google Scholar] [CrossRef]

- Sedmák, R.; Hitka, M. Analýza zmien antropometrických údajov dospelej populácie na území Slovenska. In Proceedings of the Conference Management of Human Potential in the Enterprise, Zvolen, Slovakia, 18–19 May 2004. [Google Scholar]

- Sedmák, R.; Hitka, M. Dynamika zmien vybraných antropometrických znakov populácie Slovenska. Hum. Resour. Manag. Ergon. 2007, 3, 24–34. [Google Scholar]

- Malina, R.M. Secular trends in growth, maturation and physical performance: A review. Anthropol. Rev. 2004, 67, 3–31. [Google Scholar]

- Hauspie, R.C.; Vercauteren, M.; Susanne, C. Secular changes in growth and maturation: An update. Acta Paediatr. 1997, 423, 20–27. [Google Scholar] [CrossRef]

- Cole, T.J. Secular trends in growth. Proc. Nutr. Soc. 2000, 59, 317–324. [Google Scholar] [CrossRef]

- Cole, T.J. The secular trend in human physical growth: A biological view. Econ. Hum. Biol. 2003, 1, 161–168. [Google Scholar] [CrossRef]

- Sharp, M.A.; Patton, J.F.; Knapik, J.J.; Hauret, K.; Mello, R.P.; Ito, M.; Frykman, P.N. Comparison of the physical fitness of men and women entering the U.S. Army: 1978–1998. Med. Sci. Sports Exerc. 2002, 34, 356–363. [Google Scholar] [CrossRef]

- Knapik, J.J.; Sharp, M.A.; Darakjy, S.; Jones, S.B.; Hauret, K.G.; Jones, B.H. Temporal changes in the physical fitness of US Army recruits. Sports Med. 2006, 36, 613–634. [Google Scholar] [CrossRef]

- Yokota, M.; Barthalon, G.P.; Berglund, L.D. Assessment of male anthropometric trends and the effects on simulated heat stress responses. Eur. J. Appl. Psychol. 2008, 104, 297–302. [Google Scholar] [CrossRef] [PubMed]

- Bolstad, G.; Benum, B.; Rokne, A. Anthropometry of Norwegian light industry and Office workers. Appl. Ergon. 2001, 32, 239–246. [Google Scholar] [CrossRef]

- Hanson, L.; Sperling, L.; Gard, G.; Ipsen, S.; Vergara, C.O. Swedish anthropometrics for product and workplace design. Appl. Ergon. 2009, 40, 797–806. [Google Scholar] [CrossRef]

- Sundet, J.M. The Flynn Effect in Families: Studies of Register Data on Norwegian Military Conscripts and Their Families. J. Intell. 2014, 2, 106–118. [Google Scholar] [CrossRef]

- Barroso, M.P.; Arezes, P.M.; Da Costa, L.G.; Miguel, A.S. Anthropometric study of Portuguese workers. Int. J. Ind. Ergon. 2005, 35, 401–410. [Google Scholar] [CrossRef]

- Leitão, R.B.; Rodrigues, L.P.; Neves, L.; Carvalho, G.S. Development of adiposity, obesity and age at menarche: An 8-year follow-up study in Portuguese schoolgirls. Int. J. Adolesc. Med. Health 2013, 25, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Kayis, B.; Ozok, A.F. The anthropometry of Turkish army men. Appl. Ergon. 1991, 22, 49–54. [Google Scholar] [CrossRef]

- Jelačič, D.; Greger, K.; Grladinovič, T. Research on anthropometric characteristics of high school students and ergonomic characteristics of high school furniture. Drvna Ind. 2002, 53, 99–106. [Google Scholar]

- Martín-Merino, E.; Huerta-Álvarez, C.; Prieto-Alhambra, D.; Álvarez-Gutiérrez, A.; Montero-Corominas, D. Secular trends of use of anti-osteoporotic treatments in Spain: A population-based cohort study including over 1.5 million people and more than 12 years of follow-up. Bone 2017, 105, 292–298. [Google Scholar] [CrossRef]

- Myburgh, J.; Staub, K.; Ruhli, F.J.; Smith, J.R.; Steyn, M. Secular trend in stature of late 20th century white South Africans and two European populations. HOMO J. Comp. Hum. Biol. 2017, 68, 433–439. [Google Scholar] [CrossRef]

- Chuan, T.K.; Hartono, M.; Kumar, N. Anthropometry of the Singaporean and Indonesian populations. Int. J. Ind. Ergon. 2010, 40, 757–766. [Google Scholar] [CrossRef]

- Zhao, J.; Su, C.; Wang, H.; Wang, Z.; Wang, Y.; Zhang, B. Secular Trends in Energy and Macronutrient Intakes and Distribution among Adult Females (1991–2015): Results from the China Health and Nutrition Survey. Nutrients 2018, 10, 115. [Google Scholar] [CrossRef]

- Zheng, W.; Suzuki, K.; Yokomichi, H.; Sato, M.; Yamagata, Z. Multilevel longitudinal analysis of sex differences in height gain and growth rate changes in Japanese school-aged children. J. Epidemiol. 2013, 23, 275–279. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wang, M.J.J.; Wang, E.M. The comparisons of anthropometric characteristics among four peoples in East Asia. Appl. Ergon. 2004, 35, 173–178. [Google Scholar] [CrossRef]

- Zong, Y.; Xie, R.; Deng, N.; Liu, L.; Tan, W.; Gao, Y.; Yang, J.; Yang, Y. Secular trends in overweight and obesity among urban children and adolescents, 2003–2012: A serial cross-sectional study in Guangzhou, China. Sci. Rep. 2017, 7, 12042. [Google Scholar] [CrossRef]

- Kothyial, K.; Tettey, S. Anthropometry data of elderly people in Australia. Appl. Ergon. 2000, 31, 329–332. [Google Scholar] [CrossRef]

- dos Santos, F.K.; Maia, J.A.R.; Gomes, T.N.Q.F.; Daca, T.; Madeira, A.; Damasceno, A.; Katzmarzyk, P.T.; Prista, A. Secular Trends in Habitual Physical Activities of Mozambican Children and Adolescents from Maputo City. Int. J. Environ. Res. Public Health 2014, 11, 10940–10950. [Google Scholar] [CrossRef]

- Mokdad, M. Anthropometric study of Algerian farmers. Int. J. Ind. Ergon. 2002, 29, 331–341. [Google Scholar] [CrossRef]

- Wang, Y.; Beydoun, M.A. The obesity epidemic in the United States—Gender, age, socioeconomic, racial/ethnic, and geographic characteristics: A systematic review and meta-regression analysis. Epidemiol. Rev. 2007, 29, 6–28. [Google Scholar] [CrossRef]

- Stevens, G.A.; Singh, G.M.; Lu, Y.; Danaei, G.; Lin, J.K.; Finucane, M.M.; Bahalim, A.N.; McIntire, R.K.; Gutierrez, H.R.; Cowman, M.; et al. National, regional, and global trends in adult overweight and obesity prevalences. Popul. Health Metr. 2012, 10, 22. [Google Scholar] [CrossRef]

- Tremmel, M.; Gerdtham, U.-G.; Nilsson, P.M.; Saha, S. Economic Burden of Obesity: A Systematic Literature Review. Int. J. Environ. Res. Public Health 2017, 14, 435. [Google Scholar] [CrossRef]

- González-Rodríguez, L.G.; Perea Sánchez, J.M.; Aranceta-Bartrina, J.; Gil, Á.; González-Gross, M.; Serra-Majem, L.; Varela-Moreiras, G.; Ortega, R.M. Intake and Dietary Food Sources of Fibre in Spain: Differences with Regard to the Prevalence of Excess Body Weight and Abdominal Obesity in Adults of the ANIBES Study. Nutrients 2017, 9, 326. [Google Scholar] [CrossRef]

- Burke, N.L.; Shomaker, L.B.; Brady, S.; Reynolds, J.C.; Young, J.F.; Wilfley, D.E.; Sbrocco, T.; Stephens, M.; Olsen, C.H.; Yanovski, J.A.; et al. Impact of Age and Race on Outcomes of a Program to Prevent Excess Weight Gain and Disordered Eating in Adolescent Girls. Nutrients 2017, 9, 947. [Google Scholar] [CrossRef]

- Vuong, Q.-H.; Hoang, A.-D.; Vuong, T.-T.; La, V.-P.; Nguyen, H.K.T.; Ho, M.-T. Factors Associated with the Regularity of Physical Exercises as a Means of Improving the Public Health System in Vietnam. Sustainability 2018, 10, 3828. [Google Scholar] [CrossRef]

- Ogden, C.L.; Carroll, M.D.; Fryar, C.D.; Flegal, K.M. Prevalence of Obesity among Adults and Youth: United States, 2011–2014. NCHS Data Brief, 219, 1–8. 2015. Available online: https://www.cdc.gov/nchs/data/databriefs/db219.pdf (accessed on 4 December 2018).

- Finucane, M.M.; Stevens, G.A.; Cowan, M.J.; Danaei, G.; Lin, J.K.; Paciorek, C.J.; Singh, G.M.; Gutierrez, H.R.; Lu, Y.; Bahalim, A.N.; et al. Global burden of metabolic risk factors of chronic diseases collaborating group (body mass index). Lancet 2011, 377, 557–567. [Google Scholar] [CrossRef]

- de Onis, M.; Blössner, M.; Borghi, E. Global prevalence and trends of overweight and obesity among preschool children. Am. J. Clin. Nutr. 2010, 92, 1257–1264. [Google Scholar] [CrossRef]

- Chan, R.S.; Woo, J. Prevention of Overweight and Obesity: How Effective is the Current Public Health Approach. Int. J. Environ. Res. Public Health 2010, 7, 765–783. [Google Scholar] [CrossRef]

- Peltzer, K.; Pengpid, S.; Samuels, T.A.; Özcan, N.K.; Mantilla, C.; Rahamefy, O.H.; Wong, M.L.; Gasparishvili, A. Prevalence of Overweight/Obesity and Its Associated Factors among University Students from 22 Countries. Int. J. Environ. Res. Public Health 2014, 11, 7425–7441. [Google Scholar] [CrossRef]

- Flegal, K.M.; Carroll, M.D.; Ogden, C.L.; Curtin, L.R. Prevalence and trends in obesity among US adults, 1999–2008. JAMA 2010, 303, 235–241. [Google Scholar] [CrossRef]

- Rockholm, B.; Baker, J.L.; Sørensen, T.I.A. The levelling off of the obesity epidemic since the year 1999—A review of evidence and perspectives. Obes. Rev. 2010, 11, 835–846. [Google Scholar] [CrossRef] [PubMed]

- Odunitan-Wayas, F.; Okop, K.; Dover, R.; Alaba, O.; Micklesfield, L.; Puoane, T.; Uys, M.; Tsolekile, L.; Levitt, N.; Battersby, J.; et al. Food Purchasing Characteristics and Perceptions of Neighborhood Food Environment of South Africans Living in Low-, Middle- and High-Socioeconomic Neighborhoods. Sustainability 2018, 10, 4801. [Google Scholar] [CrossRef]

- Hitka, M.; Sedmák, R.; Joščák, P.; Ližbetinová, L. Positive Secular Trend in Slovak Population Urges on Updates of Functional Dimensions of Furniture. Sustainability 2018, 10, 3474. [Google Scholar] [CrossRef]

- Hitka, M.; Joščák, P.; Langová, N.; Krišťák, Ľ.; Blašková, S. Loar-Carrying Capacity and the Size of Chair Joints Determined for Users with a Higher Body Weight. Bioresources 2018, 13, 6428–6443. [Google Scholar] [CrossRef]

- Bellingar, T.A.; Benden, M.E. New ANSI/BIFMA standard for testing of educational seating. Ergon. Des. Q. Hum. Factors Appl. 2015, 23, 23–27. [Google Scholar] [CrossRef]

- Dvouletá, K.; Káňová, D. Utilization of anthropometry in the sphere of sitting and bed furniture. Acta Univ. Agric. Silvic. Mendel. Brun. 2014, 62, 81–90. [Google Scholar] [CrossRef]

- Muir, M.; Archer-Heese, G. Essentials of a bariatric patient handling program. OJIN Online J. Issues Nurs. 2009, 14. [Google Scholar] [CrossRef]

- Gourash, W.; Rogula, T.; Schauer, P.R. Essential Bariatric Equipment: Making Your Facility More Accommodating to Bariatric Surgical Patients; Springer: New York, NY, USA, 2007. [Google Scholar]

- Prokopec, M. Sedací a lehací čalouněný nábytek. Antropol. Ergon. Pohled. Lignum 1998, 2, 6–10. [Google Scholar]

- Benda-Prokeinová, R.; Dobeš, K.; Mura, L.; Buleca, J. Engel’s approach as a tool for estimating consumer behavior. E M Ekon. Manag. 2017, 20, 15–29. [Google Scholar] [CrossRef]

- Veselovský, J.; Baďura, R. Slovakian folk wooden cradle design, construction, typology and kinematics. Acta Fac. Xylologiae 2017, 59, 155–165. [Google Scholar] [CrossRef]

- Igaz, R.; Macek, Š.; Zemiar, J. The influence of unidirectional cyclic bend loading on initial relaxation speed of beech lamellas. Acta Fac. Xylologiae 2014, 56, 27–35. [Google Scholar]

- Gejdoš, M.; Tončíková, Z.; Němec, M.; Chovan, M.; Gergeľ, T. Balcony cultivator: New biomimicry design approach in the sustainable device. Futures 2018, 98, 32–40. [Google Scholar] [CrossRef]

- Irle, M.A.; Barbu, M.C.; Réh, R.; Bergland, L.; Rowell, R.M. Wood Composites; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Barbu, M.C.; Réh, R.; Irle, M.A. Wood-Based Composites; IGI Global: Hershey, PA, USA, 2014. [Google Scholar]

- Willard, D.T.; Loferski, J.R. Skateboards as a Sustainable Recyclable Material. Recycling 2018, 3, 20. [Google Scholar] [CrossRef]

- Smardzewski, J. Furniture Design; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar]

- Smardzewski, J.; Preklad, S. Stress distribution in disconnected furniture joints. Electron. J. Pol. Agric. Univ. 2002, 5, 1–7. [Google Scholar]

- Rohanová, A.; Nunez, E. Prediction models of Slovakian structural timber. Wood Res. 2014, 5, 757–767. [Google Scholar]

- Kasal, A.; Kuskun, T.; Haviarova, E.; Erdil, Y.Z. Static front to back loading capacity of wood chairs and relationships between chair strength and individual joint strength. Bioresources 2016, 11, 9359–9372. [Google Scholar] [CrossRef]

- Horman, I.; Hajdarevič, S.; Martinovič, S.; Vukas, N. Numerical analysis of stress and strain in a wooden chair. Drvna Ind. 2010, 61, 151–158. [Google Scholar]

- Horman, I.; Martinovič, S.; Hajdarevič, S. Finite volume method for analysis of stress and strain in wood. Drvna Ind. 2009, 60, 27–32. [Google Scholar]

- Gustafsson, S.I. Furniture design by use of finite element method. Holy Roh. Werkst. 1995, 53, 257–260. [Google Scholar] [CrossRef]

- Gustafsson, S.I. Finite element modelling versus reality for birch chairs. Holz Roh. Werkst. 1996, 54, 355–359. [Google Scholar] [CrossRef]

- Ministry of Health of the Slovak Republic. Report on health status in Slovakia. HEALTH 2016. Available online: http://health.gov.sk (accessed on 1 February 2018).

- Public Health Authority of the Slovak Republic. Annual Report on the Activities of the Public Health Office for 2017. Available online: http://uvzsr.sk/docs/vs/vyrocna_sprava_2017.pdf (accessed on 1 February 2018).

- Statistical Office of the Slovak Republic. View of Health Status of the Slovak Population and Its Determinants (Results of EHIS 2016). Available online: http://slovak.statistics.sk (accessed on 1 February 2018).

- Ng, M.; Fleming, T.; Robinson, M.; Tomson, B.; Graetz, N.; Margono, C.; Mullany, E.C.; Biryukov, S.; Abbafati, C.; Abera, S.F.; et al. Global, regional, and national prevalence of overweight and obesity in children and adults during 1980-2013: A systematic analysis for the Global Burden of Disease Study 2013. Lancet 2014, 384, 766–781. [Google Scholar] [CrossRef]

- Di Cesare, M.; Bentham, J.; Stevens, G.A.; Zhou, B.; Danaei, G.; Lu, Y.; Bixby, H.; Cowan, M.J.; Riley, L.M.R.; Hajifathalian, K.; et al. Trends in adult body-mass index in 200 countries from 1975 to 2014: A pooled analysis of 1698 population-based measurement studies with 19.2 million participants. Lancet 2016, 387, 1377–1396. [Google Scholar] [CrossRef]

- World Health Organization Regional Office for Europe. The Health Systems in Transition (HiT). Available online: http://euro.whoint/en/countries/slovakia (accessed on 1 February 2018).

- Tokarčíková, E.; Kucharčíková, A.; Ďurišová, M. Corporate social responsibility managers and their decision making. Turk. Online J. Educ. Technol. 2017, pp. 654–664. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-85048209196&origin=resultslist&sort=plf-f&src=s&st1=tokarcikova%2c+E.&st2=&sid=747c912fb7e26aef1630dbe062108b21&sot=b&sdt=b&sl=28&s=AUTHOR-NAME%28tokarcikova%2c+E.%29&relpos=0&citeCnt=0&searchTerm= (accessed on 10 November 2018).

- Vaňová, J.; Babeľová, Z.G.; Holková, A. Organizational information transfer as a tool for building-up employees economic awareness. In Proceedings of the European Conference on Knowledge Management, Famalicao, Portugal, 2–3 September 2010. [Google Scholar]

- Ližbetinová, L.; Lorincová, S.; Caha, Z. The application of the organizational culture assessment instrument (OCAI) to logistics enterprises. Nase More 2016, 63, 170–176. [Google Scholar] [CrossRef]

- EN 1725:1998 Domestic Furniture—Bed and Mattresses—Safety Requirements and Test Methods. Available online: https://furnitest.com/testing/furniture-testing/standards/en-17251998/ (accessed on 18 November 2018).

- Potkány, M.; Gejdoš, M.; Debnár, M. Sustainable innovation approach for wood quality evaluation in green business. Sustainability 2018, 10, 2984. [Google Scholar] [CrossRef]

- Matušková, M.; Klement, I. Colour change in high temperature drying of spruce wood. Acta Fac. Xylologiae 2009, 51, 47–53. [Google Scholar]

- Klement, I.; Huráková, T. The influence of drying characteristics and quality of spruce timber with content of reaction wood. Acta Fac. Xylologiae 2015, 57, 75–82. [Google Scholar]

- Požgaj, A.; Chovanec, D.; Kurjatko, S.; Babiak, M. Štruktúra a Vlastnosti Dreva; Príroda a.s.: Bratislava, Slovakia, 1993. [Google Scholar]

- Klement, I.; Huráková, T. Determining the influence of sample thickness on the high-temperature drying of beech wood (Fagus sylvatica L.). BioResources 2016, 11, 5424–5434. [Google Scholar] [CrossRef]

- Čuta, M.; Kukla, L.; Novák, L. Modelling the development of body height (length) in children using parental height data. Československá Pediatrie 2010, 65, 159–166. [Google Scholar]

- Mitterpach, J.; Hroncová, E.; Ladomerský, J.; Štefko, J. Quantification of Improvement in Environmental Quality for Old Residential Buildings Using Life Cycle Assessment. Sustainability 2016, 8, 1303. [Google Scholar] [CrossRef]

- Lorincová, S.; Potkány, M. The proposal of innovation support in Small and Medium-sized Enterprises. In Production Management and Engineering Sciences; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2016. [Google Scholar]

- Burton, P.J. Striving for Sustainability and Resilience in the Face of Unprecedented Change: The Case of the Mountain Pine Beetle Outbreak in British Columbia. Sustainability 2010, 2, 2403–2423. [Google Scholar] [CrossRef]

- May, N.; Guenther, E.; Haller, P. Environmental Indicators for the Evaluation of Wood Products in Consideration of Site-Dependent Aspects: A Review and Integrated Approach. Sustainability 2017, 9, 1897. [Google Scholar] [CrossRef]

- Delios, A. How can organizations be competitive but dare to care? Acad. Manag. Perspect. 2010, 24, 25–36. [Google Scholar] [CrossRef]

- Pfeffer, J. Building sustainable organizations: The human factor. Acad. Manag. Perspect. 2010, 24, 34–45. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).