Figure 1.

Building stereogram and plan of a typical building model.

Figure 1.

Building stereogram and plan of a typical building model.

Figure 2.

Heat consumption testing equipment.

Figure 2.

Heat consumption testing equipment.

Figure 3.

Building stereogram and plan of the model for project 1.

Figure 3.

Building stereogram and plan of the model for project 1.

Figure 4.

Building stereogram and plan of the model for project 10.

Figure 4.

Building stereogram and plan of the model for project 10.

Figure 5.

Relationship between thermal performance improvement and the heat load of a residential building.

Figure 5.

Relationship between thermal performance improvement and the heat load of a residential building.

Figure 6.

Proportion of heat load in each part of the residential building envelope.

Figure 6.

Proportion of heat load in each part of the residential building envelope.

Figure 7.

Relationship between thermal performance improvement and the heat load of a public building.

Figure 7.

Relationship between thermal performance improvement and the heat load of a public building.

Figure 8.

Proportion of heat load in each part of the public building envelope.

Figure 8.

Proportion of heat load in each part of the public building envelope.

Figure 9.

Proportion of building envelope materials.

Figure 9.

Proportion of building envelope materials.

Figure 10.

Relationship between the thickness of a rock wool insulation layer and the thermal performance of an exterior wall.

Figure 10.

Relationship between the thickness of a rock wool insulation layer and the thermal performance of an exterior wall.

Figure 11.

Relationship between the thickness of a rock wool insulation layer and the thermal performance of a roof.

Figure 11.

Relationship between the thickness of a rock wool insulation layer and the thermal performance of a roof.

Figure 12.

Relationship between thermal performance improvement of an exterior wall and the environmental impact.

Figure 12.

Relationship between thermal performance improvement of an exterior wall and the environmental impact.

Figure 13.

Relationship between thermal performance improvement of a roof and the environmental impact.

Figure 13.

Relationship between thermal performance improvement of a roof and the environmental impact.

Figure 14.

Relationship between thermal performance improvement of an exterior wall and costs.

Figure 14.

Relationship between thermal performance improvement of an exterior wall and costs.

Figure 15.

Relationship between thermal performance improvement of a roof and costs.

Figure 15.

Relationship between thermal performance improvement of a roof and costs.

Figure 16.

The relationship between heat consumption and the limit value.

Figure 16.

The relationship between heat consumption and the limit value.

Figure 17.

The relationship between thermal performance improvement and heat consumption.

Figure 17.

The relationship between thermal performance improvement and heat consumption.

Figure 18.

Relationship between the comprehensive heat transfer coefficient and heat consumption.

Figure 18.

Relationship between the comprehensive heat transfer coefficient and heat consumption.

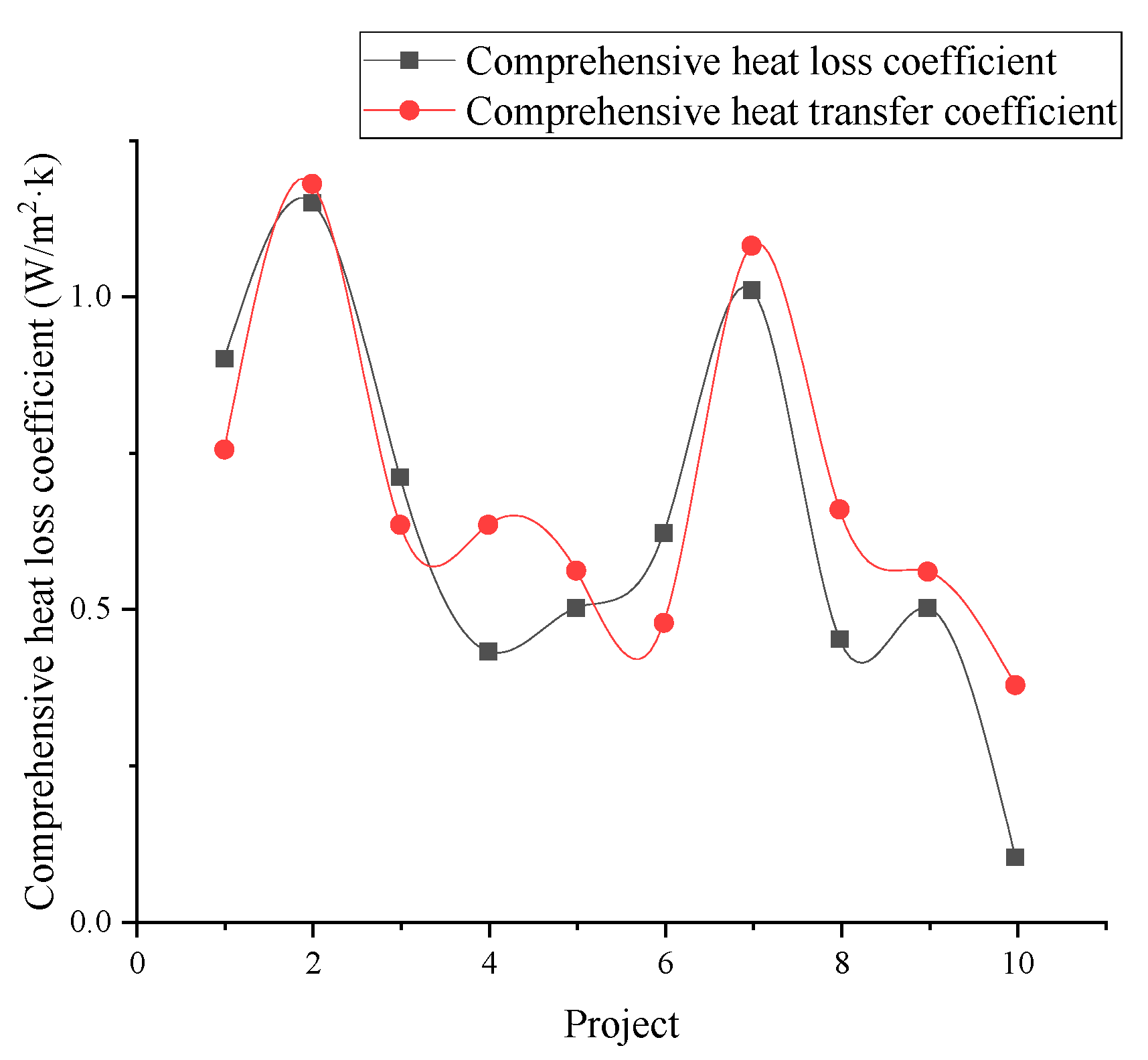

Figure 19.

Variation trend of the comprehensive heat loss coefficient and comprehensive heat transfer coefficient.

Figure 19.

Variation trend of the comprehensive heat loss coefficient and comprehensive heat transfer coefficient.

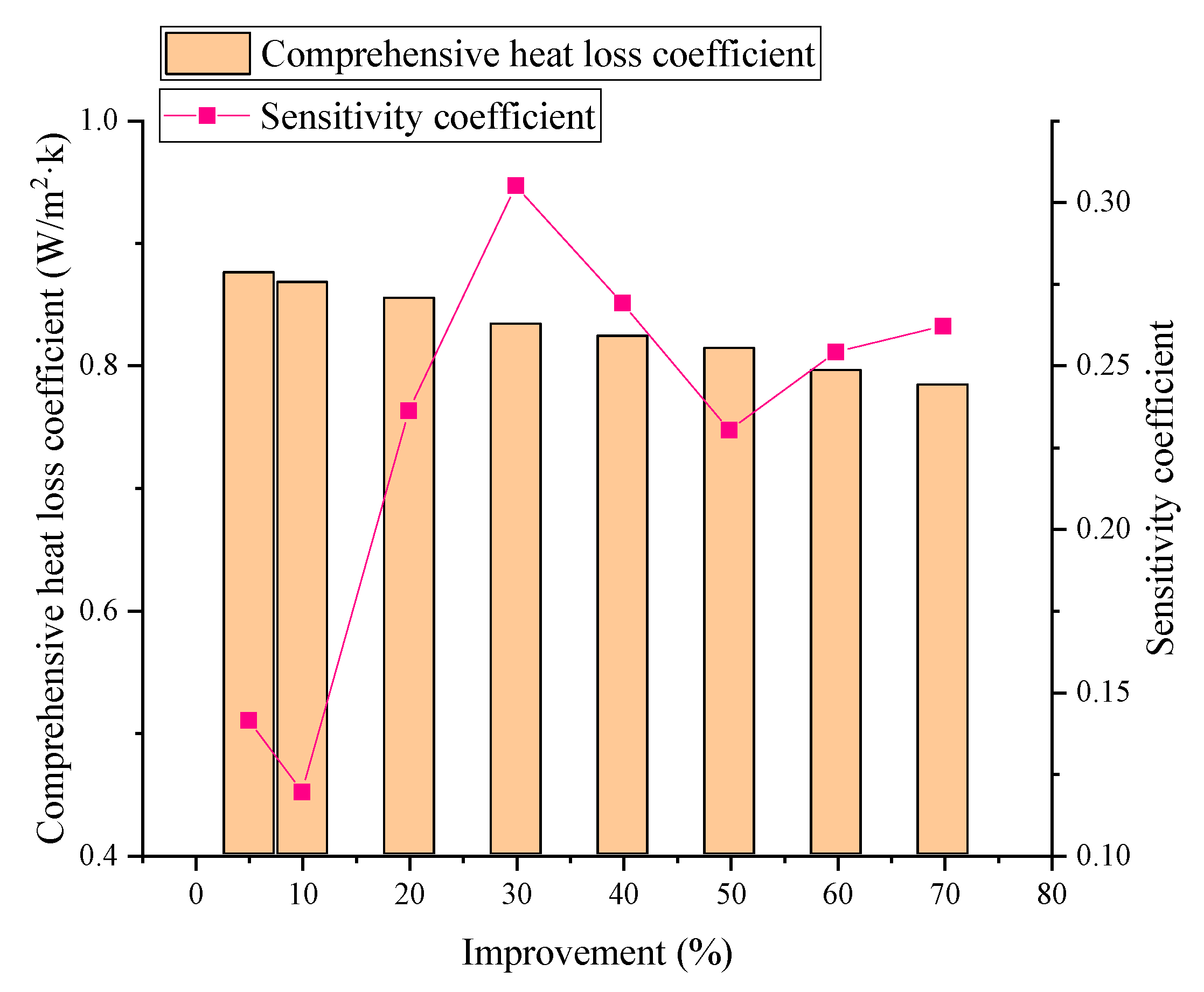

Figure 20.

Sensitivity analysis of public building exterior walls.

Figure 20.

Sensitivity analysis of public building exterior walls.

Figure 21.

Sensitivity analysis of residential building exterior walls.

Figure 21.

Sensitivity analysis of residential building exterior walls.

Figure 22.

Sensitivity analysis of public building roofs.

Figure 22.

Sensitivity analysis of public building roofs.

Figure 23.

Sensitivity analysis of residential building roofs.

Figure 23.

Sensitivity analysis of residential building roofs.

Figure 24.

Sensitivity analysis of public building exterior windows.

Figure 24.

Sensitivity analysis of public building exterior windows.

Figure 25.

Sensitivity analysis of residential building exterior windows.

Figure 25.

Sensitivity analysis of residential building exterior windows.

Figure 26.

Validation of the comprehensive heat loss coefficient.

Figure 26.

Validation of the comprehensive heat loss coefficient.

Table 1.

Building prototype modeling parameters in a cold area.

Table 1.

Building prototype modeling parameters in a cold area.

| Building Type | Shape Coefficient | External Window U (W/m2·K) | External Wall U (W/m2·K) | Roof U (W/m2·K) | Window-Wall Ratio | Length (m) × Width (m) × Height (m) |

|---|

| Residential building | 0.3 | 2.7 | 0.7 | 0.45 | 0.3 | 15 × 15 × 30 |

| Public building | 0.4 | 1.9 | 0.45 | 0.4 | 0.5 | 11 × 11 × 30 |

Table 2.

Information of ten green buildings.

Table 2.

Information of ten green buildings.

| Project | Location | Type | Grade |

|---|

| 1 | Tianjin | Office | Three-star design |

| 2 | Tianjin | Office | Two-star operation |

| 3 | Shijiazhuang | Office | Three-star design |

| 4 | Tianjin | School | Three-star operation |

| 5 | Tianjin | Office | Three-star design |

| 6 | Tianjin | Office | Three-star operation |

| 7 | Tianjin | Office | Two-star design |

| 8 | Hezei | Residence | Three-star operation |

| 9 | Hezei | Residence | Three-star operation |

| 10 | Taian | Residence | Two-star operation |

Table 3.

Non-renewable energy consumption (PED) and greenhouse effect (GWP) of different types of insulation layer [

42] (pp. 90–95).

Table 3.

Non-renewable energy consumption (PED) and greenhouse effect (GWP) of different types of insulation layer [

42] (pp. 90–95).

| Material | PED (kgce/kg) | GWP (kg CO2 eq/kg) |

|---|

| Rock wool | 2.6 | 5.02 |

| Polyurethane (PU) | 6.74 | 11.5 |

| Polystyrene (EPS/XPS) | 8.46 | 12.1 |

Table 4.

PED and GWP of different types of external window [

42] (pp. 117–120).

Table 4.

PED and GWP of different types of external window [

42] (pp. 117–120).

| Frame | Glass | PED (kgce/m2) | GWP (kg CO2 eq/m2) |

|---|

| PVC | 5low-e + 12Ar + 5 | 4.51 | 9.89 |

| Heat broke aluminum | 5low-e + 6A + 5 | 6.73 | 15.25 |

| Heat broke aluminum | 5low-e + 8A + 5 | 6.73 | 15.25 |

| Heat broke aluminum | 5low-e + 6Ar + 5 | 6.73 | 15.25 |

| Heat broke aluminum | 5low-e + 12A + 5 | 6.73 | 15.25 |

| Heat broke aluminum | 5low-e + 13Ar + 5 | 6.73 | 15.25 |

| PVC | 5low-e + 12A + 5 + 12A + 5 | 5.31 | 11.7 |

| PVC | 5low-e + 10Ar + 5 + 6Ar + 5 | 5.31 | 11.7 |

| PVC | 5low-e + 10Ar + 5 + 8Ar + 5 | 5.31 | 11.7 |

| PVC | 5low-e + 13Ar + 5 + 13Ar + 5 | 5.31 | 11.7 |

Table 5.

Costs of different types of insulation layer.

Table 5.

Costs of different types of insulation layer.

| Material | Unit Price (RMB/m3) |

|---|

| Rock wool | 302 |

| Polyurethane | 680 |

| Polystyrene (EPS/XPS) | 348/501 |

Table 6.

Costs of different types of external window.

Table 6.

Costs of different types of external window.

| Frame | Glass | Unit Price (RMB/m2) |

|---|

| PVC | 5low-e + 12Ar + 5 | 359 |

| Heat broke aluminum | 5low-e + 6A + 5 | 450 |

| Heat broke aluminum | 5low-e + 8A + 5 | 474 |

| Heat broke aluminum | 5low-e + 6Ar + 5 | 613 |

| Heat broke aluminum | 5low-e + 12A + 5 | 568 |

| Heat broke aluminum | 5low-e + 13Ar + 5 | 650 |

| PVC | 6low-e + 12A + 6 + 12A + 6 | 483 |

| PVC | 6low-e + 10Ar + 6 + 6Ar + 6 | 495 |

| PVC | 6low-e + 10Ar + 6 + 8Ar + 6 | 512 |

| PVC | 6low-e + 13Ar + 6 + 13Ar + 6 | 540 |

Table 7.

Heat load of a prototype residential building.

Table 7.

Heat load of a prototype residential building.

| Improvement | U-Value(W/m2·K) | Heat Load (kWh/m2·a) | Heat Load Decrease (kWh/m2·a) | Decline Rate |

|---|

| External Window | External Wall | Roof |

|---|

| 0% | 2.7 | 0.7 | 0.45 | 41.02 | N/A | N/A |

| 5% | 2.57 | 0.67 | 0.43 | 38.57 | 2.45 | 5.97% |

| 10% | 2.43 | 0.63 | 0.41 | 35.18 | 3.39 | 8.79% |

| 20% | 2.16 | 0.56 | 0.36 | 31.73 | 3.45 | 9.81% |

| 30% | 1.89 | 0.49 | 0.315 | 27.72 | 4.01 | 12.64% |

| 40% | 1.62 | 0.42 | 0.27 | 23.02 | 4.7 | 16.96% |

| 50% | 1.35 | 0.35 | 0.225 | 20.56 | 2.46 | 10.69% |

| 60% | 1.08 | 0.28 | 0.18 | 19.99 | 0.57 | 2.77% |

| 65% | 0.95 | 0.25 | 0.16 | 19.86 | 0.13 | 0.65% |

Table 8.

Proportion of heat load in each part of the residential building envelope.

Table 8.

Proportion of heat load in each part of the residential building envelope.

| Improvement | External Window | External Wall | Roof |

|---|

| Heat Load (kWh/m2·a) | Proportion | Heat Load (kWh/m2·a) | Proportion | Heat Load (kWh/m2·a) | Proportion |

|---|

| 0% | 20.93 | 51.02% | 18.06 | 44.03% | 2.03 | 4.95% |

| 5% | 20.07 | 50.73% | 17.52 | 44.29% | 1.97 | 4.97% |

| 10% | 18.52 | 51.20% | 15.85 | 43.80% | 1.81 | 5.00% |

| 20% | 16.60 | 50.71% | 14.50 | 44.30% | 1.63 | 4.98% |

| 30% | 14.35 | 48.27% | 13.83 | 46.54% | 1.54 | 5.20% |

| 40% | 12.21 | 46.92% | 12.44 | 47.80% | 1.37 | 5.28% |

| 50% | 10.40 | 45.51% | 11.22 | 49.11% | 1.23 | 5.38% |

| 60% | 9.63 | 46.88% | 9.85 | 47.97% | 1.06 | 5.14% |

| 65% | 9.50 | 50.81% | 8.24 | 44.08% | 0.95 | 5.11% |

Table 9.

Heat load of a prototype public building.

Table 9.

Heat load of a prototype public building.

| Improvement | U-Value (W/m2·k) | Heat Load (kWh/m2·a) | Heat Load Decrease (kWh/m2·a) | Decline Rate |

|---|

| External Window | External Wall | Roof |

|---|

| 0% | 1.9 | 0.45 | 0.4 | 57.07 | N/A | N/A |

| 5% | 1.8 | 0.428 | 0.38 | 51.92 | 5.15 | 9.02% |

| 10% | 1.71 | 0.405 | 0.36 | 46.63 | 5.29 | 10.19% |

| 20% | 1.52 | 0.36 | 0.32 | 41.27 | 5.36 | 11.49% |

| 30% | 1.33 | 0.315 | 0.28 | 34.45 | 6.82 | 16.53% |

| 40% | 1.14 | 0.27 | 0.24 | 30.53 | 3.92 | 11.38% |

| 50% | 0.95 | 0.225 | 0.2 | 27.41 | 3.12 | 10.22% |

| 60% | 0.76 | 0.18 | 0.16 | 25.66 | 1.75 | 6.38% |

| 65% | 0.7 | 0.16 | 0.14 | 25.57 | 0.09 | 0.35% |

Table 10.

Proportion of heat load in each part of the public building envelope.

Table 10.

Proportion of heat load in each part of the public building envelope.

| Improvement | External Window | External Wall | Roof |

|---|

| Heat Load (kWh/m2·a) | Proportion | Heat Load (kWh/m2·a) | Proportion | Heat Load (kWh/m2·a) | Proportion |

|---|

| 0% | 41.19 | 72.18% | 13.78 | 24.14% | 2.10 | 3.68% |

| 5% | 38.17 | 70.79% | 13.70 | 25.40% | 2.05 | 3.81% |

| 10% | 37.48 | 71.22% | 13.18 | 25.05% | 1.96 | 3.73% |

| 20% | 33.86 | 70.13% | 12.54 | 25.98% | 1.87 | 3.88% |

| 30% | 25.49 | 67.71% | 10.56 | 28.06% | 1.59 | 4.23% |

| 40% | 21.50 | 66.10% | 9.44 | 29.03% | 1.59 | 4.87% |

| 50% | 18.22 | 64.11% | 8.88 | 31.26% | 1.31 | 4.63% |

| 60% | 18.84 | 68.61% | 7.50 | 27.33% | 1.11 | 4.05% |

| 65% | 18.15 | 71.01% | 6.38 | 24.95% | 1.03 | 4.04% |

Table 11.

Common practices of non-transparent envelopes.

Table 11.

Common practices of non-transparent envelopes.

| Position | Inner Layer | Foundation Layer | Leveling Course | Insulation Layer | Outer Layer |

|---|

| Wall | Cement mortar | Aerated concrete block | Cement mortar | Rock wool/PU/EPS/XPS | Cement mortar |

| Roof | Cement mortar | Aerated concrete block | Cement mortar | Rock wool/PU/EPS/XPS | Cement mortar |

Table 12.

Quantification of the heat transfer coefficient of a rock wool insulation exterior wall.

Table 12.

Quantification of the heat transfer coefficient of a rock wool insulation exterior wall.

| Material | Thickness mm | Thermal Conductivity W/m·K | U-Value W/m2·K |

|---|

| Rock wool | 10 | 0.041 | 0.528 |

| 20 | 0.041 | 0.468 |

| 40 | 0.041 | 0.381 |

| 60 | 0.041 | 0.321 |

| 80 | 0.041 | 0.278 |

| 100 | 0.041 | 0.244 |

| 120 | 0.041 | 0.218 |

| 140 | 0.041 | 0.197 |

| 160 | 0.041 | 0.180 |

| 180 | 0.041 | 0.166 |

| 200 | 0.041 | 0.153 |

| Cement mortar | 20 | 0.93 | N/A |

| Aerated concrete block | 200 | 0.14 | N/A |

Table 13.

Quantification of the heat transfer coefficient of a rock wool insulation roof.

Table 13.

Quantification of the heat transfer coefficient of a rock wool insulation roof.

| Material | Thickness mm | Thermal Conductivity W/m·K | U-Value W/m2·K |

|---|

| Rock wool | 10 | 0.041 | 1.91 |

| 20 | 0.041 | 1.30 |

| 40 | 0.041 | 0.80 |

| 60 | 0.041 | 0.57 |

| 80 | 0.041 | 0.45 |

| 100 | 0.041 | 0.37 |

| 120 | 0.041 | 0.31 |

| 140 | 0.041 | 0.27 |

| 160 | 0.041 | 0.24 |

| 180 | 0.041 | 0.21 |

| 200 | 0.041 | 0.19 |

| Cement mortar | 20 | 0.93 | N/A |

| Reinforced concrete | 100 | 1.74 | N/A |

Table 14.

Level of thermal performance improvement for different insulation exterior walls.

Table 14.

Level of thermal performance improvement for different insulation exterior walls.

| Thickness (mm) | Thermal Performance Improvement |

|---|

| Rock wool | PU | EPS | XPS |

|---|

| 10 | 24.61% | 30.91% | 26.89% | 28.01% |

| 20 | 33.21% | 42.50% | 36.71% | 38.36% |

| 40 | 45.61% | 56.94% | 50.11% | 52.13% |

| 60 | 54.13% | 65.59% | 58.82% | 60.87% |

| 80 | 60.34% | 71.34% | 64.95% | 66.91% |

| 100 | 65.07% | 75.44% | 69.48% | 71.34% |

| 120 | 68.79% | 78.52% | 72.98% | 74.72% |

| 140 | 71.80% | 80.91% | 75.76% | 77.39% |

| 160 | 74.28% | 82.83% | 78.02% | 79.55% |

| 180 | 76.35% | 84.39% | 79.90% | 81.33% |

| 200 | 78.12% | 85.69% | 81.48% | 82.83% |

Table 15.

Level of thermal performance improvement for different insulation roofs.

Table 15.

Level of thermal performance improvement for different insulation roofs.

| Thickness mm | Insulating Layer Material |

|---|

| Rock Wool | PU | EPS | XPS |

|---|

| 10 | N/A | N/A | N/A | N/A |

| 20 | N/A | N/A | N/A | N/A |

| 40 | N/A | N/A | N/A | N/A |

| 60 | N/A | 20.06% | N/A | 2.53% |

| 80 | 0.40% | 38.50% | 17.82% | 24.58% |

| 100 | 18.27% | 50.02% | 32.87% | 38.50% |

| 120 | 30.70% | 57.91% | 43.26% | 48.08% |

| 140 | 39.85% | 63.65% | 50.86% | 55.08% |

| 160 | 46.87% | 68.01% | 56.67% | 60.41% |

| 180 | 52.42% | 71.44% | 61.25% | 64.61% |

| 200 | 56.92% | 74.20% | 64.95% | 68.01% |

Table 16.

Improvement in the thermal performance of different types of windows.

Table 16.

Improvement in the thermal performance of different types of windows.

| Frame | Glass | U-Value W/(m2·k) | Improvement |

|---|

| Residential | Public |

|---|

| PVC | 5 + 12Ar + 5 | 2.511 | 7.00% | N/A |

| Heat broke aluminum | 5low-e + 6A + 5 | 2.43 | 10.00% | N/A |

| Heat broke aluminum | 5low-e + 8A + 5 | 2.1 | 22.22% | N/A |

| Heat broke aluminum | 5low-e + 6Ar + 5 | 1.988 | 26.37% | N/A |

| Heat broke aluminum | 5low-e + 12A + 5 | 1.774 | 42.87% | 6.63% |

| Heat broke aluminum | 5low-e + 13Ar + 5 | 1.495 | 44.63% | 21.32% |

| PVC | 5low-e + 12A + 5 + 12A + 5 | 1.3 | 51.85% | 31.58% |

| PVC | 5low-e + 10Ar + 5 + 6Ar + 5 | 1.2 | 55.56% | 36.84% |

| PVC | 5low-e + 10Ar + 5 + 8Ar + 5 | 1.13 | 58.15% | 40.53% |

| PVC | 5low-e + 13Ar + 5 + 13Ar + 5 | 1.06 | 60.74% | 44.21% |

Table 17.

PED of the thermal insulation layer.

Table 17.

PED of the thermal insulation layer.

| Thickness mm | PED (kgce/m2) |

|---|

| Rock Wool | PU | EPS | XPS |

|---|

| 10 | 2.860 | 2.359 | 1.692 | 2.961 |

| 20 | 5.720 | 4.718 | 3.384 | 5.922 |

| 40 | 11.440 | 9.436 | 6.768 | 11.844 |

| 60 | 17.160 | 14.154 | 10.152 | 17.766 |

| 80 | 22.880 | 18.872 | 13.536 | 23.688 |

| 100 | 28.600 | 23.590 | 16.920 | 29.610 |

| 120 | 34.320 | 28.308 | 20.304 | 35.532 |

| 140 | 40.040 | 33.026 | 23.688 | 41.454 |

| 160 | 45.760 | 37.744 | 27.072 | 47.376 |

| 180 | 51.480 | 42.462 | 30.456 | 53.298 |

| 200 | 57.200 | 47.180 | 33.840 | 59.220 |

Table 18.

GWP of the thermal insulation layer.

Table 18.

GWP of the thermal insulation layer.

| Thickness mm | GWP (kg CO2 eq/m2) |

|---|

| Rock Wool | PU | EPS | XPS |

|---|

| 10 | 5.522 | 4.025 | 2.420 | 4.235 |

| 20 | 11.044 | 8.050 | 4.840 | 8.470 |

| 40 | 22.088 | 16.100 | 9.680 | 16.940 |

| 60 | 33.132 | 24.150 | 14.520 | 25.410 |

| 80 | 44.176 | 32.200 | 19.360 | 33.880 |

| 100 | 55.220 | 40.250 | 24.200 | 42.350 |

| 120 | 66.264 | 48.300 | 29.040 | 50.820 |

| 140 | 77.308 | 56.350 | 33.880 | 59.290 |

| 160 | 88.352 | 64.400 | 38.720 | 67.760 |

| 180 | 99.396 | 72.450 | 43.560 | 76.230 |

| 200 | 110.440 | 80.500 | 48.400 | 84.700 |

Table 19.

Thermal performance and environmental impact of a rockwool exterior wall and roof.

Table 19.

Thermal performance and environmental impact of a rockwool exterior wall and roof.

| Thickness mm | Exterior Wall | Roof | PED/m2 | GWP/m2 |

|---|

| U-Value W/(m2·K) | Improvement | U-Value W/(m2·K) | Improvement |

|---|

| 10 | 0.53 | 24.61% | 1.91 | N/A | 2.86 | 5.522 |

| 20 | 0.47 | 33.21% | 1.30 | N/A | 5.72 | 11.044 |

| 40 | 0.38 | 45.61% | 0.80 | N/A | 11.44 | 22.088 |

| 60 | 0.32 | 54.13% | 0.57 | N/A | 17.16 | 33.132 |

| 80 | 0.28 | 60.34% | 0.45 | 0.40% | 22.88 | 44.176 |

| 100 | 0.24 | 65.07% | 0.37 | 18.27% | 28.6 | 55.22 |

| 120 | 0.22 | 68.79% | 0.31 | 30.70% | 34.32 | 66.264 |

| 140 | 0.20 | 71.80% | 0.27 | 39.85% | 40.04 | 77.308 |

| 160 | 0.18 | 74.28% | 0.24 | 46.87% | 45.76 | 88.352 |

| 180 | 0.17 | 76.35% | 0.21 | 52.42% | 51.48 | 99.396 |

| 200 | 0.15 | 78.12% | 0.19 | 56.92% | 57.2 | 110.44 |

Table 20.

Thermal performance and costs of a rock wool exterior wall and roof.

Table 20.

Thermal performance and costs of a rock wool exterior wall and roof.

| Thickness mm | Exterior Wall | Roof | RMB/m2 |

|---|

| U-Value W/(m2·k) | Improvement | U-Value W/(m2·k) | Improvement |

|---|

| 10 | 0.53 | 24.61% | 1.91 | N/A | 2.86 |

| 20 | 0.47 | 33.21% | 1.30 | N/A | 5.72 |

| 40 | 0.38 | 45.61% | 0.80 | N/A | 11.44 |

| 60 | 0.32 | 54.13% | 0.57 | N/A | 17.16 |

| 80 | 0.28 | 60.34% | 0.45 | 0.40% | 22.88 |

| 100 | 0.24 | 65.07% | 0.37 | 18.27% | 28.6 |

| 120 | 0.22 | 68.79% | 0.31 | 30.70% | 34.32 |

| 140 | 0.20 | 71.80% | 0.27 | 39.85% | 40.04 |

| 160 | 0.18 | 74.28% | 0.24 | 46.87% | 45.76 |

| 180 | 0.17 | 76.35% | 0.21 | 52.42% | 51.48 |

| 200 | 0.15 | 78.12% | 0.19 | 56.92% | 57.2 |

Table 21.

External wall insulation of residential buildings in a cold area.

Table 21.

External wall insulation of residential buildings in a cold area.

| Material | Index | Improvement |

|---|

| 5% | 10% | 20% | 30% | 40% | 50% | 60% | 70% |

|---|

| Rock wool | Thickness (mm) | 10 | 10 | 10 | 20 | 40 | 60 | 80 | 140 |

| PED/m2 | 2.86 | 2.86 | 2.86 | 5.72 | 11.44 | 17.16 | 22.88 | 40.04 |

| GWP/m2 | 5.52 | 5.52 | 5.52 | 11.04 | 22.09 | 33.13 | 44.18 | 77.31 |

| RMB/m2 | 3.02 | 3.02 | 3.02 | 6.03 | 12.06 | 18.10 | 24.13 | 42.22 |

| PU | Thickness (mm) | 10 | 10 | 10 | 10 | 20 | 40 | 60 | 80 |

| PED/m2 | 2.36 | 2.36 | 2.36 | 2.36 | 4.72 | 9.44 | 14.15 | 18.87 |

| GWP/m2 | 4.03 | 4.03 | 4.03 | 4.03 | 8.05 | 16.10 | 24.15 | 32.20 |

| RMB/m2 | 6.80 | 6.80 | 6.80 | 6.80 | 13.60 | 27.20 | 40.80 | 54.40 |

| EPS | Thickness (mm) | 10 | 10 | 10 | 20 | 40 | 60 | 80 | 120 |

| PED/m2 | 1.69 | 1.69 | 1.69 | 3.38 | 6.77 | 10.15 | 13.54 | 20.30 |

| GWP/m2 | 2.42 | 2.42 | 2.42 | 4.84 | 9.68 | 14.52 | 19.36 | 29.04 |

| RMB/m2 | 3.48 | 3.48 | 3.48 | 6.96 | 13.92 | 20.88 | 27.84 | 41.76 |

| XPS | Thickness (mm) | 10 | 10 | 10 | 20 | 40 | 40 | 60 | 100 |

| PED/m2 | 2.96 | 2.96 | 2.96 | 5.92 | 11.84 | 11.84 | 17.77 | 29.61 |

| GWP/m2 | 4.24 | 4.24 | 4.24 | 8.47 | 16.94 | 16.94 | 25.41 | 42.35 |

| RMB/m2 | 5.01 | 5.01 | 5.01 | 10.02 | 20.04 | 20.04 | 30.06 | 50.10 |

Table 22.

Roof insulation of residential buildings in a cold area.

Table 22.

Roof insulation of residential buildings in a cold area.

| Material | Index | Improvement |

|---|

| 5% | 10% | 20% | 30% | 40% | 50% | 60% | 70% |

|---|

| Rock wool | Thickness (mm) | 100 | 100 | 120 | 140 | 160 | 180 | 220 | 300 |

| PED/m2 | 28.60 | 28.60 | 34.32 | 40.04 | 45.76 | 51.48 | 62.92 | 85.80 |

| GWP/m2 | 55.22 | 55.22 | 66.26 | 77.31 | 88.35 | 99.40 | 121.48 | 165.66 |

| RMB/m2 | 30.16 | 30.16 | 36.19 | 42.22 | 48.26 | 54.29 | 66.35 | 90.48 |

| PU | Thickness (mm) | 60 | 60 | 60 | 80 | 100 | 100 | 140 | 180 |

| PED/m2 | 14.15 | 14.15 | 14.15 | 18.87 | 23.59 | 23.59 | 33.03 | 42.46 |

| GWP/m2 | 24.15 | 24.15 | 24.15 | 32.20 | 40.25 | 40.25 | 56.35 | 72.45 |

| RMB/m2 | 40.80 | 40.80 | 40.80 | 54.40 | 68.00 | 68.00 | 95.20 | 122.40 |

| EPS | Thickness (mm) | 80 | 80 | 100 | 100 | 120 | 140 | 180 | 240 |

| PED/m2 | 13.54 | 13.54 | 16.92 | 16.92 | 20.30 | 23.69 | 30.46 | 40.61 |

| GWP/m2 | 19.36 | 19.36 | 24.20 | 24.20 | 29.04 | 33.88 | 43.56 | 58.08 |

| RMB/m2 | 27.84 | 27.84 | 34.80 | 34.80 | 41.76 | 48.72 | 62.64 | 83.52 |

| XPS | Thickness (mm) | 80 | 80 | 80 | 100 | 120 | 140 | 160 | 220 |

| PED/m2 | 23.69 | 23.69 | 23.69 | 29.61 | 35.53 | 41.45 | 47.38 | 65.14 |

| GWP/m2 | 33.88 | 33.88 | 33.88 | 42.35 | 50.82 | 59.29 | 67.76 | 93.17 |

| RMB/m2 | 40.08 | 40.08 | 40.08 | 50.10 | 60.12 | 70.14 | 80.16 | 110.22 |

Table 23.

External window of residential buildings in a cold area.

Table 23.

External window of residential buildings in a cold area.

| Improvement | Frame | Glass | PED | GWP | RMB/m2 |

|---|

| 5% | PVC | 5 + 12Ar + 5 | 4.51 | 9.88 | 359 |

| 10% | Heat broke aluminum | 5low-e + 6A + 5 | 6.73 | 15.25 | 450 |

| 20% | Heat broke aluminum | 5low-e + 8A + 5 | 6.73 | 15.25 | 474 |

| 30% | Heat broke aluminum | 5low-e + 12A + 5 | 6.73 | 15.25 | 568 |

| 40% | Heat broke aluminum | 5low-e + 13Ar + 5 | 6.73 | 15.25 | 650 |

| 50% | PVC | 5low-e + 12A + 5 + 12A + 5 | 5.31 | 11.7 | 483 |

| 60% | PVC | 5low-e + 13Ar + 5 + 13Ar + 5 | 5.31 | 11.7 | 540 |

Table 24.

Roof insulation of public buildings in a cold area.

Table 24.

Roof insulation of public buildings in a cold area.

| Material | Index | Improvement |

|---|

| 5% | 10% | 20% | 30% | 40% | 50% | 60% | 70% |

|---|

| Rock wool | Thickness (mm) | 40 | 40 | 60 | 80 | 100 | 120 | 180 | 240 |

| PED/m2 | 11.44 | 11.44 | 17.16 | 22.88 | 28.60 | 34.32 | 51.48 | 68.64 |

| GWP/m2 | 22.09 | 22.09 | 33.13 | 44.18 | 55.22 | 66.26 | 99.40 | 132.53 |

| RMB/m2 | 12.06 | 12.06 | 18.10 | 24.13 | 30.16 | 36.19 | 54.29 | 72.38 |

| PU | Thickness (mm) | 20 | 20 | 20 | 40 | 60 | 80 | 100 | 140 |

| PED/m2 | 4.72 | 4.72 | 4.72 | 9.44 | 14.15 | 18.87 | 23.59 | 33.03 |

| GWP/m2 | 8.05 | 8.05 | 8.05 | 16.10 | 24.15 | 32.20 | 40.25 | 56.35 |

| RMB/m2 | 13.60 | 13.60 | 13.60 | 27.20 | 40.80 | 54.40 | 68.00 | 95.20 |

| EPS | Thickness (mm) | 40 | 40 | 40 | 60 | 80 | 100 | 140 | 200 |

| PED/m2 | 6.77 | 6.77 | 6.77 | 10.15 | 13.54 | 16.92 | 23.69 | 33.84 |

| GWP/m2 | 9.68 | 9.68 | 9.68 | 14.52 | 19.36 | 24.20 | 33.88 | 48.40 |

| RMB/m2 | 13.92 | 13.92 | 13.92 | 20.88 | 27.84 | 34.80 | 48.72 | 69.60 |

| XPS | Thickness (mm) | 30 | 40 | 40 | 60 | 80 | 100 | 120 | 180 |

| PED/m2 | 8.88 | 11.84 | 11.84 | 17.77 | 23.69 | 29.61 | 35.53 | 53.30 |

| GWP/m2 | 12.71 | 16.94 | 16.94 | 25.41 | 33.88 | 42.35 | 50.82 | 76.23 |

| RMB/m2 | 15.03 | 20.04 | 20.04 | 30.06 | 40.08 | 50.10 | 60.12 | 90.18 |

Table 25.

External window of public buildings in a cold area.

Table 25.

External window of public buildings in a cold area.

| Material | Index | Improvement |

|---|

| 5% | 10% | 20% | 30% | 40% | 50% | 60% | 70% |

|---|

| Rock wool | Thickness (mm) | 100 | 120 | 120 | 140 | 160 | 200 | 260 | 330 |

| PED/m2 | 28.60 | 34.32 | 34.32 | 40.04 | 45.76 | 57.20 | 74.36 | 94.38 |

| GWP/m2 | 55.22 | 66.26 | 66.26 | 77.31 | 88.35 | 110.44 | 143.57 | 182.23 |

| RMB/m2 | 30.16 | 36.19 | 36.19 | 42.22 | 48.26 | 60.32 | 78.42 | 99.53 |

| PU | Thickness (mm) | 60 | 60 | 80 | 80 | 100 | 120 | 160 | 200 |

| PED/m2 | 14.15 | 14.15 | 18.87 | 18.87 | 23.59 | 28.31 | 37.74 | 47.18 |

| GWP/m2 | 24.15 | 24.15 | 32.20 | 32.20 | 40.25 | 48.30 | 64.40 | 80.50 |

| RMB/m2 | 40.80 | 40.80 | 54.40 | 54.40 | 68.00 | 81.60 | 108.80 | 136.00 |

| EPS | Thickness (mm) | 80 | 100 | 100 | 120 | 140 | 160 | 200 | 280 |

| PED/m2 | 13.54 | 16.92 | 16.92 | 20.30 | 23.69 | 27.07 | 33.84 | 47.38 |

| GWP/m2 | 19.36 | 24.20 | 24.20 | 29.04 | 33.88 | 38.72 | 48.40 | 67.76 |

| RMB/m2 | 27.84 | 34.80 | 34.80 | 41.76 | 48.72 | 55.68 | 69.60 | 97.44 |

| XPS | Thickness (mm) | 80 | 80 | 100 | 100 | 120 | 160 | 180 | 260 |

| PED/m2 | 23.69 | 23.69 | 29.61 | 29.61 | 35.53 | 47.38 | 53.30 | 76.99 |

| GWP/m2 | 33.88 | 33.88 | 42.35 | 42.35 | 50.82 | 67.76 | 76.23 | 110.11 |

| RMB/m2 | 40.08 | 40.08 | 50.10 | 50.10 | 60.12 | 80.16 | 90.18 | 130.26 |

Table 26.

External window of public buildings in a cold area.

Table 26.

External window of public buildings in a cold area.

| Improvement | Frame | Glass | PED | GWP | RMB/m2 |

|---|

| 5% | Heat broke aluminum | 5low-e + 12A + 5 | 6.73 | 15.25 | 568 |

| 10% | Heat broke aluminum | 5low-e + 13Ar + 5 | 6.73 | 15.25 | 650 |

| 20% | Heat broke aluminum | 5low-e + 13Ar + 5 | 6.73 | 15.25 | 650 |

| 30% | PVC | 5low-e + 12A + 5 + 12A + 5 | 5.31 | 11.7 | 483 |

| 40% | PVC | 5low-e + 10Ar + 5 + 8Ar + 5 | 5.31 | 11.7 | 495 |

Table 27.

Heat consumption of green buildings in a cold area.

Table 27.

Heat consumption of green buildings in a cold area.

| Project | Floor Area m2 | Heat Consumption GJ/a | Heat Consumption Per Unit Area GJ/m2·a | Constraint Value GJ/m2·a | Bootstrap Value GJ/m2·a |

|---|

| 1 | 10,723 | 1922.3 | 0.18 | 0.25 | 0.2 |

| 2 | 129,928 | 41,281.9 | 0.13 | 0.25 | 0.2 |

| 3 | 6628.1 | 1139.6 | 0.17 | 0.23 | 0.15 |

| 4 | 10,762 | 1838.0 | 0.17 | 0.25 | 0.2 |

| 5 | 14,700 | 788.9 | 0.05 | 0.25 | 0.2 |

| 6 | 8091 | 736.5 | 0.09 | 0.25 | 0.2 |

| 7 | 24,648 | 4616.4 | 0.19 | 0.25 | 0.2 |

| 8 | 20,861 | 1766.7 | 0.08 | 0.21 | 0.14 |

| 9 | 16,724 | 1416.4 | 0.08 | 0.21 | 0.14 |

| 10 | 3283.8 | 599.3 | 0.18 | 0.21 | 0.14 |

Table 28.

Improvement of the thermal performance in practical projects.

Table 28.

Improvement of the thermal performance in practical projects.

| Project | U-Value of External Wall W/(m2·K) | U-Value of Roof W/(m2·K) | U-Value of External Window W/(m2·K) | Heat Consumption Per Unit Area GJ/m2·a |

|---|

| Design | Limit | Improvement | Design | Limit | Improvement | Design | Limit | Improvement |

|---|

| 1 | 0.4 | 0.6 | 33.33% | 0.41 | 0.55 | 25.45% | 2.2 | 2.7 | 18.52% | 0.18 |

| 2 | 0.5 | 0.6 | 16.67% | 0.35 | 0.55 | 36.36% | 2 | 2.7 | 25.93% | 0.13 |

| 3 | 0.43 | 0.6 | 28.33% | 0.39 | 0.5 | 22.00% | 2.8 | 2.8 | 0.00% | 0.17 |

| 4 | 0.44 | 0.6 | 26.67% | 0.15 | 0.55 | 72.73% | 2.5 | 2.7 | 7.41% | 0.17 |

| 5 | 0.461 | 0.6 | 23.17% | 0.418 | 0.55 | 24.00% | 2 | 2.3 | 13.04% | 0.05 |

| 6 | 0.18 | 0.6 | 70.00% | 0.14 | 0.55 | 74.55% | 1.1 | 2.4 | 54.17% | 0.09 |

| 7 | 0.51 | 0.6 | 15.00% | 0.49 | 0.55 | 10.91% | 2.7 | 2.7 | 0.00% | 0.19 |

| 8 | 0.34 | 0.6 | 43.33% | 0.42 | 0.55 | 23.64% | 2 | 2.3 | 13.04% | 0.08 |

| 9 | 0.42 | 0.7 | 40.00% | 0.27 | 0.45 | 40.00% | 2 | 2.3 | 13.04% | 0.08 |

| 10 | 0.31 | 0.63 | 50.79% | 0.49 | 0.55 | 10.91% | 2.7 | 2.8 | 3.57% | 0.18 |

Table 29.

Basic information of typical projects.

Table 29.

Basic information of typical projects.

| Type | U-Value W/m2·K | Heat Consumption kWh/a | Envelope Area m2 |

|---|

| External Window | External Wall | Roof |

|---|

| Public building | 2.2 | 0.4 | 0.41 | 522,327.1 | 7081.5 |

| Residential building | 2.7 | 0.31 | 0.49 | 174,024.8 | 21,084.2 |

Table 30.

Modified calculation results.

Table 30.

Modified calculation results.

| Project | | | Error |

|---|

| 1 | 0.9 | 0.80 | −11.2% |

| 2 | 1.15 | 1.26 | 9.4% |

| 3 | 0.71 | 0.63 | −11.4% |

| 4 | 0.43 | 0.37 | −13.2% |

| 5 | 0.50 | 0.56 | 11.4% |

| 6 | 0.62 | 0.58 | −7.2% |

| 7 | 1.01 | 0.93 | −7.5% |

| 8 | 0.45 | 0.43 | −3.6% |

| 9 | 0.5 | 0.43 | −13.3% |

| 10 | 0.1 | 0.28 | 184.0% |

Table 31.

Comprehensive score table of a rock wool insulation exterior wall.

Table 31.

Comprehensive score table of a rock wool insulation exterior wall.

| Thickness mm | Weight Value of Index | Score Z |

|---|

| | | |

|---|

| 0.5 | 0.125 | 0.125 | 0.25 |

|---|

| 10 | 0.00 | 1 | 1 | 1 | 0.50 |

| 20 | 0.098 | 0.947 | 0.947 | 0.947 | 0.523 |

| 40 | 0.278 | 0.842 | 0.842 | 0.842 | 0.560 |

| 60 | 0.439 | 0.737 | 0.737 | 0.737 | 0.588 |

| 80 | 0.579 | 0.632 | 0.632 | 0.632 | 0.605 |

| 100 | 0.699 | 0.526 | 0.526 | 0.526 | 0.613 |

| 120 | 0.800 | 0.421 | 0.421 | 0.421 | 0.610 |

| 140 | 0.880 | 0.316 | 0.316 | 0.316 | 0.598 |

| 160 | 0.940 | 0.211 | 0.211 | 0.211 | 0.575 |

| 180 | 0.980 | 0.105 | 0.105 | 0.105 | 0.543 |

| 200 | 1 | 0 | 0 | 0 | 0.50 |

Table 32.

Comprehensive score table of a rock wool insulation roof.

Table 32.

Comprehensive score table of a rock wool insulation roof.

| Thickness mm | Weight Value of Index | Score Z |

|---|

| | | |

|---|

| 0.5 | 0.125 | 0.125 | 0.25 |

|---|

| 10 | 0 | 1 | 1 | 1 | 0.500 |

| 20 | 0.354 | 0.947 | 0.947 | 0.947 | 0.651 |

| 40 | 0.649 | 0.842 | 0.842 | 0.842 | 0.745 |

| 60 | 0.779 | 0.737 | 0.737 | 0.737 | 0.758 |

| 80 | 0.852 | 0.632 | 0.632 | 0.632 | 0.742 |

| 100 | 0.899 | 0.526 | 0.526 | 0.526 | 0.712 |

| 120 | 0.931 | 0.421 | 0.421 | 0.421 | 0.676 |

| 140 | 0.955 | 0.316 | 0.316 | 0.316 | 0.636 |

| 160 | 0.974 | 0.211 | 0.211 | 0.211 | 0.592 |

| 180 | 0.988 | 0.105 | 0.105 | 0.105 | 0.547 |

| 200 | 1 | 0 | 0 | 0 | 0.500 |

Table 33.

Multi-index evaluation results of a residential building envelope in a cold area.

Table 33.

Multi-index evaluation results of a residential building envelope in a cold area.

| Type | Rock Wool | PU | EPS | XPS |

|---|

| Exterior wall | 0.56 (40 mm) | 0.579 (20 mm) | 0.598 (30 mm) | 0.604 (30 mm) |

| Roof | 0.712 (100 mm) | 0.776 (60 mm) | 0.747 (80 mm) | 0.750 (80 mm) |

| Exterior window | Heat broke aluminum frame (5low-e + 13Ar + 5) |