A Framework for Assessing Green Capacity Utilization Considering CO2 Emissions in China’s High-Tech Manufacturing Industry

Abstract

:1. Introduction

2. Literature Review

2.1. Performance Assessment of the High-Tech Manufacturing Industry

2.2. Capacity Utilization and Its Measurement

2.3. A Summary of the Literature Review

3. Methodology

3.1. Green CU indicator

3.2. Implications of the Green CU Indicator

- ▪

- and hold simultaneously. Then, the assessed DMU can be said to be at under-utilized capacity and the variable inputs are absolutely insufficient.

- ▪

- and do not hold simultaneously. Then, the assessed DMU can be said to be at under-utilized capacity, and the variable inputs are insufficient.

- ▪

- and hold simultaneously. Then, the assessed DMU can be said to be at fully utilized capacity and the variable inputs are in optimum condition.

- ▪

- and hold simultaneously. Then, the assessed DMU can be said to be at fully utilized capacity and the variable inputs are absolutely redundant.

- ▪

- and do not hold simultaneously. Then, the assessed DMU can be said to be at fully utilized capacity and the variable inputs are redundant.

4. Data and Indicators

4.1. Data Set

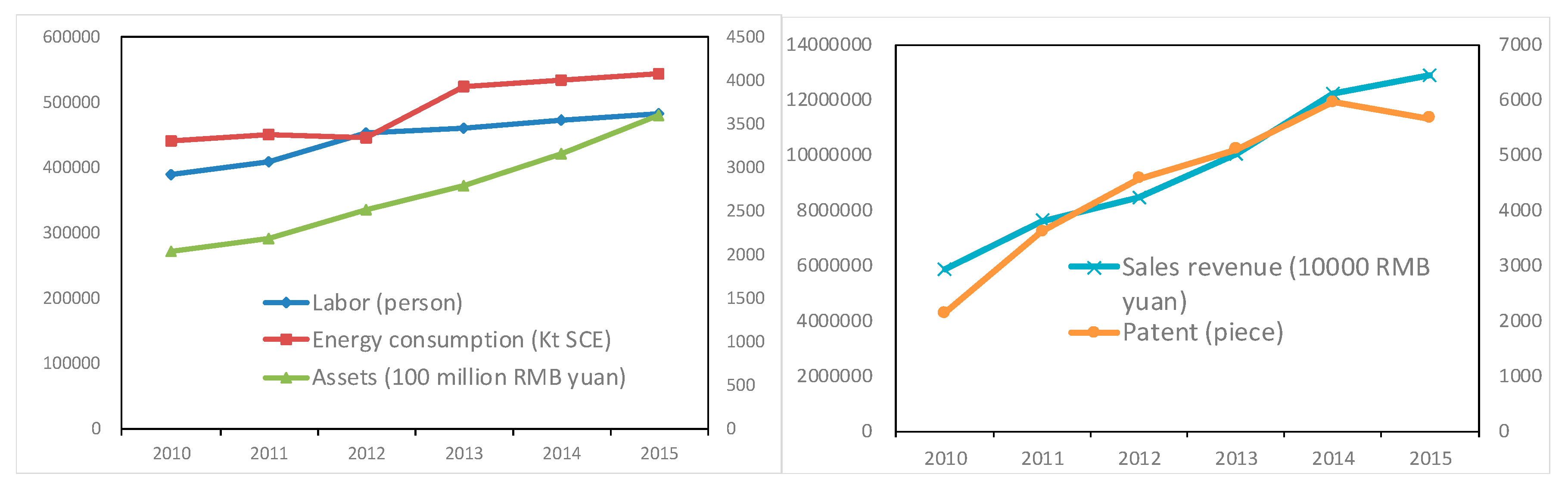

4.2. Input and Output Variables

- (i)

- Labor: the annual average number of employed personnel in the high-tech manufacturing industry. In this study, labor is used as an input variable.

- (ii)

- Energy consumption: the total consumption of all energy types in China’s high-tech manufacturing industry during a certain period. It is not easy to directly obtain data on energy consumption directly from the high-tech manufacturing industry. However, it cannot be ignored that the classification criteria for different types of statistical yearbooks in China are based on national economic industry classifications. Hence, according to the specific description of each industrial sector in the National Economic Industry Classification Notes 2017, we selected industrial sectors that are very similar to the high-tech manufacturing industry from the China Energy Statistical Yearbook [38] and CEAD. We used the data on energy consumption as the proxy for energy consumption by the high-tech manufacturing industry. The industrial sectors include medical and pharmaceutical products, chemical fibers, ordinary machinery, equipment for a special purpose, electrical equipment and machinery, electronic and telecommunications equipment, instruments, meters, and cultural and office machinery. The guidelines issued by the Intergovernmental Panel on Climate Change (IPCC) regarding the allocation of greenhouse gas (GHG) emissions [43] include 20 types of energy. This study follows this approach. Different types of energy consumption were converted into uniform unit standard coal equivalents (SCEs) [44]. The conversion coefficients used in this study are shown in Table A1 in Appendix A.

- (iii)

- Assets: economic resources that are owned by the enterprise and that can be assessed in monetary terms, including various capitals, claims, and other rights. In this study, assets are used as a (quasi-)fixed input variable that cannot change quickly in the short term. The Consumer Price Index (CPI) is used to deal with inflation to ensure the continuity and comparability of data, which are shown in Table A2 in Appendix A.

- (iv)

- Patent: the number of patent applications filed by China’s high-tech manufacturing industry for a certain period, which is the sum of the number of invention patent applications, utility model patent applications, and design patent applications. As a relevant carrier of knowledge output, patents reflect the contribution of industry development to knowledge growth. Furthermore, the number of patents may be the most applicable proxy for knowledge growth [1,16,22,45]. In this study, the patent is used as a desirable output.

- (v)

- Sales revenue: the sales revenue of new products is a continuous source of capital and development, reflecting the growth potential of the industry’s economic output. In this study, sales revenue is also used as a proxy for desirable output. The CPI is used to deflate the data to ensure the comparability of continuous data.

- (vi)

- CO2 emissions: the average GHG emissions generated by China’s high-tech manufacturing industry during the life cycle of certain products. CO2 emissions are the undesirable output in this study. However, CO2 emission data could not be obtained directly from any of China’s statistical yearbooks. Therefore, these data are estimated based on the different types of energy consumption. IPCC provides a general method for estimating CO2 emissions in the 2006 Guidelines for National Greenhouse Gas Inventories [46]. The technique is widely used by national governments, research institutions, and researchers [47,48].

4.3. Descriptive Statistics of the Variables

5. Empirical Results and Discussion

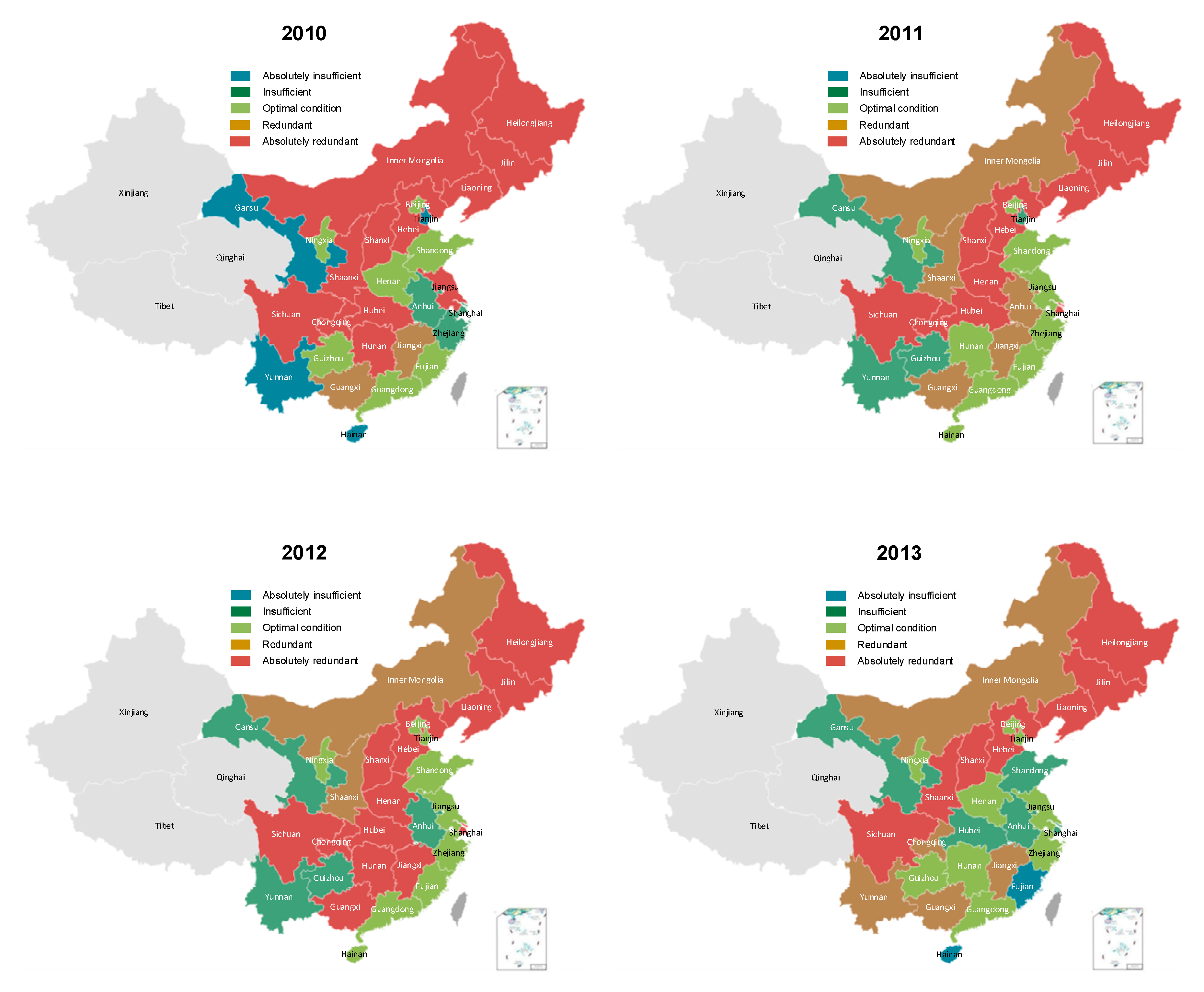

5.1. Provincial Green CU indicator

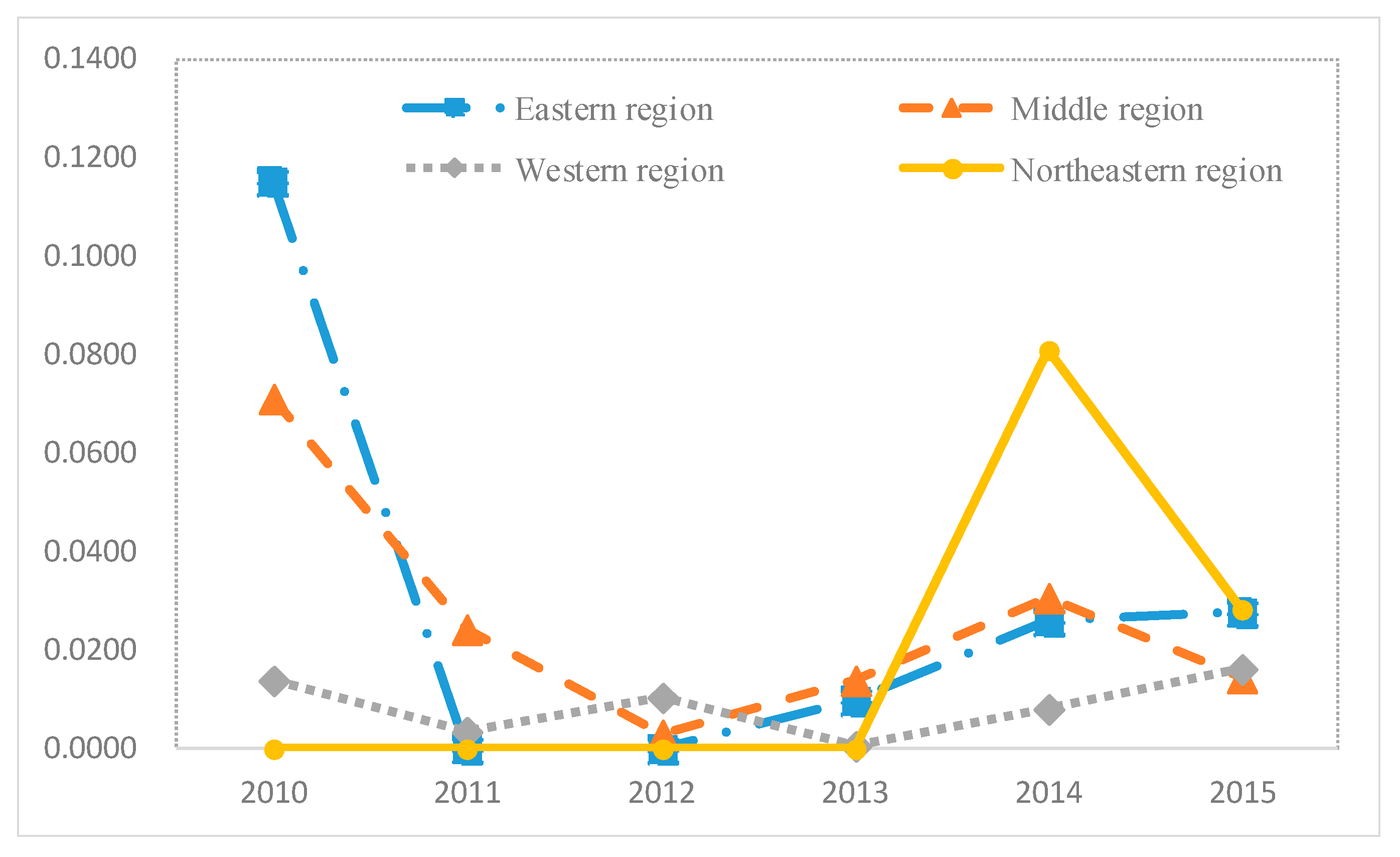

5.2. Analysis from a Time Perspective

5.3. Analysis from the Regional Perspective

5.4. Analysis Based on the Variable Inputs’ Scale

5.5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| No. | Energy Types | Conversion Factors from Physical Units to Standard Coal Equivalent | No. | Energy Types | Conversion Factors from Physical Units to Standard Coal Equivalent |

|---|---|---|---|---|---|

| 1 | Raw coal | 0.714 | 11 | Kerosene | 1.471 |

| 2 | Cleaned coal | 0.900 | 12 | Diesel oil | 1.471 |

| 3 | Other Washed Coal | 0.286 | 13 | Fuel oil | 1.429 |

| 4 | Briquettes | 0.714 | 14 | Liquefied petroleum gas | 1.714 |

| 5 | Coke | 0.971 | 15 | Refinery Gas | 1.571 |

| 6 | Coke oven gas | 0.614 | 16 | Other Petroleum Products | 1.429 |

| 7 | Other Gas | 0.714 | 17 | Natural gas | 1.330 |

| 8 | Other Coking Products | 0.714 | 18 | Heat | 0.034 |

| 9 | Crude oil | 1.429 | 19 | Electricity | 0.123 |

| 10 | Gasoline | 1.471 | 20 | Other Energy | 1.000 |

| Year | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|---|

| CPI value | 100.000 | 105.600 | 108.300 | 111.200 | 113.300 | 114.900 |

| Energy Types | NCV (PJ/104t, 108m3,tec.) | EF(Mt CO2/PJ) | OE |

|---|---|---|---|

| Raw coal | 0.209 | 0.087 | 0.885 |

| Cleaned coal | 0.263 | 0.087 | 0.885 |

| Other Washed Coal | 0.154 | 0.087 | 0.885 |

| Briquettes | 0.178 | 0.087 | 0.885 |

| Coke | 0.284 | 0.104 | 0.970 |

| Coke oven gas | 1.631 | 0.071 | 0.990 |

| Other Gas | 0.843 | 0.071 | 0.990 |

| Other Coking Products | 0.284 | 0.091 | 0.970 |

| Crude oil | 0.418 | 0.073 | 0.980 |

| Gasoline | 0.431 | 0.069 | 0.980 |

| Kerosene | 0.431 | 0.072 | 0.980 |

| Diesel oil | 0.427 | 0.074 | 0.000 |

| Fuel oil | 0.418 | 0.077 | 0.980 |

| Liquefied petroleum gas | 0.502 | 0.063 | 0.990 |

| Refinery Gas | 0.461 | 0.073 | 0.990 |

| Other Petroleum Products | 0.418 | 0.074 | 0.980 |

| Natural gas | 3.893 | 0.056 | 0.990 |

| Non-fossil heat | 0.010 | 0.000 | 0.000 |

| Non-fossil electricity | 0.360 | 0.000 | 0.000 |

| Other Energy | 0.293 | 0.000 | 0.000 |

| Energy Types | Unit | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|---|---|

| Heat | Mt CO2/1010KJ | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Electricity | Mt CO2/108KWh | 0.063 | 0.064 | 0.063 | 0.062 | 0.057 | 0.054 |

References

- Hong, J.; Feng, B.; Wu, Y.; Wang, L. Do government grants promote innovation efficiency in China’s high-tech industries? Technovation 2016, 57–58, 4–13. [Google Scholar] [CrossRef]

- Zhang, B.; Luo, Y.; Chiu, Y.-H. Efficiency evaluation of China’s high-tech industry with a multi-activity network data envelopment analysis approach. Socio Econ. Plan. Sci. 2019, 66, 2–9. [Google Scholar] [CrossRef]

- National Bureau of Statistics (NBS). China Statistical Yearbook on Science and Technology 2016; China Statistics Press: Beijing, China, 2017.

- Sahoo, B.K.; Tone, K. Decomposing capacity utilization in data envelopment analysis: An application to banks in India. Eur. J. Oper. Res. 2009, 195, 575–594. [Google Scholar] [CrossRef]

- Johansen, L. Production functions and the concept of capacity. Econ. Math. Econom. 1968, 2, 49–72. [Google Scholar]

- Sun, X. Industrial capacity utilization index survey and research—Take the United States as an example. China Stat. 2017, 5, 32–34. [Google Scholar]

- Board of Governors of the Federal Reserve System. Industrial production and Capacity Utilization. 2019. Available online: https://www.federalreserve.gov/feeds/g17.html (accessed on 20 November 2019).

- Yang, G.-L.; Fukuyama, H. Measuring the Chinese regional production potential using a generalized capacity utilization indicator. Omega 2018, 76, 112–127. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, X.; Ni, G. Decomposing capacity utilization under carbon dioxide emissions reduction constraints in data envelopment analysis: An application to Chinese regions. Energy Policy 2020, 139, 111299. [Google Scholar] [CrossRef]

- Ray, S.C. Nonparametric measures of scale economies and capacity utilization: An application to U.S. manufacturing. Eur. J. Oper. Res. 2015, 245, 602–611. [Google Scholar] [CrossRef] [Green Version]

- Yang, G.-L.; Fukuyama, H.; Song, Y.-Y. Estimating capacity utilization of Chinese manufacturing industries. Socio Econ. Plan. Sci. 2019, 67, 94–110. [Google Scholar] [CrossRef]

- Karagiannis, R. A system-of-equations two-stage DEA approach for explaining capacity utilization and technical efficiency. Ann. Oper. Res. 2015, 227, 25–43. [Google Scholar] [CrossRef]

- Yu, M.-M.; Chang, Y.-C.; Chen, L.-H. Measurement of airlines’ capacity utilization and cost gap: Evidence from low-cost carriers. J. Air Transp. Manag. 2016, 53, 186–198. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, W.; Li, H.; Olanipekun, A.O.; Skitmore, M. Measuring the capacity utilization of China’s regional construction industries considering undesirable output. J. Clean. Prod. 2020, 252, 119549. [Google Scholar] [CrossRef]

- Chen, C.-J.; Wu, H.-L.; Lin, B.-W. Evaluating the development of high-tech industries: Taiwan’s science park. Technol. Forecast. Soc. Chang. 2006, 73, 452–465. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Z.; Zhu, Q. Performance evaluation of China’s high-tech innovation process: Analysis based on the innovation value chain. Technovation 2018, 74–75, 42–53. [Google Scholar] [CrossRef]

- Guan, J.; Chen, K. Measuring the innovation production process: A cross-region empirical study of China’s high-tech innovations. Technovation 2010, 30, 348–358. [Google Scholar] [CrossRef]

- Han, C.; Thomas, S.R.; Yang, M.; Ieromonachou, P.; Zhang, H. Evaluating R&D investment efficiency in China’s high-tech industry. J. High Technol. Manag. Res. 2017, 28, 93–109. [Google Scholar] [CrossRef]

- Li, L.-B.; Liu, B.-L.; Liu, W.-L.; Chiu, Y.-H. Efficiency evaluation of the regional high-tech industry in China: A new framework based on meta-frontier dynamic DEA analysis. Socio Econ. Plan. Sci. 2017, 60, 24–33. [Google Scholar] [CrossRef]

- Tseng, F.M.; Chiu, Y.J.; Chen, J.S. Measuring business performance in the high-tech manufacturing industry: A case study of Taiwan’s large-sized TFT-LCD panel companies. Omega Int. J. Manag. Sci. 2009, 37, 686–697. [Google Scholar] [CrossRef]

- Wang, C.-H.; Lu, Y.-H.; Huang, C.-W.; Lee, J.-Y. R&D, productivity, and market value: An empirical study from high-technology firms. Omega 2013, 41, 143–155. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, K. Hierarchical network systems: An application to high-technology industry in China. Omega 2019, 82, 118–131. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, J.-F.; Pei, R.-M.; Yi, B.-W.; Yang, G.-L. Assessing the technological innovation efficiency of China’s high-tech industries with a two-stage network DEA approach. Socio Econ. Plan. Sci. 2020. [Google Scholar] [CrossRef]

- Morrison, C.J. Primal and Dual Capacity Utilization: An Application to Productivity Measurement in the U.S. Automobile Industry. J. Bus. Econ. Stat. 1985, 3, 312–324. [Google Scholar] [CrossRef]

- Klein, L.R. Some Theoretical Issues in the Measurement of Capacity. Econometrica 1960, 28, 272–286. [Google Scholar] [CrossRef]

- Segerson, K.; Squires, D. On the measurement of economic capacity utilization for multi-product industries. J. Econom. 1990, 44, 347–361. [Google Scholar] [CrossRef] [Green Version]

- Berndt, E.R.; Morrison, C.J. Capacity Utilization Measures: Underlying Economic Theory and an Alternative Approach. Am. Econ. Rev. 1981, 71, 48–52. [Google Scholar]

- Cassels, J.M. Excess Capacity and Monopolistic Competition. Q. J. Econ. 1937, 51, 426–443. [Google Scholar] [CrossRef]

- Lindebo, E.; Hoff, A.; Vestergaard, N. Revenue-based capacity utilisation measures and decomposition: The case of Danish North Sea trawlers. Eur. J. Oper. Res. 2007, 180, 215–227. [Google Scholar] [CrossRef]

- Fare, R.; Grosskopf, S.; Kokkelenberg, E.C. Measuring Plant Capacity, Utilization and Technical Change: A Nonparametric Approach. Int. Econ. Rev. 1989, 30, 655–666. [Google Scholar] [CrossRef]

- Fare, R.; Grosskopf, S.; Lovell, C.K. Production Frontiers; Cambridge University Press: New York, NY, USA, 1994. [Google Scholar]

- Liu, Z.-W.; Balezentis, T.; Song, Y.-Y.; Yang, G.-L. Estimating Capacity Utilization of Chinese State Farms. Sustainability 2019, 11, 4894. [Google Scholar] [CrossRef] [Green Version]

- Shephard, R.W.; Färe, R. The law of diminishing returns. Z. Natl. 1974, 34, 69–90. [Google Scholar] [CrossRef]

- Shephard, R.W. Dynamic Indirect Production Functions; Springer: Berlin/Heidelberg, Germany, 1977; pp. 418–434. [Google Scholar]

- Fare, R.; Grosskopf, S. A Comment on Weak Disposability in Nonparametric Production Analysis. Am. J. Agric. Econ. 2009, 91, 535–538. [Google Scholar] [CrossRef]

- National Bureau of Statistics (NBS). China Statistics Yearbook of the High Technology Industry-Variable Years; China Statistics Press: Beijing, China, 2011–2016c.

- National Bureau of Statistics (NBS). China Statistical Yearbook-Variable Years; China Statistics Press: Beijing, China, 2011–2016b.

- National Bureau of Statistics (NBS). China Energy Statistical Yearbook-Variables Years; China Statistics Press: Beijing, China, 2011–2016a.

- Cooper, W.W.; Seiford, L.M.; Tone, K. Data Envelopment Analysis: A Comprehensive Text with Models, Applications, References and Dea-Solver Software; Kluwer Academic Publishers: Boston, MA, USA, 2000. [Google Scholar]

- Shi, X.; Li, L. Green total factor productivity and its decomposition of Chinese manufacturing based on the MML index: 2003–2015. J. Clean. Prod. 2019, 222, 998–1008. [Google Scholar] [CrossRef]

- Kang, Y.-Q.; Xie, B.-C.; Wang, J.; Wang, Y.-N. Environmental assessment and investment strategy for China’s manufacturing industry: A non-radial DEA based analysis. J. Clean. Prod. 2018, 175, 501–511. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Yang, G.-L. CO2 emissions reduction of Chinese light manufacturing industries: A novel RAM-based global Malmquist–Luenberger productivity index. Energy Policy 2016, 96, 397–410. [Google Scholar] [CrossRef] [Green Version]

- Intergovernmental Panel on Climate Change (IPCC). Guidelines for National Greenhouse Gas Inventories; Institute for Global Environmental Strategies: Hayama, Japan, 2006. [Google Scholar]

- National Bureau of Statistics (NBS). China Energy Statistical Yearbook 2015; China Statistics Press: Beijing, China, 2016.

- Bronzini, R.; Piselli, P. The impact of R&D subsidies on firm innovation. Res. Policy 2016, 45, 442–457. [Google Scholar] [CrossRef]

- Edenhofer, O.; Seyboth, K.; Intergovernmental Panel on Climate Change (IPCC). Encyclopedia of Energy, Natural Resource, and Environmental Economics; Shogren, J.F., Ed.; Elsevier: Waltham, MA, USA, 2013; pp. 48–56. [Google Scholar] [CrossRef]

- Shan, Y.; Liu, Z.; Guan, D. CO2 emissions from China’s lime industry. Appl. Energy 2016, 166, 245–252. [Google Scholar] [CrossRef]

- Zhou, W.; Zhu, B.; Li, Q.; Ma, T.; Hu, S.; Griffy-Brown, C. CO2 emissions and mitigation potential in China’s ammonia industry. Energy Policy 2010, 38, 3701–3709. [Google Scholar] [CrossRef]

- Shan, Y.; Liu, J.; Liu, Z.; Xu, X.; Shao, S.; Wang, P.; Guan, D. New provincial CO2 emission inventories in China based on apparent energy consumption data and updated emission factors. Appl. Energy 2016, 184, 742–750. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Guan, D.; Wei, W.; Davis, S.J.; Ciais, P.; Bai, J.; Peng, S.; Zhang, Q.; Hubacek, K.; Marland, G.; et al. Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature 2015, 524, 335. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Lin, H.; Zou, W. Research on the Regional Differences and Influencing Factors of the Innovation Efficiency of China’s High-Tech Industries: Based on a Shared Inputs Two-Stage Network DEA. Sustainability 2020, 12, 3284. [Google Scholar] [CrossRef] [Green Version]

- Zhou, A.; Wu, S.; Chu, Z.; Huang, W.-C. Regional Differences in Municipal Solid Waste Collection Quantities in China. Sustainability 2019, 11, 4113. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Zhu, D.; Wu, X.; Yan, Y. Study on environment performance evaluation and regional differences of strictly-environmental-monitored cities in China. Sustainability 2017, 9, 2094. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Wei, X.; Liu, J.; He, L.; Gao, M. Impact of high-speed rail on population mobility and urbanisation: A case study on Yangtze River Delta urban agglomeration, China. Transp. Res. Part A Policy Pract. 2019, 127, 99–114. [Google Scholar] [CrossRef]

- Fortuński, B. Sustainable Development and Energy Policy: Actual CO2 Emissions in the European Union in the Years 1997–2017, Considering Trade with China and the USA. Sustainability 2020, 12, 3363. [Google Scholar] [CrossRef] [Green Version]

- Xu, B.; Lin, B. Investigating the role of high-tech industry in reducing China’s CO2 emissions: A regional perspective. J. Clean. Prod. 2018, 177, 169–177. [Google Scholar] [CrossRef]

- Chiu, S.-H.; Lin, T.-Y.; Yang, H.-L. Measuring Energy Performance for Regional Sustainable Development in China: A New Framework based on a Dynamic Two-Stage SBM Approach. Sustainability 2020, 12, 2851. [Google Scholar] [CrossRef] [Green Version]

| Authors (Year) | China’s Industries | Input Indicators | Output Indicators |

|---|---|---|---|

| Zhang and Chen [22] | High-technology industries | Stage 1: R&D personnel, R&D expenses Stage 2: Patent applications, number of patents in force | Stage 1: patent applications, number of patents in force Stage 2: prime operating revenue, sales revenue of new products, export delivery value |

| Zhang et al. [2] | High-tech industry | Stage 1: intramural expenditure on R&D, R&D personnel Stage 2: Patent applications, number of patents in force | Stage 1: patent applications, number of patents in force Stage 2: sales revenue of new products and value of contract deals in domestic technical markets |

| Shi and Li [40] | Manufacturing industry | Capital stock, labor, and energy | Desirable outputs: manufacturing output Undesirable output: CO2 emissions |

| Yang et al. [11] | Manufacturing industries | Labor, asset, and energy | Desirable outputs: gross industrial output value Undesirable output: CO2 emissions |

| Kang et al. [41] | Manufacturing industry | Labor, asset, and energy consumption | Desirable output: industrial value-added Undesirable output: CO2 emissions |

| Emrouznejad and Yang [42] | Light manufacturing industries | Labor, asset and energy | Desirable outputs: Gross Industrial Output Value Undesirable output: CO2 emissions |

| Variables | Units | Definitions | Data Resource | |

|---|---|---|---|---|

| Variable inputs | Labor | Person | The annual average number of employed personnel | China Statistics Yearbook on High Technology Industry |

| Energy consumption | Kt SCE | Total consumption of all energy types | China Energy Statistical Yearbook; http://www.ceads.net/data/ | |

| Fixed input | Assets | 100 million RMB yuan | Economic resources that can be measured in monetary terms | China Statistics Yearbook on High Technology Industry |

| Desirable outputs | Patent | Piece | The number of patent applications | China Statistics Yearbook on High Technology Industry |

| Sales revenue | 10,000 RMB yuan | Sales revenue of new products | China Statistics Yearbook on High Technology Industry | |

| Undesirable output | CO2 emissions | Mt | Average GHG emissions | http://www.ceads.net/data/ |

| Year | Statistics | Labor (person) | Energy Consumption (Kt SCE) | Assets (100 million RMB yuan) | Patent (piece) | Sales Revenue (10,000 RMB yuan) | CO2 Emissions (Mt) |

|---|---|---|---|---|---|---|---|

| 2015 | Mean | 482,950.036 | 4077.859 | 3602.437 | 5653.143 | 12,862,903.146 | 11.741 |

| St.Dev. | 814,922.631 | 4498.175 | 5041.029 | 10,165.915 | 23,065,154.275 | 14.191 | |

| Max | 3,890,108.000 | 19,091.098 | 23,396.519 | 50,629.000 | 107,300,765.883 | 58.801 | |

| Min | 11,270.000 | 66.389 | 208.790 | 64.000 | 109,450.827 | 0.258 | |

| Median | 268,610.000 | 2497.846 | 2134.682 | 2400.500 | 5,395,556.571 | 7.184 | |

| 2014 | Mean | 472,663.357 | 4014.042 | 3154.955 | 5951.643 | 12,210,364.046 | 11.515 |

| St.Dev. | 810,213.032 | 4168.320 | 4529.664 | 11,551.278 | 20,957,089.708 | 14.424 | |

| Max | 3,872,690.000 | 17,194.896 | 20,926.831 | 58,119.000 | 95,829,398.941 | 60.281 | |

| Min | 7417.000 | 64.732 | 100.177 | 62.000 | 110,744.925 | 0.229 | |

| Median | 249,207.000 | 2574.036 | 1766.284 | 2112.500 | 4,416,525.596 | 6.335 | |

| 2013 | Mean | 461,610.571 | 3926.611 | 2794.155 | 5104.643 | 10,028,263.489 | 11.895 |

| St.Dev. | 802,099.366 | 4119.565 | 4059.598 | 9757.610 | 18,876,946.751 | 14.821 | |

| Max | 3,803,831.000 | 16,216.372 | 18,447.032 | 49,691.000 | 87,848,688.849 | 61.798 | |

| Min | 6726.000 | 52.269 | 77.158 | 58.000 | 126,353.417 | 0.229 | |

| Median | 224,917.000 | 2474.826 | 1483.138 | 2117.000 | 2,983,875.899 | 5.547 | |

| 2012 | Mean | 452,714.357 | 3340.708 | 2521.541 | 4564.250 | 8,431,725.465 | 11.370 |

| St.Dev. | 811,198.714 | 3701.806 | 3768.429 | 8918.651 | 17,326,078.498 | 14.508 | |

| Max | 3,842,156.000 | 14,221.251 | 17,085.780 | 45,449.000 | 78,666,235.457 | 58.542 | |

| Min | 7161.000 | 47.387 | 72.484 | 39.000 | 94,606.648 | 0.210 | |

| Median | 214,612.000 | 1848.413 | 1271.699 | 1689.000 | 1,959,469.067 | 5.443 | |

| 2011 | Mean | 409,142.536 | 3383.951 | 2189.259 | 3615.071 | 7,596,671.672 | 11.661 |

| St.Dev. | 763,903.207 | 3618.830 | 3453.653 | 7703.026 | 15,231,155.433 | 14.360 | |

| Max | 3,614,903.000 | 13,713.957 | 15,730.398 | 39,338.000 | 69,700,292.614 | 55.918 | |

| Min | 5612.000 | 42.001 | 56.723 | 54.000 | 61,770.833 | 0.199 | |

| Median | 204,627.000 | 2092.588 | 1041.572 | 1333.000 | 2,227,925.663 | 6.044 | |

| 2010 | Mean | 389,591.429 | 3307.680 | 2046.279 | 2130.964 | 5,843,456.393 | 10.604 |

| St.Dev. | 749,772.004 | 3645.856 | 3440.257 | 5089.295 | 12,195,594.898 | 13.348 | |

| Max | 3,547,488.000 | 13,288.428 | 16,273.900 | 26,740.000 | 60,464,340.000 | 50.501 | |

| Min | 6708.000 | 38.750 | 55.700 | 12.000 | 15,401.000 | 0.164 | |

| Median | 185,207.000 | 1961.722 | 900.250 | 691.000 | 1,354,860.500 | 5.815 |

| DMUs | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | Average | |

|---|---|---|---|---|---|---|---|---|

| Value | Rank | |||||||

| Beijing | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Tianjin | 0.050 | 0.002 | 0.000 | 0.000 | 0.000 | 0.062 | 0.019 | 19 |

| Hebei | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Shanxi | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Inner Mongolia | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Liaoning | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.037 | 0.006 | 15 |

| Jilin | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Heilongjiang | 0.000 | 0.000 | 0.000 | 0.000 | 0.243 | 0.049 | 0.049 | 24 |

| Shanghai | 0.060 | 0.000 | 0.000 | 0.002 | 0.083 | 0.040 | 0.031 | 22 |

| Jiangsu | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Zhejiang | 0.442 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.074 | 26 |

| Anhui | 0.425 | 0.145 | 0.017 | 0.056 | 0.186 | 0.039 | 0.145 | 28 |

| Fujian | 0.000 | 0.000 | 0.000 | 0.044 | 0.019 | 0.051 | 0.019 | 21 |

| Jiangxi | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Shandong | 0.000 | 0.000 | 0.000 | 0.033 | 0.159 | 0.124 | 0.053 | 25 |

| Henan | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Hubei | 0.000 | 0.000 | 0.000 | 0.029 | 0.000 | 0.049 | 0.013 | 18 |

| Hunan | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Guangdong | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Guangxi | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Hainan | 0.599 | 0.000 | 0.000 | 0.022 | 0.000 | 0.000 | 0.104 | 27 |

| Chongqing | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Sichuan | 0.000 | 0.000 | 0.000 | 0.000 | 0.076 | 0.038 | 0.019 | 20 |

| Guizhou | 0.000 | 0.005 | 0.005 | 0.000 | 0.000 | 0.055 | 0.011 | 16 |

| Yunnan | 0.018 | 0.009 | 0.050 | 0.000 | 0.000 | 0.000 | 0.013 | 17 |

| Shaanxi | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Gansu | 0.110 | 0.016 | 0.039 | 0.005 | 0.000 | 0.053 | 0.037 | 23 |

| Ningxia | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 1 |

| Eastern region | 0.115 | 0.000 | 0.000 | 0.010 | 0.026 | 0.028 | 0.030 | - |

| Middle region | 0.071 | 0.024 | 0.003 | 0.014 | 0.031 | 0.015 | 0.026 | - |

| Western region | 0.014 | 0.003 | 0.010 | 0.001 | 0.008 | 0.016 | 0.009 | - |

| Northeastern region | 0.000 | 0.000 | 0.000 | 0.000 | 0.081 | 0.029 | 0.018 | - |

| Average | 0.061 | 0.006 | 0.004 | 0.007 | 0.027 | 0.021 | 0.021 | - |

| Year | Average | Average | Average CU |

|---|---|---|---|

| 2010 | 0.448 | 0.508 | 0.061 |

| 2011 | 0.447 | 0.453 | 0.006 |

| 2012 | 0.459 | 0.463 | 0.004 |

| 2013 | 0.415 | 0.422 | 0.007 |

| 2014 | 0.363 | 0.391 | 0.027 |

| 2015 | 0.345 | 0.366 | 0.021 |

| Average | 0.413 | 0.434 | 0.021 |

| Year | ||||

|---|---|---|---|---|

| 2010 | 10,908,560.000 | 10,225,762.079 | 92,615.034 | 52,833.226 |

| 2011 | 11,455,991.000 | 10,386,412.015 | 94,750.627 | 64,537.784 |

| 2012 | 12,676,002.000 | 11,306,516.038 | 93,539.811 | 65,652.029 |

| 2013 | 12,925,096.000 | 12,624,306.251 | 109,945.099 | 71,073.112 |

| 2014 | 13,234,574.000 | 12,883,696.261 | 112,393.171 | 73,368.365 |

| 2015 | 13,522,601.000 | 14,204,768.163 | 114,180.041 | 77,408.230 |

| Year | ||

|---|---|---|

| 2010 | 0.079 * | 0.001 *** |

| 2011 | 0.003 *** | 0.013 ** |

| 2012 | 0.002 *** | 0.003 *** |

| 2013 | 0.334 | 0.016 ** |

| 2014 | 0.616 | 0.001 *** |

| 2015 | 0.334 | 0.002 *** |

| Anhui | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 |

|---|---|---|---|---|---|---|

| 189,879.648 | 252,315.153 | 261,694.649 | 296,279.782 | 398,366.905 | 487,423.505 | |

| 958.370 | 1858.608 | 1328.680 | 1427.159 | 1292.159 | 2098.346 | |

| 1.297 | 1.684 | 1.397 | 1.444 | 1.580 | 1.826 | |

| 0.4960 | 0.912 | 0.786 | 0.715 | 0.612 | 0.901 | |

| 146,412.000 | 149,818.000 | 187,326.000 | 205,182.000 | 252,133.000 | 266,994.000 | |

| 1932.689 | 2037.722 | 1689.883 | 1994.827 | 2110.712 | 2329.205 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Pan, J.; Pei, R.; Yang, G.; Yi, B. A Framework for Assessing Green Capacity Utilization Considering CO2 Emissions in China’s High-Tech Manufacturing Industry. Sustainability 2020, 12, 4424. https://doi.org/10.3390/su12114424

Wang Y, Pan J, Pei R, Yang G, Yi B. A Framework for Assessing Green Capacity Utilization Considering CO2 Emissions in China’s High-Tech Manufacturing Industry. Sustainability. 2020; 12(11):4424. https://doi.org/10.3390/su12114424

Chicago/Turabian StyleWang, Ya, Jiaofeng Pan, Ruimin Pei, Guoliang Yang, and Bowen Yi. 2020. "A Framework for Assessing Green Capacity Utilization Considering CO2 Emissions in China’s High-Tech Manufacturing Industry" Sustainability 12, no. 11: 4424. https://doi.org/10.3390/su12114424