1. Introduction

In Germany, more than 90 percent of the population supports energy transition to reach the climate policy goals in principle [

1,

2]. However, further steps towards more renewable power generation, such as the impending phasing-out of nuclear power, the targeted phasing-out of lignite-fired power generation and the construction of new transmission lines and wind turbines, require profound structural changes and huge transfer payments. It is still not clear how these challenges can be dealt with in order to achieve a socially acceptable implementation. It is necessary to increase the participation of people to ensure the success of the energy transition. In addition, there is a need for solutions that can be accepted by all relevant stakeholders on the one hand and, on the other hand, integrated into the overall system in a structured way [

2].

In 2018, German grid operators used feed-in management for renewable energy due to local transmission bottlenecks of about 5.4 TWh [

3]. This corresponds to around one percent of the yearly electricity consumption in Germany. For the first quarter of 2019 alone, the compensation payments for feed-in management were estimated at 364 million EUR [

3]. These are passed on via grid fees to the electricity consumers [

3]. Therefore, solutions are necessary to cost-effectively integrate renewable energy sources into the grid. Among others, e.g., flexibility on the supply side, grid expansion, storages, and sector coupling, demand side management (DSM) seems to be a promising solution [

4]. It originally consisted of several activities to influence customers’ use of electricity [

5,

6]. The German federal research project “SynErgie” from the funding program “Kopernikus” [

7] analyzes the potential of so-called energy-flexible factories to balance electricity consumption with the volatile electricity generation by renewable energy sources. The industrial sector holds significant potential [

4,

8], as it exhibits a share of about 42% of electrical energy consumption in Germany in 2018 [

9].

To exploit this potential and put energy flexibility into business practice, it is necessary to determine the technical feasibility of exemplary industrial demand-side flexibilities. Some essential prerequisites for this are economic incentives that enable energy flexibility to trade flexibility services at national and, in the future, regional markets. In addition, the social impact of flexibility measures, such as changes for employees (e.g., adaption of shift models), need to be taken into account to ensure sustainable implementation. Some contributions in the literature reveal that the investigation of energy-flexible factories has so far dealt with technological, economic, and social aspects separately. Hence, a part of the “SynErgie” project addresses the above-mentioned questions holistically in the so-called model region Augsburg. The region is located in southwestern Bavaria, Germany and consists of the city of Augsburg and the two surrounding districts, Augsburg and Aichach-Friedberg. Altogether, the model region is populated by around 660,000 people, which constitutes about 0.7% of the German population. The model region has an area of approximately 2000 square kilometers, and thus a population density of around 330 people per square kilometer. A broad variety of associations, several energy-intensive companies and a large number of small and medium-sized companies from various industries, including mechanical engineering and vehicle construction, metal production, processing industry and the chemical and paper industry, as well as rubber and plastics production, are based in the model region [

10]. Thus, the region represents a comprehensive cross-section of the German industrial sector. The model region offers a suitable framework to discuss and examine the possibilities and effects of energy-flexible factories and their impact on the environment as well as on society and politics.

This paper presents the research approach and stems from the study of energy-flexible factories in the model region. First, the design-thinking-based method used for transdisciplinary collaboration is presented in

Section 2. The next section describes stakeholder participation by the co-creative discourse, followed by

Section 4, which deals with the modeling and simulation of flexibility measures in the considered system. Based on the co-creative discourse and the simulation results, three sections dealing with the most important challenges and opportunities of energy-flexible factories address the following questions:

Which regional market mechanisms are available and necessary for economic incentives? (

Section 5);

How can energy-flexible factories be integrated into the solution kit of energy transition? (

Section 6);

How interdependent are participation and acceptance? (

Section 7).

The transferability of the results and requirements for the implementation of the energy-flexible factory are addressed in

Section 8. Finally,

Section 9 concludes and offers a view of further research questions. The nine sections of this paper are depicted and correlated in

Figure 1.

2. Research Mode: Primal Transdisciplinary Steps

In the following section, we will briefly explain our fundamental research mode: transdisciplinarity. Throughout this paper, the terms “transdisciplinarity” and “transdisciplinary” will refer to “a reflexive research approach that addresses societal problems by means of interdisciplinary collaboration as well as the collaboration between researchers and extra-scientific actors” [

11]. The main aim of transdisciplinary research is to obtain socially robust knowledge for complex problems, such as, in our case, energy transition and climate change. The comparison of different research modes based on their scientific and societal results has revealed that certain societal and practice-relevant outcomes are positively influenced when practitioners contribute to the early stages of the research project [

12].

It is important to note that, in Anglo-American research contexts, “transdisciplinary” often refers to multiple academic disciplines working on the same research question parallel (we would refer to this setting as “multidisciplinary”), yet not working together (we would refer to that setting as “interdisciplinary”). Transdisciplinarity in our terminology refers to what readers socialized in the Anglo-American academia might refer to as “Mode 2”-research or post-normal science [

13].

Some important characteristics of transdisciplinary research are:

Cooperation between science and society: transdisciplinary research includes disciplinary and interdisciplinary research on the science arena, but also adds the society arena to the research process;

Iterative research process: as introduced by [

11], the transdisciplinary research process consists of two arenas: science and society. These interact in a co-process initiated by defining a boundary object (

Figure 2). The co-definition is followed by two more phases—the co-production of knowledge and the co-communication of the new common knowledge—integrated in both arenas, respectively;

Variety of methods: transdisciplinarity is not a methodology or a theory, but a research approach. Therefore, all kinds of different scientific and non-scientific methods can be used throughout the course of the project;

Reflexiveness: overall, transdisciplinarity is a reflexive mode of research, which means that it systematically scrutinizes the ways in which knowledge is obtained and used by different actors.

Transdisciplinary research comes with several challenges, such as:

A long and laborious phase zero: in the beginning of a funded research project, and even before, there is a phase of intensive personal exchange and the building of understanding and trust as a precondition for future collaboration, before any co-creation in the conventional sense can take place;

Finding a common language: different disciplines, but also different societal actors, often have a very specific terminology which is not necessarily understandable for all parties involved. Especially in the beginning of a project, and continuously throughout its progress, it is therefore essential to establish a common language and build a shared understanding of what core terms mean to everybody;

Distinct motivations and interests: societal and industrial actors usually are not interested in publications and citations, like science employees. That makes it important to reflect their interests and motivations sufficiently to enable sustained collaboration. It is crucial to ensure that progress is made in their cases, because it would be fatal to think of societal actors as a homogenous group, which means that there might be divergent interests and motivations;

Highly different time regimes: when planning a research project, there are many variables and requirements that must be met, for instance, funding criteria, journal deadlines, conference presentations, working hours, and political or economic events. Transdisciplinary approaches add a whole new layer to the planning process—considering the time regimes of societal actors;

Huge discrepancies concerning resources: whereas researchers are certainly funded for their working time, and often stakeholders from companies and the administration are too, the case is very different for civil society actors. In several cases, there are volunteers participating as stakeholders from civil society organizations. A good exercise might be to turn the tables [

14] and ask the stakeholders at the beginning of the project what they need for participation on an equal level.

As stated above, transdisciplinarity is very demanding both for researchers and societal actors. The ideal typical transdisciplinarity process could not be fully adapted in our case. For instance, the research questions were formulated by the science partners without consulting stakeholders in phase zero. Therefore, we would describe this project as taking transdisciplinarity steps towards a more complete and deeper adaptation of transdisciplinarity approaches in the following project phases.

In the next section, we will describe the co-production-process in our case and introduce the concrete methods we have used.

3. Co-Production of Socially Robust Knowledge: Some Concrete Methods

In this section, we outline the transdisciplinary setting in the model region Augsburg and introduce the methods we have used to co-produce new knowledge. Note that co-production is in the middle of a three-phase co-creation process amongst co-definition and co-communication (

Figure 3).

In our case, transdisciplinarity had an advocate in form of a project partner, which is a network of non-governmental organizations (NGOs) and NGO networks pushing for sustainable development. Whereas some project partners already have deeper ties from previous cooperations, the advocate was a new actor in the project consortium. Therefore, trust-building in a new player, new colleagues, and new methods was crucial to kick-off the transdisciplinary process. Trust-building often is iterative, which means that it depends on continuously creating opportunities of exchange and tentative, which means it is not linear and takes time [

15]. After having created some common ground in the team, stakeholders were brought to the project.

To find and invite stakeholders to the project, local and regional actors were mapped and assigned to three spheres: the Technosphere, bringing together experts on industry and technology; the Ecosphere, bringing together experts on ecology and sustainability; and the Sociosphere, bringing together experts on society and culture (

Figure 3). Here, “expert” refers to a person obtaining specific knowledge, e.g., academic or use-oriented. Overall, around 50 stakeholders from corporations, the administration at the local and state level, unions, environmental NGOs, and citizen initiatives were consulted in biannual meetings. The respective spheres had meetings quarterly. The spheres themselves were transdisciplinary insofar as experts from different sectors such as research, companies, and civil society were present. In September 2018, an additional 60 stakeholders were part of a one-day stakeholder dialogue (

Section 7).

Both the meetings and the one-day stakeholder dialogue consisted of input-phases and actual co-production. The methods used are detailed below.

3.1. Design Thinking

Design Thinking is a creative and user-oriented process based on design methods to create new ideas [

16]. Nowadays, there is a very broad method portfolio based on the Design Thinking approach. From this portfolio, we have chosen methods that are low-threshold for people who are not used to interactive settings, and methods that can be applied within two hours. These facilitation methods include timeboxing (short, structured sprints to achieve stated goals), working with flexible mobiliary and post-its, as well as brainstorming methods. Using Design Thinking methods extensively might need a certain routine, but in our experience it is worthwhile to adapt some methods for a common experiment.

3.2. Personas

A persona is a fictive figure with typical attributes for a specific user group [

17]. We have generated personas to make different stakeholder positions visible and create empathy for different issues and needs (

Figure 4). Personas for the following sectors were created: Civil Society, Science, Companies, Administration. In our experience, personas are a great help in changing perspectives and making them more concrete.

3.3. Scenario Planning

We have used the scenario-planning method in combination with personas to evaluate utopias and dystopias concerning the energy-flexible factory in a biannual stakeholder meeting. Scenario planning is a suitable way to foster discussion on frame conditions and variables, and also interests. It is a rather complex method which needs good preparation and enough time to become accustomed to the setting.

3.4. Sketchnote

A sketchnote is a kind of mind map with illustrations [

18]. To create a common ground for the one-day stakeholder dialogue, a Sketchnote including a glossary of important terms was created with the following key questions: What is the energy transition? What is the energy-flexible factory? What is the potential of the energy-flexible factory? Which surrounding conditions are necessary for the energy-flexible factory? Which transitions will the energy-flexible factory initiate? In our experience, sketchnotes can help to develop a vision and a narrative, and might be a great exercise to condense for experiments.

3.5. Theses Paper

For the one-day stakeholder dialogue, a thesis paper with five topics and three theses was created. Beforehand, more than 40 theses were collected in the research team and then discussed and prioritised with the Sociosphere. The thesis paper obviously does not cover the whole complex of energy-flexible factories extensively but does serve as an impetus for further discussion. Furthermore, it sensitizes different groups to the complexity of the subject.

In a nutshell, to co-produce knowledge requires the ability and will of both the researchers and the stakeholders to open themselves to different and sometimes new methods from various disciplines and contexts. It is crucial to design a broad portfolio of methods, triggering diverse types of thinking and developing, and factoring in different kinds of learning and personality types.

In

Section 7, we will critically reflect on what participation actually means and reconsider common misconceptions of trandisciplinary approaches. Additionally, we will discuss the outcomes of the stakeholder consultation in the model region of Augsburg. In the next section, the simulation environment created for stakeholder discourse will be introduced.

4. Simulation Studies and Ecological Analysis

The transdisciplinary dialogue between stakeholders requires a suitable information base to investigate and assess potential flexibility measures, especially in scenarios with an increased share of renewable power generation. Thus, we developed a simulation environment to analyze the impact of energy-flexible factories on regional supply systems, using the residual load as a characteristic for the evaluation. Residual load is an indicator of the degree of supply by fluctuating renewable energy in a balance area. It is calculated as the difference between the demanded electrical power and the power offered by fluctuating renewable energy at a given time. For instance, a residual load of −50 MW means that 50 MW more power from renewable energy is generated than is currently consumed in the area under consideration. Using a mathematical optimization model, the flexibility measures are applied, with the aim of reducing positive as well as negative peaks of the residual load. By reducing the residual load as the target of optimization, the local transmission bottlenecks described in the paper’s motivation are to be counteracted, as the need for grid-based energy balancing is reduced.

In order to carry out the optimization, it is necessary to model future supply scenarios and flexibility measures. This, as well as the optimization model, will be described below. Then, the results of the optimization are visualized.

4.1. Modeling of the Regional Consumption and Sypply Scenario

The aim of this step is to determine the residual load as the determining factor for the use of flexibility for today and the future in the model region. The methodological approach is demonstrated in

Figure 5.

The starting point for the analysis is the “Climate Protection Scenario 2050 [

19] (Step 1 in

Figure 5). This scenario, KS95, demonstrates the necessary measurements to keep the global average temperature well below 2 °C, above pre-industrial levels [

20]. The developments in electricity consumption in the commercial, industrial, and private household sectors (Step 2 in

Figure 5), as well as the expansion of photovoltaics and wind energy plants (Step 3 in

Figure 5), form the basis for the following regionalization of electricity consumption and renewable electricity generation.

In the next step, KS95 was regionalized with a regional model, called “FREM” [

21,

22], with suitable key figures at district level and then systematically continued for the years 2020, 2030, 2040, and 2050 (Steps 4 and 5 in

Figure 5). Finally, consumption is adjusted on the basis of the development indicated in KS95.

We chose the following approach to move from electricity consumption levels to electricity consumption load curves (Step 6 in

Figure 5). The corresponding standard load profiles, H0 and G0, [

23] are used for the household and commercial, trade, and services sectors. These are then scaled according to annual consumption. In addition, the total load profile for Germany in each hour is scaled to the load of the European Network of Transmission System Operators for Electricity (ENTSO-E) for each sector [

24]. The industrial sector has its own load profiles, which were compiled using a regression analysis for various industry groups on the basis of real industrial load profiles [

25].

In addition to the consumption load curve, the generation curve of renewable energy is required to determine the residual load. The starting point for quantifying the generation profiles of renewable energy in the model region (Step 7 in

Figure 5) is the analysis of the actual inventory and the potential, as well as the modelling of the expansion of the capacity of renewable energy. The inventory is defined as the complete list of available renewable power generation facilities in a region. It mainly results from the system registers of the transmission system operators and the results of the tendering procedures.

For photovoltaic systems, the procedure differs between roof-mounted and ground-mounted systems. The historical expansion dynamics of the roof-mounted systems can be used to determine the future expansion per district. For ground-mounted systems, the future expansion is determined by a suitable weighting of area potential and yield potential. The area potential of wind turbines is made up of the results of a white area analysis and the designated wind suitability areas. Finally, by weighting the locations, the expansion of wind power is modelled.

With the regionally available potential, the installed capacity of photovoltaic plants is expected to increase by 780 MW by 2050 under the given legal framework conditions. The usable potential of hydropower has already been tapped in the region. Depending on the specific conditions of the region, wind power accounts for a small proportion of the installed capacity. Hence, as electricity generation from biomass can be regulated, it is not included in the consideration of fluctuating generation. The total input of volatile renewable power generation in the modelled scenarios is therefore around 1500 MW in 2050.

The generation profiles for photovoltaics and wind energy are based on the weather year 2012, as the yields in this year corresponded to the long-term average and are therefore regarded as representative.

Based on the assumptions in KS95 for increasing energy efficiency, the demand for electrical energy will fall by around 1100 GWh by 2050. At the same time, due to the strong expansion of photovoltaic, the generation of volatile renewable energy plants will increase by around 70% to 2100 GWh. As a result, the residual load will be significantly increased by 2050. As can be seen in

Figure 6, the fluctuations in the energy supply, and thus also the residual load, are increasing due to the expansion of renewable energy. As a result, energy from the region is exported in some hours, mainly during the summer months, due to oversupply (negative residual load). The level of residual load depends strongly on the weather and the regional energy demand and is therefore subject to strong fluctuations. Around 400 MW is seen to occur at peak times over the year 2030. In the summer months of 2050, surpluses with an electrical output of up to 700 MW can be expected.

Figure 6 illustrates the necessary energy balancing over hours and days in the regional context. It clearly depicts that future challenges will consist of balancing the times of day with high and low residual loads on the one hand, and in the necessity of seasonal energy balancing on the other hand. The flexibility potential of the industry can be used in particular for intraday balancing. The next section describes which flexibility options are available in the model region.

4.2. Description of Exemplary Flexibility Measures

In the research project “SynErgie”, various energy-intensive industries were examined for flexible processes [

26,

27]. For the model region, we chose three exemplary flexibility measures, as they provide a good cross-section of the energy-intensive industries and are representative of flexibilization measures in accordance with a directive of the Association of German Engineers [

28]. In addition, these three industries, as well as the other energy-flexible factories in the model region, exhibit further flexibilities. For this reason, the simulation represents the lower limit of the available potential.

Table 1 gives an overview of exemplary flexibility measures, which were chosen and modeled in a simplified way for mathematical optimization.

The second column in

Table 1 describes the exemplary flexibility measure in a foundry where pig iron and steel are melted in electric furnaces, followed by casting and machining. The molten material can serve as inherent energy storage for a certain period of time before it is further processed. This allows a shift in the process to start within predefined restrictions. Therefore, furnace capacities, the required casting quantity, and the start times of subsequent processes have to be taken into account. Thus, a technical flexibility potential of around 6 MW, in a time window between 10:00 p.m. and 02:00 p.m., is given every day [

29];

The paper industry requires wood-based pulp, which is produced in thermomechanical pulp (TMP)-plants and further processed in paper machines. In the TMP-process, steam is added to wood chips at high temperatures to defiber them. A downstream vat allows the storage of the produced pulp and thus enables a brief shutdown of the TMP plant after overproduction. Storage volume and raw material requirements for subsequent processes are limiting factors for the availability of the flexibility measure, which must be considered. In the given example, the flexibility measure, in the form of an interruption to the TMP plant, leads to a 2.5 h load shedding of 35 MW (

Table 1). This flexibility measure can only be used once a day [

30];

Graphitization is the most energy-intensive process step in the production of graphite electrodes used in the recycling of steel in arc furnaces. In this process step, carbon blanks are heated up to above 2600 °C until a graphite structure is formed [

31]. The load of the graphitization process can be reduced for about 15 min without affecting the quality of the final product, provided that the energy input lost by the pause is compensated later in the process. Due to the characteristics of the heating curve, this compensation leads to a higher overall energy demand. Consequently, with this exemplary flexibility measure, a load shedding of 6 MW is possible, which has to be compensated later in the process with a power input of 8 MW (

Table 1) [

32].

4.3. Optimization Module

The objective of the optimization is to reduce positive and negative residual load peaks by the use of flexibility measures of energy-flexible factories. Smoothing the residual load is the basic goal of regional energy balancing. Therefore, the flexibility measures are modeled as residual load increase mechanisms and residual load reduction mechanisms, respectively. We apply a simulation model to compare two scenarios [

33]:

Scenario 1: a random use of the measures, to simulate an untargeted use of the production facilities as comparison scenario;

Scenario 2: use of flexibility measures with the objective to reduce residual load peaks.

By comparing the random use in Scenario 1 with the energy-flexible use in Scenario 2, the potential of an intelligent control of flexibility measures to smooth the residual load can be assessed.

4.4. Results of the Optimization Studies

The analysis of the supply data of the model region has demonstrated that a positive contribution of industrial flexibility measures to regional energy balancing is possible and meaningful. We discuss the target year 2030 as an example. The described flexibility measures were applied in accordance with the corresponding restrictions. In the considered year, 1092 start times of foundry’s melting processes were postponed by the optimization, the pulp production was paused 364 times, and the flexibility measure, interrupting the graphitization processes, was used 126 times. As a result, 14 GWh of energy has been shifted from low-energy times to phases with a high share of renewable energy power production. This amount of energy equals 200 maximum load hours of a typical 70 MW combined cycle power plant. Peak loads of the residual load were also reduced by 22 and 28 MW, respectively. If this was to be achieved with a lithium–ion storage, it would require twice the power of the largest commercially used battery storage in Europe. [

34]

Figure 7 illustrates an exemplary summer week of the analysis, in 2030. The residual load without the use of the flexibilities is depicted in red. The blue load profile represents the reduction in load peaks due to flexible starts, and the pausing and interruption of the processes. In this week, about 330 MWh were shifted at times of electrical overproduction. Peak loads were reduced by 36.8 MW (negative residual load) and 41.4 MW (positive residual load), respectively.

For the example of pulp production,

Figure 8 depicts the temporal effects of applying flexibility measures to the processes by a comparison of the starting points with random use and optimized use of the measure. The abscissa of the diagram depicts the time of day with a highlighted day shift. The ordinate represents the days of the week. Without optimization, the flexibility measure for pausing the TMP process is often placed outside the day shift. In business practice, this is often due to the availability of staff and logistical goals. With the optimization, the appropriate times are postponed to the evening hours, with high energy consumption and decreasing solar energy supply. Thus, when implementing the energy-flexible factory, many internal factors must be taken into account. Among others, these can include the shift times of employees, effects on subsequent processes, and delivery dates. Therefore, appropriate economic incentives are necessary to justify the effort involved in energy-oriented planning and control tasks.

4.5. Ecological Impact

The life cycle assessment (LCA), with the aim of quantifying the ecological impacts of the use of energy flexibility measures in energy-intensive industrial processes, was based on the standards ISO 14040 and ISO 14044. Based on the reference processes and their exemplary modelled flexibility measures and production quantities, we analyzed both internal—from the companies’ perspective—and regional—concerning the effects on the model region—impacts. The annual production of each reference process was selected as the functional unit. When defining the impact categories, the focus was on global warming potential, renewable and non-renewable primary energy, and nitrogen oxide emissions [

35].

4.5.1. Internal, Company-Related Perspective

The results of the evaluation are presented in

Table 2. For the reference processes—foundry and pulp production—the investigation revealed no relevant energetic or material effects. For the graphitization process, an increased consumption of electricity, changes in cooling water demand, and changes in consumption of and emissions from packing masses (oxidation) were identified.

4.5.2. External Perspective of the Model Region

The results in 4.2 show that the use of flexibility measures leads to changes in the residual load.

Table 2 also demonstrates that, apart from in one scenario, the required energy and material flows remain the same throughout the application of the flexibility measures. Only in the case of graphitization is more energy and material required due to the shift, and additional emissions are released. However, the shifting of 14 GWh of energy from low-energy times to phases with a high share of renewable energy power production has an effect on the life cycle inventory, which is defined by the input and output flows for the analyzed system, in the form of the displacement of conventional energy generation. Therefore, the ecological impacts of the use of flexibility measures were determined based on the so-called displacement mix. This approach attempts to assess the power generation option that is no longer used due to flexibility measures. The environmental impacts resulting from the use of the electricity mix are saved if renewable electricity is used as a result of energy flexibilization. [

19]

To illustrate the greenhouse gas savings, emission savings are presented as a saved, full-load hour of a combined cycle power plant.

Table 3 depicts the life cycle impact of flexibility measures using a combined cycle power plant as reference. If this amount of electricity—corresponding to the residual load avoided in the year 2030—is not needed, environmental pollution is avoided.

Finally, under the underlying assumptions, the flexibility measures examined and the associated consumption of renewable energy can be assessed as advantageous from an ecological perspective. Due to the increased share of renewable energy in electricity generation, the identified negative effects of additional electricity consumption caused by the use of flexibility measures are mitigated.

5. Regional Market Mechanisms

Based on the co-creative discourse and the simulation results, an analysis of available regional market mechanisms and a necessary new one for economic incentives were made.

In the course of the energy transition, the share of photovoltaic and wind energy plants installed at low voltage levels in the grid is rising. Wind and sunshine, and thus also the production of electricity from photovoltaic plants and wind turbines, are subject to both daily and seasonal fluctuations [

36]. In Germany, the current uniformal price system assumes a copper plate. Consequently, physical restrictions, such as the capacities of transmission lines burdened by increasingly fluctuating feed-in, are not taken into account when electricity prices are determined on the electricity markets.

5.1. The Need for Regional Market Mechanisms

Due to the increasingly fluctuating supply of renewable energy, the distribution and transmission grids are increasingly stressed. Grid bottlenecks cause the curtailment of renewable power production to prevent grid failures. At one point in 2018, up to 5.8 GW—equivalent to the output of almost four nuclear power plants—of renewable electricity generation remained unused by feed-in management. In the first three months of 2019, in 86.3% of cases, grid bottlenecks in the transmission grid led to feed-in management. Nevertheless, 77.5% of the deregulated electricity was switched off in the distribution grid [

3]. An efficient and sustainable energy system must avoid such waste. For this reason, regional flexibility is becoming increasingly important alongside the existing trans-regional market mechanisms to avoid feed-in management in distribution grids. As mentioned in the introduction, redispatch and feed-in management are associated with high costs. These are currently paid for by all electricity customers. Appropriate regional market mechanisms for flexibility can contribute to this, thereby ensuring that everyone has to pay less for electricity [

37].

However, there are currently only few incentives at the regional level to effectively counteract this undesirable development and use regional electricity surpluses, for example, in industrial companies [

38,

39]. In the following, we analyze regional and trans-regional market mechanisms and indicate which kinds of mechanisms will be necessary in the future.

5.2. Classification of Market Machinisms

For the analysis of existing and the development of future market mechanisms, we use four dimensions to cluster those mechanisms. The first dimension describes whether the flexibility of a mechanism is applied regionally or trans-regionally. The second dimension contains the information whether the mechanism is already in use today or represents future possibilities. The third dimension refers to the mode of operation of the market mechanism and thus to the purpose for which it is used. The explicit consideration of this dimension emphasizes that individual market mechanisms contribute to the stability of the electricity grid in different ways:

Self-optimization: From a company perspective, this mode of operation aims to optimize generation from own-power generation plants (e.g., photovoltaic or gas power plants). In addition, self-optimization can also reduce levies/charges or grid fees;

Market-serving: This mode of operation describes market mechanisms that use price fluctuations directly at wholesale markets, such as the day-ahead market, or indirectly via time-variable tariffs. These mechanisms reduce market price volatility and enable energy-flexible factories to minimize their electricity procurement costs with their flexibilities;

Network-serving: This mode of operation describes market mechanisms that reduce network congestion;

System-serving: This mode of operation describes market mechanisms that contribute to the system-wide security of supply.

Finally, the fourth dimension indicates to which network state the individual mechanism can be applied. For this assignment, the traffic light concept of the German Federal Association of Energy and Water Management [

40] was used, which constitutes the current network status using the three traffic light colors:

Green: In the green traffic light phase there is no congestion and there are no critical network states. This allows for system and market flexibility to be traded. The distribution system operator’s task is limited to monitoring the grid, and react if the network status changes;

Yellow: In the yellow traffic light phase, the distribution system operator calls for flexibility offered by other players, as a bottleneck is becoming apparent in the network. Such a grid bottleneck is predicted on the basis of forecasts;

Red: In the red traffic light phase, the distribution network operator must also intervene outside the market, as the network stability is directly endangered.

5.3. Discrepancy between Regional and Trans-Regional Market Mechanisms

At the trans-regional level, there are numerous options for market flexibility in established markets: energy-only markets, balancing power, and switchable loads. At the regional level, there are several possible mechanisms: equalization within the balancing group, regional over-the-counter contracts, optimization of own consumption, load management, and telephone emergency shutdown. However, as there are no markets offering these services, these are usually associated with high effort. Moreover, such mechanisms do not take short-term adjustments into account.

Figure 9 puts the market mechanisms mentioned into context.

At the regional level, regional markets will be needed in the future where companies can trade flexibility in non-critical network states. In addition, companies may offer flexibility to the responsible distribution grid operator on a market which can be used preventively to avoid grid congestion [

39,

41]. The regionalization of the balancing power market is another option for using flexibility regionally.

In the model region Augsburg, various possibilities will be tested in practice. A platform will enable network operators to demand, and industrial companies to offer, regional flexibility. This enables both the suppliers and purchasers of flexibility to employ new regional market mechanisms, and thus supports the use of regional electricity surpluses. For this purpose, in 2020, how the communication between the network operator and the energy-flexible factories can be structured must first be elaborated, as well as which information must be exchanged in this respect. Subsequently, the extent to which regional flexibility can contribute to the electricity balance in the model region Augsburg will be evaluated. Consequently, appropriate incentives for flexibility through regional market mechanisms lead to the increased use of flexibility, allow a higher share of renewable energy and, ultimately, a reduction in the use of fossil fuels.

6. Integration and Comparison

Demand-side energy flexibility of the industrial sector is the focus of this project. However, whether its integration into the energy supply system provides a significant added value, has to be determined by a holistic analysis of its potential and characteristics compared with other flexibility options. A supplementary analysis, described in detail in [

42], presents the characteristics of non-industrial flexibilities and gives an estimate of their current as well as future potential in the model region Augsburg. Of most importance are the flexibility of:

Boundary conditions for the evaluation of the potential of each flexibility technology are extracted from [

19] and [

43], combined with regional data from the regionalized energy system model of [

21,

22]. Here, the analysis focuses on the estimation of on-switchable loads. The exact methodology of flexible potential estimation, which differs by technology, is described in [

42] in detail.

The results for flexible energy per year are depicted in

Figure 10.

The results indicate that the flexibility potential of DSM in the industry evaluated in [

43] dominates every year. However, estimation of potential seems to be highly sensitive to assumptions, as the comparison between the evaluated industrial flexibility in [

44] and [

43] shows. Due to limited information on the methodology of flexibility determination in these sources, a holistic comparison of the results is not possible.

In the future, electric vehicles and power-to-heat in households will become much more relevant, as these are expected to be dominant technologies. However, it should be noted that in this estimation restrictions due to limited heat storage capacities are not included.

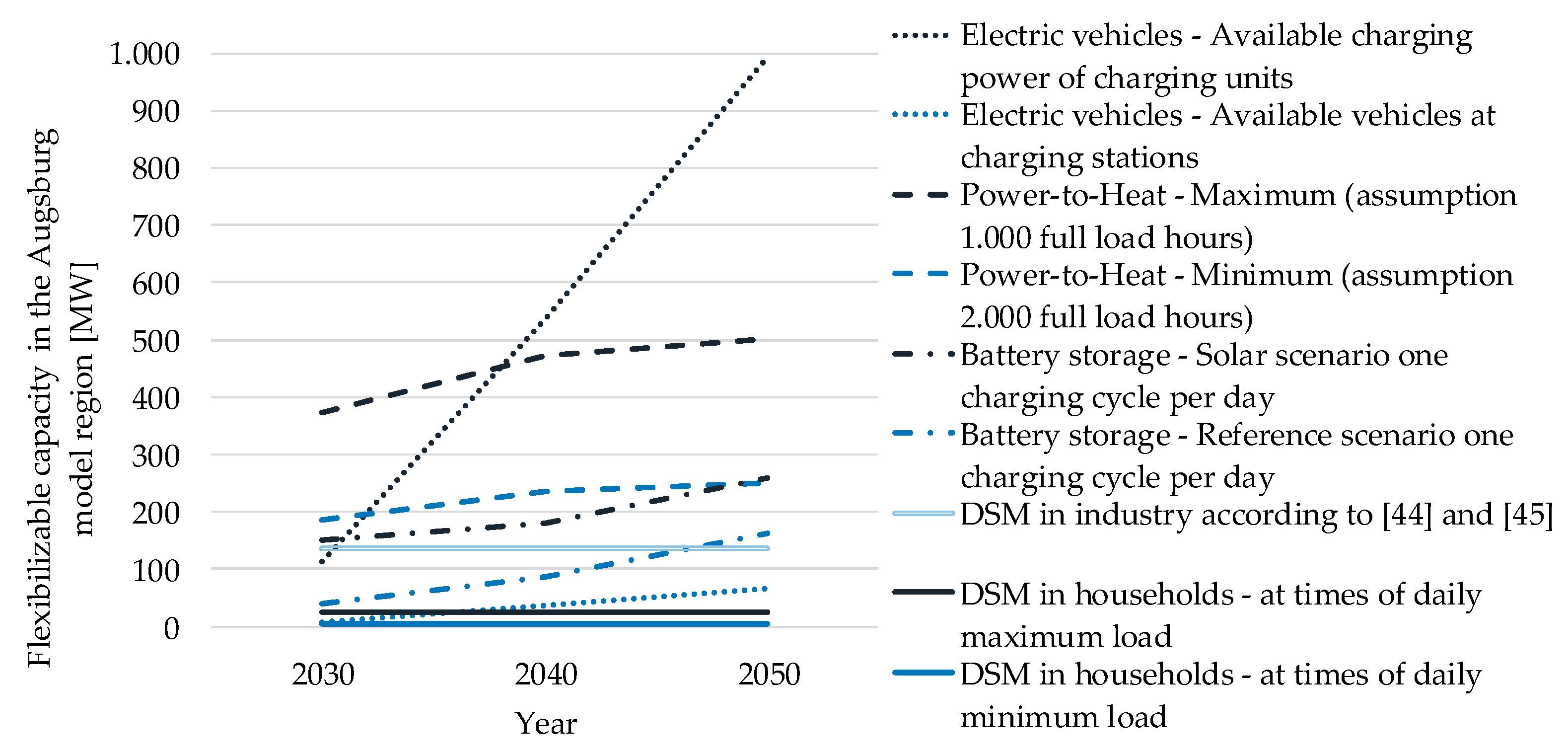

A completely different picture emerges when the comparison is not made on the basis of energy, but on overall available electric power (in GW, for further details see

Figure 11 and [

42]).

Firstly it becomes clear that the available installed charging capacity for electric vehicle charging stations from 2040 represents the largest flexibility potential. However, if the average available charging capacity of electric vehicles is used, the flexibility potential is lower than those of power-to-heat, battery storage, and DSM in industry.

Secondly, power-to-heat technologies and electric cars will significantly dominate industrial flexibility in the future. This is due to the fact that industrial plants have high operating hours, and therefore the installed electrical power per energy demand is low, even at high annual energy consumption. Similar to power-to-heat devices, battery storage systems have very low operating hours, so even their installed flexible electrical power is slightly higher than that of industry. In terms of both flexible energy and capacity, DSM in households will only have a minor role in the region.

As well as to the flexibility potential of the different technologies, the following considerations are important. Overall, industrial flexibilities have the advantage of significantly higher specific electrical power per connected unit than non-industrial flexibilities, which results in a lower coordination effort. Furthermore, in industrial plants, technicians are always on site, so technical adaptations can be translated into practice more easily.

However, non-industrial flexibilities are connected at the same voltage level as the majority of photovoltaic systems. This means that grid problems caused locally by renewable energy, such as grid overload due to generation peaks, can be better solved by local non-industrial flexibilities. Moreover, the integration of non-industrial flexibilities into the energy supply system also allows private individuals to actively contribute to the energy system transformation [

45,

46].

Overall, the analysis of the different characteristics of the potentials indicates that these two types of flexibilities complement each other well, while they compete equally for the monetization of flexibility.

7. Participation Creates Acceptance? Reflections on Common Misconceptions and Pitfalls

In this section, we will first critically reflect on common misconceptions of participatory research based on the co-produced knowledge from the model region Augsburg and further transdisciplinary projects. Then, we will outline the most important outcomes of the stakeholder dialogue in the model region of Augsburg.

7.1. Misconceptions and Pitfalls

7.1.1. Misconception One: Participation Creates Acceptance

In many cases, participation seems to be considered as a means to create acceptance of techno-social innovations [

47]. Additionally, in many cases, “participation” does not involve any more than informing the public, ergo communication (see misconception three). Trust is fundamental for creating acceptance, and, to gain trust, stakeholders must feel taken seriously, which means that they must have a say in the outcome. Thus, carefully designed participation is a way to achieve socially robust results. However, fake participation is more likely to lead to protest.

7.1.2. Misconception Two: Everybody Can Participate Equally

When working in a transdisciplinary context for the first time, the first impulse of many researchers is to claim that they somehow want to involve “the general public” or “citizens”. If they do not properly analyze their potential stakeholders, they risk ignoring their respective resources, needs and interests, such as schedules, competing actors or power relations. One of the founding principles of participatory research is that “it should level the power relations between researchers and the community in the research itself: in who sets the research agenda, who drives the research process and governs it and who interprets information” [

48]. In order to reflect on these power relations, it is not only necessary to analyze the potential stakeholders and to speak and listen to them, but also to reflect on possible biases in the research team itself and in project government (access to knowledge and project insides, e.g., confidentiality agreements).

7.1.3. Misconception Three: Including Stakeholders Means that Research is Participatory

As Arnstein [

49] states, “there is a critical difference between going through the empty ritual of participation and having the real power needed to affect the outcome of the process.“ In her “ladder of participation“, she differentiates three degrees and eight rungs of citizen participation (

Figure 12). Only one degree truly fulfills the criteria of citizen power and the chance to influence the outcome. For researchers, this means that they have to be aware that simply including stakeholders does not mean that their research is transdisciplinary and/or participatory. Moreover, whether potential stakeholders are being included in the decision process, and which level of participation makes sense in which phase of the research process (which, for instance, depends on resources, see misconception two) depends on who designs the participation. In addition, it is also crucial to define the level of participation to properly manage the expectations of the stakeholders.

7.1.4. Misconception Four: Conventional Research with Some Elements Added

As became clear in the previous sections, transdisciplinary research needs to be designed and governed from the beginning with certain attitudes, values, and principles. A project is not transdisciplinary when it is planned in the conventional way and then complemented with some participatory elements. Transdisciplinary research needs expertise in co-creation, process design, facilitation, and participation methods. Therefore, a transdisciplinary team needs to add transdisciplinary experts to the team, who can play the role of “transdisciplinary watchdogs”. This setting requires the researchers to consider themselves as learning actors.

In our experience, it can be helpful to make these possible misconceptions explicit in the mid-kick-off phase of a research process. This way, there is a chance for researchers to develop a routine of reflecting their ideas in the research process.

7.2. Outcomes and Learnings of the Stakeholder Dialoge in the Model Region of Augsburg

For the stakeholder dialogue in September 2018, five subgroups were arranged in advance by the organizers. These five groups could pick their own focus for the facilitated afternoon co-creation session. The two leading questions for picking a focus were:

The foci of the five subgroups turned out to be the regulation and adaptation of the energy market and the possible contribution of their region as a real laboratory. Each subgroup drafted a hypothesis, making up five hypotheses in total:

If regulation is simplified, industrial companies offer flexibility to stabilize the power system on a large scale;

The market must follow physics;

If there is enough freedom and if the objective is regularly assessed, then the energy-flexible factory can be implemented;

If a regulatory framework is created in Augsburg without disincentives, it can be transferred to other regions;

The removal of obstacles is necessary to implement the concept of the energy-flexible factory sustainably and successfully;

In order to advance implementation, disincentives should be diminished, and positive incentives should be created.

Analyzing the output of the one-day stakeholder dialogue and the prior continuous dialogue-process in the spheres, we have concluded the following: stakeholders are committed to implementing energy flexibility in their region. They urged that policy frameworks need to be changed in order to give industry appropriate incentives and opportunities for greater energy flexibility. The identification with the model region Augsburg appeared high, so this can be spoken of as an active acceptance.

In the next section, the transferability of the Augsburg results will be further investigated by referring to regional clusters in Germany.

8. Transferability

The knowledge gained in the model region Augsburg should also be applied in other areas. Therefore, the question arises as to what extent the results can be transferred to other regions. The current and future need for flexibility in the energy system can be determined by the characteristics of electricity consumption and generation. On the generation side, volatile generation is of particular interest in the need for flexibility. However, wind power plants have a fundamentally different generation profile to photovoltaic plants.

The nomenclature of territorial units for statistics (Nomenclature des Unités territoriales statistiques (NUTS)) is a geographical system, according to which the territory of the European Union is divided into hierarchical levels. Germany’s NUTS-3 regions are generally districts known as Kreise or as kreisfreie Städte. Therefore, in the first step, all German NUTS-3 regions are classified according to their area-specific generation from photovoltaics and wind power. On the electric consumption side, the most relevant factor for transferability is the industrial load in the region. Therefore, the area-specific electricity consumption of industry, and other electricity consumption from services and private households, are distinguished. The data for this were taken from the regional model FREM [

22]. The extent to which the 401 NUTS-3 regions in Germany can be aggregated and made comparable with other regions was tested in [

50] using six methods. The method and results of the most appropriate method are presented below.

All 401 NUTS-3 regions in Germany are subjected to the following cluster and aggregation procedure. First, the 26 independent cities bordering only one district are assigned to this district. In the next step, these initial regions are classified in 16 clusters, which result from the two characteristics, high or low, of the four descriptive parameters for production and consumption. Neighbouring districts or regions are then aggregated, if the characterizing parameters from photovoltaic, wind, industrial and residual electricity (private housholds and services) demands of the resulting region result in a classification into a cluster of the larger district or region. The order of aggregation of the considered pairs of districts or regions is determined by the similarity between the four parameters. The area of the regions is limited to the area of five average districts (4443 km2). The resulting regions are assigned to the 16 cluster.

Certain clusters, such as an industry-dominated region with very low generation from wind and photovoltaic, are very poorly represented. In contrast, regions dominated by wind on the generation side, and with hardly any demand for electricity, occur in almost all regions of north-eastern Germany and in several regions in central Germany. The cluster with high photovoltaic production and high power consumption is also very common. The model region Augsburg, is also part of this cluster. From this, it can be deduced that the methods and results developed in the research project for the model region Augsburg can also be applied to many other regions in Germany. If industrial electricity consumption is taken as a key criterion, the results can be transferred to around 28% of the regions in Germany. However, it should be noted that the specific grid situation is not taken into account in the methods presented. Many of the flexibility market approaches are grid-driven and integrating this aspect into the future methodology of aggregation and clustering is recommended.

9. Conclusions and Outlook

9.1. Conclusions

Economic solutions and incentives for the integration of volatile renewable electricity generation are key to ensuring socially supported energy transition. By adapting their electricity demand to a volatile power generation, so-called energy-flexible factories may support the system balance and counteract local network bottlenecks. For this purpose, this paper describes the potential, obstacles, effects, and opportunities of the energy-flexible factory as part of the model region Augsburg, a research and demonstration area of a federal research project.

Representative industrial flexibility measures were analyzed by a simulation-based optimization in supply scenarios with the advanced expansion of fluctuating renewable electricity generation. Furthermore, the environmental impact of the implementation of these measures was identified in a life-cycle assessment. Additionally, to follow a holistic approach, a network of actors from science, industry, associations, and civil society organizations was established and actively collaborated in a transdisciplinary work process.

By means of simulation-based optimization it could be shown that energy-flexible factories have a positive influence on the energy balance on the scale of medium-sized power plants. Internal environmental additional expenses of the companies to implement the measures were classified as mitigated by the increased share of renewable energy in the generation mix. The flexibility measures examined, and the associated consumption of renewable energy, could be assessed as advantageous from an ecological perspective.

However, the implementation of industrial energy flexibility requires appropriate economic incentives on both national and regional levels [

51]. The involvement of stakeholders has demonstrated that the question of compensation models and a suitable regulatory framework must be clarified in order to create acceptance and active participation. In the upcoming practical test runs, communication between the network operator and the energy-flexible factories will be implemented first. In the second step, the benefit of local flexibility is evaluated.

9.2. Outlook

The following aspects were identified for the further development of the energy-flexible factory as well as its integration into the supply system and social structures:

A decisive factor for the success of the prototype operation is the establishment of suitable and trustworthy interfaces between companies, grid operators, and aggregators. Therefore, reliable communication structures must be developed. These include organizational responsibilities, appropriate information and communication technology solutions, respectively. For this purpose, possible communication processes will be developed and tested;

A company’s sometimes very heterogeneous manufacturing execution and enterprise resource-planning system needs to be connected to suitable platforms that offer companies planning security in the flexibilization of production processes and enable a connection to centralized and decentralized markets;

Different uses of industrial energy flexibility need to be considered and provided with appropriate market mechanisms that exhibit financial incentives for the industrial sector. Therefore, regulations of existing markets are considered, and innovative concepts for regional markets are developed further;

It is crucial to discuss how energy-flexible factories interact with other energy conversion technologies. This includes, for example, the use of battery storage and sector coupling. For this, the transdisciplinary dialogue will be expanded. Stakeholders are also involved in enhancing portability and extending the scope to smaller companies and other regions;

Further stakeholder participation needs to be designed carefully and at an early stage, ideally involving the stakeholders themselves.

Finally, it will be important for the model region Augsburg, to comprehensively integrate the concept of the energy-flexible factory into the progress of energy transition. To achieve this, visions and models need to be developed that interlock regional activities with nationwide, European, and global processes and measures.