Evaluating the Environmental Performance of Solar Energy Systems Through a Combined Life Cycle Assessment and Cost Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Photovoltaics

2.2. Solar Thermal Collectors

3. Results and Discussion

3.1. Photovoltaics

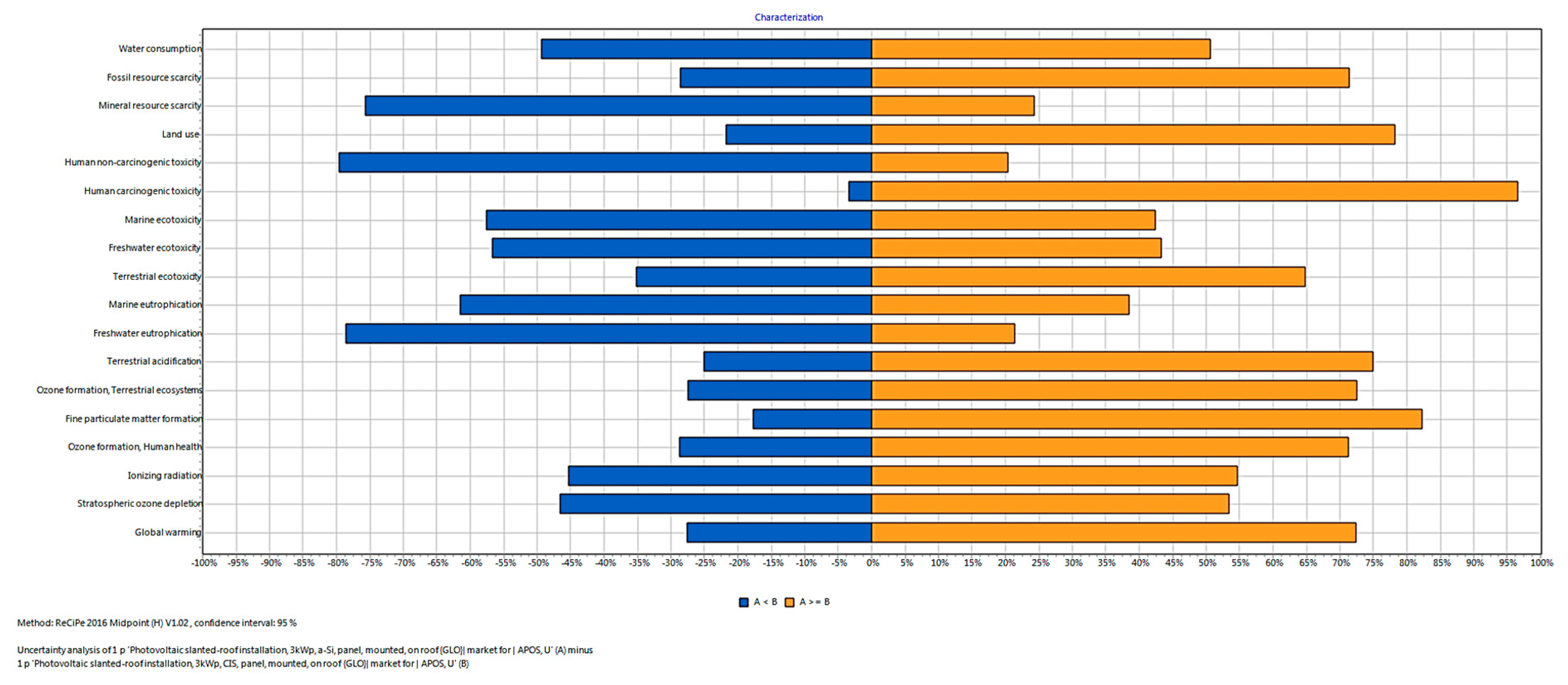

3.1.1. LCA Analysis of PV Systems

- Energy consumption;

- Air and waterborne process-specific pollutants at all production stages (materials, chemicals, etc.);

- Transport of materials, energy carriers, semi-finished products, and the complete power plant;

- Waste treatment processes for production wastes;

- Dismantling of all components;

- Infrastructure for all production facilities with its land use.

3.1.2. Energy and Economic Assessment of PV Systems

3.2. Solar Thermal Systems

3.2.1. LCA Analysis of Solar Thermal Systems

3.2.2. Energy and Economic Assessment of Solar Thermal Systems

3.3. Life Cycle Carbon Footprint

4. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- IEA. Key World Energy Statistics 2018. International Energy Agency 2018. Available online: www.iea.org/statistics (accessed on 22 March 2019).

- REN21. Renewables 2018, Global Status Report. 2018. Available online: www.ren21.net (accessed on 22 March 2019).

- IRENA 2018. Renewable Energy Prospects for the European Union; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2018. [Google Scholar]

- IRENA 2017. Planning for the Renewable Future: Long-Term Modelling and Tools to Expand Variable Renewable Power in Emerging Economies; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2017. [Google Scholar]

- IEA. Market Report Series: Renewables 2017, Analysis and Forecasts to 2022. International Energy Agency 2017. Available online: www.iea.org/publications/renewables2017 (accessed on 22 March 2019).

- REN21. Advancing the Global Renewable Energy Transition: Highlights of the REN21 Renewables 2017 Global Status Report in Perspective; REN21 Secretariat: Paris, France, 2018. [Google Scholar]

- Finnveden, G.; Hauschild, M.; Ekvall, T.; Guinee, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Turconi, R.; Boldrin, A.; Astrup, T. Life cycle assessment (LCA) of electricity generation technologies: Overview, comparability and limitations. Renew. Sustain. Energy Rev. 2013, 28, 555–565. [Google Scholar] [CrossRef] [Green Version]

- Weidema, B.P.; Thrane, M.; Christensen, P.; Schmidt, J.; Løkke, S. Carbon Footprint. J. Ind. Ecol. 2008, 12, 3–6. [Google Scholar] [CrossRef] [Green Version]

- Mahmud, M.A.; Huda, N.; Farjana, S.H.; Lang, C. Environmental impacts of solar-photovoltaic and solar-thermal systems with life-cycle assessment. Energies 2018, 11, 2346. [Google Scholar] [CrossRef]

- Constantino, G.; Freitas, M.; Fidelis, N.; Pereira, M.G. Adoption of photovoltaic systems along a sure path: A life-cycle assessment (LCA) study applied to the analysis of GHG emission impacts. Energies 2018, 11, 2806. [Google Scholar] [CrossRef]

- Weisser, D. A guide to life-cycle greenhouse gas (GHG) emissions from electric supply technologies. Energy 2007, 32, 1543–1559. [Google Scholar] [CrossRef]

- ISO. EN ISO 14040, Environmental Management—Life Cycle Assessment—Principles and Framework. 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 22 March 2019).

- EC-JRC. International Reference Life Cycle Data System (ILCD), Handbook—General Guide for Life Cycle Assessment—Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Sima Pro. 2018. Available online: simapro.com (accessed on 22 March 2019).

- RETScreen Expert. 2018. Available online: www.nrcan.gc.ca/energy/software-tools/7465 (accessed on 22 March 2019).

- Ghafghazi, S.; Sowlati, T.; Sokhansanj, S.; Bi, X.; Melin, S. Life cycle assessment of base-load heat sources for district heating system options. Int. J. Life Cycle Assess. 2011, 16, 212–223. [Google Scholar] [CrossRef]

- Amponsah, N.Y.; Troldborg, M.; Kington, B.; Aalders, I.; Hough, R.L. Greenhouse gas emissions from renewable energy sources: A review of lifecycle considerations. Renew. Sustain. Energy Rev. 2014, 39, 461–475. [Google Scholar] [CrossRef]

- Itten, R.; Stucki, M. Highly efficient 3rd generation multi-junction solar cells using silicon heterojunction and perovskite tandem: Prospective life cycle environmental impacts. Energies 2017, 10, 841. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2017; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2018. [Google Scholar]

- Varun, R.P.; Bhat, I.K. Energy, economics and environmental impacts of renewable energy systems. Renew. Sustain. Energy Rev. 2009, 13, 2716–2721. [Google Scholar] [CrossRef]

- Papaefthimiou, S.; Souliotis, M.; Andriosopoulos, K. Grid parity of solar energy: Imminent fact or future′s fiction? Energy J. 2016, 37, 263–276. [Google Scholar] [CrossRef]

- Jungbluth, N.; Stucki, M. Life Cycle Inventories of Photovoltaics; ESU-Services Ltd.: Uster, Switzerland, 2012; p. 250. [Google Scholar]

- Frischknecht, R.; Itten, R.; Sinha, P.; de Wild-Scholten, M.; Zhang, J.; Fthenakis, V.; Kim, H.C.; Raugei, M.; Stucki, M. Life Cycle Inventories and Life Cycle Assessment of Photovoltaic Systems; PVPS 12, Report T12-04; International Energy Agency (IEA): Paris, France, 2015. [Google Scholar]

- Fthenakis, V.M.; Kim, H.C. Photovoltaics: Life-cycle analyses. Sol. Energy 2011, 85, 1609–1628. [Google Scholar] [CrossRef]

- Jungbluth, N.; Tuchschmid, M.; de Wild-Scholten, M. Life Cycle Assessment of Photovoltaics: Update of Ecoinvent Data v2.0; ESU-Services Ltd.: Uster, Switzerland, 2008. [Google Scholar]

- Lenzen, M. Greenhouse gas analysis of solar-thermal electricity generation. Sol. Energy 1999, 65, 353–368. [Google Scholar] [CrossRef]

- Kreith, F.; Norton, P.; Brown, D. A comparison of CO2 emissions from fossil and solar power plants in the United States. Energy 1990, 15, 1181–1198. [Google Scholar] [CrossRef]

- Lechón, Y.; de la Rúa, C.; Sáez, R. Life Cycle Environmental Impacts of Electricity Production by Solarthermal Power Plants in Spain. J. Sol. Energy Eng. 2008, 130, 021012. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. Overview and Methodology. Data Quality Guideline for the Ecoinvent Database Version 3; The ecoinvent Centre: St. Gallen, Switzerland, 2013. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; de Schryver, A.; Struijs, J.; Van Zelm, R.; ReCiPe 2008. A life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level. Report I: Characterisation. 2013. Available online: https://www.pre-sustainability.com/download/ReCiPe_main_report_MAY_2013.pdf (accessed on 22 March 2019).

- Fthenakis, V.M. End-of-life management and recycling of PV modules. Energy Policy 2000, 28, 1051–1058. [Google Scholar] [CrossRef] [Green Version]

- Fthenakis, V.; Wang, W.; Kim, H.C. Life cycle inventory analysis of the production of metals used in photovoltaics. Renew. Sustain. Energy Rev. 2009, 13, 493–517. [Google Scholar] [CrossRef] [Green Version]

- Pauls, K.; Mitchell, K.W.; Chesarak, W.; King, R.R. Silicon Concentrator Solar Cells Using Mass-Produced, Flat-Plate Cell Fabrication Technology. In Proceedings of the Conference Record of the Twenty-Third IEEE Photovoltaic Specialists Conference, Louisville, KY, USA, 10–14 May 1993; Volume 2, pp. 824–827. [Google Scholar]

- RAE. Regulatory Authority for Energy (RAE). Available online: http://www.rae.gr/site/en_US/portal.csp (accessed on 11 April 2019).

- Maroulis, G. Legal Sources on Renewable Energy, Feed-in Tariff (Rooftop PV). 2019. Available online: http://www.res-legal.eu/search-by-country/greece/single/s/res-e/t/promotion/aid/feed-in-tariff-ii-pv-on-rooftops/lastp/139/ (accessed on 11 April 2019).

- HELAPCO. Hellenic Association of Photovoltaic Companies. 2014. Available online: http://helapco.gr/en/ (accessed on 11 April 2019).

- Van der Vlies, D.; van Breevoort, P.; Winkel, T. The Value of Distributed Solar PV in Spain; GreenPeace: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Calpak. 2018. Available online: www.calpak.gr (accessed on 22 March 2019).

- Schlömer, S.; Bruckner, T.; Fulton, L.; Hertwich, E.; McKinnon, A.; Perczyk, D.; Roy, J.; Schaeffer, R.; Sims, R.; Smith, P.; et al. ANNEX III: Technology-specific Cost and Performance Parameters. In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Edenhofer, O.; Pichs-Madruga, R.; Sokona, Y.; Seyboth, K.; Matschoss, P.; Kadner, S.; Zwickel, T.; Eickemeier, P.; Hansen, G.; Schlömer, S.; von Stechow, C. Special Report on Renewable Energy Sources and Climate Change Mitigation. In Summary for Policymakers and Technical Summary. A Report of Working Group III of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2011. [Google Scholar]

- Moomaw, W.; Yamba, F.; Kamimoto, M.; Maurice, L.; Nyboer, J.; Urama, K.; Weir, T.; Bruckner, T.; Jäger-Waldau, A.; Krey, V.; et al. Renewable Energy and Climate Change. In Renewable Energy Sources and Climate Change Mitigation; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Seyboth, K., Matschoss, P., Kadner, S., Zwickel, T., Eickemeier, P., Hansen, G., Schlomer, S., et al., Eds.; Cambridge University Press: Cambridge, UK, 2011; pp. 161–208. [Google Scholar]

- Sullivan, J.L.; Clark, C.E.; Han, J.; Wang, M. Life-Cycle Analysis Results of Geothermal Systems in Comparison to Other Power Systems. 2010. Available online: https://www.energy.gov/eere/geothermal/downloads/life-cycle-analysis-results-geothermal-systems-comparison-other-power (accessed on 22 March 2019).

- Krey, V.; Masera, O.; Blanford, G.; Bruckner, T.; Cooke, R.; Fisher-Vanden, K.; Haberl, H.; Hertwich, E.; Kriegler, E.; Mueller, D.; et al. Annex II: Metrics & Methodology. In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Sovacool, B.K. Valuing the greenhouse gas emissions from nuclear power: A critical survey. Energy Policy 2008, 36, 2950–2963. [Google Scholar] [CrossRef]

| Photovoltaic Technology | Technical Characteristics | |

|---|---|---|

| Crystalline technologies | Single crystalline silicon cells (sc-Si) | The active material is made from a single crystal without grain boundaries. The sc-Si cells have the highest efficiencies (for commercial cells: 13%–18%). |

| Multi-crystalline silicon cells (mc-Si) | The cell material consists of different crystals. The cells have a lower efficiency, but it is cheaper in production. Commercial mc-Si cells have efficiencies in the range of 11% to 16%. | |

| Thin-Film Technologies | Copper-Indium-diSelenide (CIS) | CIS modules are constructed by depositing extremely thin layers of photovoltaic materials on a low cost layer (such as glass, stainless steel, or plastic). Material costs are lower because less semi-conductor material is required; secondly, labor costs are reduced because the thin films are produced as large, complete modules and not as individual cells that have to be mounted in frames and wired together. The efficiency is about 8% to 11%. |

| Amorphous cells (a-Si) | The efficiency of amorphous cells is about 6% to 9% and decreases during the first 100 operation hours. A recently developed thin-film technology is hydrogenated amorphous silicon. |

| Impact Category | Unit | a-Si | CIS | mc-Si | sc-Si |

|---|---|---|---|---|---|

| Global warming | kg CO2-eq /kWh | 4.35 × 10−2 | 3.95 × 10−2 | 4.43 × 10−2 | 5.24 × 10−2 |

| Stratospheric ozone depletion | kg CFC11-eq/kWh | 1.70 × 10−8 | 1.75 × 10−8 | 2.06 × 10−8 | 2.45 × 10−8 |

| Ionizing radiation | kBq Co-60-eq/kWh | 3.95 × 10−3 | 3.96 × 10−3 | 4.08 × 10−3 | 4.45 × 10−3 |

| Ozone formation, human health | kg NOx-eq/kWh | 9.83 × 10−5 | 9.09 × 10−5 | 1.05 × 10−4 | 1.20 × 10−4 |

| Fine particulate matter formation | kg PM2.5-eq/kWh | 1.09 × 10−4 | 9.39 × 10−5 | 1.04 × 10−4 | 1.23 × 10−4 |

| Ozone formation, terrestrial ecosystems | kg NOx-eq/kWh | 1.01 × 10−4 | 9.26 × 10−5 | 1.10 × 10−4 | 1.25 × 10−4 |

| Terrestrial acidification | kg SO2-eq/kWh | 2.25 × 10−4 | 2.07 × 10−4 | 2.21 × 10−4 | 2.47 × 10−4 |

| Freshwater eutrophication | kg P-eq/kWh | 3.55 × 10−5 | 4.62 × 10−5 | 3.78 × 10−5 | 4.07 × 10−5 |

| Terrestrial ecotoxicity | kg1,4-DCB-eq/kWh | 4.69 × 10−1 | 4.62 × 10−1 | 1.17 | 1.13 |

| Freshwater ecotoxicity | kg1,4-DCB-eq/kWh | 1.11 × 10−2 | 1.30 × 10−2 | 1.16 × 10−2 | 1.17 × 10−2 |

| Marine ecotoxicity | kg1,4-DBC-eq/kWh | 1.43 × 10−2 | 1.69 × 10−2 | 1.53 × 10−2 | 1.54 × 10−2 |

| Human carcinogenic toxicity | kg1,4-DBC-eq/kWh | 6.50 × 10−3 | 4.19 × 10−3 | 4.17 × 10−3 | 4.33 × 10−3 |

| Human non-carcinogenic toxicity | kg1,4-DBC-eq/kWh | 1.46 × 10−1 | 2.00 × 10−1 | 1.63 × 10−1 | 1.64 × 10−1 |

| Land use | m2a crop-eq/kWh | 1.13 × 10−3 | 9.60 × 10−4 | 1.23 × 10−3 | 1.23 × 10−3 |

| Mineral resource scarcity | kg Cu-eq/kWh | 6.60 × 10−4 | 8.21 × 10−4 | 5.54 × 10−4 | 5.42 × 10−4 |

| Fossil resource scarcity | kg oil-eq/kWh | 1.04 × 10−2 | 9.40 × 10−3 | 1.08 × 10−2 | 1.27 × 10−2 |

| Water consumption | m3/kWh | 4.51 × 10−4 | 3.22 × 10−4 | 1.35 × 10−3 | 1.17 × 10−3 |

| PV Technology | Cell Efficiency [%] | Frame Area [m2] | Capacity Per Unit [W] | Total Area [m2] | Cost [€/kW] | Capacity Factor [%] | Total Electricity Exported to Grid [MWh] | Annual Revenue [€/yr] | IRR [%] | Payback Time [years] | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Crystalline | sc-Si | 17 | 1.18 | 200 | 17.7 | 1600 | 20.6 | 162.6 | 542 | 11.5 | 10 |

| mc-Si | 12.3 | 1.02 | 125 | 24.5 | 1500 | 20.6 | 162.6 | 542 | 12.3 | 9.3 | |

| Thin-film | CIS | 10.6 | 0.94 | 100 | 28.2 | 1600 | 20.2 | 159.3 | 531 | 12 | 9.6 |

| a-Si | 6.1 | 0.82 | 50 | 49.2 | 1500 | 21.8 | 171.6 | 572 | 13.1 | 8.8 |

| Impact Category | Unit (per m2) | Flat Plate Collector | Vacuum Tube Collector |

|---|---|---|---|

| Global warming | kg CO2-eq/kWh | 2.38 × 10−2 | 2.22 × 10−2 |

| Stratospheric ozone depletion | kg CFC11-eq/kWh | 1.29 × 10−8 | 1.36 × 10−8 |

| Ionizing radiation | kBq Co-60-eq/kWh | 1.61 × 10−3 | 1.88 × 10−3 |

| Ozone formation, human health | kg NOx-eq/kWh | 6.50 × 10−5 | 6.89 × 10−5 |

| Fine particulate matter formation | kg PM2.5-eq/kWh | 8.78 × 10−5 | 8.61 × 10−5 |

| Ozone formation, terrestrial ecosystems | kg NOx-eq/kWh | 6.66 × 10−5 | 7.07 × 10−5 |

| Terrestrial acidification | kg SO2 eq/kWh | 2.07 × 10−4 | 2.01 × 10−4 |

| Freshwater eutrophication | kg P-eq/kWh | 3.89 × 10−5 | 4.16 × 10−5 |

| Terrestrial ecotoxicity | kg1,4-DCB-eq/kWh | 8.55 × 10−1 | 9.31 × 10−1 |

| Freshwater ecotoxicity | kg1,4-DCB-eq/kWh | 6.42 × 10−3 | 6.94 × 10−3 |

| Marine ecotoxicity | kg1,4-DBC-eq/kWh | 9.27 × 10−3 | 1.00 × 10−2 |

| Human carcinogenic toxicity | kg1,4-DBC-eq/kWh | 6.56 × 10−3 | 6.53 × 10−3 |

| Human non-carcinogenic toxicity | kg1,4-DBC-eq/kWh | 2.24 × 10−1 | 2.44 × 10−1 |

| Land use | m2a crop-eq/kWh | 1.25 × 10−3 | 1.52 × 10−3 |

| Mineral resource scarcity | kg Cu-eq/kWh | 1.02 × 10−3 | 1.03 × 10−3 |

| Fossil resource scarcity | kg oil-eq/kWh | 5.45 × 10−3 | 5.38 × 10−3 |

| Water consumption | m3/kWh | 2.39 × 10−4 | 2.33 × 10−4 |

| Solar Collector Type | Aperture Area [m2] | FrUL [(W/m2)/°C] | Cost [€] | Total Energy Saved [kWh] | Total Energy Saved Per Aperture Area [kWh/m2] | Solar Fraction [%] | Annual Savings [€/yr] | IRR [%] | Payback Time [years] |

|---|---|---|---|---|---|---|---|---|---|

| Flat plate | 2.32 | 4.6 | 900 | 27,260 | 11,750 | 55.3 | 352 | 41.8 | 2.6 |

| Vacuum tube | 2.61 | 1.7 | 1300 | 29,980 | 11,487 | 62.7 | 341 | 28.5 | 3.8 |

| Carbon Footprint [g CO2-eq/kWh] * | References | Carbon Footprint [g CO2-eq/kWh] ** | Total Emitted GHG [g CO2-eq] | Total Avoided GHG [g CO2-eq] | Lifetime GHG Balance [g CO2-eq] | Total Energy Produced [kWh] | |

|---|---|---|---|---|---|---|---|

| a-Si PV | 26–60 | [40,42,43,44] | 43.5 | 7.47 × 106 | 1.24 × 108 | 1.17 × 108 | 1.72 × 105 |

| CIS PV | 39.5 | 6.29 × 106 | 1.15 × 108 | 1.09 × 108 | 1.59 × 105 | ||

| mc-Si PV | 44.3 | 7.20 × 106 | 1.17 × 108 | 1.10 × 108 | 1.63 × 105 | ||

| sc-Si PV | 52.4 | 8.52 × 106 | 1.17 × 108 | 1.08 × 108 | 1.63 × 105 | ||

| Flat plate collector | 20–45 | [42,44] | 23.8 | 3.44 × 106 | 2.60 × 107 | 2.26 × 107 | 3.12 × 104 |

| Vacuum tube collector | 22.2 | 2.68 × 106 | 2.50 × 107 | 2.23 × 107 | 3.54 × 104 | ||

| Wind | 9–35 | [40,42,43,44] | |||||

| Geothermal plant | 6–79 | [40,43,44] | |||||

| Hydroelectric | 1–24 | [42,43,44] | |||||

| Nuclear | 4–110 | [40,44,45] | |||||

| Natural gas | 410–650 | [40,41,44] | |||||

| Oil | 778 | [40,41,44] | |||||

| Coal | 740–1050 | [40,41,44] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Milousi, M.; Souliotis, M.; Arampatzis, G.; Papaefthimiou, S. Evaluating the Environmental Performance of Solar Energy Systems Through a Combined Life Cycle Assessment and Cost Analysis. Sustainability 2019, 11, 2539. https://doi.org/10.3390/su11092539

Milousi M, Souliotis M, Arampatzis G, Papaefthimiou S. Evaluating the Environmental Performance of Solar Energy Systems Through a Combined Life Cycle Assessment and Cost Analysis. Sustainability. 2019; 11(9):2539. https://doi.org/10.3390/su11092539

Chicago/Turabian StyleMilousi, Maria, Manolis Souliotis, George Arampatzis, and Spiros Papaefthimiou. 2019. "Evaluating the Environmental Performance of Solar Energy Systems Through a Combined Life Cycle Assessment and Cost Analysis" Sustainability 11, no. 9: 2539. https://doi.org/10.3390/su11092539

APA StyleMilousi, M., Souliotis, M., Arampatzis, G., & Papaefthimiou, S. (2019). Evaluating the Environmental Performance of Solar Energy Systems Through a Combined Life Cycle Assessment and Cost Analysis. Sustainability, 11(9), 2539. https://doi.org/10.3390/su11092539