Greening Industry in Vietnam: Environmental Management Standards and Resource Efficiency in SMEs

Abstract

:1. Introduction

2. Background and Context

2.1. Industrialization and Associated Environmental Problems

2.2. Environmental Regulations and EMS Certificates

3. Theoretical Foundation and Literature Review

3.1. Theoretical Framework

3.2. Empirical Evidence

4. Data and Methodology

4.1. Data

4.2. Empirical Model

4.2.1. Panel Regression Method

4.2.2. Problem of Endogeneity: Instrumental Variable Approach

5. Results and Discussion

5.1. Results

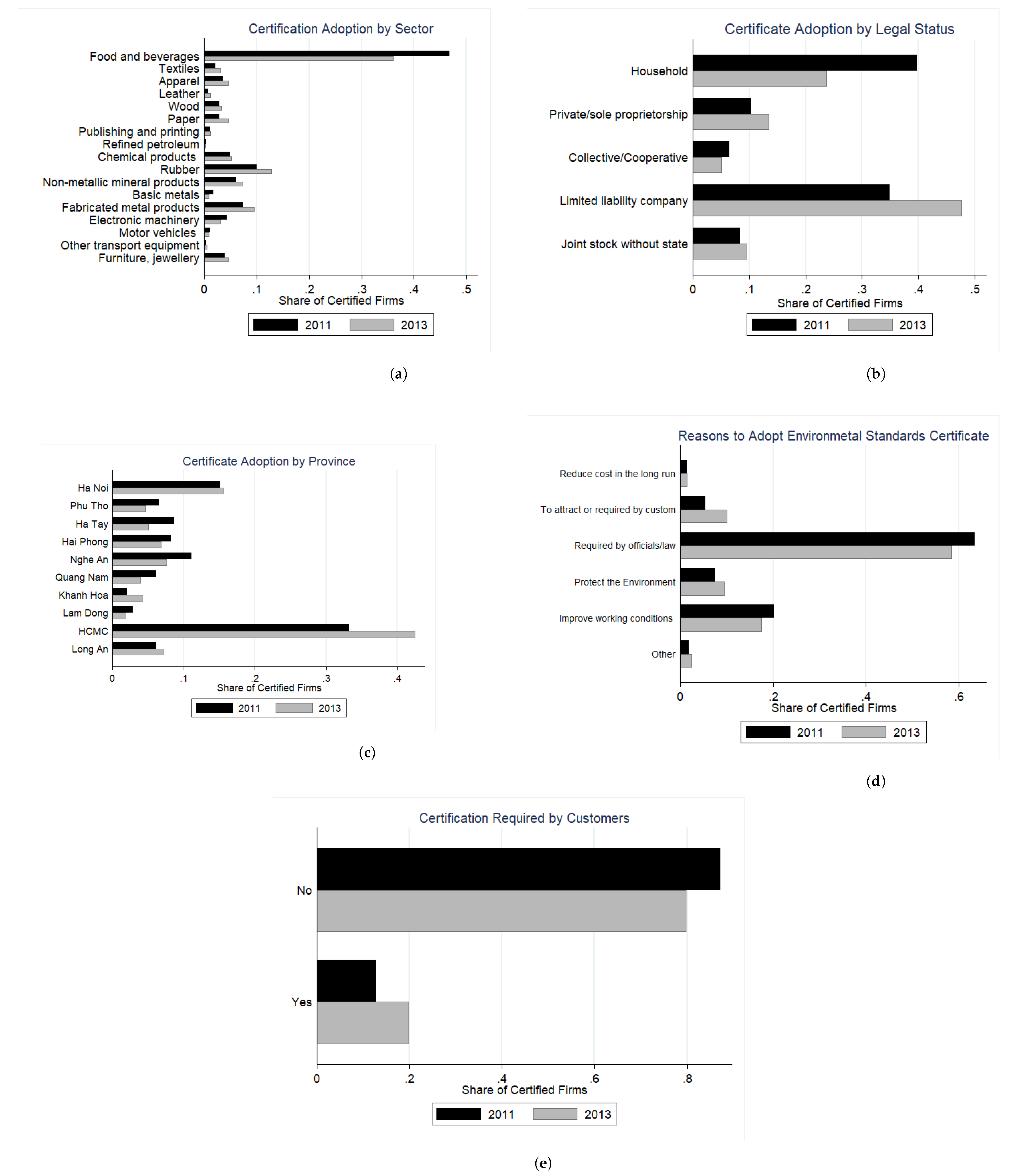

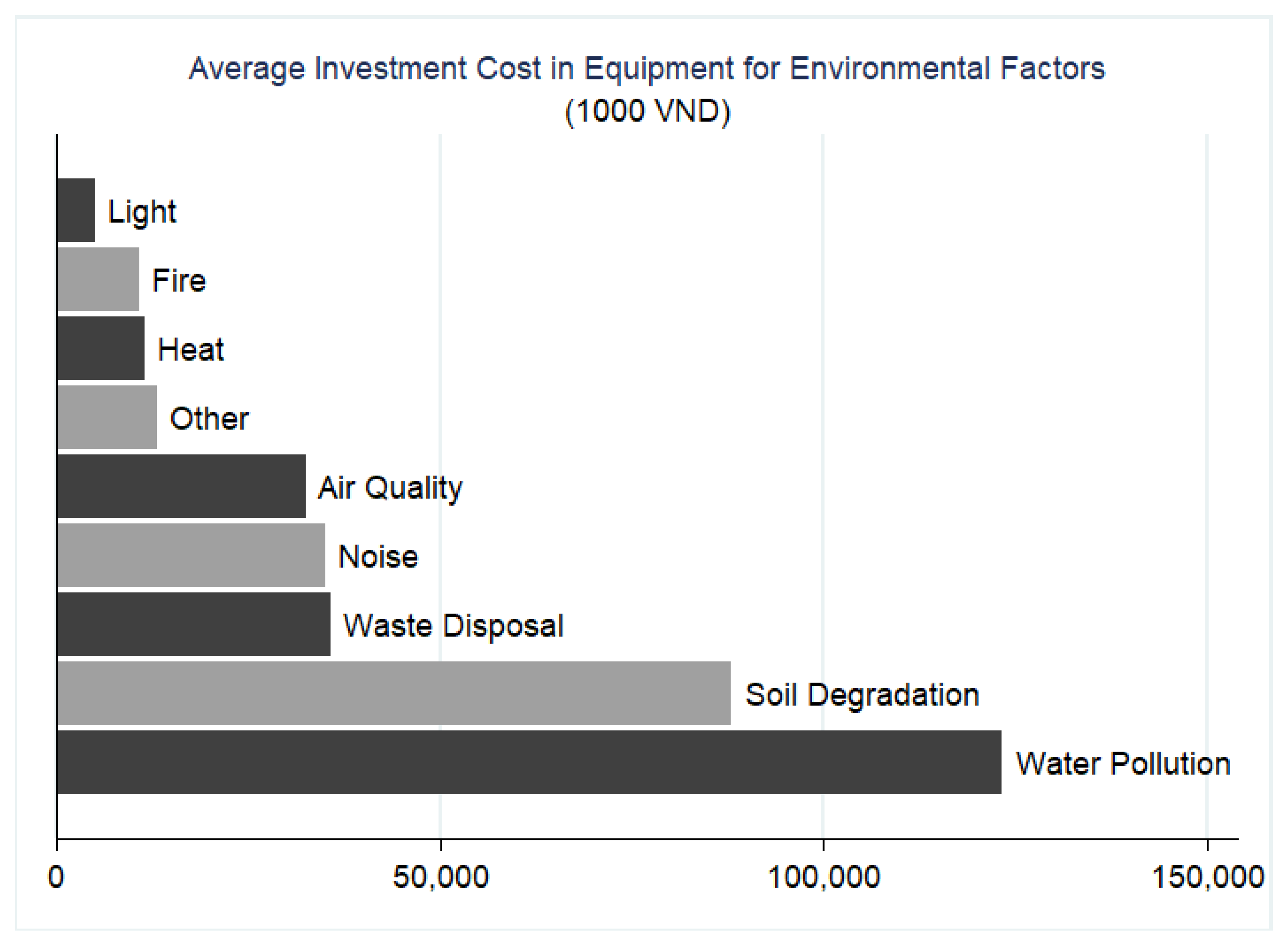

5.1.1. Descriptive Statistics

5.1.2. Empirical Results

5.2. Robustness Checks

5.3. Discussion

6. Conclusions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| EMS | Environmental Management Standards |

| FE | Fixed Effects |

| GOV | Government of Vietnam |

| GSO | General Statistics Office |

| IV | Instrumental Variable |

| SME | Small and Medium-Size Enterprises |

| WDI | World Development Indicators |

| WTO | World Trade Organization |

| 2SlS | Two-stage least squares |

Appendix A. Tables and Figures

| 2011 | 2013 | All Years, Balanced | All Years, Unbalanced | |||||

| Sector | Freq. | Percent | Freq. | Percent | Freq. | Percent | Freq. | Percent |

| Food and beverages | 301 | 22.58 | 298 | 22.36 | 599 | 22.47 | 1466 | 30.99 |

| Fabricated metal products | 275 | 20.63 | 275 | 20.63 | 550 | 20.63 | 842 | 17.80 |

| Wood | 136 | 10.20 | 144 | 10.80 | 280 | 10.50 | 491 | 10.38 |

| Furniture, jewelry | 130 | 9.75 | 125 | 9.38 | 255 | 9.56 | 392 | 8.29 |

| Rubber | 81 | 6.08 | 86 | 6.45 | 167 | 6.26 | 238 | 5.03 |

| Apparel | 81 | 6.08 | 73 | 5.48 | 154 | 5.78 | 235 | 4.97 |

| Non-metallic mineral products | 68 | 5.10 | 72 | 5.40 | 140 | 5.25 | 209 | 4.42 |

| Textiles | 57 | 4.28 | 64 | 4.80 | 121 | 4.54 | 192 | 4.06 |

| Electronic machinery | 46 | 3.45 | 44 | 3.30 | 90 | 3.38 | 129 | 2.73 |

| Paper | 41 | 3.08 | 41 | 3.08 | 82 | 3.08 | 131 | 2.77 |

| Publishing and printing | 30 | 2.25 | 27 | 2.03 | 57 | 2.14 | 108 | 2.28 |

| Chemical products etc. | 25 | 1.88 | 26 | 1.95 | 51 | 1.91 | 87 | 1.84 |

| Leather | 23 | 1.73 | 25 | 1.88 | 48 | 1.80 | 97 | 2.05 |

| Basic metals | 23 | 1.73 | 18 | 1.35 | 41 | 1.54 | 60 | 1.27 |

| Motor vehicles etc. | 9 | 0.68 | 8 | 0.60 | 17 | 0.64 | 26 | 0.55 |

| Other transport equipment | 4 | 0.30 | 3 | 0.23 | 7 | 0.26 | 14 | 0.30 |

| Refined petroleum etc. | 3 | 0.23 | 4 | 0.30 | 7 | 0.26 | 14 | 0.30 |

| Total | 1333 | 100.00 | 1333 | 100.00 | 2666 | 100.00 | 4731 | 100.00 |

| Dependent Variable: Adoption of EMS Certificate | ||||||||

|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | |

| Variables | Probit Full | Probit Balance | 2SLS | 2SLS | 2SLS | 2SLS | 2SLS | 2SLS |

| Pooled | RE | |||||||

| EMS Adoption: IV | 0.364 *** | 0.306 *** | 0.290 *** | 0.199 *** | 0.191 *** | 0.088 ** | ||

| (0.023) | (0.023) | (0.024) | (0.026) | (0.027) | (0.043) | |||

| Firm Age (logs) | 0.0889 * | 0.111 | 0.005 | 0.006 | 0.002 | 0.001 | 0.266 *** | |

| (0.0497) | (0.120) | (0.012) | (0.013) | (0.013) | (0.014) | (0.091) | ||

| Firm size (logs) | 0.424 *** | 0.727 *** | 0.102 *** | 0.093 *** | 0.090 *** | 0.096 *** | −0.011 | |

| (0.0403) | (0.0997) | (0.011) | (0.013) | (0.012) | (0.012) | (0.025) | ||

| Innovation (dummy) | −0.143 ** | 0.0873 | −0.019 | −0.019 | 0.002 | −0.001 | 0.022 | |

| (0.0603) | (0.124) | (0.015) | (0.016) | (0.015) | (0.016) | (0.022) | ||

| Training (dummy) | 0.0235 | −0.168 | 0.012 | 0.002 | −0.002 | 0.001 | −0.014 | |

| (0.0630) | (0.120) | (0.018) | (0.018) | (0.017) | (0.018) | (0.023) | ||

| Intermediate output (%) | −0.00202 ** | −0.00130 | 0.000 | 0.000 | 0.000 | 0.000 | −0.000 | |

| (0.000902) | (0.00196) | (0.000) | (0.000) | (0.000) | (0.000) | (0.000) | ||

| Association (dummy) | 0.104 | 0.435 ** | 0.044 | 0.04 | 0.057 * | 0.060 ** | 0.040 | |

| (0.0951) | (0.213) | (0.029) | (0.030) | (0.030) | (0.030) | (0.048) | ||

| Loans (dummy) | 0.0638 | −0.0616 | 0.008 | 0.001 | 0.005 | −0.001 | −0.016 | |

| (0.0651) | (0.135) | (0.017) | (0.017) | (0.017) | (0.017) | (0.024) | ||

| Raw Material from Household (%) | −0.00352 | −0.0113 ** | −0.001 ** | −0.001 * | −0.002 *** | −0.002 *** | −0.001 | |

| (0.00256) | (0.00519) | (0.001) | (0.001) | (0.001) | (0.001) | (0.001) | ||

| KL Ratio | 0.168 *** | 0.231 *** | 0.025 *** | 0.031 *** | 0.019 *** | 0.023 *** | 0.014 | |

| (0.0274) | (0.0615) | (0.007) | (0.007) | (0.007) | (0.007) | (0.012) | ||

| Capacity (dummy) | 0.00907 | 0.255 ** | 0.030 ** | 0.028 * | 0.036 ** | 0.034 ** | 0.040 * | |

| (0.0601) | (0.126) | (0.015) | (0.015) | (0.015) | (0.015) | (0.023) | ||

| E-trade (dummy) | 0.126 | 0.316 | 0.067 * | 0.065 * | 0.059 * | 0.066 * | −0.022 | |

| (0.101) | (0.194) | (0.036) | (0.037) | (0.036) | (0.036) | (0.045) | ||

| Competition (dummy) | 0.0102 | 0.321 * | 0.034 | 0.031 | 0.037 * | 0.040 * | 0.030 | |

| (0.0918) | (0.188) | (0.023) | (0.023) | (0.023) | (0.023) | (0.035) | ||

| Assistance (dummy) | −0.0862 | −0.150 | −0.029 | −0.029 | −0.028 | −0.026 | −0.008 | |

| (0.0759) | (0.159) | (0.020) | (0.020) | (0.021) | (0.020) | (0.026) | ||

| Vintage (%) | −0.0000 | −0.00137 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| (0.00108) | (0.00224) | (0.000) | (0.000) | (0.000) | (0.000) | (0.000) | ||

| Constant | −2.703 *** | −3.900 *** | 0.068 *** | −0.221 *** | −0.297 *** | −0.061 | −0.128 * | 0.278 |

| (0.218) | (0.551) | (0.009) | (0.047) | (0.058) | (0.056) | (0.066) | (0.236) | |

| Observations | 3.680 | 2.662 | 2.666 | 2.666 | 2.666 | 2.666 | 2.666 | 2.666 |

| Number of id | 2.350 | 1.332 | 1.333 | 1.333 | 1.333 | 1.333 | 1.333 | 1.333 |

| R-squared Adj. | 0.1562 | 0.143 | 0.215 | 0.226 | 0.25 | 0.253 | ||

| t-stats | 15.58 | 13.23 | 12.02 | 7.67 | 7.14 | |||

| Legal FE | YES | YES | NO | NO | YES | YES | YES | NO |

| Province FE | YES | YES | NO | NO | YES | NO | YES | NO |

| Sector | NO | YES | NO | NO | NO | YES | YES | NO |

| Year FE | YES | YES | NO | NO | YES | YES | YES | YES |

| Firm FE | NO | NO | NO | NO | NO | NO | NO | YES |

| Kleibergen–Paap F-statistic (weak) | 242,606 | 175,04 | 144,694 | 58,978 | 51,043 | 4.178 | ||

| Kleibergen–Paap LM-statistic (under) | 134,677 | 125,488 | 110,373 | 45,012 | 40,296 | 8.282 | ||

| Cragg–Donald Wald F-statistic (weak) | 445,593 | 31,533 | 255,064 | 99,847 | 85,719 | 12,911 | ||

| Dependent Variable: Resource Intensity (Logs) | ||||||

|---|---|---|---|---|---|---|

| Variables | (1) | (2) | (3) | (4) | (5) | (6) |

| EMS Certificate | −1.769 *** | −2.497 *** | −2.993 *** | −1.283 * | −0.182 | −3.592 |

| (0.395) | (0.572) | (0.586) | (0.760) | (0.835) | (3.208) | |

| Firm Age (logs) | 0.341 *** | −0.028 | −0.014 | −0.118 * | 1.084 | |

| (0.079) | (0.081) | (0.067) | (0.067) | (0.981) | ||

| Firm size (logs) | 0.088 | 0.271 *** | 0.091 | 0.1 | −0.077 | |

| (0.102) | (0.100) | (0.097) | (0.107) | (0.129) | ||

| Innovation (dummy) | −0.995 *** | 0.217 ** | 0.066 | 0.097 | 0.082 | |

| (0.115) | (0.099) | (0.085) | (0.082) | (0.123) | ||

| Training (dummy) | 1.075 *** | 0.197 | 0.223 ** | 0.158 | −0.008 | |

| (0.140) | (0.122) | (0.105) | (0.105) | (0.147) | ||

| Intermediate inputs (%) | −0.001 | 0.002 | −0.001 | 0 | −0.002 | |

| (0.002) | (0.002) | (0.001) | (0.001) | (0.002) | ||

| Association | 0.754 *** | 0.165 | 0.146 | −0.116 | −0.047 | |

| (0.191) | (0.174) | (0.155) | (0.154) | (0.274) | ||

| Loans (dummy) | 0.742 *** | 0.496 *** | 0.517 *** | 0.353 *** | 0.068 | |

| (0.122) | (0.109) | (0.094) | (0.093) | (0.141) | ||

| Raw material from households (%) | 0.039 *** | −0.001 | 0.001 | 0.006 | −0.015 *** | |

| (0.005) | (0.004) | (0.004) | (0.004) | (0.005) | ||

| KL ratio | −0.228 *** | 0.107 ** | 0.086 ** | 0.121 *** | 0.146 * | |

| (0.050) | (0.048) | (0.040) | (0.042) | (0.078) | ||

| Capacity | 0.286 ** | −0.025 | 0.092 | −0.055 | 0.085 | |

| (0.117) | (0.102) | (0.088) | (0.089) | (0.165) | ||

| E-trading (dummy) | 0.633 *** | 0.569 *** | 0.349 * | 0.286 | 0.636 *** | |

| (0.232) | (0.213) | (0.190) | (0.184) | (0.229) | ||

| Competition | 0.328 * | 0.07 | −0.096 | −0.093 | −0.086 | |

| (0.182) | (0.156) | (0.140) | (0.136) | (0.207) | ||

| Assistance (dummy) | −0.530 *** | −0.275 ** | −0.204 * | −0.190 * | −0.276 ** | |

| (0.159) | (0.132) | (0.116) | (0.112) | (0.138) | ||

| Vintage | 0 | 0 | 0 | −0.001 | 0 | |

| (0.002) | (0.002) | (0.001) | (0.001) | (0.002) | ||

| Constant | −0.965 *** | −1.823 *** | −4.231 *** | −4.648 *** | −4.751 *** | −0.313 |

| (0.078) | (0.337) | (0.374) | (0.262) | (0.295) | (1.609) | |

| Observations | 4733 | 3685 | 3685 | 3685 | 3685 | 3685 |

| Year FE | No | No | Yes | Yes | Yes | Yes |

| Province FE | No | No | Yes | No | Yes | No |

| Legal FE | No | No | Yes | Yes | Yes | No |

| Sector FE | No | No | No | Yes | Yes | No |

| Firm FE | No | No | No | No | No | Yes |

Appendix B. Robustness Checks Tests

| Dependent Variable: Resource Intensity (Logs) | ||

|---|---|---|

| Balanced | Unbalanced | |

| VARIABLES | Model 1 | Model 2 |

| IV | −0.122 | 0.0218 |

| (0.173) | (0.167) | |

| Constant | −4.637 *** | −4.455 *** |

| (0.389) | (0.323) | |

| Observations | 2147 | 2980 |

| Number of id | 1157 | 1990 |

| Legal FE | Yes | Yes |

| Province FE | Yes | Yes |

| Sector | Yes | Yes |

| Year FE | Yes | Yes |

References

- Borck, J.C.; Coglianese, C. Voluntary environmental programs: Assessing their effectiveness. Ann. Rev. Environ. Resour. 2009, 34, 305–324. [Google Scholar]

- Harrison, A.; Martin, L.A.; Nataraj, S. Green Industrial Policy in Emerging Markets. Ann. Rev. Resour. Econ. 2017, 9, 253–274. [Google Scholar]

- Ferenhof, H.A.; Vignochi, L.; Selig, P.M.; Lezana, Á.G.R.; Campos, L.M. Environmental management systems in small and medium-sized enterprises: An analysis and systematic review. J. Clean. Prod. 2014, 74, 44–53. [Google Scholar]

- Singh, M.; Brueckner, M.; Padhy, P.K. Environmental management system ISO 14001: Effective waste minimisation in small and medium enterprises in India. J. Clean. Prod. 2015, 102, 85–301. [Google Scholar]

- Chen, F.; Ngniatedema, T.; Li, S. A cross-country comparison of green initiatives, green performance and financial performance. Manag. Dec. 2018, 56, 1008–1032. [Google Scholar]

- Schaltegger, S.; Synnestvedt, T. The link between green and economic success: Environmental management as the crucial trigger between environmental and economic performance. J. Environ. Manag. 2002, 65, 339–346. [Google Scholar]

- Del Río González, P. Analysing the factors influencing clean technology adoption: A study of the Spanish pulp and paper industry. Bus. Strateg. Environ. 2005, 14, 20–37. [Google Scholar]

- Flachenecker, F.; Rentschler, J. (Eds.) Investing in Resource Efficiency: The Economics and Politics of Financing the Resource Transition; Springer: New York, NY, USA, 2018. [Google Scholar]

- Van Ewijk, S. An Introduction to Resource Efficiency: Concepts and Definitions. In Investing in Resource Efficiency: The Economics and Politics of Financing the Resource Transition; Flachenecker, F., Rentschler, J., Eds.; Springer: New York, NY, USA, 2018; pp. 13–29. [Google Scholar]

- Porter, M.E.; Van Der Linde, C. Toward a new conception of the environment-competitiveness relationship. J. Econ. Perspect. 1995, 9, 97–118. [Google Scholar]

- Shrivastava, P. Environmental technologies and competitive advantage. Strateg. Manag. J. 1995, 16, 183–200. [Google Scholar]

- Goedhuys, M.; Sleuwaegen, L. The impact of international standards certification on the performance of firms in less developed countries. World Dev. 2013, 47, 87–101. [Google Scholar]

- Goedhuys, M.; Sleuwaegen, L. International standards certification, institutional voids and exports from developing country firms. Int. Bus. Rev. 2016, 25, 1344–1355. [Google Scholar]

- Darnall, N.; Rigling Gallagher, D.; Andrews, R.N.; Amaral, D. Environmental management systems: Opportunities for improved environmental and business strategy? Environ. Qual. Manag. 2000, 9, 1–9. [Google Scholar]

- Khanna, M.; Damon, L. EPA’s voluntary 33/50 program: Impact on toxic releases and economic performance of firms. J. Environ. Econ. Manag. 1999, 37, 1–25. [Google Scholar]

- Fontagné, L.; Orefice, G.; Piermartini, R.; Rocha, N. Product standards and margins of trade: Firm-level evidence. J. Int. Econ. 2015, 97, 29–44. [Google Scholar]

- Nishitani, K. Demand for ISO 14001 adoption in the global supply chain: An empirical analysis focusing on environmentally conscious markets. Resour. Energy Econ. 2010, 32, 395–407. [Google Scholar]

- Nishitani, K. An empirical analysis of the effects on firms’ economic performance of implementing environmental management systems. Environ. Resour. Econ. 2011, 48, 569–586. [Google Scholar]

- Maertens, M.; Swinnen, J. Trade, Standards, and Poverty: Evidence from Senegal. World Dev. 2009, 37, 161–178. [Google Scholar]

- Cramer, J. Environmental management: From ‘fit’ to ‘stretch’. Bus. Strateg. Environ. 1998, 7, 162–172. [Google Scholar]

- Massoud, M.A.; Fayad, R.; Kamleh, R.; El-Fadel, M. Environmental Management System (ISO14001) Certification in Developing Countries: Challenges and Implementation Strategies. Environ. Sci. Technol. 2010, 44, 1884–1887. [Google Scholar]

- Pesce, M.; Shi, C.; Critto, A.; Wang, X.; Marcomini, A. SWOT analysis of the application of international standard ISO 14001 in the Chinese context. A case study of Guangdong Province. Sustainability 2018, 10, 3196. [Google Scholar]

- Riaz, H.; Saeed, A.; Baloch, M.S.; Khan, Z.A. Valuation of Environmental Management Standard ISO 14001: Evidence from an Emerging Market. J. Risk Financ. Manag. 2019, 12, 21. [Google Scholar]

- GOV. Decision No. 256/2003/QD-TTg on Approval of the National Environment Protection Strategies to 2010 with Vision to 2020. 2003. Available online: www.wisdom-vn.org/organisational_documents/legal_documents/en/Decision%2025-2003-QD-TTg.pdf (accessed on 3 March 2018).

- Yoshino, N.; Wignaraja, G. SMEs Internationalization and Finance in Asia; Asian Development Bank Institute: Tokyo, Japan, 2015; Available online: www.imf.org/external/np/seminars/eng/2015/jica2015/pdf/1-B1.pdf (accessed on 3 June 2018).

- GOV. Strategy on Cleaner Industrial Production to 2020. 2009. Available online: http://www.chinhphu.vn/portal/page/portal/English/strategies/strategiesdetails?categoryId=30&articleId=10051863 (accessed on 25 March 2018).

- Babakri, K.A.; Bennett, R.A.; Franchetti, M. Critical factors for implementing ISO 14001 standard in United States industrial companies. J. Clean. Prod. 2003, 11, 749–752. [Google Scholar]

- Bansal, P.; Bogner, W.C. Deciding on ISO 14001: Economics, institutions and context. Long Range Plan. 2002, 35, 269–290. [Google Scholar]

- Endrikat, J.; Guenther, E.; Hoppe, H. Making sense of conflicting empirical findings: A meta-analytic review of the relationship between corporate environmental and financial performance. Eur. Manag. J. 2014, 32, 735–751. [Google Scholar]

- Jaffe, A.B.; Peterson, S.R.; Portney, P.R.; Stavins, R.N. Environmental Regulation and International Competitiveness: What Does the Evidence Tell Us? J. Econ. Lit. 1995, 33, 132–163. [Google Scholar]

- Molina-Azorin, J.F.; Tarí, J.J.; Claver-Cortés, E.; López-Gamero, M.D. Quality management, environmental management and firm performance: A review of empirical studies and issues of integration. Int. J. Manag. Rev. 2009, 11, 197–222. [Google Scholar]

- Hillary, R. Environmental management systems and the smaller enterprise. J. Clean. Prod. 2004, 12, 561–569. [Google Scholar]

- Agan, Y.; Acar, M.F.; Borodin, A. Drivers of environmental processes and their impact on performance: A study of Turkish SMEs. J. Clean. Prod. 2013, 51, 23–33. [Google Scholar]

- Campos, L.M. Environmental management systems (EMS) for small companies: A study in Southern Brazil. J. Clean. Prod. 2012, 32, 141–148. [Google Scholar]

- Gavronski, I.; Ferrer, G.; Paiva, E.L. ISO 14001 certification in Brazil: Motivations and benefits. J. Clean. Prod. 2008, 16, 87–94. [Google Scholar]

- Nguyen, Q.A.; Hens, L. Environmental performance of the cement industry in Vietnam: The influence of ISO 14001 certification. J. Clean. Prod. 2015, 96, 362–378. [Google Scholar]

- Masakure, O.; Cranfield, J.; Henson, S. Factors affecting the incidence and intensity of standards certification evidence from exporting firms in Pakistan. Appl. Econ. 2011, 43, 901–915. [Google Scholar]

- De Oliveira, O.J.; Serra, J.R.; Salgado, M.H. Does ISO 14001 work in Brazil? J. Clean. Prod. 2010, 18, 1797–1806. [Google Scholar]

- Rao, P.; la O’Castillo, O.; Intal, P.S., Jr.; Sajid, A. Environmental indicators for small and medium enterprises in the Philippines: An empirical research. J. Clean. Prod. 2006, 14, 505–515. [Google Scholar]

- Seiffert, M.E.B. Environmental impact evaluation using a cooperative model for implementing EMS (ISO 14001) in small and medium-sized enterprises. J. Clean. Prod. 2008, 16, 1447–1461. [Google Scholar]

- Trifković, N. Spillover effects of international standards: Working Conditions in the Vietnamese SMEs. World Dev. 2017, 97, 79–101. [Google Scholar]

- Rietbergen-McCracken, J.; Abaza, H. (Eds.) Economic Instruments for Environmental Management: A Worldwide Compendium of Case Studies; Routledge: London, UK, 2014. [Google Scholar]

- Rand, J.; Tarp, F. Characteristics of the Vietnamese Business Environment: Evidence from a SME Survey in 2011; Central Institute for Economic Management (CIEM): Hanoi, Vietnam, 2012. [Google Scholar]

- The World Bank. The World bank in Vietnam (2018); The World Bank: Washington, DC, USA, 2018; Available online: www.worldbank.org/en/country/vietnam/overview (accessed on 21 January 2018).

- Asian Development Bank. Economic and Social Data: Viet Nam, Key Indicators; ADB Economic Research and Regional Cooperation Department (ERCD): Manila, Philippines, 2018. [Google Scholar]

- Frijns, J.; Phuong, P.T.; Mol, A.P. Developing countries: Ecological modernisation theory and industrialising economies: The case of Viet Nam. Environ. Politics 2000, 9, 257–292. [Google Scholar]

- Vu-Thanh, T.A. The Political Economy of Industrial Development in Viet Nam. In The Practice of Industrial Policy: Government-Business Coordination in Africa and East Asia; Oxford University Press: New York, NY, USA, 2017. [Google Scholar]

- GSO. General Statistics Office of Viet Nam. 2019. Available online: https://www.gso.gov.vn/default_en.aspx?tabid=780 (accessed on 18 February 2019).

- GOV. Resolution on Five-Year Socio-Economic Plan from 2016–2020. 2019. Available online: http://www.chinhphu.vn/portal/page/portal/English/strategies/strategiesdetails?categoryId=30&articleId=10057712 (accessed on 3 June 2018).

- Dore, G.; Brylski, P.; Nygard, J.; Tran, T.T.P. Review and Analysis of the Pollution Impacts from Vietnamese Manufacturing Sectors; The World Bank: Washington, DC, USA, 2008. [Google Scholar]

- Hoang, T.A.; Chu, N.X.; Van Tran, T. The Environmental Pollution In Vietnam: Source, Impact and Remedies. Int. J. Sci. Technol. Res. 2017, 6, 249–253. [Google Scholar]

- GOV. Law on Environmental Protection No. 52/2005/QH11. 2005. Available online: https://www.ilo.org/dyn/natlex/natlex4.detail?p_lang=en&p_isn=73671&p_country=VNM&p_count=548 (accessed on 30 March 2018).

- GOV. Decree No. 175/CP on Providing Guidance for the Implementation of the Law on Environmental Protection. 1994. Available online: https://www.aecen.org/sites/default/files/vietnam_eia_decree_175cp_1994.pdf (accessed on 2 March 2018).

- IISD International Institute for Sustainable Development. Trade and Sustainable Development in Vietnam Report; IISD: Winnepeg, MB, Canada, 2003. [Google Scholar]

- USAID. Vietnam 2005 Rapid Country Assessment Report: Environmental Compliance and Enforcement Program; USAID: Washington, DC, USA, 2005. [Google Scholar]

- Rennings, K. Redefining innovation-ecoinnovation research and the contribution from ecological economics. Ecol. Econ. 2000, 32, 319–332. [Google Scholar]

- Koilara, S. SMEs: Key Drivers of Green and Inclusive Growth; OECD Policy Paper; OECD: Paris, France, 2018. [Google Scholar]

- Iraldo, F.; Testa, F.; Frey, M. Is an environmental management system able to influence environmental and competitive performance? The case of the eco-management and audit scheme (EMAS) in the European union. J. Clean. Prod. 2009, 17, 1444–1452. [Google Scholar]

- Ambec, S.; Lanoie, P. Does it pay to be green? A systematic overview. Acad. Manag. Perspect. 2008, 22, 45–62. [Google Scholar]

- Wagner, M.; Van Phu, N.; Azomahou, T.; Wehrmeyer, W. The relationship between the environmental and economic performance of firms: An empirical analysis of the European paper industry. Corp. Soc. Responsib. Environ. Manag. 2002, 9, 133–146. [Google Scholar]

- Wagner, M.; Schaltegger, S.; Wehrmeyer, W. The relationship between the environmental and economic performance of firms. Greener Manag. Int. 2001, 34, 94–111. [Google Scholar]

- Testa, F.; Iraldo, F.; Frey, M. The effect of environmental regulation on firms’ competitive performance: The case of the building and construction sector in some EU regions. J. Environ. Manag. 2011, 92, 2136–2144. [Google Scholar]

- Horváthová, E. Does environmental performance affect financial performance? A meta-analysis. Ecol. Econ. 2010, 70, 52–59. [Google Scholar]

- Porter, M.E. America’s Green Strategy. Sci. Am. 1991, 264, 168. [Google Scholar]

- Babool, A.; Reed, M. The impact of environmental policy on international competitiveness in manufacturing. Appl. Econ. 2010, 42, 2317–2326. [Google Scholar]

- Lanoie, P.; Laurent-Lucchetti, J.; Johnstone, N.; Ambec, S. Environmental policy, innovation and performance: New insights on the Porter hypothesis. J. Econ. Manag. Strateg. 2011, 20, 803–842. [Google Scholar]

- Hart, S.L. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar]

- Hart, S.L.; Ahuja, G. Does it pay to be green? An empirical examination of the relationship between emission reduction and firm performance. Bus. Strateg. Environ. 1996, 5, 30–37. [Google Scholar]

- Russo, M.V.; Fouts, P.A. A resource-based perspective on corporate environmental performance and profitability. Acad. Manag. J. 1997, 40, 534–559. [Google Scholar]

- Jaffe, A.B.; Newell, R.G.; Stavins, R.N. Environmental policy and technological change. Environ. Resour. Econ. 2002, 22, 41–70. [Google Scholar]

- Hawkins, R. The use of economic instruments and green taxes to complement an environmental regulatory regime. Water Air Soil Pollut. 2000, 123, 379–394. [Google Scholar]

- Blanco, E.; Rey-Maquieira, J.; Lozano, J. The economic impacts of voluntary environmental performance of firms: A critical review. J. Econ. Surv. 2009, 23, 462–502. [Google Scholar]

- Arimura, T.H.; Hibiki, A.; Katayama, H. Is a voluntary approach an effective environmental policy instrument? A case for environmental management systems. J. Environ. Econ. Manag. 2008, 55, 281–295. [Google Scholar]

- Zobel, T. ISO 14001 certification in manufacturing firms: A tool for those in need or an indication of greenness? J. Clean. Prod. 2005, 43, 37–44. [Google Scholar]

- Shetty, S.; Kumar, S. Are voluntary environment programs effective in improving the environmental performance: Evidence from polluting Indian Industries. Environ. Econ. Policy Stud. 2017, 19, 659–676. [Google Scholar]

- Nazer, D.W.; Siebel, M.A. Reducing the environmental impact of the unhairing-liming process in the leather tanning industry. J. Clean. Prod. 2006, 14, 65–74. [Google Scholar]

- Van Hoof, B.; Lyon, T.P. Cleaner production in small firms taking part in Mexico’s Sustainable Supplier Program. J. Clean. Prod. 2013, 41, 270–282. [Google Scholar]

- Tan, L.P. Implementing ISO 14001: Is it beneficial for firms in newly industrialized Malaysia? J. Clean. Prod. 2005, 13, 397–404. [Google Scholar]

- Kamande, M.W.; Lokina, R.B. Clean production and profitability: An eco-efficiency analysis of kenyan manufacturing firms. J. Environ. Dev. 2013, 22, 169–185. [Google Scholar]

- Dowell, G.; Hart, S.; Yeung, B. Do corporate global environmental standards create or destroy market value? Manag. Sci. 2000, 46, 1059–1074. [Google Scholar]

- Ziegler, A.; Schröoder, M.; Rennings, K. The effect of environmental and social performance on the stock performance of European corporations. Environ. Resour. Econ. 2007, 37, 661–680. [Google Scholar]

- Konar, S.; Cohen, M.A. Does the market value environmental performance? Rev. Econ. Stat. 2001, 83, 2814–2890. [Google Scholar]

- Bellesi, F.; Lehrer, D.; Tal, A. Comparative advantage: The impact of ISO 14001 environmental certification on exports. Environ. Sci. Technol. 2005, 39, 1943–1953. [Google Scholar]

- Delmas, M.A.; Pekovic, S. Environmental standards and labor productivity: Understanding the mechanisms that sustain sustainability. J. Organ. Behav. 2013, 34, 230–252. [Google Scholar]

- King, A.; Lenox, M. Who Adopts Management Standards Early? An Examination of ISO 14001 Certifications. Proc. Acad. Manag. Ann. Conf. 2001, 2001, A1–A6. [Google Scholar]

- Potoski, M.; Prakash, A. Green clubs and voluntary governance: ISO 14001 and firms’ regulatory compliance. Am. J. Political Sci. 2005, 49, 235–248. [Google Scholar]

- Heras-Saizarbitoria, I.; Molina-Azorín, J.F.; Dick, G.P. ISO 14001 certification and financial performance: Selection-effect versus treatment-effect. J. Clean. Prod. 2011, 19, 1–12. [Google Scholar]

- Yang, M.G.M.; Hong, P.; Modi, S.B. Impact of lean manufacturing and environmental management on business performance: An empirical study of manufacturing firms. Int. J. Prod. Econ. 2011, 129, 251–261. [Google Scholar]

- Calza, E.; Goedhuys, M.; Trifković, N. Drivers of productivity in Vietnamese SMEs: The role of management standards and innovation. Econ. Innov. New Technol. 2019, 28, 23–44. [Google Scholar]

- Sampaio, P.; Saraiva, P.; Guimarães Rodrigues, A. ISO 9001 Certification Research: Questions, Answers and Approaches’. Int. J. Qual. Reliab. Manag. 2009, 26, 38–58. [Google Scholar]

- Sartor, M.; Orzes, G.; Touboulic, A.; Culot, G.; Nassimbeni, G. ISO 14001 standard: Literature review and theory-based research agenda. Qual. Manag. J. 2019, 26, 32–64. [Google Scholar]

- Djupdal, K.; Westhead, P. Environmental certification as a buffer against the liabilities of newness and smallness: Firm performance benefits. Int. Small Bus. J. 2015, 33, 148–168. [Google Scholar]

- Viet Nam SME Survey. CIEM, ILSSA, UCPH, and UNU-WIDER (2011 and 2013 Rounds). Available online: https://www.wider.unu.edu/database/viet-nam-sme-database (accessed on 10 February 2018).

- Cleveland, C.J.; Ruth, M. Indicators of Dematerialization and the Materials Intensity of Use. J. Ind. Ecol. 1998, 2, 15–50. [Google Scholar]

- Bahn-Walkowiak, B.; Steger, S. Resource targets in Europe and worldwide: An overview. Resources 2015, 4, 597–620. [Google Scholar]

- OECD. Resource Productivity in the G8 and the OECD: A Report in the Framework of the Kobe 3R Action Plan; OECD Publishing: Paris, France, 2011; Available online: http://www.oecd.org/env/waste/47944428.pdf (accessed on 20 May 2018).

- Calantone, R.J.; Cavusgil, S.T.; Zhao, Y. Learning orientation, firm innovation capability, and firm performance. Ind. Market. Manag. 2002, 31, 515–524. [Google Scholar]

- Wooldridge, J. Econometric Analysis of Cross-Section and Panel Data; The MIT Press: Cambridge, MA, USA; London, UK, 2002. [Google Scholar]

- Halila, F. Networks as a means of supporting the adoption of organizational innovations in SMEs: The case of Environmental Management Systems (EMSs) based on ISO 14001. Corp. Soc. Responsib. Environ. Manag. 2007, 14, 167–181. [Google Scholar]

- Barla, P. ISO 14001 certification and environmental performance in Quebec’s pulp and paper industry. J. Environ. Econ. Manag. 2007, 53, 291–306. [Google Scholar]

- World Development Indicators Database. Available online: https://databank.worldbank.org/source/world-development-indicators (accessed on 30 June 2018).

- Staiger, D.; Stock, J.H. Instrumental variables regression with weak instruments. Econometrica 1997, 65, 557–586. [Google Scholar]

- Fischer, S.; O’Brien, M. Eco-innovation in Business: Reducing cost and increasing profitability via Material Efficiency Measures. Eco-Innov. Obs. 2012, 10, 1–6. [Google Scholar]

- Verbeek, M.; Nijman, T. Testing for selectivity bias in panel data models. Int. Econ. Rev. 1992, 33, 681–703. [Google Scholar]

- Nakamura, M.; Takahashi, T.; Vertinsky, I. Why Japanese Firms Choose to Certify: A Study of Managerial Responses to Environmental Issues. J. Environ. Econ. Manag. 2001, 42, 23–52. [Google Scholar]

- Hillary, R. (Ed.) Small and Medium-Sized Enterprises and the Environment: Business Imperatives; Greenleaf Publishing: Sheffield, UK, 2000. [Google Scholar]

- Biondi, V.; Frey, M.; Iraldo, F. Environmental management systems and SMEs. Greener Manag. Int. 2000, 29, 55–69. [Google Scholar]

- OECD. Enhancing the Contributions of SMEs in Global and Digitalised Economy; OECD Publishing: Paris, France, 2017; Available online: https://www.oecd.org/industry/C-MIN-2017-8-EN.pdf (accessed on 20 August 2020).

| 2011 | 2013 | All Years, Balanced | All Years, Unbalanced | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Variables | Definition | Mean | SD | Mean | SD | Mean | SD | Mean | SD |

| EMS certificate | Firm adopts EMS certificate (1/0) | 0.183 | 0.387 | 0.206 | 0.405 | 0.195 | 0.396 | 0.159 | 0.366 |

| Intensity | Resource cost per unit of output (million VND/unit) | 0.821 | 4.123 | 36.272 | 106.048 | 18.547 | 77.096 | 19.073 | 84.299 |

| Resource cost | Real total cost of resources (million 2010 VND) | 129,438.9 | 337,963 | 101,598.8 | 238,941.2 | 115,518.9 | 292,946.5 | 106,891.1 | 315,657.5 |

| Input-cost share | Total inputs cost as a proportion of total indirect cost (%) | 51.775 | 24.632 | 52.731 | 24.312 | 52.253 | 24.473 | 55.875 | 24.73 |

| Output_value | Real Production output (million 2010 VND) | 10,963.93 | 226,678.4 | 3907.911 | 9490.459 | 7435.92 | 160,435 | 5552.355 | 121,084.2 |

| Output_units | Total production units (thousands) | 14,200 | 32,500 | 445.827 | 4953 | 7309 | 24,200 | 5749 | 20,800 |

| Age | Firm age at the time of survey (years) | 13.106 | 9.252 | 15.106 | 9.252 | 14.106 | 9.304 | 14.876 | 9.974 |

| Firm size | Total Number of regular full-time employees | 15.89 | 27.283 | 14.16 | 23.517 | 15.025 | 25.48 | 12.804 | 25.261 |

| Innovation | Firm introduced new technology/new product group (1/0) | 0.517 | 0.5 | 0.237 | 0.425 | 0.377 | 0.485 | 0.318 | 0.466 |

| Training | Firm provides training to new/existing workers(1/0) | 0.15 | 0.357 | 0.243 | 0.429 | 0.197 | 0.397 | 0.155 | 0.362 |

| Intermediate output | Output used as intermediate input in manufacturing (%) | 17.712 | 33.46 | 13.843 | 29.143 | 15.777 | 31.429 | 13.488 | 29.667 |

| Association | Firm is a member of a business association(1/0) | 0.094 | 0.292 | 0.107 | 0.31 | 0.101 | 0.301 | 0.078 | 0.269 |

| Loan | Firm applied for formal loan in previous year (1/0) | 0.356 | 0.479 | 0.302 | 0.459 | 0.329 | 0.47 | 0.276 | 0.447 |

| Raw material | The share of raw material from households (%) | 3.727 | 9.316 | 8.946 | 12.303 | 6.336 | 11.218 | 6.964 | 11.942 |

| KL ratio | The ratio between total real assets and wages | 23.579 | 49.186 | 17.48 | 34.118 | 20.53 | 42.43 | 21.878 | 71.524 |

| Capacity | Firm can increase production capacity by 25% or more (1/0) | 0.298 | 0.457 | 0.302 | 0.459 | 0.3 | 0.458 | 0.317 | 0.465 |

| E-trade | Firm sells its output via E-trade (1/0) | 0.08 | 0.271 | 0.059 | 0.236 | 0.069 | 0.254 | 0.055 | 0.227 |

| Assistance | Firm received some sort of government assistance (1/0) | 0.153 | 0.36 | 0.122 | 0.328 | 0.138 | 0.345 | 0.13 | 0.336 |

| Vintage | Percentage of equipment under 3 years old | 17.655 | 29.342 | 12.998 | 22.585 | 15.327 | 26.281 | 15.475 | 27.629 |

| Competition | Firm faces competition from same field of activity (1/0) | 0.901 | 0.299 | 0.907 | 0.291 | 0.904 | 0.295 | 0.871 | 0.335 |

| Real net profits | Real total net profits (million 2010 VND) | 718.175 | 8373.029 | 401.572 | 1497.209 | 561.615 | 6046.427 | 471.081 | 4856.273 |

| Indirect Cost | Real total indirect cost (million 2010 VND) | 292,746.5 | 978,626.6 | 229,722.3 | 617,605.2 | 261,234.4 | 818,727.8 | 236,791.4 | 925,568.3 |

| Price | Average Price per unit of output (1000 VND) | 4076.263 | 26,187.71 | 3717.606 | 16,699.95 | 3896.935 | 21,958.91 | 3892.277 | 22,893.03 |

| Observations | 1333 | 1333 | 2666 | 4733 | |||||

| All | Non-Adopters | Adopters | |||||

|---|---|---|---|---|---|---|---|

| VARIABLES | Mean | S.D | Mean | S.D | Mean | S.D | t-Test |

| Intensity (million VND/unit) | 18.547 | 77.096 | 19.242 | 76.596 | 15.672 | 79.141 | 0.946 |

| Resource costs (million 2010 VND) | 115,518.9 | 292,946.5 | 81,705.86 | 176,669.2 | 255,396.6 | 536,529.8 | −12.468 *** |

| Input-Cost Share (%, indirect cost) | 52.253 | 24.473 | 51.493 | 24.48 | 55.395 | 24.212 | −3.265 *** |

| Output_value (million 2010 VND) | 7435.92 | 160,435 | 6822.54 | 178,521.6 | 9973.349 | 19,568.92 | −0.4014 |

| Output_units (thousands) | 7309 | 24,200 | 6203 | 22,100 | 11,900 | 31,100 | −4.815 *** |

| Firm Age (years) | 14.106 | 9.304 | 14.253 | 9.307 | 13.495 | 9.275 | 1.666 ** |

| Firm size | 15.025 | 25.48 | 11.721 | 21.024 | 28.694 | 35.727 | −14.115 |

| Innovation (dummy) | 37.7 | 48.5 | 37.7 | 48.5 | 37.8 | 48.5 | −0.035 |

| Training (dummy) | 19.7 | 39.7 | 17.9 | 38.3 | 27.0 | 44.4 | −4.693 *** |

| Intermediate output (%) | 15.777 | 31.429 | 15.209 | 30.946 | 18.129 | 33.281 | −1.9 * |

| Association (dummy) | 10.1 | 30.1 | 8.20 | 27.5 | 17.5 | 38.1 | −6.361 *** |

| Loan (dummy) | 32.9 | 47.0 | 31.5 | 46.5 | 38.5 | 48.7 | −3.072 *** |

| Raw material from Household (%) | 6.336 | 11.218 | 6.558 | 11.528 | 5.421 | 9.791 | 2.072 ** |

| KL Ratio | 20.53 | 42.43 | 20.819 | 44.94 | 19.334 | 29.894 | 0.715 |

| Capacity | 30.0 | 45.8 | 29.9 | 45.8 | 30.3 | 46.0 | −0.134 |

| e-trading (dummy) | 6.9 | 25.4 | 5.2 | 22.1 | 14.3 | 35.0 | −7.383 *** |

| Assistance (dummy) | 13.8 | 34.5 | 13.4 | 34.1 | 15.2 | 36.0 | −1.072 |

| Vintage (%) | 15.3 | 26.28 | 16.0 | 26.659 | 14.478 | 24.662 | 0.819 |

| Competition (%) | 0.904 | 0.295 | 0.900 | 0.299 | 0.919 | 0.273 | 0.193 |

| Profit (million 2010 VND) | 561.615 | 6046.427 | 459.278 | 6563.745 | 984.302 | 3069.88 | −1.767 * |

| Indirect cost (million 2010 VND) | 261,234.4 | 818,727.8 | 187,370.6 | 584,140.8 | 566,794.4 | 1,385,222 | −9.636 *** |

| Price (1000 VND) | 3896.935 | 21,958.91 | 3972.549 | 22,695.12 | 3584.133 | 18,622.73 | 0.361 |

| Observations | 2666 | 2147 | 519 | ||||

| Dependent Variable: Resource Intensity (Logs) | ||||||||

|---|---|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | |

| Variables | OLS | Fixed Effects | 2 SLS | 2 SLS | 2 SLS | 2 SLS | 2 SLS | 2 SLS |

| EMS Adoption | −0.505 *** | −0.247 | −2.282 *** | −2.391 *** | −3.361 *** | −1.353 * | −0.841 | −2.305 |

| (0.161) | (0.166) | (0.453) | (0.542) | (0.565) | (0.752) | (0.778) | (2.027) | |

| Firm Age (logs) | 0.171 | 0.511 *** | −0.039 | −0.034 | −0.098 | 0.733 | ||

| (0.346) | (0.095) | (0.102) | (0.082) | (0.082) | (0.674) | |||

| Firm size (logs) | −0.0479 | −0.044 | 0.283 ** | 0.085 | 0.131 | −0.066 | ||

| (0.113) | (0.111) | (0.114) | (0.106) | (0.115) | (0.118) | |||

| Innovation (dummy) | 0.0127 | −0.922 *** | 0.379 *** | 0.160 * | 0.191 ** | 0.056 | ||

| (0.0915) | (0.135) | (0.112) | (0.094) | (0.091) | (0.106) | |||

| Training (dummy) | 0.0631 | 1.155 *** | 0.281 ** | 0.360 *** | 0.271 ** | 0.019 | ||

| (0.111) | (0.164) | (0.139) | (0.117) | (0.117) | (0.128) | |||

| Intermediate inputs (%) | −0.000745 | −0.002 | 0.001 | −0.001 | 0.000 | −0.002 | ||

| (0.00171) | (0.002) | (0.002) | (0.002) | (0.002) | (0.002) | |||

| Association (dummy) | −0.203 | 0.937 *** | 0.151 | 0.046 | −0.179 | −0.107 | ||

| (0.187) | (0.228) | (0.204) | (0.173) | (0.174) | (0.225) | |||

| Loans (dummy) | 0.127 | 0.713 *** | 0.420 *** | 0.424*** | 0.305 *** | 0.091 | ||

| (0.118) | (0.143) | (0.127) | (0.107) | (0.106) | (0.128) | |||

| Raw Material from Household (%) | −0.0130 *** | 0.028 *** | −0.012 *** | −0.008* | −0.005 | −0.014 *** | ||

| (0.00422) | (0.006) | (0.005) | (0.004) | (0.004) | (0.005) | |||

| KL Ratio | 0.0941 | −0.261 *** | 0.113 * | 0.103 ** | 0.137 *** | 0.126 * | ||

| (0.0591) | (0.060) | (0.058) | (0.047) | (0.049) | (0.067) | |||

| Capacity (dummy) | −0.0360 | 0.419 *** | 0.126 | 0.148 | 0.043 | 0.039 | ||

| (0.0991) | (0.138) | (0.118) | (0.102) | (0.102) | (0.129) | |||

| E-trade (dummy) | 0.704 *** | 0.414 | 0.488 * | 0.321 | 0.262 | 0.662 *** | ||

| (0.202) | (0.277) | (0.258) | (0.226) | (0.219) | (0.212) | |||

| Competition (dummy) | −0.165 | 0.445 ** | 0.203 | 0.018 | 0.006 | −0.116 | ||

| (0.182) | (0.215) | (0.186) | (0.161) | (0.158) | (0.190) | |||

| Assistance (dummy) | −0.259 ** | −0.494 ** | −0.288 * | −0.182 | −0.2 | −0.269 ** | ||

| (0.126) | (0.195) | (0.155) | (0.132) | (0.128) | (0.129) | |||

| Vintage (%) | −0.000175 | −0.005 ** | −0.003 | −0.002 | −0.003 * | 0.000 | ||

| (0.00169) | (0.002) | (0.002) | (0.002) | (0.002) | (0.002) | |||

| Constant | −1.005 *** | −3.575 *** | −0.659 *** | −1.959 *** | −4.530 *** | −4.745 *** | −4.923 *** | −0.827 |

| (0.0709) | (0.860) | (0.103) | (0.407) | (0.464) | (0.318) | (0.359) | (1.203) | |

| Observations | 2.666 | 2.666 | 2.666 | 2.666 | 2.666 | 2.666 | 2.666 | 2.666 |

| Number of id | 1.333 | 1.333 | 1.333 | 1.333 | 1.333 | 1.333 | 1.333 | 1.333 |

| R-squared | 0.004 | 0.811 | 0.042 | 0.044 | 0.404 | 0.574 | 0.597 | 0.773 |

| Legal FE | NO | YES | NO | NO | YES | YES | YES | NO |

| Province FE | NO | YES | NO | NO | YES | NO | YES | NO |

| Sector | NO | YES | NO | NO | NO | YES | YES | NO |

| Year FE | NO | YES | NO | NO | YES | YES | YES | YES |

| Firm FE | NO | NO | NO | NO | NO | NO | NO | YES |

| Electricity Intensity | Fuel Intensity | Water Intensity | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Variables | Model 1a | Model 2a | Model 3a | Model 1b | Model 2b | Model 3b | Model 1c | Model 2c | Model 3c |

| EMS Adoption | −2.723 *** | −3.780 *** | −1.203 | −2.686 *** | −3.583 *** | −1.797 ** | −1.512 ** | −2.804 *** | −1.323 |

| (0.582) | (0.625) | (0.801) | (0.596) | (0.613) | (0.844) | (0.587) | (0.566) | (0.843) | |

| Constant | −2.773 *** | −5.230 *** | −5.782 *** | −3.064 *** | −5.802 *** | −5.617 *** | −6.867 *** | −7.134 *** | −7.078 *** |

| (0.428) | (0.491) | (0.330) | (0.444) | (0.505) | (0.358) | (0.502) | (0.382) | (0.422) | |

| Observations | 2664 | 2664 | 2664 | 2466 | 2466 | 2466 | 1966 | 1966 | 1966 |

| Number of id | 1333 | 1333 | 1333 | 1305 | 1305 | 1305 | 1145 | 1145 | 1145 |

| R-squared | 0.019 | 0.360 | 0.571 | 0.030 | 0.373 | 0.523 | 0.085 | 0.395 | 0.540 |

| Controls | YES | YES | YES | YES | YES | YES | YES | YES | YES |

| Legal FE | NO | YES | YES | NO | YES | YES | NO | YES | YES |

| Province FE | NO | YES | NO | NO | YES | NO | NO | YES | NO |

| Sector | NO | NO | YES | NO | NO | YES | NO | NO | YES |

| Year FE | NO | YES | YES | NO | YES | YES | NO | YES | YES |

| Dependent Variable: Resource Intensity (Logs) | ||||||

|---|---|---|---|---|---|---|

| Heavy Industrial Activities | Light Industrial Activities | |||||

| Variables | (1) | (2) | (3) | (4) | (5) | (6) |

| EMS Adoption | −1.505 *** | −1.588 ** | −2.407 *** | −3.611 *** | −3.465 *** | −4.475 *** |

| (0.542) | (0.792) | (0.796) | (0.780) | (0.822) | (0.898) | |

| Firm Age (logs) | 0.380 *** | −0.033 | 0.581 *** | −0.032 | ||

| (0.141) | (0.141) | (0.129) | (0.149) | |||

| Firm size (logs) | −0.195 | 0.019 | 0.153 | 0.517 *** | ||

| (0.181) | (0.192) | (0.145) | (0.139) | |||

| Innovation (dummy) | −1.179 *** | 0.064 | −0.733 *** | 0.588 *** | ||

| (0.199) | (0.170) | (0.186) | (0.156) | |||

| Training (dummy) | 1.622 *** | 0.634 *** | 0.737 *** | −0.042 | ||

| (0.228) | (0.202) | (0.230) | (0.191) | |||

| Intermediate inputs (%) | −0.005 * | 0.001 | −0.006 | −0.007 * | ||

| (0.003) | (0.002) | (0.004) | (0.003) | |||

| Association | 0.858 ** | 0.196 | 0.886 *** | 0.104 | ||

| (0.356) | (0.324) | (0.316) | (0.262) | |||

| Loans (dummy) | 0.489 ** | 0.314 * | 0.845 *** | 0.445 ** | ||

| (0.215) | (0.179) | (0.194) | (0.179) | |||

| Raw material from households (%) | 0.024 ** | −0.011 | 0.034 *** | −0.011 * | ||

| (0.012) | (0.008) | (0.007) | (0.006) | |||

| KL ratio | −0.303 *** | −0.05 | −0.200 ** | 0.257 *** | ||

| (0.089) | (0.085) | (0.081) | (0.078) | |||

| Capacity | 0.416 ** | 0.173 | 0.458 ** | 0.137 | ||

| (0.198) | (0.174) | (0.186) | (0.162) | |||

| E-trade (dummy) | 0.442 | 0.630 * | 0.388 | 0.285 | ||

| (0.404) | (0.372) | (0.405) | (0.359) | |||

| Competition | 0.37 | 0.116 | 0.494 * | 0.308 | ||

| (0.322) | (0.261) | (0.291) | (0.260) | |||

| Assistance (dummy) | −0.689 ** | −0.353 | −0.376 | −0.269 | ||

| (0.307) | (0.246) | (0.249) | (0.203) | |||

| Vintage | −0.009 *** | −0.003 | −0.005 | −0.004 | ||

| (0.003) | (0.003) | (0.003) | (0.003) | |||

| Constant | −0.536 *** | −0.779 | −3.099 *** | −0.593 *** | −2.824 *** | −5.859 *** |

| (0.129) | (0.605) | (0.641) | (0.167) | (0.558) | (0.639) | |

| Observations | 1070 | 1070 | 1070 | 1596 | 1596 | 1596 |

| Year FE | No | No | Yes | No | No | Yes |

| Province FE | No | No | Yes | No | No | Yes |

| Legal FE | No | No | Yes | No | No | Yes |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fadly, D. Greening Industry in Vietnam: Environmental Management Standards and Resource Efficiency in SMEs. Sustainability 2020, 12, 7455. https://doi.org/10.3390/su12187455

Fadly D. Greening Industry in Vietnam: Environmental Management Standards and Resource Efficiency in SMEs. Sustainability. 2020; 12(18):7455. https://doi.org/10.3390/su12187455

Chicago/Turabian StyleFadly, Dalia. 2020. "Greening Industry in Vietnam: Environmental Management Standards and Resource Efficiency in SMEs" Sustainability 12, no. 18: 7455. https://doi.org/10.3390/su12187455

APA StyleFadly, D. (2020). Greening Industry in Vietnam: Environmental Management Standards and Resource Efficiency in SMEs. Sustainability, 12(18), 7455. https://doi.org/10.3390/su12187455