1. Introduction

Construction automation (CA) is defined as the integration of intelligent machines (e.g., building robots and/or embedded and dedicated systems) [

1], printing methods (such as 3D printing, concrete printing, contour crafting, D-Shape [

2]), traditional construction methods [

3] and advanced construction technologies (such as i) extrusion-based AM and ii)binder jetting) [

4]. CA promises several benefits to the construction industry to enhance the productivity, quality, and sustainability of architectural practices and building construction [

5].

Additive Manufacturing (AM) technologies allow the horizon of the 3D printing to be expanded in the construction sector. In this context, binder jetting AM is a technology that performs the selective deposition of a binder solution through a print nozzle onto a previously deposited powder layer [

6]. Furthermore, the additive manufacturing of concrete extrusion-based has recently employed in the construction industry. This technology involves extruding the cement-based material with nozzles of different sizes to build a layered structure model [

7].

The technology of 3D printing in construction applications can be considered as a process where various materials are successively solidified layer upon layer by extrusion, to form solid models [

8]. The major applications of 3D printing in large scale infrastructure are divided into three scenarios: D-Shape [

9], contour crafting (CC) [

10] and concrete printing [

11]. The former, D-Shape, is based on binder injection and, despite its high effectiveness, it is only used for customized constructions [

12]. For the second case, CC, it is a computer-controlled method with portability and cost improvements: it enables to build smooth surfaces in a short time [

13,

14]. Finally, concrete printing is very similar to CC, but it is associated with the development of components without formwork [

15].

The success of 3D printing in CA depends on the quality of the materials. The printable mixture is similar and varies in composition from the traditional cement paste. For this reason, the printing materials must have appropriate rheological and compositional properties that allow: easy extrusion, strong adhesion between the printing layers, avoid the collapse of the structure and maintain the printing pattern during and after the material deposition process [

4]. In this context, [

16] presents an ultra-high performance concrete (UHPC) developed to accelerate the printing process and to improve the mechanical strength for layer-by-layer construction. One of the main motivations to consider UHPC is the high mechanical performance to build concrete-based structures, which is an alternative to more traditional construction methods (see [

17,

18,

19] for further details). Furthermore, to achieve structural integrity, durability, reliability, and robustness without any support structures. Thus, ref. [

20] presents a 3D printing based on Engineered Cementitious Composites (ECC), whose advantages are sustainable mix design, rheology control, and long-term durability of the 3D printing.

Additive Manufacturing (AM) technology using the extrusion-based method has been improving with the integration of robotic systems; specifically, a robot manipulator handling the extrusor and controlling the material deposition [

21,

22,

23]. For example, in [

24,

25] it is shown the customisation of a robotic arm in the construction industry, aimed at printing concrete walls of different geometries. The main advantage of using robot manipulators is their workload capacity, their accuracy in repetitive tasks and the flexible programming [

26,

27]. Nevertheless, robot manipulators in construction applications are mainly used as fixed machinery, without interacting with the environment or moving within the construction site [

16].

The construction industry uses robots for assembly and disassembly of various components. In particular, ref. [

28] identifies four stages for assembling building components: (i) no assembly components, (ii) assembly of a large element formed with several small components, (iii) placement of components in the final position, and (iv) assembly of non-printed external components. In this context, ref. [

29] presents a Robotic Prefabrication System (RPS) that allows the automatic disassembly of a prefabricated structure and determinates the needs and gaps in knowledge in the current prefabrication.

Moreover, as a mechanical tools, robotic arms have advantages that attract the attention of the construction industry, such as their dexterity and their reachability. However, such advantages also restrict the scale size of the construction: when fixed in the ground, a robot manipulator with an extrusor (used for printing) can only print elements that fall within its workspace. Otherwise, the robot has to be manually displaced [

30,

31,

32,

33].

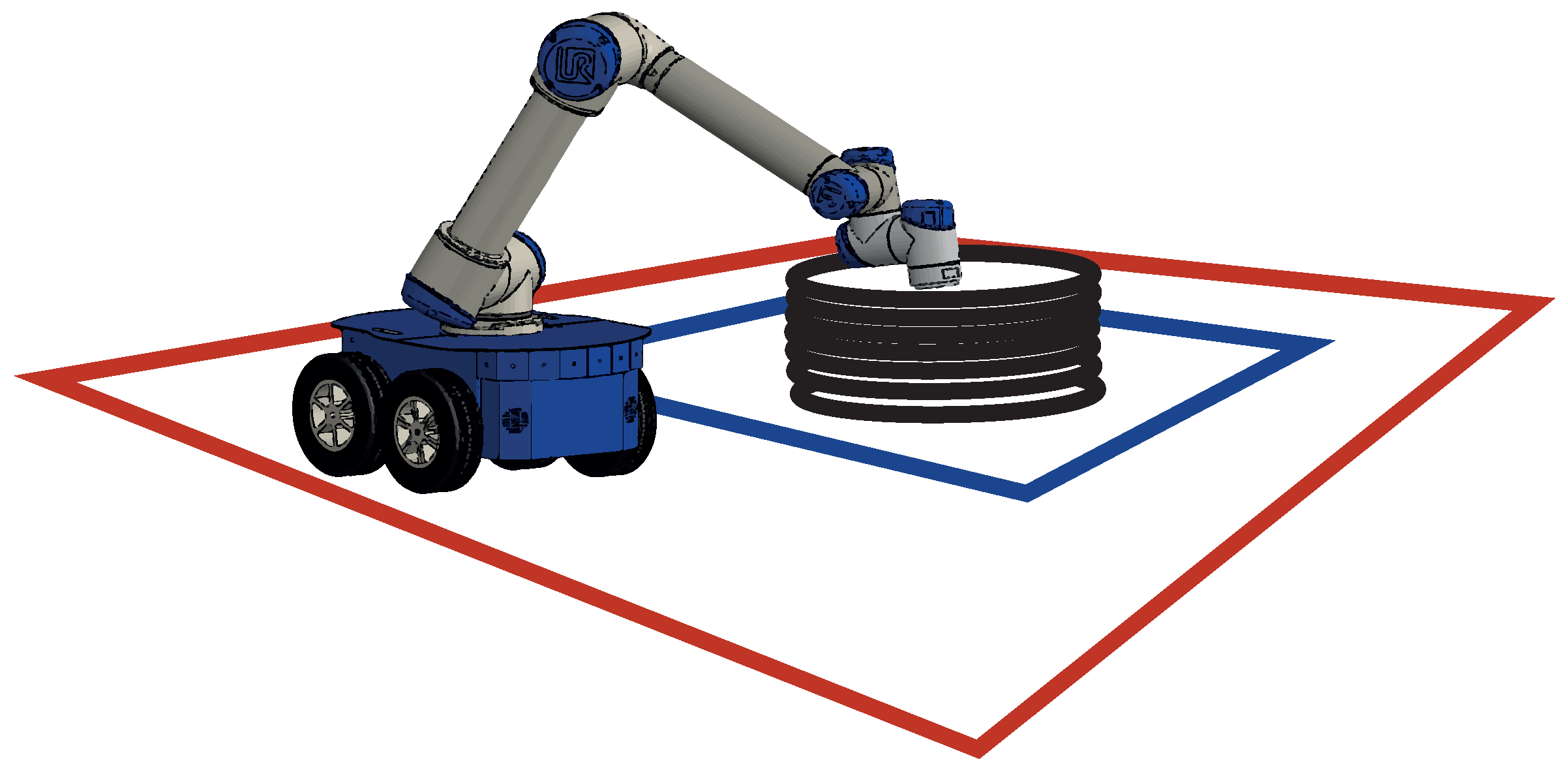

To overcome the later problem, in this work we propose to study the usability of a robotic arm mounted on a mobile platform (also robotic), to cover bigger areas of the construction site and to print convex geometries (for example, the walls of a room). By integrating a mobile platform to the robot manipulator used as 3D printer, we increase its dexterity, its workspace and its capabilities. However, since we use the same robot manipulator, we change the mobile platform to find which one is the most appropriate to be used in the construction site. In particular, we test the following configurations: unicycle, car-like and four wheeled omnidirectional with mecanum wheels [

34,

35]. We test the performance of the mobile manipulator mounted on the three different platforms in terms of error and effort, when printing several types of building elements. For the remainder of this work, we will refer to the robotic platform as the

mobile manipulator.

The selection of proper machine and printing strategy according to the building pieces printed is crucial for a successful efficiency and versatility of this emerging technology for 3D-printed construction with robotic systems. In this context, the efficient use of robotic platforms is related to their operational power consumption [

36]. When the robot performs a printing task, the power consumption varies significantly during the operation of the robot, and comprise the actuation systems that will interact with the environment and the construction process.

For example, the use of energy resources of the mobile manipulator depends on the interaction of the platform with the environment and the motion it executes. For this reason, their energy use is governed by the irregularity of the surface of the construction environment, the complexity of the print model, and the payload it supports. In this work, we relate the energy consumption to the cost function in terms of minimum trajectory tracking error with the motion speeds of the mobile manipulator.

As previously stated, this work is focused on studying the usability of mobile manipulator platforms as 3D printing machinery in construction sites, with emphasis in the different existing mobile platforms, in order to provide a novel review and suggest adequate methodologies for buildings construction. Previous work has been done on materials, machines and/or specific printing experiments, but lack of rigorous studies and general approaches about printing procedures with mobile robot platforms. Movement and operation of robots are complex tasks to be combined in a printing process of large pieces, and building execution requires a diversity of elements to be printed in different locations, then to test and define proper strategies is essential to develop the construction with robots. In this context, [

8,

37] exposes strategies of mobile systems for printing building elements but do not study the toolpath in relation to the machine type and piece design. Such procedure is relevant to develop the printing methodology and define effective approaches and equipments.

This work is organized as follows:

Section 2 shows the trajectory profiles in the construction environment, the mathematical derivation of the mobile manipulator model, the strategy followed by the mobile manipulator trajectory tracking controller, and the metrics followed to find mobile platform performance.

Section 3 presents the results using the mobile manipulator with the three different mobile platforms previously introduced for different building scenarios.

Section 4 shows a discussion about the tasks performed by the mobile manipulator in the construction environments. Finally, the conclusions are shown in

Section 5.

3. Results

To implement the trajectory tracking controller shown in

Section 2.5, we first set the tuning parameters presented in Equation (

7), presented in

Table 4 below.

Figure 5 shows the computational analysis obtained in the experiments for the three mobile manipulators with the four trajectory profiles. The first column corresponds to the unicycle robot, the second and third column correspond to the car-like and omnidirectional robot, respectively. The reference trajectory of the end-effector is described by the solid blue line whereas the dashed magenta line corresponds to the actual tracked trajectory. In addition, we have included the trajectory of the mobile platform in the solid cyan line. The solid black line represents the outer limit imposed on the mobile platform, whereas the dashed black line, the inner limit.

The experiments in

Figure 5 consisted of printing four medium-sized building elements (length = 2 m, width = 2 m). It is possible to observe that the tracked trajectory profile –dashed magenta line– converges to the reference path –solid cyan line– for each studied platform. The performance comparison of the mobile platforms as they are printing the building elements is shown in

Figure 5a–c, corresponding to the unicycle, car-like and omnidirectional platforms, respectively. It is worth noting that the mobile robot trajectory is independent of the end-effector trajectory.

The second experiment consisted of printing a medium-size helical building element (length = 2 m, width = 2 m, height = 0.92 m), and are shown in

Figure 5d–f. This profile is formed by 50 circular layers and the distance between layers is 0.01 m. The solid cyan line shows the displacement of the unicycle and car-like robot, as shown in

Figure 5d,e. These two platforms have a circular motion that increases as printing progresses, without exceeding the proposed inner limit of the workspace. The omnidirectional platform follows a circular trajectory with a sinusoidal movement, as can be seen in

Figure 5f.

The third experiment consists of printing a mesh profile, as shown in

Figure 5g–i. The profile is of medium size (length = 2 m, width = 2 m, height = 0.55 m) and is formed by 50 square layers; the distance between layers is 0.01m. The displacement of the mobile platform is described by a solid cyan line.

Figure 5g,h show the trajectory described by the unicycle and car-like robot, respectively. Both mobile robots have a nearly square trajectory with curves in the corners, in contrast to the omnidirectional robot that describes a square trajectory with sharp turns at the corners, as shown in

Figure 5i.

The performance comparison between mobile platforms for a medium-size square profile of length = 2 m, width = 2 m, height = 0.26 m is shown in

Figure 5j–l. The solid cyan line describes of displacement of the mobile platforms.

Figure 5j,k show that the unicycle and car-like robot performs a quasi-circular trajectory. Both mobile robots have a transient before the desired trajectory is achieved. On the other hand, the omnidirectional robot describes a quasi-square trajectory without a transient, this result can be seen in

Figure 5l.

The results obtained from the printing of building elements –circular and helical– of different sizes are summarized in

Table 5. The statistical analysis was performed based on the cost function defined in

Section 2.6. It can be seen that the omnidirectional robot has the lowest cost function.

For the square and mesh profiles, the platform performance is shown in

Table 6. For small and large sizes of square profiles, the platform with the lowest costs is the omnidirectional robot. For the medium square profile, the car-like platform presents the lowest cost. The omnidirectional robot has the lowest cost function for all sizes of the mesh profile.

4. Discussion

In this work, we proposed a performance comparison of a robotic arm mounted on three different widely used mobile platforms.

Table 7 summarises the capabilities and skills of the different mobile platforms considered in this work, showing their pros and cons in the problem faced herein. The analysis of results shows that the omnidirectional robot is the best option for 3D printing of building elements used in the construction industry. In terms of the cost function, the omnidirectional robot has the lowest cost function for the mesh and square trajectory. For circular and helical trajectory, the best platform is the omnidirectional robot.

The car-like robot has a high sensitivity to the initial state error of the robot, which produces an error at the beginning of the printing that is then corrected. However, the unicycle robot has a lower initial state error. The initial state of the robot varies with the trajectory (see [

55] for further details).

Controlling the height between layers is an important parameter during printing to avoid deviation in either direction that influences the quality, geometry, and appearance of the final printed product. In this work, we considered a height between layers of 0.01 m, which is the minimum distance of printing in the construction process [

57] and a vertical displacement of 0.50 m for our experiments.

A crucial factor in 3D printing is the velocity of operation of the robotic system. Our work tries to address this challenge, which is a function of the printing material. For all the tests carried out, we set the velocity to a maximum of 0.01 ms. However, the velocity might vary depending on the trajectory shape, size and the complexity of the geometry profile. A pre-analysis of the effect of speed on the different trajectory profiles is an advantage in the area of construction to improve the performance of 3D printing.

The workspace is another important item to consider. In the experiments carried out, a square-shaped workspace is proposed, that establish the limits of operation of the mobile manipulator, considering that the end-effector does not invade the printing area. Under real site conditions, the system should be modified to avoid obstacles (e.g., people and construction tools).

This work proposes a kinematic model of the mobile manipulator, whose analysis is based on the application of 3D printing for the construction industry. This analysis does not consider the dynamic model of the system and the forces involved in 3D printing. Furthermore, a future analysis may be to study the effects of putting a nozzle on the end-effector, where variables such as weight, size and diameter of the nozzle are considered.

5. Conclusions

An experimental comparison of a robotic arm mounted on three mobile platforms in 3D printing applications was presented. The evaluation of the printing performance was based in two well known metrics used in robotics: the cumulative control effort and cumulative integral absolute error index. As a case study, we proposed four profiles (circular, helical, mesh and square), which are representative of the geometry of building elements usually printed using robotic technology. Three mobile platforms were used: unicycle like, car-like and omnidirectional with four mecanum wheels; combined with a robotic arm UR5. The experiments have shown that the printing error converges to zero for all three proposed trajectories and that the car-like showed the lowest cost for squared and mesh building elements. On the other hand, the car-like and unicycle showed the lowest cost for the circle and helical profile. The omnidirectional showed promising results, but the nature of its wheels makes the platform difficult to use in non-flat terrains, as it is in construction sites.

On the other hand, the greater effectiveness demonstrated by the mobile platforms studied to print circular and helical building elements is probably driving a preference for these architectural forms in the first printed constructions carried out. That suggests buildings with curved and sinuous walls that can have new spatial expressions.

Future developments will be focused on studying and modelling the dynamics of the system. As the performance of cooperative installations for the impression of constructive elements. As well as the effectiveness of different architectural forms.