Leveraging Digital Approaches for Transparency in Sustainable Supply Chains: A Conceptual Paper

Abstract

1. Introduction

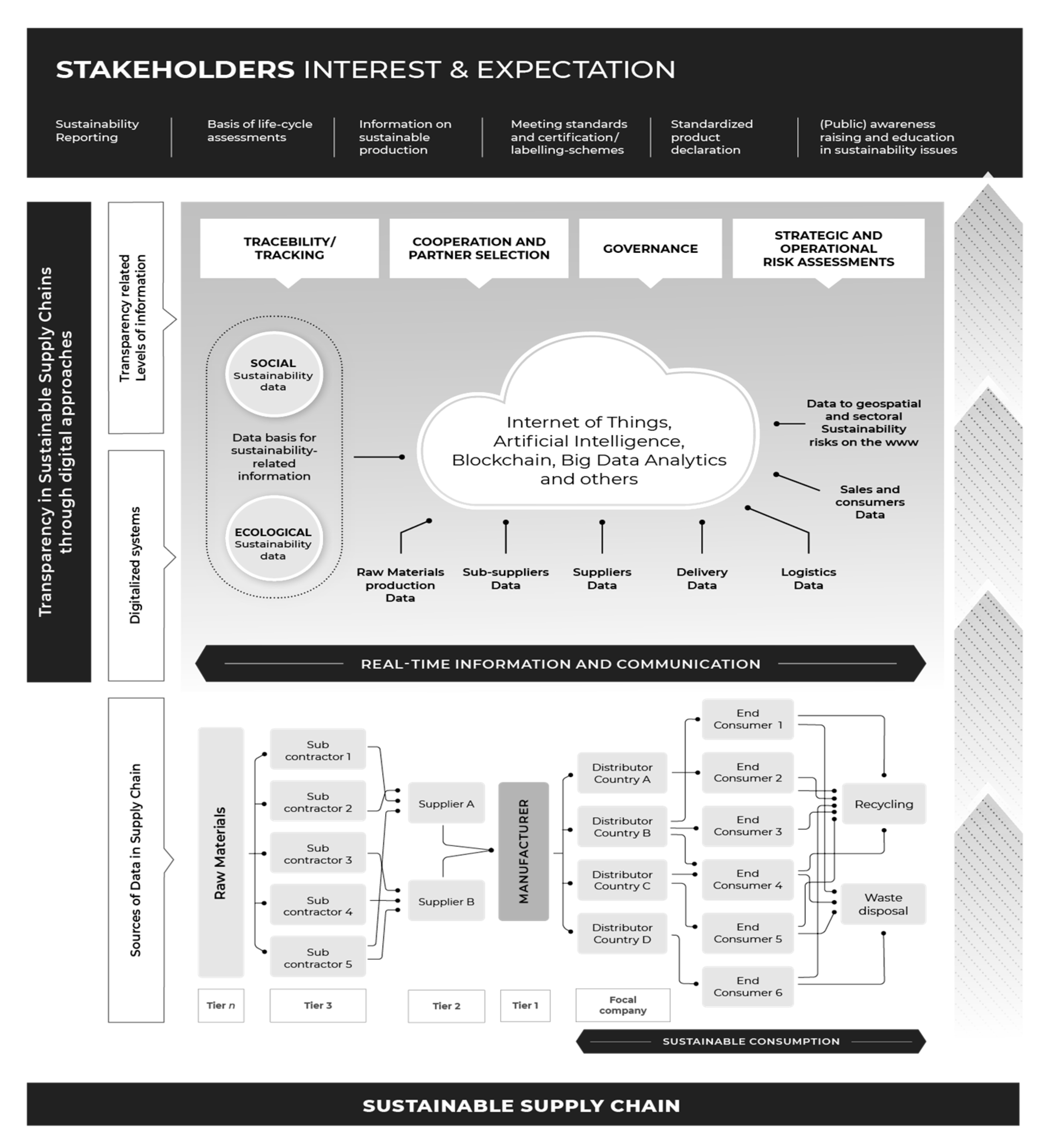

2. Dimension and Challenges of SSCT

2.1. Overview of SSCM

2.2. Transparency in Sustainable Supply Chains

2.2.1. The Concept of Transparency

2.2.2. Transparency Information Dimensions

2.2.3. Challenges to Transparency in SCs

3. Digital Approaches and SSCT

3.1. Digital Approaches in SSCM

3.2. Discussion of Incorporating Digital Approaches into Dimensions of SCT

3.2.1. Traceability/Tracking

3.2.2. Cooperation and Partner Selection

3.2.3. Control (Governance)

3.2.4. Strategic and Operational Risk Assessments

4. Conclusion and Contribution

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yawar, S.A.; Seuring, S. Management of Social Issues in Supply Chains: A Literature Review Exploring Social Issues, Actions and Performance Outcomes. J. Bus. Ethics 2015, 141, 621–643. [Google Scholar] [CrossRef]

- Campos, P.F.; Trucco, P.; Huatuco, L.H. Managing structural and dynamic complexity in supply chains: Insights from four case studies. Prod. Plan. Control. 2019, 30, 611–623. [Google Scholar] [CrossRef]

- Schmeisser, B. A Systematic Review of Literature on Offshoring of Value Chain Activities. J. Int. Manag. 2013, 19, 390–406. [Google Scholar] [CrossRef]

- Egels-Zandén, N.; Hulthen, K.; Wulff, G. Trade-offs in supply chain transparency: The case of Nudie Jeans Co. J. Clean. Prod. 2015, 107, 95–104. [Google Scholar] [CrossRef]

- Khalid, R.U.; Seuring, S. Analyzing Base-of-the-Pyramid Research from a (Sustainable) Supply Chain Perspective. J. Bus. Ethics 2017, 155, 663–686. [Google Scholar] [CrossRef]

- Heuer, M.A.; Khalid, U.; Seuring, S. Bottoms up: Delivering sustainable value in the base of the pyramid. Bus. Strat. Environ. 2020, 29, 1605–1616. [Google Scholar] [CrossRef]

- Boström, M.; Jönsson, A.M.; Lockie, S.; Mol, A.P.; Oosterveer, P. Sustainable and responsible supply chain governance: Challenges and opportunities. J. Clean. Prod. 2015, 107, 1–7. [Google Scholar] [CrossRef]

- Sauer, P.; Seuring, S. Extending the reach of multi-tier sustainable supply chain management—Insights from mineral supply chains. Int. J. Prod. Econ. 2019, 217, 31–43. [Google Scholar] [CrossRef]

- Ebinger, F.; Goldbach, M.; Schneidewind, U. Greening supply chains: A competence-based perspective. In Greening the Supply Chain; Springer: London, UK, 2006; pp. 251–269. [Google Scholar]

- Busse, C.; Schleper, M.C.; Niu, M.; Wagner, S.M. Supplier development for sustainability: Contextual barriers in global supply chains. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 442–468. [Google Scholar] [CrossRef]

- Hofmann, H.; Busse, C.; Bode, C.; Henke, M. Sustainability-Related Supply Chain Risks: Conceptualization and Management. Bus. Strat. Environ. 2013, 23, 160–172. [Google Scholar] [CrossRef]

- Sustainabill. Supply Chain Insights for Sustainable Business. 2020. Available online: https://www.sustainabill.de (accessed on 15 April 2020).

- Sustainable Outdoor Clothing Gear: VAUDE. 2020. Available online: https://www.vaude.com/en-INT/ (accessed on 15 June 2020).

- Bastian, J.; Zentes, J. Supply chain transparency as a key prerequisite for sustainable agri-food supply chain management. Int. Rev. Retail. Distrib. Consum. Res. 2013, 23, 553–570. [Google Scholar] [CrossRef]

- Singh, A.; Mishra, N.; Ali, S.I.; Shukla, N.; Shankar, R. Cloud computing technology: Reducing carbon footprint in beef supply chain. Int. J. Prod. Econ. 2015, 164, 462–471. [Google Scholar] [CrossRef]

- Hannibal, C.; Kauppi, K. Third party social sustainability assessment: Is it a multi-tier supply chain solution? Int. J. Prod. Econ. 2019, 217, 78–87. [Google Scholar] [CrossRef]

- Gold, S.; Heikkurinen, P.P. Transparency fallacy: Unintended consequences of stakeholder claims on responsibility in supply chains. Account. Audit. Account. J. 2018, 31, 318–337. [Google Scholar] [CrossRef]

- Frentrup, M.; Theuvsen, L. Transparency in supply chains: Is trust a limiting factor? In Trust and Risk in Business Networks: Proceedings of the 99th Seminar of the European Association of Agricultural Economists (EAAE), Bonn, Germany, 8–10 February 2006; Univ. ILB: Bonn, Germany, 2009. [Google Scholar]

- Garcia-Torres, S.; Albareda, L.; Rey-Garcia, M.; Seuring, S. Traceability for sustainability—Literature review and conceptual framework. Supply Chain Manag. Int. J. 2019, 24, 85–106. [Google Scholar] [CrossRef]

- Espiñeira, M.; Santaclara, F.J. (Eds.) Advances in Food Traceability Techniques and Technologies: Improving Quality throughout the Food Chain; Woodhead Publishing: Amsterdam, Netherlands, 2016. [Google Scholar]

- Behnke, K.; Janssen, M. Boundary conditions for traceability in food supply chains using blockchain technology. Int. J. Inf. Manag. 2020, 52, 101969. [Google Scholar] [CrossRef]

- Astill, J.; Dara, R.A.; Campbell, M.; Farber, J.M.; Fraser, E.D.; Sharif, S.; Yada, R.Y. Transparency in food supply chains: A review of enabling technology solutions. Trends Food Sci. Technol. 2019, 91, 240–247. [Google Scholar] [CrossRef]

- Ahmed, W.; Omar, M. Drivers of supply chain transparency and its effects on performance measures in the automotive industry: Case of a developing country. Int. J. Serv. Oper. Manag. 2019, 33, 159–186. [Google Scholar]

- Mol, A.P. The Future of Transparency: Power, Pitfalls and Promises. Glob. Environ. Politics 2010, 10, 132–143. [Google Scholar] [CrossRef]

- Valentinov, V.; Verschraegen, G.; Van Assche, K. The limits of transparency: A systems theory view. Syst. Res. Behav. Sci. 2019, 36, 289–300. [Google Scholar] [CrossRef]

- Krause, R. The Promotion of Labour Standards Through International Framework Agreements. In Labour Standards in International Economic Law; Springer: Cham, Switzerland, 2018; pp. 319–339. [Google Scholar]

- Montecchi, M.; Plangger, K.; Etter, M. It’s real, trust me! Establishing supply chain provenance using blockchain. Bus. Horiz. 2019, 62, 283–293. [Google Scholar] [CrossRef]

- Hosseini, M.; Shahri, A.; Phalp, K.; Ali, R. Four reference models for transparency requirements in information systems. Requir. Eng. 2017, 23, 251–275. [Google Scholar] [CrossRef]

- Grzybowska, K. Sustainable Logistics and Production in Industry 4.0: New Opportunities and Challenges; Springer Nature: Cham, Switzerland, 2020. [Google Scholar]

- Müller, M.; Gaudig, S. An empirical investigation of antecedents to information exchange in supply chains. Int. J. Prod. Res. 2011, 49, 1531–1555. [Google Scholar] [CrossRef][Green Version]

- Adiputra, I.M.P.; Utama, S.; Rossieta, H. Transparency of local government in Indonesia. Asian J. Account. Res. 2018, 3, 123–138. [Google Scholar] [CrossRef]

- Lotfi, Z.; Mukhtar, M.; Sahran, S.; Taeizadeh, A. Information Sharing in Supply Chain Management. Procedia Technol. 2013, 11, 298–304. [Google Scholar] [CrossRef]

- Gurzawska, A. Towards Responsible and Sustainable Supply Chains—Innovation, Multi-stakeholder Approach and Governance. Philos. Manag. 2019, 1–29. [Google Scholar] [CrossRef]

- Zhu, S.; Song, J.; Hazen, B.T.; Lee, K.; Cegielski, C. How supply chain analytics enables operational supply chain transparency. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 47–68. [Google Scholar] [CrossRef]

- Kaitharath, T.J. New Paradigm of CSR for the Global Economy. J. Manag. Res. Anal. 2015, 2, 231–237. [Google Scholar]

- Agan, Y.; Kuzey, C.; Acar, M.F.; Açıkgöz, A. The relationships between corporate social responsibility, environmental supplier development, and firm performance. J. Clean. Prod. 2016, 112, 1872–1881. [Google Scholar] [CrossRef]

- Lim, M.K.; Tseng, M.-L.; Tan, K.; Bui, T.D. Knowledge management in sustainable supply chain management: Improving performance through an interpretive structural modelling approach. J. Clean. Prod. 2017, 162, 806–816. [Google Scholar] [CrossRef]

- Li, G.; Li, S.; Yang, X. Relationships among CSR, Innovation and Value Creation: An Empirical Study Based on China Listed Companies. ICLEM 2014, 2014, 1169–1174. [Google Scholar] [CrossRef]

- Awaysheh, A.; Klassen, R.D. The impact of supply chain structure on the use of supplier socially responsible practices. Int. J. Oper. Prod. Manag. 2010, 30, 1246–1268. [Google Scholar] [CrossRef]

- Pagell, M.; Wu, Z. Building a More Complete Theory of Sustainable Supply Chain Management Using Case Studies of 10 Exemplars. J. Supply Chain Manag. 2009, 45, 37–56. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Haelixa. Unravelling Global Supply Chain Complexity. 2020. Available online: http://www.haelixa.com/ (accessed on 20 April 2020).

- Gött, H. (Ed.) Labour Standards in International Economic Law; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Khan, S.R. Apparel Sector: Ensuring Transparency in Global Supply Chain. Available online: https://thefinancialexpress.com.bd/views/apparel-sector-ensuring-transparency-in-global-supply-chain-1557933407 (accessed on 14 June 2020).

- Perks, K.J.; Viana, M.R.; Farache, F.; Kollat, J. A critical reflection on the role of dialogue in communicating ethical CSR through digital platforms. In Communicating Corporate Social Responsibility in the Digital Era; Routledge: Abingdon, Oxon, UK, 2017; pp. 133–143. [Google Scholar]

- Pagell, M.; Shevchenko, A. Why Research in Sustainable Supply Chain Management Should Have no Future. J. Supply Chain Manag. 2014, 50, 44–55. [Google Scholar] [CrossRef]

- Lund-Thomsen, P.; Oxborrow, L. Sustainable supply chain management. In Business Student’s Guide to Sustainable Management, The Principles and Practice; Greenleaf Publishing: Sheffield, UK, 2015; pp. 218–238. [Google Scholar]

- Zhang, D. A network economic model for supply chain versus supply chain competition. Omega 2006, 34, 283–295. [Google Scholar] [CrossRef]

- Tan, K.C. A framework of supply chain management literature. Eur. J. Purch. Supply Manag. 2001, 7, 39–48. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S.; Beske, P. Sustainable supply chain management and inter-organizational resources: A literature review. Corp. Soc. Responsib. Environ. Manag. 2009, 17, 230–245. [Google Scholar] [CrossRef]

- Kwon, I.-W.G.; Suh, T. Factors Affecting the Level of Trust and Commitment in Supply Chain Relationships. J. Supply Chain Manag. 2004, 40, 4–14. [Google Scholar] [CrossRef]

- Sahay, B. Understanding trust in supply chain relationships. Ind. Manag. Data Syst. 2003, 103, 553–563. [Google Scholar] [CrossRef]

- Aschehoug, S.H.; Boks, C. Towards a framework for sustainability information in product development. Int. J. Sustain. Eng. 2013, 6, 94–108. [Google Scholar] [CrossRef]

- Francisco, K.; Swanson, D. The Supply Chain Has No Clothes: Technology Adoption of Blockchain for Supply Chain Transparency. Logistics 2018, 2, 2. [Google Scholar] [CrossRef]

- Brun, A.; Karaosman, H.; Barresi, T. Supply Chain Collaboration for Transparency. Sustainability 2020, 12, 4429. [Google Scholar] [CrossRef]

- Alvarado Moore, K. Value Mapping Framework Involving Stakeholders for Supply Chain Improvement when Implementing Information Technology Projects. Ph.D. Thesis, University of Central Florida, Orlando, FL, USA, 2008. [Google Scholar]

- Econsense—Forum Nachhaltige Entwicklung der Deutschen Wirtschaft e.V. Wert(e) Schaffen. Vier Hebel für Nachhaltigere Wertschöpfungsnetzwerke. Unter Mitarbeit von Laura Franken und Carolin Gürtürk. 2019. Available online: https://econsense.de/app/uploads/2019/11/econsense-Diskussionsbeitrag-2019-Werte-schaffen.pdf (accessed on 15 April 2020).

- Bell, S.; Berg, T.; Morse, S. Rich Pictures: Sustainable Development and Stakeholders - The Benefits of Content Analysis. Sustain. Dev. 2015, 24, 136–148. [Google Scholar] [CrossRef]

- Moser, R.; Schaefers, T.; Meise, J.N. Consumer Preferences for Product Transparency in Emerging Markets—Lessons Learned from India. Mark. Rev. St. Gallen 2012, 29, 22–27. [Google Scholar] [CrossRef]

- Hofstede, G.J. Transparency in Netchains. Information Technology for a Better Agri-Food Sector, Environment and Rural Living; Debrecen University: Debrecen, Hungary, 2003; pp. 17–29. [Google Scholar]

- Dickson, M.; Warren, H. A Look at Labor Issues in the Manufacturing of Fashion through the Perspective of Human Trafficking and Modern-day Slavery. Dangers Fash. 2020, 103. [Google Scholar] [CrossRef]

- Hsu, C.-W.; Lee, W.-H.; Chao, W.-C. Materiality analysis model in sustainability reporting: A case study at Lite-On Technology Corporation. J. Clean. Prod. 2013, 57, 142–151. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Ivanova, M. Literature review on disruption recovery in the supply chain. Int. J. Prod. Res. 2017, 55, 6158–6174. [Google Scholar] [CrossRef]

- Fritz, M.; Schiefer, G. The Challenge of Reaching Transparency: ‘T-readiness’ of Enterprises and Sector Networks. Int. J. Food Syst. Dyn. 2010, 3, 182–183. [Google Scholar]

- Ebinger, F.; Omondi, B. Transparenz und Digitalisierung in Nachhaltigen Wertschöpfungsketten: Ansätze für ein Erfolgreiches CSR-Management, 4th ed.; Hildebrandt, A., Ed.; CSR und Digitalisierung: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Berzau, L. Prozessschritte Nachhaltiges Lieferkettenmanagement. Praxisorientierter Leitfaden für Unternehmen; Econsense—Forum Nachhaltige Entwicklung der Deutschen Wirtschaft e. V.: Berlin, Germany, 2017. [Google Scholar]

- Gupta, A. Transparency Under Scrutiny: Information Disclosure in Global Environmental Governance. Glob. Environ. Politics 2008, 8, 1–7. [Google Scholar] [CrossRef]

- Duman, G.M. Big Data Analytics in Supply Chain Management: A Literature Review on Supply Chain Analytics. Eng. Posters 2017. Available online: https://core.ac.uk/reader/80106956 (accessed on 10 March 2020).

- Menon, S.; Shah, S. An overview of digitalisation in conventional supply chain management. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2019; Volume 292, p. 01013. [Google Scholar]

- Alkahtani, M.; Abidi, M.H. Supply Chain 4.0: A Shift in Paradigm. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Pilsen, Czech Republic, 23–26 July 2019; IEOM Society International: Southfield, MI, USA, 2019; pp. 1698–1705. [Google Scholar]

- Sivarajah, U.; Kamal, M.; Irani, Z.; Weerakkody, V. Critical analysis of Big Data challenges and analytical methods. J. Bus. Res. 2017, 70, 263–286. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Wamba, S.F. World class sustainable supply chain management: Critical review and further research directions. Int. J. Logist. Manag. 2017, 28, 332–362. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Manogaran, G.; Mohamed, M.; Gunasekaran, M. Internet of Things (IoT) and its impact on supply chain: A framework for building smart, secure and efficient systems. Future Gener. Comput. Syst. 2018, 86, 614–628. [Google Scholar] [CrossRef]

- Tsai, K. Where Graph Technology and Supply Chain Transparency Meet Corporate Social Responsibility. Available online: https://neo4j.com/case-studies/transparency-one/ (accessed on 26 May 2020).

- Mehta, S. Socially Responsible Supply Chain Management: An Essence of Value Creation. J. Supply Chain Manag. Syst. 2016, 5, 28. [Google Scholar] [CrossRef]

- Basta, M.; Lapalme, J.; Paquet, M.; Saint-Louis, P.; Abu Zwaida, T. How are supply chains addressing their social responsibility dilemmas? Review of the last decade and a half. Corp. Soc. Responsib. Environ. Manag. 2018, 25, 833–843. [Google Scholar] [CrossRef]

- Min, H. Artificial intelligence in supply chain management: Theory and applications. Int. J. Logist. Res. Appl. 2009, 13, 13–39. [Google Scholar] [CrossRef]

- Ardron, J.A.; Ruhl, H.A.; Jones, D.O.B. Incorporating transparency into the governance of deep-seabed mining in the Area beyond national jurisdiction. Mar. Policy 2018, 89, 58–66. [Google Scholar] [CrossRef]

- Wu, Y.; Cegielski, C.G.; Hazen, B.T.; Hall, D.J. Cloud Computing in Support of Supply Chain Information System Infrastructure: Understanding When to go to the Cloud. J. Supply Chain Manag. 2013, 49, 25–41. [Google Scholar] [CrossRef]

- Choi, T.-M. Blockchain-technology-supported platforms for diamond authentication and certification in luxury supply chains. Transp. Res. Part. E: Logist. Transp. Rev. 2019, 128, 17–29. [Google Scholar] [CrossRef]

- Chod, J.; Trichakis, N.; Tsoukalas, G.; Aspegren, H.; Weber, M. On the Financing Benefits of Supply Chain Transparency and Blockchain Adoption. Manag. Sci. 2020. [Google Scholar] [CrossRef]

- Saini, V. Blockchain in Supply Chain: Journey from Disruptive to Sustainable. J. Mech. Contin. Math. Sci. 2019, 14, 498–508. [Google Scholar] [CrossRef]

- Pradhan, A.; Stevens, A.; Johnson, J. Blockchain Fundamentals for Supply Chain: A Guide to the New Boardroom Buzzword. Available online: https://www.gartner.com/en/doc/344447-blockchain-fundamentals-for-supply-chain-a-guide-to-the-new-boardroom-buzzword (accessed on 15 June 2020).

- Salah, K.; Nizamuddin, N.; Jayaraman, R.; Omar, M. Blockchain-Based Soybean Traceability in Agricultural Supply Chain. IEEE Access 2019, 7, 73295–73305. [Google Scholar] [CrossRef]

- Pilkington, M. Blockchain technology: Principles and applications. In Research Handbook on Digital Transformations; Edward Elgar Publishing: Cheltenham, UK, 2016. [Google Scholar]

- Thomassey, S.; Zeng, X. Introduction: Artificial Intelligence for Fashion Industry in the Big Data Era. In Artificial Intelligence for Fashion Industry in the Big Data Era; Springer: Singapore, 2018; pp. 1–6. [Google Scholar]

- Baryannis, G.; Dani, S.; Validi, S.; Antoniou, G. Decision Support Systems and Artificial Intelligence in Supply Chain Risk Management. In Revisiting Supply Chain Risk; Springer: Cham, Switzerland, 2019; pp. 53–71. [Google Scholar]

- Toka, A.; Aivazidou, E.; Antoniou, A.; Arvanitopoulos-Darginis, K. Cloud computing in supply chain management: An overview. In E-logistics and E-Supply Chain Management: Applications for Evolving Business; IGI Global: Hershey, PA, USA, 2013; pp. 218–231. [Google Scholar]

- Lindner, M.; Robinson, P.; McLarnon, B.; McDonald, F. The cloud supply chain: A framework for information, monitoring, accounting and billing. In Proceedings of the 2nd International ICST Conference on Cloud Computing (CloudComp 2010), Barcelona, Spain, 25–28 October 2010. [Google Scholar]

- Carroll, A.B. The pyramid of corporate social responsibility: Toward the moral management of organizational stakeholders. Bus. Horiz. 1991, 34, 39–48. [Google Scholar] [CrossRef]

- Ghanchi, J. Principal Ways IoT Can Benefit Supply Chain Management. Available online: https://theiotmagazine.com/principal-ways-iot-can-benefit-supply-chain-management-1be9981b1f1f (accessed on 10 July 2020).

- Fitzgerald, J.; Mussomeli, A.; Daecher, A.; Chandramouli, M. Smart Sensors and Supply Chain Innovation: Deloitte US. Available online: https://www2.deloitte.com/us/en/pages/operations/articles/smart-sensors-and-supply-chain.html (accessed on 21 July 2020).

- Abdullayeva, A. Impact of Artificial Intelligence on Agricultural, Healthcare and Logistics Industries. Ann. Spiru Haret Univ. Econ. Ser. 2019, 19, 167–175. [Google Scholar] [CrossRef]

- BMUB (Bundesministerium für Umwelt, Naturschutz, Bau und Reaktorsicherheit); UBA (Umweltbundesamt). Schritt für Schritt zum nachhaltigen Lieferkettenmanagement—Praxisleitfaden für Unternehmen; BMUB: Berlin/Dessau, Germany, 2017. [Google Scholar]

- Accenture. Blockchain. 2020. Available online: https://www.accenture.com/de-de/insights/blockchain-index (accessed on 15 April 2020).

- IBM Vinturas. Redefining the Automobile Customer Journey with IBM Blockchain. 2020. Available online: https://www.ibm.com/case-studies/vinturas-ibm-blockchain (accessed on 15 April 2020).

- iPoint. iPoint SustainHub. Die Universelle Plattform für Compliance & Nachhaltigkeit. 2020. Available online: https://www.ipoint-systems.com/de/loesungen/sustainhub/ (accessed on 15 April 2020).

- Minespider. Sustainable & Responsible Supply Chain Tracking. 2020. Available online: https://www.minespider.com (accessed on 15 April 2020).

- Pournader, M.; Shi, Y.; Seuring, S.; Koh, S.L. Blockchain applications in supply chains, transport and logistics: A systematic review of the literature. Int. J. Prod. Res. 2019, 58, 2063–2081. [Google Scholar] [CrossRef]

- McKendrick, J. Artificial Intelligence Works Its Way into Supply Chains. Available online: https://www.zdnet.com/article/artificial-intelligence-works-its-way-into-supply-chains/ (accessed on 9 July 2020).

- Lee, A.H.I. A fuzzy supplier selection model with the consideration of benefits, opportunities, costs and risks. Expert Syst. Appl. 2009, 36, 2879–2893. [Google Scholar] [CrossRef]

- Econsense—Forum Nachhaltige Entwicklung der Deutschen Wirtschaft e. V. Ansätze für Lieferantenabfrage und –Management. Exemplarische Darstellung Webbasierter Lösungen. 2014. Available online: https://econsense.de/app/uploads/2018/06/econsense-Diskussionsbeitrag_Ans%C3%A4tze-f%C3%BCr-Lieferantenabfrage_2014.pdf (accessed on 15 April 2020).

- Gandon, F. Distributed Artificial Intelligence and Knowledge Management: Ontologies and multi-Agent Systems for A Corporate Semantic Web. Ph.D. Dissertation, University of Nice Sophia Antipolis, Nice, France, 2002. Available online: https://tel.archives-ouvertes.fr/tel-00378201/document (accessed on 15 April 2020).

- Fossas-Olalla, M.; Lopez-Sanchez, J.I.; Minguela-Rata, B. Cooperation with suppliers as a source of innovation. Afr. J. Bus. Manag. 2010, 4, 3491–3499. [Google Scholar]

- EcoVadis. Die Weltweit Vertrauenswürdigsten Nachhaltigkeitsratings für Unternehmen. 2020. Available online: https://ecovadis.com/de/ (accessed on 15 April 2020).

- Fair Factories Clearinghouse. Compliance Solutions for A Better World. 2020. Available online: https://www.fairfactories.org/ (accessed on 15 April 2020).

- Scoutbee. Smarte Lieferantensuche. 2020. Available online: https://scoutbee.com/de/ (accessed on 15 April 2020).

- Tran, T.H.; Dobrovnik, M.; Kummer, S. Supply chain risk assessment: A content analysis-based literature review. Int. J. Logist. Syst. Manag. 2018, 31, 562–591. [Google Scholar] [CrossRef]

- MVO Risk Check. CSR Risiko Check. 2020. Available online: https://www.mvorisicochecker.nl/de (accessed on 15 April 2020).

- Gilson, L.L.; Goldberg, C.B. Editors’ comment: So, what is a conceptual paper? Group Organ. Manag. 2015, 40, 127–130. [Google Scholar] [CrossRef]

| Digital Approaches | Traceability and Tracking | Cooperation and Partners Selection | Governance | Strategic and Operational Risk Assessment |

|---|---|---|---|---|

| Blockchain Technologies | Transactional records with unique and encrypted digital signatures and unique identities for products and partners facilitates tracing and tracking of products to individual suppliers and sub-suppliers (the products’ country of origin, compliance with sustainability certifications and standards etc.). | Consensus- based trust and collaboration facilitates the connection between stakeholders in SCs. Flexibility of information access and sharing among stakeholders bridges the gap between them. | Distributed and shared ledgers Limited and authorized access to information among the stakeholders Multiple and synchronized data thus facilitating SC resilience. | Tamper-roof and incorruptible platforms with multiple copies of ledgers limits risk assessments to only information sharing and not the identification of risks and hot spots. |

| Artificial Intelligences and Big Data Analytics | Collection and processing of Big Data to real-time information facilitate Visibility of the entire SC | Multi-agent systems operations tools facilitate interaction of stakeholders in the SCs. Conceptualization of real-time information for decision making processes | End to end data collection and processing. | Predicable analytics for risk identification, risk assessment and risk mitigation Real-time information |

| Cloud Computing Platforms | Unique identities to verify authentic goods and thus the identification of the suppliers and sub-suppliers involved. | Multi-agent systems operations tools used for SC mapping and information sharing. | Resource and costs optimizing platform Graphic networks of the entire Sustainable SC thus necessary for the management and ranking of suppliers and sub-suppliers. | Visibility of the entire SC. Real-time identification of the sustainability related risks |

| IoTs-Sensors-driven applications | Connected ecosystems of sensors facilitates massive collection and processing sustainability-related information and sharing SC stakeholders for decision making process | Efficient and reliable networking and communication Real-time and valuable information resulting from analytical features facilitates stakeholders interactions and collaboration. | Production, transportation, storage and delivery of products and services monitored and managed by using real-time data and real-time analytics, the parts of the IoTs ecosystem can be better networked | Connected ecosystems of sensors facilitates massive collection and processing data for predicting strategic and operational risks. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebinger, F.; Omondi, B. Leveraging Digital Approaches for Transparency in Sustainable Supply Chains: A Conceptual Paper. Sustainability 2020, 12, 6129. https://doi.org/10.3390/su12156129

Ebinger F, Omondi B. Leveraging Digital Approaches for Transparency in Sustainable Supply Chains: A Conceptual Paper. Sustainability. 2020; 12(15):6129. https://doi.org/10.3390/su12156129

Chicago/Turabian StyleEbinger, Frank, and Bramwel Omondi. 2020. "Leveraging Digital Approaches for Transparency in Sustainable Supply Chains: A Conceptual Paper" Sustainability 12, no. 15: 6129. https://doi.org/10.3390/su12156129

APA StyleEbinger, F., & Omondi, B. (2020). Leveraging Digital Approaches for Transparency in Sustainable Supply Chains: A Conceptual Paper. Sustainability, 12(15), 6129. https://doi.org/10.3390/su12156129