Numerical Simulation of the Aeroelastic Response of Wind Turbines in Typhoons Based on the Mesoscale WRF Model

Abstract

:1. Introduction

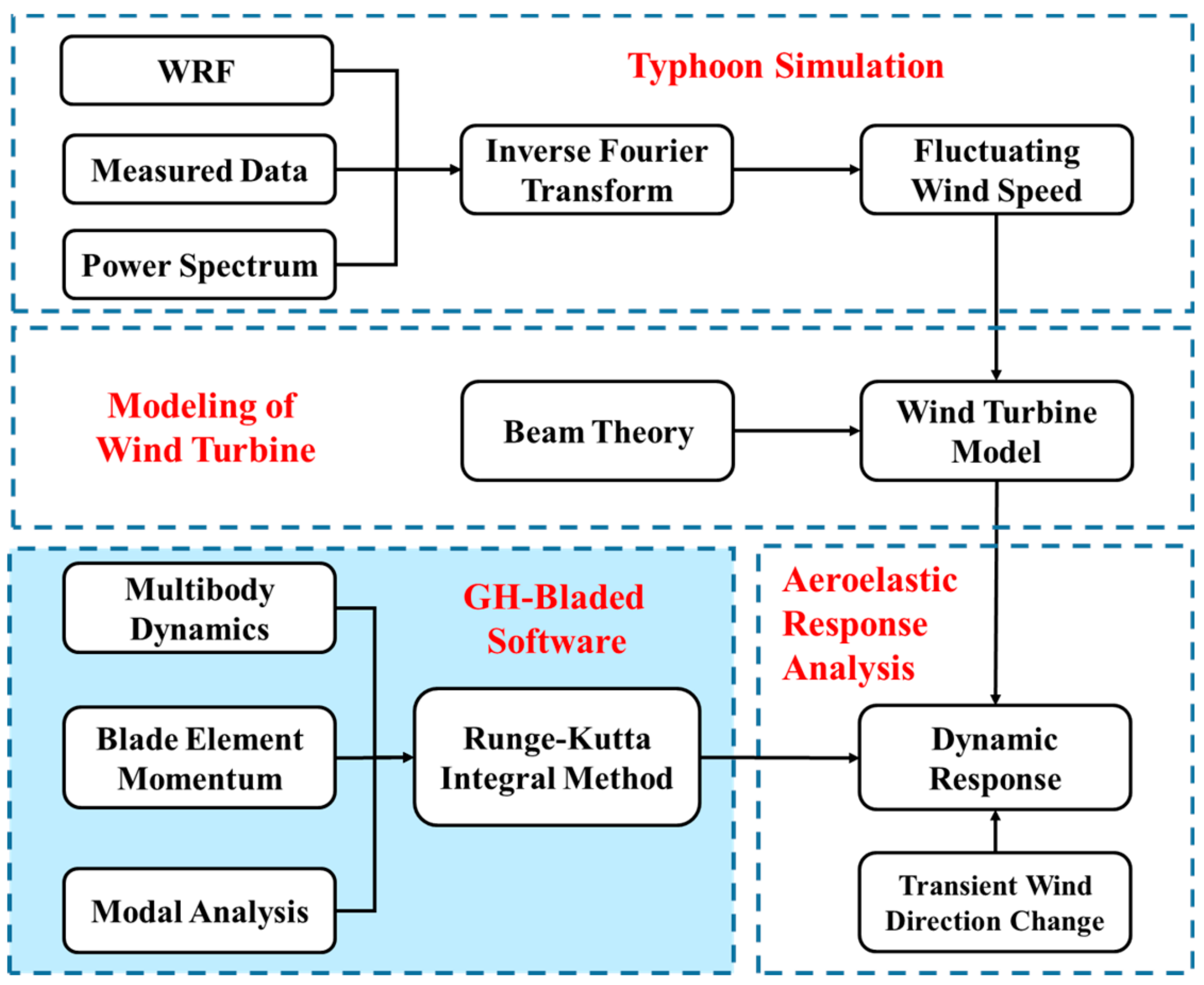

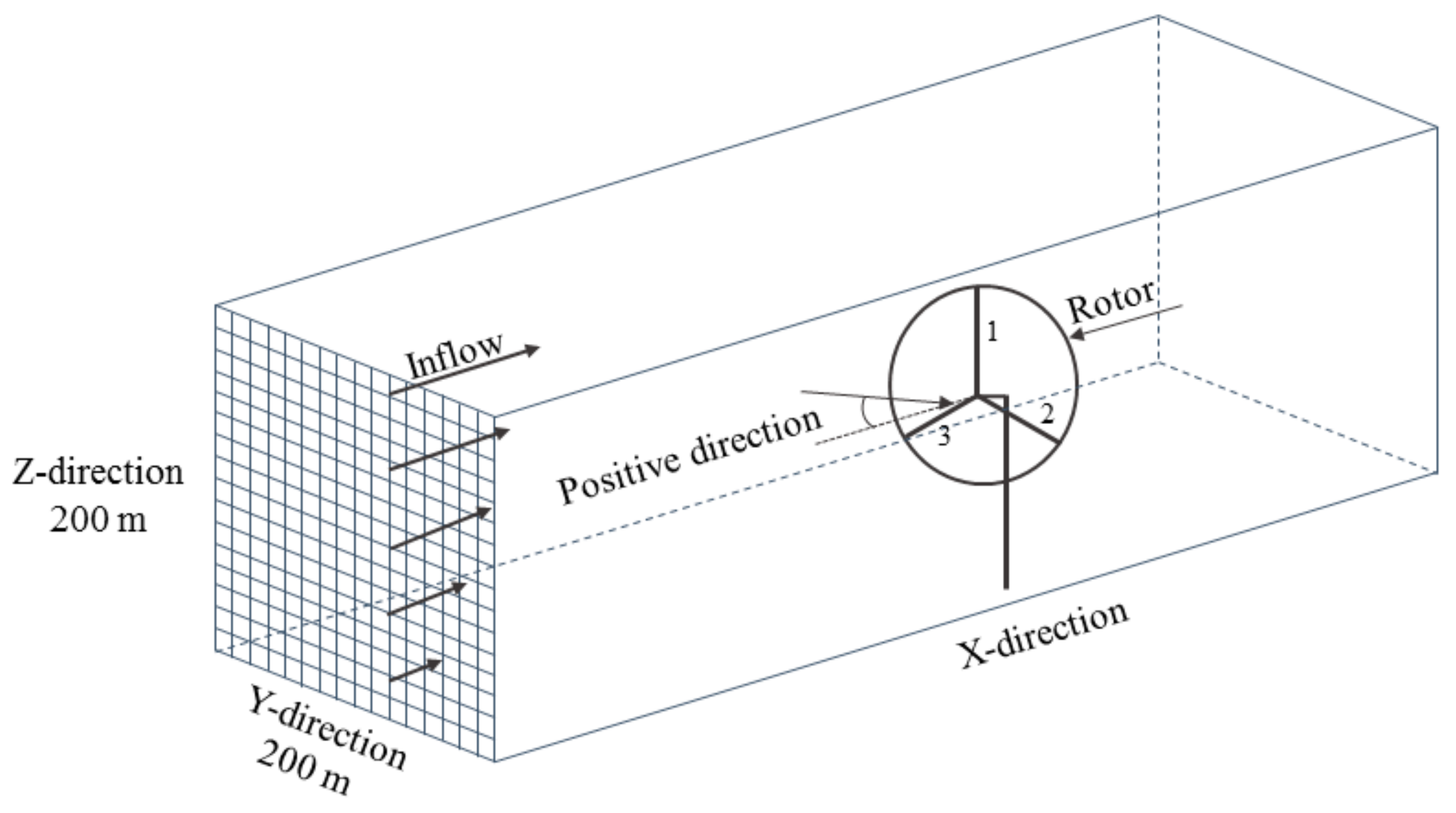

2. Methods

- (1)

- Knowing the pulsating power spectrum S(n) and the simulation time T, since the time history of pulsating wind speed has ergodic characteristics, the Fourier amplitude spectrum F(n) can be calculated via the following formula:

- (2)

- The discrete Fourier transform is applied to the complex sequence F(n); t is the real component which determines the pulsating wind speed:

3. Analysis of Calculation Results

3.1. Wind Turbine Model

3.2. Analysis of Wind Characteristics

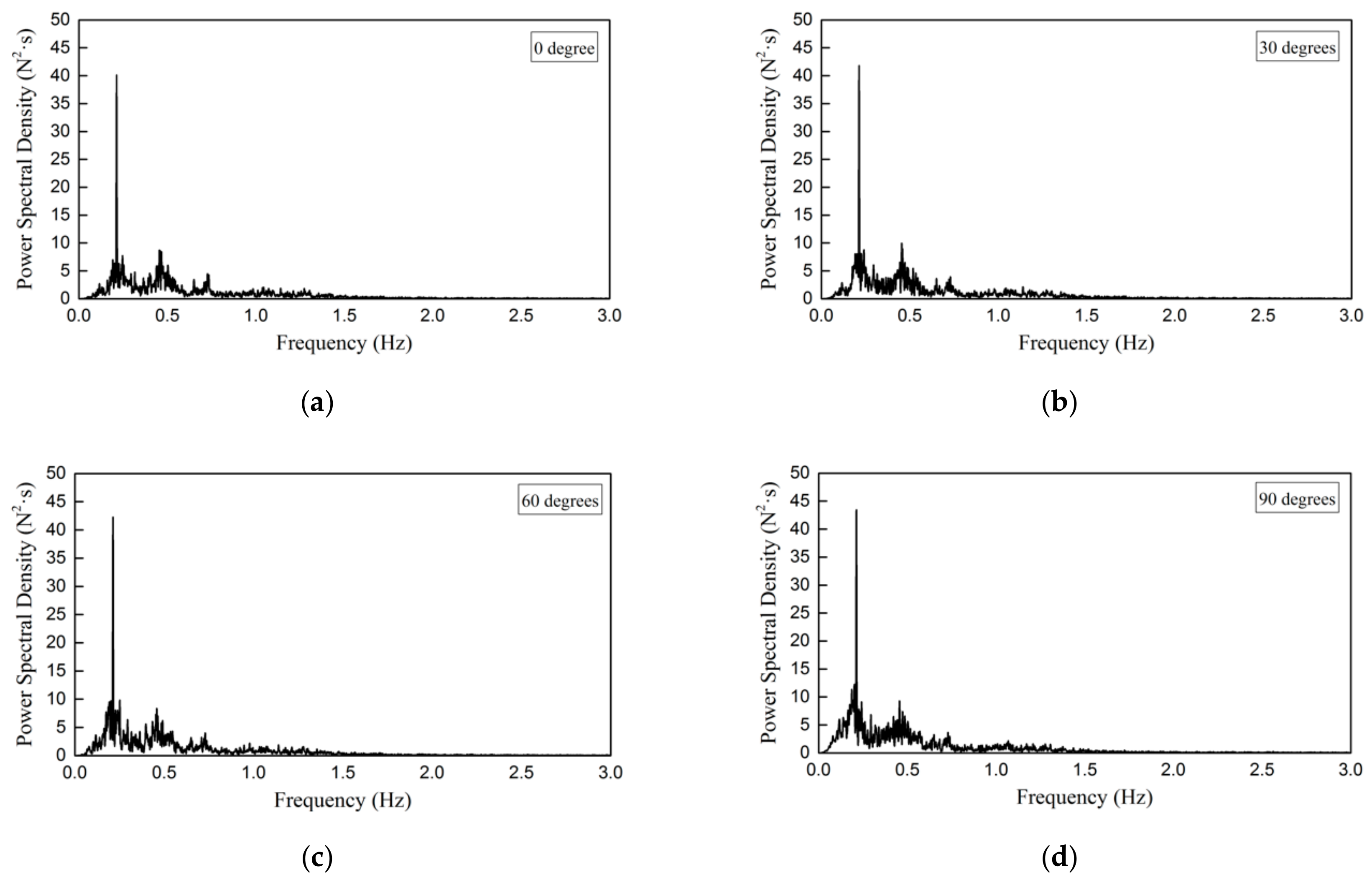

3.3. Analysis of Aeroelastic Response

4. Conclusions

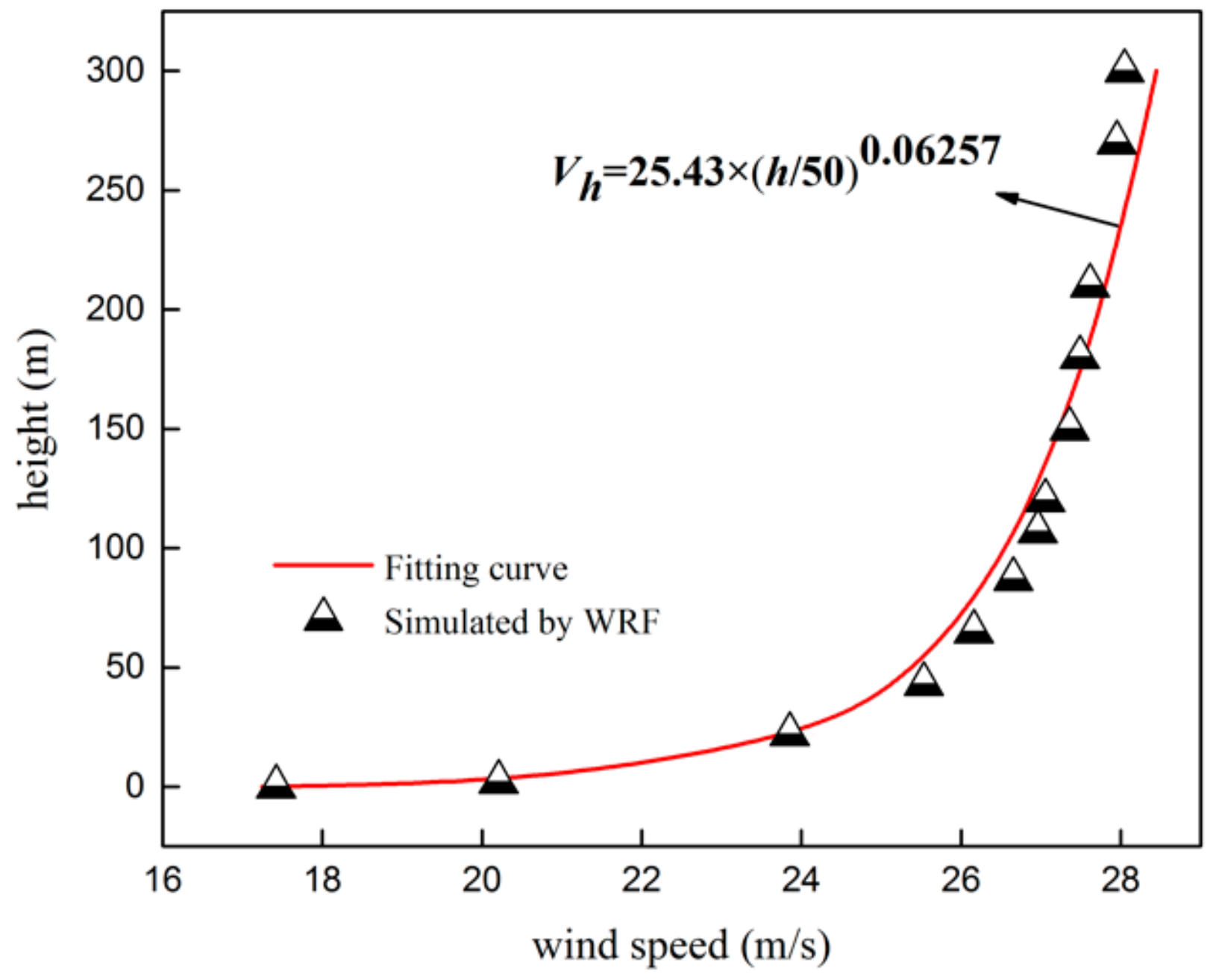

- An entire process simulation of the typhoon Hagupit (Nina) was carried out, and the wind speeds and wind direction changes within 24 h were compared with the measured values. It was found that the simulated average wind speeds and directional fluctuations agreed well with the measured trend; the wind speed exhibited an “M” type distribution within the specified 24 h, and the wind direction changed by nearly 200°. The maximum error between simulated and measured wind speeds was 3.9%. The wind profile index was as small as 0.06257 and complied with the observations. This indicates that the results of the typhoon’s average wind speed field obtained based on the WRF model are reliable.

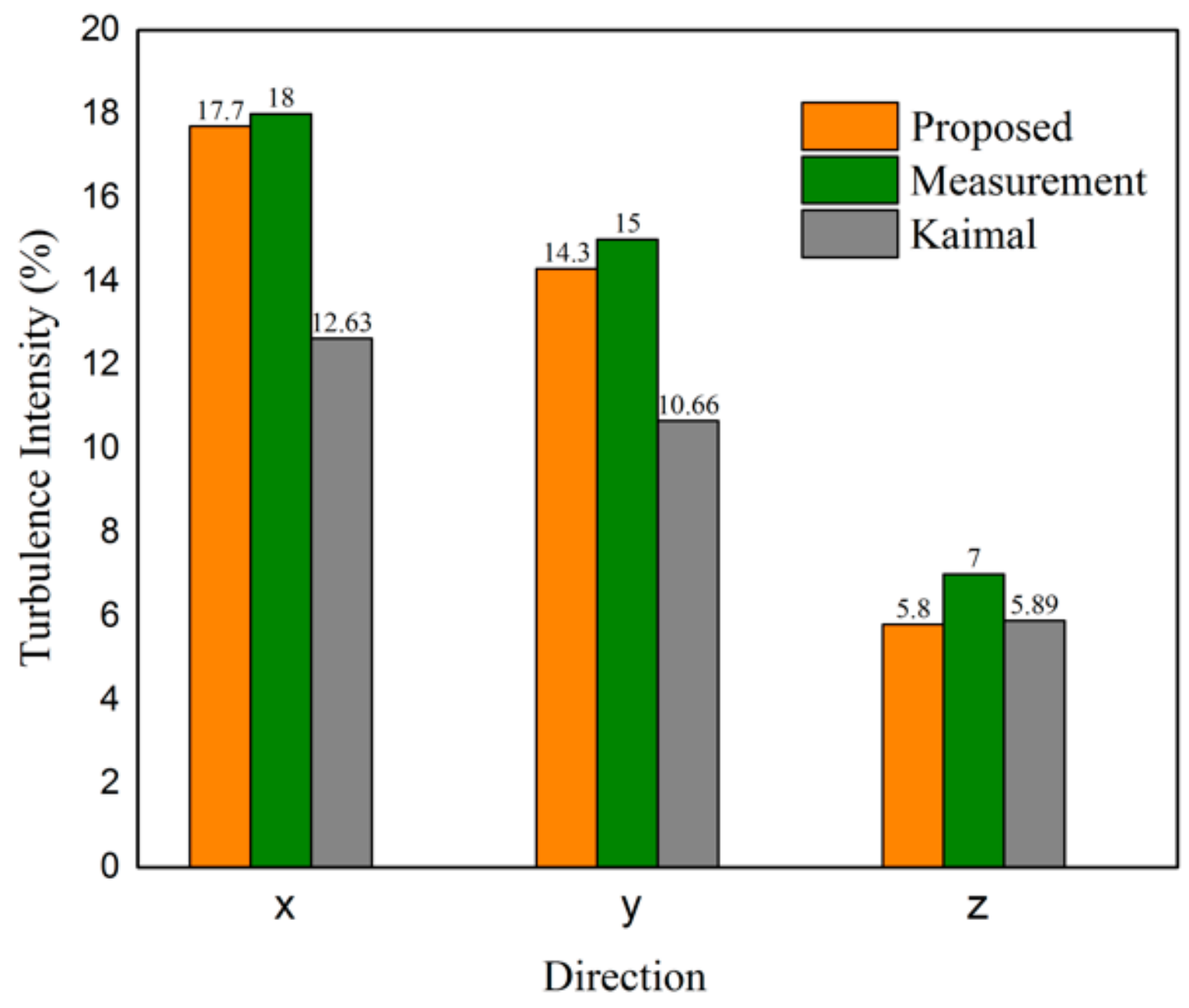

- The coupled wind power spectrum method and the inverse Fourier transform method were jointly applied to generate the typhoon’s pulsating wind speed, which had turbulence characteristics which were close to the measured values. The turbulence intensity error in the X-direction, which had the greatest influence on the vibration of the WT blade, was only 1.7%, which outperformed that derived via the Kaimal spectrum. The simulation results show that the turbulent vortex scale in a typhoon is generally higher than that of a normal wind.

- Under typhoon and normal wind conditions, the aeroelastic responses of the WT at the average wind speeds of 24.4, 25.3, and 40 m/s were analyzed. The tip vibration scope responses in the typhoon exceeded those of the normal wind by 14.4%, 150.1%, and 39.4%, respectively. In addition, the vibration amplitude of the WT under normal operation was significantly higher than that under shutdown conditions.

- The vibration scope of the WT blade increases with wind direction fluctuation. When the latter reached 90° under normal operating conditions, the vibration scope increased by 27.9%, as compared to zero fluctuation. In particular, the maximum blade tip deflection in the X-axis direction reached 28.4 m, which seriously exceeded the safety threshold of the design standard. Therefore, early protection measures, such as early shutdown, should be applied to the WT under the typhoon conditions.

Author Contributions

Funding

Conflicts of Interest

References

- Li, Q.S.; Li, X.; He, Y.C.; Yi, J. Observation of wind fields over different terrains and wind effects on a super-tall building during a severe typhoon and verification of wind tunnel predictions. J. Wind Eng. Ind. Aerodyn. 2017, 162, 73–84. [Google Scholar] [CrossRef]

- Hazelton, A.T.; Rogers, R.F.; Hart, R.E. Analyzing simulated convective bursts in two Atlantic hurricanes. Mon. Weather Rev. 2017, 145, 3073–3094. [Google Scholar] [CrossRef]

- Kepert, J.D. Time and space scales in the tropical cyclone boundary layer and the location of the eyewall updraft. J. Atmos. Sci. 2017, 74, 1–53. [Google Scholar] [CrossRef]

- Williams, G.J. The thermodynamic evolution of the hurricane boundary layer during eyewall replacement cycles. Meteorol. Atmos. Phys. 2017, 129, 611–627. [Google Scholar] [CrossRef]

- Li, L.; Kareem, A.; Xiao, Y.; Song, L.; Zhou, C. A comparative study of field measurements of the turbulence characteristics of typhoon and hurricane winds. J. Wind Eng. Ind. Aerodyn. 2015, 140, 49–66. [Google Scholar] [CrossRef]

- Cao, S.; Tamura, Y.; Kikuchi, N.; Saito, M.; Nakayama, I.; Matsuzaki, Y. Wind characteristics of a strong typhoon. J. Wind Eng. Ind. Aerodyn. 2009, 97, 11–21. [Google Scholar] [CrossRef]

- Dai, K.S.; Sheng, C.; Zhao, Z. Nonlinear response history analysis and collapse mode study of a WT tower subjected to tropical cyclonic winds. Wind Struct. 2017, 25, 79–100. [Google Scholar]

- Han, T.; McCann, G.; Freudenreich, K. How can a WT survive in a tropical cyclone? Renew. Energy 2014, 70, 3–10. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.F. Failure investigation on a coastal wind farm damaged by super typhoon: A forensic engineering study. J. Wind Eng. Ind. Aerodyn. 2015, 147, 132–142. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.Z. Structural failure analysis of WTs impacted by super typhoon Usagi. Eng. Fail. Anal. 2016, 36, 391–404. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.F.; Tang, J. Structural integrity of WTs impacted by tropical cyclones: A case study from China. J. Phys. Conf. Ser. 2016, 753, 1–12. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Li, J.H.; Zhuge, P. Failure analysis of large-scale wind power structure under simulated typhoon. Math. Probl. Eng. 2003, 4, 30–32. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.X.; Deng, Z.W.; Gao, Q.F. Typhoon-resistance analysis of WTs with different towers based on the time-domain method. J. Hunan Univ. 2017, 44, 82–88. [Google Scholar]

- Bangga, G.; Guma, G.; Lutz, T. Numerical simulations of a large offshore WT exposed to turbulent inflow conditions. Wind Eng. 2018, 42, 88–96. [Google Scholar] [CrossRef]

- Vickery, P.J.; Masters, F.J.; Powell, M.D.; Wadhera, D. Hurricane hazard modeling: The past, present, and future. J. Wind Eng. Ind. Aerodyn. 2009, 97, 392–405. [Google Scholar] [CrossRef]

- Wyszogrodzki, A.A.; Miao, S.; Chen, F. Evaluation of the coupling between mesoscale WRF and LES-EULAG models for simulating fine-scale urban dispersion. Atmos. Res. 2012, 118, 324–345. [Google Scholar] [CrossRef]

- Bauer, P.; Thorpe, A.; Brunet, G. The quiet revolution of numerical weather prediction. Nature 2015, 525, 47–55. [Google Scholar] [CrossRef] [PubMed]

- Reeves, H.; Snyder, C.; Rotenone, R. Prediction of landfalling hurricanes with the advanced hurricane WRF model. Mon. Weather Rev. 2008, 136, 1990–2005. [Google Scholar]

- Xiao, Q.N.; Zhang, X.Y.; Davis, C.; Tuttle, J.; Holland, G. Experiments of hurricane initialization with airborne Doppler radar data for the advanced research hurricane WRF (AHW) model. Mon. Weather Rev. 2009, 137, 2758–2777. [Google Scholar] [CrossRef]

- Huang, M.F.; Wang, Y.F.; Lou, W.J.; Cao, S.Y. Multi-scale simulation of time-varying wind fields for Hangzhou Jiubao Bridge during Typhoon Chan-Hom. J. Wind Eng. Ind. Aerodyn. 2018, 179, 419–437. [Google Scholar] [CrossRef]

- Liu, D.H.; Song, L.; Li, G.P. Study on wind profile of typhoon Hagupit using wind observed tower and wind profile radar measurements. J. Trop. Meteorol. 2011, 27, 317–326. [Google Scholar]

- Germanischer, L. Guideline for the Certification of WTs 2010 Edition; Brooktorkai 18, 20457; Brooktorkai: Hamburg, Germany, 2010; pp. 131–174. [Google Scholar]

- Dai, L.P.; Zhou, Q.A.; Zhang, Y.W. Analysis of WT blades aeroelastic performance under yaw conditions. J. Wind Eng. Ind. Aerodyn. 2017, 171, 273–287. [Google Scholar] [CrossRef]

- Dong, X.F.; Lian, J.J.; Wang, H.J. Structural vibration monitoring and operational modal analysis of offshore WT structure. Ocean Eng. 2018, 150, 280–297. [Google Scholar] [CrossRef]

- Han, R.; Wang, L.; Wang, T.G.; Gao, Z.T.; Wu, J.H. Study of dynamic response characteristics of the WT based on measured power spectrum in the eyewall region of typhoons. Appl. Sci. 2019, 9, 1–14. [Google Scholar]

- Kaimal, J.C.; Wyngaard, J.C.; Izumi, Y.; Coté, O.R. Spectral characteristics of surface-layer turbulence. Q. J. R. Meteorol. Soc. 1972, 98, 563–589. [Google Scholar] [CrossRef]

- Tony, B.; David, S.; Nick, J.; Ervin, B. Wind Energy; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2001. [Google Scholar]

- Li, L.X.; Xiao, Y.Q.; Kareem, A.; Song, L.; Qin, P. Modeling typhoon wind power spectra near sea surface based on measurements in the South China sea. J. Wind Eng. Ind. Aerodyn. 2012, 104, 565–576. [Google Scholar] [CrossRef]

- Xu, Y.L.; Zhu, L.D. Buffeting response of long-span cable-supported bridges under skew winds. Part 2, Study. J. Sound Vib. 2005, 281, 675–697. [Google Scholar] [CrossRef]

- Rossi, R.; Lazzari, M.; Vitaliani, R. Wind field simulation for structural engineering purposes. Int. J. Numer. Methods Eng. 2004, 61, 738–763. [Google Scholar] [CrossRef]

- Shiotani, M.; Avai, H. Honorary Advisory Council for Scientific and Industrial Research. In Proceedings of the International Research Seminar on Wind Effects on Buildings and Structures, Ottawa, ON, Canada, 11–15 September 1967; pp. 535–555. [Google Scholar]

- Glauert, H. Airplane Propellers; Dover Publications: New York, NY, USA, 1963. [Google Scholar]

- Prandtl, L.; Betz, A. Vier Abhandlungen zur Hydrodynamik und Aerodynamik; Göttinger Nachr: Göttingen, Germany, 1927; pp. 88–92. [Google Scholar]

- Leishman, J.G.; Beddoes, T.S. A semi-empirical model for dynamic stall. J. Am. Helicopter Soc. 1989, 34, 3–17. [Google Scholar]

- Gao, Y.W.; Li, C.; Cheng, X. Research on foundation response of a tri-floater offshore WT. Conf. Ser. Mater. Sci. Eng. 2013, 52, 66–71. [Google Scholar]

- Rezaei, M.M.; Behzad, M.; Haddadpour, H. Aeroelastic analysis of a rotating WT blade using a geometrically exact formulation. Nonlinear Dyn. 2017, 84, 2367–2392. [Google Scholar] [CrossRef]

- Ho, J.Y.L. Direct path method for flexible multibody spacecraft dynamics. J. Spacecr. Rocket. 2012, 14, 102–110. [Google Scholar] [CrossRef]

- Bossanyi, E.A. GH Bladed Theory Manual; Garrad Hassan and Partners: Bristol, UK, 2009; pp. 13–19. [Google Scholar]

| WRF Parameters | Main Area (d01) | Nested Area (d02) |

|---|---|---|

| Horizontal resolution (km) | 15 | 5 |

| Integration time step (s) | 180 | 180 |

| Microphysical process scheme | Lin | Lin |

| Long wave radiation | Rapid Radiative Transfer Model (RRTM) | RRTM |

| Short wave radiation | Dudhai | Dudhai |

| Near ground layer scheme | Jimenez | Jimenez |

| Land surface process scheme | Noah | Noah |

| Planetary boundary layer scheme | YSU | YSU |

| Cumulus convection parameterization scheme | Kain–Fritsch | Kain–Fritsch |

| Technical Parameter | Value | Technical Parameter | Value |

|---|---|---|---|

| Rated wind speed, m/s | 10 | Hub height | 100 m |

| Number of blades | 3 | Blade length | 78 m |

| Windwheel diameter, m | 160.7 m | Tip prebending | 10 m |

| First-order natural frequency (out of plane) | 0.508 Hz | First-order natural | 0.826 Hz |

| frequency (in plane) | |||

| Second-order natural frequency (out of plane) | 1.364 Hz | Second-order natural | 2.565 Hz |

| frequency (in plane) | |||

| Tower first-order natural frequency, Hz | 0.217 Hz | Second-order natural | 1.321 Hz |

| Frequency of tower |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Chen, C.; Wang, T.; Wang, W. Numerical Simulation of the Aeroelastic Response of Wind Turbines in Typhoons Based on the Mesoscale WRF Model. Sustainability 2020, 12, 34. https://doi.org/10.3390/su12010034

Wang L, Chen C, Wang T, Wang W. Numerical Simulation of the Aeroelastic Response of Wind Turbines in Typhoons Based on the Mesoscale WRF Model. Sustainability. 2020; 12(1):34. https://doi.org/10.3390/su12010034

Chicago/Turabian StyleWang, Long, Cheng Chen, Tongguang Wang, and Weibin Wang. 2020. "Numerical Simulation of the Aeroelastic Response of Wind Turbines in Typhoons Based on the Mesoscale WRF Model" Sustainability 12, no. 1: 34. https://doi.org/10.3390/su12010034