Quest for Sustainability: Life-Cycle Emissions Assessment of Electric Vehicles Considering Newer Li-Ion Batteries

Abstract

:1. Introduction

2. LCA Data and Methodology

2.1. Vehicle Characterization

2.2. Batteries

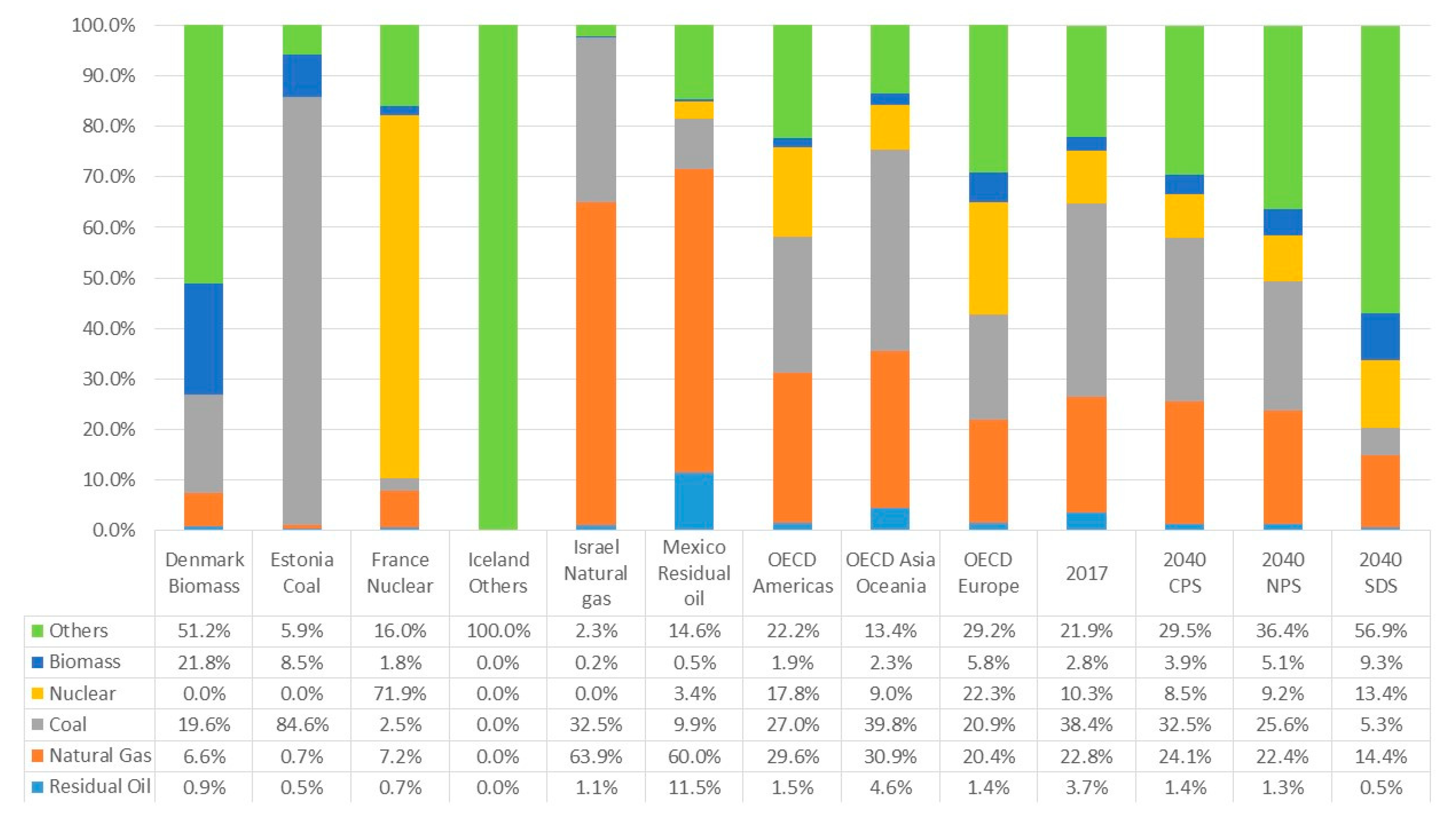

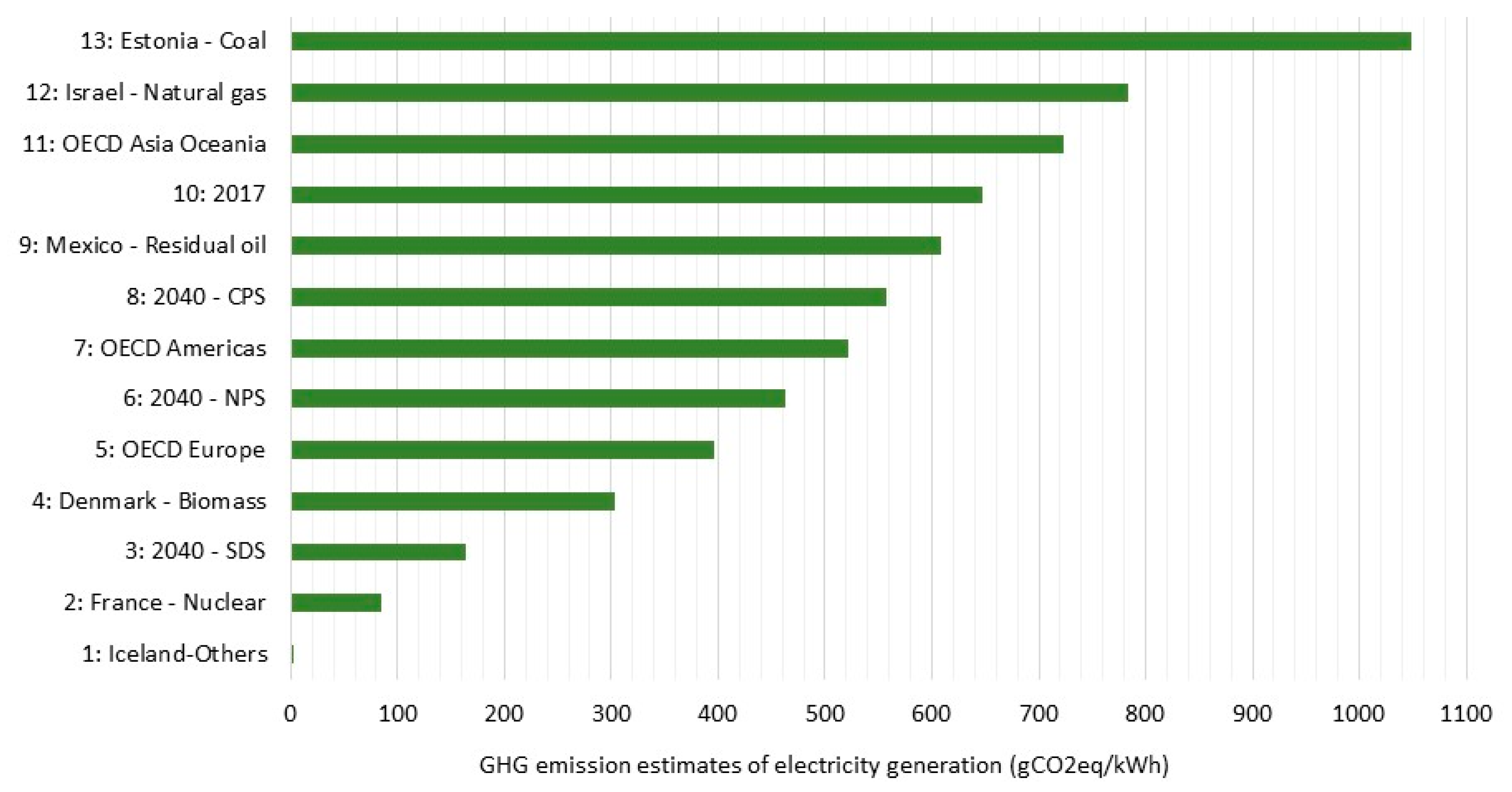

2.3. Electricity Generation Mix

2.4. Procedure and Statistical Methods

3. Results and Discussion

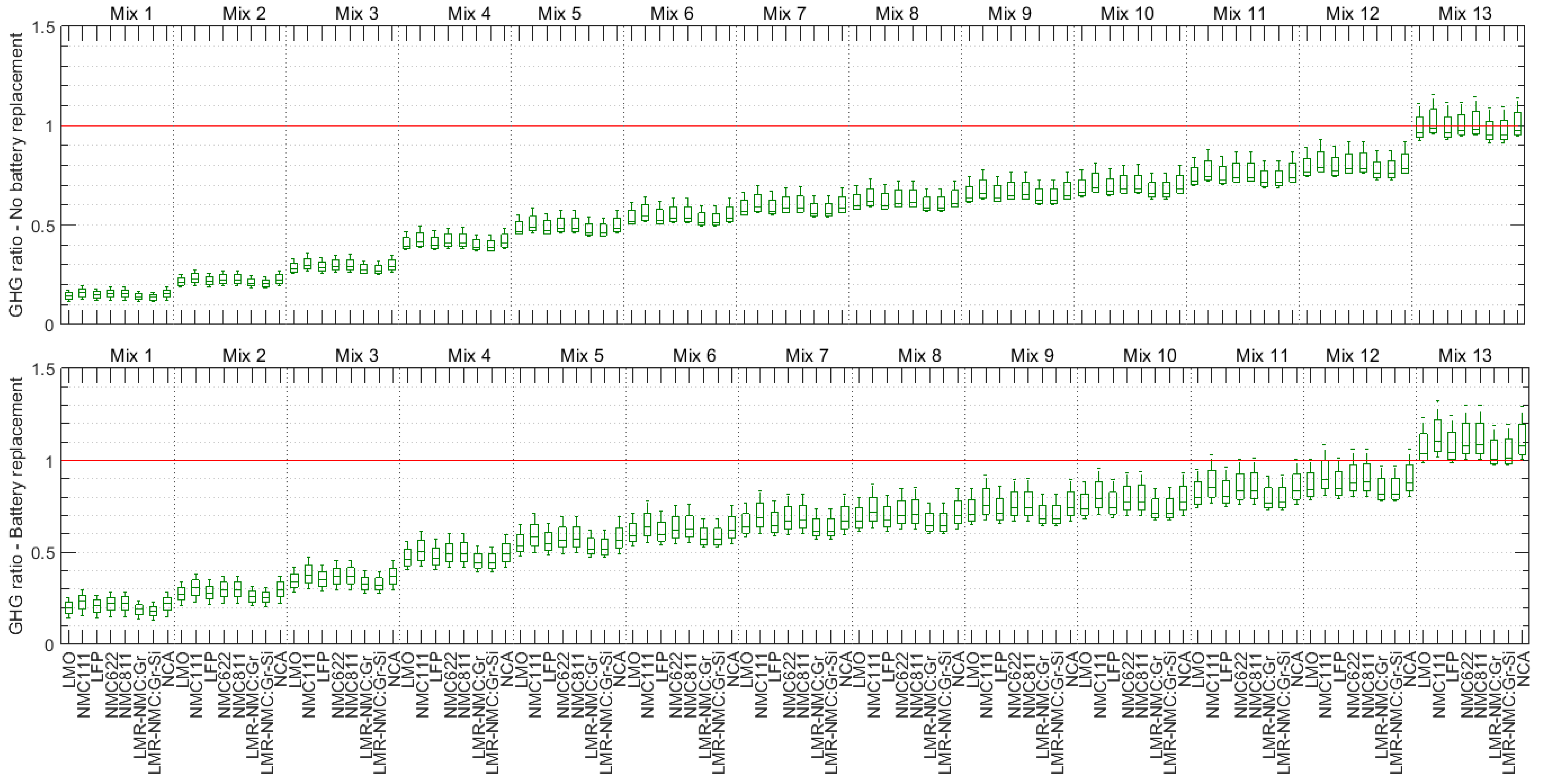

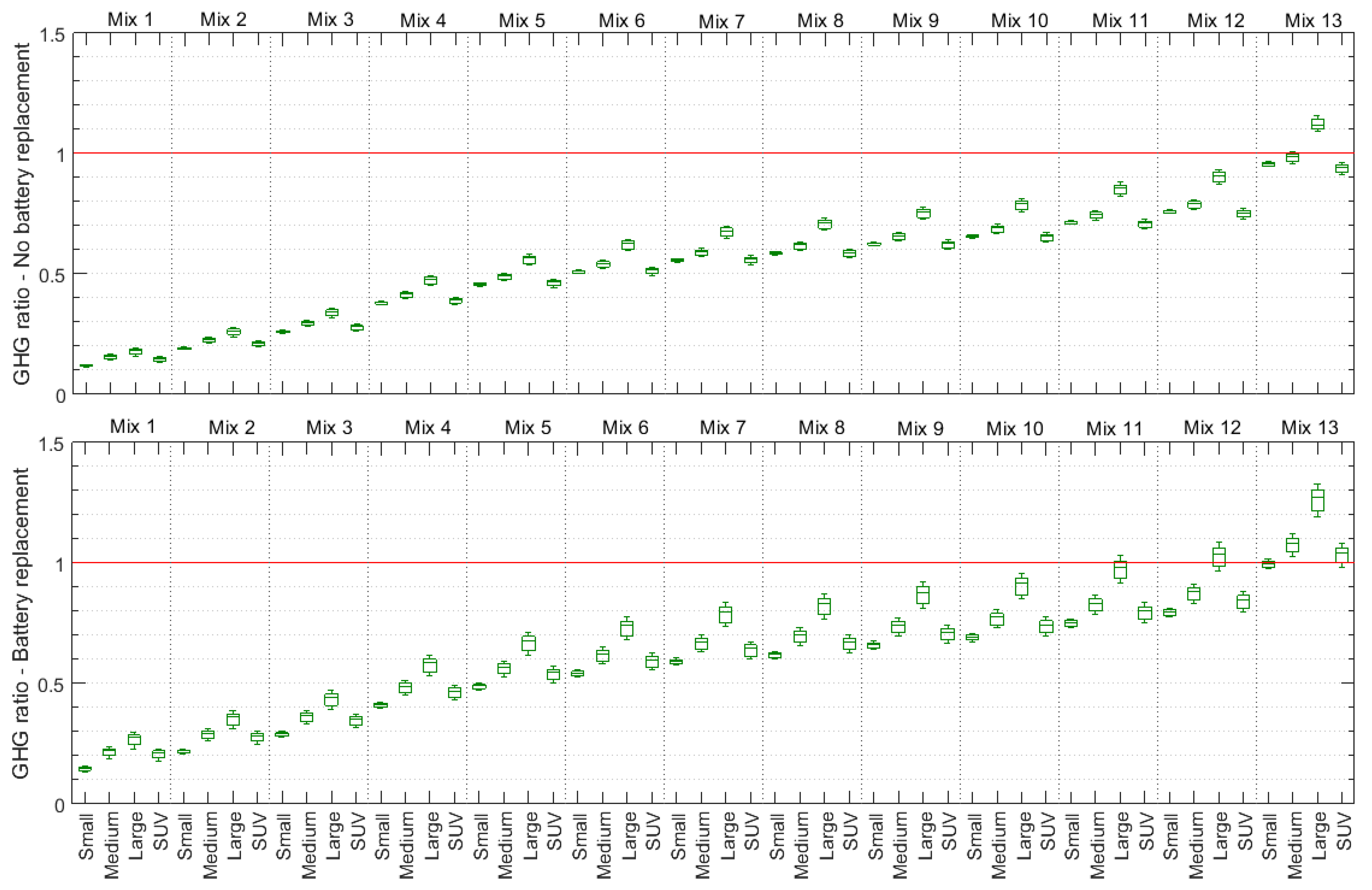

3.1. Statistical Analysis

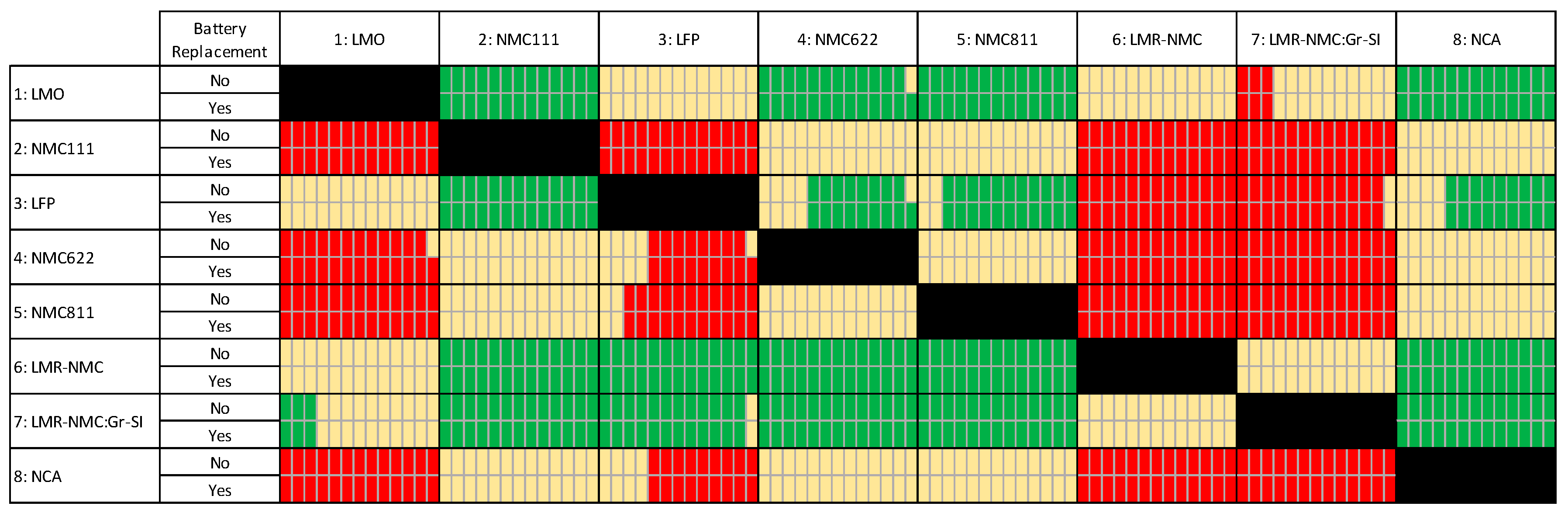

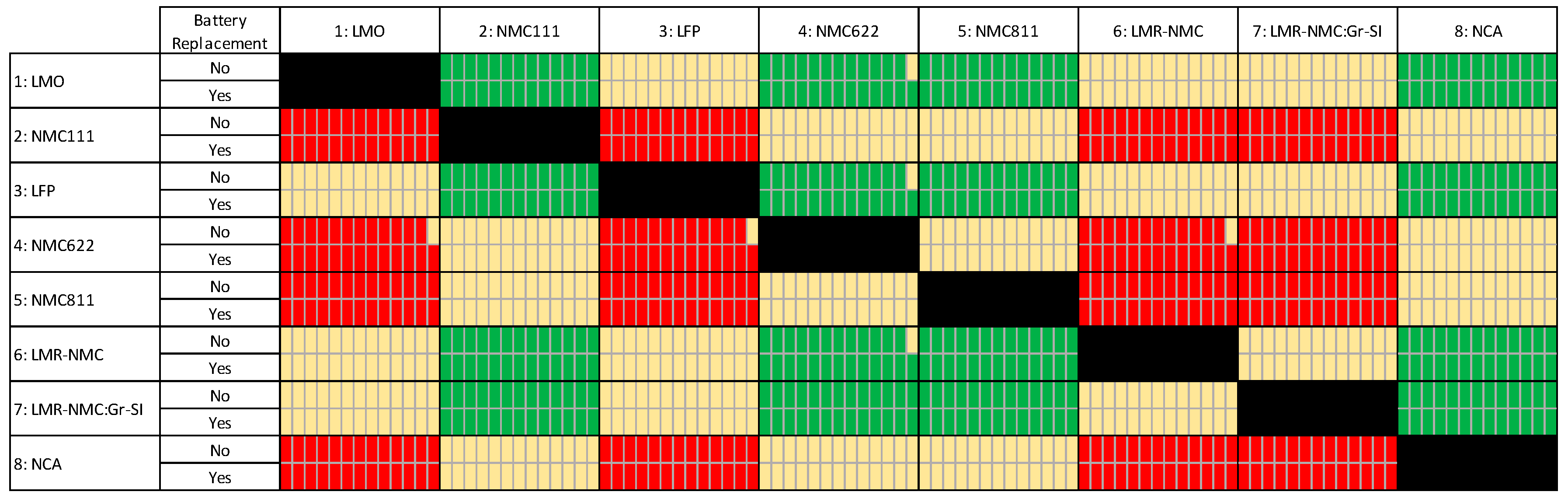

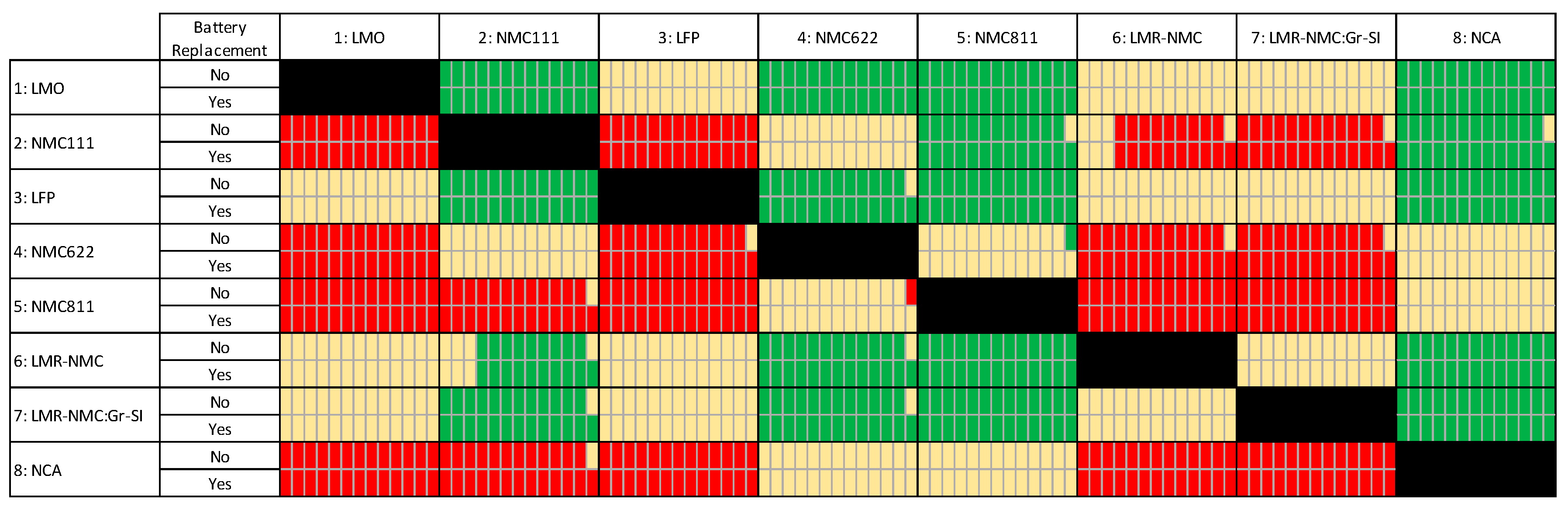

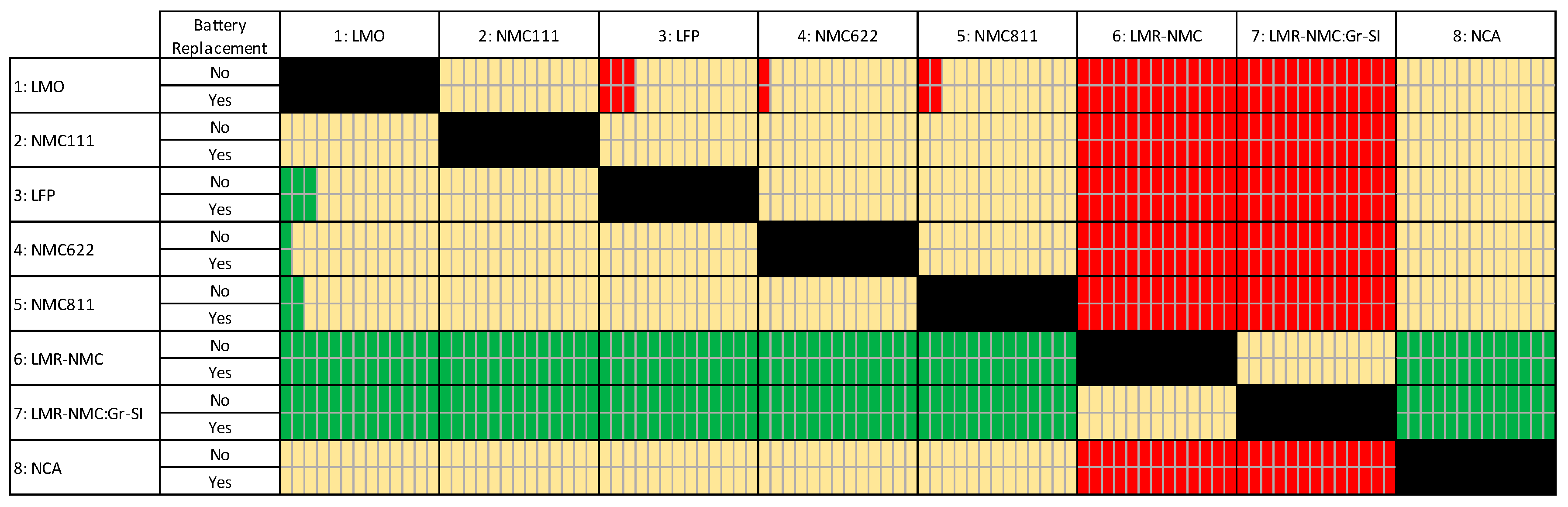

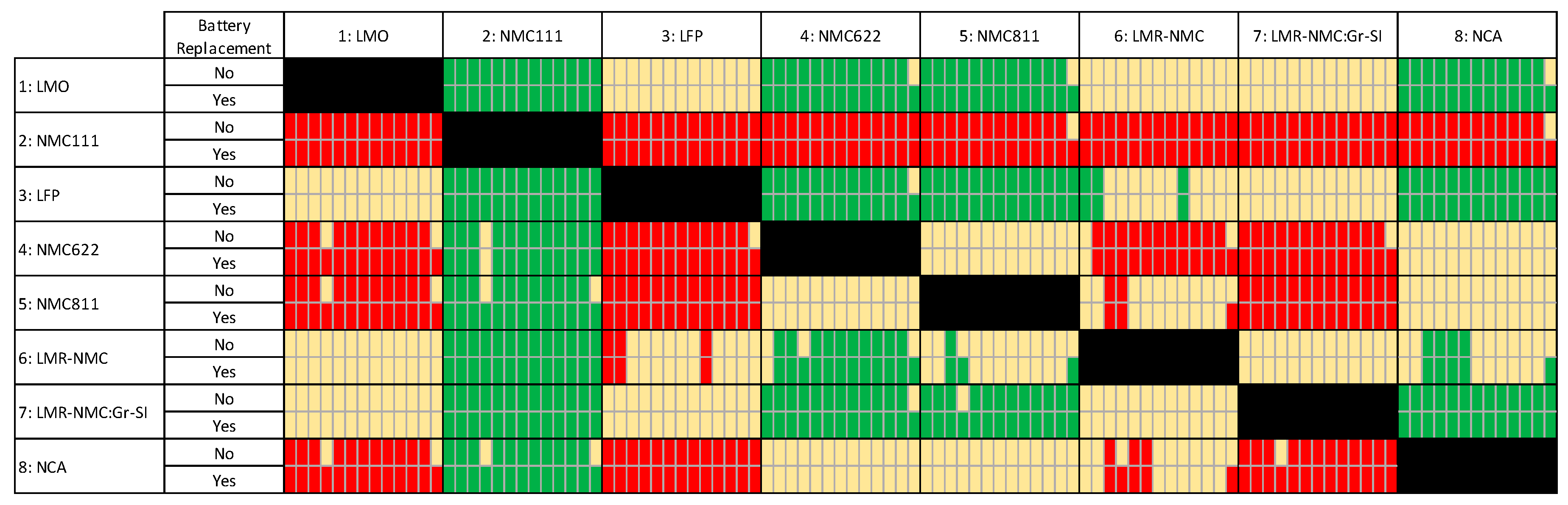

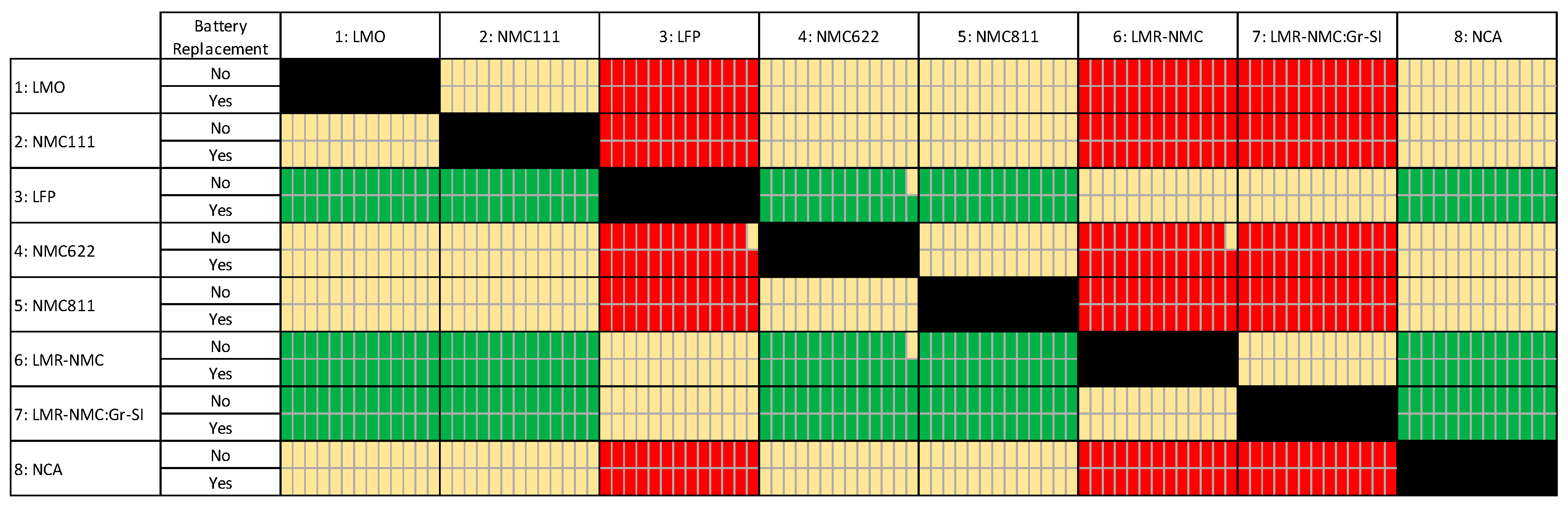

- In general, results show a clear trend for LIB chemistries 1, 3, 6, and 7 to be cleaner than chemistries 2, 4, 5, and 8.

- That trend is mildly affected by the carbon content of the electricity mix and primary energy source. High coal mixes tend to make all LIB chemistries more similar to each other for most pollutants, whereas for PM10, the same also happens for high biomass mixes.

- The consideration of one battery replacement has only a marginal effect in the results, again, biasing chemistries towards equality.

- LIB chemistries 6 and 7 (LMR-MNC and LMR-NMC: Gr-Si) are more resilient against effects coming from either electricity mix or battery replacement factors and are cleaner when it comes to VOC. These are, thus, the more promising LIB technologies for reaching cleaner automotive transportation in the long run.

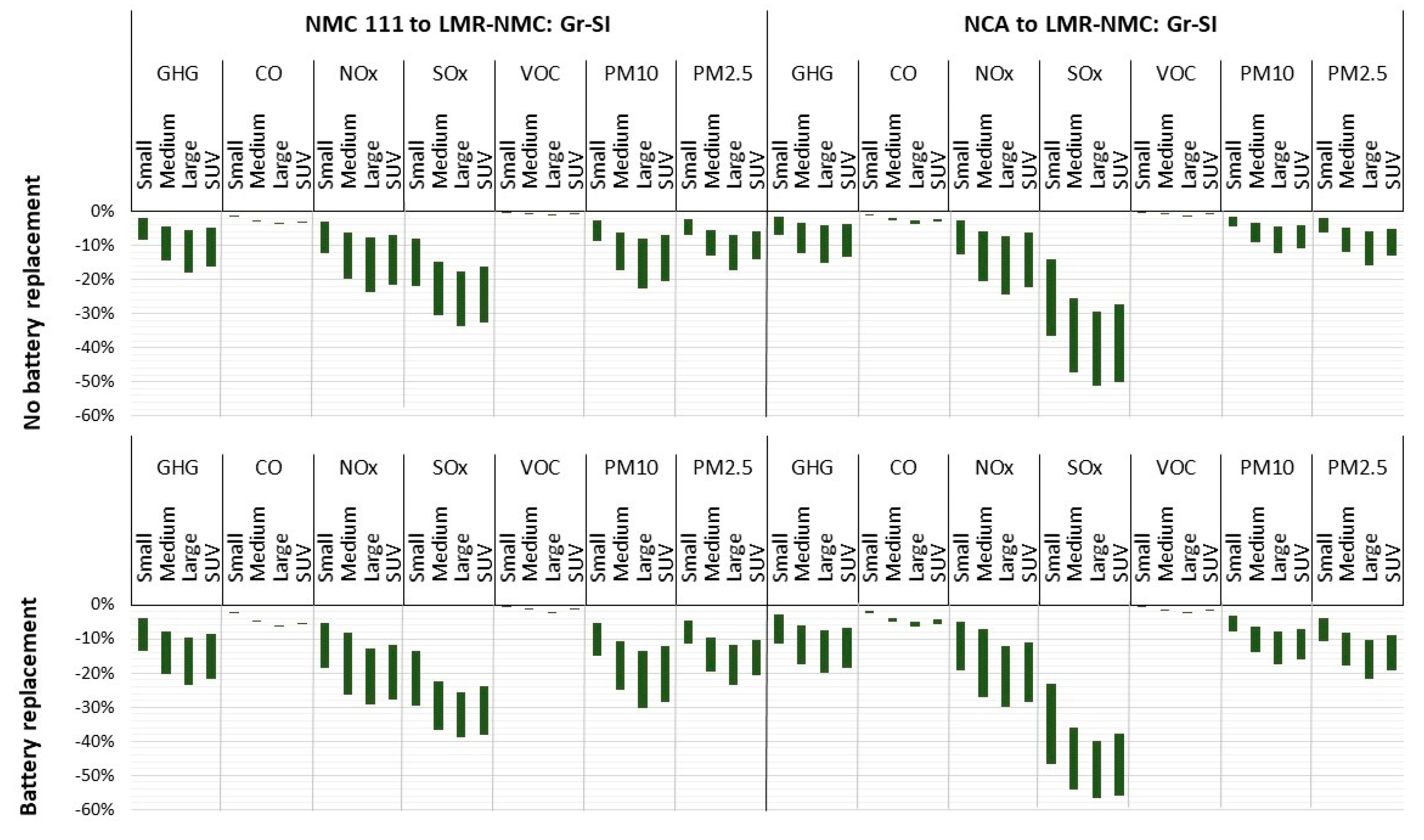

3.2. How Much Cleaner Does It Get?

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- EEA. Transport Greenhouse Gas Emissions; European Environment Agency: Copenhagen, Denmark, 2018; Available online: https://www.eea.europa.eu/downloads/9da27f7e2c9849a6948ed6e0a20d6216/1544193381/transport-ghg-emissions.pdf (accessed on 19 April 2019).

- IEA. Transport, Tracking Clean Energy Progress. International Energy Agency. Available online: https://www.iea.org/tcep/transport/ (accessed on 15 March 2019).

- ACEA. The Automobile Industry Pocket Guide 2018/2019; European Automobile Manufacturers’ Association: Brussels, Belgium, 2018; Available online: https://www.acea.be/uploads/publications/ACEA_Pocket_Guide_2018-2019.pdf (accessed on 19 April 2019).

- Lorenzi, G.; Baptista, P. Promotion of renewable energy sources in the Portuguese transport sector: A scenario analysis. J. Clean. Prod. 2018, 186, 918–932. [Google Scholar] [CrossRef]

- Irle, R. Global Plug-in Sales for the 1st Half of 2018. Available online: http://www.ev-volumes.com/country/total-world-plug-in-vehicle-volumes/ (accessed on 10 March 2019).

- ICCT. Electric Vehicles. Available online: https://www.theicct.org/electric-vehicles (accessed on 20 December 2018).

- Burch, I.; Gilchrist, J. Survey of Global Activity to Phase Out Internal Combustion Engine Vehicles; Center of Climate Protection: Santa Rosa, CA, USA, 2018. [Google Scholar]

- OECD/IEA. Global EV Outlook 2018—Towards Cross-Modal Electrification; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Ding, Y.; Cano, Z.P.; Yu, A.; Lu, J.; Chen, Z. Automotive Li-Ion Batteries: Current Status and Future Perspectives. Electrochem. Energy Rev. 2019, 2, 1–28. [Google Scholar] [CrossRef]

- Keshavarzmohammadian, A.; Cook, S.M.; Milford, J.B. Cradle-to-gate environmental impacts of sulfur-based solid-state lithium batteries for electric vehicle applications. J. Clean. Prod. 2018, 202, 770–778. [Google Scholar] [CrossRef]

- Wang, Y.; Sahadeo, E.; Rubloff, G.; Lin, C.-F.; Lee, S.B. High-capacity lithium sulfur battery and beyond: A review of metal anode protection layers and perspective of solid-state electrolytes. J. Mater. Sci. 2019, 54, 3671–3693. [Google Scholar] [CrossRef]

- Shoji, M.; Cheng, E.J.; Kimura, T.; Kanamura, K. Recent progress for all solid state battery using sulfide and oxide solid electrolytes. J. Phys. D Appl. Phys. 2019, 52, 103001. [Google Scholar] [CrossRef]

- Laslau, C.; Xie, L.; Robinson, C. The Next-Generation Battery Roadmap: Quantifying How Solid-State, Lithium-Sulfur, and Other Batteries Will Emerge after 2020; Lux Research Inc.: Boston, MA, USA, 2015; Available online: https://members.luxresearchinc.com/research/report/17977 (accessed on 19 April 2019).

- Scrosati, B.; Garche, J. Lithium batteries: Status, prospects and future. J. Power Sour. 2010, 195, 2419–2430. [Google Scholar] [CrossRef]

- Feng, K.; Li, M.; Liu, W.; Kashkooli, A.G.; Xiao, X.; Cai, M.; Chen, Z. Silicon-Based Anodes for Lithium-Ion Batteries: From Fundamentals to Practical Applications. Small 2018, 14, 1702737. [Google Scholar] [CrossRef]

- ISO 14040. Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Ke, W.; Zhang, S.; He, X.; Wu, Y.; Hao, J. Well-to-wheels energy consumption and emissions of electric vehicles: Mid-term implications from real-world features and air pollution control progress. Appl. Energy 2017, 188, 367–377. [Google Scholar] [CrossRef]

- Bicer, Y.; Dincer, I. Life cycle assessment of ammonia utilization in city transportation and power generation. J. Clean. Prod. 2018, 170, 1594–1601. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, M.; Zheng, J.; Sun, X.; Zhao, M.; Wang, X. Life cycle greenhouse gas emission reduction potential of battery electric vehicle. J. Clean. Prod. 2018, 190, 462–470. [Google Scholar] [CrossRef]

- Wang, M.; Elgowainy, A.; Benavides, P.T.; Burnham, A.; Cai, H.; Dai, Q.; Hawkins, T.R.; Kelly, J.C.; Kwon, H.; Lee, D.-Y.; et al. Summary of Expansions and Updates in GREET2018; Systems Assessment Group, Energy Systems Division, Argonne National Laboratory. Available online: https://greet.es.anl.gov/files/greet-2018-summary (accessed on 10 March 2019).

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Pachauri, R.K., Meyer, L.A., Eds.; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Nordelöf, A.; Messagie, M.; Tillman, A.-M.; Ljunggren Söderman, M.; Van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—What can we learn from life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2012, 17, 53–64. [Google Scholar] [CrossRef] [Green Version]

- De Souza, L.L.P.; Lora, E.E.S.; Palacio, J.C.E.; Rocha, M.H.; Renó, M.L.G.; Venturini, O.J. Comparative environmental life cycle assessment of conventional vehicles with different fuel options, plug-in hybrid and electric vehicles for a sustainable transportation system in Brazil. J. Clean. Prod. 2018, 203, 444–468. [Google Scholar] [CrossRef]

- Afif, A.; Radenahmad, N.; Cheok, Q.; Shams, S.; Kim, J.H.; Azad, A.K. Ammonia-fed fuel cells: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 60, 822–835. [Google Scholar] [CrossRef]

- Yu, A.; Wei, Y.; Chen, W.; Peng, N.; Peng, L. Life cycle environmental impacts and carbon emissions: A case study of electric and gasoline vehicles in China. Transp. Res. Part D Transp. Environ. 2018, 65, 409–420. [Google Scholar] [CrossRef]

- Raugei, M.; Hutchinson, A.; Morrey, D. Can electric vehicles significantly reduce our dependence on non-renewable energy? Scenarios of compact vehicles in the UK as a case in point. J. Clean. Prod. 2018, 201, 1043–1051. [Google Scholar] [CrossRef]

- Burchart-Korol, D.; Jursova, S.; Folęga, P.; Korol, J.; Pustejovska, P.; Blaut, A. Environmental life cycle assessment of electric vehicles in Poland and the Czech Republic. J. Clean. Prod. 2018, 202, 476–487. [Google Scholar] [CrossRef]

- Choi, H.; Shin, J.; Woo, J. Effect of electricity generation mix on battery electric vehicle adoption and its environmental impact. Energy Policy 2018, 121, 13–24. [Google Scholar] [CrossRef]

- Moro, A.; Lonza, L. Electricity carbon intensity in European Member States: Impacts on GHG emissions of electric vehicles. Transp. Res. Part D Transp. Environ. 2017. [Google Scholar] [CrossRef]

- Woo, J.; Choi, H.; Ahn, J. Well-to-wheel analysis of greenhouse gas emissions for electric vehicles based on electricity generation mix: A global perspective. Transp. Res. Part D Transp. Environ. 2017, 51, 340–350. [Google Scholar] [CrossRef]

- Onat, N.; Kucukvar, M.; Tatari, O. Towards Life Cycle Sustainability Assessment of Alternative Passenger Vehicles. Sustainability 2014, 6, 9305–9342. [Google Scholar] [CrossRef] [Green Version]

- Karaaslan, E.; Zhao, Y.; Tatari, O. Comparative life cycle assessment of sport utility vehicles with different fuel options. Int. J. Life Cycle Assess. 2018, 23, 333–347. [Google Scholar] [CrossRef]

- Ambrose, H.; Kendall, A. Effects of battery chemistry and performance on the life cycle greenhouse gas intensity of electric mobility. Transp. Res. Part D Transp. Environ. 2016, 47, 182–194. [Google Scholar] [CrossRef] [Green Version]

- Hao, H.M.Z.; Jiang, S.; Liu, Z.; Zhao, F. GHG Emissions from the Production of Lithium-Ion Batteries for Electric Vehicles in China. Sustainability 2017, 9, 504. [Google Scholar] [CrossRef]

- Peters, J.F.; Weil, M. Providing a common base for life cycle assessments of Li-Ion batteries. J. Clean. Prod. 2018, 171, 704–713. [Google Scholar] [CrossRef]

- Fan, Y.V.; Perry, S.; Klemeš, J.J.; Lee, C.T. A review on air emissions assessment: Transportation. J. Clean. Prod. 2018, 194, 673–684. [Google Scholar] [CrossRef]

- EEA. Air Quality in Europe—2018 Report; European Environment Agency: Luxembourg; Publications Office of the European Union: Luxembourg, 2018; Available online: https://www.eea.europa.eu/publications/air-quality-in-europe-2018 (accessed on 19 April 2019).

- Anenberg, S.; Miller, J.; Henze, D.; Minjares, R. A Global Snapshot of the Air Pollution-Related Health Impacts of Transportation Sector Emissions in 2010 and 2015; International Council on Clean Transportation: Washington, DC, USA, 2019; Available online: https://www.theicct.org/sites/default/files/publications/Global_health_impacts_transport_emissions_2010-2015_20190226.pdf (accessed on 19 April 2019).

- EV Database. Electric Vehicle Database. Available online: https://ev-database.uk (accessed on 10 March 2019).

- Pavlovic, J.; Ciuffo, B.; Fontaras, G.; Valverde, V.; Marotta, A. How much difference in type-approval CO2 emissions from passenger cars in Europe can be expected from changing to the new test procedure (NEDC vs. WLTP)? Transp. Res. Part A Policy Pract. 2018, 111, 136–147. [Google Scholar] [CrossRef]

- Pavlovic, J.; Marotta, A.; Ciuffo, B. CO2 emissions and energy demands of vehicles tested under the NEDC and the new WLTP type approval test procedures. Appl. Energy 2016, 177, 661–670. [Google Scholar] [CrossRef]

- Tsiakmakis, S.; Fontaras, G.; Cubito, C.; Pavlovic, J.; Anagnostopoulos, K.; Ciuffo, B. From NEDC to WLTP: Effect on the Type-Approval CO2 Emissions of Light-Duty Vehicles; EUR 28724 EN; Publications Office of the European Union: Luxembourg, 2017. [Google Scholar]

- Dai, Q.; Kelly, J.C.; Dunn, J.; Benavides, P.T. Update of Bill-of-Materials and Cathode Materials Production for Lithium-Ion Batteries in the GREET Model; Systems Assessment Group, Energy Systems Division, Argonne National Laboratory: Lemont, IL, USA, 2018. Available online: https://greet.es.anl.gov/publication-update_bom_cm (accessed on 19 April 2019).

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- OECD/IEA. Electricity Information; International Energy Agency: Paris, France, 2018. [Google Scholar]

- OECD/IEA. World Energy Outlook 2018; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Argonne National Laboratory. GREET Life-Cycle Model; Argonne National Laboratory: Lemon, IL, USA, 2014. Available online: https://greet.es.anl.gov/files/greet-model (accessed on 19 April 2019).

- Curran, S.J.; Wagner, R.M.; Graves, R.L.; Keller, M.; Green, J.B., Jr. Well-to-wheel analysis of direct and indirect use of natural gas in passenger vehicles. Energy 2014, 75, 194–203. [Google Scholar] [CrossRef] [Green Version]

- Tong, F.; Jaramillo, P.; Azevedo, I.M.L. Comparison of Life Cycle Greenhouse Gases from Natural Gas Pathways for Light-Duty Vehicles. Energy Fuels 2015, 29, 6008–6018. [Google Scholar] [CrossRef] [Green Version]

- Mitropoulos, L.K.; Prevedouros, P.D.; Kopelias, P. Total cost of ownership and externalities of conventional, hybrid and electric vehicle. Transp. Res. Procedia 2017, 24, 267–274. [Google Scholar] [CrossRef]

| Vehicle Segment | Curb Weight of BEV (without Battery) (kg) | Battery Capacity (kwh) | Consumption (kwh/100 km) | Curb Weight of ICEV (kg) | Consumption (L/100 km) |

|---|---|---|---|---|---|

| Small | 950 | 18 | 12 | 1000 | 5.0 |

| Medium | 1250 | 50 | 14 | 1500 | 6.0 |

| Large | 1600 | 90 | 20 | 2000 | 7.5 |

| SUV | 1900 | 90 | 22 | 2300 | 10.0 |

| 1: LMO | Lithium Manganese Oxide coupled with a graphite anode material LiMn2O4 |

| 2: LFP | Lithium iron phosphate oxide coupled with a graphite anode material LiFePO4 |

| 3: NMC111 | Lithium-Nickel Manganese Cobalt oxide coupled with a graphite anode material LiNi0.33Mn0.33Co0.33O2 |

| 4: NMC622 | Lithium-Nickel Manganese Cobalt oxide coupled with a graphite anode material LiNi0.6Mn0.2Co0.2O2 |

| 5: NMC811 | Lithium-Nickel Manganese Cobalt oxide coupled with a graphite anode material LiNi0.8Mn0.1Co0.1O2 |

| 6: LMR-NMC: Gr | Lithium Manganese Rich-Nickel Manganese Cobalt oxide coupled with a graphite anode material 0.5Li2MnO3.0.5Li-Ni0.44Co0.25Mn0.31O2 |

| 7: LMR-NMC: Gr-SI | Lithium Manganese Rich-Nickel Manganese Cobalt oxide coupled with a graphite-silicon blend anode material 0.5Li2MnO3.0.5Li-Ni0.44Co0.25Mn0.31O2 |

| 8: NCA | Lithium- Nickel Cobalt Aluminium oxide coupled with a graphite anode material LiNiCoAlO2 |

| Component | LMO | NMC111 | LFP | NMC622 | NMC811 | LMR-NMC: Gr | LMR-NMC: Gr-SI | NCA |

|---|---|---|---|---|---|---|---|---|

| Cathode active material | 30.7 | 25.2 | 23.8 | 23.1 | 22.2 | 19.5 | 23.9 | 21.6 |

| Wrought aluminum | 22.7 | 23.9 | 23.1 | 24.6 | 24.5 | 22.4 | 25.0 | 24.9 |

| Graphite/Carbon | 12.7 | 15.7 | 13.8 | 16.5 | 15.9 | 20.2 | 5.6 | 17.1 |

| Copper | 11.6 | 11.7 | 10.4 | 11.8 | 11.5 | 14.8 | 19.8 | 12.1 |

| Silicon | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 1.7 | 0.0 |

| Binder | 2.3 | 2.2 | 2.0 | 2.1 | 2.5 | 2.1 | 2.0 | 2.0 |

| Electrolyte | 10.9 | 10.6 | 16.1 | 10.5 | 12.1 | 12.9 | 13.0 | 10.5 |

| Plastic | 1.66 | 1.67 | 1.50 | 1.67 | 1.64 | 3.8 | 4.5 | 1.7 |

| Steel | 0.6 | 0.6 | 0.7 | 0.6 | 0.6 | 1.4 | 1.2 | 0.6 |

| Thermal insulation | 0.4 | 0.5 | 0.5 | 0.5 | 0.5 | 0.4 | 0.4 | 0.5 |

| Coolant (Glycol) | 3.4 | 4.3 | 5.1 | 4.6 | 4.6 | 1.1 | 1.3 | 4.8 |

| Electronic parts | 3.1 | 3.7 | 3.0 | 4.0 | 3.8 | 1.5 | 1.7 | 4.1 |

| No battery Replacement | Battery Replacement | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GHG | CO | NOx | SOx | VOC | PM10 | PM2.5 | GHG | CO | NOx | SOx | VOC | PM10 | PM2.5 | |

| 1: Iceland Others | 0% | 0% | 0% | 0% | 0% | 99% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 44% |

| 2: France Nuclear | 0% | 0% | 0% | 0% | 0% | 0% | 22% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| 3: 2040 SDS | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| 4: Denmark Biomass | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| 5: OECD Europe | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| 6: 2040 NPS | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| 7: OECD Americas | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| 8: 2040 CPS | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| 9: Mexico Residual oil | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% |

| 10: 2017 | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 18% | 0% | 0% | 0% | 0% |

| 11: OECD Asia Oceania | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 27% | 0% | 0% | 0% | 0% |

| 12: Israel Natural gas | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 20% | 0% | 0% | 0% | 0% |

| 13: Estonia Coal | 99% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 0% | 59% | 0% | 0% | 0% | 0% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almeida, A.; Sousa, N.; Coutinho-Rodrigues, J. Quest for Sustainability: Life-Cycle Emissions Assessment of Electric Vehicles Considering Newer Li-Ion Batteries. Sustainability 2019, 11, 2366. https://doi.org/10.3390/su11082366

Almeida A, Sousa N, Coutinho-Rodrigues J. Quest for Sustainability: Life-Cycle Emissions Assessment of Electric Vehicles Considering Newer Li-Ion Batteries. Sustainability. 2019; 11(8):2366. https://doi.org/10.3390/su11082366

Chicago/Turabian StyleAlmeida, Arminda, Nuno Sousa, and João Coutinho-Rodrigues. 2019. "Quest for Sustainability: Life-Cycle Emissions Assessment of Electric Vehicles Considering Newer Li-Ion Batteries" Sustainability 11, no. 8: 2366. https://doi.org/10.3390/su11082366

APA StyleAlmeida, A., Sousa, N., & Coutinho-Rodrigues, J. (2019). Quest for Sustainability: Life-Cycle Emissions Assessment of Electric Vehicles Considering Newer Li-Ion Batteries. Sustainability, 11(8), 2366. https://doi.org/10.3390/su11082366