More Sustainable Bioenergy by Making Use of Regional Alternative Biomass?

Abstract

1. Introduction

2. Materials and Methods

- (a)

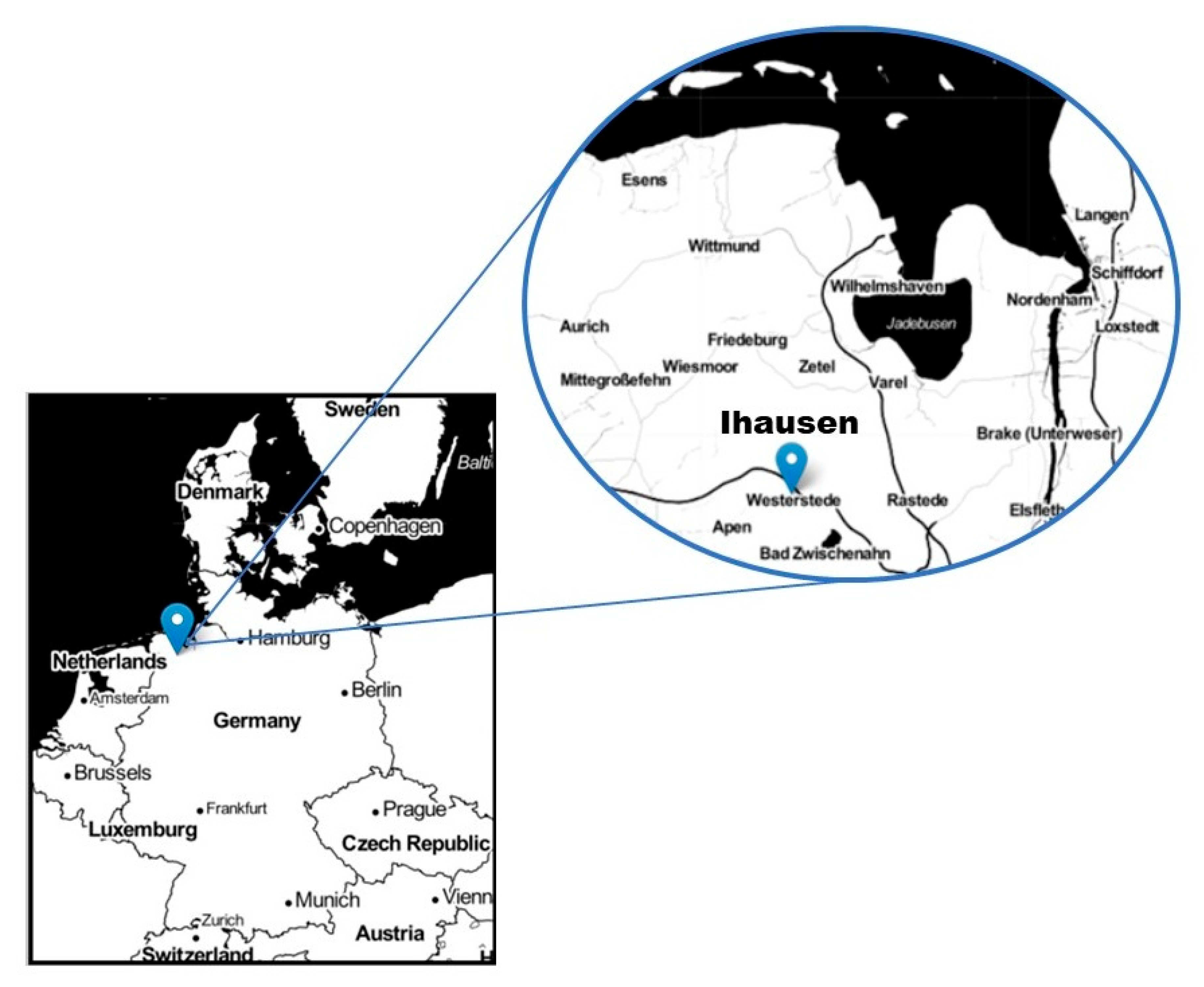

- Identification of the regionally available biomass potentials in a bioenergy region typical for both natural and socioeconomic conditions of established German regional bioenergy structures (agriculture and grassland areas as typical regions in the rural northwestern area of Germany, cf. Section 2.1). This step established an inventory of the regional preconditions for a sustainable bioenergy production.

- (b)

- Analysis of the socio-ecological context of bioenergy supply chains for the assessment of the potential of so far unused biomass (cf. Section 2.2). This step introduced a generic framework for the analysis of the regional bioenergy structure, using the criteria of economic, social, and environmental conditions for all phases of the bioenergy process chain.

- (c)

- Participatory definition of realistic options for optimized biomass mixtures (cf. Section 2.3). Bioenergy producers together with regional stakeholders identified options for modified bioenergy chains at this step. They aimed at the integration of alternative substrates that could be made available for bioenergy purposes at high levels of feasibility.

- (d)

- Gathering of site-specific data and reference data sets (cf. Section 2.3). Quantitative and semiquantitative data on the criteria of the analytical framework were gathered from bioenergy plant owners and literature at this step.

- (e)

- MCDA according to the socio-ecological context and data with a preference analysis of the identified options according to PROMETHEE outranking method (cf. Section 2.4). The final step aimed at the identification of alternative bioenergy chains that could optimize the current regional bioenergy structures most.

2.1. Identification of the Regionally Available Biomass Potentials for Bioenergy

2.2. Analysis of the Socio-Ecological Context of Bioenergy Supply Chains for the Assessment—Definition of Criteria

2.3. Participatory Definition of Realistic Scenarios of Options for Optimized Biomass Mixtures with Applicable and Regional-Specific Options

- Scenario A—Baseline: The current mix of substrate is based upon an operator survey executed within a project performed on cross-country borders in Germany and the Netherlands (GroenGas-DELaND, EU-project, Dutch-German cross-border program).

- Scenario B—Max 60% corn silage: The German Renewable Energy Sources Act (EEG) 2012 used to allow farmers a maximum usage of corn silage of 60% (EEG § 27 Biomasse Abs. 5 Nr. 2, 2012). As discussed in the introduction, because the EEG 2012 applied to the majority of biogas plants, this value was preferred to the latest version of EEG in 2017. Since corn silage has a very high gas-yield-to-material cost ratio many operators can maximize the revenue of the plant by using the highest possible amount of corn silage. However, this always has to be considered within the regional context and the increased usage of corn silage is connected to negative social and ecologic impacts on biodiversity in the region.

- Scenario C—Alternative substrates: Alternative substrates to biomass are available in the region that are not yet considered for bioenergy production and are mainly provided by external stakeholders outside the classic bioenergy supply chain (e.g., municipalities, water body authorities, etc.). Besides energy crops, a detailed observation of substrates that are not produced for the target of biogas production was conducted. Alternative substrates were classified within the groups of (i) municipal and industrial (process) waste (biowaste), (ii) agricultural side products (cow dung, rye silage, corn-cob mix, liquid cow manure, roadside and buffer strips along water courses, and grass waste from local residents), and (iii) plant material from landscape conservation (grass from permanent grassland and conservation areas). Potentials were calculated with the support of geographic information systems (GIS) [14] and data from the Federal Statistical Office of Germany [51]. For the scenario of the potential of alternative substrates several assumptions were made. Firstly, all alternative substrates are available for usage in the case study biogas plant. Therefore, no competition with other industries (e.g., direct usage of cow dung) is considered. Secondly, alternative substrates from group (iii), plant material from landscape conservation, can be used free of charge in this region, excluding the costs for transport. Emissions and costs resulting from the process of landscape conservation were not considered within this study. It should be noted, that these alternative substrates are fully in line with the emission reduction targets of RED II and these substrates are generally not in conflict with land-use change. Material costs for substrates other than grass are specific to the considered region. Thirdly, the usage of a diverse mix of alternative substrates requires technical adjustments of the plant and could lead to instable operation. This was not considered as extra costs.

- Scenario D—100% Grass from Grassland: The northwestern area of Germany is covered by a huge amount of grassland, and therefore, biogas farmers tend to use grass from grassland as feed to the biogas plant as well. On average, material costs for grass from grassland is zero in this area, therefore, their actual costs represent the harvesting costs, including transportation, since the operator of the plant can use the substrate as long as he harvests the area on own expense.

2.4. Substrate Compositions

2.5. Multi-Criteria Decision Analysis (MCDA) According to the Socio-Ecological Context and Data with a Preference Analysis of the Identified Options According to PROMETHEE Outranking Method

3. Results

3.1. Criteria Values

3.2. Preference Rankings

4. Discussion

- (i).

- From mono-substrates to diverse substrates with alternative biomasses

- (ii).

- From sectoral bioenergy to multi-faceted bioeconomy (the lock-ins of former bioenergy and bioeconomy as an open way out of it)

- (iii).

- Bioenergy as part of regional actions toward sustainable development (bioenergy as an element of solutions and SDGs guiding the way)

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zabaniotou, A. Redesigning a bioenergy sector in EU in the transition to circular waste-based Bioeconomy—A multidisciplinary review. J. Clean. Prod. 2018, 177, 197–206. [Google Scholar] [CrossRef]

- McGovern, G.; Klenke, T. Towards a driver framework for regional bioenergy pathways. J. Clean. Prod. 2018, 185, 610–618. [Google Scholar] [CrossRef]

- Cavicchi, B.; Bryden, J.M.; Vittuari, M. A comparison of bioenergy policies and institutional frameworks in the rural areas of Emilia Romagna and Norway. Energy Policy 2014, 67, 355–363. [Google Scholar] [CrossRef]

- Diaz-Chavez, R.A. Land use for integrated systems: A bioenergy perspective. Environ. Dev. 2012, 3, 91–99. [Google Scholar] [CrossRef]

- Guo, M.; Richter, G.M.; Holland, R.A.; Eigenbrod, F.; Taylor, G.; Nilay, S. Implementing land-use and ecosystem service effects into an integrated bioenergy value chain optimization framework. Comput. Chem. Eng. 2016, 91, 392–406. [Google Scholar] [CrossRef]

- UN. Transforming Our World: The 2030 Agenda for Sustainable Development. 2015. Available online: https://sustainabledevelopment.un.org/post2015/transformingourworld (accessed on 21 August 2019).

- Linser, S.; Lier, M. The Contribution of Sustainable Development Goals and Forest-Related Indicators to National Bioeconomy Progress Monitoring. Sustainability 2020, 12, 2898. [Google Scholar] [CrossRef]

- Biber-Freudenberger, L.; Ergeneman, C.; Förster, J.J.; Dietz, T.; Börner, J. Bioeconomy futures: Expectation patterns of scientists and practitioners on the sustainability of bio-based transformation. Sustain. Dev. 2020, 1–16. [Google Scholar] [CrossRef]

- Helming, K.; Daedlow, K.; Paul, C.; Techen, A.-K.; Bartke, S.; Bartkowski, B.; Kaiser, D.; Wollschläger, U.; Vogel, H.-J. Managing soil functions for a sustainable bioeconomy—Assessment framework and state of the art. Land Degrad. Dev. 2018, 29, 3112–3126. [Google Scholar] [CrossRef]

- Geldermann, J.; Kolbe, L.M.; Krause, A.; Mai, C.; Militz, H.; Osburg, V.-S.; Schöbel, A.; Schumann, M.; Toporowski, W.; Westphal, S. Improved resource efficiency and cascading utilization of renewable materials. J. Clean. Prod. 2016, 110, 1–8. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.-F.; Monforti-Ferrario, F.; Nita, V. The role of biomass and bioenergy in a future bioeconomy: Policies and facts. Environ. Dev. 2015, 15, 3–34. [Google Scholar] [CrossRef]

- Keegan, D.; Kretschmer, B.; Elbersen, B.; Panoutsou, C. Cascading use: A systematic approach to biomass beyond the energy sector. Biofuels Bioprod. Biorefin. 2013, 7, 193–206. [Google Scholar] [CrossRef]

- Haberl, H.; Geissler, S. Cascade utilization of biomass: Strategies for a more efficient use of a scarce resource. Ecol. Eng. 2000, 16, 111–121. [Google Scholar] [CrossRef]

- Pehlken, A.; Madena, K.; Aden, C.; Klenke, T. Forming stakeholder alliances to unlock alternative and unused biomass potentials in bioenergy regions. J. Clean. Prod. 2016, 110, 66–77. [Google Scholar] [CrossRef]

- Schmehl, M.; Eigner-Thiel, S.; Ibendorf, J.; Hesse, M.; Geldermann, J. Development of an Information System for the Assessment of Different Bioenergy Concepts Regarding Sustainable Development. In Corporate Environmental Management Information Systems: Advancements and Trends; Teutenberg, F., Gomez, J.M., Eds.; IGI Global: Hershey, PA, USA, 2010; pp. 318–336. [Google Scholar]

- Karpenstein-Machan, M.; Schmuck, P. The bioenergy village in Germany—A lighthouse project for sustainable energy production in rural areas. In Local Perspectives on Bioproduction, Ecosystems and Humanity; Osaki, M., Braimoh, A., Nakagami, K., Eds.; United Nations University Press: Tokyo, Japan, 2010; pp. 184–194. [Google Scholar]

- Esteves, E.; Herrera, A.; Esteves, V.; Morgadi, C. Life cycle assessment of manure biogas production: A review. J. Clean. Prod. 2019, 219, 411–423. [Google Scholar] [CrossRef]

- Timonen, K.; Sinkko, T.; Luostarinen, S.; Tampio, E.; Joensuu, K. LCA of anaerobic digestion: Emission allocation for energy and digestate. J. Clean. Prod. 2019, 235, 1567–1579. [Google Scholar] [CrossRef]

- Tamburini, E.; Gaglio, M.; Castaldelli, G.; Fano, E.A. Is Bioenergy Truly Sustainable When Land-Use-Change (LUC) Emissions Are Accounted for? The Case-Study of Biogas from Agricultural Biomass in Emilia-Romagna Region. Italy. Sustainability 2020, 12, 3260. [Google Scholar] [CrossRef]

- Rasi, S.; Timonen, K.; Joensuu, K.; Regina, K.; Virkajärvi, P.; Heusala, H.; Tampio, E.; Luostarinen, S. Sustainability of Vehicle Fuel Biomethane Produced from Grass Silage in Finland. Sustainability 2020, 12, 3994. [Google Scholar] [CrossRef]

- Lokesh, K.; Ladu, L.; Summerton, L. Bridging the Gaps for a ‘Circular’ Bioeconomy: Selection Criteria, Bio-Based Value Chain and Stakeholder Mapping. Sustainability 2018, 10, 1695. [Google Scholar] [CrossRef]

- Herrmann, A. Biogas production from maize: Current state, challenges and prospects. 2. Agronomic and environmental aspects. Bioenergy Res. 2013, 6, 372–387. [Google Scholar] [CrossRef]

- Fachagentur Nachwachsende Rohstoffe, e.V.(FNR). Basisdaten Bioenergie Deutschland. 2019. Available online: https://www.fnr.de/fileadmin/allgemein/pdf/broschueren/basisdaten_bioenergie_2019_web.pdf (accessed on 21 August 2019).

- EU. Directive 2018/2001 on the Promotion of the Use of Energy from Renewable Sources. 2018. Available online: https://eur-lex.europa.eu/legal-content/de/TXT/?uri=CELEX:32018L2001 (accessed on 21 August 2019).

- EU. Bioeconomy Strategy. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52018DC0673 (accessed on 21 August 2019).

- Ronzon, T.; Sanjuánc, A.I. Friends or foes? A compatibility assessment of bioeconomy-related Sustainable Development Goals for European policy coherence. J. Clean. Prod. 2020, 254, 119832. [Google Scholar] [CrossRef]

- Capodaglio, A.G.; Callegari, A.; Lopez, M.V. European Framework for the Diffusion of Biogas Uses: Emerging Technologies, Acceptance, Incentive Strategies, and Institutional-Regulatory Support. Sustainability 2016, 8, 298. [Google Scholar] [CrossRef]

- Wüste, A.; Schmuck, P. Bioenergy Villages and Regions in Germany: An Interview Study with Initiators of Communal Bioenergy Projects on the Success Factors for Restructuring the Energy Supply of the Community. Sustainability 2012, 4, 244–256. [Google Scholar] [CrossRef]

- Meyer-Aurich, A.; Lochmann, Y.; Klauss, H.; Prochnow, A. Comparative Advantage of Maize- and Grass-Silage Based Feedstock for Biogas Production with Respect to Greenhouse Gas Mitigation. Sustainability 2016, 8, 617. [Google Scholar] [CrossRef]

- Appel, F.; Ostermeyer-Wiethaup, A.; Balmann, A. Effects of the German Renewable Energy Act on structural change in agriculture. The case of biogas. Util. Policy 2016, 41, 172–182. [Google Scholar] [CrossRef]

- Dale, V.H.; Efroymson, R.A.; Kline, K.L.; Langholtz, M.H.; Leiby, P.N.; Oladosu, G.N.; Davies, M.R.; Downing, M.E.; Hilliard, M.R. Indicators for assessing socioeconomic sustainability of bioenergy systems: A short list of practical measures. Ecol. Indic. 2013, 26, 87–102. [Google Scholar] [CrossRef]

- Scott, J.A.; Ho, W.; Dey, P.K. A review of multi-criteria decision-making methods for bioenergy systems. Energy 2012, 42, 146–156. [Google Scholar] [CrossRef]

- Kaya, D.; Türk, M.; Kaya, T. Examining the Effect of Dimension Reduction on EEG Signals by K-Nearest Neighbors Algorithm. El-Cezerî J. Sci. Eng. 2018, 5, 591–595. [Google Scholar] [CrossRef]

- Alizadeh, R.; Soltanisehat, L.; Lund, P.D.; Zamanisabzi, H. Improving renewable energy policy planning and decision-making through a hybrid MCDM method. Energy Policy 2020, 137, 111174. [Google Scholar] [CrossRef]

- Isermann, K.; Isermann, R. Possibilities and limitations of the Nutrients cycle of C, N, P, S, K within the food and farming sector—Möglichkeiten und Grenzen des Kreislaufes der Nährstoffe C, N, P, S, K innerhalb des Ernährungsbereiches und der Landwirtschaft. In Proceedings of the VDLUFA-Schriftenreihe 61/2006, Bonn, Germany, 27–29 September 2005; pp. 454–463. [Google Scholar]

- Dobslaw, D.; Engesser, K.-H.; Störk, H.; Gerl, T. Low-cost process for emission abatement of biogas internal combustion engines. J. Clean. Prod. 2019, 227, 1079–1092. [Google Scholar] [CrossRef]

- Ledo, A.; Heathcote, R.; Hastings, A.; Smith, P.; Hillier, J. Perennial-GHG: A new generic allometric model to estimate biomass accumulation and greenhouse gas emissions in perennial food and bioenergy crops. Environ. Model. Softw. 2018, 102, 292–305. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, S.; Bi, X.; Clift, R. Greenhouse gas emission reduction potential and cost of bioenergy in British Columbia, Canada. Energy Policy 2020, 138, 111285. [Google Scholar] [CrossRef]

- Association for Supply-Chain Management. “Supply-Chain Operations Reference Model”, Version 12.0. 2020. Available online: http://www.apics.org/ (accessed on 16 February 2020).

- Meyerholt, D.; Gerdes, H. Decision support for Sustainable Supply Chain Management in praxis. In IT-gestütztes Ressourcen und Energiemanagement (Konferenzband zu den 5. BUIS-Tagen); Gómez, J.M., Lang, C., Wohlgemuth, V., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 167–179. [Google Scholar]

- Pehlken, A.; Meyerholt, D.; Osmers, M. An Approach for the Assessment of Sustainable Supply Chain of Biomass. In Proceedings of the First International Conference on Resource Efficiency in Interorganizational Networks—ResEff, Göttingen, Germany, 13–14 November 2013; pp. 334–337. [Google Scholar]

- Federal Statistical Office of Germany (Destatis—Statistisches Bundesamt). Available online: https://www.destatis.de/DE/Startseite.html (accessed on 21 August 2019).

- Bavarian State Research Institute for Agriculture (LfL—Bayerische Landesanstalt für Landwirtschaft). Available online: https://www.lfl.bayern.de/ (accessed on 21 August 2019).

- Association for Technology and Structures in Agriculture (KTBL—Kuratorium für Technik und Bauwesen in der Landwirtschaft e.V.). Available online: https://www.ktbl.de/ (accessed on 21 August 2019).

- Kuratorium für Technik und Bauwesen in der Landwirtschaft (KTBL), Feasibility Calculator/Wirtschaftlichkeitsrechner Biogas. 2015. Available online: http://daten.ktbl.de/biogas/ (accessed on 21 August 2019).

- Deutsches Biomasseforschungszentrum (DBFZ), Vergütungsrechner. 2015. Available online: www.dbfz.de/eeg-monitoring (accessed on 21 August 2019).

- Software DungInfo Plus; Version 2007.1; Master Data; DLR-RLP: Rheinbach, Germany, 2007.

- Dawes, R.M.; Corrigan, B. Linear models in decision making. Psychol. Bull. 1974, 81, 95–106. [Google Scholar] [CrossRef]

- Zimmermann, H.J.; Gutsche, L. Multi-Criteria-Entscheidungen. In Multi-Criteria Analyse: Heidelberger Lehrtexte Wirtschaftswissenschaften; Springer: Berlin/Heidelberg, Germany, 1991. [Google Scholar]

- Walther, G.; Spengler, T.; Queiruga, D. Facility location planning for treatment of large household appliances in Spain. Int. J. Environ. Technol. Manag. 2008, 8, 405–425. [Google Scholar] [CrossRef]

- Destatis—Statistisches Bundesamt, Agrarstrukturerhebung. 2015. Available online: https://www.destatis.de/ (accessed on 21 August 2019).

- Bayerische Landsanstalt für Landwirtschaft (LfL), Biogas: ‘Was kosten Substrate frei Fermenter?’. 2008. Available online: https://www.lfl.bayern.de/mam/cms07/publikationen/daten/informationen/p_32444.pdf (accessed on 21 August 2019).

- Bollmann, C.; KWS Mais GmbH. Sachgerechte Kalkulation der Ernte- u. Transportkosten für Biogassubstrate. 2013. Available online: http://docplayer.org/25939156-Sachgerechte-kalkulation-der-ernte-u-transportkosten-fuer-biogassubstrate.html (accessed on 21 August 2019).

- Kuratorium für Technik und Bauwesen in der Landwirtschaft (KTBL). Basic Figures Biogas/Faustzahlen Biogas, 1st ed.; KTBL: Darmstadt, Germany, 2007. [Google Scholar]

- Brans, J.; Vincke, P. A preference ranking organisation method (The PROMETHEE Method for Multiple Criteria Decision-Making). Manag. Sci. 1985, 31, 647–656. [Google Scholar] [CrossRef]

- Behzadian, M.; Kazemzadeh, R.B.; Albadvi, A.; Aghdasi, M. PROMETHEE: A comprehensive literature review on methodologies and applications. Eur. J. Oper. Res. 2010, 200, 198–215. [Google Scholar] [CrossRef]

- Cinelli, M.; Coles, S.R.; Kirwan, K. Analysis of the potentials of multi criteria decision analysis methods to conduct sustainability assessment. Ecol. Indic. 2014, 46, 138–148. [Google Scholar] [CrossRef]

- Papapostolou, A.; Karakosta, C.; Kourti, K.-A.; Doukas, H.; Psarras, J. Supporting Europe’s Energy Policy Towards a Decarbonised Energy System: A Comparative Assessment. Sustainability 2019, 11, 4010. [Google Scholar] [CrossRef]

- Mardani, A.; Jusoh, A.; Nor, K.M.D.; Khalifah, Z.; Zakwan, N.; Valipour, A. Multiple criteria decision-making techniques and their applications—A review of the literature from 2000 to 2014. Econ. Res.-Ekonomska Istraživanja 2015, 28, 516–571. [Google Scholar] [CrossRef]

- Oberschmidt, J.; Geldermann, J.; Ludwig, J.; Schmehl, M. Modified PROMETHEE approach for assessing energy technologies. Int. J. Energy Sect. Manag. 2010, 4, 183–212. [Google Scholar] [CrossRef]

- Lerche, N.; Wilkens, I.; Schmehl, M.; Eigner-Thiel, S.; Geldermann, J. Using methods of Multi-Criteria Decision Making to provide decision support concerning local bioenergy projects. Socio-Econ. Plan. Sci. 2017, 68, 1–15. [Google Scholar] [CrossRef]

- Schröder, T.; Lauven, L.P.; Beyer, B.; Lerche, N.; Geldermann, J. Using PROMETHEE to assess bioenergy pathways. Cent. Eur. J. Oper. Res. 2019, 27, 287–309. [Google Scholar] [CrossRef]

- Mareschal, B.; Smet, Y.D. Visual PROMETHEE: Developments of the PROMETHEE & GAIA multicriteria decision aid methods. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Hong Kong, China, 8–11 December 2009; pp. 1646–1649. [Google Scholar]

- Project “Dezentrale Energielandschaften Niederlande-Deutschland”/Decentralised Energy Landscapes Netherlands-Germany (DELaND), Operator Survey. Unpublished work. 2014.

- Eder, B.; Krieg, A. Biogas Praxis—Grundlagen, Planung, Beispiele, Wirtschaftlichkeit/Biogas in Praxis—Basics, Planning, Examples, Feasibility, 5th ed.; Ökobuch: Staufen im Breisgau, Germany, 2012. [Google Scholar]

- Bachmeier, J.; Gronauer, A. Klimabilanz von Biogasstrom: Klimabilanz der Energetischen Nutzung von Biogas aus Wirtschaftsdüngern und Nachwachsenden Rohstoffen/Carbon footprint of biogas electricity: Carbon Footprint of the Energetic Use of Biogas from Manure and Renewable Raw Materials; Bayerische Landesansalt für Landwirtschaft: Freising, Germany, 2007. [Google Scholar]

- Dilger, M.; Faulhaber, I. Materialsammlung Futterwirtschaft: Daten, Fakten und Berechnungsgrundlagen zu den Kosten der Grundfuttererzeugung und der Futterwirtschaft/Collection of Materials for the Feed Industry: Data, Facts and Calculation Bases for the Costs of Forage Production and the Feed Industry; Bayerische Landsanstalt für Landwirtschaft (LfL): München, Germany, 2006. [Google Scholar]

- Geldermann, J.; Schmehl, M.; Hesse, M. Ökobilanzielle Bewertung von Biogasanlagen unter Berücksichtigung der Niedersächsischen Verhältnisse/Life Cycle Assessment of Biogas Plants Taking into Account the Conditions in Lower Saxony; Georg-August-Universität Göttingen: Göttingen, Germany, 2012. [Google Scholar]

- Kranke, A.; Schmied, M.; Schön, A.D. CO2—Berechnung in der Logistik: Datenquellen, Formeln, Standards/CO2 Calculations in Logistics: Sources, Formulas, Standards, 1st ed.; Vogel: München, Germany, 2011. [Google Scholar]

- Wagner, A.; Juschkat, M.; Heitkämper, K.; Stadelmann, M.; Hartmann, S.; Schick, M. Arbeitszeitbedarf zur Betreuung von Biogasanlagen/Working hours related to biogas plants. In Tagungsband der 12. Wissenschaftstagung Ökologischer Landbau/Proceedings of the 12th Scientific Conference on Organic Farming, Berlin, Germany, 9 September 2013; Neuhoff, D., Stumm, C., Ziegler, S., Rahmann, G., Hamm, U., Köpke, U., Eds.; Verlag Dr. Köster: Berlin, Germany, 2013; pp. 760–763. [Google Scholar]

- Amon, T.; Amon, B.; Kryvoruchko, V.; Machmüller, A.; Hopfner-Sixt, K.; Bodiroza, V.; Hrbek, R.; Friedel, J.; Pötsch, E.; Wagentristl, H.; et al. Methane production through anaerobic digestion of various energy crops grown in sustainable crop rotations. Bioresour. Technol. 2007, 98, 3204–3212. [Google Scholar] [CrossRef] [PubMed]

- Faller, F.; Schulz, C. Sustainable Practices of the Energy Transition—Evidence from the Biogas and Building Industries in Luxembourg. Appl. Geogr. 2017, 90, 331–338. [Google Scholar] [CrossRef]

- Lutz, L.M.; Fischer, L.-T.; Newig, J.; Lang, D.J. Driving Factors for the Regional Implementation of Renewable Energy—A Multiple Case Study on the German Energy Transition. Energy Policy 2017, 105, 136–147. [Google Scholar] [CrossRef]

| Substrate in t/a | Scenario A | Scenario B | Scenario C | Scenario D |

|---|---|---|---|---|

| Corn silage | 1209 | 5844 | - | - |

| Rye silage (whole crop) | 429 | - | 429 | - |

| Corn-Cob Mix | 80 | - | 80 | - |

| Liquid cow manure | 5762 | 3896 | 2881 | - |

| Separated cow dung | - | - | 722 | - |

| Grass from grassland | 8423 | - | 715 | 14,153 |

| Plant material from | ||||

| (a) Conservation areas | - | - | 620 | - |

| (b) Roadside and buffer strips along water courses | - | - | 2400 | - |

| (c) Grass waste from local residents | - | - | 2547 | - |

| Biowaste | - | - | 1880 | - |

| Annual mass of substrate | 15,903 | 9740 | 12,274 | 14,153 |

| Annual methane yield | 721,816 | 721,843 | 721,838 | 721,803 |

| Criteria | Unit | Scenario A Baseline | Scenario B Max 60% Corn Silage | Scenario C Alternative Substrates | Scenario D 100% Grass from Grasslands | Reference | |

|---|---|---|---|---|---|---|---|

| 1. Material | |||||||

| 1.1 | Use of material not directly competing with food production | % | 89.20 | 40 | 95.85 | 100 | |

| 1.2 | Material costs | cent/m3 CH4 | 14.20 | 32.38 | 6.81 | 5.88 | [64] |

| 1.3 | Soil quality (change in humus balance) | tHum.C/a | −6.70 | −93.50 | −21.36 | 62.44 | [47,65] |

| 1.4 | Fuel consumption agriculture | L/t | 1.19 | 6.64 | 0.46 | 0 | [53,66] |

| 1.5 | Share of maize plants in area | ha | 24 | 117 | 0 | 0 | [42] |

| 1.6 | Working hours agriculture | hours/a | 1491 | 888 | 1974 | 1549 | [52,67] |

| 2. Logistic | |||||||

| 2.1 | Transport costs | EUR/t | 5.29 | 4.60 | 7.80 | 6.42 | [53,64] |

| 2.2 | Avg. transport distance | km | 10.57 | 13.00 | 16.35 | 10.00 | [68,69] |

| 2.3 | CO2 balance transport | gCO2/ m3 CH4 | 15.64 | 11.79 | 18.68 | 13.18 | [45] |

| 2.4 | Working hours transport | hours/a | 1683 | 897 | 1916 | 1816 | |

| 3. Production | |||||||

| 3.1 | Costs per production unit | cent/kWhel | 17.00 | 18.78 | 14.01 | 15.97 | [64,70] |

| 3.2 | CO2 balance production | gCO2/kWhel | 47.2 | 26.1 | 24.3 | 63.6 | [54] |

| 3.3 | Working hours plant | hours/a | 876.30 | 786.90 | 798.40 | 921.40 | [54,71] |

| 4. Usage | |||||||

| 4.1 | Total income p.a. | EUR/a | 124,496 | 40,938 | 145,004 | 169,712 | [70] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pehlken, A.; Wulf, K.; Grecksch, K.; Klenke, T.; Tsydenova, N. More Sustainable Bioenergy by Making Use of Regional Alternative Biomass? Sustainability 2020, 12, 7849. https://doi.org/10.3390/su12197849

Pehlken A, Wulf K, Grecksch K, Klenke T, Tsydenova N. More Sustainable Bioenergy by Making Use of Regional Alternative Biomass? Sustainability. 2020; 12(19):7849. https://doi.org/10.3390/su12197849

Chicago/Turabian StylePehlken, Alexandra, Kalle Wulf, Kevin Grecksch, Thomas Klenke, and Nina Tsydenova. 2020. "More Sustainable Bioenergy by Making Use of Regional Alternative Biomass?" Sustainability 12, no. 19: 7849. https://doi.org/10.3390/su12197849

APA StylePehlken, A., Wulf, K., Grecksch, K., Klenke, T., & Tsydenova, N. (2020). More Sustainable Bioenergy by Making Use of Regional Alternative Biomass? Sustainability, 12(19), 7849. https://doi.org/10.3390/su12197849