The Impact of Fractional Composition on the Mechanical Properties of Agglomerated Logging Residues

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

Methodology for Preparing Biomass Mixtures

2.2. Material Moisture Content

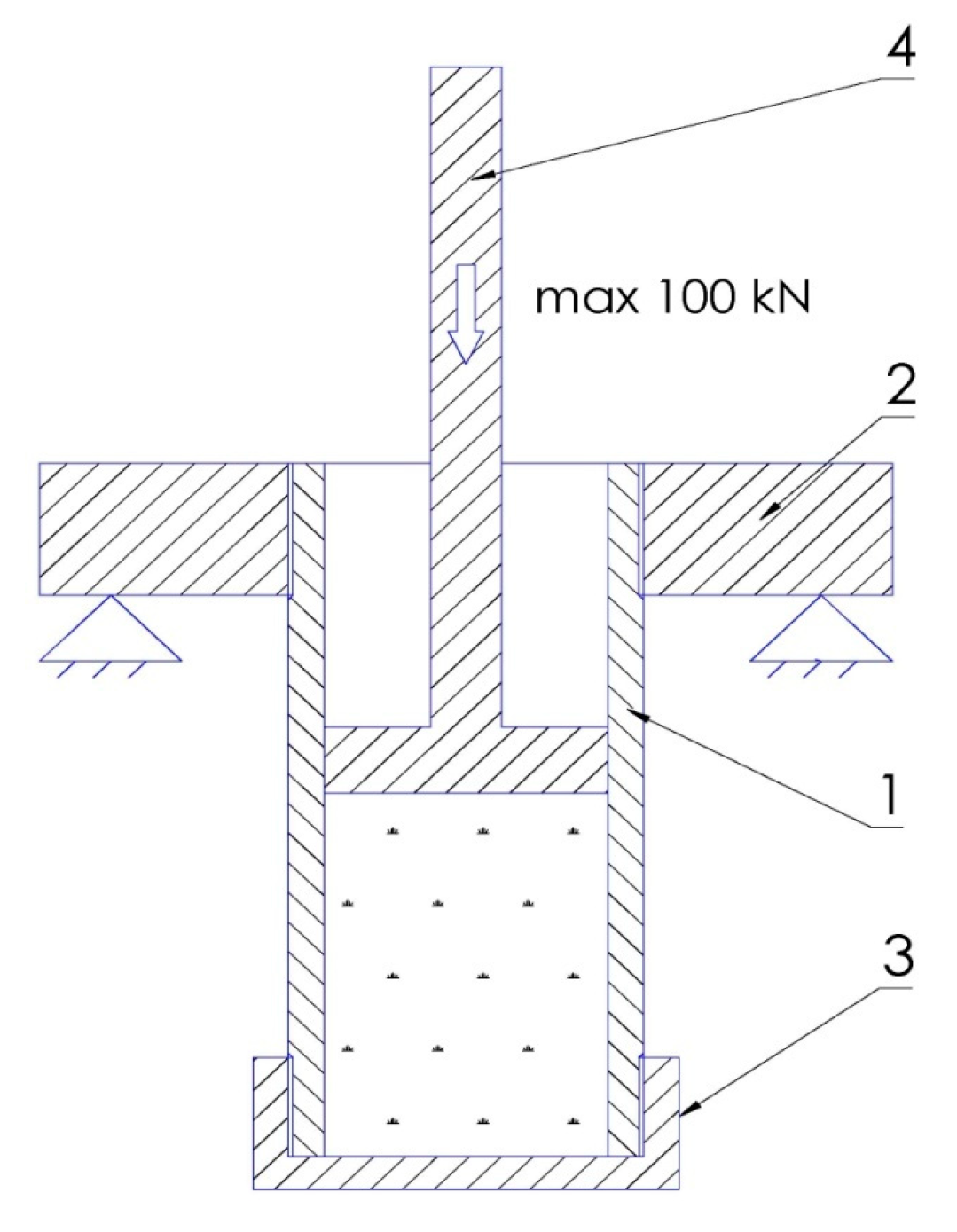

2.3. The Agglomeration Process

2.4. The Density of the Briquettes

2.5. Specific Work of Compaction

2.6. Durability of Briquettes and Biomass Susceptibility to Compaction

2.7. Statistical Analysis

3. Results

3.1. The Effects of the Temperature and Fractional Composition of Compacted Biomass on the Density of Briquettes and Specific Work of Compaction

3.2. The Effects of the Temperature and Fractional Composition of Compacted Biomass on the Susceptibility to Compaction and Durability of Briquettes

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Davis, S.J.; Caldeira, K. Consumption-based accounting of CO2 emissions. Proc. Natl. Acad. Sci. USA 2010, 107, 5687–5692. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Veum, K.; Bauknecht, D. How to reach the EU renewables target by 2030? An analysis of the governance framework. Energy Policy 2019, 127, 299–307. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Wasiak, A.; Botwińska, K.; Gola, A. Simulation of the Operation of a Spark Ignition Engine Fueled with Various Biofuels and Its Contribution to Technology Management. Sustainability 2019, 11, 2799. [Google Scholar] [CrossRef] [Green Version]

- Jacobson, M.Z. Review of solutions to global warming, air pollution, and energy security. Energy Environ. Sci. 2009, 2, 148–173. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Wasiak, A.; Świć, A. Thermodynamic Fundamentals for Fuel Production Management. Sustainability 2019, 11, 4449. [Google Scholar] [CrossRef] [Green Version]

- Abbas, D.; Current, D.; Phillips, M.; Rossman, R.; Hoganson, H.; Brooks, K.N. Guidelines for harvesting forest biomass for energy: A synthesis of environmental considerations. Biomass Bioenergy 2011, 35, 4538–4546. [Google Scholar] [CrossRef]

- Aherne, J.; Posch, M.; Forsius, M.; Lehtonen, A.; Härkönen, K. Impacts of forest biomass removal on soil nutrient status under climate change: A catchment-based modelling study for Finland. Biogeochemistry 2012, 107, 471–488. [Google Scholar] [CrossRef]

- Eggers, J.; Melin, Y.; Lundström, J.; Bergström, D.; Öhman, K. Management Strategies for Wood Fuel Harvesting—Trade-Offs with Biodiversity and Forest Ecosystem Services. Sustainability 2020, 12, 4089. [Google Scholar] [CrossRef]

- Yazan, D.M.; van Duren, I.; Mes, M.; Kersten, S.; Clancy, J.; Zijm, H. Design of sustainable second-generation biomass supply chains. Biomass Bioenergy 2016, 94, 173–186. [Google Scholar] [CrossRef] [Green Version]

- Koirala, A.; Kizha, A.R.; De Hoop, C.F.; Roth, B.E.; Han, H.-S.; Hiesl, P.; Abbas, D.; Gautam, S.; Baral, S.; Bick, S.; et al. Annotated Bibliography of the Global Literature on the Secondary Transportation of Raw and Comminuted Forest Products (2000–2015). Forests 2018, 9, 415. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, K.; Bilek, E.; Bergman, R.; Mani, S. Techno-economic analysis of producing solid biofuels and biochar from forest residues using portable systems. Appl. Energy 2019, 235, 578–590. [Google Scholar] [CrossRef]

- Moskalik, T.; Sadowski, J.; Zastocki, D. Some technological and economic aspects of logging residues bundling. Sylwan 2016, 160, 31–39. [Google Scholar]

- Moskalik, T.; Sadowski, J.; Sarzyński, W.; Zastocki, D. Efficiency of slash bundling in mature coniferous stands. Sci. Res. Essays 2013, 8, 1478–1486. [Google Scholar] [CrossRef]

- Moskalik, T.; Gendek, A. Production of Chips from Logging Residues and Their Quality for Energy: A Review of European Literature. Forests 2019, 10, 262. [Google Scholar] [CrossRef] [Green Version]

- Hakkila, P.; Parikka, M. Fuel resources from the forest. In Bioenergy from Sustainable Forestry: Guiding Principles and Practice; Richardson, J., Björheden, R., Hakkila, P., Lowe, A.T., Smith, C.T., Eds.; Springer: Dordrecht, The Netherlands, 2002; pp. 19–48. [Google Scholar] [CrossRef]

- Gendek, A.; Malaťák, J.; Velebil, J. Effect of harvest method and composition of wood chips on their caloric value and ash content. Sylwan 2018, 162, 248–257. [Google Scholar]

- Asikainen, A.; Pulkkinen, P. Comminution of Logging Residues with Evolution 910R chipper, MOHA chipper truck, and Morbark 1200 tub grinder. Int. J. For. Eng. 1998, 9, 47–53. [Google Scholar]

- Spinelli, R.; Hartsough, B.R.; Magagnotti, N. Testing Mobile Chippers for Chip Size Distribution. Int. J. For. Eng. 2005, 16, 29–36. [Google Scholar] [CrossRef]

- Nati, C.; Spinelli, R.; Fabbri, P. Wood chips size distribution in relation to blade wear and screen use. Biomass Bioenergy 2010, 34, 583–587. [Google Scholar] [CrossRef]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 2005, 544, 191–198. [Google Scholar] [CrossRef]

- Barontini, M.; Scarfone, A.; Spinelli, R.; Gallucci, F.; Santangelo, E.; Acampora, A.; Jirjis, R.; Civitarese, V.; Pari, L. Storage dynamics and fuel quality of poplar chips. Biomass Bioenergy 2014, 62, 17–25. [Google Scholar] [CrossRef]

- Gendek, A.; Nawrocka, A. Effect of chipper knives sharpening on the forest chips quality. Ann. Wars. Univ. Life Sci.-SGGW Agric. 2014, 64, 97–107. [Google Scholar]

- Lisowski, A.; Świętochowski, A. Mechanical durability of pellets and briquettes made from a miscanthus mixture without and with the separation of long particles. Pol. Soc. Agric. Eng. 2014, 1, 93–100. [Google Scholar]

- Ishii, K.; Furuichi, T. Influence of moisture content, particle size and forming temperature on productivity and quality of rice straw pellets. Waste Manag. 2014, 34, 2621–2626. [Google Scholar] [CrossRef] [PubMed]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Križan, P.; Šooš, L.; Vukelič, D. A study of impact technological parametres on the briquetting process. Work. Living Environ. Prot. 2009, 6, 39–47. [Google Scholar]

- Lee, S.H.; Lee, M.; Yoon, W.J.; Kim, Y. Frost growth characteristics of spirally-coiled circular fin-tube heat exchangers under frosting conditions. Int. J. Heat Mass Transf. 2013, 64, 1–9. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef] [Green Version]

- Gürdil, G.A.K.; Demirel, B. Effect of Particle Size on Surface Smoothness of Bio-Briquettes Produced from Agricultural Residues. Manuf. Technol. 2018, 18, 742–747. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Strategies to improve durability of switchgrass briquettes. Trans. ASABE 2009, 52, 1943–1953. [Google Scholar] [CrossRef]

- Taulbee, D.; Patil, D.P.; Honaker, R.Q.; Parekh, B.K. Briquetting of Coal Fines and Sawdust Part I: Binder and Briquetting-Parameters Evaluations. Int. J. Coal Prep. Util. 2009, 29, 1–22. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.; Kenney, K.; Hess, R. A technical review on biomass processing: Densification, preprocessing, modeling and optimization. In Proceedings of the American Society of Agricultural and Biological Engineers Annual International Meeting 2010 (ASABE 2010), Pittsburgh, PA, USA, 20–23 June 2010; Volume 6, pp. 20–23. [Google Scholar]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Lisowski, A.; Dąbrowska-Salwin, M.; Ostrowska-Ligęza, E.; Nawrocka, A.; Stasiak, M.; Świętochowski, A.; Klonowski, J.; Sypuła, M.; Lisowska, B. Effects of the biomass moisture content and pelleting temperature on the pressure-induced agglomeration process. Biomass Bioenergy 2017, 107, 376–383. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K. Forest Residues as a Renewable Source of Energy: Elemental Composition and Physical Properties. BioResources 2019, 14, 6–20. [Google Scholar] [CrossRef]

- Nurek, T.; Gendek, A.; Roman, K.; Dąbrowska, M. The effect of temperature and moisture on the chosen parameters of briquettes made of shredded logging residues. Biomass Bioenergy 2019, 130, 105368. [Google Scholar] [CrossRef]

- International Organization for Standardization. Solid Biofuels—Determination of Particle Size Distribution for Uncompressed Fuels—Part 1: Oscillating Screen Method Using Sieves with Apertures of 3,15 mm and Above; ISO 17827-1:2016; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- International Organization for Standardization. Solid Biofuels—Determination of Particle Size Distribution for Uncompressed Fuels—Part 2: Vibrating Screen Method Using Sieves with Aperture of 3,15 mm and Below; ISO 17827-2:2016; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- Wang, Y.; Wu, K.; Sun, Y. Effects of raw material particle size on the briquetting process of rice straw. J. Energy Inst. 2018, 91, 153–162. [Google Scholar] [CrossRef]

- European Committee for Standardization. Moisture Content of a Piece of Sawn Timber—Part 1: Determination by Oven Dry Method; EN 13183-1:2004; European Committee for Standardization: Brussels, Belgium, 2004. [Google Scholar]

- Hejft, R. Manufacturing of briquettes from plant waste in a worm tool-in-use system. Inż. Rol. 2006, 5, 231–238. [Google Scholar]

- Kers, J.; Kulu, P.; Aruniit, A.; Laurmaa, V.; Križan, P.; Šooš, L.; Kask, Ü. Determination of physical, mechanical and burning characteristics of polymeric waste material briquettes. Est. J. Eng. 2010, 16, 307–316. [Google Scholar] [CrossRef] [Green Version]

- Frączek, J.; Mudryk, K.; Wróbel, M. Energy expenditures in the process involving Salix viminalis L. Willow briquetting. Inż. Rol. 2010, 3, 45–52. [Google Scholar]

- Sergeev, P.V.; Beletskiy, V.S. Briquetting the carbon phase from the sludge ponds at the Anzhersk deposit. Coke Chem. 2013, 56, 282–285. [Google Scholar] [CrossRef]

- Kulig, R.; Skonecki, S.; Gawłowski, S.; Zdybel, A.; Łysiak, G. The effect of pressure on efficiency of chosen soft wood sawdust. Acta Sci. Pol. Tech. Agrar. 2013, 12, 31–40. [Google Scholar]

- Laskowski, J.; Skonecki, S. Effect of chamber parameters and material weight on densification of lupine seeds. Inż. Rol. 2005, 9, 101–108. [Google Scholar]

- Polish Committee for Standardization. Solid Biofuels—Methods for the Determination of Mechanical Durability of Pellets and Briquettes—Part 2: Briquettes; EN-ISO 17831-2:2016-02; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- Hebda, T.; Złobecki, A. Influence of straw moisture on kinetics durability of briquettes. Inż. Rol. 2011, 6, 45–52. [Google Scholar]

- Temmerman, M.; Rabier, F.; Daugbjerg Jensen, P.; Hartmann, H.; Böhm, T. Comparative study of durability test methods for pellets and briquettes. Biomass Bioenergy 2006, 30, 964–972. [Google Scholar] [CrossRef]

- Dell Inc. Dell Statistica (Data Analysis Software System); Version 13; Dell Inc.: Round Rock, TX, USA, 2016; Available online: software.dell.com (accessed on 19 June 2019).

- International Organization for Standardization. Solid Biofuels—Fuel Specifications and Classes—Part 3: Graded Wood Briquettes; ISO 17225-3:2014; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Chen, W.-H.; Kuo, P.-C. A study on torrefaction of various biomass materials and its impact on lignocellulosic structure simulated by a thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Kaur, A.; Roy, M.; Kundu, K. Densification of biomass by briquetting: A review. Int. J. Recent Sci. Res. 2017, 8, 20561–20568. [Google Scholar] [CrossRef]

- Gendek, A.; Aniszewska, M.; Malaťák, J.; Velebil, J. Evaluation of selected physical and mechanical properties of briquettes produced from cones of three coniferous tree species. Biomass Bioenergy 2018, 117, 173–179. [Google Scholar] [CrossRef]

- Niedziółka, I.; Szymanek, M.; Zuchniarz, A. Durability evaluation for briquettes made of fodder corn phytomass. Inż. Rol. 2008, 9, 235–240. [Google Scholar]

- Niedziółka, I.; Szpryngiel, M.; Kraszkiewicz, A.; Kachel-Jakubowska, M. Assessments of briquetting efficiency and briquettes quality produced out of selected plant raw materials. Inż. Rol. 2011, 6, 149–155. [Google Scholar]

- Fiszer, A. Influence of straw humidity and temperature of briquetting processon the quality of agglomerate. J. Res. Appl. Agric. Eng. 2009, 54, 68–70. [Google Scholar]

- Borkowski, Ł.; Gendek, A. Określenie trwałości brykietów wytworzonych z materiału pochodzenia rolniczego i leśnego (Determining the durability of briquettes produced from agricultural and forest materials). In Proceedings of the XXI Międzynarodowa Konferencja Naukowa Studentów: Współczesne Aspekty inżynierii Produkcji, Warszawa, Poland, 23 May 2012; pp. 19–26. [Google Scholar]

- Mudryk, K. Quality assessment for briquettes made of biomass from maple [Acer negundo L.] and black locust [Robinia pseudoacacia L.]. Agric. Eng. 2011, 7, 115–121. [Google Scholar]

- Ndindeng, S.A.; Mbassi, J.E.G.; Mbacham, W.F.; Manful, J.; Graham-Acquaah, S.; Moreira, J.; Dossou, J.; Futakuchi, K. Quality optimization in briquettes made from rice milling by-products. Energy Sustain. Dev. 2015, 29, 24–31. [Google Scholar] [CrossRef]

- Chou, C.-S.; Lin, S.-H.; Peng, C.-C.; Lu, W.-C. The optimum conditions for preparing solid fuel briquette of rice straw by a piston-mold process using the Taguchi method. Fuel Process. Technol. 2009, 90, 1041–1046. [Google Scholar] [CrossRef]

- Ryu, C.; Yang, Y.B.; Khor, A.; Yates, N.E.; Sharifi, V.N.; Swithenbank, J. Effect of fuel properties on biomass combustion: Part I. Experiments—Fuel type, equivalence ratio and particle size. Fuel 2006, 85, 1039–1046. [Google Scholar] [CrossRef]

- Lisowski, A.; Pajor, M.; Świętochowski, A.; Dąbrowska, M.; Klonowski, J.; Mieszkalski, L.; Ekielski, A.; Stasiak, M.; Piątek, M. Effects of moisture content, temperature, and die thickness on the compaction process, and the density and strength of walnut shell pellets. Renew. Energy 2019, 141, 770–781. [Google Scholar] [CrossRef]

| No | Fraction Share (), % | Series Symbol | |||

|---|---|---|---|---|---|

| f1 (0 ÷ 1 mm) | f1 (1 ÷ 4 mm) | f1 (4 ÷ 8 mm) | f1 (8 ÷ 16 mm) | ||

| 1. | 100 | 0 | 0 | 0 | A1 |

| 2. | 0 | 100 | 0 | 0 | A2 |

| 3. | 0 | 0 | 100 | 0 | A3 |

| 4. | 0 | 0 | 0 | 100 | A4 |

| 5. | 50 | 25 | 25 | 0 | B |

| 6. | 75 | 0 | 0 | 25 | C |

| 7. | 75 | 0 | 25 | 0 | D |

| 8. | 75 | 25 | 0 | 0 | E |

| df | SS | MS | F | p-Value | |

|---|---|---|---|---|---|

| Briquette density | |||||

| MIX (A) | 3 | 0.63 | 0.21 | 31.95 | <0.0001 |

| Temperature (B) | 1 | 0.02 | 0.02 | 3.01 | 0.0867 |

| Interaction (A × B) | 10 | 0.06 | 0.01 | 0.94 | 0.5055 |

| Error | 80 | 0.53 | 0.01 | ||

| Specific work of compaction Lc | |||||

| MIX (A) | 3 | 870.46 | 290.15 | 210.95 | <0.0001 |

| Temperature (B) | 1 | 0.36 | 0.36 | 0.26 | 0.6120 |

| Interaction (A × B) | 10 | 158.92 | 15.89 | 11.55 | <0.0001 |

| Error | 80 | 110.04 | 1.38 | ||

| Susceptibility to compaction index kc | |||||

| MIX (A) | 3 | 2897.95 | 965.98 | 105.94 | <0.0001 |

| Temperature (B) | 1 | 36.30 | 36.30 | 3.98 | 0.0494 |

| Interaction (A × B) | 10 | 527.70 | 52.77 | 5.79 | 0.0002 |

| Error | 80 | 729.48 | 9.12 | ||

| Durability coefficient Ψ | |||||

| MIX (A) | 3 | 0.14 | 0.05 | 14.28 | 0.0004 |

| Temperature (B) | 1 | 0.06 | 0.06 | 18.74 | 0.0001 |

| Interaction (A × B) | 3 | 0.20 | 0.07 | 20.58 | <0.0001 |

| Error | 32 | 0.11 | 0.003 | ||

| Series Symbol | Temp. | Briquettes Density | Specific Work of Compaction |

|---|---|---|---|

| °C | kg·m−3 | J·g−1 | |

| A1 | 22 | 1.04 ± 0.11 | 15.52 ± 0.82 |

| 73 | 1.10 ± 0.12 | 11.61 ± 0.74 | |

| 103 | 1.11 ± 0.07 | 12.38 ± 0.66 | |

| A2 | 22 | 0.98 ± 0.05 | 17.15 ± 1.25 |

| 73 | 1.04 ± 0.09 | 11.72 ± 0.97 | |

| 103 | 1.05 ± 0.08 | 15.80 ± 1.38 | |

| A3 | 22 | 0.84 ± 0.09 | 15.97 ± 1.19 |

| 73 | 1.01 ± 0.08 | 14.17 ± 1.72 | |

| 103 | 1.04 ± 0.08 | 13.90 ± 1.27 | |

| A4 | 22 | 0.77 ± 0.08 | 28.26 ± 1.38 |

| 73 | 0.80 ± 0.07 | 20.39 ± 1.75 | |

| 103 | 0.86 ± 0.06 | 20.06 ± 2.30 | |

| B | 73 | 1.06 ± 0.03 | 29.40 ± 0.72 |

| 103 | 1.14 ± 0.06 | 34.25 ± 0.53 | |

| C | 73 | 0.90 ± 0.07 | 31.83 ± 0.91 |

| 103 | 0.96 ± 0.09 | 33.62 ± 0.83 | |

| D | 73 | 1.02 ± 0.08 | 29.83 ± 0.84 |

| 103 | 1.06 ± 0.10 | 34.13 ± 0.94 | |

| E | 73 | 1.14 ± 0.09 | 28.14 ± 0.78 |

| 103 | 1.11 ± 0.06 | 34.55 ± 0.79 |

| Series Symbol | Temp. | Susceptibility to Compaction Index | Durability Coefficient |

|---|---|---|---|

| °C | (J·g−1)/(g·cm−3) | % | |

| A1 | 22 | 18.82 ± 1.86 | 0.0 |

| 73 | 13.20 ± 2.20 | 0.0 | |

| 103 | 13.92 ± 1.78 | 0.0 | |

| A2 | 22 | 20.49 ± 1.65 | 0.0 |

| 73 | 13.11 ± 0.83 | 0.0 | |

| 103 | 17.63 ± 2.40 | 0.0 | |

| A3 | 22 | 22.54 ± 4.01 | 0.0 |

| 73 | 15.92 ± 2.15 | 0.0 | |

| 103 | 15.22 ± 1.31 | 0.0 | |

| A4 | 22 | 42.40 ± 4.57 | 0.0 |

| 73 | 29.26 ± 4.72 | 0.0 | |

| 103 | 26.34 ± 2.59 | 0.0 | |

| B | 73 | 26.93 ± 0.97 | 68.1 ± 6.2 |

| 103 | 24.17 ± 1.93 | 72.5 ± 3.0 | |

| C | 73 | 39.62 ± 6.22 | 42.0 ± 2.9 |

| 103 | 30.12 ± 3.36 | 67.4 ± 5.2 | |

| D | 73 | 29.83 ± 3.27 | 64.2 ± 5.9 |

| 103 | 26.84 ± 2.70 | 50.9 ± 5.3 | |

| E | 73 | 23.58 ± 2.79 | 51.1 ± 1.0 |

| 103 | 26.44 ± 3.02 | 66.1 ± 2.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nurek, T.; Gendek, A.; Roman, K.; Dąbrowska, M. The Impact of Fractional Composition on the Mechanical Properties of Agglomerated Logging Residues. Sustainability 2020, 12, 6120. https://doi.org/10.3390/su12156120

Nurek T, Gendek A, Roman K, Dąbrowska M. The Impact of Fractional Composition on the Mechanical Properties of Agglomerated Logging Residues. Sustainability. 2020; 12(15):6120. https://doi.org/10.3390/su12156120

Chicago/Turabian StyleNurek, Tomasz, Arkadiusz Gendek, Kamil Roman, and Magdalena Dąbrowska. 2020. "The Impact of Fractional Composition on the Mechanical Properties of Agglomerated Logging Residues" Sustainability 12, no. 15: 6120. https://doi.org/10.3390/su12156120

APA StyleNurek, T., Gendek, A., Roman, K., & Dąbrowska, M. (2020). The Impact of Fractional Composition on the Mechanical Properties of Agglomerated Logging Residues. Sustainability, 12(15), 6120. https://doi.org/10.3390/su12156120