1. Introduction

With increasing environmental pollution, especially increases in the urban air pollution index and hazy weather, environmental pollution and the energy crisis have become worldwide problems. Low-carbon environmental protection has gradually become the focus of attention in all countries. The continuous increase of traditional fuel vehicles has led to excessive consumption of nonrenewable energy and emission of pollutants, and severely damaged the living environment [

1]. As a result, more countries are developing and using sustainable energy as an alternative in order to protect the environment [

2]. The rapid development of new energy vehicles (NEVs) can largely alleviate the pressure on energy and the environment. Promoting technological innovation and transformation and upgrading the NEV industry have become important strategic moves in all countries [

3]. In 2017, European countries announced that they would stop selling traditional fuel vehicles between 2025 and 2050 [

4]. In 2018, automobile manufacturers such as China Chang’an Automobile, Beiqi Group, and Haima Automobile also indicated that they would eliminate traditional fuel vehicles by 2025 [

5]. While reducing energy consumption and pollution emissions, transforming and upgrading the NEV industry will also be accomplished [

6].

In order to alleviate the increasingly prominent contradiction between environmental pollution and energy supply, China is vigorously developing and popularizing NEVs [

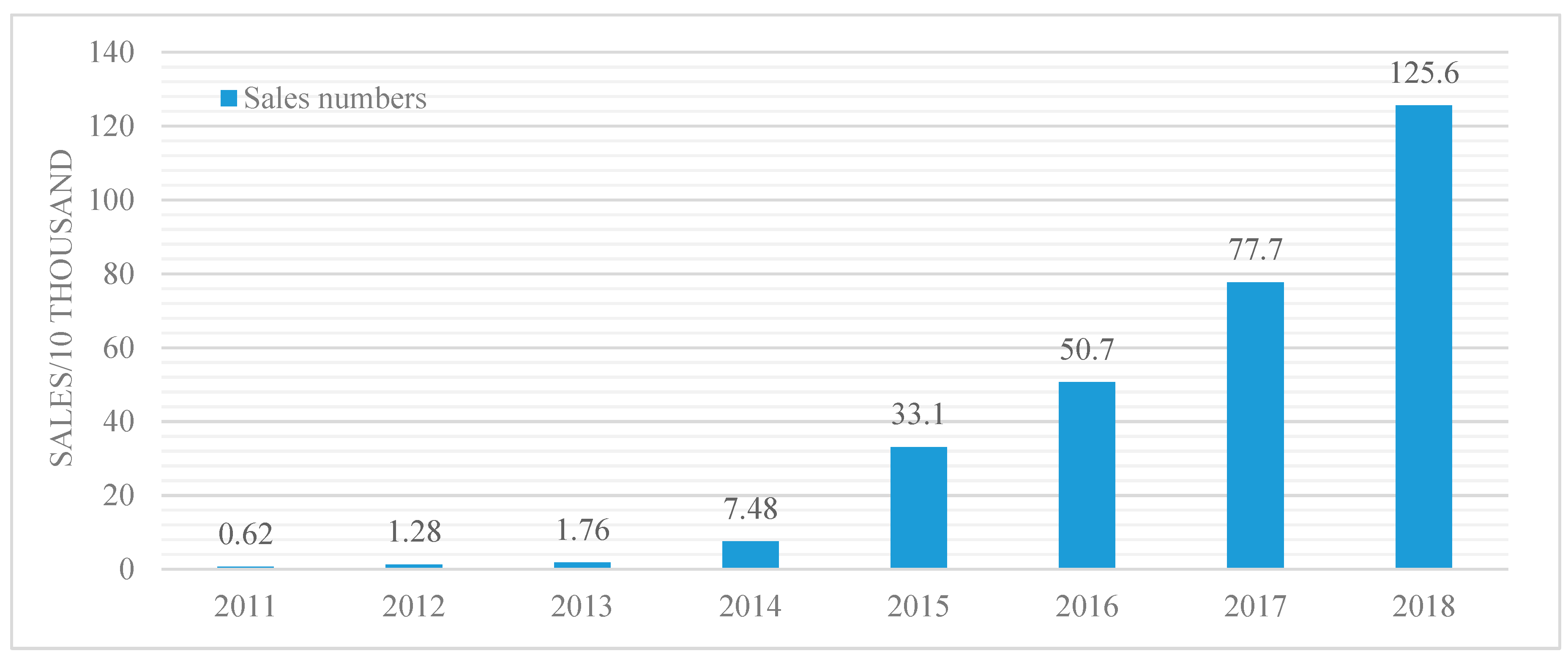

7]. In recent years, China’s NEV industry has shown a rapid development trend (

Figure 1). The data show that in 2018, the sales volume of NEVs in China was 1.256 million units, an increase of 61.7% year-on-year [

8]. The sales volume ranks first in the world, as the world’s largest NEV market [

8]. However, there is still a problem in that the proportion of NEVs among total vehicle sales is not very high. The core technologies for the manufacture of NEVs have not yet fully addressed the outstanding problems that need to be solved, such as autonomy and control [

9]. With the proposed concept of “Made in China 2025,” the comprehensive strength of intelligent manufacturing of China’s new energy equipment has been significantly improved, especially in the rapid rise of NEVs, which is gradually catching up with the pace of developed countries [

10]. At present, the level of development of China’s high-tech industry is still far from that of developed countries, so the development of NEVs has also encountered bottlenecks [

11]. This also reveals that China is insufficient in terms of independent innovation, and it lacks autonomous and controllable core products. The core technologies are still subject to human malpractice.

Traditional cars will still dominate consumption in the next 30 years (see the technical roadmap of the key areas of “Made in China 2025” for details). The rapid spread of NEVs can greatly alleviate the pressure brought by energy and the environment. Therefore, NEVs will have a broad market and will become a key industry in the world [

12]. The energy revolution, consumption upgrades, market competition, and other factors have prompted the rapid development of NEVs to become a strategic emerging industry worldwide [

13]. In order to alleviate the energy and environmental crises and seize market dividends, all countries consider self-determination, controllability, safety, and stability as the basic principles for the development of NEVs [

14]. Many countries have had outstanding achievements in innovation and exploration, independent key technology research and development, and enhancement of core competitiveness [

15]. Although China temporarily ranks first in the sales of NEVs, its core technology lacks independent controllability, which is big but not strong. At any time, it may lose its rapidly developing and huge NEV market without the support of other countries. A comprehensive evaluation of the development capability of the NEV industry can objectively describe its current status, determine the current problems, and then propose targeted countermeasures to promote innovation and development.

The remainder of the paper is arranged as follows: the second section provides a literature review and research framework. The third section introduces research methods and data resources. We conduct an empirical analysis of the development capabilities of China’s NEV industry in the fourth section. The fifth section discusses the influencing factors and conducts a robustness test. In the last part, we summarize the conclusions and propose new measures to adopt.

2. Literature Review

NEVs are different from traditional fuel-powered vehicles, in that they use unconventional fuel as their power source [

16]. “Made in China 2025” defines the concept of NEVs [

17]. According to the concept, NEVs include hybrid electric vehicles (HEVs), especially plug-in hybrid electric vehicles (PHEVs), battery electric vehicles (BEVs), and fuel cell vehicles (FCVs) [

15]. This concept sometimes leads to a wider range of vehicle technologies, such as alternative fuel vehicles (AFVs) [

18].

NEVs started earlier in countries in Europe and in the United States. The US Department of Energy began funding research and development of electric vehicles in 1993, providing financial support for the research and development (R&D) of advanced rechargeable batteries and fuel cells [

19]. The most important thing for emerging economies in terms of NEVs is innovation. We should increase our focus on technological innovation to increase our degree of autonomy and control [

20]. The government playing a role in developing alternatives to traditional fuel vehicles, the effectiveness of government programs, and the flexibility of technology in government support programs are also essential [

21]. NEVs are becoming increasingly intelligent, driving new developments in the field of intelligent transportation systems and improving the ability of independent control to ensure market competitiveness [

22,

23]. In addition, a high degree of autonomous control can shorten the cycle of results conversion in the new energy sector and reduce the initial cost of discovery [

24]. Studies have shown that the electric vehicle market grew by 40% year-on-year in 2018, and manufacturing is possible with core components such as traction motors that are independently developed and safe [

25].

As one of the major countries in the development of NEVs, China faces many difficulties and challenges [

26]. It must accelerate the industrialization of energy-saving and independent innovations of NEVs [

27]. The most important obstacle in China at present is the lack of skilled scientists, while legal and institutional barriers have also hindered further development of the new energy industry [

28,

29]. China’s NEV manufacturing enterprises have not broken through the key technologies of complete vehicles and some core components, and the cost of products is high [

30]. It is necessary to focus on solving the autonomy of key components and gradually build an intelligent networked automobile industry chain to realize the strategic goal of being an automobile manufacturing powerhouse [

31]. Under the new economic normal, NEV manufacturers need to support government subsidies, encourage innovation and other policies [

32], improve the industrial chain, and attract social capital to promote the expansion and technological progress of NEV manufacturing [

33]. In view of the many problems that exist in the independent innovation of NEV manufacturing enterprises, some scholars have proposed increasing government support [

34], establishing their own technology systems [

35], developing leading enterprises [

36], unifying common standards [

37], and formulating roadmaps for technological development [

38]. Improving the independent innovation capability of China’s NEV manufacturing enterprises needs to start from the three levels of enterprises, industries, and countries [

39].

From a global perspective, many countries have given policy support to the development of NEVs [

10]. The United States and Germany have clearly defined the goal of developing NEVs [

40]. In recent years, China has also formulated a number of policies to support the development of NEVs [

41]. In fact, as early as 2009, China’s industry adjustment plan has had incentive policies for NEVs [

42]. However, the original policy did not take into account the classification of NEVs [

43]. With the development of NEVs, HEVs, FCVs, and pure electric vehicles have gradually become the focus of attention [

44]. The policies developed by countries have also changed with changes of NEV types [

45]. In the last decade, NEVs have undergone a process of shifting from the laboratory to the market [

46]. With the gradual development of the industry, the NEV industry achieved rapid growth in 2018, so this is also known as the first year of NEVs [

47]. In recent years, China’s NEV industry has achieved rapid development and has become the world’s largest NEV market, thanks to the diversification of government policies [

48].

Most studies have analyzed the necessity and influencing factors of developing NEVs, and proposed countermeasures from different angles. However, most of the research is limited to one or several influencing factors, and few of these factors are combined to comprehensively evaluate the development capabilities of the NEV industry. In addition, qualitative research methods are mostly used, and quantitative empirical analysis is used less. Based on previous research of experts and scholars [

49,

50] and various research methods such as improved entropy and catastrophe progression methods, this paper constructs an industry development capability evaluation index system and empirically analyzes 15 Chinese NEV manufacturers as samples, makes a relatively objective and comprehensive evaluation of the development capacity of China’s NEV industry, and performs cluster analysis of the comprehensive evaluation results to provide a certain theoretical basis for the upgrading of China’s NEV industry and policy formulation.

5. Discussion

5.1. Analysis of Influencing Factors

Based on the above analysis, China’s NEV industry development capability (S) is affected by many factors, such as autonomy (A), controllability (B), and stability (C). This paper further analyzes the influence of various factors on the development capability of China’s NEV industry by constructing multiple regression models.

S is assumed to be a dependent variable, and the independent variables are A, B, and C, assuming that each one has a linear effect on the dependent variable. Based on this, we built a multivariate population regression model

where

are the regression parameters and

is the random error term.

The following is an estimate of the model parameters using the results of China’s NEV industry development capability evaluation and a hypothesis test, and a regression model to predict the dependent variable S. Substituting the evaluation results of China’s NEV industry development capability into (20), using the ordinary least squares (OLS) method for multiple regression analysis, the calculation results are shown in

Table 11.

The adjusted R

2 value in

Table 11 is 1, indicating that the independent variable can fully explain the change of the dependent variable, which means the multivariate regression model has a very high degree of fit and a small error.

According to the output of

Table 12,

, we can explain the constructed multiple regression equation. In addition, the value of

represents the significance test result of the regression equation, indicating whether the linear relationship between the dependent variable S and all the independent variables A, B, and C in the model is generally significant. If

, where

is the number of independent variables,

is the sample size, and

is the degree of freedom, then the null hypothesis is rejected and it can be considered that the individual independent variables in the model have a significant impact on the dependent variable; otherwise, there is no significant impact. In this paper, the number of independent variables is

, the sample capacity is

, and

indicates the significance level, which is generally 0.05, corresponding to

. In

Table 12,

is much larger than 3.5874, indicating that the independent variables A, B, and C have a significant influence on the dependent variable S.

However, the result of the analysis of variance is an overall test of multiple independent variables, and cannot explain the effect of each independent variable on the dependent variable alone. Therefore, we continued to perform a one-sample test for each independent variable. The analysis results are shown in

Table 13.

According to the output results listed in

Table 13, it can be seen that the independent variables A, B, and C all have a significant positive effect on the dependent variable S, and the degree of influence is B (0.548), A (0.544), and C (0.415). That is to say, autonomy, controllability, and stability have a significant positive impact on the development capability of China’s new energy auto industry, and the degree of control has the greatest impact, followed by autonomy and weaker stability.

5.2. Robustness Test

In order to ensure the validity of the regression analysis, the heteroscedasticity of the regression equation needs to be tested. In this paper, we use the White test of no cross terms and use EViews 10 software to calculate the results, shown in

Table 14.

Obs*R2 represents the value of the statistic of the White test, and the accompanying probability of the corresponding heteroscedasticity test is . In the case of significance level , it is shown that there is no heteroscedasticity in the regression model, and the regression analysis is effective.

5.3. Cluster Analysis of Evaluation Results

We used MATLAB 2016a to perform K-means cluster analysis on the comprehensive evaluation results of China’s NEV industry development capabilities. The results are shown in

Figure 3. From the results of the cluster analysis, it can be seen that the comprehensive evaluation of China’s NEV industry development capabilities can be divided into three categories.

The first category is companies with strong development capability. The comprehensive evaluation results of these enterprises are above 0.6, the scores are relatively high, and the development ability is relatively strong, including NEV2, NEV7, NEV9, NEV10, NEV12, and NEV14.

The second category is enterprises with general development capability. The comprehensive evaluation results of these enterprises are between 0.4 and 0.6, the scores are relatively centered, and the development ability is relatively general, including NEV1, NEV3, NEV4, NEV5, NEV8, and NEV13.

The third category is manufacturing enterprises with poor development capability. The comprehensive evaluation results of these enterprises are less than 0.35, the scores are relatively low, and the development ability is relatively poor, including NEV5, NEV6, and NEV11.

It can be seen from the cluster analysis results that the overall level of China’s NEV industry development capability is not high, and the gap between individuals is large. The average scores of the comprehensive evaluation results of the development capability of the three types of NEV enterprises are 0.6966, 0.4912, and 0.2420. The average score of the first category is higher than the second category by 0.2054, which is higher than the third category by 0.4546, and the gap is very obvious.

6. Conclusions and Policy Implications

6.1. Conclusions

This paper took 15 representative NEV manufacturing enterprises in China as a sample, and analyzed and evaluated their development capability by constructing a development capability evaluation system and applying various theories and evaluation methods. The study found that autonomy, controllability, and stability have significant positive impacts on the development capability of the NEV industry, and the degree of control has the greatest impact, followed by autonomy and weaker stability.

Overall, the outlook for the development capability of China’s new energy auto industry is not optimistic. The analysis shows that the development capacity of most sample enterprises is at a medium or low level, and the industry development is still in its infancy. Especially in terms of product autonomy, stability and reliability, and cost control, there is still a big gap compared with other countries.

From the perspective of individuals, the gap in development capability among NEV manufacturers is more obvious. The analysis shows that there are many leading enterprises with strong development capability in China, such as NEV7 (0.7992) and NEV12 (0.7513), but enterprises with weaker development capability account for the majority. In particular, the development of enterprises in the same industry is very uneven, and it is difficult to form a benign pattern for competition and promotion of coordinated development.

From the perspective of indicators, the current outstanding problem that restricts the development of China’s NEV industry is a lack of core technologies and insufficient capacity for independent innovation. The analysis results show that more than 40% of the sample enterprises have very low autonomy. Based on the results, it is found that the core technologies and operating systems required by China’s new energy auto companies rely heavily on imports, and the localization level of key components such as engines, sensors, and chips is not high. Although China has been vigorously developing the NEV industry, there are still no complete domestic alternatives, and it is impossible for the country to completely rid itself of its dependence on imports.

6.2. Policy Implications

In response to the status quo of China’s NEV industry development capability, we propose the following countermeasures:

Increase R&D investment and improve the industrial chain—National and NEV manufacturing enterprises should value the power of knowledge and technology, strengthen R&D investment, fully carry forward the spirit of artisans, establish basic technology research institutions, focus on research on core components and key technologies, and strengthen internal cooperation within the industry, sharing common technologies and creating a complete chain of independent and controllable technologies.

Intensify innovation and build independent brands—The Technical Roadmap for Key Areas of Made in China 2025 puts forward clear requirements for China’s NEV industry. This requires relying on market power, taking NEV manufacturing enterprises as the leading factor, taking development as the orientation, combining the advantages of production, education, and research, driving innovation, improving the level of localization, forming independent and controllable innovative products, maintaining long-term stable development, and getting rid of dependence on imports.

Improve policy protection and encourage industrial upgrading—Developing the industry is inseparable from providing policy support. At the national level, the leading role of the government should be fully exploited, and the development of enterprises should be free from worries. On the basis of existing policies, the state can further increase R&D subsidies, car purchase discounts, tax reductions, and other efforts, and provide policy support for NEVs from production to sales, create a good market environment, narrow the gap in the industry, and comprehensively improve the development capability of China’s NEV industry.