The Effect of Carbon Nanotubes on the Flowability, Mechanical, Microstructural and Durability Properties of Cementitious Composite: An Overview

Abstract

:1. Introduction

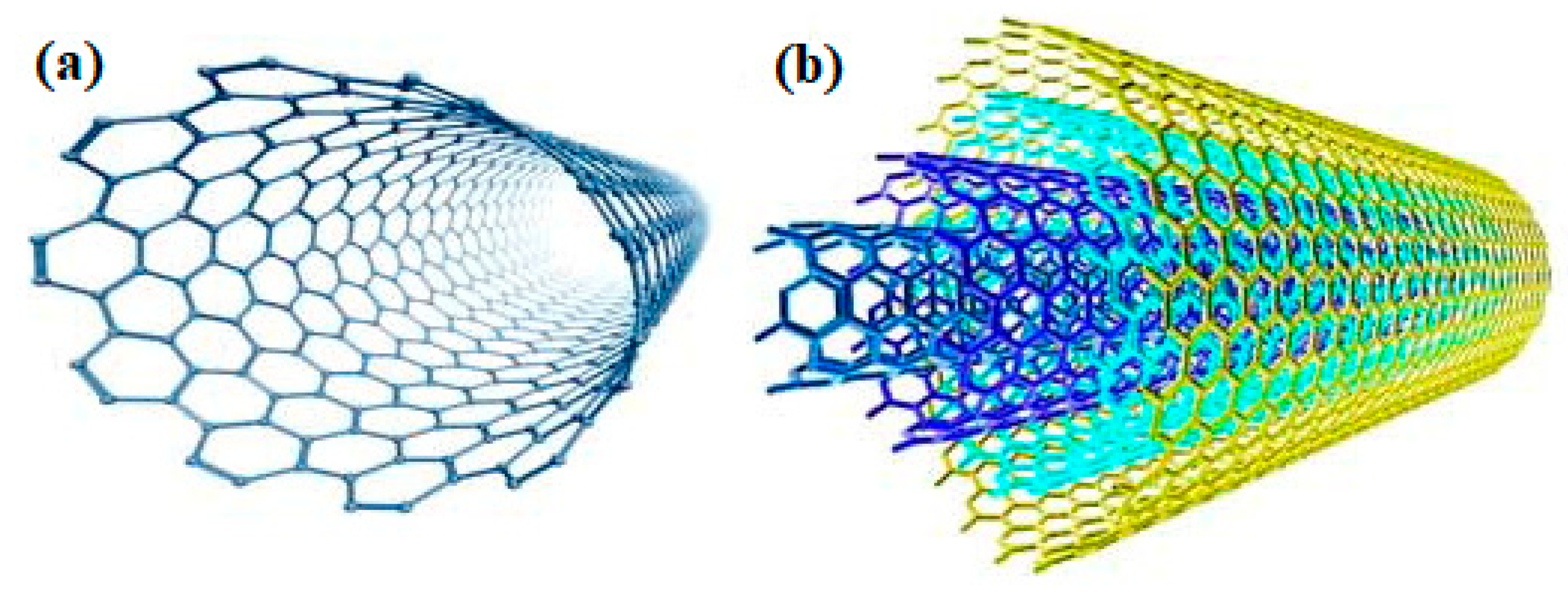

2. Overview of CNT Types

3. Dispersion of CNTs

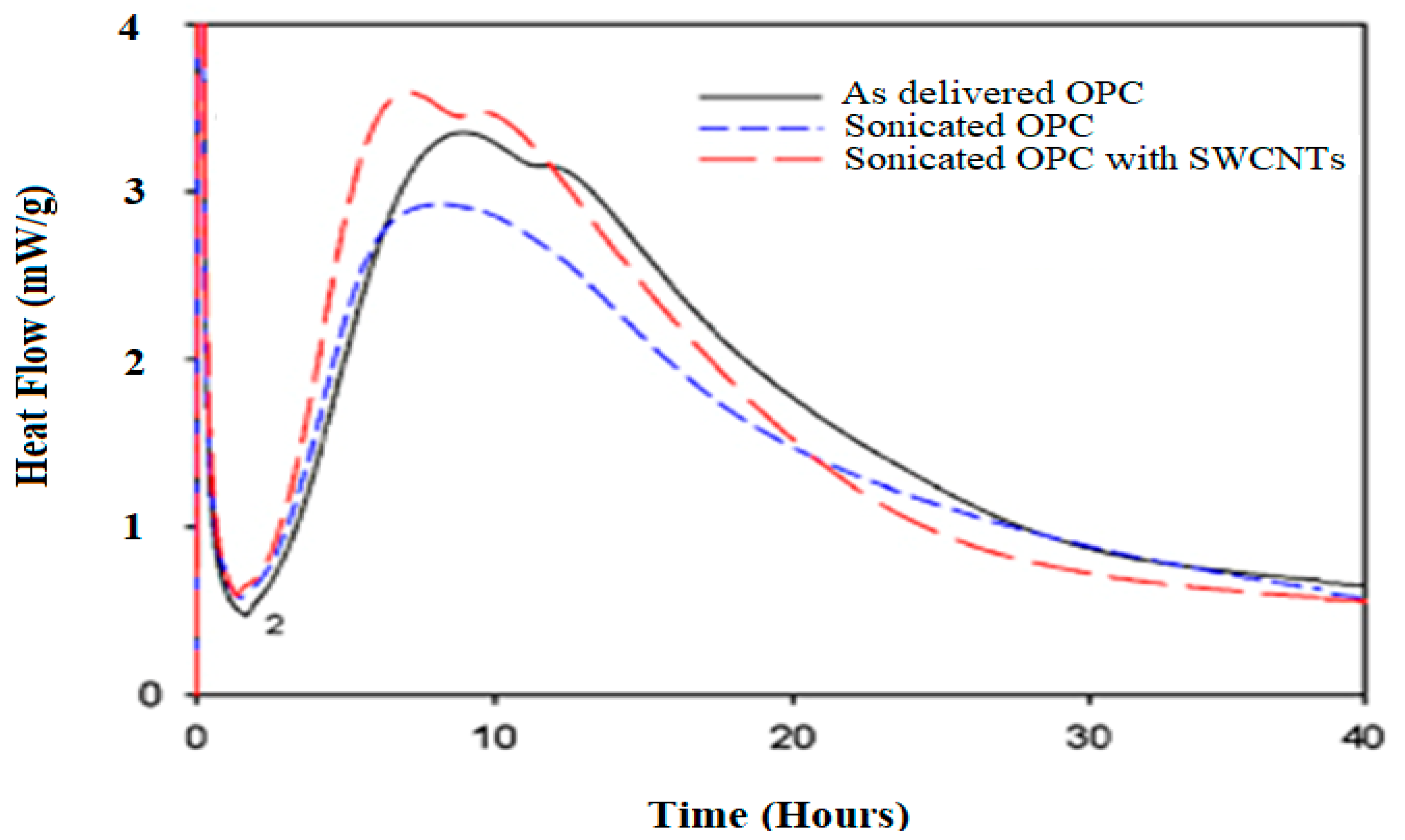

4. The Effect of CNTs on Cementitious Composite Hydration

5. Flowability of Cementitious Composites Incorporating CNTs

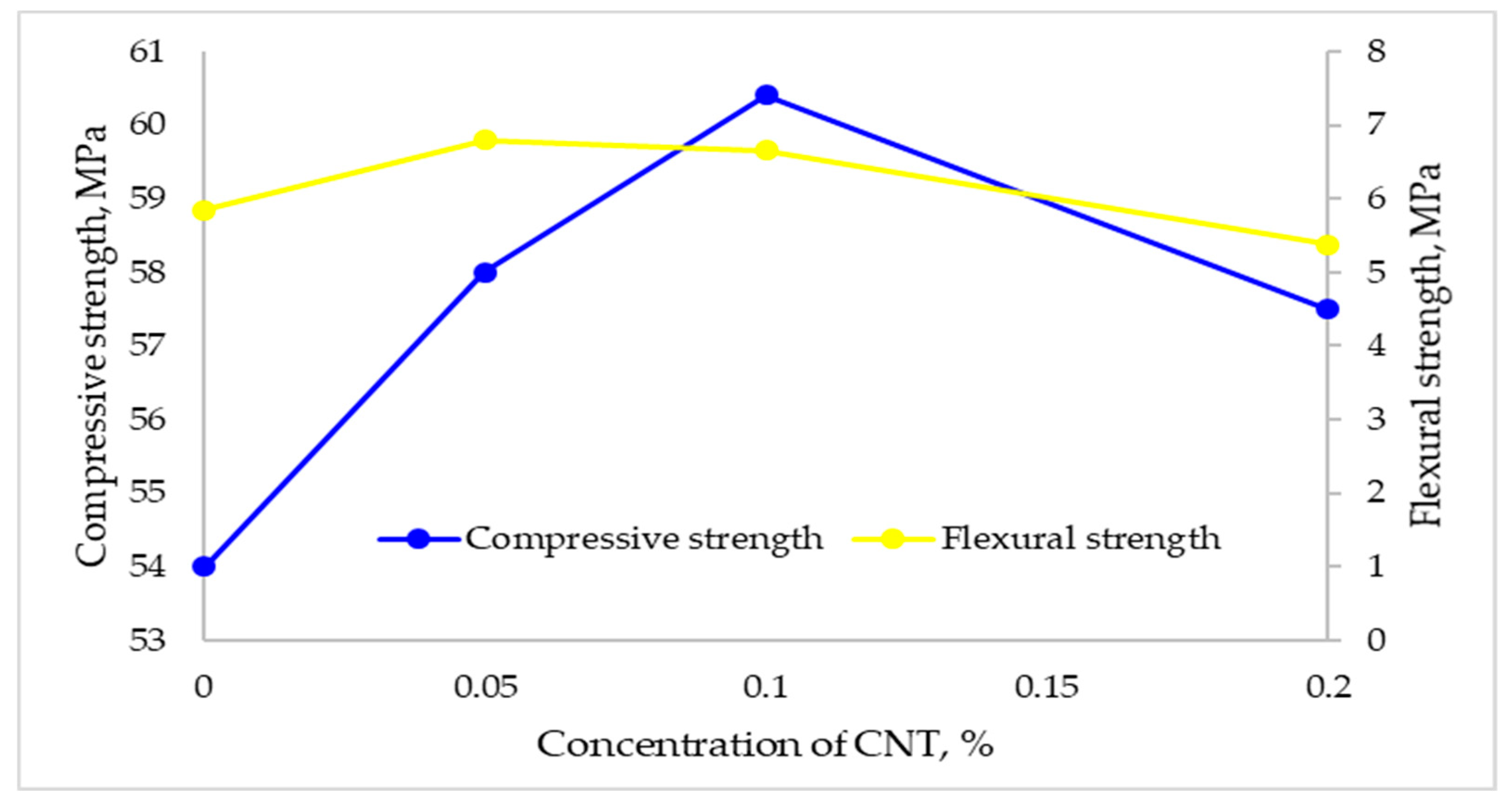

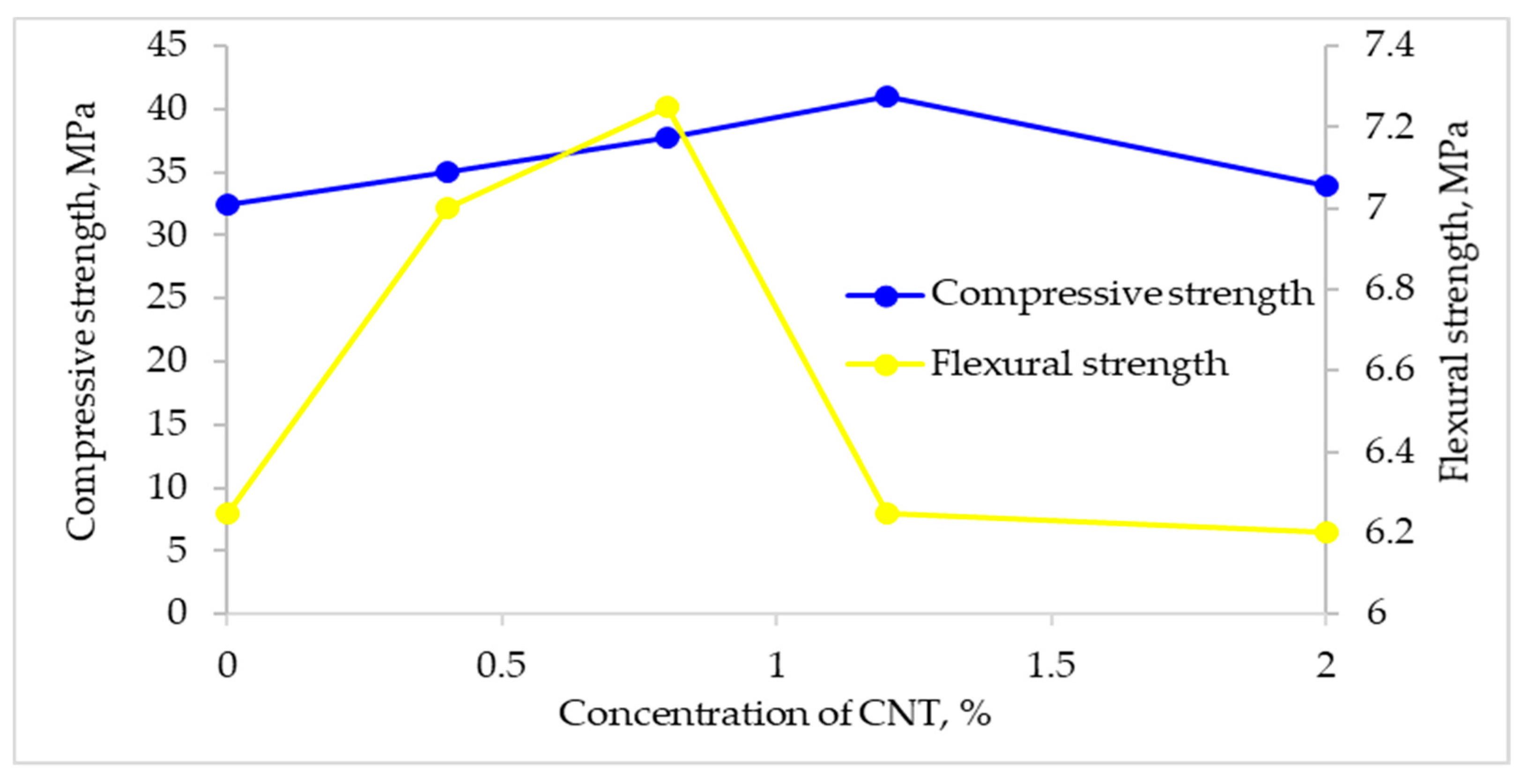

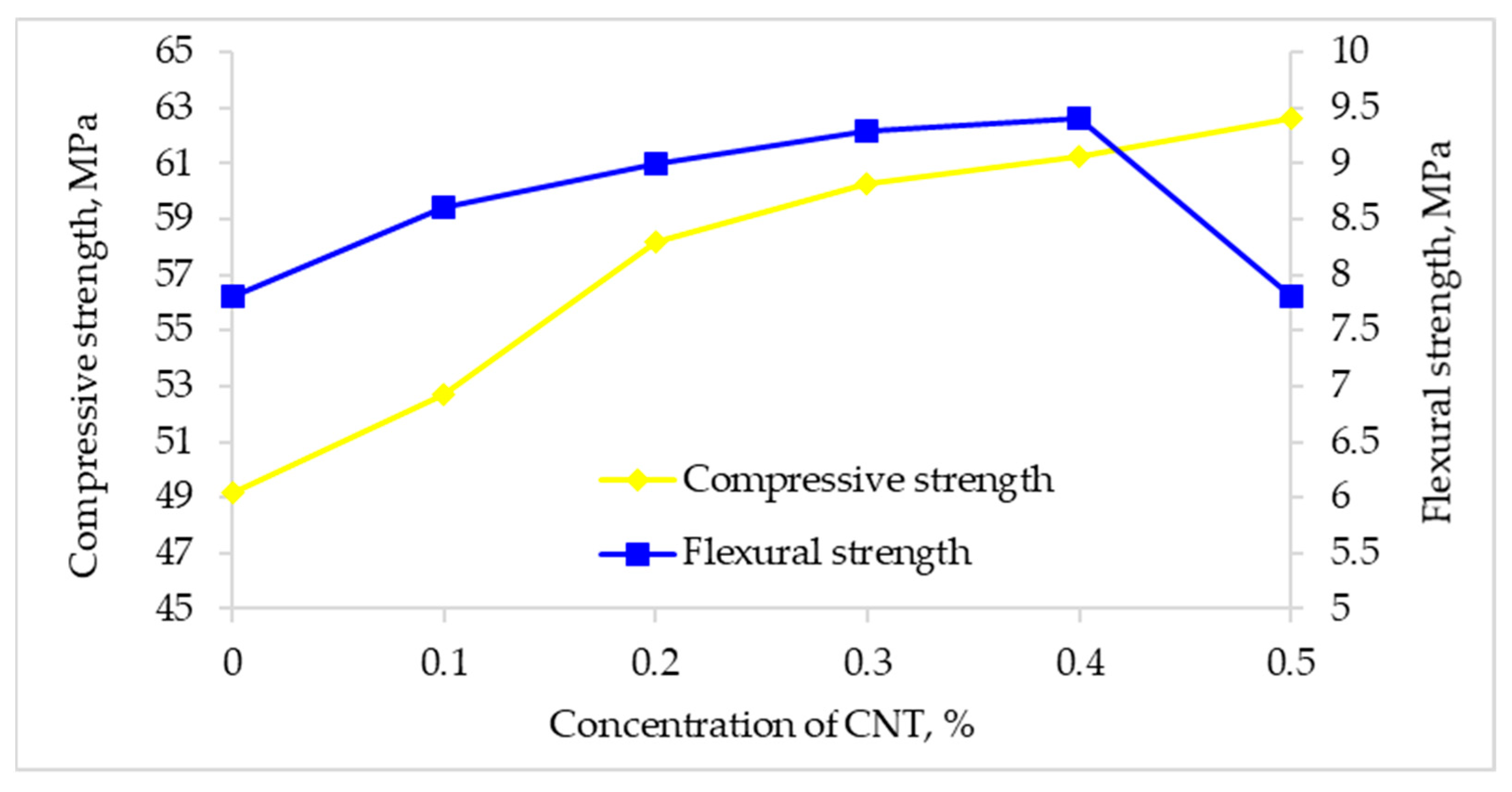

6. Mechanical Properties of Cementitious Composites Incorporating CNTs

7. Durability Properties of Cementitious Composites Incorporating CNTs

8. Conclusions

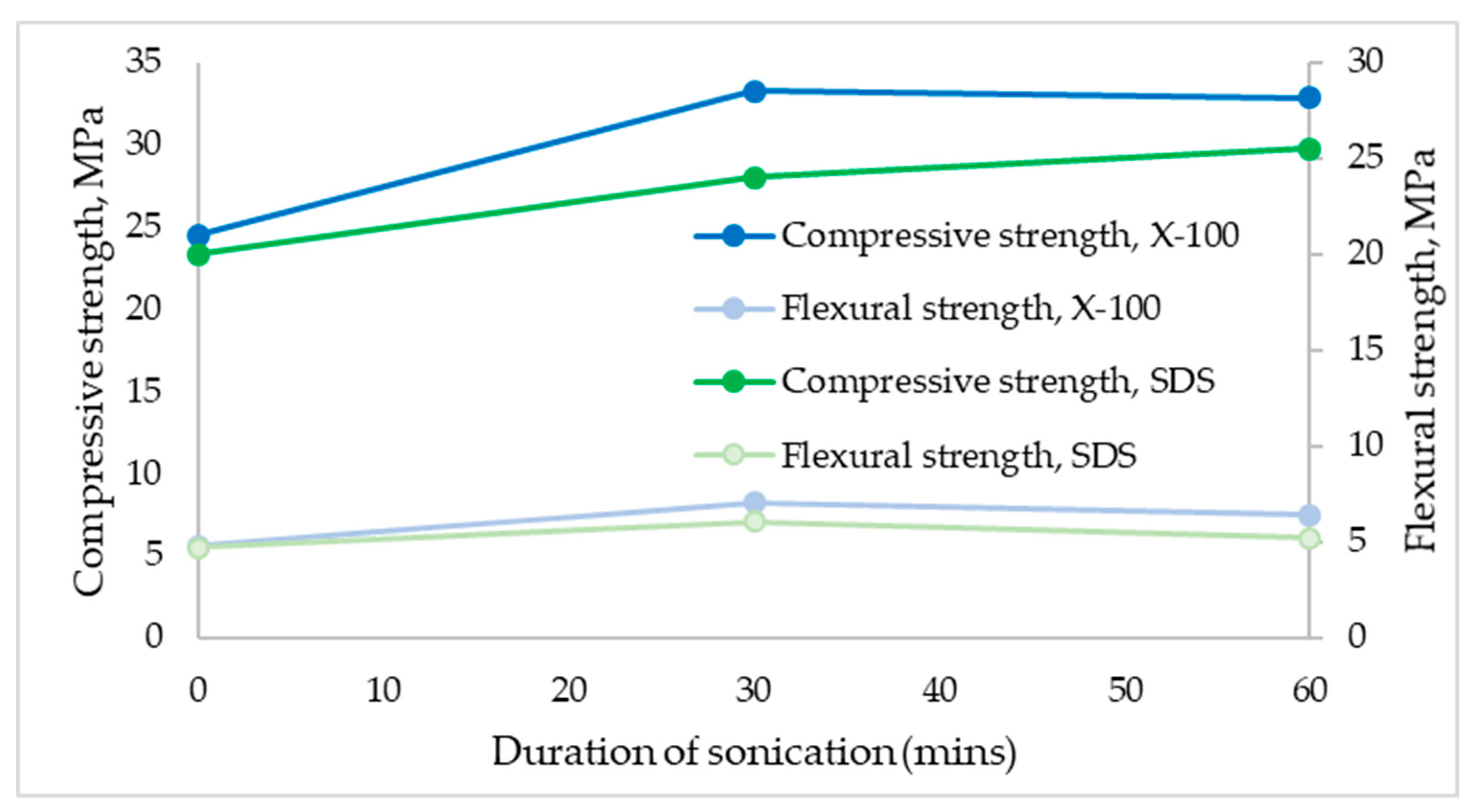

- Carbon nanotubes have a remarkable chemical stability and mechanical performance and can be used, due to their structural characteristics, in concrete, to improve its performance. To get a better mechanical and microstructural performance, a proper dispersion of CNTs should be ensured. Different physical and mechanical dispersion techniques are used with certain advantages and disadvantages. Study results suggest that sonication and a polycarboxylate-based superplasticizer are the most common methods, and that both the sonication energy and duration time influence the degree of CNT dispersion.

- Flowability is one of the most critical factors of fresh concrete influenced by the addition of CNTs. The influences of CNTs summarized in this paper reveal that the flowability of cement-based composites incorporating CNTs decrease with increased CNT concentration.

- A CNT is a chemically inert material that does not participate in the hydration process but accelerates the hydration process by nucleation effects. Several studies show both that CNTs accelerate the hydration process and that cement composites incorporating CNTs also achieve the maximum level of generated heat during the hydration process.

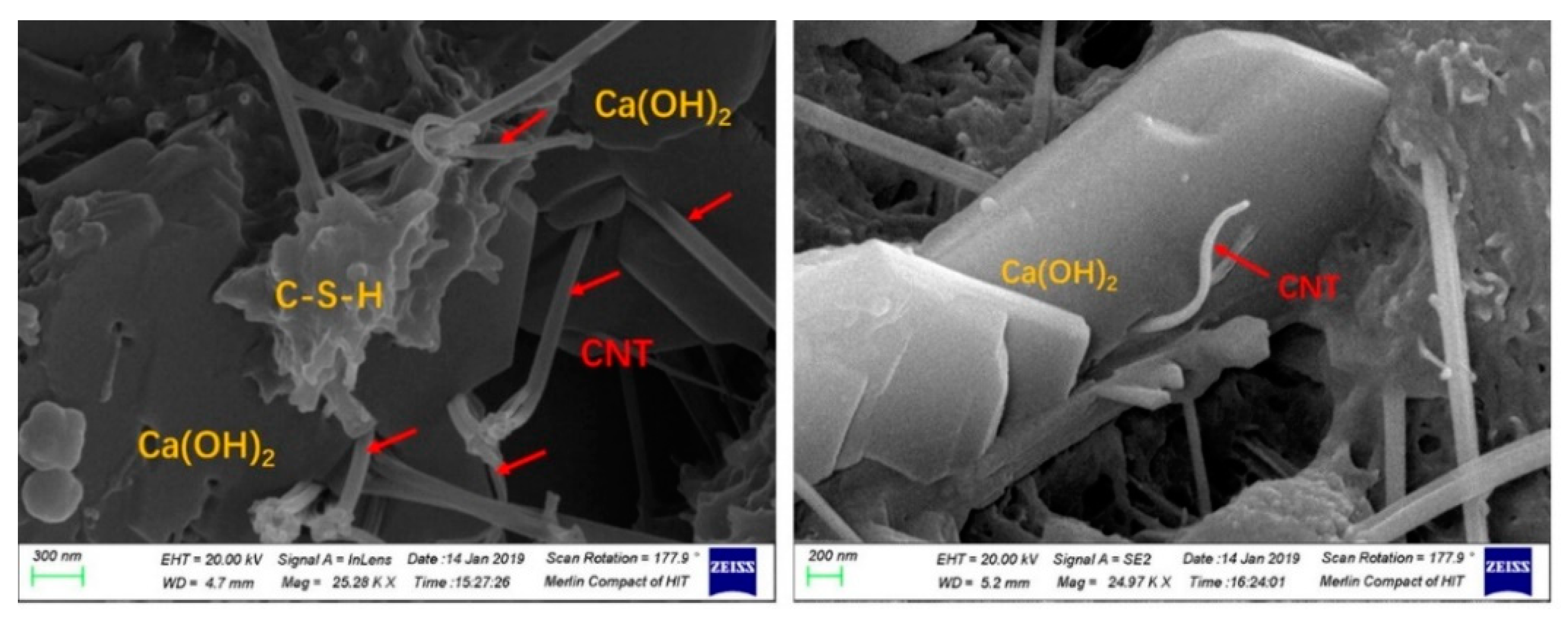

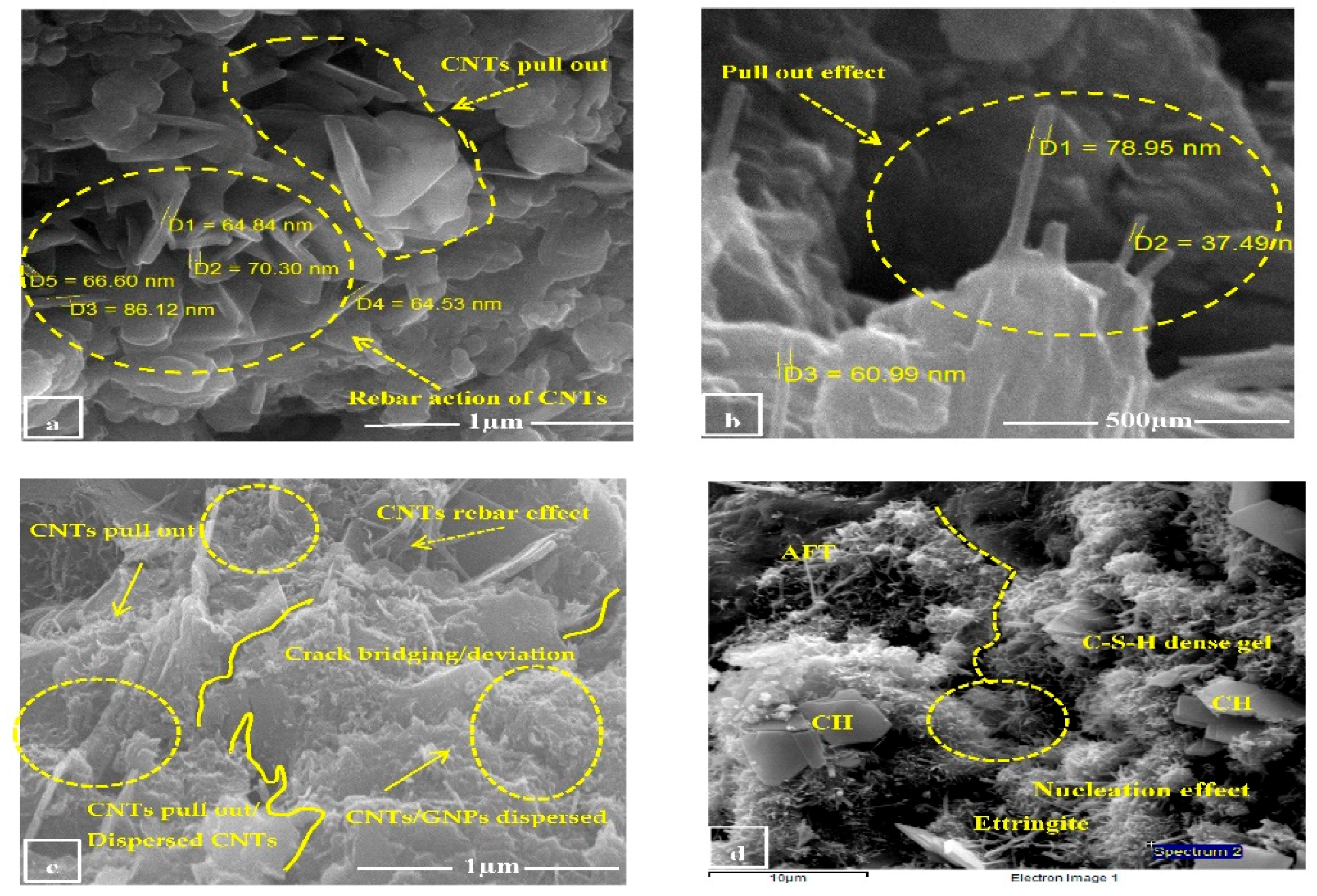

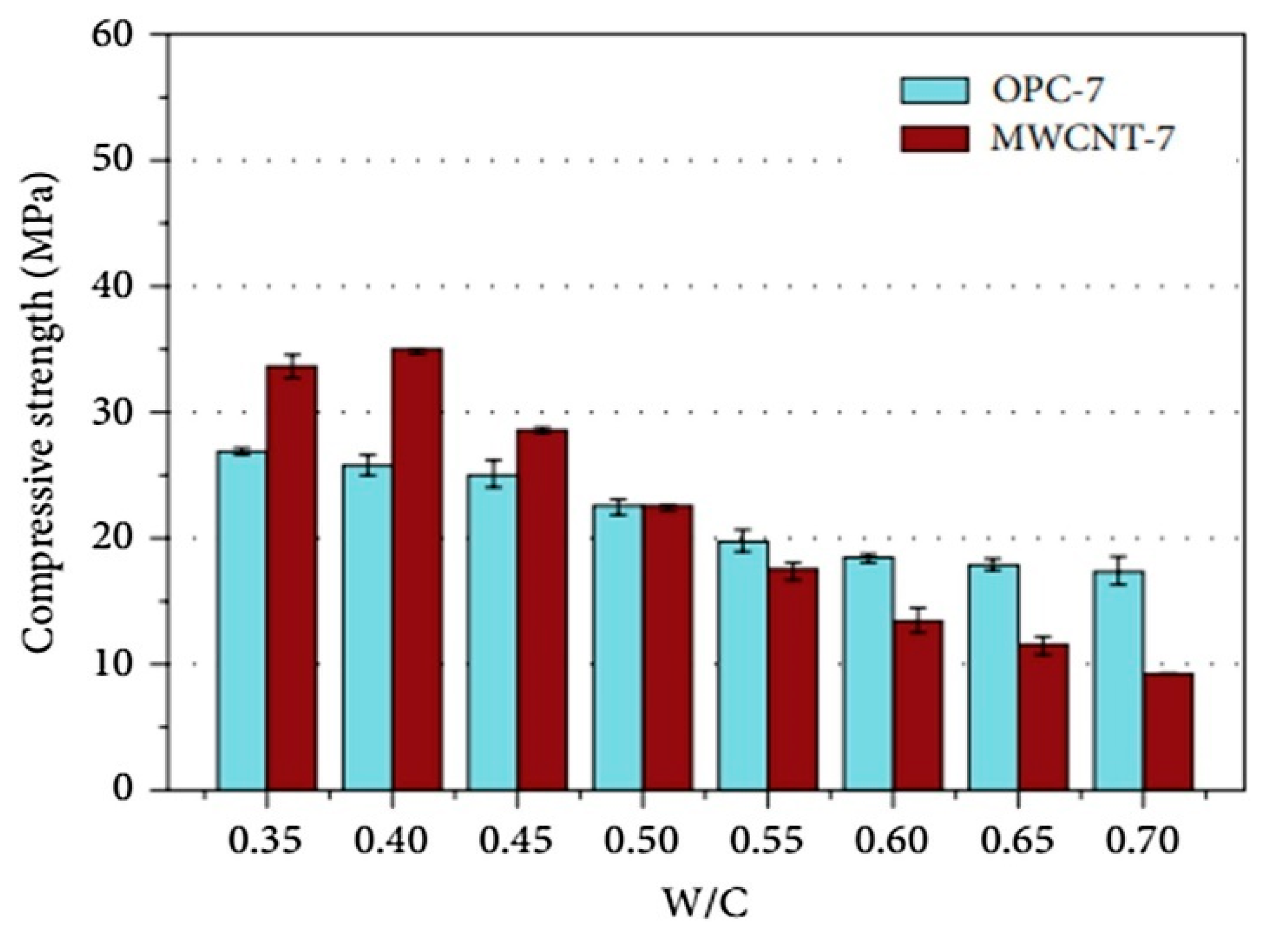

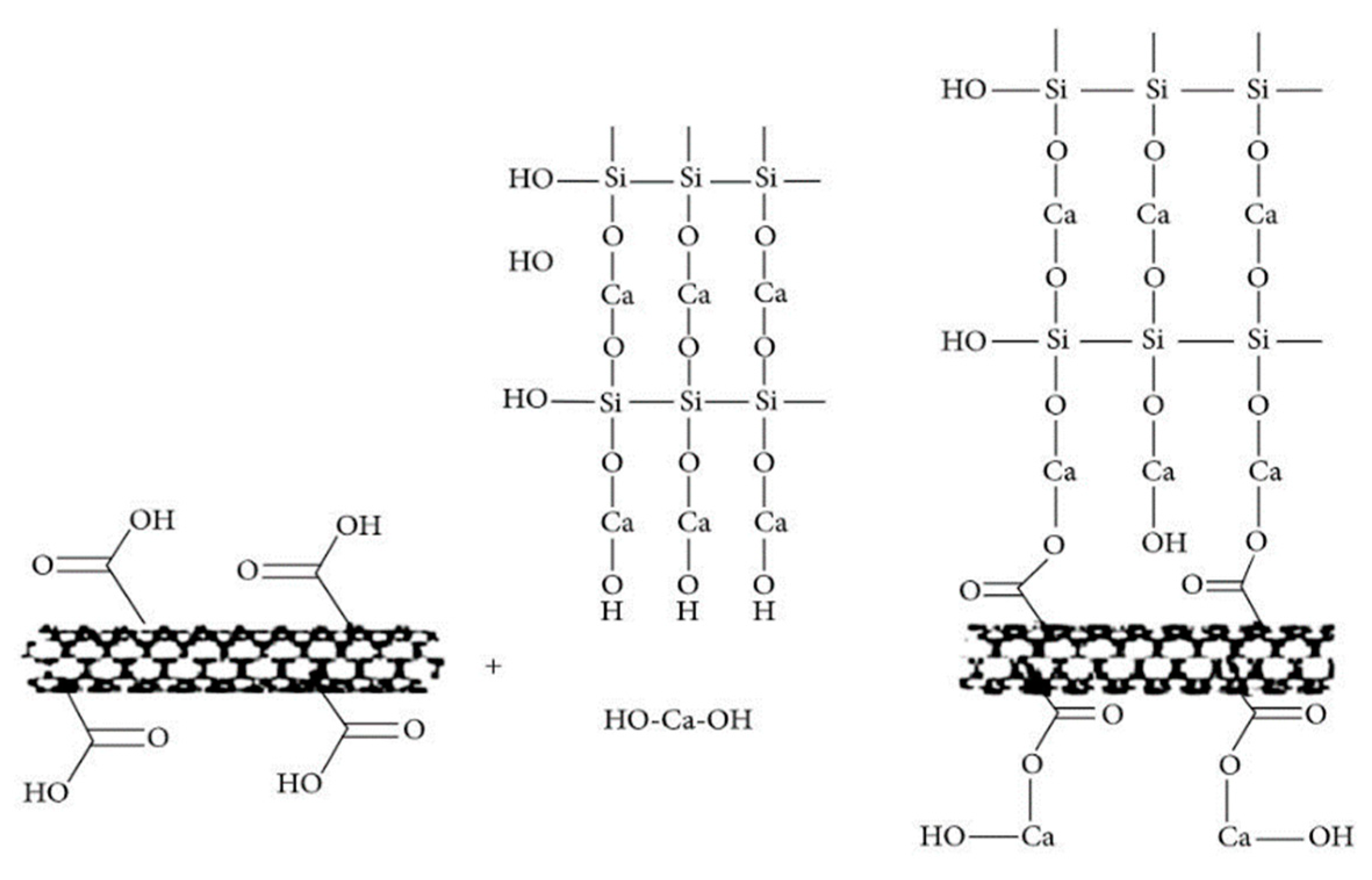

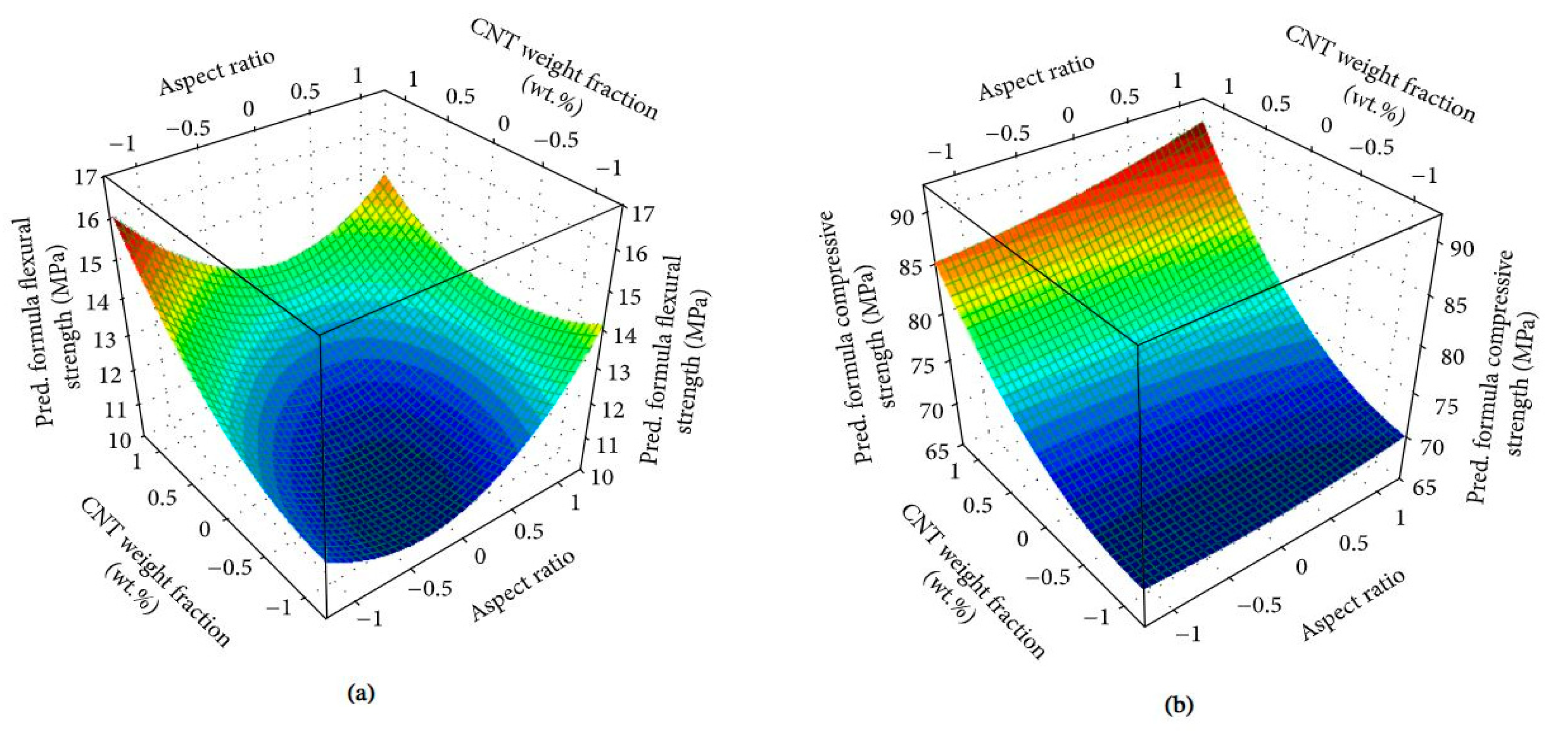

- CNTs embedding cement-based composites demonstrate an excellent mechanical performance due to CNTs’ nucleation effects, crack bridging effects and better adhesion to hydration products. The studies also suggest that CNTs provide sites for the formation of C-S-H in higher quantity, leading to a higher mechanical strength of cement-based composites. The mechanical performance of cement-based composites can be influenced by several parameters, such as the degree of CNT dispersion, the techniques used for CNT dispersion, water/cement ratio, type and properties of CNTs, the surfactants used and the geometry of CNTs.

- Long CNTs improve the microstructure of cement-based composites by crack bridging and interacting with the surrounding hydrates but reduce the degree of dispersion of CNTs within the composite structure.

- Compared to plain cement paste, the flexural strength of CNTs incorporated in cement pastes was observed to increase with the inclusion of CNTs. In the case of CNTs with a higher aspect ratio, the flexural strength of cement-based composites was observed to increase with higher concentrations of CNTs.

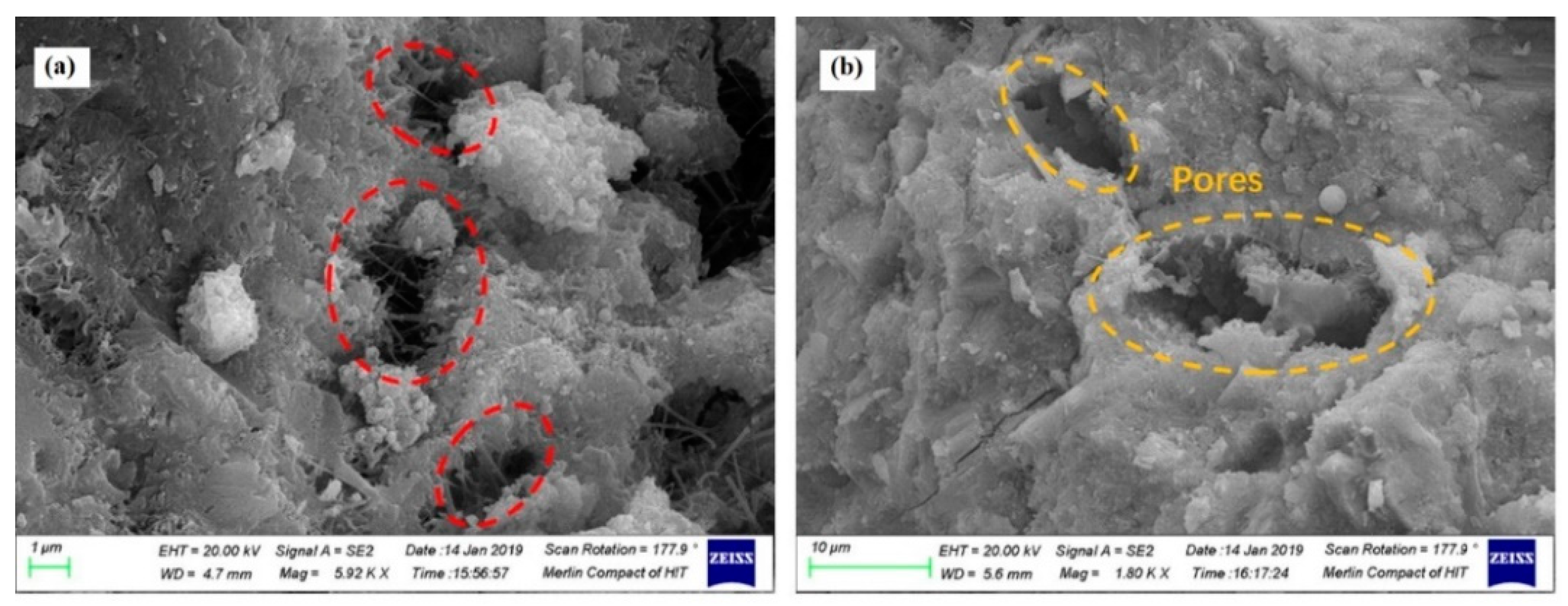

- The microstructure of CNTs incorporated in cementitious composites shows that the compatibility between cementitious materials and CNTs is excellent. The improvement of the microstructure was noticed by the addition of carbon nanotubes. Denser structure and a pore, void and crack filling ability were observed by the addition of CNTs. Besides, a better bonding between CNTs and hydration products was also noticed. The agglomerated CNTs were also observed by SEM, which can be attributed to improper CNT dispersion techniques.

- CNT incorporating cementitious composites with a low water-cement ratio have better durability performance. In the same way, the chemically treated CNTs have a high resistance to chloride ion permeation. Moreover, CNTs have a greater effect on the long time-dependent creep and shrinkage.

- The enhanced durability properties are attained by the pore filling and nucleation effect of CNTs, which, in turn, reduce the number of micropores and nanopores. Thus, the incorporation of CNTs not only improves the shrinkage and water loss characteristics of cementitious materials but also improves their freeze-thaw resistance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Peyvandi, A.; Soroushian, P.; Abdol, N.; Balachandra, A.M. Surface-modified graphite nanomaterials for improved reinforcement efficiency in cementitious paste. Carbon 2013, 63, 175–186. [Google Scholar] [CrossRef]

- Alrekabi, S.; Cundy, A.; Lampropoulos, A.; Savina, I. Experimental investigation on the effect of ultrasonication on dispersion and mechanical performance of multi-wall carbon nanotube-cement mortar composites. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2016, 111, 268–274. [Google Scholar]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Ruan, Y.; Han, B.; Yu, X.; Zhang, W.; Wang, D. Carbon nanotubes reinforced reactive powder concrete. Compos. Part A Appl. Sci. Manuf. 2018, 112, 371–382. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N.; Emon, A.B. Effect of carbon nanotube size on compressive strengths of nanotube reinforced cementitious composites. J. Mater. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Zou, B.; Chen, S.J.; Korayem, A.H.; Collins, F.; Wang, C.; Duan, W.H. Effect of ultrasonication energy on engineering properties of carbon nanotube reinforced cement pastes. Carbon 2015, 85, 212–220. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube–OPC paste mixtures. Cem. Concr. Compos. 2012, 34, 201–207. [Google Scholar] [CrossRef]

- Du, M.; Jing, H.; Gao, Y.; Su, H.; Fang, H. Carbon nanomaterials enhanced cement-based composites: Advances and challenges. Nanotechnol. Rev. 2020, 9, 115–135. [Google Scholar] [CrossRef] [Green Version]

- Douba, A.; Emiroğlu, M.; Kandil, U.F.; Taha, M.M.R. Very ductile polymer concrete using carbon nanotubes. Constr. Build. Mater. 2019, 196, 468–477. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A. Creep, shrinkage and mechanical properties of concrete reinforced with different types of carbon nanotubes. Constr. Build. Mater. 2019, 198, 70–81. [Google Scholar] [CrossRef]

- Carriço, A.; Bogas, J.A.; Hawreen, A.; Guedes, M. Durability of multi-walled carbon nanotube reinforced concrete. Constr. Build. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Hassan, N.M.; Fattah, K.P.; Al-Tamimi, A.K. Modelling mechanical behavior of cementitious material incorporating CNTs using design of experiments. Constr. Build. Mater. 2017, 154, 763–770. [Google Scholar] [CrossRef]

- Azeem, M.; Saleem, M. Role of electrostatic potential energy in carbon nanotube augmented cement paste matrix. Constr. Build. Mater. 2020, 239, 117875. [Google Scholar] [CrossRef] [Green Version]

- Parveen, S.; Rana, S.; Fangueiro, R.; Paiva, M.C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 2015, 73, 215–227. [Google Scholar] [CrossRef]

- Ha, S.-J.; Kang, S.-T. Flowability and strength of cement composites with different dosages of multi-walled CNTs. J. Korea Concr. Inst. 2016, 28, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Aydın, A.C.; Nasl, V.J.; Kotan, T. The synergic influence of nano-silica and carbon nano tube on self-compacting concrete. J. Build. Eng. 2018, 20, 467–475. [Google Scholar] [CrossRef]

- Barodawala, Q.I.; Shah, S.G. Modifying the strength and durability of self Compacting concrete using carbon nanotubes. In Proceedings of the International Conference on Advances in Construction Materials and Structures (ACMS-2018) IIT Roorkee, Roorkee, Uttarakhand, India, 7–8 March 2018. [Google Scholar]

- MacLeod, A.J.N.; Fehervari, A.; Gates, W.P.; Garcez, E.O.; Aldridge, L.P.; Collins, F. Enhancing fresh properties and strength of concrete with a pre-dispersed carbon nanotube liquid admixture. Constr. Build. Mater. 2020, 247, 118524. [Google Scholar] [CrossRef]

- Makar, J.; Chan, G.W. Growth of cement hydration products on single-walled carbon nanotubes. J. Am. Ceram. Soc. 2009, 92, 1303–1310. [Google Scholar] [CrossRef]

- Cui, H.; Yang, S.; Memon, S.A. Development of carbon nanotube modified cement paste with microencapsulated phase-change material for structural–functional integrated application. Int. J. Mol. Sci. 2015, 16, 8027–8039. [Google Scholar] [CrossRef]

- Jung, S.; Oh, S.; Kim, S.-W.; Moon, J.-H. Effects of CNT Dosages in Cement Composites on the Mechanical Properties and Hydration Reaction with Low Water-to-Binder Ratio. Appl. Sci. 2019, 9, 4630. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Pang, B. Properties improvement of multiwall carbon nanotubes-reinforced cement-based composites. J. Compos. Mater. 2019, 54, 2379–2387. [Google Scholar] [CrossRef]

- Isfahani, F.T.; Li, W.; Redaelli, E. Dispersion of multi-walled carbon nanotubes and its effects on the properties of cement composites. Cem. Concr. Compos. 2016, 74, 154–163. [Google Scholar] [CrossRef]

- Leonavičius, D.; Pundienė, I.; Girskas, G.; Pranckevičienė, J.; Kligys, M.; Kairytė, A. The effect of multi-walled carbon nanotubes on the rheological properties and hydration process of cement pastes. Constr. Build. Mater. 2018, 189, 947–954. [Google Scholar] [CrossRef]

- Braidy, N.; El Khakani, M.; Botton, G.A. Single-wall carbon nanotubes synthesis by means of UV laser vaporization. Chem. Phys. Lett. 2002, 354, 88–92. [Google Scholar] [CrossRef]

- Rafique, I.; Kausar, A.; Anwar, Z.; Muhammad, B. Exploration of epoxy resins, hardening systems, and epoxy/carbon nanotube composite designed for high performance materials: A review. Polym. Technol. Eng. 2015, 55, 312–333. [Google Scholar] [CrossRef]

- Overney, G.; Zhong, W.; Tomanek, D. Structural rigidity and low frequency vibrational modes of long carbon tubules. Eur. Phys. J. D 1993, 27, 93–96. [Google Scholar] [CrossRef]

- Treacy, M.J.; Ebbesen, T.; Gibson, J. Exceptionally high Young’s modulus observed for individual carbon nanotubes. Nature 1996, 381, 678–680. [Google Scholar] [CrossRef]

- Guan, X.; Bai, S.; Li, H.; Ou, J. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cementitious composites under the early-age freezing conditions. Constr. Build. Mater. 2020, 233, 117317. [Google Scholar] [CrossRef]

- Ebbesen, T.W.; Hiura, H.; Bisher, M.E.; Treacy, M.M.; Shreeve-Keyer, J.L.; Haushalter, R.C. Decoration of carbon nanotubes. Adv. Mater. 1996, 8, 155–157. [Google Scholar] [CrossRef]

- Cwirzen, A.; Habermehl-Cwirzen, K.; Penttala, V. Surface decoration of carbon nanotubes and mechanical properties of cement/carbon nanotube composites. Adv. Cem. Res. 2008, 20, 65–73. [Google Scholar] [CrossRef]

- Nam, I.; Kim, H.; Lee, H. Influence of silica fume additions on electromagnetic interference shielding effectiveness of multi-walled carbon nanotube/cement composites. Constr. Build. Mater. 2012, 30, 480–487. [Google Scholar] [CrossRef]

- Sanchez, F.; Ince, C. Microstructure and macroscopic properties of hybrid carbon nanofiber/silica fume cement composites. Compos. Sci. Technol. 2009, 69, 1310–1318. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- Kerienė, J.; Kligys, M.; Laukaitis, A.; Yakovlev, G.; Špokauskas, A.; Aleknevičius, M. The influence of multi-walled carbon nanotubes additive on properties of non-autoclaved and autoclaved aerated concretes. Constr. Build. Mater. 2013, 49, 527–535. [Google Scholar] [CrossRef]

- Kim, H.; Park, I.; Lee, H. Improved piezoresistive sensitivity and stability of CNT/cement mortar composites with low water–binder ratio. Compos. Struct. 2014, 116, 713–719. [Google Scholar] [CrossRef]

- Vesmawala, G.R.; Vaghela, A.R.; Yadav, K.; Patil, Y. Effectiveness of polycarboxylate as a dispersant of carbon nanotubes in concrete. Mater. Today Proc. 2020, 28, 1170–1174. [Google Scholar] [CrossRef]

- Han, B.; Zhang, K.; Yu, X.; Kwon, E.; Ou, J. Fabrication of piezoresistive CNT/CNF cementitious composites with superplasticizer as dispersant. J. Mater. Civ. Eng. 2012, 24, 658–665. [Google Scholar] [CrossRef]

- Alatawna, A.; Birenboim, M.; Nadiv, R.; Buzaglo, M.; Peretz-Damari, S.; Peled, A.; Regev, O.; Sripada, R. The effect of compatibility and dimensionality of carbon nanofillers on cement composites. Constr. Build. Mater. 2020, 232, 117141. [Google Scholar] [CrossRef]

- Skripkiunas, G.; Karpova, E.; Barauskas, I.; Bendoraitiene, J.; Yakovlev, G. Rheological properties of cement pastes with multiwalled carbon nanotubes. Adv. Mater. Sci. Eng. 2018, 2018, 8963542. [Google Scholar] [CrossRef] [Green Version]

- Wille, K.; Loh, K.J. Nanoengineering ultra-high-performance concrete with multiwalled carbon nanotubes. Transp. Res. Rec. 2010, 2142, 119–126. [Google Scholar] [CrossRef]

- Kang, S.-T.; Seo, J.-Y.; Park, S.-H. The characteristics of CNT/cement composites with acid-treated MWCNTs. Adv. Mater. Sci. Eng. 2015, 2015, 308725. [Google Scholar] [CrossRef]

- You, I.; Yoo, D.-Y.; Kim, S.; Kim, M.-J.; Zi, G. Electrical and self-sensing properties of ultra-high-performance fiber-reinforced concrete with carbon nanotubes. Sensors 2017, 17, 2481. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoo, D.-Y.; You, I.; Lee, S.-J. Electrical and piezoresistive sensing capacities of cement paste with multi-walled carbon nanotubes. Arch. Civ. Mech. Eng. 2018, 18, 371–384. [Google Scholar] [CrossRef]

- Naeem, F.; Lee, H.; Kim, H.; Nam, I. Flexural stress and crack sensing capabilities of MWNT/cement composites. Compos. Struct. 2017, 175, 86–100. [Google Scholar] [CrossRef]

- Nasibulina, L.I.; Anoshkin, I.V.; Nasibulin, A.G.; Cwirzen, A.; Penttala, V.; Kauppinen, E.I. Effect of carbon nanotube aqueous dispersion quality on mechanical properties of cement composite. J. Nanomater. 2012, 2012, 169262. [Google Scholar] [CrossRef] [Green Version]

- Irshidat, M.R.; Al-Nuaimi, N.; Salim, S.; Rabie, M. Carbon Nanotubes Dosage Optimization for Strength Enhancement of Cementitious Composites. Procedia Manuf. 2020, 44, 366–370. [Google Scholar] [CrossRef]

- Singh, A.P.; Gupta, B.K.; Mishra, M.; Chandra, A.; Mathur, R.; Dhawan, S.K. Multiwalled carbon nanotube/cement composites with exceptional electromagnetic interference shielding properties. Carbon 2013, 56, 86–96. [Google Scholar] [CrossRef]

- Mohammadyan-Yasouj, S.E.; Ghaderi, A. Experimental investigation of waste glass powder, basalt fibre, and carbon nanotube on the mechanical properties of concrete. Constr. Build. Mater. 2020, 252, 119115. [Google Scholar] [CrossRef]

- Xu, S.-L.; Gao, L.; Jin, W. Production and mechanical properties of aligned multi-walled carbon nanotubes-M140 composites. Sci. China Ser. E Technol. Sci. 2009, 52, 2119–2127. [Google Scholar] [CrossRef]

- Thang, N.C.; Duc, H.N. Effect of Carbon Nanotube on properties of lightweight concrete using recycled Expanded Polystyrene (EPS). In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 869. [Google Scholar]

- Zhan, M.; Pan, G.; Zhou, F.; Mi, R.; Shah, S.P. In situ-grown carbon nanotubes enhanced cement-based materials with multifunctionality. Cem. Concr. Compos. 2020, 108, 103518. [Google Scholar] [CrossRef]

- Manzur, T.; Yazdani, N. Effect of different parameters on properties of multiwalled carbon nanotube-reinforced cement composites. Arab. J. Sci. Eng. 2016, 41, 4835–4845. [Google Scholar] [CrossRef]

- Liew, K.; Kai, M.; Zhang, L. Carbon nanotube reinforced cementitious composites: An overview. Compos. Part A Appl. Sci. Manuf. 2016, 91, 301–323. [Google Scholar] [CrossRef]

- Farooq, F.; Akbar, A.; Khushnood, R.A.; Muhammad, W.L.B.; Rehman, S.K.-U.; Javed, M.F. Experimental Investigation of Hybrid Carbon Nanotubes and Graphite Nanoplatelets on Rheology, Shrinkage, Mechanical, and Microstructure of SCCM. Materials 2020, 13, 230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Choi, H.; Kang, D.; Seo, G.S.; Chung, W. Effect of some parameters on the compressive strength of MWCNT-cement composites. Adv. Mater. Sci. Eng. 2015, 2015, 340808. [Google Scholar] [CrossRef] [Green Version]

- Elkashef, M.; Abou-Zeid, M. Performance of carbon nanotubes in mortar using different surfactants. Can. J. Civ. Eng. 2017, 44, 619–625. [Google Scholar] [CrossRef]

- Musso, S.; Tulliani, J.-M.; Ferro, G.; Tagliaferro, A. Influence of carbon nanotubes structure on the mechanical behavior of cement composites. Compos. Sci. Technol. 2009, 69, 1985–1990. [Google Scholar] [CrossRef]

- Abu Al-Rub, R.K.; Tyson, B.M.; Yazdanbakhsh, A.; Grasley, Z. Mechanical properties of nanocomposite cement incorporating surface-treated and untreated carbon nanotubes and carbon nanofibers. J. Nanomech. Micromech. 2012, 2, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Mohsen, M.O.; Taha, R.; Abu Taqa, A.; Al Nuaimi, N.; Abu Al-Rub, R.K.; Bani-Hani, K.A. Effect of nanotube geometry on the strength and dispersion of CNT-cement composites. J. Nanomater. 2017, 2017, 6927416. [Google Scholar] [CrossRef] [Green Version]

- Abu Al-Rub, R.K.; Ashour, A.I.; Tyson, B.M. On the aspect ratio effect of multi-walled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Li, W.; Ji, W.-M.; Wang, Y.-C.; Liu, Y.; Shen, R.-X.; Xing, F. Investigation on the mechanical properties of a cement-based material containing carbon nanotube under drying and freeze-thaw conditions. Materials 2015, 8, 8780–8792. [Google Scholar] [CrossRef] [Green Version]

- Hawreen, A.; Bogas, J.A.; Dias, A.P.S. On the mechanical and shrinkage behavior of cement mortars reinforced with carbon nanotubes. Constr. Build. Mater. 2018, 168, 459–470. [Google Scholar] [CrossRef]

- Kim, G.; Yoon, H.; Lee, H. Autogenous shrinkage and electrical characteristics of cement pastes and mortars with carbon nanotube and carbon fiber. Constr. Build. Mater. 2018, 177, 428–435. [Google Scholar] [CrossRef]

- Blandine, F.; Habermehi-Cwirzen, K.; Cwirzen, A. Contribution of CNTs/CNFs morphology to reduction of autogenous shrinkage of Portland cement paste. Front. Struct. Civ. Eng. 2016, 10, 224–235. [Google Scholar] [CrossRef]

- Souza, D.J.; Yamashita, L.Y.; Dranka, F.; Medeiros, M.H.F.; Medeiros-Junior, R.A. Repair mortars incorporating multiwalled carbon nanotubes: Shrinkage and sodium sulfate attack. J. Mater. Civ. Eng. 2017, 29, 04017246. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Lu, L.; Ouyang, D.; Xu, W. Mechanical properties and durability of ultra high strength concrete incorporating multi-walled carbon nanotubes. Materials 2016, 9, 419. [Google Scholar] [CrossRef] [Green Version]

- Du, H.; Pang, S.D. Transport of water and chloride ion in cement composites modified with graphene nanoplatelet. Key Eng. Mater. 2014, 629, 162–167. [Google Scholar] [CrossRef]

- Dalla, P.T.; Tragazikis, I.K.; Exarchos, D.A.; Dassios, K.G.; Barkoula, N.-M.; Matikas, T.E. Effect of carbon nanotubes on chloride penetration in cement mortars. Appl. Sci. 2019, 9, 1032. [Google Scholar] [CrossRef] [Green Version]

- Stynoski, P.; Mondal, P.; Marsh, C. Effects of silica additives on fracture properties of carbon nanotube and carbon fiber reinforced Portland cement mortar. Cem. Concr. Compos. 2015, 55, 232–240. [Google Scholar] [CrossRef]

- Alafogianni, P.; Dalla, P.T.; Tragazikis, I.K.; Barkoula, N.-M.; Matikas, T.E. Rapid chloride permeability test for durability study of carbon nanoreinforced mortar. In Smart Sensor Phenomena, Technology, Networks, and Systems Integration 2015; International Society for Optics and Photonics: San Diego, CA, USA, 2015; Volume 9436. [Google Scholar]

- Wang, X.; Rhee, I.; Wang, Y.; Xi, Y. Compressive strength, chloride permeability, and freeze-thaw resistance of MWNT concretes under different chemical treatments. Sci. World J. 2014, 2014, 572102. [Google Scholar] [CrossRef]

| Notation | CNTSS | CNTSL | CNTPL | CNTCOOH | CNTOH |

|---|---|---|---|---|---|

| Commercial Name | TNIM8 | TNIM6 | TNIM6 | TNIMC6 | TNIMH4 |

| Form as Supplied | Suspension | Suspension | Powder | Powder | Powder |

| Purity (%) | >90 | >90 | >90 | >90 | >90 |

| Outer diameter (nm) | >50 | 20–40 | 20–40 | 20–40 | 10–30 |

| Inner diameter (nm) | 5–15 | 5–10 | 5–10 | 5–10 | 5–10 |

| Length (μm) | 10–20 | 10–30 | 10–30 | 10–30 | 10–30 |

| Aspect ratio | ~300 | ~667 | ~667 | ~667 | ~1000 |

| True density (g/cm3) | ~2.1 | ~2.1 | ~2.1 | ~2.1 | ~2.1 |

| COOH (%) | 1.36–1.5 | ||||

| OH (%) | 2.48 |

| Matrix | The Fabrication Process | Refs. | |

|---|---|---|---|

| Ultrasonication | Surfactant and Flowing Mixing Process | ||

| Paste | yes | Dispersed with polycarboxylate-based superplasticizer and mixed according to ASTM standard C1738 | [6] |

| Paste | Yes, 30 min (6 times with 5 min duration) | Dispersed with TNWDIS, dispersed CNT mixed under stirring | [3] |

| Paste | Yes, 5 h (5 times with 1-h duration) | Dispersed with water, CNT mixed into cement simultaneously stirred by multifunctional mixer | [29] |

| Paste | Yes, 3 h | Dispersed with methylcellulose and Stirred with cement for 5 min | [34] |

| Mortar | Yes, 2 h | Dispersed with epoxy resin by magnetically stirred at 800 rpm for 2 h | [9] |

| Mortar | Yes, 3 min | Dispersed with (70–90 °C) distilled water for 15 min under mixing, | [35] |

| Mortar | Yes, 30 min | Dispersed with polycarboxylate-based superplasticizer and mixed d with cement under stirring | [23] |

| Mortar | Yes, 1 h | Dispersed with a defoaming agent, magnetic stirring for 10 min for proper mixing of CNT. | [14] |

| Mortar | No | Mixed with cementitious material in a dry state by electrical hand mixer for 6 min, after adding superplasticizer and water again mixed for 3 min. | [36] |

| Concrete | Yes, 45 min | Dispersed with a polyethylene-based surfactant, mixed by magnetic stirring for 1 h | [11] |

| Concrete | Yes, 30 min | Dispersed with water containing an anionic surfactant, Dolapix PC67, after that suspension was magnetically stirred for 4 h | [10] |

| Matrix | W/C | Carbon Nanotube Content (wt%) | Changes of Fluidity/Flowability | Ref. | |

|---|---|---|---|---|---|

| Method | Increased/Decreased | ||||

| Mortar | 0.5 | 0.1% MWCNT | Flow table | 3.17% decrease in flow | [14] |

| 0.1% SWCNT | 6.34% decrease in flow | ||||

| Concrete | 0.4 | 0.08% MWCNT | T500 test | 7.48% increase in flow | [16] |

| Paste | 0.21 | 0.022% MWCNT | Flow table | 0.6% increase in flow | [41] |

| Concrete | 0.22 | 0.023% MWCNT | 1.42% decrease in flow | ||

| Paste | 0.4 | 0.1% MWCNT | Flow table | ~4.16% decrease in flow | [42] |

| Mortar | 0.4 (w/b) | 0.1% MWCNT | Flow table | 8.5% decrease in flow | [15] |

| 0.5% MWCNT | 23.4% decrease in flow | ||||

| Mortar | 0.2 (w/b) | 0.5% MWCNT | Flow table | 18.18%decrease in flow | [43] |

| SCC4 | 0.45 | 0.3% MWCNT | Slump flow test | 4.54% increase in flow | [17] |

| 0.5% MWCNT | 1.51% increase in flow | ||||

| Paste | 0.35 (w/b) | 0.1% MWCNT | ASTMC 1437 | 6.25% decrease in flow | [44] |

| Paste | 0.5 | 0.5% MWCNT | Mini slump | 14.5 decrease in flow | [7] |

| 1% MWCNT | 32.8 decrease in flow | ||||

| 2% MWCNT | 48.9 decrease in flow | ||||

| Concrete | 0.49 | 2.5%CNT-liquid admixture | slump test | 22.72% increase in flow | [18] |

| 5% CNT-liquid admixture | 63.63% increase in flow | ||||

| 10% CNT-liquid admixture | 109% increase in flow | ||||

| Concrete | 0.55 | 0.1% MWCNT | EN 12350-2 | 11.81% increase in flow | [10] |

| 0.5% MWCNT | 23.62% increase in flow | ||||

| Paste | 0.25 (w/b) | 0.1% MWCNT | ASTM C230 | 6.71% decrease in flow | [45] |

| 0.3% MWCNT | 2.23% decrease in flow | ||||

| Matrix | W/C | Carbon Nanotube Content (wt%) | Compressive Strength (Increase/Decrease) | Flexural Strength (Increase/Decrease) | Ref. |

|---|---|---|---|---|---|

| Mortar | 0.5 | 0.1%MWCNT | ~8.98% decrease | ~16.09% decrease | [14] |

| 0.1%SWCNT | ~19.1% increase | ~6.71% increase | |||

| Concrete | 0.5 | 0.1% MWCNT | +19.76% increase | 2.81% increase | [49] |

| Paste | 0.33 | 0.025 | 6.25% increase | 7.5% increase | [3] |

| 0.100 | 14.62% increase | 30% increase | |||

| Mortar | 0.45 | 0.5% MWCNT | 19% increase | 25% increase | [34] |

| Paste | 0.35 | 0.05% MWCNT | ~8.33% increase | 16.9% increase | [29] |

| 0.2% MWCNT | ~7.4% increase | 8.6% decrease | |||

| Mortar | Uk 1 | 2.0% MWCNT | 14% decrease | Nt 2 | [9] |

| Concrete | 0.4 | 0.1% MWCNT | 7.11% increase | 10.25% increase | [37] |

| 0.4% MWCNT | 24.5% increase | 20.5% increase | |||

| Mortar | Uk | 0.2% MWCNT | 15.9% increase | 20.7% increase | [50] |

| NAC (mortar) | 0.51, W/S 3 | 0.004% MWCNT | 7.35% increase | 11.23% increase | [32] |

| 0.04% MWCNT | 8.08% increase | 8.99% increase | |||

| AAC | 0.55, W/S | 0.001% MWCNT | 10.7% increase | 19.4% increase | |

| 0.02% MWCNT | 24.5% increase | 24.10% increase | |||

| Concrete | 0.32, W/B | 0.1% CNT | 14.3% increase | Nt | [51] |

| Concrete | 0.55 | 0.05% MWCNT | 9.68% increase | Nt | [11] |

| Paste | 0.4 | 0.2% MWCNT | 19.2% increase | Nt | [13] |

| 0.4% MWCNT | 4.3% increase | Nt | |||

| Mortar | 0.6 W/B | 0.4% MWCNT | ~8.02% increase | ~10.5% increase | [52] |

| 1.2% MWCNT | ~26.54% increase | ~2.7% increase | |||

| Concrete | 0.55 | 0.1% MWCNT | 21.05% increase | Nt | [10] |

| 0.5% MWCNT | 7.79% increase | Nt | |||

| Mortar | 0.55 W/B | 0.05% CNT | 14.58% increase | 0.91% increase | [47] |

| 0.15% CNT | 10.41% increase | 28.04% increase | |||

| Paste | 0.485 | 0.3% MWCNT | 4.86% decrease | Nt | [53] |

| Paste | 0.4 | 0.02% MWCNT | 83.33% increase | Nt | [46] |

| 0.09% MWCNT | 63.8% increase | Nt | |||

| Mortar | 0.3 W/B | 0.25% MWCNT | ~33% increase | ~25% increase | [4] |

| 0.50% MWCNT | ~35% increase | ~12% increase | |||

| SSC | 0.45 | 0.1% MWCNT | 16.58% increase | 21.25% increase | [17] |

| 0.5% MWCNT | 38.62% increase | 38.63% increase |

| Matrix | Material | Durability Performance | Impact +/- | References |

|---|---|---|---|---|

| Mortar | MWCNT | Lower rate of drying shrinkage Reduction in water-loss | + + | [62] |

| Concrete | CNT | Lower water absorption rate Reduced accelerated carbonation Resistance to chloride ion penetration | + + + | [11] |

| Mortar | MWCNT | Decreased porosity rate | + | [34] |

| Concrete/Paste | MWCNT | Decreased pore volume | + | [67] |

| Paste | MWCNT | Lower autogenous shrinkage | + | [54] |

| Ultra HSC | CNT | Reduced chloride diffusion coefficient | + | [68] |

| Concrete | Modified CNT | Resistance to freezing cycles | + | [69] |

| Mortar | CNT | Increased chloride ion penetration | - | [70] |

| Mortar | CNT | Improved abrasion resistance Smaller crack sizes | + + | [71] |

| Paste | MWCNT | Reduced shrinkage | + | [63] |

| Paste | CNT | Decreased autogenous shrinkage | + | [64] |

| Mortar | MWCNT | Lowered shrinkage rate Resistance to sulfate attack | + + | [66] |

| Paste | CNT | Lower rate of autogenous shrinkage | + | [65] |

| Concrete | CNT | Reduced long term creep and shrinkage | + | [10] |

| Mortar | CNT | Resistance to chloride ion penetration | + | [72] |

| Concrete | CNT | The lower chloride penetration depth | + | [73] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adhikary, S.K.; Rudžionis, Ž.; Rajapriya, R. The Effect of Carbon Nanotubes on the Flowability, Mechanical, Microstructural and Durability Properties of Cementitious Composite: An Overview. Sustainability 2020, 12, 8362. https://doi.org/10.3390/su12208362

Adhikary SK, Rudžionis Ž, Rajapriya R. The Effect of Carbon Nanotubes on the Flowability, Mechanical, Microstructural and Durability Properties of Cementitious Composite: An Overview. Sustainability. 2020; 12(20):8362. https://doi.org/10.3390/su12208362

Chicago/Turabian StyleAdhikary, Suman Kumar, Žymantas Rudžionis, and R Rajapriya. 2020. "The Effect of Carbon Nanotubes on the Flowability, Mechanical, Microstructural and Durability Properties of Cementitious Composite: An Overview" Sustainability 12, no. 20: 8362. https://doi.org/10.3390/su12208362

APA StyleAdhikary, S. K., Rudžionis, Ž., & Rajapriya, R. (2020). The Effect of Carbon Nanotubes on the Flowability, Mechanical, Microstructural and Durability Properties of Cementitious Composite: An Overview. Sustainability, 12(20), 8362. https://doi.org/10.3390/su12208362