3.1. Data Collection

The first step is to identify the available conversion technologies with local settings in Malaysia. This includes conventional methods, such as direct combustion of MF and PKS for heat generation, as well as other commercialized and potential technologies. The life cycle of the palm industry, as well as the biorefineries, are then assessed to obtain two types of parameters: (i) The conversion ratio of inputs to outputs, and (ii) the expenses, such as capital (CAPEX) and operating (OPEX) expenses.

The scope of the palm oil industry includes the oil palm plantation and palm oil mill, both of which act as the source of biomass. The economic performance of these two sectors will not be assessed as their operations occur before the biomass conversion in the biorefineries. In other words, the profit and expenses are considered as constant regardless of which combination of biorefineries are chosen, i.e., they do not affect the result of optimization. However, the input resources of these sectors, such as steam, electricity, and fertilizer, are assessed to allow the integration of recycle flow of these materials. In the case of biorefineries, the CAPEX and OPEX must be assessed as they are a few of the major factors in combinatorial optimization. Furthermore, the usage of steam and electricity is separated from their OPEX and listed as input parameters if such data were available. Similarly, this is to allow the integration of the recycle flows of steam and electricity for modeling and optimization.

These parameters are mostly obtained from research works related to the circular economy or the palm oil industry. Some recent processes and supply chain configurations are supplemented by the government and business reports. On the other hand, several assumptions and simulations are used to approximate the parameters, such as conversion ratio, if unavailable. This includes the manipulation of certain information, such as the properties of the material and the operating conditions of the technology.

3.2. Model Formulation

The optimization of the superstructure in

Figure 2 is carried out by P-graph Studio based on a series of formulations as follows:

Constraint (1) is used to ensure the total flowrate of waste

sending to all biorefineries

are capped at availability limit at each site

:

The amount of waste

collected in each biorefinery

is then computed using Equation (2), while Equation (3) describes the mass balance of the collected waste

at technology

:

where

denotes the flowrate of waste

to be consumed by technology

at biorefinery

.

The production rates of intermediate

and product

at biorefinery

are then determined using Equations (4) and (5), respectively:

where

and

refer to the conversion ratios of waste

to intermediate

and intermediate

to product

at respective technology

and

. It is worth noting that not all pathways are involved with an intermediate material. In that case,

can be set as 1 so

. Meanwhile,

denotes the consumption rate of intermediate

by technology

that is expressed in Equation (6):

Next, the collected product

is either sent to recycle

for further utilization or sold to customer

for profit. For that, Equation (7) denotes the distribution of product

to both sectors:

where

and

are the flowrates of product

distributed to sectors

and

, respectively.

From there, Equations (8) and (9) describes the amount of product

received at recycle

and customer

, respectively:

At recycle

, Equation (10) describes the mass balance of product

collected by technology

, followed by Equations (11) and (12), which determine the production rates of intermediate

and resource

, respectively:

where

refers to the conversion ratios of product

to intermediate

by technology

, and

refers to intermediate

to regenerated resource

by technology

. Likewise, the conversion ratios can be set as 1 if no intermediates are involved. Meanwhile,

denotes the consumption rate of intermediate

by technology

, which is shown in Equation (13):

On the other hand, the demand of the resource needed in a given biomass network is defined as the sum of the imported and regenerated resources. Let this resource demand be

, the flowrate of imported resources

required by the biomass network (

) will be conveniently expressed in Equation (14) as follows:

In this biomass network,

can be determined using Equation (15). The first term shows the consumption rate of resource

, which is determined by multiplying the processing rate of fresh fruit bunches (FFB)

with a scale factor

. As for technology

and

, the respective consumption rates are determined by multiplying the processing rate of waste

and intermediate

with scale factors

and

, respectively. The total consumption rate of resource

then represents the resource demand of the biomass network, which is expressed in Equation (15):

Next, the gross profit

of the biomass network is calculated by subtracting the costs of imported resources

and technology expenses (CAPEX:

; OPEX:

) from the sales of exported products

. Equations (16) and (17) represent the calculations of

and

, which are obtained by multiplying the unit cost (

,

) with the respective flowrates (

,

):

As for

and

, both are assumed to be proportional to the processing rate of input materials at each technology. Thus,

is calculated by multiplying the processing rate of input materials with scale factors (

,

,

,

) at respective technology

,

,

, and

, which is expressed in Equation (18):

Similarly, Equation (19) calculates the

using the scale factors

,

,

,

:

Lastly,

is maximized by the P-graph optimization using Equation (20), which forms the basis in the ranking of each solution structure as follows:

To focus on the economic performance of the conversion and recycling pathways, factors of site location, such as cost of transportation, land, construction, etc., will be omitted from this work. Once the configuration of biomass network is identified, these factors can be incorporated into the model later to obtain a more practical gross profit.

On the other hand, the supplementary formulation of steam and electricity generation is given in Equations (21)–(23) as described here. The energy consumption in steam generation

. and electricity generation from steam

is approximated by taking the difference of enthalpies

. Additional considerations for operational units, such as the efficiency of the boiler and turbine, are accounted for the steam and electricity generation. Based on Reference [

32], the efficiencies are taken at 80% for the boiler and 100% for the turbine (rounded from 99.625%). In this case,

and

are simulated using Aspen HYSYS V10 [

33].

In addition, the operating conditions of the water and steam are taken from the recommendation by Reference [

32] as follows: (i) ambient water: 1 bar and 30 °C, (ii) medium pressure steam (MPS): 10 bar and 200 °C, and (iii) high pressure steam (HPS): 48 bar and 350 °C. Note that this MPS can be used for other purposes, such as heating, drying, sterilization, etc., to fulfill the steam demand of the technologies.

3.3. P-graph Modeling of Biomass Network

P-graph is a type of bipartite graph that consists of two types of vertices: material vertex

(including raw material, intermediate, and final product) denoted as a dot and operating unit vertex

denoted as a rectangular bar. The general rule in P-graph modeling is to only connect

to

or

to

by arcs, whereas the arc represents the direction of the material flowrate. In particular, five axioms [

34] must be satisfied to generate a viable mathematical model as follows:

The final product must be displayed in the model.

vertex must be a raw material if it has no input arcs.

Every vertex must be well-defined by the input and output arcs.

Every vertex must be connected in such a way that it leads to the final product vertex.

Every vertex must be an input or output of the vertex.

In the P-graph framework, all the operating units are treated as a black box, whereby the inputs and outputs are related by the conversion ratio of output to input. Besides, additional attributes, such as flowrate constraint and costs, can be embedded into every

and

vertex if necessary, which are then evaluated alongside with the conversion ratios during the optimization. On the other hand, three algorithms are developed to manage the axioms [

35]. Firstly, Maximal Structure Generation (MSG) algorithm provides a graphical overview of the process network that is rigorously defined in mathematics. Secondly, the Solution Structure Generation (SSG) algorithm generates all the possible solutions that link all the raw materials and the final products. Thirdly, Accelerated Branch and Bound (ABB) algorithm, is applied, which is an enhanced version of the branch and bound algorithm to perform combinatorial optimization. Each solution structure is then ranked accordingly based on the objective function.

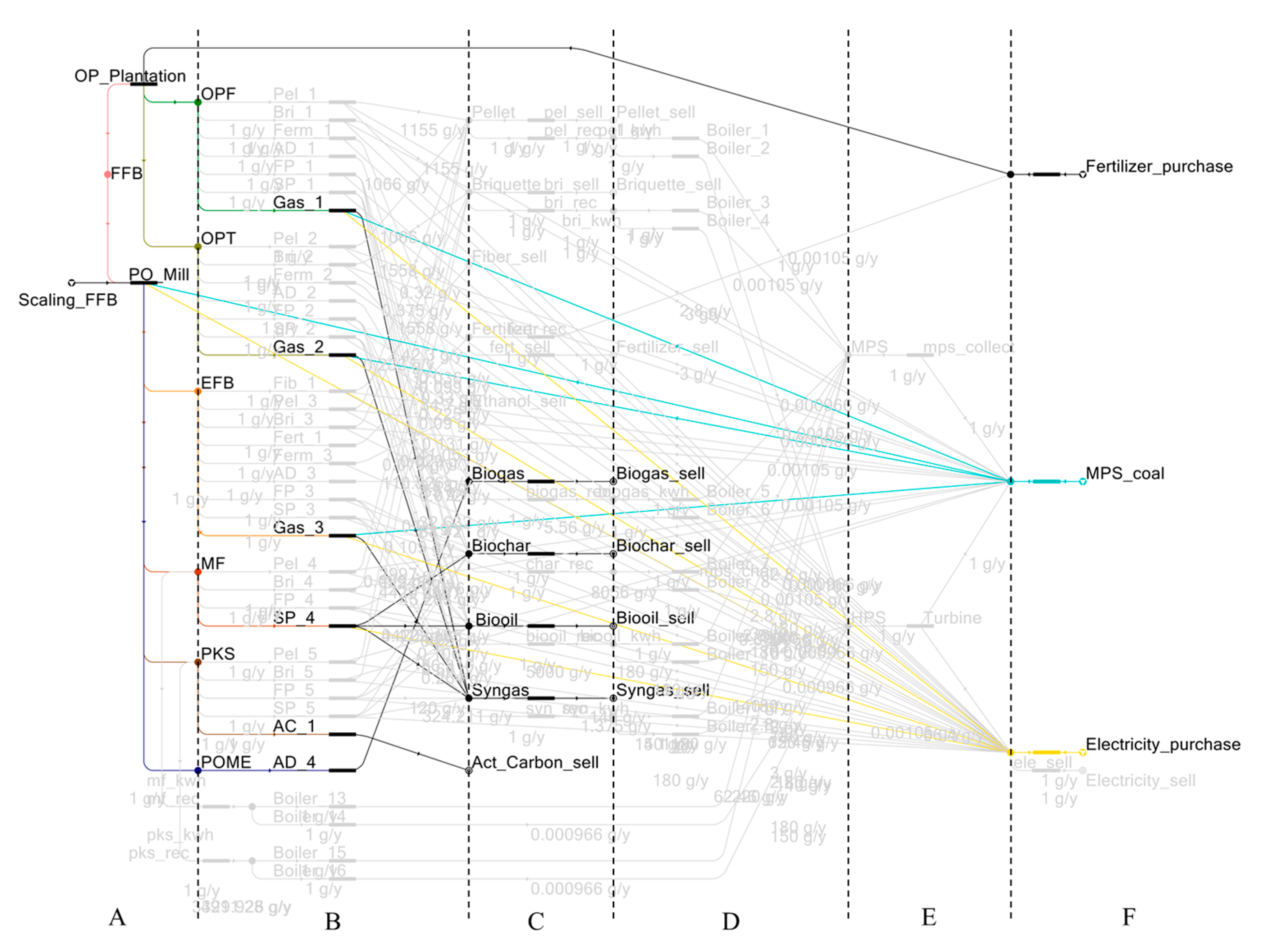

Note that the algorithms and calculations are executed in the backend processes, whereas the user only needs to generate the model by connecting the vertices. Given its graphical user interface and self-explanatory axioms, this makes P-graph a friendly approach in process network synthesis that is suitable for the actors in industries and policymakers where advanced programming knowledge is not required. With that,

Figure 3 illustrates a generic biomass network that is modeled in the P-graph framework. For better visualization, this biomass network is divided vertically into six sections at the intermediate material vertices as shown in

Figure 3.

Starting from the left, section A represents the generation of biomass, which resembles the site in the superstructure. The life cycle of the industry is assessed to identify the distribution of the biomass. Next, sections B and C are involved with the conversion of wastes to products, which resembles biorefinery in the superstructure. More precisely, section B represents the decision-making on choosing the right technologies, whereas section C represents the decision-making on the outcome of the product that is to sell or recycle.

Moving on, sections D and E represent the recycle , which is involved in the handling processes of products into useful resources. Three resources: fertilizer, MPS, and electricity are taken as an example in the illustration of these sections. In this example, D can be described as the decision-making on generating MPS or HPS, whereas section E represents the outcome of the decision made in the previous section. If the product is used as a biofuel and the HPS route is chosen (shown in red), both electricity and MPS are generated using turbine and then collected at the end of section E. Otherwise, only MPS is collected if the MPS route is selected (shown in blue), which requires lesser fuel compared to the formal route. On the other hand, if the product is used as a fertilizer, it will be collected at the end of E without needing further conversions. In short, the design of sections D and E may or may not require the operating units depending on the end-use of the products.

Lastly, section F represents the management of resources. Considering the same example, these resources would be fertilizer, MPS, and electricity. In this case, fertilizer and MPS can only be imported, whereby the MPS is ‘imported’ through the combustion of imported fuel. Besides, electricity can be either imported at a set price or exported if any excess were found and is profitable. In other words, electricity can be seen as a product for export or a resource for recycling. All the imported and regenerated resources are ‘collected’ at the checkpoint between section E and section F, which are then distributed to the operating units in sections A and B.

Similar to the generic superstructure, both linear and circular economic model can be obtained from the biomass network model by observing the material flow. For example, the model is considered as linear if the material flows from F→A→B→C where all products are exported without recycling. On the other hand, circularity is observed if a loop is formed. Using the above example, loop F→A→B→C→D→E→F will be observed if the steam and electricity are regenerated, whereas loop F→A→B→C→F will be observed in the case of fertilizer production and recycling.