1. Introduction

Agri-food supply chains play a pivotal role in providing farmers with access to markets, which affect the social, economic, and environmental sustainability of rural peasants [

1]. Farmers, agribusinesses, governments, and civil society must cooperate to promote inclusive and efficient food systems, better integrate small farmers into supply chains and agribusiness, and improve their access to markets. These models can increase the value added by raw materials, thereby boosting local rural economies, food security, and nutrition, and off-farm employment. Small-scale producers provide over 70% of the world’s food needs, and agribusiness is an important source of global employment and income. Improving the sustainability of the agri-food supply chain can benefit hundreds of millions of poor households in developing countries.

In the past few decades, much literature on supply chain management in the manufacturing and service sectors has been produced, but little attention has been paid to the agriculture sector [

2]. The agriculture sector contributes a major part of human livelihoods and raw materials to other industries in developing countries, such as Pakistan. Among agricultural products, food items have been least explored in supply chain management [

3]. Pakistan relies heavily on agriculture, which accounts for about 19% of the GDP, 43% of the labor force, and about 67% of rural farmers’ livelihoods [

4]. Although agriculture is the mainstay of rural farmers in Pakistan, rural poverty is widespread [

5].

The main cause of this widespread poverty is the dependence of the country’s agriculture on traditional agricultural production systems. However, due to the recognition of the importance of high-value agriculture (HVA), such as animal husbandry and horticultural products, farmers are now shifting from traditional agriculture to agribusiness [

6,

7]. Therefore, to improve profitability, SSCM of agri-food is now very important. However, Pakistan’s agricultural performance remains sluggish. The main factors contributing to this slow performance include the slow rate of technological innovation, limited adoption of progressive farming techniques, problems with the quality, quantity, and timeliness of inputs, limited investment in construction and infrastructure maintenance, marketing and trade restrictions, pest and livestock diseases, and limited amounts of credit for agricultural production and processing [

4].

The growth of HVA, the development of institutions for vertical integration, and other structural changes in agricultural supply chains present opportunities and challenges for farmers in developing countries. The opportunity for small farmers is to increase their income by participating in the modern supply chains for HVA commodities. The challenge for smallholders is that HVA commodities usually have a high cost of production and there are more risks in production and marketing. To overcome these types of challenges, there should be strong vertical linkages between farmers and other supply chain actors, but in some cases, farmers cannot meet modern food demands [

7]. The background and nature of these challenges must be fully understood throughout the production and marketing process of the agri-food industry to develop and implement appropriate solutions for the improvement of SSCM. Therefore, this study aims to identify and analyze key production and marketing constraints in the SSCM of the citrus industry at the upstream level of the chain.

In recent years, production and marketing constraints at the upstream level of agri-food industries have received enormous importance as a way of implementing SSCM practices. However, in the developing country of Pakistan, farmers still face several challenges in sustainable supply chain management practices. There is a need to address these constraints to facilitate widespread and successful SSCM practices. Therefore, the basic aim of this study is to investigate the critical production and marketing constraints of the citrus industry.

Supply chains operating in the Pakistan citrus industry are a typical example. They provides low value to the farmers as well as to the consumers, and the challenges in the SSCM negatively affect the overall performance of the industry, preventing it from reaching its full potential, particularly the meager share of exports to the total mandarin production [

8]. At the same time, the development of the horticultural industry is in the government’s priority policy area, and public and private stakeholders are deeply concerned with identifying solutions to resolve emerging challenges for the development of the horticultural industry. To overcome these problems, this study provides guidance on how these challenges and issues should be addressed in a developing country, much less in a single industry, such as Pakistan’s citrus industry.

Citrus is the leading fruit in terms of production in Pakistan, i.e., 2.36 million tons is produced from an area of 206.6 thousand hectares [

9]. Pakistan is also the 13th largest producer and 5th largest exporter of citrus in the world [

10]. The citrus market in Pakistan is segmented broadly in traditional or informal and modern or formal sectors. The traditional sector includes direct sales as village retailers, sales to intermediaries, and sales at traditional fruit and vegetable markets that exist in almost every city in the country. The modern sector includes the sales to the local processors or juice manufacturing factories, from where it is processed in different juices or exported after waxing and processing by increasing its shelf life. Most of the small village farmers sell their produce through the traditional channel [

8,

11].

In Pakistan, the fruit-bearing life of citrus orchard trees is 20 to 30 years, which is low compared with other citrus producing countries, where its span goes up to 50 years [

12]. The basic factor affecting the citrus supply chain is a lesser use of high-quality citrus production techniques. Farmers do not realize the orchard as an endeavor; rather, they grow citrus as additional crops in the field. So, they are not able to fulfill the demand of the citrus crop at the time of need; they create a huge gap in citrus production as they do intercrop different crops in the citrus orchard, which cause unfavorable losses to the citrus plants and production [

12]. Intercropping of valuable crops may increase crop diversification and increase the sustainability of family farms, as crop diversification improves food security and household diets, and reduces market and weather risks, not to mention environmental sustainability [

13]. However, this is not the case for Pakistan, as most citrus growers only cultivate forage crops in citrus orchards. Due to the growth of several weeds in the orchard, the cultivation of different forage crops leads to a reduction in citrus production [

14]. In addition, the cultivation and harvesting of forage crops can damage citrus fruits. This effect is more pronounced in the fruiting stage of citrus [

15].

The citrus supply chain along with other agri-food commodities has become ineffective, resulting in a decrease in net returns with the passage of time [

16]. Multiple factors are responsible for this ineffective supply chain, including variant climatic conditions [

17,

18]. Inadequate technical support, poor availability of improved varieties, outdated irrigation approaches, an infestation of diseases, and abrupt climatic changes are stressors for the supply chain [

19]. Poor planning and quality ignorance are additional factors affecting supply [

20]. Poor quality assurance followed by the adoption of traditional packaging practices appears inconvenient for higher returns in the international market [

6]. This miserable condition is costing a loss of millions to the national economy and the livelihoods of the growers.

In the true sense, effective SSCM of citrus can harness the best outcomes and attract the international market. Quality produce can boost livelihoods and present a significant share in the national economy [

21]. Apart from citrus, all HVA commodities are highly competitive in the international market and get high returns. Citrus, in this regard, is special because of the strong comparative advantage in mandarins [

6]. Despite being one of the world’s largest exporters of mandarins, entry into high-value markets has been tough thus far, possibly due to quality issues.

Despite the considerable amount of literature on the downstream levels of agri-food industries for SSCM in Pakistan [

7,

22,

23,

24], no studies have attempted to empirically identify the constraints of the upstream level for SSCM of agri-food industries, especially citrus. The upstream level of the citrus supply chain is of prime importance for two reasons. First, it includes farmers who are the main actors in the SSCM of the citrus industry. Second, the upstream level also severely affects participants at the downstream level, ultimately affecting citrus exports. Considering the importance of citrus fruit in the national economy and livelihoods, this study was planned to empirically identify the key constraints on the upstream level in SSCM of the citrus industry in Punjab, Pakistan.

Theoretical Background

There are several studies that have emphasized the constraints in the citrus supply chain in Pakistan. These constraints cause enormous post-harvest losses in citrus fruits. For example, Johnson [

25] estimated that these losses were about 40% in Pakistani citrus fruit. Some studies have shown that 35% of Pakistan’s total citrus production is lost in the process of supplying fruit from one place to another [

12]. The percentage of total post-harvest losses is even higher at the farmer level [

26]. These statistics show that agri-food supply chains, such as citrus, are affected by various factors at the upstream level of the chain.

The main actor at the upstream of the supply chain is the farmer, and the associated factors can be aggregated into production and marketing constraints. In the past, SSCM only dealt with the efficient production marketing of the raw material to its final destination [

27]. However, today, several other factors are also involved in SSCM, such as climatic factors and quality standards [

27,

28,

29]. In the future, it will become one of the biggest opportunities in the history of economics and commerce [

30]. As incomes rise, there will be an increase in the demand for environmental standards and people will become more concerned regarding environmental standards [

31].

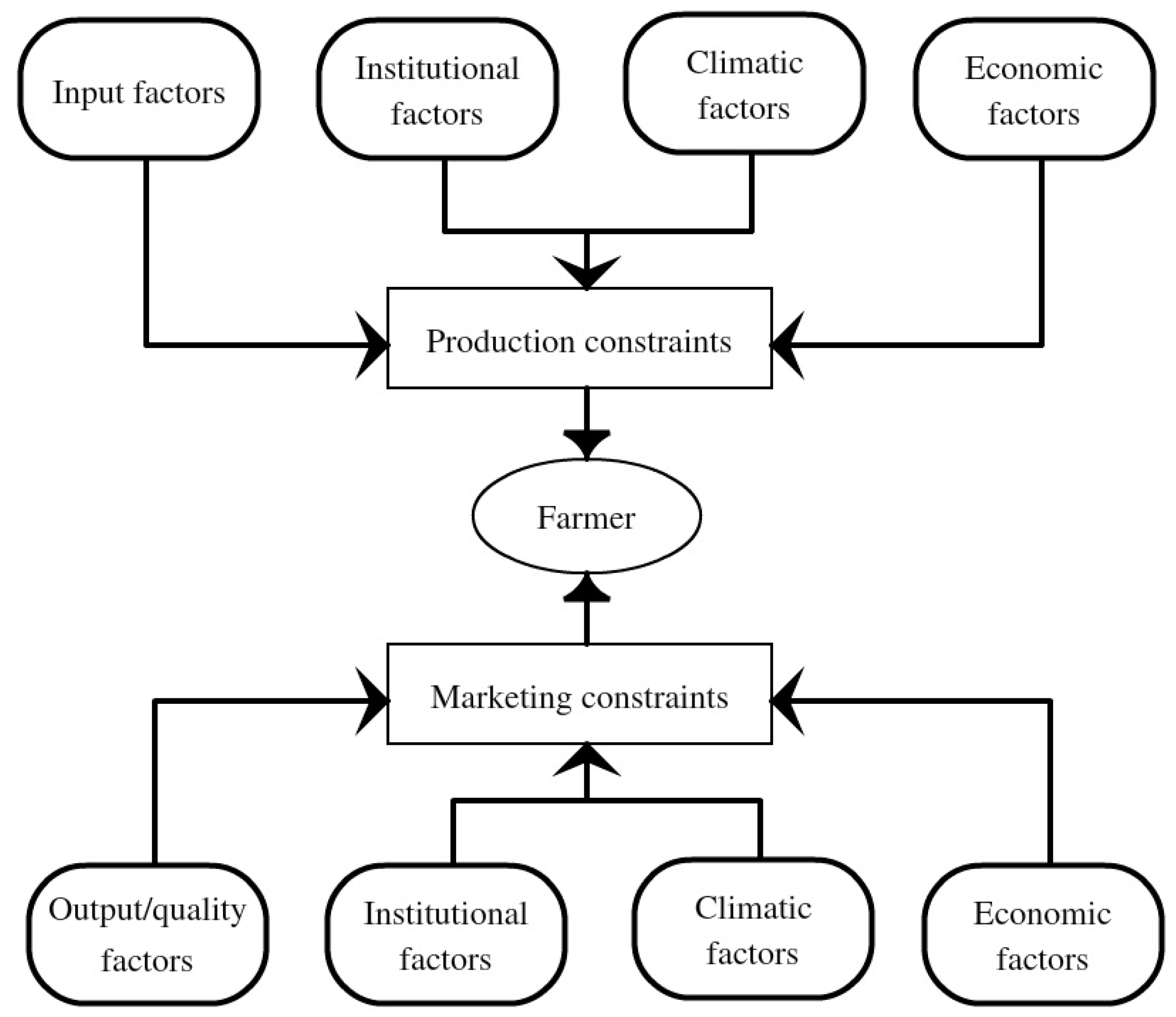

The literature suggests that at the upstream level of the supply chain, farmers are associated with production and marketing related constraints [

26,

32,

33] as shown in

Figure 1. On the production side, input related factors include the use of pesticides, fertilizers, irrigation, and seed, and all inputs used in the production of such crops; institutional factors, such as the extension department and the access of credit related institutions; climatic factors, including rainfall patterns, severe temperatures, smog, and humidity, etc.; and economic factors, including farmers’ income related issues. On the marketing side, input factors are replaced by output related factors and all others remain the same. Output related factors include any quality issues of the produce, output packaging, and output grading, etc.

5. Concluding Remarks

The implementation of SSCM practices at the upstream level of the chain in agri-food industries has received a high level of global attention. However, like many other developing countries, SSCM practices are still in their infancy and face many constraints in agri-food industries of Pakistan. The citrus industry in Pakistan is a typical example of poor management of SSCM. However, improving SSCM of the citrus industry can significantly increase export earnings for the country. This can be achieved by effectively addressing the issues and constraints in the entire citrus supply chain. Although there is a large body of literature on the downstream levels for SSCM in agri-food industries, no studies have attempted to empirically determine the limiting factors for the upstream level. The upstream level of the SSCM includes farmers who are the main participants. Addressing upstream issues can improve the performance of the entire citrus supply chain. To this end, this study aimed to identify and analyze the key constraints and issues in the upstream level that affect the production and marketing of the citrus industry in Pakistan. The study was conducted in three locations in the Sargodha district of Punjab, Pakistan. We conducted five farmer group discussions (FGDs) to identify or list important constraints for SSCM of the citrus industry. Farmers reported 30 constraints in the production and marketing of citrus. These constraints were also validated by an extensive literature survey. Further, we used Kendal’s coefficient of concordance (Kendall’s W- technique) and the mean score normalization technique to identify 11 critical constraints that severely influence production and marketing at the upstream level in the citrus supply chain. On the production side, the quality of fertilizer, high input costs, quality of pesticide, harsh climatic conditions, and performance of labor are found to be the most critical constraints faced by the farmers in the study area. Whereas, on the marketing side, a lack of packaging facilities in the village and union councils, lack of quality incentives (premium price) for proper grading of the fruit size, the perishable nature of the product, lack of storage infrastructure, and lack of quality incentives for proper packaging are the most critical citrus marketing constraints.

Furthermore, we used principal component analysis to classify the 30 constraints identified in the FGDs into six different groups, namely quality-related constraints, risk and climate-related constraints, economic constraints, knowledge and information-related constraints, geographic and transport-related constraints, and infrastructure-related constraints. The results of this study not only fill the literature gap of SSCM at the upstream level of the chain, but also help to develop policies and take appropriate measures to address the problems and constraints faced by farmers in the SSCM of Pakistan’s citrus industry. While developing an SSCM policy to improve the citrus industry in Pakistan, the government should consider the constraints identified in this study.